Micromeritics Gemini VII 2390 Service Manual

Surface area analyzer

Hide thumbs

Also See for Gemini VII 2390:

- Installation instructions and checklist (113 pages) ,

- Installation instructions and checklist (80 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Micromeritics Gemini VII 2390

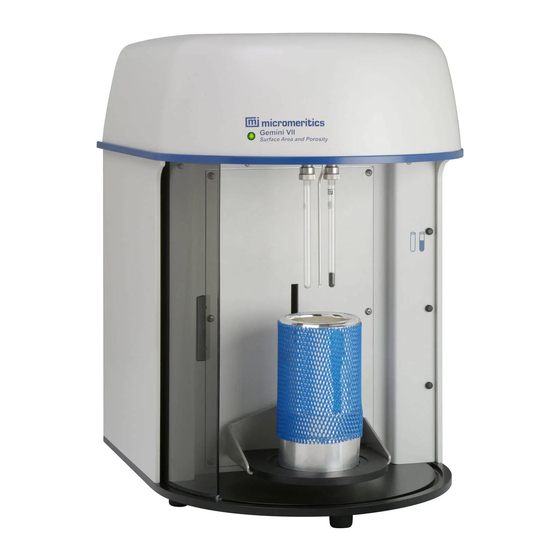

- Page 1 Gemini VII 2390 Surface Area Analyzer Service Manual February 2009...

- Page 2 Windows is a registered trademark of Microsoft Corporation. © Micromeritics Instrument Corporation, 2009. All rights reserved.

-

Page 3: Table Of Contents

Gemini VII 2390 Service Manual Table of Contents TABLE OF CONTENTS 1. GENERAL INFORMATION Organization of the manual ........... . . 1-1 Gemini Configurations. - Page 4 Table of Contents Gemini VII 2390 Service Manual 4. PREINSTALLATION 5. INSTALLATION 6. OPERATOR TRAINING 7. MAINTENANCE DOCUMENTS 8. CALIBRATION PROCEDURE 9. MECHANICAL AND ELECTRICAL DRAWINGS Mechanical ..............9-1 Electrical .

-

Page 5: General Information

1. GENERAL INFORMATION This service manual contains information and instructions for providing instrument service on the Micromeritics Gemini VII 2390, and is intended for use by Micromerit- ics' factory-trained and supported service personnel. It contains information and instructions for servicing the Gemini VII 2390 Series analyzers. It does not contain a description of software commands, nor procedures for operating the instrument (refer to the operator’s manual for this type of information). - Page 6 Organization of the manual Gemini VII 2390 Service Chapter 8 CALIBRATION PROCEDURE Provides a copy of the Factory Calibration Procedure. Chapter 9 MECHANICAL AND ELECTRICAL DRAWINGS Contains mechanical and electrical drawings. Chapter 10 SERVICE PARTS Contains a list of service replacement parts.

-

Page 7: Gemini Configurations

® *Windows XP Professional or Windows Vista Business or Ultimate Installation Qualification and Operational Qualification (IQ/OQ) packages are available for all configurations and may be purchased from Micromeritics. 239-00000-00IQ Installation Qualification 239-00000-00OQ Operational Qualification Also available for Windows-based systems is the Confirm software, which addresses the requirements specified by 21 CFR Part 11 validation, security, audit trails, report- ing and more. -

Page 8: Using This Manual

Using This Manual Gemini VII 2390 Service Using This Manual This manual is most efficiently used from the Micromeritics web site. However, it can be downloaded to a portable media device, such as a CD or a USB stick. Feb 09... -

Page 9: Functional Description

Gemini VII 2390 Service 2. FUNCTIONAL DESCRIPTION This chapter describes the systems and components that comprise the Gemini VII 2390 instrument. The basic function of the Gemini Series of surface area analyzers is to determine the surface area of solid materials. Analyses are performed using a static volumetric technique in which the adsorptive flows into a tube containing the sample and into a balance tube, at the same time. -

Page 10: New Product Features

New Product Features Gemini VII 2390 Service New Product Features Listed below are some of the new features added to the Gemini VII 2390 analyzers and software. Cabinetry & Sample Chamber • Two cabinet sizes are offered. • A rotating door allows easy access to the sample and balance ports for mounting and removing sample tubes. -

