Table of Contents

Advertisement

Quick Links

Machine Controller MP3000 Series

Motion Control

USER'S MANUAL

SVC/SVR, SVC32/SVR32

MANUAL NO. SIEP C880725 11E

Basic Information on

Motion Control

Basic Information on Motion

Control Function Modules

Parameters for Motion Control

Motion Control Program

Commands and Instructions

Machine-Specific

Motion Control

Other Useful Functions

Making Settings for Motion

Control with the MPE720

Sample Programming

Stepping Motor Drive Operation

Inverter Operation

Appendices

1

2

3

4

5

6

7

8

9

10

11

Advertisement

Table of Contents

Summary of Contents for YASKAWA SVC

- Page 1 Machine Controller MP3000 Series Motion Control USER’S MANUAL SVC/SVR, SVC32/SVR32 Basic Information on Motion Control Basic Information on Motion Control Function Modules Parameters for Motion Control Motion Control Program Commands and Instructions Machine-Specific Motion Control Other Useful Functions Making Settings for Motion...

- Page 2 Yaskawa. No patent liability is assumed with respect to the use of the informa- tion contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is sub- ject to change without notice.

- Page 3 About this Manual This manual describes the specifications, system configurations, and operating methods for the SVC, SVR, SVC32, and SVR32 Function Modules that are used in an MP3000-series Machine Controller for motion control. Read this manual carefully to ensure the correct usage of the Machine Controller and apply the Machine Controller to control your manufacturing system.

- Page 4 Describes the functions, specifica- Machine Controller MP2000 Series tions, and operating methods of the SIEP C880700 41 SVC-01 Motion Module User’s Manual MP2000-series SVC-01 Motion Mod- ule. Machine Controller MP2000 Series Describes the functions, specifica- Pulse Output Motion Module PO-01...

- Page 5 Continued from previous page. Category Manual Name Manual Number Contents Describes the functions, specifica- tions, operating methods, and MECHA- MECHATROLINK-III Compatible I/O SIEP C880781 04 TROLINK-III communications for the Module User’s Manual MECHA- Remote I/O Modules for MP2000/ TROLINK MP3000-series Machine Controllers. Machine Controller MP900/MP2000 Describes MECHATROLINK distrib- Series Distributed I/O Module...

- Page 6 Interface Unit. • MP3300: A generic name for the CPU Module and Base Unit. • SVC Function Module: A generic name for the SVC and SVC32. • SVR Function Module: A generic name for the SVR and SVR32. Engineering Tools Used in This Manual In this manual, the operation is described using MPE720 screen captures.

- Page 7 Safety Precautions Safety Information To prevent personal injury and equipment damage in advance, the following signal words are used to indicate safety precautions in this document. The signal words are used to classify the hazards and the degree of damage or injury that may occur if a product is used incorrectly. Information marked as shown below is important for safety.

- Page 8 Safety Precautions That Must Always Be Observed General Precautions DANGER Read and understand this manual to ensure the safe usage of the SERVOPACK. Keep this manual in a safe, convenient place so that it can be referred to whenever necessary. Make sure that it is delivered to the final user of the SERVOPACK.

- Page 9 NOTICE Do not attempt to use a SERVOPACK or Servomotor that is damaged or that has missing parts. Install external emergency stop circuits that shut OFF the power supply and stop operation immediately when an error occurs. In locations with poor power supply conditions, install the necessary protective devices (such as AC reactors) to ensure that the input power is supplied within the specified voltage range.

- Page 10 NOTICE Do not hold onto the front cover or connectors when you move a SERVOPACK. There is a risk of the SERVOPACK falling. The SERVOPACK or Servomotor is a precision device. Do not drop it or subject it to strong shock.

- Page 11 NOTICE Do not install or store the SERVOPACK in any of the following locations. • Locations that are subject to direct sunlight • Locations that are subject to ambient temperatures that exceed SERVOPACK specifications • Locations that are subject to relative humidities that exceed SERVOPACK specifications •...

- Page 12 CAUTION Wait for at least six minutes after turning OFF the power supply and then make sure that the CHARGE indicator is not lit before starting wiring or inspection work. Do not touch the power supply terminals while the CHARGE lamp is lit because high voltage may still remain in the SER- VOPACK even after turning OFF the power supply.

- Page 13 Whenever possible, use the Cables specified by Yaskawa. If you use any other cables, confirm the rated current and application environment of your model and use the wiring materials specified by Yaskawa or equivalent materials. Securely tighten cable connector lock screws and lock mechanisms.

- Page 14 Operation Precautions WARNING Before starting operation with a machine connected, change the settings of the switches and parameters to match the machine. Unexpected machine operation, failure, or personal injury may occur if operation is started before appropriate settings are made. ...

- Page 15 CAUTION Design the system to ensure safety even when problems, such as signal line disconnection, occur. For example, the P-OT and N-OT signals are set in the default settings to operate on the safe side if there is a signal line disconnection. Do not change the polarity of this type of signal. ...

- Page 16 CAUTION Always check to confirm the paths of axes when any of the following axis movement instruc- tions are used in programs to ensure that the system operates safely. • Positioning (MOV) • Linear Interpolation (MVS) • Circular Interpolation (MCC or MCW) •...

- Page 17 CAUTION The Move on Machine Coordinates (MVM) instruction temporarily performs positioning to a coordinate position in the machine coordinate system. Therefore, unexpected operation may occur if the instruction is executed without confirming the origin position in the machine coordi- nate system first.

- Page 18 NOTICE Discharge all static electricity from your body before you operate any of the buttons or switches inside the front cover of the SERVOPACK. There is a risk of equipment damage. Troubleshooting Precautions DANGER If the safety device (molded-case circuit breaker or fuse) installed in the power supply line oper- ates, remove the cause before you supply power to the SERVOPACK again.

- Page 19 We will update the document number of the manual and issue revisions when changes are made. Any and all quality guarantees provided by Yaskawa are null and void if the customer modifies the SERVOPACK in any way. Yaskawa disavows any responsibility for damages or losses that...

- Page 20 • Events for which Yaskawa is not responsible, such as natural or human-made disasters Limitations of Liability • Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer that arises due to failure of the delivered product.

- Page 21 • It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations that apply if the Yaskawa product is used in combination with any other products. • The customer must confirm that the Yaskawa product is suitable for the systems, machines, and equipment used by the customer.

-

Page 22: Table Of Contents

SVC Function Module ........2-7... - Page 23 Parameters for Motion Control Types of Motion Parameters ......3-2 Motion Parameter Registers ......3-3 Motion Parameter Tables .

-

Page 24: Machine-Specific

4.2.24 PHASE (Issue Phase Reference) ....... . .4-99 4.2.25 KIS (Change Position Loop Integral Time Constant) ....4-103 4.2.26 PPRM_WR (Write Non-volatile Parameter) . - Page 25 Related Parameters ......... . 6-10 6.3.3 Comparison with the MP2000-series SVC-01 Module ....6-10 6.3.4 The Effects of Software Limits .

-

Page 26: Making Settings For Motion

Precautions When Using Σ-7-series SERVOPACKs ..6-34 MP3000 Versions That Support the Σ-7-series SERVOPACKs ..6-34 6.8.1 Σ-7-series SERVOPACK Electronic Gear Ratio and MP3000 Settings..6-35 6.8.2 6.8.3 Link Assignments . -

Page 27: Stepping Motor Drive Operation

Stepping Motor Drive Operation Overview ......... . . 9-2 Connection Specifications . - Page 28 11.2 System Registers ........11-10 11.2.1 System Service Registers ........11-10 11.2.2 Scan Execution Status and Calendar .

-

Page 29: Basic Information On Motion Control

Basic Information on Motion Control This chapter describes the types of programs and the types of motion control that are used to perform motion control with the MP3000. Types of Programs ....1-2 Types of Motion Control . -

Page 30: Types Of Programs

1.1 Types of Programs Types of Programs Ladder programs and motion programs are used to implement motion control. This section describes each type of program. Ladder Programs Ladder programming is a programming language for executing position control, phase control, torque control, and speed control. However, programming becomes complex if you try to use ladder programs for path control. -

Page 31: Types Of Motion Control

1.2 Types of Motion Control 1.2.1 Position Control Types of Motion Control Motion control includes position control, phase control, torque control, and speed control. This section describes each type of motion control. 1.2.1 Position Control To implement position control, the target axis is moved to the target position according to the specified travel distance and travel speed. -

Page 32: Phase Control

1.2 Types of Motion Control 1.2.2 Phase Control 1.2.2 Phase Control Phase control is used to synchronize multiple axes and move a machine along a specified path. It enables continuous motion without stopping at target positions, in the same way as an elec- tronic cam or electronic shaft. -

Page 33: Basic Information On Motion Control Function Modules

Overview ......2-3 2.1.1 SVC Function Module ..... 2-3 2.1.2 SVR Function Module . - Page 34 2.6.4 Reference Output Timing ....2-20 2.6.5 Precautions When Combining with Other Modules ..... .2-21...

