Subscribe to Our Youtube Channel

Summary of Contents for Omron CS1D DUPLEX SYSTEM - 10-2009

- Page 1 Cat. No. W405-E1-09 SYSMAC CS Series CS1D-CPU_H CPU Units CS1D-CPU_S CPU Units CS1D-DPL01/02D Duplex Unit CS1D-PA/PD_ Power Supply Unit CS1D Duplex System OPERATION MANUAL...

- Page 3 CS1D-CPU@@H CPU Units CS1D-CPU@@S CPU Units CS1D-DPL01/02D Duplex Unit CS1D-PA/PD@@@ Power Supply Unit CS1D Duplex System Operation Manual Revised October 2009...

- Page 5 1. Indicates lists of one sort or another, such as procedures, checklists, etc. OMRON, 2002 All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

- Page 6 This applies to the CS1-H, CJ1-H, CJ1M, and CS1D CPU Units. Notation of Unit Versions The unit version is given to the right of the lot number on the nameplate of the on Products products for which unit versions are being managed, as shown below.

- Page 7 In the IO Table Window, right-click and select Unit Manufacturing informa- tion - CPU Unit. The following Unit Manufacturing information Dialog Box will be displayed. Unit version Use the above display to confirm the unit version of the CPU Unit connected online.

- Page 8 U n i t s . P l a c e t h e a p p r o p r i a t e l a b e l o n t h e f r o n t o f...

-

Page 9: Table Of Contents

Connecting Online to PLCs via NS-series Setting First Slot Words OK for up to 64 groups Automatic Transfers at Power ON without a Parameter File Automatic Detection of I/O Allocation Method for Automatic Transfer at Power ON Operation Start/End Times... -

Page 10: Cs1D Cpu Units

1. OK: Supported, ---: Not supported 2. The Removal/Addition of Units without a Programming Device function is supported only by CS1D CPU Units with unit version 1.3 or later and a Du- plex CPU, Dual I/O Expansion System. If the Removal/Addition of Units without a Programming Device function is... -

Page 11: Ok Ok Ok Ok Ok

Unit’s functions. Device Type Setting The unit version does not affect the setting made for the device type on the CX-Programmer. Select the device type as shown in the following table regardless of the unit version of the CPU Unit. - Page 12 CPU Units Ver. 2.0 or later to a Pre-Ver. 2.0 CPU Units. After the above message is displayed, a compiling error will be displayed on the Compile Tab Page in the Output Window. An attempt was made using CX- Check the settings in the PLC Programmer version 4.0 or higher...

- Page 13 2-10 Units on CS1D Long-distance Expansion Racks ....... . .

- Page 14 SECTION 7 I/O Allocations........221 I/O Allocations.

- Page 15 Connecting to the RS-232C Port on the CPU Unit .......

- Page 16 TABLE OF CONTENTS...

-

Page 17: About This Manual

CJ-series Power Supply Units CS1D Power Supply Units Please read this manual and all related manuals listed in the table on the next page and be sure you understand information provided before attempting to install or use CS1D-CPU@@H/S CPU Units in a PLC System. - Page 18 !WARNING Failure to read and understand the information provided in this manual may result in per- sonal injury or death, damage to the product, or product failure. Please read each section in its entirety and be sure you understand the information provided in the section and related sections before attempting any of the procedures or operations given.

- Page 19 WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY. In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted. IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS...

- Page 20 The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be suitable for the products: •...

- Page 21 PERFORMANCE DATA Performance data given in this manual is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application requirements.

- Page 22 xxii...

-

Page 23: Precautions

Conformance to EC Directives ........ -

Page 24: Intended Audience

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci- fied purpose and under the specified conditions, especially in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying a PLC System to the above-mentioned appli- cations. - Page 25 !Caution Confirm safety before transferring data files stored in the file memory (Mem- ory Card or EM file memory) to the I/O area (CIO) of the CPU Unit using a peripheral tool. Otherwise, the devices connected to the output unit may mal- function regardless of the operation mode of the CPU Unit.

-

Page 26: Operating Environment Precautions

I/O memory area. Doing either of these without confirming safety may result in injury. !Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the torque specified in the operation manual. The loose screws may result in burning or malfunction. -

Page 27: Application Precautions

The increase will be a maximum of 190 ms for the CS1D-CPU65H and 520 ms for the CS1D-CPU67H. Set the monitoring time (10 to 40,000 ms, default: 1 s) for the cycle time high enough to allow for this increase. Also, confirm that the system will operate correctly and safely even for the maximum cycle time, including the increase for duplex initialization. -

Page 28: Gramming Device

Units without a Programming Device function is enabled in the PLC Setup. If a Unit is removed while the PLC Setup is not set to enable Unit removal without a Programming Device, an I/O bus error will occur and the PLC (CPU Unit) will stop operating. - Page 29 • Always turn OFF the reserved pin (RSV) of the Duplex Unit's Communica- tions Setting DIP Switch. • Never connect pin 6 (5-V power supply) on the RS-232C port on the CPU Unit to any device other than an NT-AL001, CJ1W-CIF11 Adapter, or NV3W-M@20L Programmable Terminal.

- Page 30 BUSY indicator to go out before removing the Memory Card. • If the I/O Hold Bit is turned ON, the outputs from the PLC will not be turned OFF and will maintain their previous status when the PLC is switched from RUN or MONITOR mode to PROGRAM mode.

- Page 31 Application Precautions • Do not apply voltages to the Input Units in excess of the rated input volt- age. Excess voltages may result in burning. • Do not apply voltages or connect loads to the Output Units in excess of the maximum switching capacity.

- Page 32 Application Precautions • When replacing parts, be sure to confirm that the rating of a new part is correct. Not doing so may result in malfunction or burning. • Before touching a Unit, be sure to first touch a grounded metallic object in order to discharge any static build-up.

