Summary of Contents for Thermo Scientific appliedbiosystems SeqStudio Flex Series

- Page 1 ™ SeqStudio Flex Series Genetic Analyzer with Instrument Software v1.0 USER GUIDE Catalog Numbers A50369 Publication Number 100104689 Revision A For Research Use Only. Not for use in diagnostic procedures.

- Page 2 Life Technologies Holdings Pte Ltd | Block 33 | Marsiling Industrial Estate Road 3 | #07-06, Singapore 739256 For descriptions of symbols on product labels or product documents, go to thermofisher.com/symbols-definition. The information in this guide is subject to change without notice. DISCLAIMER: TO THE EXTENT ALLOWED BY LAW, THERMO FISHER SCIENTIFIC INC.

-

Page 3: Table Of Contents

Contents ■ CHAPTER 1 Product information ..........16 Product description . - Page 4 Contents ■ CHAPTER 2 Get started ............53 Sign in .

- Page 5 Contents ■ CHAPTER 5 Create a plate file in the Plate Manager software ....95 Options for creating plate files in the Plate Manager software ..... . . 95 Get started with the Plate Manager software (desktop) .

- Page 6 Contents Run plates with the automated barcode workflow ....... . . 147 Create the plate files before the barcoded plates are loaded into the drawer .

- Page 7 Contents Cancel injections or specify re-injections in the Remote Monitoring software ..192 Pause the instrument from the Remote Monitoring screen, resume from the instrument home screen ..........193 Monitor a run from a mobile device .

- Page 8 Contents Basic voice commands ........... . 234 Interactive voice command—start run .

- Page 9 Contents Run modules library ............272 Run module overview .

- Page 10 Contents Example spatial profiles ........... 308 Export spatial calibration results or report .

- Page 11 Contents Change and store a capillary array (wizards) ........371 Parts of the capillary array .

- Page 12 Contents Manage settings ............. . 452 Display instrument hardware and software information .

- Page 13 Contents Run self tests to check touchscreen, speakers, microphone, and proximity sensor ............485 Power off or power on the instrument .

- Page 14 Contents ■ APPENDIX B Run modules and dye sets ........526 Run modules, read lengths, size ranges, and run times .

- Page 15 Contents Safety and electromagnetic compatibility (EMC) standards ......554 Safety standards ............555 EMC standards .

-

Page 16: Chapter 1 Product Information

Product information ■ Product description ..............16 ■... -

Page 17: Precautions For Use

Chapter 1 Product information Product description IMPORTANT! The protection provided by the equipment may be impaired if the instrument is operated outside the environment and use specifications, the user provides inadequate maintenance, or the equipment is used in a manner not specified by the manufacturer (Thermo Fisher Scientific). IMPORTANT! Observe current good clinical and laboratory practices when using this instrument. -

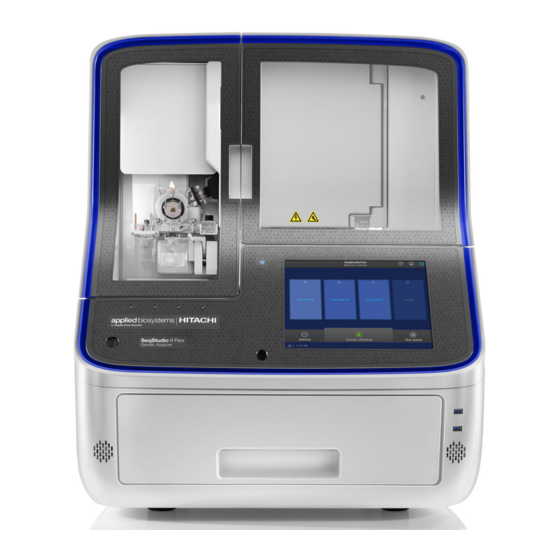

Page 18: Instrument Components

Chapter 1 Product information Product description Instrument components Figure 1 Parts of the instrument Pump compartment USB ports Microphones Touchscreen On/Off Blue LED Proximity sensor Capillary array, detection cell, detection cell heater, and oven compartment Speakers Drawer compartment SeqStudio ™ Flex Series Genetic Analyzer with Instrument Software v1.0 User Guide... - Page 19 Chapter 1 Product information Product description Part Function Pump compartment (see Figure 2 on page 21 for a detailed figure of the pump compartment) Anode buffer container Contains 1X running buffer to support all electrophoresis applications on the (ABC) instrument. Has a built-in overflow chamber to maintain constant fluid height. Polymer delivery pump Pumps polymer into the array and allows for automated maintenance procedures.

- Page 20 Chapter 1 Product information Product description (continued) Part Function Radio frequency RFID tags on the following primary instrument consumable labels are detected by identification (RFID) tags read/write units in the instrument interior: (not shown in figure) • Capillary array For more information, •...

-

Page 21: Instrument Interior Components

Chapter 1 Product information Product description Instrument interior components Figure 2 and Figure 3 are provided below for reference in this section. See also page 376 and “Parts of the capillary array” on page 372. Figure 2 Instrument interior (includes the pump compartment and capillary array compartment) Polymer delivery pump (PDP) Capillary array Water trap waste container... -

Page 22: Power And Communication Connections

Chapter 1 Product information Product description Figure 3 Detection cell heater with the door open and a capillary array installed. The detection cell in the capillary array is shown in the red box. Power and communication connections Figure 4 Instrument front panel connections USB ports used for transferring data SeqStudio ™... -

Page 23: Theory Of Operation

Chapter 1 Product information Theory of operation Figure 5 Instrument rear panel connections Recessed USB port (for use with the wireless Wired network port network adapter; adapter not shown) Circuit breaker (rear power switch; use the power switch on USB port (for optional USB barcode scanner the front panel for normal operation) connection) -

Page 24: During A Run

Chapter 1 Product information Materials for routine operation During a run During a run, the instrument: • Prepares the capillaries by pumping fresh polymer under high pressure from the polymer delivery pump to the waste position in the cathode buffer container (CBC). •... -

Page 25: Instrument Consumables Handling, Usage Limits, And Expiration

Chapter 1 Product information Instrument consumables handling, usage limits, and expiration Instrument consumables handling, usage limits, and expiration IMPORTANT! Before handling chemicals, read and understand all applicable Safety Data Sheets (SDSs) and use appropriate personal protective equipment (gloves, gowns, eye protection, etc). To obtain SDSs, see Appendix G, “Documentation and support”. -

Page 26: Buffer Storage, Usage, And Limits

Chapter 1 Product information Instrument consumables handling, usage limits, and expiration Buffer storage, usage, and limits Cat. No. Description Storage 4393927 Anode Buffer Container 3500/Flex Series (ABC), 4 pack 2–8°C Contains 1X running buffer 4408256 Cathode Buffer Container 3500/Flex Series (CBC), 4 pack 2–8°C Contains 1X running buffer See the expiration date on the label. -

Page 27: Conditioning Reagent Storage, Usage, And Limits

Chapter 1 Product information Instrument consumables handling, usage limits, and expiration Note: A polymer pouch includes a small reserve volume that is used for the Remove Bubbles maintenance wizard, which consumes ~350 μL of polymer. The reserve volume is sufficient to run the wizard ~4 times (including the remove bubbles step during other maintenance wizards). -

Page 28: Hi-Di ™ Formamide Storage And Usage

Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Hi‑Di ™ Formamide storage and usage Formamide is an injection solvent that is used to prepare samples. It is not a consumable that is installed on the instrument as are the other consumables listed in this section. It does not include an RFID tag on the label. -

Page 29: Profile And Sign In Options

Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 • Optional use with the Security, Audit, and E-Signature (SAE) module for controlled user access • Application programming interface (API) to allow automation of instrument and software functions Profile and sign in options The profile you use to sign in depends on your instrument configuration. - Page 30 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 2. In the User Profile screen, tap Get Started. Note: If SAE Sign in is displayed instead of Sign in, see “Sign in to the instrument with SAE enabled”...