-

Page 35: Overview

MP3000. 2.1.1 SVC Function Module The SVC Function Module performs motion control for MECHATROLINK-III slave devices that are connected through MECHATROLINK-III communications from the MP3000. The main slave devices are SERVOPACKs, Distributed I/O Modules, Inverters, and Stepping Motor Drives. -

Page 36: Conceptual Diagram

Module Due to the following differences between the SVR Function Module and Simulation Mode with the SVC Function Module, we recommend that you use the SVR Function Module for the virtual mas- Term ter to create master axis operating patterns. -

Page 37: External Appearance And Indicators

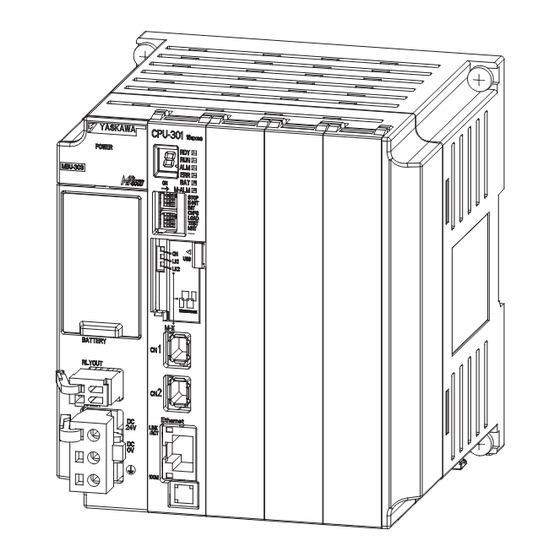

2.1 Overview 2.1.4 External Appearance and Indicators 2.1.4 External Appearance and Indicators External Appearance The following figure shows the indicators and connectors that are related to the SVC32. Indicators (LEDs) MECHATROLINK-III connector CN1 MECHATROLINK-III connector CN2 Indicators The following table describes the indicators that show the operating status of the SVC32 and error information. -

Page 38: Specifications

2.2.1 Motion Control Function Module Specifications Specifications This section provides the specifications of each Motion Control Function Module and the spec- ifications of the MECHATROLINK-III communications used with the SVC Function Module. 2.2.1 Motion Control Function Module Specifications The following table gives the specifications of the Motion Control Function Modules. -

Page 39: Mechatrolink-Iii Communications Specifications For The Svc Function Module

MECHATROLINK-III servo standard profile, MECHATROLINK-III I/O standard Supported Profiles profile, MECHATROLINK-III inverter standard profile, and MECHATROLINK-III stepping motor standard profile The transmission cycle is used to perform communications between the SVC Function Module and the slave devices through the MECHATROLINK-III transmission line. -

Page 40: Svc Function Module Specifications

Number of Link Communications 16, 32, 48, or 64 (depending on the profile) Bytes SVC32: 42 max. (32 Servo axes max.) Number of Connected Stations SVC: 21 max. (16 Servo axes max.) C1 Messaging Supported (selectable). (Master Function) Retry Function Supported (selectable). - Page 41 2.2 Specifications 2.2.3 SVC Function Module Specifications Continued from previous page. Item Specification Synchronous communications through single send transmis- sions Transmission/communications error detection (hardware) pro- vided. Communication Methods Synchronous communications error detection (software) pro- vided. No automatic recovery function (recovery occurs when alarms are cleared).

-

Page 42: Svr Function Module Specifications

2.2 Specifications 2.2.4 SVR Function Module Specifications 2.2.4 SVR Function Module Specifications Item Specification I/O using motion registers (synchronized with the high-speed I/O Registers scan) Command Modes Motion command mode Supported Servomotors Standard and linear Servomotors Position control, speed control, torque control, and phase con- Control Types trol can be selected during operation. -

Page 43: Applicable Versions For Additional Functions

2.2 Specifications 2.2.5 Applicable Versions for Additional Functions 2.2.5 Applicable Versions for Additional Functions The following tables list the MP3000 and Engineering Tool versions that support the additional functions. Engineering MP3000 Tool MPE720 CPU-201 CPU-202 CPU-301 CPU-302 Version 7 Function JAPMC- JAPMC- JEPMC-... -

Page 44: System Configuration Example

2.3 System Configuration Example System Configuration Example The following figure shows a system configuration example that uses the Motion Control Func- tion Module. Configuration with the MP3200 The following figure shows a system configuration example that uses the SVC32. MPE720 Integrated Engineering Tool Version 7 Host PLC... - Page 45 ON the power supply to the MECHATROLINK slave devices. Otherwise, MECHATROLINK communications may not be performed correctly. Important Using the MP3300 The following figure shows a system configuration example that uses the SVC. MPE720 Integrated Engineering Tool Version 7...

-

Page 46: Topologies

2.4 Topologies 2.4.1 Cascade Connections Topologies The SVC Function Module uses MECHATROLINK-III communications to control slave devices. You can connect the MP3000 and MECHATROLINK-III slave devices with cascade, star, or mixed cascade/star topologies. This section describes these topologies. 2.4.1 Cascade Connections Cascade connections allow you to connect one or more series of slave stations from the MECHATROLINK-III communications port (CN6) on the MP3000. -

Page 47: Star Connections

2.4 Topologies 2.4.2 Star Connections 1. Do not connect more than 19 stations up to the final slave stations to any one CPU Unit port. 2. The maximum number of stations that you can connect with cascade connections depends on the transmission cycle. Refer to the following section for details. Important MECHATROLINK Transmission Cycle and the Number of Connected Slave Stations (page 2-17) 2.4.2... -

Page 48: Mixed Cascade/Star Connections

2.4 Topologies 2.4.3 Mixed Cascade/Star Connections 2.4.3 Mixed Cascade/Star Connections A mixed cascade/star topology combines both cascade and star connections. CPU Unit Hub Module No terminating resistor is required. No terminating resistor is required. 1. Do not connect more than 19 stations up to the final slave stations to any one CPU Unit port, including the Hub Modules. -

Page 49: Mechatrolink Transmission Cycle And The Number Of Connected Slave Stations

MECHATROLINK Transmission Cycle and the Number of Connected Slave Stations The relationship between the MECHATROLINK transmission cycle and the number of con- nected slave stations when the SVC Function Module is used is given in the following tables. Cascade Connections... - Page 50 2.5 MECHATROLINK Transmission Cycle and the Number of Connected Slave Stations 2.4.3 Mixed Cascade/Star Connections Mixed Cascade/Star Connections Number of Connected Stations Transmission Connection Conditions Cycle SVC32 125 μs 1 to 4 1 to 4 Only star connections can be used. A single cascade connection series must con- 250 μs 1 to 8...

-

Page 51: Synchronization Of The Mechatrolink-Iii Transmission Cycle And High-Speed Scan Cycle

2.6.1 Synchronization Conditions Synchronization of the MECHATROLINK-III Transmission Cycle and High-Speed Scan Cycle To perform motion control with the SVC Function Module, the MECHATROLINK transmission cycle and the high-speed scan cycle of the CPU must be synchronized. This section describes synchronization of the MECHATROLINK transmission cycle and the high-speed scan cycle. -

Page 52: Reference Output Timing

When the high-speed scan cycle is changed, MECHATROLINK communications with all slave stations connected to the SVC Function Module are reset. If the high-speed scan setting is an integral multiple or integral fraction of the MECHATROLINK transmission cycle, operation is automatically synchronized when communications are restored. -

Page 53: Precautions When Combining With Other Modules

MECHATROLINK will not coincide even though the same transmission cycle settings are used. The SVC Function Module minimizes the delay between the time a reference is set and a response is received. Therefore, the timing at which references are transmitted to the slave sta- tions will not coincide even between the SVC Function Module and SVC-01 Module. -

Page 54: Parameters For Motion Control

Parameters for Motion Control This chapter describes motion parameters required for motion control. Types of Motion Parameters ... . 3-2 Motion Parameter Registers ... . 3-3 Motion Parameter Tables . -

Page 55: Types Of Motion Parameters

3.1 Types of Motion Parameters Types of Motion Parameters Motion parameters are necessary to perform motion control. Motion parameters include fixed parameters, setting parameters, and monitor parameters. Descriptions of the various types of motion parameters are given in the following table. Parameters Overview Fixed Parameters... -

Page 56: Motion Parameter Registers

Motion Control Function Module and the axis number that is assigned. This section describes the default settings of the motion parameter registers that are allocated to the SVC and SVR Function Modules, and the motion parameter registers that can be used. - Page 57 3.2 Motion Parameter Registers Axis Numbers 9 to 16 Axis Axis Axis Axis Axis Axis Axis Circuit Axis Number Number Number Number Number Number Number Number Number 9 8400 to 8480 to 8500 to 8580 to 8600 to 8680 to 8700 to 8780 to 847F...