Page 11: Instrument Description

Gemini VII 2390 Service Instrument Description Instrument Description The Gemini VII 2390 analyzer consists of the following components and modules: • Cabinetry • Sample compartment • Components • Analysis manifold assembly • Software configurations • Printed Circuit Boards (PCBs) •... -

Page 12: Front Panel

Instrument Description Gemini VII 2390 Service Front Panel Top Panel Power indicator Sample Compartment Door The front panel contains a removable top panel, providing access to the interior analysis module and its subassemblies. The top panel is molded from plastic and internally coated with a special conductive coating to prevent radio frequency interference. -

Page 13: Rear Panel

Gemini VII 2390 Service Instrument Description Rear Panel Helium inlet port Adsorptive inlet port Vacuum Pump connector Keypad connector Ethernet port USB connectors RS232 connector On/Off switch Power connector Gas ports Two gas ports are provided; one for the adsorptive and one for Helium. -

Page 14: Sample Compartment

Instrument Description Gemini VII 2390 Service RS-232 connector For attaching devices used to perform calibration procedures. With the standalone Gemini, this connector can be used to attach an analytical balance for automatic transmission of the sample mass. On/Off switch For turning the analyzer on and off. -

Page 15: Balance, Sample, And Po Ports

Gemini VII 2390 Service Instrument Description Balance, Sample, and Po Ports The balance port is on the left side and the sample port is on the right side (pictorially illustrated on the right side of the sample compartment). The same size sample tube must be installed on both ports. -

Page 16: Elevator

Instrument Description Gemini VII 2390 Service Elevator The elevator is used for placement of the Dewar around the sample and Po tubes. The elevator is raised automatically when the analysis is started and lowers automatically when the analysis is finished. During analysis, the elevator also lowers after the free-space measurement to allow evacuation, then raises and continues the analysis. -

Page 17: Components

Gemini VII 2390 Service Instrument Description Components Dewar Gemini VII 2390a and 2390p 600-mL capacity Gemini VII 2390t 2.75-L capacity Optional stainless-steel Dewars are available for all models. Sample Tubes Sample tubes are made of borosilicate glass in order to withstand temperatures required for degassing. -

Page 18: Keypad

Gemini should there be a power failure. A device to reduce oil vapor backstreaming is also recommended for oil-based pumps. Appropriate pumps are available from Micromeritics (shown above). The vacuum pump may be provided by the user as long as it meets the above requirements. -

Page 19: Analysis Manifold

Adsorptive inlet Vacuum pump connector The Gemini VII 2390 has two gas inlets, one for the adsorptive and one for Helium. Both inlets contain dust filters (frits) to prevent debris from entering the system. This manifold also houses the vacuum connector and attaches to the sample manifold with a 1/4-in. stainless-steel tube. -

Page 20: Sample

Analysis Manifold Gemini VII 2390 Service Sample Solenoid valves Po transducer (p, t models only) Sample Balance Transducer transducer Po valve (p, t models only) Balance port Sample port Po tube (p, t models only) The sample manifold delivers gas to the sample and balance tubes; the flow is controlled by the solenoid valves. -

Page 21: Software

Gemini VII 2390 Service Software Software The Gemini VII 2390 analyzer in a standalone configuration is operated with embedded software using the functions on the keypad. The Windows version is operated in a Windows XP Professional or Windows Vista (Business or Ultimate) environment. -

Page 22: Windows Environment

Software Gemini VII 2390 Service Windows Environment Software for the Windows environment is operated from commands on the menu bar of the application. Commands The Windows version contains additional features (such as an easy-to-access electronic operator’s manual and How-To videos), as well as additional reports (such as SPC). -

Page 23: Manual Control

Gemini VII 2390 Service Manual Control Manual Control Some components of the analyzer can be manually controlled using commands provided in the software. Embedded An overlay is used when manually controlling the analyzer with a keypad. The overlay is placed on the keypad to guide you through the functions. - Page 24 Manual Control Gemini VII 2390 Service SERVO The commands above the 4, 5, and 6 keys relate to the servo valves. ON/OFF (above 4) Turns the servo valves on and off. An asterisk (*) appears next to the servo valve letter (B or S) when the servo valves are on.