- Page 31 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 4. Tap Name, enter a local profile name, then tap Done. 5. Tap PIN (4 digits required), enter a four-digit numerical PIN, then tap Enter. 6. Tap Confirm PIN, reenter the PIN, then tap Enter. 7.

- Page 32 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 2. In the User Profile screen, tap the down arrow under Sign in, then select your profile. 3. Tap the PIN field, enter your PIN, then tap Sign in. The home screen is displayed with your user initials (for example, ) in place of (Profile).

- Page 33 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Switch user or sign out 1. Tap the profile icon for the signed-in user (for example, ). ( indicates no user is signed in.) 2. In the My Profile screen, tap either of the following buttons: •...

- Page 34 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Sign in (if another user is signed in) 1. In the home screen, tap the profile icon for the signed-in user (for example, 2. In the My Profile screen, tap either of the following buttons: •...

-

Page 35: Parts Of The Software

Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 3. Tap your profile, then enter your PIN. The home screen is displayed with your user initials. For more information, see “Local profile and cloud profile: when to use, user name, and user initials”... - Page 36 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Parts of the home screen Icon bar—See “Icon bar” on page Plate positions—See “Plate positions in the home screen” on page Actions, drawer status, and Run queue—See “Actions, drawer status, and Run queue in the home screen” on page Instrument conditions—See “Instrument conditions in the home screen”...

- Page 37 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Icon bar Instrument name and signed-in user name. Pause indicator and Resume run button—Resume run is displayed after you click Pause instrument or if the instrument is paused because of an error condition.

- Page 38 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Plate positions in the home screen Plate position and status Time remaining or Estimated end time Glowing border on a completed plate position. Sample QC (or Spectral QC or Install QC) for the plate Plate alerts Plate name Run status...

- Page 39 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 (continued) Screen element Description Time remaining Time remaining until all injections for the plate are completed. Changes to Estimated end time if the injection order for the injection or the plate is moved to a later position in the run queue.

- Page 40 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Actions, drawer status, and Run queue in the home screen Actions—Displays a screen that allows access to most functions of the instrument: Creating plate files, libraries, maintenance functions, run history, system and instrument settings, and other functions.

- Page 41 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 (continued) Status icons Description • The flags are displayed only if consumables expired/exceeded limits and/or pre-expiry Consumables warnings are enabled. For more information, see “Configure consumables usage and (or individual warnings (administrator only)”...

- Page 42 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Option Description Inbox Open a plate file that you created in the Plate Manager software and sent to the instrument. See Chapter 5, “Create a plate file in the Plate Manager software”. Note: Plate files are listed alphabetically by name.

- Page 43 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 The Inbox contains plate files from all users (it does not contain only the plate files that you send to the instrument). The Inbox accepts only the following plate files: •...

- Page 44 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Parts of the Run Queue screen Run queue (injection list) Sample QC Position of the plate in the drawer Injection status +/– (Expand/Collapse) toggle (Move) Re-injection status Filter by injection status Actions menu Injection details...

- Page 45 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 (continued) Screen element Description View plate button Active only when a single injection or plate with one injection is selected. Displays the electropherogram or plate view for the selected injection. •...

- Page 46 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 (continued) Screen element Description • Inject next—Moves the injection to the next position in the list to be injected. For Injection controls information, see “Change the injection list order” on page 163.

- Page 47 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Task Action View the injection list In the home screen, tap Run queue. Change the order of plates and In the Run queue screen, press-drag (Move) to move a plate or injections injection up or down in the list.

- Page 48 Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Actions screen The Actions screen provides access to most functions in the software other than running plates and using the run queue. SeqStudio ™ Flex Series Genetic Analyzer with Instrument Software v1.0 User Guide...

-

Page 49: Companion Software

Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Dashboard screens—Instrument Status, Consumables Status, and Upcoming Maintenance The Dashboard screens provide access to consumables status, instrument status, and upcoming maintenance tasks. For more information, see “Prepare the instrument” on page Companion software The instrument can be used with the following software:... -

Page 50: Secondary Analysis Software

Chapter 1 Product information About the SeqStudio ™ Flex Series Instrument Software v1.0 Secondary analysis software ™ Secondary analysis software is available for desktop computers and on Thermo Fisher Connect. Visit apps.thermofisher.com for the latest available secondary analysis applications. For information on using these applications to perform automated analysis, see “Automated cloud analysis with secondary analysis software”... -

Page 51: Network Connection Options

Chapter 1 Product information Network connection options Desktop secondary analysis software IMPORTANT! Older versions of the desktop secondary analysis software cannot analyze data files ™ generated by the SeqStudio Flex Series Genetic Analyzer. Contact Technical Support for information on obtaining the latest versions of software. Analysis Software Minimum version required... -

Page 52: Network And Password Security Requirements

Chapter 1 Product information Network and password security requirements Network and password security requirements Network configuration and security The network configuration and security settings of your laboratory or facility (such as firewalls, anti- virus software, network passwords) are the sole responsibility of your facility administrator, IT, and security personnel. -

Page 53: Chapter 2 Get Started

Get started ■ Sign in ................53 ■... - Page 54 Chapter 2 Get started Sign in 2. In the User Profile screen, tap the down arrow under Sign in, then select your profile. 3. Tap the PIN field, enter your PIN, then tap Sign in. The home screen is displayed with your user initials (for example, ) in place of (Profile).

-

Page 55: Profile And Sign In Options

Chapter 2 Get started Profile and sign in options Profile and sign in options The profile you use to sign in depends on your instrument configuration. • Use a local profile for a standalone instrument. Most procedures in this user guide describe using the instrument when you are signed in with a local profile. - Page 56 Chapter 2 Get started Profile and sign in options 2. In the User Profile screen, tap Get Started. Note: If SAE Sign in is displayed instead of Sign in, see “Sign in to the instrument with SAE enabled” on page 244.

-

Page 57: Sign In

Chapter 2 Get started Profile and sign in options 4. Tap Name, enter a local profile name, then tap Done. 5. Tap PIN (4 digits required), enter a four-digit numerical PIN, then tap Enter. 6. Tap Confirm PIN, reenter the PIN, then tap Enter. 7. - Page 58 Chapter 2 Get started Profile and sign in options 2. In the User Profile screen, tap the down arrow under Sign in, then select your profile. 3. Tap the PIN field, enter your PIN, then tap Sign in. The home screen is displayed with your user initials (for example, ) in place of (Profile).

-

Page 59: Switch User Or Sign Out

Chapter 2 Get started Profile and sign in options Switch user or sign out 1. Tap the profile icon for the signed-in user (for example, ). ( indicates no user is signed in.) 2. In the My Profile screen, tap either of the following buttons: •... -

Page 60: Sign In (If Another User Is Signed In)

Chapter 2 Get started Profile and sign in options Sign in (if another user is signed in) 1. In the home screen, tap the profile icon for the signed-in user (for example, 2. In the My Profile screen, tap either of the following buttons: •... - Page 61 Chapter 2 Get started Profile and sign in options 3. Tap your profile, then enter your PIN. The home screen is displayed with your user initials. For more information, see “Local profile and cloud profile: when to use, user name, and user initials”...