-

Page 33: Conformance To Ec Directives

EMC Directives OMRON devices that comply with EC Directives also conform to the related EMC standards so that they can be more easily built into other devices or the overall machine. The actual products have been checked for conformity to EMC standards (see the following note). -

Page 34: Relay Output Noise Reduction Methods

The CS1D Duplex PLCs conforms to the Common Emission Standards (EN61000-6-4) of the EMC Directives. However, noise generated by relay out- put switching may not satisfy these Standards. In such a case, a noise filter must be connected to the load side or other appropriate countermeasures must be provided external to the PLC. - Page 35 100 to 200 V, insert the varistor between the con- tacts. When switching a load with a high inrush current such as an incandescent lamp, suppress the inrush current as shown below. Countermeasure 1 Countermeasure 2...

-

Page 36: Conformance To Ec Directives

Conformance to EC Directives xxxvi... -

Page 37: Features And System Configuration

System Configuration ......... . . 1-2-1 CS1D Duplex Systems ........ -

Page 38: Cs1D Duplex System Overview And Features

Units, the CS1D can continue control operations and be restored with no need to shut down the entire system in the event of an error or malfunction. Select from either of two Duplex Systems: A Duplex CPU System or a Single CPU System. -

Page 39: Duplex Power Supply Units

CPU Unit, or if another operation switching error or a fatal error occurs.) Note Operation will be taken over by the standby CPU Unit for any of the following operation switching errors: CPU error, memory error, cycle time overrun error, program error, FALS error, or fatal Inner Board error. -

Page 40: Duplex Controller Link Units

Supply Unit that malfunctions or for which a broken line occurs can be con- firmed by means of flags in the AR Area. If a Power Supply Unit malfunctions, it can be replaced online without turning OFF the power supply or stopping operation. -

Page 41: Duplex Ethernet Units

Unit Duplex Units Note Duplex operation of Ethernet Units for a Duplex CPU System requires a CS1D CPU Unit Ver. 1.1 or later and CX-Programmer Ver. 4.0 or higher. Duplex operation of Ethernet Units for a Single CPU System is possible for any CS1D CPU Unit for Single CPU Systems, but CX-Programmer Ver. - Page 42 Cable if one Cable is damaged or disconnected. Online Replacement of If a Duplex Unit fails, the faulty Unit can now be replaced online. (The PLC Duplex Units operates in simplex mode while the Duplex Unit is being replaced.)

-

Page 43: Online Unit Replacement Using A Programming Device

Control Boards, refer to the Loop Control Boards Operation Manual (W406) and the Loop Control Board Function Block Reference Manual (W407). 2. A single Power Supply Unit can also be used, but it must be the CS1D Pow- er Supply Unit 3. -

Page 44: Ver

2. The maximum number of Units depends on the number of CS1D I/O Con- trol Units that are mounted. 3. The only CPU Units that can be mounted are CPU Units for a CS1D Du- plex System with a unit version 1.3 or later. If a CPU Unit with unit version 1.2 or earlier is mounted, an I/O bus error will occur and the system will not... - Page 45 These I/O Control Units cannot be used in a Duplex CPU, Single I/O Expansion System. Note When using a Memory Card in Duplex Mode, mount it in the active CPU Unit. (Duplex Memory Card operation is not possible.) Duplex EM File Memory operation is possible.

- Page 46 This Backplane cannot be used in a Duplex CPU, Dual I/O Expan- sion System. Note When using a Memory Card in Duplex Mode, mount it in the active CPU Unit. (Duplex Memory Card operation is not possible.) Duplex EM File Memory operation is possible.

- Page 47 CS1 Basic I/O Units I/O Interface Units CS1D-PA/PD@@@@ CS1 Special I/O Units and CPU Bus Units (See note.) Power Supply Units Note: C200H Units cannot be mounted. Note These Units are for use in a Duplex CPU, Dual I/O Expansion System only.

- Page 48 System Configuration Section 1-2 CS1D CPU Rack and CS1D Expansion Racks for a Duplex CPU, Single I/O Expansion System The same kind of CS1D Expansion Rack is used in both the Duplex CPU Sin- gle I/O Expansion Systems and Single CPU Systems. Use the following CS1D Expansion Backplane, which is specifically for the CS1D System.

-

Page 49: Cs1D Cpu

Section 1-2 System Configuration CS1D CPU Rack + CS1D Long-distance Expansion Racks for a Duplex CPU Single I/O Expansion System or Single CPU System The same Backplanes for Long-distance Expansion Racks are used in both Duplex CPU Single I/O Expansion Systems and Single CPU Systems. Use the following CS1D Expansion Backplane, which is specifically for the CS1D System. - Page 50 System Configuration Section 1-2...

-

Page 51: Specifications, Nomenclature, And Functions

Using File Memory........ - Page 52 2-11-2 Interrupt Input Units ........

-

Page 53: Specifications

(provided from CS1D Power Supply Unit) Note The number of steps in a program is not the same as the number of instruc- tions. Depending on the instruction, anywhere from one to seven steps may be required. For example, LD and OUT require one step each, but MOV(021) requires three steps. -

Page 54: Duplex Specifications

Mountable Duplex CPU Systems 1-2-1 CS1D Duplex Inner Boards Inner Boards cannot be used in a Duplex CPU System except for in the Process- Systems control CPU Units (CS1D-CPU P), which have a built-in CS1D-LCB05D Loop Control Board that cannot be removed. - Page 55 Section 2-1 Specifications Item Specifications Reference Duplex CS1D Duplex Mode A Duplex CPU System can be operated in either of the fol- 1-2-1 CS1D Duplex CPU Units lowing two modes: Systems (Supported Duplex Mode (DPL) only in Duplex The system operates with CS1D CPU Units and CS1D CPU Sys- Power Supply Units in duplex status.