-

Page 25: Windows Environment

Gemini VII 2390 Service Manual Control Windows Environment In the Windows environment, the instrument schematic is used to manually control components. Manual control is enabled by selecting Unit > Manual Control from the menu bar. Schematic legend: Vacuum port Sample servo valve... - Page 26 Manual Control Gemini VII 2390 Service When manual control is enabled, the valve symbols change color on the monitor screen to indicate their status. Green = open Yellow = closed Each component that can be manually controlled has a shortcut menu displaying the opera- tions available for that particular component.

-

Page 27: Printed Circuit Boards

Gemini VII 2390 Service Printed Circuit Boards Printed Circuit Boards Analysis Module The analysis controller PCB controls the functions of the analysis module. This includes actions for the gas inlet, reservoir, and sample manifolds. The analysis transducer interface board is located inside the upper portion of the analyzer and is partially enclosed by a metal barrier to protect its components from radio frequency interference. -

Page 28: Elevator

Printed Circuit Boards Gemini VII 2390 Service Elevator Elevator PCB The elevator PCB controls the movement of the elevator. 2-20 Feb 09... -

Page 29: Power Supply

Gemini VII 2390 Service Power Supply Power Supply Power supply (from interior of instrument) The Gemini’s power supply is mounted on the right wall of the Gemini when facing the rear of the instrument. Feb 09 2-21... -

Page 31: Analysis Sequence

Gemini Keypad version and the Windows version. Analysis Technique The Gemini VII 2390 uses an adaptive rate, static volumetric technique. It adapts the rate at which gas is delivered to the sample to the rate at which it is adsorbed. Each pressure point is allowed to equilibrate before the next point is taken. - Page 32 Analysis Sequence Gemini VII 2390 Service Volume Adsorbed transducer Reservoir Po tube, valve, and transducer reading; not displayed for Servo valve Model 2390a Balance Sample transducer volume adjustment Balance tube Sample tube Elevator Balance Pressure relief transducer valve The following icons represent valves. The state of a valve is indicated by its color:...

- Page 33 Gemini VII 2390 Service Analysis Sequence 1. The analysis is initiated by pressing the Start button in the Analysis dialog. 2. The system evacuates the sample and balance reservoirs. Feb 09...

- Page 34 Analysis Sequence Gemini VII 2390 Service 3. The servo valves close. The balance and sample valves open, and the system stabilizes. The sample and balance tubes are evacuated for the amount of time specified in the Analysis Conditions. 4. Steps 4 through 10 occur when Measure Free Space is selected in the Analysis Conditions.

- Page 35 Gemini VII 2390 Service Analysis Sequence 5. The He valve closes and the system stabilizes. 6. The system continues to stabilize with all valves closed. Feb 09...

- Page 36 Analysis Sequence Gemini VII 2390 Service 7. Helium is dosed into the sample and balance tubes, and the system is equilibrated. 8. The reservoirs are evacuated after free space is measured. Feb 09...

- Page 37 Gemini VII 2390 Service Analysis Sequence 9. The system continues to evacuate while the Dewar is lowered. 10. The system stabilizes after Helium is removed. Feb 09...

- Page 38 Analysis Sequence Gemini VII 2390 Service 11. The adsorptive valve opens. If Measure Po for each point is selected in the Analysis Conditions, the Po tube fills with adsorptive gas (Gemini 2390p and Gemini 2390t models only). 12. If Measure Po for each point is selected in the Analysis Conditions, the adsorptive valve closes, the initial Po measurement is taken, and the system is equilibrated.

- Page 39 Gemini VII 2390 Service Analysis Sequence 13. The adsorptive valve closes while the system stabilizes, then equilibrates. 14. The elevator is raised and gas doses into the sample and balance valves from their respective reservoirs to the first target pressure.

- Page 40 Analysis Sequence Gemini VII 2390 Service 15. After the target pressure is reached, the system equilibrates for the amount of time specified in the Analysis Conditions. 16. Steps 14 and 15 repeat for each target pressure set in the analysis conditions.