- Page 58 3.2 Motion Parameter Registers Axis Numbers 25 to 32 Axis Axis Axis Axis Axis Axis Axis Axis Circuit Number Number Number Number Number Number Number Number Number 8C00 to 8C80 to 8D00 to 8D80 to 8E00 to 8E80 to 8F00 to 8F80 to 8C7F...

- Page 59 3.2 Motion Parameter Registers Axis Numbers 9 to 16 Axis Axis Axis Axis Axis Axis Axis Axis Circuit Number Number Number Number Number Number Number Number Number 8400 to 8480 to 8500 to 8580 to 8600 to 8680 to 8700 to 8780 to 847F...

-

Page 60: Motion Parameter Tables

3.3 Motion Parameter Tables 3.3.1 Fixed Parameter Table Motion Parameter Tables This section provides tables of the motion parameters. 3.3.1 Fixed Parameter Table Fixed parameters are used to make settings related to the servo system. The following table lists the fixed parameters. Reference Name Description... - Page 61 3.3 Motion Parameter Tables 3.3.1 Fixed Parameter Table Continued from previous page. Reference Name Description Function Function Page Module Module Bit 0: Mask Communications Error Detection − (Communication abnormality detection mask) 0: Disabled, 1: Enabled Bit 1: Mask Watchdog Error Detection −...

- Page 62 3.3 Motion Parameter Tables 3.3.1 Fixed Parameter Table Continued from previous page. Reference Name Description Function Function Page Module Module Number of Pulses Per Motor Rotation 1 = 1 pulse/rev page 3-34 (Rotary Motor) Number of Pulses Per ...

-

Page 63: Setting Parameter Table

3.3 Motion Parameter Tables 3.3.2 Setting Parameter Table 3.3.2 Setting Parameter Table These parameters are used to set detailed aspects of control references used in motion con- trol. The following table lists the setting parameters. The boxes () in “OW00” are determined by the circuit number and the axis num- Information ber. - Page 64 3.3 Motion Parameter Tables 3.3.2 Setting Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Bit 0: Excessive Deviation Error Level Setting – 0: Alarm, 1: Warning Bits 1 and 2: Reserved. –...

- Page 65 3.3 Motion Parameter Tables 3.3.2 Setting Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Bit 0: Reserved. – – Bit 1: Disable Phase Reference Calcu- lation – 0: Enabled, 1: Disabled Bit 2: External Positioning Final Travel Distance Write Selection Function Set-...

- Page 66 3.3 Motion Parameter Tables 3.3.2 Setting Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module 0: NOP (No Operation) (No command) 1: POSING (Positioning) 2: EX_POSING (External Positioning) ...

- Page 67 3.3 Motion Parameter Tables 3.3.2 Setting Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Bit 0: Hold Command (Holds a com- mand) 0: OFF, 1: ON Bit 1: Cancel Command (Interrupt a ...

- Page 68 3.3 Motion Parameter Tables 3.3.2 Setting Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Speed Refer- The unit is set in bits 0 to 3 (Speed page 3-47 ence Setting Unit Selection) of OW03.

- Page 69 3.3 Motion Parameter Tables 3.3.2 Setting Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Linear Deceler- The unit is set in bits 4 to 7 (Accelera- ation Rate/ tion/Deceleration Rate Unit Selection) page 3-56 Deceleration of OW03.

- Page 70 3.3 Motion Parameter Tables 3.3.2 Setting Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module SERVOPACK Sets the number of the alarm to moni- Alarm Monitor – page 3-63 tor. Number SERVOPACK Sets the SERVOPACK parameter num- ...

-

Page 71: Monitor Parameter Table

3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Power OFF Pulse Position (Pulse position 1 = 1 pulse – when power is off) (Lower 2 Words) page 3-66 Power OFF... - Page 72 3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Register Reference Name Description Function Function Address Page Module Module Bit 0: Motion Operation Ready 0: Motion operation not ready 1: Motion operation ready Bit 1: Running with Servo ON (Running ...

- Page 73 3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Bit 0: SERVOPACK Error 0: No SERVOPACK alarm – 1: SERVOPACK alarm occurred Bit 1: Positive Overtravel (Positive direction overtravel) ...

- Page 74 3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Bit 10: SERVOPACK Synchronized Communications Error (Servo Driver Synch. Comm. error) 0: No synchronized communications – error 1: Synchronized communications error occurred Bit 11: SERVOPACK Communications...

- Page 75 3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Bit 0: Command Execution Flag (BUSY) 0: READY (Completed) 1: BUSY (Processing) Bit 1: Command Hold Completed (HOLDL) ...

- Page 76 3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Bit 0: Distribution Completed (DEN) (Discharging completed) 0: Distributing pulses 1: Distribution completed Bit 1: Positioning Completed (POS- COMP) ...

- Page 77 3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Machine Coor- dinate System 1 = 1 reference unit page 3-78 Feedback Posi- tion (APOS) Machine Coor- dinate System ...

- Page 78 3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Auxiliary SER- VOPACK Reports the number of the target – page 3-82 Parameter parameter. Number SERVOPACK The data of the SERVOPACK parameter ...

- Page 79 3.3 Motion Parameter Tables 3.3.3 Monitor Parameter Table Continued from previous page. Register Reference Name Description Function Function Address Page Module Module Power OFF Pulse Position (Pulse position 1 = 1 pulse – when power is off) (Lower 2 Words) page 3-84 Power OFF...

-

Page 80: Motion Parameter Details

These boxes show whether the parameter can be used with the SVC and SVR Function Modules. 3.4.1 Fixed Parameter Details This section provides details on each of the fixed parameters. Refer to the following section for a list of the fixed parameters. - Page 81 3.4 Motion Parameter Details 3.4.1 Fixed Parameter Details 3: SERVOPACK Transmission Reference Mode SERVOPACK Transmission Reference Mode is used to directly control the command-response communications with the slave SERVOPACK from an application. Setting Precautions • No processing other than communications processing with the SERVOPACK is performed in this mode.

- Page 82 3.4 Motion Parameter Details 3.4.1 Fixed Parameter Details Refer to the following section for details on the software limits. 6.3 Software Limits on page 6-9 Bit 3: Enable Positive Overtravel Enable or disable overtravel detection in the positive direction. 0: Disabled (default).

- Page 83 3.4 Motion Parameter Details 3.4.1 Fixed Parameter Details Bit C: Software Limit Parameter Selection Select whether the software limit is set in a fixed parameter or in a setting parameter. 0: Fixed parameter (default). 1: Setting parameter. Refer to the following section for details on the software limits. 6.3 Software Limits on page 6-9 ...

- Page 84 3.4 Motion Parameter Details 3.4.1 Fixed Parameter Details Reference Unit Selection Reference Unit Selection Set the reference unit. The reference unit is determined by this parameter and fixed parameter No. 5 (Number of Digits Below Decimal Point). Refer to the following section for details on reference units. 5.1.1 Reference Unit on page 5-3 Name Setting Range...

- Page 85 3.4 Motion Parameter Details 3.4.1 Fixed Parameter Details Servomotor Gear Ratio Term and Machine Gear Ratio Term Set the gear ratio between the motor and the load. The following two values are set for a machine configuration in which the load axis turns n times in response to m turns of the motor axis.

- Page 86 3.4 Motion Parameter Details 3.4.1 Fixed Parameter Details Negative Software Limit Set the position to detect the software limit in the reverse direction for the MP3000. Name Setting Range Setting Unit Default −1 Negative Software Limit Reference units to 2 Setting Precautions •...

- Page 87 3.4 Motion Parameter Details 3.4.1 Fixed Parameter Details Encoder Settings Rated Motor Speed (Rotary Motor) Set the rated motor speed in revolutions per minute. Name Setting Range Setting Unit Default Rated Motor Speed (Rotary 1 to 100,000 3,000 Motor) Setting Precautions Set this parameter based on the specifications of the motor.

