Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Micromeritics Gemini VII 2390a

- Page 1 ® Gemini Operator’s Manual V3.02 239-42828-01 Jan 2014...

- Page 2 Gemini is a registered trademark of Micromeritics Instrument Corporation. © Micromeritics Instrument Corporation 2009-2014. All rights reserved. Printed in the U.S.A. The software described in this manual is furnished under a license agreement and may be used or copied only in...

- Page 3 MICROMERITICS shall not be liable for consequential or other type damages resulting from the use of any of its products other than the liability stated above. This warranty is in lieu of all other warranties, express or implied, including, but not limited to, the implied warranties of merchantability or fitness for use.

-

Page 5: Table Of Contents

Gemini VII Table of Contents TABLE OF CONTENTS 1. GENERAL INFORMATION Introduction ..............1-1 Organization of the Operator’s Manual . - Page 6 Table of Contents Gemini VII Defining Sample Information Files ..........3-6 Advanced Format .

- Page 7 Gemini VII Table of Contents 5. FILE MENU Introduction ..............5-1 Common Fields and Buttons - File Menu Options .

- Page 8 Table of Contents Gemini VII 6. UNIT MENU Introduction..............6-1 Common Fields and Buttons - Unit Menu Options .

- Page 9 Gemini VII Table of Contents BET Surface Area Report ..........7-26 BET Surface Area Plot.

- Page 10 Table of Contents Gemini VII 10. ORDERING INFORMATION A. FORMS Sample Data Worksheet ............A-3 B.

- Page 11 Gemini VII Table of Contents Regularization ............C-38 SPC Report Variables .

- Page 12 Table of Contents Gemini VII viii 239-42828-01 - Nov 2013...

-

Page 13: General Information

Gemini VII Introduction 1. GENERAL INFORMATION Introduction This manual provides details on software installation, program menu options and operating instruc- tions. This chapter contains information on the Gemini VII hardware and software components. To help you use the analyzer system more efficiently, reference: •... - Page 14 Organization of the Operator’s Manual Gemini VII Chapter Description (continued) Chapter 7 REPORTS MENU Provides a description of the Reports menu options and field and button definitions. Chapter 8 OPTIONS MENU Provides a description of the Options menu options and field and button definitions.

-

Page 15: Conventions

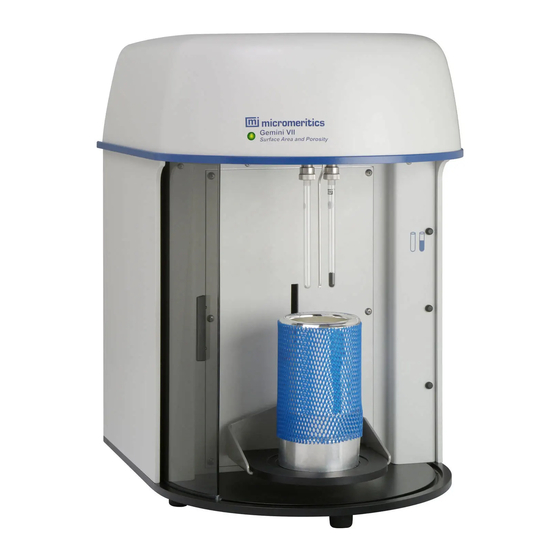

Gemini VII Equipment Description Conventions This manual uses the icons shown below to identify notes of importance, warnings and cautions. Notes contain important information pertinent to the subject matter. Warnings contain information to help prevent actions that may cause personal injury. Cautions contain information to help prevent actions that may damage the analyzer or components. - Page 16 Equipment Description Gemini VII The Gemini VII Series analyzers are easy to use, fully automatic, and provide single and multipoint surface area and pore size measurements. Three models are available: the Gemini 2390a, 2390p, and 2390t. The Gemini 2390a and 2390p are enclosed in the same size cabinet. The only physical difference is the Po (saturation pressure) tube which is installed on the Gemini 2390p, allowing continuous measure- ment of the saturation pressure.

-

Page 17: Operation

Gemini VII Equipment Description Feature (continued) 2390a 2390p 2390t MP-Method reports DFT reports Operation The sample and balance tubes are immersed in a single liquid nitrogen bath which maintains isother- mal conditions for both tubes. The analysis gas is then delivered to the sample tube by a servo valve mechanism. -

Page 18: Cryogen

The vacuum pump used with the Gemini must have an anti-suckback valve to prevent oil from being admitted to the instrument should the power fail while the system is under vacuum. Pumps available from Micromeritics are equipped with an anti- suckback valve. -

Page 19: Software

When helium is used for differential free-space measurement and nitrogen is used as the adsorbate gas, they should be of the following purity or better: • Helium - purity of 99.9% (For analysis of materials with very low surface areas, Micromeritics recommends use of helium with purity of 99.995%.) •... -

Page 20: Specifications

Specifications Gemini VII Specifications The analyzer has been designed and tested to meet the following specifications: Characteristic Specification Applicability Surface Area: From 0.1 m , total From 0.01 m /g, specific Pore Volume: From 4 × 10 Pressure Measurement Pressure Measurement 0 to 950 mmHg Range: P/Po Resolution:... - Page 21 Physical Height: 23 in (58 cm); Gemini VII 2390a and 2390p 29 in (74 cm); Gemini VII 2390t Weight: 16 in (40 cm) Depth: 20 in (51 cm)

- Page 22 Specifications Gemini VII Characteristic Specification (continued) Computer Minimum Requirements: • 1 GHz or faster 32-bit (x86) or 64-bit (x64) processor • 2 GB RAM • 40 GB minimum hard drive (formatted in NTFS) (one partition) • Video Adapter capable of 1024 × 768 minimum resolution •...

-

Page 23: User Interface

Gemini VII Introduction 2. USER INTERFACE Introduction This chapter contains information on the analyzer hardware and software components of the Gemini VII. • Shortcuts • File name conventions • Menu Structure Instrument Components and Connectors Component Description Blinks when power is applied to the analyzer; illuminates when analysis Power indicator program is initiated and ready for operation. -

Page 24: Front Panel

Instrument Components and Connectors Gemini VII Front Panel Power Indicator Sample compartment door Component Description Blinks when power is applied to the analyzer; illuminates when analysis Power indicator program is initiated and ready for operation. Sample compartment Sliding door encloses the sample compartment. door 239-42828-01 - Dec 2012... -

Page 25: Sample Compartment

Gemini VII Instrument Components and Connectors Sample Compartment Po port and tube (2390p and 2390t models) Sample port Balance Port Diagram of tube positions Elevator Component Description For installing the sample tube. Sample port For installing the balance tube. Balance port The Po (saturation pressure) tube comes installed on the Gemini II 2390p Po port and tube and 2390t. -

Page 26: Rear Panel

Instrument Components and Connectors Gemini VII Rear Panel Helium inlet port Adsorptive inlet port Vacuum pump connector Keypad connector Ethernet port USB ports RS232 connector On/Off Switch Power connector Component Description For attaching the helium gas supply. Helium inlet port For attaching the adsorptive (analysis) gas supply. -

Page 27: Turning The Analyzer On And Off

Gemini VII Turning the Analyzer On and Off Turning the Analyzer On and Off Turning the Analyzer On Place the computer, monitor and printer ON/OFF switches in the ON position. Place the analyzer ON/OFF switch in the ON position. The pump will turn on automatically if it is plugged into the electrical outlet. -

Page 28: Using The Software

Using the Software Gemini VII Using the Software The analysis program operates in the Windows environment and requires familiarity with standard Windows operations, for example, using the mouse, menus and dialog boxes. While this manual pro- vides brief instructions for such standard operations, if necessary, refer to Windows documentation or its online help system to clarify any Windows functions. - Page 29 Gemini VII Using the Software Shortcut Key(s) Function Access online operator’s manual Open a sample information file Open an analysis conditions file Open an adsorptive properties file Open a report options file Cascade windows Tile windows Start a report Close all open reports Generate a Heat of Adsorption report Exit the program Alt + F4...