-

Page 62: Workflow: Create A Plate, Start And Monitor A Run, Then View Results

Chapter 2 Get started Workflow: Create a plate, start and monitor a run, then view results Workflow: Create a plate, start and monitor a run, then view results Use the instrument Create a plate file in the Plate Manager software and print the plate layout. Prepare the instrument, prepare the samples and the plate, then load the plate into the instrument. - Page 63 Chapter 2 Get started Workflow: Create a plate, start and monitor a run, then view results Use the instrument Monitor the run in the home screen by viewing the information for a plate position, or by tapping a plate position to view the plate layout and run progress.

-

Page 64: Prepare The Instrument

Chapter 2 Get started Prepare the instrument Use the instrument View and analyze results in any of the following locations: • In the home screen, tap the plate position. • In the Run Queue screen, tap an injection. • In the home screen, select Actions4Run history. - Page 65 Chapter 2 Get started Prepare the instrument 1. Display the upcoming maintenance tasks by tapping (Dashboard) at the top right of the home screen. If the Upcoming Maintenance screen is not displayed, tap Tasks are displayed. Note the following: • Overdue tasks are displayed in orange. •...

-

Page 66: Check Consumables Status

Chapter 2 Get started Prepare the instrument Check consumables status Note: The home screen displays an alert if any consumables need replacement. 1. Display the consumables status screen by tapping (Dashboard) at the top right of the home screen. If the consumables status screen is not displayed, tap The screen displays expiration dates and lot numbers (determined from the RFID tags on the consumable containers). -

Page 67: Check Instrument Status

Chapter 2 Get started Prepare the instrument For more information, see the following sections: • “Configure consumables usage and warnings (administrator only)” on page 453 for information on consumables warnings and preventing runs with consumables that exceed limits. • “Install buffers (wizard)” on page 363 •... -

Page 68: Preheat The Instrument Oven And The Detection Cell

Chapter 2 Get started Prepare the instrument Preheat the instrument oven and the detection cell Preheat the instrument oven and the detection cell while you prepare for a run. The detection cell temperature is set by the software. If the oven is not at the set temperature when you start a run, the first injection cannot begin until the oven reaches the set temperature. - Page 69 Chapter 2 Get started Prepare the instrument 4. Check for leaks around the buffer-pin valve, check valve, and array port lock. Buffer-pin valve CV (check valve) fitting Array port lock 5. Remove dried residue and ensure that the array port lock is securely tightened. SeqStudio ™...

-

Page 70: Check Buffer Fill Levels

Chapter 2 Get started Prepare the instrument Check buffer fill levels 1. Open the front doors. 2. (Optional) Turn on the interior light: tap (Dashboard) , tap , then tap On for the LED light. 3. Check the buffer fill levels. Verify that the buffer level is at the top of the fill line. The meniscus must align with the fill line. -

Page 71: Replenish Consumables

Chapter 2 Get started Prepare the instrument Figure 8 CBC fill line CBC fill line IMPORTANT! Replace the buffer if the level is below the fill line. Replenish consumables If a consumable is expired or if the buffer fill level is below the fill line, replenish the consumables as described in the following topics: •... -

Page 72: Control The Led Light, Speaker Volume, And Screen Brightness

Chapter 2 Get started Prepare the instrument Control the LED light, speaker volume, and screen brightness 1. Display the instrument status by tapping (Dashboard) at the top right of the screen (if the instrument status is not displayed, tap 2. As needed, adjust the settings for LED light, Volume, and Screen brightness. SeqStudio ™... -

Page 73: Chapter 3 Prepare The Samples

Prepare the samples ■ Sample preparation guidelines ............73 ■... - Page 74 Chapter 3 Prepare the samples Sample preparation guidelines (continued) Item Guidelines • Prepare sequencing reactions according to kit instructions, and purify the Sequence analysis sample extension products with ethanol precipitation, spin columns, or the BigDye preparation ™ XTerminator Purification Kit. –...

-

Page 75: Plate And Strip-Tube Layout

Chapter 3 Prepare the samples Plate and strip-tube layout Plate and strip-tube layout You can print a plate layout in the Plate Manager software. See “Print the plate layout” on page 125. Figure 9 96-well plate and strip-tube capillary-to-plate Figure 10 96-well plate and strip-tube capillary-to- mapping (8 capillary) plate mapping (24 capillary) Injection 1, 3, 5, 7, 9, 11 (wells A–H) -

Page 76: Prepare And Assemble Sample Plates

Chapter 3 Prepare the samples Prepare and assemble sample plates Prepare and assemble sample plates IMPORTANT! Do not use warped or damaged plates. Prepare sample plates 1. If you use plates with barcodes, check the barcode label before proceeding. If the barcode label is dirty, wipe it clean. If the barcode label is not attached firmly to the plate, do not use the plate. -

Page 77: Prepare The Plate Assembly

Chapter 3 Prepare the samples Prepare and assemble sample plates Prepare the plate assembly Prepare the plate assembly on a clean, level surface. Wear gloves when handling septa. Do not heat plates that are sealed with septa. ™ Plate retainer required for the SeqStudio Flex Series Genetic Analyzer ™... - Page 78 Chapter 3 Prepare the samples Prepare and assemble sample plates 96-well plate assembly, standard or fast IMPORTANT! Use the correct 96-well standard plate retainer and plate base with the same catalog number. Using the wrong plate base may affect performance. See Appendix D, “Catalog numbers” for plate assembly specifications and catalog numbers.

- Page 79 Chapter 3 Prepare the samples Prepare and assemble sample plates 5. Verify that the holes of the plate retainer and the septum are aligned. If the holes are not aligned, take the assembly apart, then re-assemble. IMPORTANT! The array tips will be damaged if the plate retainer and septum holes are not aligned.

- Page 80 Chapter 3 Prepare the samples Prepare and assemble sample plates 1. If the reagents of any tube contain bubbles or are not located at the bottom of the well, briefly centrifuge the plate, remove the plate from the centrifuge, then verify that each sample is positioned correctly in the bottom of its well.

- Page 81 Chapter 3 Prepare the samples Prepare and assemble sample plates Plate retainer with one opening on side to allow barcode reading Plate with septum Plate base 4. Snap the plate retainer (cover) onto the plate base. IMPORTANT! Ensure that the plate retainer is firmly snapped in place on top of the plate (see “Prepare the plate assembly”...

- Page 82 Chapter 3 Prepare the samples Prepare and assemble sample plates Check the alignment and seating of the septum Check the alignment of the septum with the wells and ensure that the retainer is firmly snapped in place. Septum and well are not aligned Septum and well are properly aligned SeqStudio ™...

-

Page 83: Chapter 4 Create A Plate File On The Instrument

Create a plate file on the instrument ■ Create, copy, or import a plate file ............83 ■... -

Page 84: Create A Plate File

Chapter 4 Create a plate file on the instrument Create, copy, or import a plate file Create a plate file 1. In the home screen, tap Actions4Create plate file. Note: This function is the same function you access from the Create a new plate file option on the Link Plate screen and the Copy function in the Plate files library. -

Page 85: Copy A Plate File

Chapter 4 Create a plate file on the instrument Create, copy, or import a plate file Copy a plate file 1. In the home screen, tap Actions4Library4Plate files. 2. In the Manage Plate Files screen, select the plate file to copy, then tap Open. 3. -

Page 86: Import A Plate File

Chapter 4 Create a plate file on the instrument Create, copy, or import a plate file 4. Enter a name for the plate file. 5. Proceed to “Enter plate properties” on page Import a plate file PSM and CSV plate files for import into the instrument The Plate Manager software can create plate files in PSM or CSV format. - Page 87 Chapter 4 Create a plate file on the instrument Create, copy, or import a plate file Import a plate file 1. In the home screen, tap Actions4Library4Plate files. 2. In the Manage Plate Files screen, tap Import. 3. Navigate to the location where the plate file has been saved (network drive, or USB drive), then select the plate file.