- Page 88 3.4 Motion Parameter Details 3.4.1 Fixed Parameter Details Maximum Number of Absolute Encoder Rotations Set the maximum number of rotations that the absolute encoder can manage. This parameter is used to manage position information when an absolute encoder is used for an infinite-length axis.

-

Page 89: Setting Parameter Details

3.4 Motion Parameter Details 3.4.2 Setting Parameter Details 3.4.2 Setting Parameter Details This section provides details on each of the setting parameters. • Refer to the following section for a list of the setting parameters. Information 3.3.2 Setting Parameter Table on page 3-10 •... - Page 90 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Bit 6: Number of POSMAX Turns Preset Request Set this bit to 1 to preset the IL1E monitor parameter (Number of POSMAX Turns) to the value set for the OL4C setting parameter (Number of POSMAX Turns Preset Data). 0: Number of POSMAX turns preset request OFF (default).

- Page 91 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Bit B: Reset Integration Set this bit to 1 to reset the integration term in the position loop in the slave SERVOPACK. This setting is enabled when a travel motion command or a command to turn ON the Servomo- tor’s power is executed.

- Page 92 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Bit F: Clear Alarm Set this bit to 1 to clear an alarm. If a communications error occurs, communications can be reestablished by clearing the alarm. 0: Clear Alarm OFF (default). 1: Clear Alarm ON.

- Page 93 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Mode Settings 2 Mode Settings 2 Register Setting Name Setting Unit Default Control mode Address Range Phase Position − − OW02 0000 hex Mode Settings 2 Speed Torque Bits 8 to F: Stop Mode Selection Set the stop method for an axis that is in motion for a travel motion command.

- Page 94 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Bits C to F: Torque Unit Selection Set the unit for torque references. 0: Percentage of rated torque (1 = 0.01%). 1: Percentage of rated torque (1 = 0.0001%). Function Settings 2 ...

- Page 95 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Bit 2: External Positioning Final Travel Distance Write Selection This bit specifies whether or not to automatically apply the external positioning final travel dis- tance to the SERVOPACK during external positioning. This setting is applied at the start of exe- cution of the EX_POSING (External Positioning) and EX_FEED (Jog with External Positioning) motion commands.

- Page 96 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Motion Commands Motion Commands Set the motion command. Register Setting Name Setting Unit Default Control mode Address Range Phase Position − OW08 Motion Commands 0 to 39 Speed Torque 0: NOP (No Operation) 1: POSING (Positioning) 2: EX_POSING (External Positioning) 3: ZRET (Zero Point Return)

- Page 97 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Motion Command Control Flags Motion Command Control Flags Register Setting Name Setting Unit Default Control mode Address Range Phase Position Motion Command Control − − OW09 0000 hex Flags Speed Torque ...

- Page 98 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Bit 5: Position Reference Type Set the value of the OL1C setting parameter (Position Reference Setting) to either 0 (Incremental value addition method) or 1 (Absolute value specification method). 0: Incremental value addition method (default). This method adds the amount to move to the current position reference value and then issues the reference.

- Page 99 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Torque Reference Torque/Force Reference Setting or Torque Feedforward Compensa- tion This meaning of this subcommand depends on the motion command. • When the TRQ (Issue Torque/Force Reference) motion command is executed, set the torque reference.

- Page 100 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Speed Reference Setting Speed Reference Setting Set the speed reference. Register Setting Name Setting Unit Default Control mode Address Range The unit that is set in the Phase Position −1 OL10 Speed Reference Setting Speed Unit 3,000 to 2...

- Page 101 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Setting Precautions • The speed limit can be changed during operation. However, if an incorrect setting is made during operation, it may affect the movement of the machine. • If this parameter is set to 0, no speed limit check is performed. •...

- Page 102 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Override Override Set the percentage of the OL10 setting parameter (Speed Reference Setting) to output in increments of 0.01%. Register Setting Name Setting Unit Default Control mode Address Range OW18 Override 0 to 32,767 0.01% 10,000...

- Page 103 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Register Setting Name Setting Unit Default Control mode Address Range Reference OL1E Positioning Completion Width 0 to 65,535 Phase Position units Setting Precautions • After all position reference pulses have been distributed for position control, bit 1 (Positioning Completed) in the IW0C monitor parameter changes to 1 (Within positioning completed range) when the Positioning Completed signal from the slave SERVOPACK turns ON (i.e., when bit E in the IL28 monitor parameter changes to 1).

- Page 104 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Setting Precautions • When Set to 0 When bit 0 in the IW0C monitor parameter (Distribution Completed) changes to 1 (Completed), bit 3 in the IW0C changes to 1. • When Not Set to 0 Bit 3 in the IW0C changes to 1 in the following case, regardless of the status of the Dis- tribution Completed Flag.

- Page 105 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Speed Time Distribution completed Position deviation Positioning Completion Width Time Positioning Time Exceeded signal When this time exceeds the Positioning Completion Check Time, a Positioning Time Exceeded alarm occurs. Setting Precautions • If, during position control, the IW0C monitor parameter does not change to 1 (Within positioning completed range) even after the time that is set for this parameter is exceeded from when distribution is completed, a Positioning Time Exceeded alarm occurs (bit 6 in IL04 changes to 1).

- Page 106 Limit Setting Precautions for Setting Latch Zones Latch zones are implemented in a software process in the SVC Function Module. However, the actual latching is performed by the slave SERVOPACK. Therefore, depending on the transmis- sion cycle, reference speed, and position deviation, the actual zone may vary from the set zone.

- Page 107 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Gain and Compensation Position Loop Gain This parameter determines the responsiveness of the SERVOPACK’s position loop. Register Setting Name Setting Unit Default Control mode Address Range OW2E Position Loop Gain 0 to 32,767 0.1 /s Phase Position...

- Page 108 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Speed Compensation Set the speed feedforward amount as a percentage of the rated speed when the INTERPO- LATE (Interpolate), PHASE (Issue Phase Reference), or LATCH (Latch) motion command is exe- cuted. Register Setting Name...

- Page 109 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Relationship between SERVOPACK Parameters and Motion Parame- ters The above parameters (OW 2E to OW 34) are applied to the parameters of the SER- VOPACK as shown in the following block diagram. Current loop Acceleration/Deceleration Settings...

- Page 110 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Setting Precautions The unit that is set in the Acceleration/Deceleration Rate Unit Selection bits (bits 4 to 7 in the OW03 setting parameter) is used for this parameter. Specifying Acceleration/Deceleration Rates You can use either of the following two methods to specify an acceleration/deceleration rate.

- Page 111 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details • The actual machine operation follows the settings in the SERVOPACK parameters. Refer to the following section for details on automatically applying settings to the SERVOPACK parameters. 3.5 Automatically Updated Parameters on page 3-86 •...

- Page 112 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Zero Point Position Output Width Set the width for which bit 4 (Zero Point Position) in the IW0C monitor parameter will be 1 (Within zero point position range). Register Setting Name Setting Unit Default Control mode...

- Page 113 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Origin Return Example A typical example of an origin return operation is shown below. Refer to the following section for details on the origin return operation. ZSET (Set Zero Point) on page 4-60 Speed Reference Setting Speed Zero Point Return...

- Page 114 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details External Positioning Final Travel Distance External Positioning Final Travel Distance Set the travel distance from when the external signal is input for the EX_POSING (External Posi- tioning) motion command. Refer to the following section for details on the EX_POSING com- mand.

- Page 115 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Number of POSMAX Turns Preset Data Set the preset value to set in the IL1E monitor parameter (Number of POSMAX Turns) when bit 6 (Number of POSMAX Turns Preset Request) in the OW00 setting parameter changes to 1 (ON).

- Page 116 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Bits C to F: Monitor 4 Select the SERVOPACK information to report in the IL34 monitor parameter (Servo Driver User Monitor 4) from the following list. 0 to F: Same as monitor 2. SERVOPACK References ...

- Page 117 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details SERVOPACK Parameter Set Value Set the SERVOPACK parameter value to be written for the following motion commands. • PRM_WR (Write SERVOPACK Parameter) • PPRM_WR (Write Non-volatile Parameter) Refer to the following chapter for details. Chapter 4 Motion Control Program Commands and Instructions Register Setting...

- Page 118 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Address Setting Set the memory address for the following motion commands. • MEM_RD (Read Memory) • MEM_WR (Write Memory) • PMEM_RD (Read Non-volatile Memory) • PMEM_WR (Write Non-volatile Memory) Refer to the following chapter for details. Chapter 4 Motion Control Program Commands and Instructions Register Setting...