-

Page 30: Files

Using the Software Gemini VII Files File Status and Description In the Open File window, the Mic Status column and the Mic Description column display file status and file description, respectively. Columns can be sorted by clicking the column header. File Status Description All sample information files in the specified directory. -

Page 31: Menu Structure

Gemini VII Menu Structure File Type (continued) Default File Name Extension .RPO Report options .HOA Heat of Adsorption Report .THK Thickness curve .ALS Alpha-s curve The following file types are available for reports saved from the Print window: .REP Report .XLS Spreadsheet .TXT... -

Page 32: Main Menu Bar

Use to arrange the windows and icons on the computer screen and display Window a list of open windows. Refer to Menu, page 2-11. Window Use to access online operator’s manual, Micromeritics web page, and Help videos. Refer to Menu, page 2-12. Help... -

Page 33: Window Menu

Gemini VII Menu Structure Window Menu The Window menu lists open files and provides the ability to rearrange the way open windows display. A check mark appears to the left of the active window. Window Menu Description Option Stacks open windows in a fanned format so that each window title bar is Cascade visible. -

Page 34: Help Menu

Menu Structure Gemini VII Help Menu The Help menu provides access to the online operator’s manual, the Micromeritics web page, online instructional videos, and information about the analyzer. Help Menu Option Description Provides access to the online operator’s manual. Operator’s Manual Provides a link to the Micromeritics web page: ... - Page 35 Gemini VII Menu Structure Help Menu Option Description (continued) Available Videos Maintenance (continued) • Guidelines for Choosing Regulators • Guidelines for Connecting Gases • Connecting Gases • Cleaning and Verifying Gas Lines • Inspecting and Changing Vacuum Pump Oil • Inspecting and Changing Alumina •...

- Page 36 Menu Structure Gemini VII 2-14 239-42828-01 - Dec 2012...

-

Page 37: Operating Procedures

Gemini VII Introduction 3. OPERATING PROCEDURES Introduction This chapter contains information on: • specifying sample defaults • creating sample files in Advanced, Basic and Restricted formats • preparing samples and performing an analysis • printing file contents, listing file statistics, exporting isotherm data, and converting sample files •... -

Page 38: Advanced Format

Specifying Sample Defaults Gemini VII Advanced Format The values specified in the parameter portions of the default sample file (Degas Conditions, Analysis Conditions, Adsorptive Properties, and Report Options) are saved as the defaults for new sample files. To navigate from one set of parameters to another, click the parameter tab at the top of the window. Perform the following steps to establish defaults for a sample information file in the Advanced format. - Page 39 Gemini VII Specifying Sample Defaults Enter Operator, Submitter and Bar Code identification information in the respective text boxes. To omit the field and information in the sample files, select the Omit checkbox to the right of the field. The field labels for the Sample, Operator, Submitter and Bar Code fields can be modified by overwriting the default field labels.

-

Page 40: Basic Format

Specifying Sample Defaults Gemini VII Basic Format When specifying defaults in the Basic format, select from existing default parameters. The defaults established in Basic format also serve as defaults for files created using the Restricted format. To define parameter files before entering sample defaults in Basic format, refer to Defining Sample Files, page 3-6. -

Page 41: Restricted Format

Gemini VII Specifying Sample Defaults Select the dropdown arrow to the right of the Degas conditions, Analysis conditions, Adsorptive properties, and Report options fields to select default parameter files that were saved while in Advanced format and saved to the directory specified in Options > Parameter Files Directory. Click Save, then click Close. -

Page 42: Defining Sample Information Files

Defining Sample Information Files Gemini VII Defining Sample Information Files A sample information file must be created for each analysis. This file can be created in advance or at the time of analysis. The sample information file identifies the sample, guides the analysis and speci- fies report options. -

Page 43: Basic Or Restricted Format

Gemini VII Defining Sample Information Files If SPC (Statistical Process Control) information is to be reported, enter appropriate information in the User Parameters group box. These are user-definable parameters that can be entered and tracked along with other statistical process control data. After completing the Sample Description window, click the parameter tabs to edit other sample information file parameters. - Page 44 Defining Sample Information Files Gemini VII In the Mass group box, enter default values for the sample’s mass and density. Both of these values may be edited at the time of analysis. Refer to Files, page 5-8. Sample Information Click the dropdown arrows to select default parameter files for Degas conditions, Analysis conditions, Adsorptive properties, and Report options.

-

Page 45: Opening Sample Information Files

Gemini VII Defining Sample Information Files Opening Sample Information Files Be advised when working with an existing file that a copy of the file be used rather than the original. Opening Files with a Status of Complete, Analyzing, or Entered Select File >... - Page 46 Defining Sample Information Files Gemini VII The Sample Information window displays in the specified format (Advanced, Basic, or Restricted). The following is shown in Advanced format. 3-10 239-42828-01 - Dec 2012...

-

Page 47: Defining Parameter Files

Gemini VII Defining Parameter Files Defining Parameter Files The following file types can exist as part of the sample information file as well as individual parameter files: • Degas conditions • Analysis conditions • Adsorptive properties • Report options Default parameter files can be used for multiple analyses without having to re-enter the values each time an analysis is performed. -

Page 48: Degas Conditions

Defining Parameter Files Gemini VII Degas Conditions Degassing is a required step in preparation for the analysis; however, this section is only applicable if using the SmartPrep Degasser. This section contains degassing instructions that will be sent to the SmartPrep Degasser equipment. Degas Conditions files contain degassing information for sample preparation. -

Page 49: Analysis Conditions

Gemini VII Defining Parameter Files Analysis Conditions Analysis conditions specify the data used to guide an analysis. Go to File > Open > Analysis Conditions or use the F3 keyboard shortcut. Enter a name in the File name text box. Click Open. Click OK to create the file. -

Page 50: Adsorptive Properties

Defining Parameter Files Gemini VII Adsorptive Properties Adsorptive properties provide the adsorptive (analysis gas) characteristics for the analysis. Go to File > Open > Adsorptive Properties or use the F4 keyboard shortcut. Enter a name in the File name text box. Click Open. Click OK to create the file. -

Page 51: Report Options

Gemini VII Defining Parameter Files Report Options Report Options files specify the type of reports that will be generated from an analysis or from manu- ally entered data. They also contain report details, for example, axis scale, axis range and column headings. -

Page 52: Preparing For Analysis

Preparing for Analysis Gemini VII Select the Show graphic checkbox to insert a graphic in the report header. Use the Browse button to locate a .BMP or a .EMF file. Specify the graphic size in the Height and Width text fields. Deselect this option to omit a report graphic. -

Page 53: Cleaning And Labeling Sample Tubes

Sample tubes and filler rods must be clean and dry before samples are added and weighed. The follow- ing table indicates which materials are supplied by Micromeritics and which are supplied by the user. The procedures following the table are recommended. -

Page 54: Determining The Sample Mass

Preparing for Analysis Gemini VII Use rubber gloves to ensure no oils or residue are transferred to the clean tubes and filler rods and remove the sample tubes and filler rods from the unit. Clean the interior of the sample tubes with the brush supplied with the system. Rinse the sample tubes and filler rods thoroughly with hot water. - Page 55 Gemini VII Preparing for Analysis • weigh the Sample Tube Set with sample after analysis and subtract the weight of the empty Sample Tube Set for recording the weights and calculating the mass is included in Appendix A. Make copies FORMS as needed.

-

Page 56: Degassing The Sample

[C] Sample mass (Before Degas). Degassing the Sample After the sample has been weighed, use a degassing unit to remove any contaminants which may have adsorbed to the surface or pores. Appropriate degassing units are available from Micromeritics. Refer INFORMATION, page for ordering information. -

Page 57: Installing The Sample Tube

Gemini VII Preparing for Analysis Installing the Sample Tube Follow the steps below to attach the sample tube to the analysis port and the balance tube to the bal- ance port. Minimize sample exposure to air by completing the steps quickly. Remove the sample tube stopper. -

Page 58: Installing The Analysis Dewar

Preparing for Analysis Gemini VII Place the Dewar cover under the sample and balance tubes and slide upward until it is three inches from sample nuts. Installing the Analysis Dewar Prepare the analysis Dewar after installing the sample tube Always handle glass Dewars with care. Any product incorporating a vacuum is a potential safety hazard and should be treated with caution. - Page 59 Gemini VII Preparing for Analysis • Do not handle heavy objects above the Dewar. If unavoidable, place a protective cover over the Dewar’s opening. If an object of sufficient weight is accidentally dropped into the Dewar, shattering may occur. For stainless steel Dewars: •...