-

Page 88: Enter Plate Properties

Chapter 4 Create a plate file on the instrument Enter plate properties Enter plate properties After you create, copy, or import a plate file, the Create Plate or View Plate screen is displayed. Note: The figure shown below is for creating a plate file. The fields and information are the same if you copy or import a plate file. -

Page 89: Enter Injection Properties

Chapter 4 Create a plate file on the instrument Enter injection properties 3. Tap the Plate tab at the top of the screen. 4. Proceed to “Enter injection properties” on page Enter injection properties After you tap the Plate tab in the create or view screen, the plate view is displayed with the first injection group selected. - Page 90 Chapter 4 Create a plate file on the instrument Enter injection properties 2. Tap the injection pane to display the Edit Injection Properties screen. If you are creating a mixed plate, the first Edit Injection Properties screen is displayed. 3. Tap the Application type field, select the application for the wells, then tap Done. SeqStudio ™...

- Page 91 Chapter 4 Create a plate file on the instrument Enter injection properties 4. In the next Edit Injection Properties screen, specify the settings for the injection. Specify settings by doing either of the following: • In the Injection protocol field, select a protocol. An injection protocol contains the elements listed below.

-

Page 92: Specify Replicate Injections

Chapter 4 Create a plate file on the instrument Specify replicate injections 5. (Optional) Select a file name convention or a results group. • A file name convention determines the naming of results files. The default sequencing file name convention appends WellID_SampleName_Timestamp to the file name. -

Page 93: Enter Sample Names, Sample Types, And Custom Fields

Chapter 4 Create a plate file on the instrument Enter sample names, sample types, and custom fields Enter sample names, sample types, and custom fields After you tap the Sample name field in the Edit Injection Properties screen, the Edit Well Properties screen is displayed. - Page 94 Chapter 4 Create a plate file on the instrument Enter sample names, sample types, and custom fields 7. Tap Save. 8. (Optional) Lock the plate file. See “Lock or unlock a library entry” on page 255. 9. Proceed to Chapter 6, “Start and monitor a run”. SeqStudio ™...

-

Page 95: Chapter 5 Create A Plate File In The Plate Manager Software

Create a plate file in the Plate Manager software ■ Options for creating plate files in the Plate Manager software ......95 ■... -

Page 96: Get Started With The Plate Manager Software (Desktop)

Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) Get started with the Plate Manager software (desktop) ™ About the SeqStudio Plate Manager 2.0 software (desktop) ™ The SeqStudio Plate Manager 2.0 software (desktop) is used to create plate files in PSM format or CSV format. - Page 97 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) Screen element Description icon Click in any screen to display the home screen. Instrument type The instrument type determines the type of plate file you set up (SeqStudio Flex or SeqStudio).

- Page 98 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) (continued) Screen element Description Allows you to select one or more instruments, then sends the selected plate file to the Inbox on the instrument(s). (Send to instrument, in Recent plate files list) Contains the following commands:...

-

Page 99: Access The Plate Manager Software (Desktop)

Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) When you open a CSV file on the instrument, the following occurs: • If any of the settings that are named in the CSV file are not already present in the libraries on the instrument, an error message is displayed and the CSV file is not imported. - Page 100 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) 2. (First use only) In the Select an instrument screen, select SeqStudio Flex. The instrument type determines the plate type that is created. You can change the instrument type at any time in the home screen by clicking (Switch instrument) at the top right of the screen.

-

Page 101: Parts Of The Plate Manager Software (Desktop) Home Screen

Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) Parts of the Plate Manager software (desktop) home screen icon Instrument type Create or open a plate file Switch instrument, help, and settings Recent plate files list Copy, send to instrument, and actions Screen element... - Page 102 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) (continued) Screen element Description Opens the software help system. Help Displays the selections for the default Save location for plate files, connecting the Plate Manager software to an instrument, and accessing libraries.

-

Page 103: Connect The Plate Manager Software (Desktop) To An Instrument

Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) Connect the Plate Manager software (desktop) to an instrument When the Plate Manager software is connected to an instrument, you can send a plate file to the Inbox on the instrument. - Page 104 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (desktop) If the connection is not valid, check the address that you entered. 4. Click Add, enter information in the Username and PIN for the instrument fields, then click OK. Note: You can enter a local or a cloud profile.

-

Page 105: Get Started With The Plate Manager Software (Cloud)

Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) Get started with the Plate Manager software (cloud) ™ ™ About the SeqStudio Plate Manager 2.0 Software (Thermo Fisher Connect) ™ The SeqStudio Plate Manager 2.0 software is used to create plate files in PSM format or CSV format. - Page 106 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) Parts of Plate Manager software (cloud) home screen icon Switch instrument, release notes, settings, and help Instrument type Recent plate files list Create or open a plate file Copy, send to instrument, and actions Monitor runs...

- Page 107 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) (continued) Screen element Description Lists the instruments that are linked to your Thermofisher.com account or your local profile. ™ SeqStudio Flex Series Genetic Analyzer and ™...

- Page 108 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) (continued) Screen element Description Makes a copy of the selected plate file with _Copy appended to the plate name. (Copy & edit, in Recent plate files list) Allows you to select one or more instruments, then sends the selected plate file to the Inbox on the instrument(s).

- Page 109 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) ™ Secondary analysis cloud applications on Thermo Fisher Connect The secondary analysis cloud applications listed below are available for cloud analysis. Visit apps.thermofisher.com for the latest available secondary analysis applications.

- Page 110 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) PSM and CSV plate files for import into the instrument The Plate Manager software can create plate files in PSM or CSV format. Note: The instrument also creates a PSM file when you save a plate file.

-

Page 111: Access The Plate Manager Software (Cloud)

Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) Password security Thermo Fisher Scientific strongly recommends that you maintain unique passwords for all accounts in use on this product. All passwords should be reset upon first sign in to the product. Change passwords according to your organization's password policy. -

Page 112: Parts Of Plate Manager Software (Cloud) Home Screen

Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) ™ Note: You can also use the Plate Manager software with a SeqStudio instrument. To change the default instrument type, click (Switch instrument) at the top right of the screen, then select SeqStudio. - Page 113 Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) (continued) Screen element Description Create or open a plate file Allows you to do the following: • Create a new plate file. •...

-

Page 114: Connect Plate Manager Software (Cloud) To An Instrument

Chapter 5 Create a plate file in the Plate Manager software Get started with the Plate Manager software (cloud) (continued) Screen element Description Recent plate files list Lists the 10 most recently created or edited plate files and their status. The status indicates if a plate file was sent to an instrument. -

Page 115: Set Up A Plate File

Chapter 5 Create a plate file in the Plate Manager software Set up a plate file Set up a plate file As an alternative to creating a plate file in the Plate Manager software, you can create plate files in CSV format. -

Page 116: Enter Plate Properties

Chapter 5 Create a plate file in the Plate Manager software Set up a plate file Enter plate properties 1. (Optional) In the Properties tab, edit the entries in the Plate file name, Barcode, or Owner fields. 2. In the Application type list, select a type: Sequencing, Fragment analysis, or Mixed (sequencing and fragment analysis). - Page 117 Chapter 5 Create a plate file in the Plate Manager software Set up a plate file Note: All settings in the remaining steps will be assigned to all selected injection groups. If different injection groups require different settings, repeat these steps for each injection group. 2.

- Page 118 Chapter 5 Create a plate file in the Plate Manager software Set up a plate file • Select individual elements in the following fields. Selecting an individual element overrides an injection protocol selection and clears the Injection protocol field. – Application type if you are creating a mixed sequencing and fragment analysis plate –...