- Page 119 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details Absolute Infinite-length Position Management Information Power OFF Encoder Position (Lower 2 Words) and Power OFF Encoder Position (Upper 2 Words) These parameters store information for infinite-length position management when an absolute encoder is used.

- Page 120 3.4 Motion Parameter Details 3.4.2 Setting Parameter Details • If an axis attempts to move in the forward direction past this position, a positive software limit alarm occurs and bit 3 in the IL04 monitor parameter changes to 1. • The software limit is enabled only after bit 5 (Zero Point Return/Setting Completed) in the IW0C monitor parameter changes to 1 (Completed).

-

Page 121: Monitor Parameter Details

0: Motion operation not ready. 1: Motion operation ready. This bit changes to 1 when the SVC or SVR Function Module is in ready for motion operation. This bit changes to 0 in the following situations. • Major fault error occurred. - Page 122 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Bit 4: Latch Mode 0: Latch detection request not received. 1: Latch detection request received. This bit changes to 1 when a request is received in bit 4 (Latch Detection Request) in the OW00 setting parameter.

- Page 123 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Bit 4: Motion Command Setting Error 0: No command setting error. 1: Command setting error. This bit changes to 1 when an unusable motion command is set. Bit 6: Positive Overtravel 0: No positive overtravel.

- Page 124 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Alarms Alarms Register Name Range Unit Address − − IL04 Alarms Bit 0: Servo Driver Error 0: No SERVOPACK alarm. 1: SERVOPACK alarm occurred. This bit changes to 1 when an alarm occurs in the SERVOPACK. You can view the details of the alarm in the IW2D monitor parameter (SERVOPACK Alarm Code).

- Page 125 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Bit 6: Positioning Time Exceeded 0: No timeout. 1: Timeout occurred. This bit changes to 1 when positioning is not completed within the specified time in the OW26 setting parameter (Positioning Completion Check Time) after distribution is com- pleted.

- Page 126 Bit 1E: Motor Type Setting Error 0: Match. 1: Mismatch. This bit changes to 1 when the motor type in the SVC definition does not match the motor type set for the SERVOPACK. Bit 1F: Connected Encoder Model Error 0: Match.

- Page 127 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Motion Command Response Code Motion Command Response Code This parameter reports the motion command code for the command that is currently being executed. Response codes are also reported when the following processes are executed. •...

- Page 128 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Bit 8: Command Execution Completed (COMPLETE) 0: Normal execution not completed. 1: Normal execution completed. This bit changes to 1 when execution of a motion command is completed normally. Refer to the timing charts for the individual commands in the following chapter for details. Chapter 4 Motion Control Program Commands and Instructions Motion Subcommand Response Code ...

- Page 129 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Position Management Status Position Management Status Register Name Range Unit Address − − IW0C Position Management Status Bit 0: Distribution Completed (DEN) 0: Distributing pulses. 1: Distribution completed. This bit changes to 1 when distribution is completed for a travel motion command. This bit changes to 1 when the SERVOPACK finishes distribution (bit C in IL28 is set to 1), and all Motion Control Function Module internal processing related to distribution is completed.

- Page 130 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Bit 5: Zero Point Return/Setting Completed (ZRNC) 0: Zero point return/setting not completed. 1: Zero point return/setting completed. This bit changes to 1 after the completion of an origin return/setting. This bit changes to 0 when, during an origin return/setting operation, communications with the Servo Section or a slave SERVOPACK are stopped and reestablished.

- Page 131 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Machine Coordinate System Calculated Position (CPOS) This parameter reports the calculated position in the machine coordinate system managed by the Motion Control Function Module. Register Name Range Unit Address Machine Coordinate System Calculated Position −1 IL10 Reference units...

- Page 132 Machine Coordinate System Latch Position (LPOS) Reference units to 2 Position Deviation (PERR) This parameter reports the following deviation (internal Servo reference position − feedback position, converted to reference units) managed by the SVC Function Module. Register Name Range Unit Address −1...

- Page 133 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details M-III Servo Command Input Signal Monitor This parameter reports the signal information that was input to the MECHATROLINK-III. The meanings of the bits depend on the Servo profile. Register Name Range Unit Address −...

- Page 134 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Bit 3: Alarm Clear Execution Completed (ALM_CLR_CMP) 0: Alarms cleared. 1: Alarms not cleared. Bits 6 and 7: Echo-back of Command ID (RCMD_ID) This parameter reports the echo-back value of the command ID of a MECHATROLINK com- mand.

- Page 135 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Auxiliary SERVOPACK Parameter Number This parameter reports the number of the SERVOPACK parameter that is being read or written using the MECHATROLINK subcommand area. Refer to the following chapter for details. Chapter 4 Motion Control Program Commands and Instructions Register Name...

- Page 136 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Torque/Force Reference Monitor This parameter reports the value of the torque reference. Register Name Range Unit Address The unit that is set in −1 IL42 Torque/Force Reference Monitor the Torque Unit to 2 Selection bits is used.

- Page 137 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details Device Information Monitor Code This parameter reports the code for the information that was read with the INF_RD (Read Device Information) motion subcommand. Register Name Range Unit Address − IW5B Device Information Monitor Code 0 to 65,535 00 hex: Disabled 03 hex: Device version...

- Page 138 3.4 Motion Parameter Details 3.4.3 Monitor Parameter Details SERVOPACK Transmission Reference Mode Response Buffers for SERVOPACK Transmission Reference Mode This area stores MECHATROLINK Servo responses. These parameters are used in SERVOPACK Transmission Reference Mode only. Set fixed parameter No. 0 (Operation Mode Selection) to 3 (SERVOPACK Transmission Reference Mode).

-

Page 139: Automatically Updated Parameters

3.5 Automatically Updated Parameters 3.5.1 Automatically Updated Parameters When a MECHATROLINK Connection Is Established Automatically Updated Parameters Some of the parameters that are stored in SERVOPACK RAM may be overwritten automatically under certain conditions or as a result of self configuration. This includes setting parameters, fixed parameters, and fixed value SERVOPACK parameters provided in the MP3000. - Page 140 3.5 Automatically Updated Parameters 3.5.1 Automatically Updated Parameters When a MECHATROLINK Connection Is Established Automatically Updated Parameters When the Auto-write Setting Is Enabled When bit A (SERVOPACK Parameter Auto-Write) in fixed parameter No. 1 is set to 0 (Enabled), the MP3000 parameter settings shown in the following table on the left are automatically writ- ten to the SERVOPACK Servo common parameters shown in the following table on the right when a MECHATROLINK connection is established.

-

Page 141: Automatically Updated Parameters When A Setting Parameter Is Changed

3.5 Automatically Updated Parameters 3.5.2 Automatically Updated Parameters When a Setting Parameter Is Changed 3.5.2 Automatically Updated Parameters When a Setting Parameter Is Changed When bit A (SERVOPACK Parameter Auto-Write) in fixed parameter No. 1 is set to 0 (Enabled), the MP3000 setting parameter values shown in the following table on the left are automatically written to the SERVOPACK Servo common parameters shown in the following table on the right whenever any change is made to those setting parameters. -

Page 142: Automatically Updated Parameters When A Motion Command Is Executed

3.5 Automatically Updated Parameters 3.5.3 Automatically Updated Parameters When a Motion Command Is Executed 3.5.3 Automatically Updated Parameters When a Motion Command Is Executed Some setting parameters are automatically written to the SERVOPACK Servo common param- eters when the MP3000 starts the execution of a motion command. Automatically Updated Parameters That Are Not Affected by the Parameter Auto-write Setting The MP3000 parameter settings shown in the following table on the left are automatically writ-... -

Page 143: 3.5.4 Parameters Automatically Updated During Self Configuration

3.5 Automatically Updated Parameters 3.5.4 Parameters Automatically Updated during Self Configuration 3.5.4 Parameters Automatically Updated during Self Configuration The fixed values in the MP3000 are written to the SERVOPACK EEPROM or RAM during self- configuration as shown below. The SERVOPACK parameters are also written to the MP3000’s setting parameters. -

Page 144: Motion Control Program Commands And Instructions

Motion Control Program Commands and Instructions This chapter describes the motion commands required to write ladder programs and the motion language instruc- tions required to write motion programs. Commands ......4-3 4.1.1 Motion Commands . - Page 145 4.2.25 KIS (Change Position Loop Integral Time Constant) ......4-103 4.2.26 PPRM_WR (Write Non-volatile Parameter) ..4-105 4.2.27 EX_FEED (Jog with External Positioning) .