-

Page 60: Performing An Analysis

Performing an Analysis Gemini VII Dewar support (not used with Gemini VII 2390t) A Dewar support is not necessary for the larger Dewar used with the Gemini VII 2390t. Place the Dewar directly on the elevator. Close the sample compartment door. Performing an Analysis Begin analysis after the sample has been degassed and transferred to the analysis port. -

Page 61: Start Analysis

Gemini VII Performing an Analysis Start Analysis Ensure the analyzer compartment door is closed before beginning an analysis. If the analyzer is operated at an excessive pressure, the sample or balance tube could become dislodged from its port, possibly causing personal injury or damage to the equipment. -

Page 62: Quickstart Analysis

Performing an Analysis Gemini VII When the analysis is complete, remove the sample tube and store (or dispose) of the sample material as applicable. QuickStart Analysis When using the QuickStart option, it is not necessary to prepare sample files in advance. Sample files are assigned automatically and given default conditions. -

Page 63: Blank Analysis

Gemini VII Performing an Analysis File names are assigned automatically and given default conditions. To replace the parameters with those in another sample information file, click Browse and select the sample file. Verify the information populated into the sample identification, density, and mass fields. This information is pulled from the selected sample file. -

Page 64: Generating Reports

Generating Reports Gemini VII Click Report after analysis to automatically generate reports when the analysis is complete. On the Report Settings window, select the report destination. Click OK. Click Start to start the analysis. A window displays data as they are collected. A short delay is encountered before the port status changes from the Idle state at the bottom of the screen When analysis is complete, remove the sample tube and store (or dispose) of the sample material as applicable. - Page 65 Gemini VII Generating Reports If only one file was selected in step 1, the Select Reports window displays. Verify the reports to generate and click OK. If multiple files were selected, this window does not display. Click a tab across the top of the window to review each report. 239-42828-01 - Dec 2012 3-29...

-

Page 66: Printing Files

Printing Files Gemini VII Printing Files Provides the option to print the contents of one or more sample files to either the screen, a printer, or to a file. Go to File > Print > [file type] > [file]. From the Name column, select a file to print. To select more than one file, hold down the Ctrl key on the keyboard while selecting the files. -

Page 67: Listing Files

Gemini VII Listing Files Click Print. The following example shows a sample information file printed to the screen. Listing Files Provides the option to create a list of sample file information, for example, file name, date / time the file was created or last edited, file identification and file status. Go to File >... -

Page 68: Exporting Isotherm Data

Exporting Isotherm Data Gemini VII In the Report Settings window, select one of the following: • Preview - to send the file to the screen. • Print - to send the file to the default printer. • Copies - select the number of copies to print. This field is only enabled when Print is selected. •... -

Page 69: Format Of Exported Data

Gemini VII Exporting Isotherm Data Format of Exported Data The output file consists of five columns containing elapsed time during analysis, absolute pressure, rel- ative pressure, quantity adsorbed, and quantity dosed. Description Operator Submitter Sample Mass * Type of Data 0 = automatically collected... -

Page 70: Converting Files

Converting Files Gemini VII In the Export Settings window, select one of the following: • Preview - to send the file to the screen. • Print - to send the file to the default printer. • Copies - select the number of copies to print. This field is only enabled when Print is selected. •... -

Page 71: Generating Graph Overlays

Gemini VII Generating Graph Overlays Click Open. The file is automatically converted to a .SMP file and the following window displays. Click OK to close the window. Generating Graph Overlays Use the graph overlay function to compare multiple graph options. Graphical lines are differentiated by the use of varying symbols outlined on a legend. - Page 72 Generating Graph Overlays Gemini VII Click the Report Options tab at the top of the screen. Refer to the following table for instructions for the selected report. Highlight the report to overlay, then click Edit. If overlaying this type of Then..

- Page 73 Gemini VII Generating Graph Overlays If overlaying this type of Then.. report... (continued) a.) In the Selected Reports list box, highlight one of the report • BET Surface Area options shown on the left and click Edit. • Langmuir Surface Area •...

- Page 74 Generating Graph Overlays Gemini VII Click Browse to the right of the Sample [n] field. Select the file containing the graph to overlay and click Open. After selecting up to eight files, click OK to return to the Report Options tab. Click Save to save the selections to a new file name.

- Page 75 Gemini VII Generating Graph Overlays 10. The report screen displays with tabs across the top of the screen. Click each tab to view the reports. 239-42828-01 - Dec 2012 3-39...

-

Page 76: Multiple Graph Overlays

Generating Graph Overlays Gemini VII Multiple Graph Overlays Multiple graph overlays can only be generated for: • BJH Adsorption • BJH Desorption • DFT Pore Size • DFT Surface Energy • Dollimore-Heal Adsorption • Dollimore-Heal Desorption • Horvath-Kawazoe • MP-Method The following instructions use BJH Adsorption as an example. - Page 77 Gemini VII Generating Graph Overlays From the Report Options window, in the Selected Reports list box, select a sub-report and click and click Edit. Select the report variable Click Edit Click the dropdown arrow on the Overlay field and select a second variable to overlay. Click OK to return to the Report Options window.

- Page 78 Generating Graph Overlays Gemini VII Click Save to save the selections. Be advised when working with an existing file that a copy of the file be used rather than the original. Select Reports > Start Report. Select the file created in the previous steps and click Open. To select more than one file, hold down the Ctrl key on the keyboard while selecting the files.

-

Page 79: Software And Setup Modifications

This allows: • the creation or editing of sample and parameter files • the generation of reports on completed sample files Review the Micromeritics PROGRAM License Agreement for restrictions on the use of another copy of the analysis program. ... -

Page 80: Installing The Software

Installing the Software Gemini VII Installing the Software The following prerequisites must be completed prior to installing the software: • Configure an Ethernet port on the computer to communicate with the analyzer. Refer to CONFIGURATION, page D-1. ETHERNET • Attach the analyzer to the computer’s configured Ethernet port and turn on the power to the analyzer. - Page 81 Gemini VII Installing the Software On the Ethernet Introduction screen, verify that the prerequisites have all been met. If not, click Cancel and complete the steps, then restart the installation program. Do not proceed with installation until these tasks have been completed. If the prerequisites have been met, click Next. On the Choose Users screen, select one of the following, then click Next: •...

- Page 82 Installing the Software Gemini VII On the Choose Install Location screen, verify that enough disk space is available to continue the installation. If not, click Cancel and free up the minimum required disk space. If the disk space is OK, click Next to accept the default installation directory or click Browse to change the installation location, then click Next.

- Page 83 Gemini VII Installing the Software When installation completes, the Gemini VII Installed screen displays. Click Next. The Analyzer Configuration screen is used to configure the system for the each analyzer and serial number to be installed. In the Step 1 group box: If...

- Page 84 Installing the Software Gemini VII a.) In the Step 2 group box, enter the serial number for each analyzer to be attached to this computer. The analyzer’s serial number label is located near the power switch. b.) Click Next table: On the Ethernet Ports screen, select one option from the following If...

- Page 85 Gemini VII Installing the Software 10. The Analyzer S/N [n] Installed screen displays. Click Next. A screen displays for each unit installed. 11. If installing a SmartPrep at this time, on the Configure SmartPrep screen, select the number of SmartPrep instruments to be installed and the Com Port connected to the first SmartPrep. Click Next.

- Page 86 Installing the Software Gemini VII 12. The Product Release Information screen displays containing information about updates and changes included in the release. Click Next. 13. The Product Registration screen displays. Click the appropriate link to register the product or to log into your portal or click Next to register later.

-

Page 87: Starting The Setup Program

Gemini VII Installing the Software Starting the Setup Program To start the setup program: Ensure that the analysis program is not operating and the analyzer is idle. Insert the setup CD into the CD-ROM drive. The setup program starts automatically. If the program does not start automatically, navigate to the CD drive and double-click the setup.exe file. -

Page 88: Installing Software Updates Or Reverting To A Previous Version

Installing the Software Gemini VII On the Select Task screen, select the task to perform, then click . Use the following sections Next to complete the selected task. Installing Software Updates or Reverting to a Previous Version When performing a software update, existing data files are not overwritten. There are three types of subsequent installations: •... - Page 89 • Reinstall software version [n] • Downgrade software to version [n] from version [n] If the option Downgrade software to version (previous number) displays, contact your Micromeritics representative before proceeding. Reverting to a previous version can damage existing sample files. 239-42828-01 - Dec 2012...

- Page 90 Installing the Software Gemini VII The Gemini VII Installed screen displays. Click Next. The Gemini VII Reinstalled screen displays. Select one of the following: • Reboot now • I want to manually reboot later Select the Create a desktop icon checkbox to have the system install a program shortcut onto the desktop.