- Page 56 Basic I/O Units, CS-series Special I/O Units, and CS-series CPU Bus Units while ment of I/O Units, Spe- using a Pro- the power is ON and the CPU Unit is operating in any mode (PROGRAM, MON- cial I/O Units, and CPU gramming ITOR, or RUN).

- Page 57 CPU Systems cannot be used independently. Restrictions When writing to a Memory Card, the same data is written to not only the Memory 2-5-1 File Memory on Memory Card mounted in the active CPU Unit, but also to the one mounted in the...

-

Page 58: Common Specifications Other Than Duplex Specifications

CJMP, or CJPN-JME. The PV will be refreshed for the entire period it was timer instruc- H PLCs with CS1D jumped the next time it is executed (i.e., the next time it is not jumped). (With tions in PLCs CS1-H CPU Units, the PV for these timers were refreshed even when jumped.) - Page 59 Tasks Systems Extra cyclic tasks can be executed each cycle, just like cyclic tasks, making a total of 288 tasks that can be exe- cuted each cycle. Cyclic tasks are executed each cycle and are controlled with TKON(820) and TKOF(821) instructions.

- Page 60 The setting of the first word can be changed from the 8-3 I/O Area the bits are default (CIO 0000) so that CIO 0000 to CIO 0999 can be not used as used. shown here. I/O bits are allocated to Basic I/O Units (CS-series Basic I/O Units).

- Page 61 37,504 (2,344 words): CIO 380000 to CIO 614315 (words Areas CIO 3800 to CIO 6143) These bits in the CIO Area are used as work bits in pro- gramming to control program execution. They cannot be used for external I/O.

- Page 62 8-17 Index Registers Store PLC memory addresses for indirect addressing. One register is 32 bits (2 words). Index registers can be set to be shared by all tasks or to be used independently by each task. Data Registers DR0 to DR15...

- Page 63 Startup mode setting Supported Programming Manual (W394) The CPU Unit will start in RUN mode if the PLC Setup is set 6-1 Overview of PLC Setup to use the Programming Console mode (default) and a Pro- gramming Console is not connected.

- Page 64 END instruction and instruction errors. CX-Programmer can also be used to check programs. Control output signals RUN output: An internal contact turns ON when the CPU Programming Manual (W394) Unit is operating in RUN or MONITOR mode.

-

Page 65: General Specifications

Noise immunity 2 kV on power supply line (conforming to IEC61000-4-4) Vibration resistance 10 to 57 Hz, 0.075-mm amplitude, 57 to 150 Hz, acceleration: 9.8 m/s in X, Y, and Z directions for 80 minutes (Time coefficient: 8 minutes coefficient factor 10 = total time 80 min.) -

Page 66: Configuration Devices

Conforms to cULus, NK, Lloyd’s, and EC Directives. Note 1. The above inrush current value is for a cold start at normal temperatures. The inrush current circuit for this power supply includes a thermistor ele- ment (for current suppression at low temperatures). If the ambient temper-... - Page 67 CS1D CPU Rack PERIPHERAL PORT Rack Configurations Rack name Devices Remarks CPU Rack for CPU Units for Duplex CPU Sys- Two Units (or one) are Duplex CPU, Dual tems (unit version 1.3 or later) required. I/O Expansion Sys- (See note 1.) tems...

- Page 68 Install a Memory Card as required. Note 1. The CPU Units for Duplex CPU Systems are specially designed for use in Duplex CPU Systems and cannot be used in Single CPU Systems or mounted in a CS-series CPU Rack. 2. The CS1D-BC042D CPU Backplane, CS1D-DPL02D Duplex Unit, and CS1D I/O Control Unit are specially designed for use in Duplex CPU Dual I/O Expansion Systems.

- Page 69 (Especially for a Duplex CPU, Single I/O Expansion System) CPU Backplane for Single CS1D-BC082S 8 slots CPU System Power Supply Units Two CS1D Power Supply Units are required for a duplex power supply config- uration. Name Model Specifications CS1D Power Supply CS1D-PA207R 100 to 120 V AC;...

- Page 70 (for a Duplex CPU, Single I/O Expansion System) Note 1. A Host Link (SYSWAY) connection is not possible when connecting a CX- Programmer via Peripheral Bus Connecting Cable for the peripheral port. Use a peripheral bus connection. 2. A peripheral bus connection is not possible when connecting a CX-Pro-...

-

Page 71: Expansion Racks

Section 2-2 Configuration Devices 3. For precautions regarding the use of Memory Cards, refer to 5-1 File Mem- ory in the SYSMAC CS/CJ/NSJ Series Programmable Controllers Pro- gramming Manual (W394). 2-2-2 Expansion Racks It is possible to connect Expansion Racks in order to mount Units outside of the CS1D CPU Rack. - Page 72 (unit version 1.3 or later) CS1D-BC042D CPU Backplane for Duplex CPU Systems CS1D CPU Rack Up to 5 Units can be mounted. CS1 Basic I/O Units CS1D-PA/PD@@@@ CS1 Special I/O Units and CPU Bus Units Power Supply Units Note: C200H Units cannot be mounted.

- Page 73 Section 2-2 Configuration Devices CS1D CPU Rack + CS1D Expansion Racks (Duplex CPU, Single I/O Expansion System) CS1D-BC082S CS1D-CPU@@S CS1D-BC052 CPU CS1D-CPU@@H/P CPU Backplane for CPU Unit for Backplane for CPU Units for CS1D-DPL01 Single CPU Systems Single CPU Systems...