-

Page 146: Commands

4.1 Commands 4.1.1 Motion Commands Commands 4.1.1 Motion Commands Motion commands are used to perform motion control for machine operation. They are used to write motion control programs as ladder programs. A distinct command code is assigned to each motion command. Machine operation is started ... - Page 147 4.1 Commands 4.1.1 Motion Commands Continued from previous page. Com- Refer- mand Command Name Introduction Function Function ence Code Modules Modules Page Changes the acceleration/ Change Filter page deceleration filter time con- Time Constant 4-66 stant. Change Filter Changes the acceleration/ page ...

- Page 148 4.1 Commands 4.1.1 Motion Commands Continued from previous page. Com- Refer- mand Command Name Introduction Function Function ence Code Modules Modules Page Read Non-vola- Reads data from the SERVO- page PMEM_RD – tile Memory PACK non-volatile memory. 4-117 Write Non-vola- Writes data to the SERVO- page ...

-

Page 149: Motion Subcommands

4.1 Commands 4.1.2 Motion Subcommands 4.1.2 Motion Subcommands Motion subcommands are used to make settings related to the handling of status information in motion control. They can be executed at the same time as motion commands. A distinct command code exists for each motion subcommand. Motion subcommands are ... -

Page 150: Motion Command Details

4.2 Motion Command Details 4.2.1 POSING (Positioning) Motion Command Details This section describes motion commands in detail. 4.2.1 POSING (Positioning) The POSING command positions the axis to the target position according to the specified tar- get position and speed. Execution and Operating Procedures Make sure that all of the following conditions are met. - Page 151 4.2 Motion Command Details 4.2.1 POSING (Positioning) Set OW08 to 0 to execute the NOP motion command. This concludes positioning. Operating Patterns The following figure shows the operating pattern when the POSING command is executed. Speed (%) Rated speed (100%) Speed Reference Setting Position...

- Page 152 4.2 Motion Command Details 4.2.1 POSING (Positioning) Related Parameters The parameters that are related to this command are listed in the following table. Setting Parameters Register Name Setting Details Address Use this bit to turn the power to the Servomotor ON or OFF. OW00 Servo ON Set this parameter to 1 before setting OW08 to 1 (POSING).

- Page 153 4.2 Motion Command Details 4.2.1 POSING (Positioning) Continued from previous page. Register Name Setting Details Address Linear Acceleration Set the positioning acceleration rate with the acceleration rate or the OL36 Rate/Acceleration acceleration time. Time Constant Linear Deceleration Set the positioning deceleration rate with the deceleration rate or the OL38 Rate/Deceleration deceleration time.

- Page 154 4.2 Motion Command Details 4.2.1 POSING (Positioning) Timing Charts Normal Execution 08 = 1 (POSING) 08 = 1 (POSING) 09 Bit 0 (BUSY) 09 Bit 3 (FAIL) 09 Bit 8 (COMPLETE) 0C Bit 0 (DEN) 0C Bit 1 (POSCOMP) 1 scan This interval is not constant.

- Page 155 4.2 Motion Command Details 4.2.1 POSING (Positioning) Holding 08 = 1 (POSING) 09 Bit 0 (HOLD) 08 = 1 (POSING) 09 Bit 0 (BUSY) 09 Bit 1 (HOLDL) 09 Bit 3 (FAIL) 09 Bit 8 (COMPLETE) 0C Bit 0 (DEN) 0C Bit 1 (POSCOMP) This interval is not constant.

-

Page 156: Ex_Posing (External Positioning)

4.2 Motion Command Details 4.2.2 EX_POSING (External Positioning) 4.2.2 EX_POSING (External Positioning) The EX_POSING command begins positioning the axis towards the target position according to the specified target position and speed. Parameters related to acceleration and deceleration are set in advance. When the external positioning signal is turned ON during motion, the axis is moved by the external positioning final travel distance from the current position. - Page 157 4.2 Motion Command Details 4.2.2 EX_POSING (External Positioning) Operating Patterns The following figure shows the operating pattern when the EX_POSING command is executed. Speed (%) Rated speed (100%) Speed Reference Setting External Positioning Final Travel Distance Time (t) Linear Deceleration Linear Acceleration Time Constant Time Constant...

- Page 158 4.2 Motion Command Details 4.2.2 EX_POSING (External Positioning) Continued from previous page. Register Name Setting Details Address Function Settings 1 Select the speed unit, acceleration/deceleration unit, and filter type. External Positioning Set the external positioning signal. Bit 4 to 7 Signal Setting 2: Phase-C pulse, 3: /EXT1, 4: /EXT2, 5: /EXT3 Positioning is started when this parameter is set to 2 (EX_POSING).

- Page 159 4.2 Motion Command Details 4.2.2 EX_POSING (External Positioning) Continued from previous page. Register Name Setting Details Address Set the acceleration/deceleration filter time constant. Exponential acceleration/deceleration or a moving average filter can be selected Filter Time Constant in bits 8 to B in OW03. This setting can be changed only when distribution has been com- pleted (i.e., when bit 0 in IW0C is 1).

- Page 160 4.2 Motion Command Details 4.2.2 EX_POSING (External Positioning) Timing Charts For EX_POSING, the value of the OL46 setting parameter (External Positioning Final Information Travel Distance) is written to SERVOPACK common parameter No. 83 (Final Travel for Exter- nal Input Positioning). Therefore, there is a slight time lag before the axis starts moving (refer to the items with asterisks (*) in the following figure).

- Page 161 4.2 Motion Command Details 4.2.2 EX_POSING (External Positioning) Execution When an Alarm Occurs This interval is not constant.* 08 = 2 (EX_POSING) 08 = 2 (EX_POSING) 09 Bit 0 (BUSY) 09 Bit 3 (FAIL) 09 Bit 8 (COMPLETE) 0C Bit 0 (DEN) 0C Bit 1 (POSCOMP) This interval is not constant.

- Page 162 4.2 Motion Command Details 4.2.2 EX_POSING (External Positioning) Related Parameters Register Address Name Description This bit sets whether or not to automatically apply OL46 to the SERVOPACK. External Positioning Final The setting is applied at the start of motion ...

-

Page 163: Zret (Zero Point Return)

4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) 4.2.3 ZRET (Zero Point Return) When the ZRET command is executed, the axis returns to the origin of the machine coordinate system. The operation to detect the position of the origin is different for an absolute encoder and for an incremental encoder. - Page 164 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Execution and Operating Procedures Make sure that all of the following conditions are met. Execution Condition Confirmation Method There must be no alarms. Both IL02 and IL04 must be 0. The Servomotor’s power must be ON. Bit 1 in IW00 must be 1.

- Page 165 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Related Parameters The parameters that are related to this command are listed in the following table. Setting Parameters Register Name Setting Details Address Use this bit to turn the power to the Servomotor ON or OFF. ...

- Page 166 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Continued from previous page. Register Name Monitored Contents Address Command Execution This bit changes to 1 (Normal execution completed) when execution Bit 8 Completed of the ZRET command ends. This bit changes to 1 (Distribution completed) when the distribution ...

- Page 167 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Execution When Canceled 08 = 3 (ZRET) 09 Bit 1 (ABORT) 08 = 3 (ZRET) 09 Bit 0 (BUSY) 09 Bit 3 (FAIL) 09 Bit 8 (COMPLETE) 0C Bit 0 (DEN) 0C Bit 1 (POSCOMP) 1 scan This interval is not constant.

- Page 168 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Origin Return Methods and Parameters With an incremental encoder, there are 13 different methods that you can use for the origin return operation. This section explains the operations that occur after starting an origin return operation and the parameters that must be set before issuing the command.

- Page 169 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Continued from previous page. Register Address Name Setting Details This parameter allows the travel speed to be changed without changing the value of OL10. Set the value as a percent- age of the Speed Reference Setting. This parameter can be ...

- Page 170 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Setting Parameters Register Address Name Setting Details Zero Point Return 1: ZERO signal Method Zero Point Return 09 Bit 3 Set the origin return direction. Direction Selection Set the speed to use after passing the DEC1 signal. ...

- Page 171 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Setting Parameters Register Address Name Setting Details Zero Point Return 2: DEC1 + ZERO signal Method Zero Point Return 09 Bit 3 Set the origin return direction. Direction Selection Set the speed at which to begin the origin return operation.

- Page 172 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) The travel distance after the phase-C pulse is detected is set in the OL42 setting parameter (Zero Point Return Travel Distance). If an overtravel signal is detected during the origin return operation, an overtravel alarm will occur. Important ...

- Page 173 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) • Overtravel Signal Detected during Travel at the Creep Speed Speed Reference Setting Creep Speed Zero Point Return Travel Distance Origin Start Creep Speed Phase-C pulse P-OT N-OT SERVOPACK P-OT signal. SERVOPACK N-OT signal.