-

Page 91: Adding An Analyzer

Gemini VII Installing the Software Adding an Analyzer An Ethernet switch is required when connecting multiple analyzers. After connecting the Ethernet switch, continue with the Software, page section. 4-14 Ethernet Switch Connect the power cord of the Ethernet switch to an appropriate power outlet. For each analyzer to be added, connect an Ethernet cable from the Ethernet labeled port on the rear of the analyzer to a numbered port on the Ethernet switch taking care not to use the uplink port on the switch. -

Page 92: Software

Installing the Software Gemini VII Software Start the setup program. The Welcome screen displays. Click Next. On the Select Task screen, select Add an analyzer. Click Next. 4-14 239-42828-01 - Dec 2012... - Page 93 Gemini VII Installing the Software On the Add Analyzer screen, enter the serial number of the analyzer being added. Click Next. The Analyzer S/N [n] Installed screen indicates a successful install. Click Next. 239-42828-01 - Dec 2012 4-15...

-

Page 94: Moving An Analyzer From One Pc To Another Pc

Installing the Software Gemini VII The Analyzer Added screen displays. Click Finish. Moving an Analyzer from One PC to Another PC This section provides instructions on moving a configured analyzer (along with its status, calibration, and log file) from one computer (Source PC) to a another (Destination PC). This operation does not move sample or parameter files. - Page 95 Gemini VII Installing the Software On the Select Task screen, select Move an analyzer from one PC to another PC. Click Next. On the Move Analyzer screen, use the dropdown list to select the source analyzer to be moved. Click Next. 239-42828-01 - Dec 2012 4-17...

- Page 96 Installing the Software Gemini VII On the new Move Analyzer screen, select the new destination for the analyzer to be moved. This location is where the Analyzer SN [n] Installer.exe file will be located. To accept the default location, click Next or click Browse to select a new destination, then click Next. The analyzer serial number [n] files are moved to the install program and the Analyzer Installer Created screen displays.

- Page 97 Gemini VII Installing the Software The Welcome screen displays. Click Next. On the Move Analyzer screen, click Next. On the Analyzer Installed screen, click Finish. Sample and parameter files are not copied and moved with the analyzer. Use a file management program such as Explorer or a backup/restore utility to move these ...

-

Page 98: Removing An Analyzer

Installing the Software Gemini VII Removing an Analyzer Start the setup program. On the Welcome screen, click Next. On the Select Task screen, select Remove an analyzer. Click Next. 4-20 239-42828-01 - Dec 2012... - Page 99 Gemini VII Installing the Software On the Remove Analyzer screen, from the dropdown list, select the unit and serial number of the analyzer to be removed. Click Next. This operation removes the selected instrument from the list of attached instruments. It does not remove calibration and status files associated with the analyzer nor does it remove sample and parameter data files.

-

Page 100: Changing The Analyzer Setup

Installing the Software Gemini VII Changing the Analyzer Setup This section provides instructions and changing an analyzer’s Ethernet port in case of an Ethernet port malfunction. Ensure that the new Ethernet port has been configured. Start the setup program. On the Welcome screen, click Next. On the Select Task screen, select Change analyzer setup. - Page 101 Gemini VII Installing the Software table: On the Ethernet Ports screen, select one option from the following If... Then... the configured port is listed Select the port then click Next to proceed to the next step. the configured port is not Click Specify.

-

Page 102: Reinstalling Calibration Files For An Analyzer

Installing the Software Gemini VII On the Analyzer Configuration Updated screen, click Finish. Reinstalling Calibration Files for an Analyzer Calibration files specific to the analyzer are contained on the original calibration CD only and not on an update CD. Start the setup program. On the Welcome screen, click Next. 4-24 239-42828-01 - Dec 2012... - Page 103 Gemini VII Installing the Software On the Select Task screen, select Reinstall calibration files for an analyzer. Click Next. On the Reinstall Calibration Files screen, select the unit and serial number from the dropdown list. Click Next. 239-42828-01 - Dec 2012 4-25...

- Page 104 Installing the Software Gemini VII On the Analyzer S/N [n] Installed screen, click Next. On the Analyzer Calibration Reinstalled screen, click Finish. 4-26 239-42828-01 - Dec 2012...

-

Page 105: Importing An Analyzer From A Previous Installation On This Pc

Gemini VII Installing the Software Importing an Analyzer from a Previous Installation on this PC This section provides instructions on importing an analyzer from a previous installation on the same Start the setup program. On the Welcome screen, click Next. On the Select Task screen, select Import an analyzer from a previous installation on this PC. - Page 106 Installing the Software Gemini VII On the Import Analyzer screen, click the Browse button to locate the installation directory of the previously installed instrument, then select the serial number of the instrument files to be imported. Click Next. When the previously installed files have been imported, the Analyzer SN [n] Installed screen displays.

-

Page 107: Adding Or Modifying Smartprep

Gemini VII Installing the Software On the Analyzer Added screen, click Finish. Adding or Modifying SmartPrep This section provides instructions on how to configure the software to connect up to four SmartPrep instruments. Start the setup program. On the Welcome screen, click Next. 239-42828-01 - Dec 2012 4-29... - Page 108 Installing the Software Gemini VII On the Select Task screen, select Add or Modify SmartPrep. Click Next. On the Configure SmartPrep screen, select the number of SmartPrep units to be installed and the Com Port for the first SmartPrep unit. Click Next. 4-30 239-42828-01 - Dec 2012...

-

Page 109: Uninstalling The Analysis Program

Gemini VII Uninstalling the Analysis Program On the Completing the Gemini VII Setup screen, to place a shortcut icon on the desktop, select the Create a desktop icon checkbox. Click Finish to complete the process. Uninstalling the Analysis Program This section provides instructions on uninstalling the analysis program, status files, analyzer setup files and resulting empty directories. - Page 110 Uninstalling the Analysis Program Gemini VII The Uninstallation Complete screen displays. Click Next. The Completing the Gemini VII Uninstall screen displays. Click Finish to close the setup program. 4-32 239-42828-01 - Dec 2012...

-

Page 111: File Menu

Gemini VII Introduction 5. FILE MENU Introduction This chapter contains information specific to the File menu options used to manage sample and param- eter files. This chapter provides details of File menu options, commonly used functions and buttons, and field descriptions. Menu bar Arrow indicates submenu... - Page 112 Common Fields and Buttons - File Menu Options Gemini VII Field or Button Description (continued) Click to search for a file. Select from a file in the Name column and click Browse button Open or double click the file name in the Name column to open (or import) the file.

- Page 113 Gemini VII Common Fields and Buttons - File Menu Options Field or Button Description (continued) When working with report parameters screens, enter the From and To range From / To text boxes for autoscaling the X- and/or Y- axes. A list of files in the selected directory. Name column Click to save and close the active window.

-

Page 114: Open

Open Gemini VII Open Opens a sample file, parameter file, or report option. • Sample Information files - the File name text box contains the next sequential file name generated by the program. The sample information file extension is .SMP. •... -

Page 115: Save As

Gemini VII Save As Save As Saves the active window as another file type or file name. • Saves a file in the active window under a different file name. • Saves a subset (parameter) of the sample file in the active window as a standalone parameter file, for example, select Analysis Conditions from the Save As menu to create a standalone parameter file of the analysis conditions portion of the active sample file. -

Page 116: Save All

Save All Gemini VII Save All Saves all active windows under the current file names. Close Closes the active window. If changes were made and not yet saved, a prompt displays providing the option to save the file. Close All Closes all active windows. -

Page 117: Convert

Gemini VII Convert Convert Converts the following sample file types to be compatible with the Gemini VII application: File Type File Name Convention SIcarbon.DAT ASAP 2000 SMcarbon.DAT ASAP 2000 Micropore SIcarbon.DAT ASAP 2400 SKcarbon.DAT ASAP 2405 StarDriver carbon.MGD NOTE: Substitute the word carbon (shown above) for the actual filename. -

Page 118: Sample Information Files

Sample Information Files Gemini VII Sample Information Files File > Open > Sample Information (or use the F2 keyboard shortcut) Each analysis must be linked with a sample information file before the analysis can proceed. A sample information file can consist of multiple parameter files; however, parameter files can also stand alone. Parameter files allow repeated use of the file, for example, if the same analysis conditions exist for multiple analyses, create an Analysis Conditions file containing the recurring conditions. - Page 119 Gemini VII Sample Information Files Field or Button Description (continued) Enter bar code reader information if a bar code reader is connected to the Bar Code text box computer’s USB port. If a bar code reader is not used, this alpha/numeric field can be used to enter additional information about the sample;...