- Page 74 Section 2-2 Configuration Devices CS1D CPU Rack + CS1D Long-distance Expansion Racks (Duplex CPU, Single I/O Expansion System) CS1D-CPU@@H/P CS1D-CPU@@S CS1D-BC082S CS1D-BC052 CPU Unit CPU Backplane for CPU Unit for CS1D-DPL01 CPU Backplane for Single CPU Systems Single CPU Systems...

- Page 75 Expansion Backplane CS1D Power Supply Units Two Units (or one) are required. Duplex CPU, Dual I/O Expansion One (or two) CS1D I/O Con- System trol Units or I/O Interface Units are required. • Mount a CS1D-IC102D I/O Control Unit to the CS1D CPU Rack.

- Page 76 12 m Note When using a CS1W-CN313 or CS1W-CN713 CS-series I/O Expansion Cable for a CS1D System, always use a Cable manufactured on or after Sep- tember 20, 2001. The manufacturing date is indicated on the connector as a 4-digit code or a 6-digit code. Cables that were manufactured before this date, or that do not indicate a manufacturing date cannot be used.

- Page 77 The maximum number of expansion slots depends upon the system configu- Connectable Units ration, as shown in the following table. The total number of each type of Unit is not limited by the mounting location. Note Up to 16 CPU Bus Units can be mounted.

- Page 78 The following table shows the Units, Programming Devices, and Support Soft- Devices ware that can be used to configure a CS1D Duplex System. Note Always use the specified CS1D Units for the CPU Units, Power Supply Units, CPU Backplanes, and Expansion Backplanes. CS-series Units cannot be used.

- Page 79 (for a Duplex CPU, CS1D Long-distance Expan- Single I/O Expansion sion Racks can both be System or Single used. The Connecting Cable CPU System) is the same as that used for the CS Series. CS-series CS1W-BI@@@ Expansion Note When securing the Backplanes...

- Page 80 Pro- Software for CX-Programmer Ver. 4.0 gram- personal com- or higher ming puter CX-Programmer Ver. 3.0 Use Ver. 3.1 or higher for online Unit Devices or higher replacement functions. and Sup- CX-Programmer Ver. 2.1 port Soft- or higher ware CX-Protocol...

-

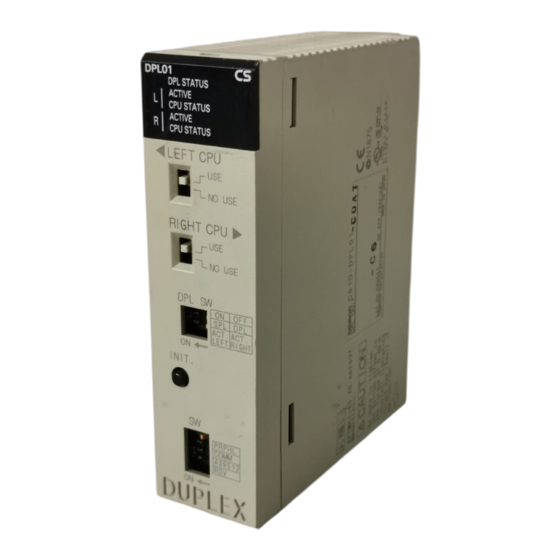

Page 81: Duplex Unit

CS1D-DPL01 (for a Duplex CPU, Single I/O Expansion System) Number mounted One Duplex Unit is required for a Duplex CPU System. Weight 200 g max. One Duplex Unit is required for a Duplex CPU System. It is not required for a Single CPU System. -

Page 82: Nomenclature

To turn OFF the power to the Duplex Unit NO USE while it is mounted, set this switch to NO USE. Duplex Unit Switches !Caution Before touching the Duplex Unit, be sure to first touch grounded metal to dis- charge static electricity. CPU Operating Switches LEFT CPU... -

Page 83: Notes

Note: Switching is disabled dur- ing operation. This switch is also disabled in a Simplex System. Note Duplex Mode and Simplex Mode can also be determined by the status of bit 08 of word A328. (2) Active Setting Switch (ACT. RIGHT/ACT. LEFT) - Page 84 PRPHL COMM A39512 In place of pins 4, 5, and 6 of the DIP switches on the right and left CPU Units, set the PRPHL and COMM pins and bit A39512 as shown in the following table. Turn OFF pins 4, 5, and 6 on both the right and left CPU Units.

- Page 85 38,400 bps, and then 115,200 bps. If the Programming Device is in a mode other than peripheral bus, or if it is set by peripheral bus to a baud rate oth- er than those that are automatically detected, the auto-detection function will not work.

-

Page 86: Ver

Memory Cards, or for front-panel DIP switch settings. Operation will continue in Duplex Mode even if these do not match for the ac- tive and standby CPU Units. The System is operating Either operation is normal in Simplex Mode, or normally in Simplex Mode. - Page 87 The left CPU Unit is active The left CPU Unit is the active (i.e., controlling) (ON) (ACT). CPU Unit. The left CPU Unit is on Either the left CPU Unit is on standby or the standby (STB). CPU Unit has stopped. Green CPU STATUS Green The left CPU Unit is in RUN The left CPU Unit is operating (i.e., in RUN or...

- Page 88 Green (ON) Green (ON) Green (ON) CPU STATUS Green (flashing) Green (ON) Green (ON) R (Non-active) ACTIVE CPU STATUS Green (flashing) Green (ON) Note The items set in bold text in the table are the main ones to indicate the status.