- Page 174 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) P-OT + C Pulse (OW3C = 12) Operation after Origin Return Starts Travel is started at the approach speed until the P-OT signal is detected. When the P-OT signal is detected, the direction will be reversed and the axis will return at the creep speed.

- Page 175 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) P-OT Only (OW3C = 13) Operation after Origin Return Starts Travel is started at the approach speed until the P-OT signal is detected. When the P-OT signal is detected, the direction will be reversed and the axis will return at the positioning speed.

- Page 176 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Setting Parameters Register Address Name Setting Details Zero Point Return 13: P-OT only Method Set the positioning speed to use after the P-OT signal is Speed Reference Set- detected. The sign is ignored. ...

- Page 177 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) • Overtravel Signal Detected during Travel at the Approach Speed Approach Speed Speed Reference Setting Creep Speed Zero Point Return Travel Distance Origin Start Approach Speed HOME signal Phase-C pulse P-OT N-OT SERVOPACK EXT1 signal.

- Page 178 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) HOME Only (OW3C = 15) Operation after Origin Return Starts Travel is started at the creep speed in the direction determined by the sign of the creep speed. When the rising edge of the HOME signal is detected, positioning will be performed at the positioning speed.

- Page 179 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Setting Parameters Register Address Name Setting Details Zero Point Return 15: HOME only Method Set the positioning speed to use after the HOME signal is Speed Reference Set- detected. The sign is ignored. ...

- Page 180 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Setting Parameters Register Address Name Setting Details Zero Point Return 16: N-OT + C pulse Method Set the positioning speed to use after the phase-C pulse is Speed Reference Set- detected.

- Page 181 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Setting Parameters Register Address Name Setting Details Zero Point Return 17: N-OT only Method Set the positioning speed to use after the N-OT signal is Speed Reference Set- detected. The sign is ignored. ...

- Page 182 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) • Overtravel Signal Detected during Travel at the Approach Speed Approach Speed Speed Reference Setting (OL Zero Point Return Travel Distance Start Origin Creep Speed INPUT signal Approach Speed (bit B in OW Phase-C pulse P-OT N-OT...

- Page 183 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) INPUT Only (OW3C = 19) Operation after Origin Return Starts Travel is started at the creep speed in the direction determined by the sign of the creep speed. When the rising edge of the INPUT signal is detected, positioning will be performed at the positioning speed.

- Page 184 4.2 Motion Command Details 4.2.3 ZRET (Zero Point Return) Setting Parameters Register Address Name Setting Details Zero Point Return 19: INPUT only Method Set the positioning speed to use after the INPUT signal is Speed Reference Set- detected. The sign is ignored. ...

-

Page 185: Interpolate (Interpolation)

4.2 Motion Command Details 4.2.4 INTERPOLATE (Interpolation) 4.2.4 INTERPOLATE (Interpolation) The INTERPOLATE command positions the axis according to target position data that changes in sync with the high-speed scan. The positioning data is created by a ladder program. • Speed feedforward compensation can be applied. Information •... - Page 186 4.2 Motion Command Details 4.2.4 INTERPOLATE (Interpolation) Operating Patterns The following figure shows the operating pattern when the INTERPOLATE command is exe- cuted. Speed (%) Position Time (t) Positioning completed range POSCOMP Holding and Canceling Commands The axis stops if there is no change in the target position each high-speed scan. Bit 0 (Hold Command) and bit 1 (Cancel Command) in the OW09 setting parameter can- not be used to stop the axis.

- Page 187 4.2 Motion Command Details 4.2.4 INTERPOLATE (Interpolation) Continued from previous page. Register Name Setting Details Address Set this parameter to the value for which bit 3 in IW0C will NEAR Signal Output change to 1 (Within near position range). Bit 3 changes to 1 when ...

- Page 188 4.2 Motion Command Details 4.2.4 INTERPOLATE (Interpolation) Timing Charts Normal Execution The target position is updated every high-speed scan. 08 = 4 (INTERPOLATE) 08 = 4 (INTERPOLATE) 09 Bit 0 (BUSY) 09 Bit 3 (FAIL) 09 Bit 8 (COMPLETE) 0C Bit 0 (DEN) 0C Bit 1 (POSCOMP) 1 scan...

-

Page 189: Latch (Latch)

4.2 Motion Command Details 4.2.5 LATCH (Latch) 4.2.5 LATCH (Latch) The LATCH command saves the current position to a register when the latch signal is detected during interpolation feeding. Set bits 0 to 3 (Latch Signal Selection) in the OW04 setting parameter to select either phase-C pulse, /EXT1, /EXT2, or /EXT3 for the latch signal. - Page 190 4.2 Motion Command Details 4.2.5 LATCH (Latch) Set OW08 to 0 to execute the NOP motion command. This concludes interpolation positioning. Operating Patterns The following figure shows the operating pattern when the LATCH command is executed. Speed (%) This position is reported in Position Time (t) Latch signal...

- Page 191 4.2 Motion Command Details 4.2.5 LATCH (Latch) Continued from previous page. Register Name Setting Details Address Positioning Comple- Set this parameter to the value for which bit 1 in IW0C will change tion Width to 1 (Within positioning completed range). Set this parameter to the value for which bit 3 in IW0C will change NEAR Signal Out- to 1 (Within near position range).

- Page 192 4.2 Motion Command Details 4.2.5 LATCH (Latch) Timing Charts Normal Execution The target position is updated every high-speed scan. This position is reported. 08 = 6 (LATCH) 08 = 6 (LATCH) 09 Bit 0 (BUSY) 09 Bit 3 (FAIL) 09 Bit 8 (COMPLETE) 0C Bit 0 (DEN) 0C Bit 1 (POSCOMP)

-

Page 193: Feed (Jog)

4.2 Motion Command Details 4.2.6 FEED (Jog) 4.2.6 FEED (Jog) The FEED command starts movement in the specified travel direction at the specified travel speed. Execute the NOP command to stop the operation. Execution and Operating Procedures Make sure that all of the following conditions are met. Execution Condition Confirmation Method There must be no alarms. - Page 194 4.2 Motion Command Details 4.2.6 FEED (Jog) Operating Patterns The following figure shows the operating pattern when the FEED command is executed. Speed (%) Rated speed (100%) NOP command Feed Speed Position Time (t) Linear Acceleration Linear Deceleration Time Constant Time Constant Holding Holding execution of the FEED command is not possible.

- Page 195 4.2 Motion Command Details 4.2.6 FEED (Jog) Continued from previous page. Register Name Setting Details Address Select the stop method to use when a command is canceled. 0: Stop according to the Linear Deceleration Rate/Deceleration Stop Mode Selection Bit 8 to F Time Constant parameter 1: Stop immediately ...

- Page 196 4.2 Motion Command Details 4.2.6 FEED (Jog) Continued from previous page. Register Name Monitored Contents Address Command Hold This bit is always 0 (Command hold not completed) for the FEED com- Bit 1 Completed mand. This bit changes to 1 (Completed with an error) when an error occurs ...

- Page 197 4.2 Motion Command Details 4.2.6 FEED (Jog) Execution When an Alarm Occurs 08 = 7 (FEED) 08 = 7 (FEED) 09 Bit 0 (BUSY) 09 Bit 3 (FAIL) 09 Bit 8 (COMPLETE) 0C Bit 0 (DEN) 1 scan Alarms 4-54...

-

Page 198: Step (Step Operation)

4.2 Motion Command Details 4.2.7 STEP (STEP Operation) 4.2.7 STEP (STEP Operation) The STEP command performs positioning for the specified travel distance based on the speci- fied travel direction, travel distance, and travel speed. Execution and Operating Procedures Make sure that all of the following conditions are met. Execution Condition Confirmation Method There must be no alarms. - Page 199 4.2 Motion Command Details 4.2.7 STEP (STEP Operation) Operating Patterns The following figure shows the operating pattern when the STEP command is executed. STEP Operating Pattern Speed (%) Rated speed (100%) Feed Speed STEP Travel Distance Time (t) Linear Acceleration Linear Deceleration Time Constant Time Constant...

- Page 200 4.2 Motion Command Details 4.2.7 STEP (STEP Operation) Continued from previous page. Register Name Setting Details Address Select the stop method to use when a command is canceled. 0: Stop according to the Linear Deceleration Rate/Deceleration Stop Mode Selection Bit 8 to F Time Constant parameter 1: Stop immediately...

