Micromeritics Gemini VII 2390 Confirm Installation Instructions And Checklist

Hide thumbs

Also See for Gemini VII 2390 Confirm:

- Installation instructions and checklist (113 pages) ,

- Service manual (60 pages)

Summary of Contents for Micromeritics Gemini VII 2390 Confirm

- Page 1 Gemini VII 2390 Confirm Installation Instructions and Checklist 239-42870-04 February 2009...

- Page 2 Windows is a registered trademark of Microsoft Corporation. Copyright Micromeritics Instrument Corporation, 2009. All rights reserved.

-

Page 3: Table Of Contents

Attaching the Hose ........................ 18 Applying Power to the Analyzer....................20 Part 2. Software Installation ......................21 Entering Ethernet Settings........................21 Configuring the Firewall Setting......................21 Installing the Micromeritics Software ....................21 Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... - Page 4 Performing a Blank Analysis ......................... 57 Installing Sample Tubes ......................... 57 Preparing the Dewar........................59 Starting the Blank Analysis......................59 Measuring Saturation Pressure....................... 61 Preparing for a Reference Material Analysis ..................62 Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

- Page 5 Installing the Analysis Program ......................71 Connecting Gases........................... 71 Cleaning and Verifying Gas Lines......................71 Verifying Instrument Operation ......................72 Exceptions .............................. 73 Signatures............................... 74 Installer ..........................74 Customer Representative ....................... 74 Final Documentation..........................74 Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

- Page 6 Table of Contents Gemini VII 2390 Confirm Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

-

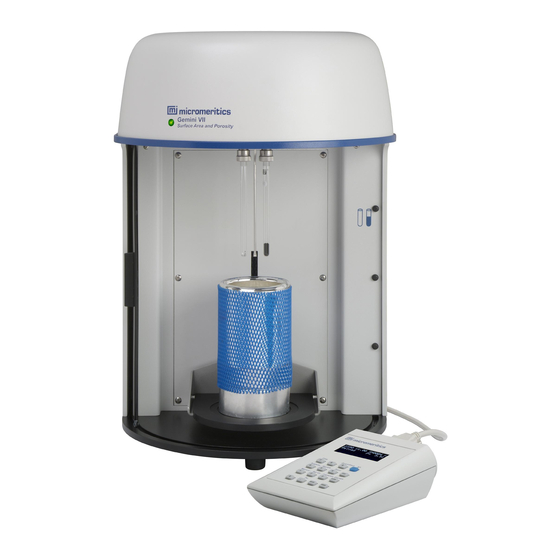

Page 7: Overview

Gemini VII 2390 Confirm Overview Overview This document describes how to install and verify operation of the Gemini VII 2390 Confirm Analyzer (21 CFR11). The document is organized into five parts: • Part 1 describes how to install the hardware. -

Page 8: Dewar Precautions

Before you begin installation, make sure the customer has thoroughly reviewed the Gemini VII 2390 Preinstallation Checklist. Make sure all required equipment and supplies are unpacked and the required personnel are available. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 9: Part 1. Hardware Installation

1. Plug the ethernet cable into the port labeled Ethernet on the side panel of the analyzer. Ethernet port 2. Plug the other end of the cable into the Ethernet port on the computer. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 10: Connecting Multiple Analyzers

3. Connect one end of an ethernet cable to the Ethernet connector on the left side of the analyzer and the other end of the cable to a numbered port on the ethernet switch. 4. Repeat Step 3 for each analyzer you are installing. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 11: Installing The Vacuum Pump

Use the appropriate instructions for the customer’s vacuum pump: • “Oil-Based Pump” on page 6 • “High-Vacuum/Oil-Free Pump Combination” on page 16 • “Non-Micromeritics Provided Vacuum Pump” on page 18 Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 12: Oil-Based Pump

Pump oil Preparing the Alumina 1. The activated alumina must be thoroughly dried before using. Turn on a drying oven and set the temperature to 300 °C to preheat. 300 °C Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... - Page 13 Do not perform this procedure on used alumina. Resultant oil vapors may cause a fire or explosion. 3. Bake the alumina for two hours. Remove the baked alumina from the oven and allow it to cool until lukewarm. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 14: Preparing The Alumina Trap

Be sure alumina pellets are cool. Adding hot pellets to the trap body may warp the body and cause an improper seal of the O-ring. 4. Screw the other end fitting onto the trap and tighten securely by hand. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 15: Closing The Ballast Valve

Closing the Ballast Valve The ballast valve should remain closed during the operation to obtain the best vacuum. Make sure the valve is turned completely clockwise. Ballast valve Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 16: Installing The Alumina Trap

Place an opened clamp around the flange of the intake port and the flange of the trap. Swing the clamp fastening screw toward the intake port until it fits into the slot in the other half of the clamp. Tighten the wing nut securely by hand. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 17: Checking The Pump Oil Level