-

Page 89: External Dimensions

CPU error. 2. This indicator will light green if a duplex error occurs during operation. 3. The items set in bold text in the table are the main ones to indicate the sta- tus. Indicator Status when... -

Page 90: Cpu Units

Models Number of I/O Programming Data Memory Model Weight points (Number (DM + EM) of Expansion Racks) CPU Units for Duplex CPU 5,120 points 250 Ksteps 448 Kwords CS1D-CPU67H 350 g max. Systems (7 Racks) 60 Ksteps 128 Kwords CS1D-CPU65H... -

Page 91: Components

Easy backup (verification with Memory Card) with pin 7 OFF and pin 8 OFF. Pin 8: Always OFF. Note In a Duplex CPU System, the DIP switch on the front panel of the active CPU Unit is enabled (and the one on the standby CPU Unit is disabled). The DIP switch settings on the active and standby CPU Units do not necessarily have to match. - Page 92 BKUP Yellow User program and Parameter Area data is being backed up to flash memory in the CPU Unit or being restored from flash memory. Do not turn OFF the power supply to the PLC while this indicator is lit.

-

Page 93: Dip Switch Settings

Memory Card is not being accessed. DIP Switch Settings A Duplex CPU System, the DIP switch on the front panel of the active CPU Unit is enabled (and the one on the standby CPU Unit is disabled). The DIP switch settings on the active and standby CPU Units do not necessarily have to match. - Page 94 DIP switch during operation. Note 1. When pin 1 is set to ON, writing is prohibited for the user program and all parameter data (PLC Setup, I/O table registration, etc.). Moreover, it is not possible to clear the user program or parameters even by executing a memory clear operation from a Programming Device.

-

Page 95: Cpu Unit Memory Map

Units after simple backup is performed. Therefore, after the data has been read to the CPU Unit, turn the power OFF and back ON and then press the Initial Switch on the Duplex Unit. If DIP switch pin 7 on the active CPU Unit is ON, a duplex verification error will occur. - Page 96 1. The Parameter Area stores system information for the CPU Unit, such as the PLC Setup. 2. Part of the EM (Extended Data Memory) Area can be converted to file memory to handle data files and program files in RAM memory format, which has the same format as Memory Cards.

-

Page 97: Battery Compartment And Peripheral Port Covers

CPU Units 2-4-4 Battery Compartment and Peripheral Port Covers Opening the Battery Insert a small flat-blade screwdriver into the opening at the bottom of the bat- Compartment Cover tery compartment cover and lift open the cover. Insert a small flat-blade... -

Page 98: File Memory

(Backplane) 22.3 File Memory For CS1D CPU Units, the Memory Card and a specified part of the EM Area can be used to store files. All user programs, the I/O Memory Area, and the Parameter Area can be stored as files. -

Page 99: File Memory Functions In Duplex Cpu Systems

Memory Card functions can be executed in duplex only when the doing so is System enabled in the PLC Setup. In Duplex Mode, the same data that is written to the Memory Card mounted in the active CPU Unit will also be written to the Memory Card in the standby CPU Unit. -

Page 100: Parameter File

Using EM File Memory Operation in a Duplex CPU When a file is written to the EM file memory in the active CPU Unit in a Duplex System System, the same file is simultaneously written to the EM file memory in the standby CPU Unit. -

Page 101: Initializing File Memory

Device (excluding Program- ming Console). Note To delete all of the contents of a Memory Card, or to format the Memory Card, use either a CX-Programmer or Programming Console with the CPU Unit. Do not use a personal computer for this purpose. -

Page 102: Using File Memory

1. Install the Memory Card into the CPU Unit. 2. Initialize the Memory Card if necessary. 3. Name the file containing the data in the CPU Unit and save the contents in the Memory Card. 4. Read the file that is saved in the Memory Card to the CPU Unit. - Page 103 PLC Setup. 2. Initialize the EM file memory using a Programming Device. 3. Name the data in the CPU Unit and save in the EM file memory using the Programming Device. 4. Read the EM file memory files to the CPU Unit using the Programming De-...

-

Page 104: Memory Card Dimensions

Between CPU Unit and EM file memory 1,2,3... 1. Convert the part of the EM Area specified by the first bank number into file memory in the PLC Setup. 2. Initialize the EM file memory using a Programming Device. 3. Using the FWRIT(701) instruction, name the specified area in I/O memory with a file name and save in the EM file memory. - Page 105 Section 2-5 File Memory 1,2,3... 1. Pull the top end of the Memory Card cover forward and remove from the Unit. 2. Insert the Memory Card with the label facing to the right. (Insert with the on the Memory Card label and the on the CPU Unit facing each other.)

- Page 106 Section 2-5 File Memory 2. Press the Memory Card eject button after the BUSY indicator is no longer lit. BUSY indicator BUSY Memory Card eject button 3. The Memory Card will eject from the compartment. 4. Remove the Memory Card cover when a Memory Card is not being used.

-

Page 107: Programming Devices

Programming Devices Section 2-6 Note When a Memory Card is inserted into a computer using a Memory Card Adapter, it can be used as a standard storage device, like a floppy disk or hard disk. Programming Devices 2-6-1 Overview There are two types of Programming Devices that can be used: the Hand-held Programming Consoles or the CX-Programmer, which is operated on a Win- dows computer. - Page 108 EM_/EXT Sheet.) CS1W-CN114 (cable length: 0.05 m) Cable included with CQM1-PRO01-E Programming Console CQM1-PRO01 Connect the CPU Unit to the Programming Console with the following cables. CS1W-CN114 (Cable length: 0.05 m) C200H-PRO27-E Programming Console PRO27 PROGRAMMING CONSOLE OGRAMMING CONSOLE OPEN...

- Page 109 Section 2-6 Programming Devices CX-Programmer There are differences in functions depending on the version of CX-Program- mer connected to the CS1D PLC. These are listed in the following table. Duplex CPU Single CPU Remarks Programmer Systems Systems Version 2.@ or...