- Page 201 4.2 Motion Command Details 4.2.7 STEP (STEP Operation) Continued from previous page. Register Name Monitored Contents Address Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. Response Code This parameter is 8 during execution of the STEP command.

- Page 202 4.2 Motion Command Details 4.2.7 STEP (STEP Operation) Execution When Canceled 08 = 8 (STEP) 09 Bit 1 (ABORT) 08 = 8 (STEP) 09 Bit 0 (BUSY) 09 Bit 3 (FAIL) 09 Bit 8 (COMPLETE) 0C Bit 0 (DEN) 0C Bit 1 (POSCOMP) 1 scan This interval is not constant.

-

Page 203: Zset (Set Zero Point)

4.2 Motion Command Details 4.2.8 ZSET (Set Zero Point) 4.2.8 ZSET (Set Zero Point) Execute the ZSET command to set the origin in the machine coordinate system. This enables the origin to be set without performing an origin return operation. When using software limits, always execute this command or an origin return operation. - Page 204 4.2 Motion Command Details 4.2.8 ZSET (Set Zero Point) Setting Parameters Register Name Setting Details Address Motion Commands The operation starts when this parameter is set to 9 (ZSET). Hold Command This bit is ignored for the ZSET command. Bit 0 ...

-

Page 205: Acc (Change Acceleration Time)

Time Constant) is issued to the Servo Selection or a slave SERVOPACK as soon as a travel motion command is executed. • This command is not required when an SVC Function Module is used, but it can still be set. Setting this command will not cause an error. The parameter settings that you have used until now can still be used with an SVC Function Module, including the settings for this command. - Page 206 4.2 Motion Command Details 4.2.9 ACC (Change Acceleration Time) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 207: Dcc (Change Deceleration Time)

Time Constant) is issued to the Servo Selection or a slave SERVOPACK as soon as a travel motion command is executed. • This command is not required when an SVC Function Module is used, but it can still be set. Setting this command will not cause an error. The parameter settings that you have used until now can still be used with an SVC Function Module, including the settings for this command. - Page 208 4.2 Motion Command Details 4.2.10 DCC (Change Deceleration Time) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 209: Scc (Change Filter Time Constant)

Constant) to the Moving Average Time or Exponential Acceleration/Deceleration Time Constant SERVOPACK parameter and enables the setting. An SVC Function Module can automatically transfer setting parameters to SERVOPACK parame- ters when they are overwritten. The SCC command is not required if this function is used. Refer to the following section for details. - Page 210 4.2 Motion Command Details 4.2.11 SCC (Change Filter Time Constant) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 211: Chg_Filter (Change Filter Type)

4.2 Motion Command Details 4.2.12 CHG_FILTER (Change Filter Type) 4.2.12 CHG_FILTER (Change Filter Type) This command enables the set value of bits 8 to B (Filter Type Selection) in the OW03 setting parameter. When bit A (SERVOPACK Parameter Auto-Write) in fixed parameter No. 1 is 0 (Enabled), the Information filter type is changed when distribution is completed, even if this command is not executed. - Page 212 4.2 Motion Command Details 4.2.12 CHG_FILTER (Change Filter Type) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 213: Kvs (Change Speed Loop Gain)

Gain) to the Speed Loop Gain SERVOPACK parameter and enables the setting. An SVC Function Module can automatically transfer setting parameters to SERVOPACK parame- ters when they are overwritten. The KVS command is not required if this function is used. Refer to the following section for details. - Page 214 4.2 Motion Command Details 4.2.13 KVS (Change Speed Loop Gain) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 215: Kps (Change Position Loop Gain)

Gain) to the Position Loop Gain SERVOPACK parameter and enables the setting. An SVC Function Module can automatically transfer setting parameters to SERVOPACK parame- ters when they are overwritten. The KPS command is not required if this function is used. Refer to the following section for details. - Page 216 4.2 Motion Command Details 4.2.14 KPS (Change Position Loop Gain) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 217: Kfs (Change Feedforward)

Compensation) to the Feedforward SERVOPACK parameter and enables the setting. An SVC Function Module can automatically transfer setting parameters to SERVOPACK parame- ters when they are overwritten. The KFS command is not required if this function is used. Refer to the following section for details. - Page 218 4.2 Motion Command Details 4.2.15 KFS (Change Feedforward) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 219: Prm_Rd (Read Servopack Parameter)

4.2 Motion Command Details 4.2.16 PRM_RD (Read SERVOPACK Parameter) 4.2.16 PRM_RD (Read SERVOPACK Parameter) The PRM_RD command reads the set value of the SERVOPACK parameter that corresponds to the specified parameter number and parameter size. The read value is then stored in the IW36 (SERVOPACK Parameter Number) and IL38 (SERVOPACK Parameter Read Data) monitor parameters. - Page 220 4.2 Motion Command Details 4.2.16 PRM_RD (Read SERVOPACK Parameter) Continued from previous page. Register Name Setting Details Address Use this bit to select the parameter to read. SERVOPACK Parame- 0: Vendor-specific parameters Bit 8 ter Access Selection 1: Common parameters SERVOPACK Parame- ...

-

Page 221: Prm_Wr (Write Servopack Parameter)

4.2 Motion Command Details 4.2.17 PRM_WR (Write SERVOPACK Parameter) 4.2.17 PRM_WR (Write SERVOPACK Parameter) The PRM_WR command overwrites the setting of a SERVOPACK parameter using the speci- fied parameter number, parameter size, and set value data. Two types of SERVOPACK parameters can be written with this command: vendor-specific parameters, which are vendor-specific specifications for the particular Servo product used, and Servo common parameters, which are defined in the MECHATROLINK-III communications specifications. - Page 222 4.2 Motion Command Details 4.2.17 PRM_WR (Write SERVOPACK Parameter) Continued from previous page. Register Name Setting Details Address Use this bit to select the parameter to write. SERVOPACK Parame- 0: Vendor-specific parameters Bit 8 ter Access Selection 1: Common parameters SERVOPACK Parame- ...

-

Page 223: Alm_Mon (Monitor Alarms)

4.2 Motion Command Details 4.2.18 ALM_MON (Monitor Alarms) 4.2.18 ALM_MON (Monitor Alarms) The ALM_MON command reads the alarm or warning that is current in the SERVOPACK and stores it in the IW2D monitor parameter (SERVOPACK Alarm Code). You can use this command to check all alarms that have occurred, even if multiple alarms occurred at the same time. - Page 224 4.2 Motion Command Details 4.2.18 ALM_MON (Monitor Alarms) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 225: Alm_Hist (Monitor Alarm History)

4.2 Motion Command Details 4.2.19 ALM_HIST (Monitor Alarm History) 4.2.19 ALM_HIST (Monitor Alarm History) The ALM_HIST command reads the alarm history stored in the SERVOPACK and stores it in the IW2D monitor parameter (SERVOPACK Alarm Code). Execution and Operating Procedures Make sure that the following condition is met. - Page 226 4.2 Motion Command Details 4.2.19 ALM_HIST (Monitor Alarm History) Monitor Parameters Register Name Monitored Contents Address Warnings This parameter reports the current warning status. Alarms This parameter reports the current alarm status. Motion Command This parameter shows the motion command currently in execution. ...

-

Page 227: Almhist_Clr (Clear Alarm History)

4.2 Motion Command Details 4.2.20 ALMHIST_CLR (Clear Alarm History) 4.2.20 ALMHIST_CLR (Clear Alarm History) When the ALMHIST_CLR command is executed, the alarm history data that is stored in the SERVOPACK is cleared. Execution and Operating Procedures Make sure that the following condition is met. Execution Condition Confirmation Method Motion command execution for the target axis... - Page 228 4.2 Motion Command Details 4.2.20 ALMHIST_CLR (Clear Alarm History) Continued from previous page. Register Name Monitored Contents Address This bit changes to 1 (Completed with an error) when an error occurs during execution of the ALMHIST_CLR command. Command Error End Bit 3 The axis will decelerate to a stop if it is moving.

-

Page 229: Abs_Rst (Reset Absolute Encoder)

4.2 Motion Command Details 4.2.21 ABS_RST (Reset Absolute Encoder) 4.2.21 ABS_RST (Reset Absolute Encoder) You can reset the absolute encoder by executing the ABS_RST command. The absolute encoder must be reset in the following cases: • When the machine is initially started •... - Page 230 4.2 Motion Command Details 4.2.21 ABS_RST (Reset Absolute Encoder) Setting Parameters Register Name Setting Details Address Use this bit to turn the power to the Servomotor ON or OFF. Servo ON Set this parameter to 0 before setting OW 08 to 22 (ABS_RST).