3. Remove the plug from the oil-fill port. 4. Slowly add fresh oil to the port until the level is midway between the indicator lines in the oil-level window on the front of the pump. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... - Page 18 Do not allow oil to rise above the midway position. Doing so may cause oil to splash into the exhaust filter and contaminate it. Oil level 5. Replace the oil-fill plug; turn clockwise to tighten. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

-

Page 19: Installing The Exhaust Port Filter

5. Swing the clamp fastener screw toward the exhaust port until it fits into the slot in the other half of the clamp. Tighten the wing nut securely by hand. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 20: Attaching The Hose

3. Place a hose clamp on the hose and tighten the retaining nut with a flat-blade screwdriver. 4. Loosen the screws on the Vacuum port on the rear panel, then remove the plug and centering ring. Analyzer Rear Panel Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... - Page 21 7. Place the vacuum hose over the Vacuum adapter. Attach a clamp and tighten the retaining nut with a flat-blade screwdriver. 8. Plug the vacuum pump power cord into an appropriate power source. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 22: High-Vacuum/Oil-Free Pump Combination

3. Route the vacuum hose from the pump to the inlet port on the rear panel of the analyzer. Place the centering ring removed in Step 2 on the hose flange. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 23: Applying Power To The Pump

ON ( | ) position. Power switch 4. Place the vacuum pump power switch on the front of the pump enclosure in the ON ( | ) position. Power switch Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 24: Non-Micromeritics Provided Vacuum Pump

2. Place the centering ring you removed in Step 1 and the vacuum adapter in the Vacuum port. 3. Tighten the two port screws by turning them clockwise with a wrench. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... - Page 25 2. Route the vacuum hose from the pump to the inlet port on the rear panel of the analyzer. Place the centering ring removed in Step 1 on the hose flange. Centering ring Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 26: Applying Power To The Analyzer

2. Observe the Power indicator on the upper front portion of the instrument. The indicator will blink green to indicate that power is applied to the instrument. Once the embedded application is running, the indicator will stop blinking and remain on. Power indicator Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 27: Part 2. Software Installation

Windows operating systems prior to these versions did not have firewalls. To prevent an initialization failure when running the Micromeritics software, you must turn off the firewall option between the computer and the analyzer. (Refer to Technical Bulletin Gen 003 for for details.) You must also do this for any third-party firewalls that may have been... - Page 28 If all of the steps have not been completed, click , perform the steps and then Cancel restart the installation program. Do not proceed with installation until these tasks have been completed. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

- Page 29 Browse 4. If you want to run the Micromeritics software from the desktop, select the check box just below the Destination Folder group box to add an icon to the desktop. If the box labeled "Install this application for All Users" is checked (see Step 6), an icon is added to the desktop for all users.

- Page 30 Browse select the location. 9. The Seat number field is used when the Micromeritics software is installed on more than one computer. If this is the case, you can enter a number representing the computer. For example, if this is the second computer on which the Micromeritics software is installed, enter 02.

- Page 31 Another Computer in the Administrator Utility computer to this one: User’s Guide.) 12. In the Step 2 group box, enter the serial number(s) for the analyzer(s) you are attaching to this computer. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

- Page 32 ; the calibration files are installed. Next If you are installing multiple analyzers, a dialog prompting you to insert the media containing the calibration files for the next analyzer is displayed. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

- Page 33 CD in a secure location in the event calibration files need to be reinstalled. 18. You may be prompted to restart the computer after installation. If so, restart the computer before running the Micromeritics application. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 34: Entering Windows User Accounts

Entering Windows User Accounts The Windows Administrator for the local computer must create user accounts in Microsoft Windows for all persons who will use the Micromeritics application software. If you need detailed instructions for performing this procedure, refer to Technical Bulletin Gen033. -

Page 35: Recording User Information

As described previously, Micromeritics application users are to be assigned to one of the Windows user groups and to one of the two Micromeritics user profiles. The table below lists the Micromeritics application functions that can be performed by users with each profile. - Page 36 User Name* _________________________________________________ Full Name ___________________________________________________ User Name* _________________________________________________ Full Name ___________________________________________________ User Name* _________________________________________________ Full Name ___________________________________________________ User Name* _________________________________________________ Full Name ___________________________________________________ User Name* _________________________________________________ Full Name ___________________________________________________ Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

- Page 37 User Name* _________________________________________________ Full Name ___________________________________________________ User Name* _________________________________________________ Full Name ___________________________________________________ User Name* _________________________________________________ Full Name ___________________________________________________ User Name* _________________________________________________ Full Name ___________________________________________________ User Name* _________________________________________________ Full Name ___________________________________________________ Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 38: Setting Up User Profiles In The Administrator Utility