- Page 110 RS-232C Cable CS1W-CN118 2. If cables with model numbers ending in -V instead of -CV are used to con- nect the computer running the CX-Programmer to the RS-232C port (in- cluding when using a CS1W-CN118 Cable), a peripheral bus connection cannot be used.

- Page 111 XW2Z-500S-V 5 m Boards/Units D-Sub, 9- (See note.) pin, female Note Serial Communications Boards are supported only for Single CPU Systems. Connection Method for USB-Serial Conversion Cable Computer CS1W-CIF31 Cable 1 Cable 2 CS1W-N226/626 CS/CJ-series Peripheral Port Programming...

- Page 112 Connector hood Protection earth Note Do not use the 5-V power from pin 6 of the RS-232C port for anything but an NT-AL001 Link Adapter, CJ1W-CIF11 Conversion Adapter, or NV3W-M@20L Programmable Terminal. Using this power supply for any other external device...

- Page 113 232C Port on the CPU Unit when converting between RS-232C and RS- 422A/485 for 1:N connections. 2. Refer to Recommended Wiring Methods under Appendix F Connecting to the RS-232C Port on the CPU Unit when making your own RS-232C ca- ble. The following connections are in peripheral bus serial communications mode.

- Page 114 Protocol Host Link, NT Link, 1:N, No-protocol, or peripheral bus Note Baud rates for the RS-232C are specified only up to 19.2 kbps. The CS Series supports serial communications from 38.4 kbps to 115.2 kbps, but some com- puters cannot support these speeds. Lower the baud rate if necessary.

-

Page 115: Precautions When Connecting Programming Devices To Duplex Cpu Systems

CPU Unit to become the standby CPU Unit. For that reason, if the CX-Programmer is to be left connected, or if it is prefer- able to not have to reconnect the cable to the other CPU Unit when a switch- ing error occurs, it is recommended that the following connection be used. - Page 116 Hirakawa Hewtech Corp. b) The CJ1W-CIF11 does not provide isolation. The total length of the transmission path must therefore be 50 m or less. If the trans- mission distance is greater than 50 m, use the NT-AL001, which provides isolation, and do not include the CJ1W-CIF11 in the transmission path.

- Page 117 CPU Unit. For that reason, it is recommended that the following connection be used. For this, it is required that the Standby CPU Unit RS-232C Port Setting in the PLC Setup be set so that independent communications are disabled (i.e., the default setting).

-

Page 118: Power Supply Units

CS1D Power Supply Units. Therefore the load per CS1D Power Supply Unit is approximately 50%. If there is a breakdown at one of the CS1D Power Supply Units, operation is continued by using only the other one. In that event, the load at the one remaining CS1D Power Supply Unit will increase to 100%. -

Page 119: Cs1D Power Supply Unit Models

Always remove the metal jumper before applying a voltage of 200 to 240 V AC. Not doing so will damage the Unit. AC Input Either a power supply of 100 to 120 V AC (50/60 Hz) or 200 to 240 V AC (50/60 Hz) can be selected. Voltage Selector Before applying a voltage of 100 to 120 V AC, close the circuit using the metal jumper. -

Page 120: Dimensions

RUN Output An internal contact turns ON when the CPU Unit is operating in RUN or MON- ITOR mode. Any of the RUN outputs at the CPU Rack, an Expansion Rack, or a Long-distance Rack can be used. When Power Supply Units are used in duplex operation, the RUN output turns ON for both Power Supply Units together. -

Page 121: Backplanes

For connecting CS1D Expansion Racks. C200H Expansion I/O Racks and CS-series Expansion Racks cannot be connected. Note Backplanes produced from July 2005 have screw holes that allow an Expan- sion Rack Cable Mounting Bracket to be attached to secure the cable. - Page 122 CPU Unit for Single CPU Systems connectors Note To protect unused connectors, always cover them with CV500-COV01 I/O Unit Connector Covers (sold separately) or mount the CS1W-SP001 Spacer Unit (sold separately). When using only one Power Supply Unit, cover the unused Power Supply Unit connector with a C500-COV01 Power Supply Unit Connec- tor Covers (sold separately).

-

Page 123: Expansion Backplanes For Online Replacement

CPU Backplane for Single CPU Systems: CS1D-BC082S 505.1 6.25 17.1 26.8 2-8-2 Expansion Backplanes for Online Replacement These Backplanes are used for CS1D Expansion Racks and CS1D Long-dis- tance Expansion Racks. Model Number of slots Model Application Weight 7 or 8... - Page 124 Section 2-8 Backplanes CPU Backplane for Duplex CPU, Single I/O Expansion Systems or Single CPU Systems: CS1D-BI092 Backplane mounting screws Slots for mounting Units Mount the Backplane with four M4 screws. The Backplane is constructed so that it can be insulated from the control panel when installed.

-

Page 125: Units For Duplex Cpu, Dual I/O Expansion Systems

Section 2-9 Units for Duplex CPU, Dual I/O Expansion Systems CPU Backplane for Duplex CPU, Single I/O Expansion Systems or Single CPU Systems: CS1D-BI092 17.1 6.25 26.8 505.1 Units for Duplex CPU, Dual I/O Expansion Systems CS1D I/O Control Units and CS1D I/O Interface Units are required to con- struct a Duplex CPU, Dual I/O Expansion System. -

Page 126: Duplex Connecting Cables

34.5 Connecting the Units Mount the CS1D I/O Control Unit in either slot 0 or slot 1 (or mount two Units in both slots) of the CS1D-BC042D CPU Backplane. If CS1D I/O Control Units are mounted in slot 0 and slot 1, the Connecting Cables can be duplexed. -