-

Page 41: Preinstallation

Gemini VII 2390 Service Preinstallation 4. PREINSTALLATION This chapter contains the Preinstallation Instructions and Checklist for the Gemini II 2390. This document helps to ensure that the customer has prepared the laboratory for installation of the instrument and that the supplies, equipment, and personnel are available for installation. -

Page 43: Installation

Gemini VII 2390 Service Installation 5. INSTALLATION Typically, the Gemini analyzers are customer-installed, except for the Confirm version which usually is installed by a qualified Micromeritics service representative. Installation instructions for the Gemini analyzers are located as shown below. • Keypad version: Chapter 2 of the operator’s manual. -

Page 45: Operator Training

Gemini VII 2390 Service Operator Training 6. OPERATOR TRAINING The Operator Training Checklist is used in conjunction with the operator’s manual and soft- ware to train the person(s) who will be operating the analyzer. Click on the following link to view the checklist. -

Page 47: Maintenance Documents

Gemini VII 2390 Service Maintenance Documents 7. MAINTENANCE DOCUMENTS The documents listed below are used for scheduled maintenance. Double-click the document you wish to view. • Maintenance Schedule, P/N: 239-42890-00 • Scheduled Maintenance Checklist, P/N: 239-42891-00 • Scheduled Maintenance Procedures, P/N: 239-42892-00 •... -

Page 49: Calibration Procedure

Calibration Procedure 8. CALIBRATION PROCEDURE This chapter contains the calibration and test procedure used in Micromeritics’ Final Assem- bly Department. It is provided as a reference so that you will be familiar with the calibration procedures and instrument tests that are performed on the instrument during manufacture. -

Page 51: Mechanical And Electrical Drawings

Gemini VII 2390 Service Mechanical 9. MECHANICAL AND ELECTRICAL DRAWINGS This section contains mechanical and electrical drawings for the Gemini analyzers. These drawings show assemblies in great detail. Some parts listed in these prints may be available only as an assembly or in a kit. The approved repair parts for servicing this instrument are listed in Chapter 10, Service Parts. -

Page 52: Electrical

Electrical Gemini VII 2390 Service Electrical Refer to the following table for a list of the electrical drawings. Double-click on the part num- ber to view the print. Print Number Description 239-17703-511 Analysis Module schematic 239-17702-511 Controller Module schematic 300-17715-511... -

Page 53: Service Parts

Gemini VII 2390 Service Service Parts 10. SERVICE PARTS This section contains a list of approved repair parts for this instrument. The Quantity column reflects the quantities included in the Service Parts Kit, P/N: 239-33680-00. Part Number Quantity Description 003-20829-00... - Page 54 Service Parts Gemini VII 2390 Service Part Number Quantity Description Frit, 2 µm SS 1/4 D x 1/16 T (for Balance port) 004-27024-00 Frit, 40 µm SS 1/4 D x 1/16 T (for Sample port) 004-27046-00 004-62611-00 Check valve, 20 psi, cracking 004-32609-00 Timing belt, 1/4 W x 10.4 L x 0.08 P...

-

Page 55: Software

Gemini VII 2390 Service Software 11. SOFTWARE A demo version of the Gemini VII 2390 software for is available for either the Windows stan- dard or Confirm versions. Double-click the demo software version you wish to view. • Gemini VII 2390 standard software •... -

Page 57: Operator's Manual

Gemini VII 2390 Service Operator’s Manual 12. OPERATOR’S MANUAL A printed operator’s manual is shipped with every Gemini analyzer. Analyzers operated in a Windows environment also have an electronic copy accessible from the Help menu. Listed below are the operator manuals available for the Gemini II 2390 series analyzers. Click the document you wish to view: •... -

Page 59: Service Training

Gemini VII 2390 Service Service Training 13. SERVICE TRAINING Service Training is provided to service personnel so that they can become familiar with the Gemini II 2390 Series analyzers. The syllabus on the following page is an outline of a typical training session. - Page 60 Service Training Gemini VII 2390 Service Training Syllabus Gemini VII Overview Comparison of Geminis Theory of Operation Overview Covered by Jeff Kenvin III. Functional Description A. Features of the three types of Geminis B. Instrument schematic overview Instrument Setup A. Installation checklist overview •...

Need help?

Do you have a question about the Gemini VII 2390 and is the answer not in the manual?

Questions and answers