-

Page 120: Degas Conditions Files

Degas Conditions Files Gemini VII Field or Button Description (continued) Close button Refer to Options, page 5-1. Preview button Common Fields and Buttons - File Menu Save button Degas Conditions Files File > Open > Degas Conditions (or click the Degas Conditions tab when in Advanced format) The Degas Conditions tab provides details for setting up the Degas Conditions parameter file. -

Page 121: Analysis Conditions Files

Gemini VII Analysis Conditions Files Field or Button Description (continued) Close button Preview button Refer to the field and button table in Replace button Common Fields and Buttons - File Options, page 5-1. Menu Save button Table buttons Analysis Conditions Files File >... - Page 122 Analysis Conditions Files Gemini VII The pressure table for automatically collected data includes the pressure points for data collection and (when the Use calculation assignments checkbox is selected) identifies calculations through which the data are processed. Field or Button Description Refer to Files, page 5-10.

- Page 123 Gemini VII Analysis Conditions Files Field or Button Description (continued) Click to enter starting pressure, ending pressure, the number of points to Insert Range insert within the specified range and whether to have linear or geometric button progression. • Linear - select to insert evenly spaced points into the table. •...

- Page 124 Analysis Conditions Files Gemini VII Field or Button Description (continued) Insert Predefined button - this button is disabled if Absolute pressure Insert Predefined dosing is selected on the previous window. The predefined pressures are button logical only if nitrogen is used as the adsorptive. These options can be used to select the system’s default pressures which can then be edited on the Entered Pressures window.

- Page 125 Gemini VII Analysis Conditions Files Field or Button Description (continued) Click to enter the type of free space measurement. Free Space button • None - select if free space will not be used. • Previously measured - select if free space has been previously measured.

- Page 126 Analysis Conditions Files Gemini VII Field or Button Description (continued) • Entered - select to manually enter the Po in the text box. and T button (continued) • Most recent measured - select to use the most recently measured saturation pressure. •...

-

Page 127: Adsorptive Properties Files

Gemini VII Adsorptive Properties Files Adsorptive Properties Files File > Open > Adsorptive Properties (or click the Adsorptive Properties tab when in Advanced for- mat or use the F4 keyboard shortcut) The Adsorptive Properties window is used to specify the characteristics of the gases used during an analysis. -

Page 128: Report Options Files

Report Options Files Gemini VII Report Options Files File > Open > Report Options [file] Use to specify report options for collected (from an analysis) or manually entered data. They also help in customizing report details such as axis scale, axis range, column headings, and components of thick- ness curve equations. - Page 129 Gemini VII Report Options Files Field or Button Description (continued) Select to correct the temperature-induced pressure difference between the Apply thermal manifold and the chilled sample tube. This option is most significant for transpiration pressures less than approximately 1.0 mmHg. Do not use filler rods in the correction checkbox sample tube when applying correction for thermal transpiration.

-

Page 130: Summary Report

Report Options Files Gemini VII Summary Report The Summary Report provides a condensed listing of selected data results. In the Selected Reports list box, highlight Summary, then click Edit. Select the data types to include in the Summary report. In the Pore Volume column, if Adsorption total or Desorption total is selected, the P/Po field is enabled. - Page 131 Gemini VII Report Options Files Field or Button Description (continued) • Pass/Fail [n] button - select the S A: Single-point BET checkbox to Select All / enable this button. Click the Pass/Fail [n] button to display the Pass/ Deselect All buttons Fail Options window for selection of pass/fail criteria.

-

Page 132: Isotherm Report Options

Report Options Files Gemini VII Isotherm Report Options The Isotherm report indicates adsorption (up to saturation pressure) and desorption (down from satu- ration pressure) of a gas by a solid held at constant temperature. In the Selected Reports list box, highlight Isotherm, then click Edit. - Page 133 Gemini VII Report Options Files Field or Button Description (continued) • Autoscale X-axis - linear X-axes begin at zero. Logarithmic X-axes Options buttons begin at an appropriate value. The X-axis field shows the relative or (continued) absolute pressure. • Autoscale Y-axis - Y-axes begin at zero. The Y-axis field shows the quantity of gas adsorbed.

-

Page 134: Bet/Langmuir Surface Area Report Options

Report Options Files Gemini VII BET/Langmuir Surface Area Report Options The Langmuir and BET Surface Area windows are identical unless otherwise specified. In the Selected Reports list box, highlight BET (or Langmuir), then click Edit. • The BET calculation obtains the sample surface area value by determining the monolayer volume of adsorbed gas from the isotherm data. - Page 135 Gemini VII Report Options Files Field or Button Description (continued) Click to enter a range of pressure points or to modify table values for Pressures button pressure points. If Use calculation assignments is not selected on the Analysis Conditions window, the isotherm is interpolated to these pressure points. The interpolated values are used in the BET (or Langmuir) calculations.

- Page 136 Report Options Files Gemini VII Field or Button Description (continued) Select to generate a traditional BET (Langmuir) surface area plot used to BET (or Langmuir) determine monolayer volume and BET C constant. Transform plot • X-axis - linear X-axes begin at zero. The X-axis field shows the relative pressure for BET and show absolute pressure for Langmuir.

-

Page 137: Freundlich Report Options

Gemini VII Report Options Files Freundlich Report Options The Freundlich Isotherm is an empirical isotherm used to model low-pressure adsorption data. It can also be applied to model some micropore isotherms. In the Selected Reports list box, highlight Freundlich, then click Edit. Field or Button Description Select and enter the monolayer capacity of the sample. -

Page 138: Temkin Isotherm Report Options

Report Options Files Gemini VII Field or Button Description (continued) Plots the absolute pressure vs quantity adsorbed. Shows best fit line. Freundlich Isotherm plot checkbox • X-axis - linear X-axes begin at zero. The X-axis field shows the absolute pressure. •... - Page 139 Gemini VII Report Options Files Field or Button Description (continued) Enter a pressure range when calculation assignments are not used. Absolute pressure range text boxes Plots a linear form of the Temkin isotherm. Transform plot checkbox • X-axis - the X-axis field shows the logarithm of pressure (ln). •...

-

Page 140: T-Plot Report Options

Report Options Files Gemini VII t-Plot Report Options The t-Plot calculation allows quantitative analysis of the area and total volume ascribed to micropores. Matrix area (the area external to micropores) is directly determined and often proves to be a valuable way of characterizing complex mixed materials. - Page 141 Gemini VII Report Options Files Field or Button Description (continued) Thickness Curve group box (continued) To import values from an existing thickness curve (.THK file), click Open and select the file containing the values. The table to be imported must be saved as ASCII text with a .THK extension.

- Page 142 Report Options Files Gemini VII Field or Button Description (continued) Pressure Range button Click to enter minimum and maximum relative pressures. If Use calculation assignments is not selected on the Analysis Conditions window, all of the non-outlier points of the collected data within the specified range are used for calculating the data for this report.

-

Page 143: Alpha-S Method

Gemini VII Report Options Files Alpha-S Method The Alpha-S plot converts the standard adsorption isotherm into a dimensionless isotherm using the quantity adsorbed at a relative pressure of 0.4. In the Selected Reports list box, highlight Alpha-S Method, then click Edit. One predefined curve is shipped with the analysis program and is located in the Reference directory. -

Page 144: F-Ratio Method

Report Options Files Gemini VII Field or Button Description (continued) Select to plot data in graph format. Alpha-S plot checkbox • X-axis - the X-axis field shows the relative pressure. • Y-axis - the Y-axis field shows the quantity of gas adsorbed. Tabular Report checkbox Refer to... - Page 145 Gemini VII Report Options Files Field or Button Description Click Browse to select a sample file to use as a reference for the isotherm. Reference isotherm Select a file containing an isotherm measured from a non-porous sample of the same material as the current sample. When the referenced file is selected, the file name appears to the left of the Browse button.

-

Page 146: Bjh Adsorption/Desorption Report Options

Report Options Files Gemini VII BJH Adsorption/Desorption Report Options The BJH calculation determines the mesopore volume/area distribution which accounts for both the change in adsorbate layer thickness and the liquid condensed in pore cores. Reports can be generated from both adsorption and desorption data. The fields for both report options are identical unless otherwise specified. - Page 147 Gemini VII Report Options Files Field or Button Description (continued) During adsorption calculations, the analysis program assumes that all Fraction of pores pores are closed at one end. Occasionally, a percentage of pores may be open at both ends text open at both ends causing disagreement in the adsorption and desorption data or in the values for total volume and total BJH pore volume.