Page 127: Cs1D-Ii102D I/O Interface Unit

CPU Bus Unit can be mounted. Cable connects to next Rack. If a CS1D I/O Control Unit is mounted in slot 1 only, a Basic I/O Unit, Special I/O Unit, or CPU Bus Unit cannot used in slot 0. If mounted here, a CS-series Basic I/O Unit, Special I/O Unit, or CPU Bus Unit will not operate. -

Page 128: Led Indicators

34.5 Connecting the Units Mount the CS1D I/O Interface Unit in either slot 0 or slot 1 (or mount Units in both slots) of the CS1D-BI082D Expansion Backplane. If CS1D I/O Interface Units are mounted in slot 0 and slot 1, the Connecting Cables can be duplexed. - Page 129 Incorrect Separate Expansion Backplanes cannot be connected. If a CS1D I/O Interface Unit is mounted in slot 0 only, a Basic I/O Unit, Special I/O Unit, or CPU Bus Unit can be used in slot 1. Single Connecting Cable connects to previous Rack.

-

Page 130: Units On Cs1D Long-Distance Expansion Racks

I/O Control Units and I/O Interface Units are required when creating CS1D Long-distance Expansion Racks. Terminators (CV500-TER01) are connected to the last CS1D Long-distance Expansion Rack in each series. (Up to two series of CS1D Long-distance Expansion Racks can be connected.) - Page 131 Connect the Backplane connector to the I/O expansion connector. IC102 TER ERR LEFT CPU RIGHT CPU Connect to I/O CPU Rack DPL SW cable connector. INIT. DUPLEX DUPLEX Series A Series B Note An I/O Control Unit cannot be mounted on an Expansion Backplane.

-

Page 132: Cs1W-Ii102 I/O Interface Units

Section 2-10 Units on CS1D Long-distance Expansion Racks 2-10-2 CS1W-II102 I/O Interface Units Mount a CS1W-II102 I/O Interface Unit to the leftmost slot on each Long-dis- tance Expansion Rack. Always use a CS1D-BI092 Expansion Backplane (for online replacement). Part Names and Functions... - Page 133 Connect the I/O Interface Unit to the input I/O cable connector on the Back- plane (left side). Always connect a Terminator (CV500-TER01) to the connec- tor for the next Rack when it is not used (i.e., on the last Long-distance Expansion Rack in the series).

-

Page 134: Basic I/O Units

Note 1. C200H I/O Units cannot be used. 2. An Interrupt Input Unit can be used to input interrupts for a Single CPU System. With a Duplex CPU System, however, interrupt inputs cannot be used, i.e., the Interrupt Input Unit will function only as a standard Input Unit. - Page 135 16-point Units CS1W-OD212 CS1W-INT01 with ERR indica- ER R 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 CS1W-IDP01 tor (load short-cir- 8 9 10 11 12 13 14 15 8 9 10 11 12 13 14 15...

-

Page 136: Interrupt Input Units

Basic I/O Units 2-11-2 Interrupt Input Units An Interrupt Input Unit can be used to input interrupts for a Single CPU Sys- tem. With a Duplex CPU System, however, interrupt inputs cannot be used, i.e., the Interrupt Input Unit will function only as a standard 16-point Input Unit. -

Page 137: Cs-Series Basic I/O Units With Connectors (32-, 64-, And 96-Pt Units)

ON time CS1W-IDP01 0.1 ms min. Dimensions The High-speed Input Unit has the same dimensions as the Units with a 20- terminal block. 2-11-4 CS-series Basic I/O Units with Connectors (32-, 64-, and 96-pt Units) CS-series Basic I/O Units are classified as Basic I/O Units. - Page 138 F (fuse burnt out) indicator Available on Output Units. 0 1 2 3 4 5 6 7 Lights when one or more fuses in the Unit blows. 8 9 10 11 12 13 14 15 Lights when external power is OFF.

- Page 139 CS1W-ID231 CS1W-OD231 CS1W-OD232 Units with Two 40-pin connectors (b) CS1W-ID261 CS1W-OD261 CS1W-OD262 CS1W-MD261 CS1W-MD262 Units with 56-pin connectors (c) CS1W-ID291 CS1W-OD291 CS1W-OD292 CS1W-MD291 CS1W-MD292 Using Soldered or Crimped Connector Approx. 169 for 32- and 64-pt Units/Approx. 179 for 96-pt Units...

-

Page 140: Unit Current Consumption

Power Supply Unit mounted), taking into account the load when an error occurs at one of the Power Supply Units. If two different kinds of Power Supply Units are to be used, calculate the current consumption using the output of the smaller-capacity Power Supply Unit. -

Page 141: Total Current And Power Consumption Calculation Example

Note 1. When duplexing by combining the CS1D-PA207R and CS1D-PD024, de- sign the total current consumption for all Units on the Rack to be within the power supply capacity of the CS1D-PD024. 2. When duplexing by combining the CS1D-PA207R and CS1D-PD025, de- sign the total current consumption for all Units on the Rack to be within the power supply capacity for the CS1D-PA027R. -

Page 142: Current Consumption Tables

Section 2-12 Unit Current Consumption 2-12-3 Current Consumption Tables Note For the current consumption of Units not shown in these tables, refer to the individual user manuals for those Units. 5-V Voltage Group Name Model Current consumption (A) CPU Backplane for Single CPU Systems CS1D-BC082S 0.17 CPU Backplane for Duplex CPU, Dual I/O CS1D-BC042D 1.2... - Page 143 CS1W-PDC01 0.15 Isolated Control Output Unit CS1W-PMV01 0.15 (Analog Output Unit) Power Transducer Input Unit CS1W-PTR01 0.15 DC Input Unit (100 mV) CS1W-PTR02 0.15 Isolated Pulse Input Unit CS1W-PPS01 0.20 Motion Control Units CS1W-MC221(-V1) 0.6 (0.80 when connected to a Teaching Box) CS1W-MC421(-V1) 0.7 (1.00 when connected...