-

Page 119: Save A Plate File

Chapter 5 Create a plate file in the Plate Manager software Set up a plate file 3. (Optional) Under Additional settings, assign a File name convention and Results group to each injection as needed. • A file name convention determines the naming of results files. The default sequencing file name convention appends WellID_SampleName_Timestamp to the file name. - Page 120 Chapter 5 Create a plate file in the Plate Manager software Set up a plate file 1. In the Save tab, perform these optional tasks as needed. • Change the settings for Plate file name and File save location. This location specifies the default location for plate files only.

-

Page 121: Keyboard Shortcuts And Examples

Chapter 5 Create a plate file in the Plate Manager software Keyboard shortcuts and examples Keyboard shortcuts and examples You can use the following shortcuts in the Plate Manager software. You can use some of the shortcuts in the plate view. You can use all of the shortcuts in the list view. Shortcuts ™... - Page 122 Chapter 5 Create a plate file in the Plate Manager software Keyboard shortcuts and examples (continued) ™ ™ Windows Mac OS Action Backspace Backspace Delete a cell entry before pressing Enter or Escape Open the help system. Note: If you use a smaller keyboard that displays multiple items on the keys, you may have to press-hold FN (function key) when you press F1.

- Page 123 Chapter 5 Create a plate file in the Plate Manager software Keyboard shortcuts and examples SeqStudio ™ Flex Series Genetic Analyzer with Instrument Software v1.0 User Guide...

-

Page 124: Set Up Cloud Analysis In The Plate Manager Software (Cloud)

Chapter 5 Create a plate file in the Plate Manager software Set up cloud analysis in the Plate Manager software (cloud) Set up cloud analysis in the Plate Manager software (cloud) ™ You can create a plate file that specifies automatic secondary analysis in a Thermo Fisher Connect application. -

Page 125: Print The Plate Layout

Chapter 5 Create a plate file in the Plate Manager software Print the plate layout 5. For VA, NGC, or MSA cloud applications, select the name of a template that you created in the secondary analysis software. Analysis templates are optional for QC and PS software. 6. -

Page 126: Send A Plate File To The Inbox On The Instrument

Chapter 5 Create a plate file in the Plate Manager software Send a plate file to the Inbox on the instrument 4. Click Actions4Print plate layout. A PDF file of the plate layout is downloaded. Send a plate file to the Inbox on the instrument If you do not send a plate file to an instrument when you save the plate file, you can send it from the Recent plate files list in the Plate Manager software. -

Page 127: Additional Functions In The Plate Manager Software

Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software Additional functions in the Plate Manager software Load or download an example plate file You can load an example plate file to use as a starting point for creating a new plate file. You can download an example plate file if you are going to create a plate file in CSV format. -

Page 128: Specify Replicate Injections (Add Run Module Function)

Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software Specify replicate injections (Add run module function) 1. In the Plate tab, click (Actions) at the top right of the Injection settings table, then select Add run module. -

Page 129: Define Custom Fields

Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software 3. For remaining selection fields, double-click the first cell to display the list of options, then select an option. 4. For entry fields, double-click a field to type an entry or use shortcuts to copy and paste, click-drag to fill down, and so on. - Page 130 Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software • To export a PSM file from a saved plate file: a. Click to display the home screen of the Plate Manager software. b.

-

Page 131: Manage The Software

Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software Manage the software Manage plate files in the Plate Manager software The Plate Manager software does not include a Plate files library as the instrument does. To manage plate files, edit the Recent plate files list in the Plate Manager software home screen. - Page 132 Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software Manage libraries Overview of libraries The following libraries are available in the software. These libraries are also available on the instrument. For information on how the instrument imports library entries from plate files that are created in the Plate Manager software, see “PSM and CSV plate files for import into the instrument”...

- Page 133 Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software (continued) Library Description File name conventions A file name convention specifies the naming convention for sample data files. If you do not specify a file name convention for a plate, the following default file name conventions are used: •...

- Page 134 Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software 3. Click the library of interest. This example shows the injection protocols library. Items listed with (Instrument) are factory provided and cannot be modified. SeqStudio ™...

- Page 135 Chapter 5 Create a plate file in the Plate Manager software Additional functions in the Plate Manager software 4. Perform any of the following actions as needed. • Select Actions4Import or Actions4Create new. Note: Some libraries provide only the Import option. If you are importing or creating a plate file, see “PSM and CSV plate files for import into the instrument”...

-

Page 136: Load And Unload A Plate

Start and monitor a run ■ Load and unload a plate ............. . 136 ■... - Page 137 Chapter 6 Start and monitor a run Load and unload a plate 2. Pull the drawer open. IMPORTANT! Do not open and close the drawer rapidly. Doing so can cause vibration and disruption of the samples in the plates. Results may be adversely affected. Drawer unlocked status Drawer closed Drawer open...

-

Page 138: Chapter 6 Start And Monitor A Run

Chapter 6 Start and monitor a run Load and unload a plate 3. If no empty positions are available, remove a plate from the drawer. If you remove a plate from the drawer, a warning message is displayed asking if you intentionally removed the plate (see the following figure). -

Page 139: Unload A Plate From The Instrument

Chapter 6 Start and monitor a run Load and unload a plate 5. Push the drawer closed. IMPORTANT! To avoid injury, keep your hands away from any empty spaces in the drawer when you push the drawer closed. Proceed to “Link a plate file and start a run” on page 140. -

Page 140: Link A Plate File And Start A Run

Chapter 6 Start and monitor a run Link a plate file and start a run 4. Push the drawer closed. IMPORTANT! To avoid injury, keep your hands away from any empty spaces in the drawer when you push the drawer closed. Link a plate file and start a run IMPORTANT! Before linking a plate, check consumables status (see “Check consumables status”... - Page 141 Chapter 6 Start and monitor a run Link a plate file and start a run Note: After a plate is linked, you cannot display the plate properties tab. To view plate properties for linked or running plates, open the plate file in the Plates file library. See “Plate files library” on page 258.

- Page 142 Chapter 6 Start and monitor a run Link a plate file and start a run Option Description Inbox Open a plate file that you created in the Plate Manager software and sent to the instrument. See Chapter 5, “Create a plate file in the Plate Manager software”. Note: Plate files are listed For more information, see “About the Inbox on the instrument”...

- Page 143 Chapter 6 Start and monitor a run Link a plate file and start a run Note: If you select the Inbox or My Instrument option, only plate files with properties that match the polymer and capillary array configuration of the instrument are available for selection. 4.

-

Page 144: Unlink A Plate File

Chapter 6 Start and monitor a run Unlink a plate file Unlink a plate file If a plate position is linked to a plate file, the plate position displays information about the plate and the run. If a plate position is not linked to a plate file, the plate position status displays Link a plate file. For more information, see “Parts of the home screen”... - Page 145 Chapter 6 Start and monitor a run Processes that the instrument performs during a run Plate run status is set to running if no other plates are in the run queue Time remaining for a running plate Plate run status is set to In queue if other plates are in the run queue Estimated end time for a plate that is in the run queue but has not started Plate alerts and number of alerts For more information on plate run statuses, see “Plate position status and plate run status”...

-

Page 146: Pre-Run Check Messages And Plate Alerts During A Run

Chapter 6 Start and monitor a run Pre-run check messages and plate alerts during a run Pre-run check messages and plate alerts during a run Pre-run checks are performed at the following times during a run: • When a plate run starts •... -

Page 147: Run Plates With The Automated Barcode Workflow

Chapter 6 Start and monitor a run Run plates with the automated barcode workflow Run plates with the automated barcode workflow The automated barcode workflow includes the following steps and instrument actions: • You create plate files, then load the plates into the instrument. •... - Page 148 Chapter 6 Start and monitor a run Run plates with the automated barcode workflow b. In the Properties tab, tap the Plate barcode section, enter the plate barcode by typing or using an external USB barcode reader, then tap Enter. If you are creating a new plate, proceed to “Create a plate file”...