-

Page 148: Tabular Report Options

Report Options Files Gemini VII Field or Button Description (continued) Pressure Range button Click to enter minimum and maximum relative pressures. If Use calculation assignments is not selected on the Analysis Conditions window, all of the non-outlier points of the collected data within the specified range are used for calculating the data for this report. - Page 149 Gemini VII Report Options Files Field or Button Description (continued) Click the dropdown arrow and select the data types to include in the report. Columns button These selections indicate the column order and data contents for the report. The fixed pore size table must contain a minimum of two points. The Table button points must be strictly decreasing.

-

Page 150: Plot Options

Report Options Files Gemini VII Plot Options The fields for all plot options are identical for specifying plotting methods and customizing plots. Highlight any plot option in the Selected Reports list box and click Edit. Field or Button Description Refer to Options, page 5-22. -

Page 151: Dollimore-Heal Adsorption/Desorption Report Options

Gemini VII Report Options Files Dollimore-Heal Adsorption/Desorption Report Options This report option generates Dollimore-Heal reports from both adsorption and desorption data. In the Selected Reports list box, highlight Dollimore-Heal Adsorption (or Dollimore-Heal Desorption), then click Edit. Dollimore-Heal Adsorption/Desorption fields and buttons are identical to the BJH Adsorption/ Options, page 5-36. - Page 152 Report Options Files Gemini VII Horvath-Kawazoe Report Options The Horvath-Kawazoe method plots individual peaks for different pore sizes even if the difference between one pore size and the next is only one Angstrom (0.10 nm) or less. In the Selected Reports list box, highlight Horvath-Kawazoe, then click Edit.

- Page 153 Gemini VII Report Options Files Field or Button Description (continued) Click to view or edit the constants describing the physical properties of the Properties button adsorbent and adsorptive. These options are disabled if Entered is selected in the Interaction Parameter group box. Adsorbent group box - Contains the parameters for the sample.

- Page 154 Report Options Files Gemini VII Field or Button Description (continued) • Diameter at zero energy - enter the diameter of an atom at zero Properties button (continued) interaction energy: (2/5) × diameter. • Polarizability - enter the polarizability of the adsorbent (or adsorptive).

-

Page 155: Tabular Report Options

Gemini VII Report Options Files Tabular Report Options Highlight H-K Tabular Report in the Selected Reports list box and click Edit. To customize the order and data contents of reports, click the dropdown arrow for a column, and select the data type for that column. -

Page 156: Dft Pore Size Report Options

Report Options Files Gemini VII Field or Button Description (continued) • X-Axis - the X-axis field shows pore radius or diameter in angstroms X-Axis / Y-Axis or nanometers. • Y-Axis - the Y-axis field shows the quantity of gas adsorbed. •... - Page 157 One model must be selected. Click to hyperlink to the NLDFT Model Table on the Link to Micromeritics Micromeritics web page. NLDFT Models button Select the extent of smoothing to apply to the data.

- Page 158 Report Options Files Gemini VII Field or Button Description (continued) Click the checkbox to select the reports to generate. To edit Reports to Generate graph details, highlight the graph option and click Edit. The Log list box Goodness of Fit and Goodness of Fit graphs cannot be edited. •...

-

Page 159: Dft Surface Energy Report Options

Gemini VII Report Options Files DFT Surface Energy Report Options The DFT Surface Energy report contains the results of surface energy distribution analyses. In the Selected Reports list box, highlight DFT Surface Energy, then click Edit. DFT Surface Energy Report Options fields and buttons are identical to the DFT Pore Size Report Options, page 5-46. -

Page 160: Tabular Report Options

Report Options Files Gemini VII Field or Button Description Select the checkbox to specify report types. If Astakhov is selected, either Report Type select the Optimize exponent checkbox or enter an appropriate exponent group box value in the text box. Enter the minimum and maximum limits on relative pressures included in Fitted Radushkevich ... -

Page 161: Transformed Isotherm Plot Options

Gemini VII Report Options Files Transformed Isotherm Plot Options Highlight Transformed Isotherm in the Selected Reports list box and click Edit. The transformed Dubinin isotherm is the logarithm of quantity adsorbed as a function of the log of rel- ative pressure raised to a power. Isotherms for which the Dubinin method is applicable produce straight lines when transformed in this way. -

Page 162: Pore Volume Options

Report Options Files Gemini VII Pore Volume Options Highlight dV/dw Pore Volume in the Selected Reports list box and click Edit. This option plots differential pore volume as a function of pore width Field or Button Description Refer to Options, page 5-22. -

Page 163: Mp-Method Report Options

Gemini VII Report Options Files MP-Method Report Options The MP method provides pore volume distributions for microporous materials by correlating quantity adsorbed with the thickness of the adsorbed layer as determined from a user-selected thickness curve. In the Selected Reports list box, highlight MP-Method, then click the Equation button. Pore size can be expressed in angstroms or nanometers. -

Page 164: Tabular Report Options

Report Options Files Gemini VII Tabular Report Options Highlight MP Tabular Report in the Selected Reports list box and click Edit. To customize the order of columns 3 through 6 and data contents of reports, click the dropdown arrow for a column, and select the data type for that column. -

Page 165: Options Report

Gemini VII Report Options Files Field or Button Description (continued) Autoscale checkboxes Refer to Options, page 5-1. Cancel button Common Fields and Buttons - File Menu OK button Options Report The Options report provides a subset of the contents report. The Options report cannot be edited. It provides pertinent information for: •... -

Page 166: Validation Report

Report Options Files Gemini VII Validation Report Use this report to have the data examined by the software to determine if the results are within typical ranges. If the data selected for validation are determined to be out of range, a warning displays and suggestions are given for corrective action. -

Page 167: Entered Or Collected Data File

Gemini VII Entered or Collected Data File Entered or Collected Data File If Manually Entered is selected on the Advanced view of the Sample information window, an Entered Data tab displays. If Automatically Collected is selected, a Collected Data tab displays after the analysis is completed. 239-42828-01 - Dec 2012 5-57... - Page 168 Entered or Collected Data File Gemini VII Field or Button Description For manually entered data only, select if the pressures are Relative or Pressures group box Absolute. Select if calculation data are to be used. Use calculation assignments checkbox Refer to Files, page 5-11.

-

Page 169: Unit Menu

Gemini VII Introduction 6. UNIT MENU Introduction This chapter contains information specific to the Unit menu options. These options are used to run analyses on one or more units attached to a controlling computer. This chapter provides details of Unit menu options, and descriptions of commonly used functions and buttons. -

Page 170: Common Fields And Buttons - Unit Menu Options

Common Fields and Buttons - Unit Menu Options Gemini VII Common Fields and Buttons - Unit Menu Options The following fields and buttons are common to many of the Unit menu options. References are made to these fields and buttons throughout this manual. Field or Button Description Click to search for a file. - Page 171 Gemini VII Start Analysis Port Activity window Status window Field or Button Description • Operation - displays the current mode of the operation. View dropdown • Instrument Log - displays a list of recent analyses, calibrations, and error or messages. Refer to Log, page 6-15.

- Page 172 Start Analysis Gemini VII Field or Button Description (continued) Use to modify the weight of the sample plus the sample tube. If the field is Sample + Tube text disabled, click Edit then click the Enter option in the Mass group box on field the Sample Description tab.