Setting Up User Profiles in the Administrator Utility Starting the Administrator Utility 1. Select Start > Programs > Micromeritics > AdminUtil for Gemini VII Confirm. 2. Enter "cfradministrator" in the User name field. 3. Enter "password" in the Password field, then click The following message displays: Your password has expired. -

Page 39: Entering Password Configuration Parameters

Entering Password Configuration Parameters 1. Click the Configuration tab to display the Configuration dialog. 2. The Password parameters you enter in this dialog will apply for all Micromeritics software users. Enter the number of days in which a user’s password will expire in the Expire in field. -

Page 40: Entering Application User Profiles

6. You may specify that the User ID must match the user’s Windows ID and the user must be logged into the Windows application. This ensures that only the current Windows user can operate the Micromeritics application. Otherwise, any user with the same access level (Developer or Analyst) can log into the application. - Page 41 8. The Change password on next logon box is checked because the user’s assigned password is temporary and must be changed when the user logs onto the application. 9. Click to save the user information and close the Add User dialog. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 42: Setting Up A Service User Account

Gemini VII 2390 Confirm Setting Up a Service User Account A user account should be set up during installation to provide Micromeritics service personnel access to system functions if a service call is required. To set up a service account: 1. -

Page 43: Exiting The Administrator Utility

To start the Gemini application, click its icon on the desktop or select the Gemini application from the Windows program list. The next step is Attaching and Preparing Gas for analysis. Proceed to the next page. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 44: Part 3. Gas Connections

Specify Units of Measure The software allows the user to set the units of measure to fit the laboratory’s needs. For the remainder of the installation, the units will be set as follows. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 45: Connecting Gases

Expansion kits or other accessories may be used in the lab. If so, you will have to give consideration to these configurations when installing the gas lines. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 46: Connecting A Gas Bottle

Observe the pressure on the high-pressure gauge. If the pressure is stable, proceed with the next step. If the pressure decreases, tighten the regulator connector nut until it becomes stable. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... - Page 47 Connect the gas line to the regulator connector. b. Use two 7/16-in. (11 mm) wrenches to tighten the gas line connection; one to hold the fitting steady and one to tighten the connector nut. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 48: Connecting The Gas To The Instrument

He port, to attach Helium to the instrument. 1. Loosen, then remove the plug from the port. 2. Insert the gas line into the port and hand-tighten the connector nut. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... - Page 49 4. Open the gas line, then apply a leak test agent to the gas port connection to make sure there is no leak at the fitting. Tighten if needed. 5. Connect the helium to the instrument repeating steps 1-4. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 50: Cleaning And Verifying The Gas Lines

Gas Line Rev. [latest revision letter]. This procedure uses the analysis gas as an example. Select Clean and Verify Helium Gas Line Rev. [latest revision letter] if the helium bottle is being verified. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... - Page 51 Low-pressure gauge Gas Bottle Shut-Off valve Pressure Control knob Regulator Shut-Off valve After the test is finished, a dialog stating the test is complete is displayed; click close the dialog. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

- Page 52 Fail if above = 0.1000 mmHg/min Observe the Leak Rate field; it should display Passed, indicating that the gas line from the instrument to the gas bottle is clean and leak-free. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

- Page 53 If you wish to run the test again, be sure to close the gas bottle valve before starting the test. 10. Click to close the test report. Close 11. Click on the test dialog to close the test. Close Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 54: Part 4. Operational Verification

Select Unit [n] > Show Instrument Schematic, Unit [n] > Enable Manual Control. b. Close all valves (double-click a valve to open or close it). c. Open valves 4-b and 4-s. Open valve 2 (adsorptive) for 15 seconds. d. Close all valves. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... - Page 55 Select Options > Service Test Mode. b. Enter the password, then click OK. c. From the main menu, select Unit[n] > Calibration > Zero Pressure. The following dialog is displayed. d. Select all transducers. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

- Page 56 From the main menu, for the unit number being operated, select Calibration > Pressure Scale.The following dialog is displayed. e. Select the Sample Port Transducers and Po Port Transducers, if present. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

- Page 57 Repeat step 2, but change the servo setting in step 2e to 380 mmHg. l. Proceed if the values for the transducers and pressure gauge are within 2 mmHg of 380 mmHg. If the values are not within this range, repeat the calibration. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

-

Page 58: Calibrate The Servo Valves

From the main menu, for the unit number being operated, select Unit [n] > Calibration > Balance Servo. b. Press button to begin the calibration routine. Start c. When the calibration is complete, a message is displayed. Click Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 59: Cleaning And Labeling Sample Tubes