-

Page 149: Pre-Run Checks And Plate Alerts In An Automated Barcode Run

Chapter 6 Start and monitor a run View alert and notification details • Starts the run for the first installed plate. • Performs pre-run checks as described in “Processes that the instrument performs during a run” page 144. • Scans the barcode for the next plate loaded into the instrument, performs pre-run checks, then adds the plate to the Run queue. -

Page 150: Auto-Spectral Calibration During An Injection

Chapter 6 Start and monitor a run Auto-spectral calibration during an injection Tap an alert to display the Notifications screen. The number above the symbol indicates the number of notifications for the plate. Examples of plate alerts are displayed below. 2. -

Page 151: Auto-Spectral Calibration Requirements

Chapter 6 Start and monitor a run Auto-spectral calibration during an injection changes in the spectral characteristics from the original manual calibration dye matrix. The instrument performs an auto-spectral calibration for system and custom dyes. The auto-spectral calibration process is iterative. For all capillaries in each injection, the instrument evaluates the spectral characteristics of the current sample. -

Page 152: Auto-Spectral Calibration Results

Chapter 6 Start and monitor a run Auto-spectral calibration during an injection Auto-spectral calibration results The software reports the status of auto-spectral calibration in the well details screen for each sample (tap (Information) in the electropherogram screen or Wells tab). (Information), then swipe up to display Spectral calibration status. -

Page 153: View Real-Time Results In The Home Screen

Chapter 6 Start and monitor a run View real-time results in the home screen The software reports one of the following statuses. • Optimized successfully for this run on Date_Timestamp—The spectral calibration was optimized during auto-spectral calibration using spectral data from the sample and the optimized auto-spectral dye matrix was applied to the sample and saved for future use. - Page 154 Chapter 6 Start and monitor a run View real-time results in the home screen 1. If a plate alert symbol ( ) is displayed for a plate position, see “View alert and notification details” on page 149. 2. In the home screen, tap a running plate position. The plate view is displayed.

- Page 155 Chapter 6 Start and monitor a run View real-time results in the home screen 3. (Optional) Tap the Injections tab. 4. Tap an injection to display the electropherogram screen. For information see, “Use the electropherogram screen” on page 173. 5. Tap Done in the electropherogram screen, then tap the Wells tab. If needed, swipe up to view all wells.

- Page 156 Chapter 6 Start and monitor a run View real-time results in the home screen 6. Tap (Information) to display the details for the well. If needed, swipe up to view all wells. For more information, see: • “Sample QC and quality alerts” on page 172 •...

-

Page 157: Pause The Instrument In The Home Screen

Chapter 6 Start and monitor a run Pause the instrument in the home screen Pause the instrument in the home screen Note: You can also pause the run in the run queue (see “Pause the instrument in the Run Queue screen”... - Page 158 Chapter 6 Start and monitor a run Pause the instrument in the home screen 2. In the Pause Instrument screen, tap a pause option: Pause after current injection completes or Cancel current injection and pause immediately. If you select the pause immediately option, the status of the injection changes to Aborted and the wells for the injection are marked X (canceled/aborted) in the plate view.

- Page 159 Chapter 6 Start and monitor a run Pause the instrument in the home screen 4. Tap Resume run when needed. SeqStudio ™ Flex Series Genetic Analyzer with Instrument Software v1.0 User Guide...

-

Page 160: Use The Run Queue To Monitor A Run On The Instrument

Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument Use the Run queue to monitor a run on the instrument Parts of the Run Queue screen Run queue (injection list) Sample QC Position of the plate in the drawer Injection status +/–... - Page 161 Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument (continued) Screen element Description View plate button Active only when a single injection or plate with one injection is selected. Displays the electropherogram or plate view for the selected injection. •...

-

Page 162: View Real-Time Results In The Run Queue Screen

Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument (continued) Screen element Description • Inject next—Moves the injection to the next position in the list to be injected. For Injection controls information, see “Change the injection list order”... -

Page 163: Change The Injection List Order

Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument The Run Details electropherogram view or the plate view is displayed. Change the injection list order 1. In the home screen, tap Run queue. - Page 164 Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument • Select a plate or one or more injections, then tap Inject next. The plate or injections is moved up to the next position in the list to be injected. An example of using Inject next for an injection is shown below.

-

Page 165: Cancel Or Add Injections Or Specify Re-Injections In The Run Queue Screen

Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument Cancel or add injections or specify re-injections in the Run Queue screen 1. In the home screen, tap Run queue. 2. In the Run Queue screen, do any of the following: select a plate or an injection, then specify the action: •... -

Page 166: Pause The Instrument In The Run Queue Screen

Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument • To specify re-injections—Select an injection, then tap Edit & Re-inject. Change the settings if needed, then tap Done. IMPORTANT! The Edit & Re-inject button is inactive if you select more than one injection, a spectral calibration, or an install run injection. - Page 167 Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument 3. In the Pause Instrument screen, tap a pause option: Pause after current injection completes or Cancel current injection and pause immediately. If you select the pause immediately option, the status of the injection changes to Aborted and the wells for the injection are marked X (canceled/aborted) in the plate view.

- Page 168 Chapter 6 Start and monitor a run Use the Run queue to monitor a run on the instrument 4. Tap Resume run when needed. SeqStudio ™ Flex Series Genetic Analyzer with Instrument Software v1.0 User Guide...

-

Page 169: Chapter 7 View Results On The Instrument

View results on the instrument ■ Options for viewing results on the instrument ......... . . 169 ■... -

Page 170: View Results For A Completed Run (Run History)

Chapter 7 View results on the instrument View results for a completed run (Run history) View results for a completed run (Run history) Note: For information on viewing completed results for a spectral calibration or an install run, see “View and export the spectral calibration history”... -

Page 171: Export Results From The Instrument-Results And Data Files, Logs, And Reports

Chapter 7 View results on the instrument Export results from the instrument—Results and data files, logs, and reports 3. Do any of the following as needed. • Tap a well, then tap View to view the raw, EPT, or analyzed electropherogram for a well. •... -

Page 172: Sample Qc And Quality Alerts

Chapter 7 View results on the instrument Sample QC and quality alerts Note: It can take up to 15 seconds for the instrument to recognize a USB drive after the drive is inserted in a USB port. exFAT-formatted USB drives are recommended. A message is displayed when the file is exporting. -

Page 173: Use The Electropherogram Screen

Chapter 7 View results on the instrument Use the electropherogram screen Table 2 QC thresholds and quality alerts that are used to determine Sample QC (these tests and alerts are not shown in the software) (continued) QC tests Quality alert Fragment analysis QC tests SQ (size quality) (green, good)—≤0.75... - Page 174 Chapter 7 View results on the instrument Use the electropherogram screen 1. Press-drag the thumbnail pane to the region of interest. Thumbnail pane is at start of trace by default Press-drag to move the thumbnail pane to the region of interest 2.