-

Page 173: Quickstart Analysis

Gemini VII QuickStart Analysis QuickStart Analysis Unit [n] > QuickStart Analysis Use to analyze samples of the same type using the same analysis conditions, adsorptive properties, and report options. The QuickStart Analysis option automatically creates a sample information file for and assigns the default parameters. -

Page 174: Start Po Measurement

Start Po Measurement Gemini VII Start Po Measurement Use to measure the saturation pressure. Not displayed for Model 2390a Analyzer Model Description Model 2390a Measure the Po only in the Sample tube. Ensure a sample tube with no filler rod is attached to the sample port then click Start to begin the measurement. -

Page 175: Blank Analysis

Gemini VII Blank Analysis Blank Analysis Unit [n] > Blank Analysis Use to obtain sample tube parameters when using a calculated free space. A blank analysis can also be used for diagnostic purposes. Blank Analysis fields are identical to the Analysis, page window with the exception of Den- Start... -

Page 176: Enable Manual Control

Enable Manual Control Gemini VII Enable Manual Control Unit [n] > Enable Manual Control Use to enable the manual control of certain system valves and elevator components. When this option is enabled, a checkmark appears to the left of the menu item. Enable this option by selecting Enable Manual Control on the menu. -

Page 177: Instrument Schematic Components

The reading for the sample pressure transducer is displayed just below the analysis servo valve and valve 5-s. Balance volume adjustment. Can be adjusted only by a Micromeritics service representative. Pressure relief valve. Prevents excessive pressure build-up in the event of abnormal operation. -

Page 178: System Valves

Enable Manual Control Gemini VII Component Description (continued) Saturation pressure (Po) tube. Not displayed for Gemini VII 2390a. Po tube, valve, and transducer reading not displayed on Model 2390a System Valves Select Unit [n] > Show Instrument Schematic to display the instrument schematic. -

Page 179: Instrument Schematic Shortcut Menus

Gemini VII Enable Manual Control Valves Description (continued) Analysis port valve Po port valve (Models 22390a and 2390t) Instrument Schematic Shortcut Menus Each manually controlled component has a shortcut menu displaying the operations available for that particular component such as, Open, Close, Pulse. To access the shortcut menu, hover the mouse cur- sor over the component and right click. -

Page 180: Show Instrument Schematic

Show Instrument Schematic Gemini VII Shortcut Icon Description (continued) • For Servo Valve On/Off - turns the servo valve on or off. Increase / Decrease - increased pressure by dosing the sample. Decreases pressure by evacuating the sample. Enter target - displays the Servo Valve Settings window. The entered target pressure displays to the left of the sample servo valve icon. -

Page 181: Show Status

Gemini VII Show Status Refer to Control, page for additional details on this schematic. Enable Manual Valve State Description Green indicates an open valve. Yellow indicates a closed valve. Show Status Unit [n] > Show Status Use to show only the status window of the analyzer. If multiple instruments are attached to the computer, the status window for each instrument is displayed in a different color. - Page 182 Show Status Gemini VII Field or Button Description • Preliminary - evacuation and free space measurement. Displays green Analysis status bar during progression. • Analysis - data are collected. Displays blue during progression. • Termination - the device lowers the elevator and analysis terminates. Displays grey during progression.

-

Page 183: Show Instrument Log

Gemini VII Show Instrument Log Show Instrument Log Unit [n] > Show Instrument Log Use to display a log of recent analyses, calibrations, errors or messages. This information is logged for a 7-day period for analyses and a 30-day period for messages and calibrations. Field or Button Description ... -

Page 184: Unit Configuration

Click to display the Unit IP Setup window. Shows the IP address and Change IP button Subnet mask assigned during installation. Do not edit these fields unless instructed by a Micromeritics service representative. Deletes all stored analysis data and resets instrument parameters to factory Restore Factory defaults. -

Page 185: Diagnostics

Gemini VII Diagnostics Diagnostics Unit [n] > Diagnostics Use to clean and verify gas lines when connecting or changing a gas. Refer to Cleaning and Verifying Line, page 9-22. Also used to perform diagnostic tests requested by a service representative. the Gas This option is typically used and/or requested by a service representative. - Page 186 Diagnostics Gemini VII Field or Button Description Refer to Analysis, page 6-2. View dropdown Start Click to skip an analysis. This button is only visible when an analysis is in Skip button progress. Select the ports containing the analysis to skip. Click to suspend or resume an analysis in progress.

-

Page 187: Calibration

Gemini VII Calibration Refer to Bar, page for additional information on viewing, customizing, and printing Report Tool 7-14 reports. Calibration Unit [n] > Calibration Use to perform system calibrations. Disabled calibration options can be accessed only with the assis- tance of a service representative and are not covered in this manual. 239-42828-01 - Dec 2012 6-19... -

Page 188: Zero Pressure

Calibration Gemini VII Zero Pressure Unit [n] > Calibration > Zero Pressure Use to evacuate the manifold and zero out the selected transducers. Refer to Pressure, page 9-30. Zero Match Transducers Unit [n] > Calibration > Match Transducers Use to zero and match the selected transducers to the main manifold transducer. Refer to Match Transducers, page 9-31. -

Page 189: Reset Pressure Calibration

Gemini VII Calibration Reset Pressure Calibration Unit [n] > Calibration > Reset Pressure Calibration Use to reset the unit’s pressure scale to factory defaults. Sample Servo Unit [n] > Calibration > Sample Servo Use to calibrate the servo valve to the sample pressure transducer. The sample pressure transducer should be calibrated before starting this calibration procedure. -

Page 190: Save To File

Calibration Gemini VII Save to File Unit [n] > Calibration > Save to File Use to save the current calibration settings to a backup file which can later be reloaded using Unit [n] > Calibration > Load from File menu option. Field or Button Description File name dropdown list... -

Page 191: Load From File

Service Test Unit [n] > Service Test Use for service tests performed only with the assistance of a trained Micromeritics service representa- tive. These tests provide the service representative with troubleshooting tools and readouts. This option is enabled only when the analysis program is operating in Service Test mode. Refer to... - Page 192 Service Test Gemini VII 6-24 239-42828-01 - Dec 2012...

-

Page 193: Reports Menu

Gemini VII Introduction 7. REPORTS MENU Introduction This chapter contains information specific to the Reports menu options used to customize and run reports. This chapter provides details of Reports menu options, commonly used functions and buttons, field-by-field descriptions, and sample reports. Reports can be generated for data: •... -

Page 194: Common Fields And Buttons - Reports Menu Options

Common Fields and Buttons - Reports Menu Options Gemini VII Common Fields and Buttons - Reports Menu Options The following fields and buttons are common to many of the report files. References are made to these fields and buttons throughout this chapter. Field or Button Description Click to locate another file. -

Page 195: Close Reports

Gemini VII Close Reports Close Reports Reports > Close Reports (or use the F9 keyboard shortcut) Use to close all open report windows. This option is unavailable if reports are being generated. Open Report Reports > Open Report > [file] Use to open a saved report. - Page 196 SPC Report Options Gemini VII If additional report options are required, click the More button. The selected items also appear as options on the Reports > Control Chart screen. (Click the Graph [n] button, then click the Statistic dropdown arrow.) 239-42828-01 - Dec 2012...

-

Page 197: Regression Report

Gemini VII Regression Report Regression Report Reports > Regression Report Use to generate an SPC (Statistical Process Control) Regression report to determine the interdepen- dency between two variables. Up to three dependent variables (Y-axis) may be plotted against a single independent variable (X-axis). - Page 198 Regression Report Gemini VII Field or Button Description (continued) Select to generate a tabular report of the included samples. A tabular Tabular report checkbox report contains the numeric values contributed by each sample. Select to have archived SPC values recalculated ensuring any changes Recalculate archived made to the SPC Report Options are included in the new report.

-

Page 199: Control Chart

Gemini VII Control Chart Field or Button Description (continued) Click to view the report for the items selected. Report button Click to save selected report options as default report settings. Save as Default button Browse button Refer to Cancel button Common Fields and Buttons - Reports Menu Options, page 7-2. - Page 200 Control Chart Gemini VII Field or Button Description Select the order in which X-axis statistics are placed. X Axis Order by group box • Time - sorts by the time the files were analyzed. • File name - sorts in alphanumeric order. •...

- Page 201 Gemini VII Control Chart Field or Button Description (continued) • Center Line group box - displays placement options for the center line Graph [n] buttons in the graph. Choose Entered to specify placement of the line. (continued) • Limit Lines group box - displays limiting lines options. Lines can be placed at some multiple of the standard deviation or at specified positions (Entered).

-

Page 202: Heat Of Adsorption Report

Heat of Adsorption Report Gemini VII Heat of Adsorption Report Reports > Heat of Adsorption Use to select sample files, define quantities and generate a Heat of Adsorption report. The isosteric heat of adsorption is an important parameter for characterizing the surface heterogeneity and for pro- viding information about the adsorbent and the adsorption capacity. - Page 203 Gemini VII Heat of Adsorption Report Field or Button Description (continued) Click to remove all samples from the table. Clear Samples button Use to specify the range of surface coverage to include in the report. Edit Quantities button •...