1. Turn on the drying oven used for heating the sample tubes and set the temperature to 110 ºC. 2. Check the reservoir of the ultrasonic cleaning unit to make sure it is clean. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... - Page 60 7. Rinse the sample tubes thoroughly with hot water, then with isopropyl alcohol or acetone. If isopropyl alcohol or acetone is not available, deionized water may be used to rinse the sample tubes. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

- Page 61 10. Remove the sample tubes from the oven and allow them to cool. 11. Rinse stoppers with isopropyl alcohol. 12. Wipe a rubber stopper with a lint-free cloth. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

- Page 62 14. Insert the stopper into the opening of the sample tube. Cleaning the sample tube is complete. The next step is performing a blank tube analysis. Proceed to the next page. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

-

Page 63: Performing A Blank Analysis

O-ring. If the O-ring does not come out of the port with the plug, you may need to pry it out of the port. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... - Page 64 4. For Model t, slide the Dewar cover over the sample tubes. Insert the Po tube (if present) into the center hole of the Dewar cover and slide the cover up. For Models a & p, attach the 2-piece Dewar cover. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

-

Page 65: Preparing The Dewar

Preparing the Dewar Place a Dewar of water at ambient temperature on the elevator. Starting the Blank Analysis 1. Select Unit [n] > Blank Analysis; the Blank analysis dialog is displayed. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... - Page 66 Review the analysis results to see if they are within the tolerances shown in the following table. If these results are not achieved, perform a detailed leak check to determine the cause. P/Po Tolerance in cm ±0.008 ±0.010 ±0.012 ±0.014 ±0.016 ±0.018 ±0.020 ±0.022 ±0.024 Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

-

Page 67: Measuring Saturation Pressure

Place the analysis Dewar onto the elevator. Close the sample compartment door. Allow approximately 30 minutes for the temperature of the Dewar to stabilize with that of the bath liquid. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 68: Preparing For A Reference Material Analysis

1. Place the sample weighing support on the balance. Tare the balance and allow it to stabilize at zero (0). 2. Place the sample tube set (empty sample tube and stopper) on the sample weighing support, and place it on the balance. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 69: Degassing The Sample

Gemini application. You can degas the sample using commands on this menu and information you enter in the Degas Conditions dia- log. Refer to the SmartPrep operator’s manual for operating instructions. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 70: Determining The Sample Mass

- _________ = (Step 3 of the previous procedure) Sample Mass _________ This is the mass you will enter when you create a sample information file for the reference material analysis. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 71: Performing A Reference Analysis

Check the level of the analysis bath liquid in the Dewar. It should be about 2 cm (3/4 in.) from the top for the small Dewar and 5 cm (2 in.) for the large Dewar. Top off if necessary.. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 72: Starting The Reference Analysis

Click the template named Carbon Reference Material, then . This template Create contains the appropriate conditions for analyzing the carbon reference material; all values will be copied into the file you are creating. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... - Page 73 Open to the Analysis dialog. a. Enter the sample’s mass in the Sample Mass field. b. Click . Ensure that Report after analysis is selected and that Report After Analysis Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist...

- Page 74 “Cleaning and Verifying the Gas Lines” on page 44) The measured free space is too high. This Be sure your helium is 99.999% pure. indicates the helium may not be pure enough. Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09...

-

Page 75: Part 5. Installation Checklist

Indicates that this procedure does not apply to your system. Initial/Date Enter your initials and the date. If the procedure was completed by another person, that person should enter his or her initials and the date. Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 76: Preparing For Installation

F N/A Turn on the analyzer power switch. F N/A Entering Ethernet Settings Evaluation Initial/ Procedure Code Date Enter the ethernet settings. F N/A Configure the firewall setting. F N/A Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 77: Installing The Analysis Program

Make sure the helium gas line valves are in the correct state: F N/A Gas bottle shut-off valve Closed. Regulator shut-off valve fully Open. Pressure control knob fully Open. Perform the helium gas line test. F N/A Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 78: Verifying Instrument Operation

F N/A Degas the sample. F N/A Determine the sample mass. F N/A Install the sample tube with reference material. F N/A Check the LN level in the Dewar F N/A Gemini VII 2390 Confirm Installation Instructions and Checklist Feb 09... -

Page 79: Exceptions

The Actual results must match the Expected results, within the specified tolerance range, in order for this procedure to pass. Exceptions Procedures categorized as Fail should be explained below. Initial/ Procedure Comments Date Feb 09 Gemini VII 2390 Confirm Installation Instructions and Checklist... -

Page 80: Signatures

Service Support Center in Norcross, Georgia, USA. After completing the installation process, representatives of Micromeritics who install instruments are required to send the documents listed below to Micromeritics for inclusion in the customer's instrument history.

Need help?

Do you have a question about the Gemini VII 2390 Confirm and is the answer not in the manual?

Questions and answers