-

Page 175: Sequence Analysis Results

Chapter 7 View results on the instrument Sequence analysis results Sequence analysis results Parts of the sequencing electropherogram screen Quality Value bars. For more information, see “Understanding Quality Values (QVs)” on page 178. Pure basecall with QV ≥20 • Pure basecall with QV 15–19 •... -

Page 176: Sequencing Results And Well Details

Chapter 7 View results on the instrument Sequence analysis results Sequencing results and well details If needed, swipe up to see all information. SeqStudio ™ Flex Series Genetic Analyzer with Instrument Software v1.0 User Guide... - Page 177 Chapter 7 View results on the instrument Sequence analysis results Table 3 Results Result Description • —All QC tests passed. QC (Sample QC) • —At least 1 caution quality alert was triggered. • —At least 1 error quality alert was triggered. For more information see “Sample QC and quality alerts”...

-

Page 178: Understanding Quality Values (Qvs)

Chapter 7 View results on the instrument Sequence analysis results Table 4 Well details (continued) Result Description Spectral calibration status For information, see “Auto-spectral calibration during an injection” on page 150. Export status Indicates whether the results were saved to a location in addition to the instrument, either during data collection or by exporting the Run history. -

Page 179: Fragment Analysis Results

Chapter 7 View results on the instrument Fragment analysis results Fragment analysis results Parts of the fragment analysis electropherogram screen Basepair or scan display selection. Trace color hide/show—Tap to open, then tap a color to hide or show. Analyzed trace. By default, the low-base pair size region is selected and the size standard trace is visible. Size standard curve (red line). -

Page 180: Fragment Analysis Results And Well Details

Chapter 7 View results on the instrument Fragment analysis results Fragment analysis results and well details If needed, swipe up to see all information. Table 5 Results Setting Description • —All QC tests passed. QC (Sample QC) • —At least 1 caution quality alert was triggered. •... - Page 181 Chapter 7 View results on the instrument Fragment analysis results Table 6 Well details Setting Description Sample identification, settings used to collect the data, and re-injection status. Sample file name, Sample name, Capillary number, Size standard, Run module, Dye set, Analysis settings name, Re-injection Lists the causes of the QC issue.

-

Page 182: Chapter 8 Use The Remote Monitoring Software To Monitor Runs

Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis ■ Monitor a run from the Remote Monitoring software ........182 ■... -

Page 183: Open The Remote Monitoring Software From The Instrumentconnect Software

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software 2. (If you are using a SeqStudio ™ Flex instrument) Click an instrument in the Monitor runs pane in the Plate Manager software home screen. -

Page 184: Parts Of The Remote Monitoring Software Home Screen

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software Parts of the Remote Monitoring software home screen Plate positions for the selected instrument Instrument status pane Run History tab Actions menu Cloud Analysis tab... - Page 185 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software (continued) Screen element Description Cloud Analysis tab Lists the projects that have been generated by cloud analysis.

- Page 186 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software Plate position status and plate run status in the Remote Monitoring software home screen Status Description Plate position status Occupied A plate is present in the corresponding position in the instrument drawer.

-

Page 187: Plate File Requirements For Viewing Analyzed And Cloud Results

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software Plate file requirements for viewing analyzed and cloud results To view the analyzed data, a results report, or cloud analysis results in the Remote Monitoring software, you must do the following: •... -

Page 188: View Instrument Notifications In Your Thermo Fisher ™ Connect Account

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software View instrument notifications in your Thermo Fisher ™ Connect account 1. In any screen in Thermo Fisher ™... -

Page 189: Set Up Email Notifications From The Instrument

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software Set up email notifications from the instrument When an instrument is linked to your cloud profile, email notifications from the instrument are automatically sent to the email address that is associated with your Thermofisher.com account. -

Page 190: View Real-Time Results In The Remote Monitoring Software

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software 3. In the Email Notifications screen, select or deselect the options for which you want to receive email notifications, then tap Done. - Page 191 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software Note: A gray symbol in the Sample QC field indicates that the data files are being exported from the instrument to the Remote Monitoring software.

-

Page 192: Sequencing Results

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from the Remote Monitoring software Sequencing results Result Description • —All QC tests passed. QC (Sample QC) • —At least 1 warning quality alert was triggered. •... -

Page 193: Instrument Home Screen

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from a mobile device The changes that you make in the Remote Monitoring software are shown in the Run Queue screen on the instrument. - Page 194 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from a mobile device 3. Tap Yes or No to select your region. 4. If the SeqStudio Flex instrument is not already listed, register the instrument to link your Thermofisher.com account to the instrument: a.

-

Page 195: Monitor A Run From A Mobile Device

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from a mobile device Monitor a run from a mobile device 1. On your mobile device, launch the InstrumentConnect app, then sign in. 2. - Page 196 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from a mobile device 4. Swipe right to view consumables status. Swipe left to return to the injection list. 5. Tap to display the plate positions.

- Page 197 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Monitor a run from a mobile device 6. Tap a plate position to display the injection list, then tap to display the well list. 7.

-

Page 198: View Results In The Remote Monitoring Software

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis View results in the Remote Monitoring software View results in the Remote Monitoring software View results for a completed run in the Remote Monitoring software (Run History tab) Plates are listed in the Run history tab only if the Save location in the plate file specifies Connect Platform. - Page 199 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis View results in the Remote Monitoring software Note: You can use the mouse scroll wheel to zoom on the trace. SeqStudio ™ Flex Series Genetic Analyzer with Instrument Software v1.0 User Guide...

- Page 200 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis View results in the Remote Monitoring software 4. As needed, click the EPT (electrophoresis and telemetry) or Analyzed tabs. SeqStudio ™ Flex Series Genetic Analyzer with Instrument Software v1.0 User Guide...

-

Page 201: Export A Results Report From The Remote Monitoring Software

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis View results in the Remote Monitoring software For more information, see: • “Sample QC and quality alerts” on page 172 • “Sequencing results” on page 192 •... -

Page 202: Viewing Spectral Calibration Or Install Run Results In The Remote

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Use cloud analysis in the Remote Monitoring software Viewing spectral calibration or install run results in the Remote Monitoring software When viewing results for spectral calibration or install runs in the Remote Monitoring software, only raw data is displayed. -

Page 203: Workflow: Cloud Analysis

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Use cloud analysis in the Remote Monitoring software Workflow: cloud analysis Cloud analysis Open the secondary analysis application. For a list of the supported applications, see “Automated cloud analysis with secondary analysis software”... - Page 204 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Use cloud analysis in the Remote Monitoring software Cloud analysis In the Save tab, save the plate file and optionally send it to the Inbox on the instrument. Start the run.

-

Page 205: Set Up Cloud Analysis For A Completed Run In The Remote Monitoring Software

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Use cloud analysis in the Remote Monitoring software Cloud analysis Click the Cloud Analysis tab to display the list of projects that have been generated by cloud analysis. - Page 206 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Use cloud analysis in the Remote Monitoring software The Cloud Analysis Status field does not reflect the status of the cloud analysis. 2. To view results before you set up cloud analysis, click a plate. By default, the RAW tab is displayed.

-

Page 207: Access Cloud Analysis Results From The Remote Monitoring Software

Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Use cloud analysis in the Remote Monitoring software 7. Select the name of a template with analysis settings that you created in the secondary analysis software. - Page 208 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Use cloud analysis in the Remote Monitoring software If the cloud analysis settings in the plate file specify a new project, the project is created and added to the list in the Cloud Analysis tab, and results are generated in the secondary analysis application.

- Page 209 Chapter 8 Use the Remote Monitoring software to monitor runs, view results, and use cloud analysis Use cloud analysis in the Remote Monitoring software (continued) Application type Software Description • All variants list (VCF file) Sequencing Variant Analysis (VA) module •...