-

Page 204: Report Features And Shortcuts

Report Features and Shortcuts Gemini VII Field or Button Description (continued) Refer to Report, page 7-5. Tabular report Regression checkbox Select to generate a graph showing quantities of gas adsorbed versus the Isostere plot temperature. checkbox Select to generate the Heat of Adsorption data in a graphical format. Heat of adsorption plot checkbox Click to select and open a Heat of Adsorption file. -

Page 205: Report Header

Gemini VII Report Features and Shortcuts Report Header All reports contain a header displaying file statistics. If configured, the report header can also contain a graphic and a title. • Tabular and graphical reports contain sample and instrument statistics such as analysis date / time, analysis conditions, etc. -

Page 206: Report Tool Bar

Report Features and Shortcuts Gemini VII Report Tool Bar Each report has a tool bar and selectable tabs across the top of the report header. To view a specific report, select its tab or select the report in the Reports list box and click Show. Reports can be customized and manipulated using the tool bar, shortcut menus, the zoom feature, or axis cross-hairs. - Page 207 Gemini VII Report Features and Shortcuts Field or Button Description (continued) Displays a print window for report output. Print button • Printer group box - Name dropdown list and Properties button - select the printer and click the Properties button to change printout orientation, etc. •...

- Page 208 Report Features and Shortcuts Gemini VII Field or Button Description (continued) Click to specify default report parameters for fonts and curve properties. Default Style button • Font group box - Font Type list box - allows font type and attributes to be edited for the selected item.

-

Page 209: Report Shortcut Menus

Gemini VII Report Features and Shortcuts Field or Button Description (continued) • Curve group box - Default Style button (continued) Thickness text box - enter a thickness number for the curve. Histogram Fill dropdown list - select a histogram fill option from the list. -

Page 210: Tabular Reports Shortcuts

Report Features and Shortcuts Gemini VII Tabular Reports Shortcuts Display tabular report shortcuts by right-clicking in the body of the tabular report. Column shortcuts require right-clicking on the column to be modified. Option Description Right-click on the column to be resized. Select Resize Column on the Resize column shortcut menu and enter the new column width in inches. -

Page 211: Graph Shortcuts

Gemini VII Report Features and Shortcuts Option Description (continued) Select to edit the report title and/or title font attributes. Edit title Select to copy the report contents to the clipboard as tab delimited text. It Copy table as text can then be pasted into another document. Graph Shortcuts Display graph report shortcuts by right-clicking in the body of the graph report. - Page 212 Report Features and Shortcuts Gemini VII Option Description (continued) Use to edit selected curve properties. Edit curve • Title text box - use to change the title of the selected curve. • Style dropdown list - use to select another style for the collected data curve.

- Page 213 Gemini VII Report Features and Shortcuts Option Description (continued) Graph Label Use to edit axis properties. Edit axis • Title group box - use to edit the selected axis label. Title text box - use to modify the label of the selected axis. Title font button - use to modify the font for the selected axis label.

- Page 214 Report Features and Shortcuts Gemini VII Option Description (continued) Autoscale minimum / maximum - select the Autoscale checkbox to Edit axis enable the option. To manually specify minimum / maximum, deselect (continued) the Autoscale checkbox and enter the new amount in the text box. Invert scale checkbox - select to invert the scale.

-

Page 215: Other On-Screen Features

Gemini VII Report Features and Shortcuts Other On-Screen Features Zoom Feature Use the zoom feature to closer examine graph details. To use this feature: Open the graph. Hold down the left mouse button and drag the cursor across the graphical area to be enlarged. A box will display in the area to be enlarged. -

Page 216: Report Examples

Report Examples Gemini VII Report Examples This section of the manual contains samples of some of the available reports. Most of the reports can be customized. 7-24 239-42828-01 - Dec 2012... -

Page 217: Isotherm Linear Plot

Gemini VII Report Examples Isotherm Linear Plot 239-42828-01 - Dec 2012 7-25... -

Page 218: Bet Surface Area Report

Report Examples Gemini VII BET Surface Area Report 7-26 239-42828-01 - Dec 2012... -

Page 219: Bet Surface Area Plot

Gemini VII Report Examples BET Surface Area Plot 239-42828-01 - Dec 2012 7-27... -

Page 220: T-Plot

Report Examples Gemini VII t-Plot 7-28 239-42828-01 - Dec 2012... -

Page 221: Bjh Adsorption Cumulative Pore Volume

Gemini VII Report Examples BJH Adsorption Cumulative Pore Volume 239-42828-01 - Dec 2012 7-29... -

Page 222: Bjh Adsorption Dv/Dlog(W) Pore Volume

Report Examples Gemini VII BJH Adsorption dV/dlog(w) Pore Volume 7-30 239-42828-01 - Dec 2012... -

Page 223: Options Menu

Gemini VII Introduction 8. OPTIONS MENU Introduction This chapter contains information specific to the Options menu selections used to configure the system by setting defaults for sample and parameter files. This chapter contains information on: • changing the default presentation format - Restricted, Basic, or Advanced •... -

Page 224: Sample Defaults

Sample Defaults Gemini VII Sample Defaults Options > Sample Defaults Use to specify default parameters for sample information files and report option files in either Advanced, Basic, or Restricted format. The Restricted format requires a password when entering or exiting the Restricted format. It is s typically used in laboratories where analysis conditions must remain constant, for example, in the pharmaceutical industry. -

Page 225: Units

Gemini VII Units Units Options > Units Use to specify how data should appear on the application windows and reports. This menu option is not available if using Restricted format. Graph Grid Lines Options > Graph Grid Lines Use to select how grid lines appear on reports. This menu option is not available if using Restricted format. -

Page 226: Service Test Mode

Service Test mode is a password protected option used to perform certain service tests with the assis- tance of a trained Micromeritics service representative. This password is supplied by your service representative. After Service Test Mode has been enabled, the service tests are accessible from the Unit menu (Unit >... -

Page 227: Troubleshooting And Maintenance

Gemini VII Introduction 9. TROUBLESHOOTING AND MAINTENANCE Introduction The analyzer has been designed to provide efficient and continuous service; however, certain mainte- nance procedures should be followed to obtain the best results over the longest period of time. This chapter includes maintenance and calibration procedures. Troubleshooting Most operational problems are caused by: •... - Page 228 Troubleshooting Gemini VII What Happened What To Do (continued) Unable to reach a Vacuum pump oil level is low or Inspect the oil to see if it is low satisfactory vacuum. needs to be changed. or needs changing. Refer to Inspecting and Changing Oil, page 9-8.

- Page 229 Power cord damaged. Have electrician check cord using a test meter. Replace the cord if defective. Loose internal connection or Call a Micromeritics Service broken wire. Representative for repair or replacement information. Expected results are not Sample improperly degassed.

-

Page 230: Preventive Maintenance

** For oil-free pumps only: After 12 to 18 months of operation, the diaphragm in the pump will wear out and the pump becomes completely inoperable. To prevent instrument downtime due to an inoperable pump, it is recommend that the diaphragm be replaced by a Micromeritics Service Rep- resentative every 12 months. -

Page 231: Lubricating Elevator Drive Assembly

Lubricating Elevator Drive Assembly The elevator screw is lubricated before it leaves the factory and should not require lubricating. If the elevator starts to vibrate or becomes noisy when traveling, contact a Micromeritics Service Represen- tative for disposition. Cleaning the Analyzer The exterior casing of the analyzer may be cleaned using a clean cloth, dampened with isopropyl alco- hol (IPA), a mild detergent, or a 3% hydrogen peroxide solution. -

Page 232: Replacing Port Filter (Frit) And O-Ring

Preventive Maintenance Gemini VII Rinse the Dewar with warm water to melt any ice accumulation which may remain in the Dewar, then dry thoroughly. Replacing Port Filter (Frit) and O-ring A filter (frit) is located in each analysis port. If the filter is contaminated, the contaminant may adsorb or desorb during analysis, affecting the results. -

Page 233: Replacing The Sample Tube O-Ring

Gemini VII Preventive Maintenance Replacing the Sample Tube O-ring It is important to maintain a vacuum-tight seal near the top of the sample tube stem. If an O-ring becomes worn or cracked, it does not provide a good seal and will need to be replaced. Before removing (or installing) a sample tube, ensure that the port valve is closed. -

Page 234: Inspecting And Changing Vacuum Pump Oil

Always drain the vacuum pump while the pump is warm and disconnected from the power source. Use oil supplied by Micromeritics or refer to the vacuum pump manual for other acceptable oils. Unplug the vacuum pump from the power source. - Page 235 Gemini VII Preventive Maintenance Loosen the wing nut on the clamp at the top of the oil vapor trap. Swing the clamp open and remove the trap from the hose. Grasp the handle on top of the vacuum pump and place it on a work table. If adding oil, skip to step 5.