-

Page 210: Connect

Use the instrument with Thermo ™ Fisher Connect ■ ™ Overview of Thermo Fisher Connect features ......... . 211 ■... -

Page 211: Chapter 9 Use The Instrument With Thermo Fisher

Chapter 9 Use the instrument with Thermo Fisher ™ Connect ™ Overview of Thermo Fisher Connect features ™ Overview of Thermo Fisher Connect features ™ The following features are available when Thermo Fisher Connect is enabled on an instrument, and your Thermofisher.com account is linked to the instrument. -

Page 212: User Set Up For Thermo Fisher ™ Connect

Chapter 9 Use the instrument with Thermo Fisher ™ Connect ™ User set up for Thermo Fisher Connect b. Sign in to the instrument with your personal local administrator profile (username and PIN). See “Sign in” on page ™ ™ c. -

Page 213: Local Profile And Cloud Profile: When To Use, User Name, And User Initials

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Local profile and cloud profile: when to use, user name, and user initials b. If you have a local profile, obtain a link code for the instrument. See “Link a local profile to your Thermofisher.com account (one time)”... - Page 214 Chapter 9 Use the instrument with Thermo Fisher ™ Connect Local profile and cloud profile: when to use, user name, and user initials User name and initials The following figure shows the user name and initial format for local and cloud profiles. Local profile Cloud profile Originally cloud profile, but now local profile because it is not linked to an instrument...

-

Page 215: Sign In To Apps.thermofisher.com And Access The Instrumentconnect Software

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Sign in to apps.thermofisher.com and access the InstrumentConnect software (continued) Type of user Description profile • A cloud profile is created automatically when you link an instrument or your local profile to Cloud your Thermofisher.com account. - Page 216 Chapter 9 Use the instrument with Thermo Fisher ™ Connect Sign in to apps.thermofisher.com and access the InstrumentConnect software 3. Click (InstrumentConnect) to display the InstrumentConnect screen. If no instruments are linked, the screen below is displayed. If an instrument is linked, the screen below is displayed. In this example, 2 plates have been run on the instrument, and all results passed all quality checks (plates are green).

-

Page 217: (Recommended) Link Directly To Your Thermofisher.com Account

Chapter 9 Use the instrument with Thermo Fisher ™ Connect (Recommended) Link directly to your Thermofisher.com account (Recommended) Link directly to your Thermofisher.com account Follow this procedure if you do not have a local profile on the instrument. This is typically a one-time procedure. However, you may need to re-link if an administrator removes you from an instrument in the InstrumentConnect software or disconnects the instrument from the InstrumentConnect software. - Page 218 Chapter 9 Use the instrument with Thermo Fisher ™ Connect (Recommended) Link directly to your Thermofisher.com account 3. Tap Log In. 4. Tap a connection option. Note: This function links the instrument to your Thermofisher.com account, not to a specific mobile device or PC.

- Page 219 Chapter 9 Use the instrument with Thermo Fisher ™ Connect (Recommended) Link directly to your Thermofisher.com account Note: If a time-out error is displayed after you tap a connection option, check the home screen on the instrument to ensure that (cloud) is displayed.

-

Page 220: Link A Local Profile To Your Thermofisher.com Account (One Time)

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Link a local profile to your Thermofisher.com account (one time) Link a local profile to your Thermofisher.com account (one time) Follow this procedure if you have a local profile on the instrument. This is typically a one-time procedure. - Page 221 Chapter 9 Use the instrument with Thermo Fisher ™ Connect Link a local profile to your Thermofisher.com account (one time) Option Action Mobile devices Note: Before selecting this option, install and sign in to the With this option, the InstrumentConnect software on your mobile device. See “Monitor a run from instrument generates a a mobile device”...

-

Page 222: Sign In To The Instrument With A Cloud Profile

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Sign in to the instrument with a cloud profile If this is the first time you link, your cloud profile is created. For more information, see “Local profile and cloud profile: when to use, user name, and user initials” on page 213. -

Page 223: Re-Link The Instrument To Your Cloud Profile

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Re-link the instrument to your cloud profile 1. In the home screen, tap (Profile). If user initials are displayed instead of , see “Sign in (if another user is signed in)” on page 2. -

Page 224: Disconnect The Instrument From Your Cloud Profile

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Disconnect the instrument from your cloud profile 4. Tap your initials, tap Edit, then enter your PIN. 5. Tap Connect profile. 6. In the Connect to the Connect Platform screen, tap a connection option. Note: This function links the instrument to your Thermofisher.com account, not to a specific mobile device or PC. -

Page 225: Change Your Cloud Profile Pin

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Change your cloud profile PIN 3. Select the instrument, then click Disconnect. 4. Tap Confirm. Change your cloud profile PIN A cloud profile PIN is associated with your profile, not with an instrument. When you update your PIN from any location, it is automatically updated in other locations. -

Page 226: Set Up Email Notifications From The Instrument

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Set up email notifications from the instrument Set up email notifications from the instrument When an instrument is linked to your cloud profile, email notifications from the instrument are automatically sent to the email address that is associated with your Thermofisher.com account. Note: Plate alerts are not instrument errors. - Page 227 Chapter 9 Use the instrument with Thermo Fisher ™ Connect Set up email notifications from the instrument 3. In the Email Notifications screen, select or deselect the options for which you want to receive email notifications, then tap Done. SeqStudio ™...

-

Page 228: Tasks For The Cloud Administrator Of An Instrument

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Tasks for the cloud administrator of an instrument Tasks for the cloud administrator of an instrument ™ Enable or disable Thermo Fisher Connect access on the instrument (administrator only) Note: The Connect platform button is inactive if you are not an administrator or if the SAE function is enabled. -

Page 229: Thermo Fisher ™ Connect Cloud Administrator Functions

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Tasks for the cloud administrator of an instrument ™ The home screen is displayed with a cloud icon in the lower left corner if Thermo Fisher Connect access is enabled on the instrument. ™... -

Page 230: Change The Instrument Name In The Instrumentconnect Software

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Tasks for the cloud administrator of an instrument 4. To perform administrator tasks: Task Action Assign the Admin Click Manage users, select the Admin checkbox for the user that you want to role to an change to administrator, then click Close. -

Page 231: For More Information On Using Thermo Fisher ™ Connect

Chapter 9 Use the instrument with Thermo Fisher ™ Connect ™ For more information on using Thermo Fisher Connect ™ For more information on using Thermo Fisher Connect ™ In the top left of any Thermo Fisher Connect screen, click , then select Help guide. -

Page 232: Disable The Voice Command Function

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Use voice commands Note: A microphone icon is not displayed if you are signed in with a local profile. 2. Tap the gray disabled icon to start registration. During registration, the icon changes to the amber disabled icon . - Page 233 Chapter 9 Use the instrument with Thermo Fisher ™ Connect Use voice commands Microphone Proximity sensor Speakers 3. Say "Alexa". A blue bar is displayed on the touchscreen when Alexa can accept a command (see the following figure). Blue bar at the top of the touchscreen indicates that Alexa can accept a command 4.

-

Page 234: Basic Voice Commands

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Use voice commands Basic voice commands Note: If the blue bar is not displayed on the touchscreen, say Alexa. Wait until the blue bar is displayed, then say Open flex instrument. When Alexa responds with How may I help, say a command. -

Page 235: Microphone Icon

Chapter 9 Use the instrument with Thermo Fisher ™ Connect Use voice commands (continued) Step User command Instrument action and Alexa reply A (or the position of interest). You can also say Drawer A, The Link Plate File screen is Position A, or Plate A. - Page 236 Chapter 9 Use the instrument with Thermo Fisher ™ Connect Use voice commands (continued) Microphone icon states Status of voice commands The microphone is muted and cannot accept voice commands. Tap the icon to unmute the microphone. The icon turns gray if the proximity sensor does not detect a person or ™...