-

Page 144: Cpu Bus Unit Setting Area Capacity

The CPU Bus Units are allocated the required number of words for settings from this area. There is a limit to the capacity of the CPU Bus Unit Setting Area of 10,752 bytes (10 Kbytes). The system must be designed so that the number of words... -

Page 145: I/O Table Settings

Section 2-14 I/O Table Settings used in the CPU Bus Unit Setting Area by all of the CPU Bus Units and the Inner Board does not exceed this capacity. If the wrong combination of Units is used, the capacity will be exceeded and either Units will operate from default settings only or will not operate at all. -

Page 146: Basic I/O Units

64-point I/O Unit Unit CS1W-MD291/292 96-point I/O Unit Note 1. An I/O setting error will occur if Units are not set correctly. 2. An I/O verification error will occur if the number of input or output words is set incorrectly. -

Page 147: Cs-Series Special I/O Units

High-speed Counter Unit CS1W-CT021/041 Other Special I/O Units GPIB Interface Unit CS1W-GPI01 Other Special I/O Units Note A Special I/O setting error will occur if Units, the number of input, or the num- ber of output words is set incorrectly. -

Page 148: Cs-Series Cpu Bus Units

PROFIBUS-DP Master Unit CS1W-PRM21 PROFIBUS Master Unit Loop Control Unit CS1W-LC001 Loop Control Unit High-resolution Motion Con- CS1W-MCH71 High Function Numerical trol Unit Control Unit Open Network Controllers ITNC-EIS/EIX-CST ONC/CS1 Bus IF ITBC-CST01 Note Supported from CS-Programmer version 4.0 or higher. -

Page 149: Duplex Functions

3-1-1 Duplex CPU Systems ........ -

Page 150: Duplex Cpu Units

Memory Cards, make sure that the contents and the capacities are the same for both of the Memory Cards. If the free space or the contents are different, write processing to the Memory Cards may not be completely correctly. - Page 151 • The setting at the Active Setting Switch on the Duplex Unit determines which of the two CPU Units is to be active. • The R and L ACTIVE indicators on the Duplex Unit show which of the two CPU Units is active. The active/standby status can also be checked using A32809 in the Auxiliary Area.

- Page 152 IOWR(223) (INTELLIGENT I/O WRITE), PID(190) (PID), RXD(235) (RECEIVE), FREAD(700) (READ DATA FILE), and FWRIT(701) (WRITE DATA FILE). The following table shows the processing related to duplex operation. For details, refer to SECTION 9 CPU Unit Operation and the Cycle Time. Processing Duplex-related processing Startup processing Duplex status is checked (i.e., whether the Unit status is active...

-

Page 153: Errors Causing Operation To Switch To The Standby Cpu Unit

The mode does not change between Duplex Mode and Simplex Mode as a result of Power Supply Unit errors. Note CS1D Power Supply Units must be used. Duplex Optical Controller Link Units or Ethernet Units can be used in a duplex config- Communications uration. Units The mode does not change between Duplex Mode and Simplex Mode as a result of Communications Unit errors. - Page 154 CPU Unit online replacement function. Note 1. To determine the cause of a switch to the standby CPU Unit, refer to A023 in the Auxiliary Area or to Mode Switch Reference, below. 2. In Simplex Mode, or in a Simplex System, operation stops when any of the above errors occur.

-

Page 155: Duplex Errors

A02608 to A02615: Year (00 to 99) The above Auxiliary Area words are cleared when the mode is restored from Simplex Mode to Duplex Mode. At that time, the contents of A023 are transferred to A019, and the contents of A024 to A026 are transferred to A020 to A022, as an error log. -

Page 156: Automatic Recovery To Duplex Operation By Self-Diagnosis

1. In order for automatic recovery to be enabled, the power to the other CPU Unit must not be OFF and the Mode Setting Switch must be set to DPL. If the mode cannot be automatically returned to Duplex Mode, the following bits in the Auxiliary Area (CPU Unit Duplex Unit Recovery Flags) will turn Right CPU Unit: A32814 turns ON. -

Page 157: Duplex Initialization

Duplex CPU Units Section 3-1 reason the standby CPU Unit previously failed (i.e., the reason for switch- ing to Simplex Operation) or the time the switch was made, use A019 (rea- sons for switching) and A020 to A022 (time of switching). 3-1-5... -

Page 158: Duplex Cpu Units With Different Unit Versions

Duplex CPU Unit operation is not possible if the unit version of the active CPU Unit Operation Is Not Unit is earlier than that of the standby CPU Unit and the Active CPU Unit uses functions not supported by the Standby CPU Unit. If this happens, a Duplex Possible Verification Error will occur and operation will be in Simplex Mode. -

Page 159: Duplex Cpu System Restrictions

The CX-Programmer will not update the unit version following online replace- ment of a Unit, and thus any data transfers will be performed as if the previous unit version was still valid even if the unit version has been changed in the online replacement procedure. - Page 160 MTIMX(554), TIMW(813), TIMWX(816), TMHW(815), TMHWX(817): (10 ms + cycle time) Note If the mode is changed from Duplex Mode to Simplex Mode during execution of a timer instruction, the accuracy in the first cycle following the mode switch is less than normal (as shown below).

- Page 161 LIGENT I/O WRITE), PID(190) (PID), RXD(235) (RECEIVE), FREAD(700) (READ DATA FILE), and FWRIT(701) (WRITE DATA FILE) • If the active and standby CPU Units cannot be synchronized when any of the above instructions are executed (except for PID), the ER Flag will turn ON.

- Page 162 1. When a duplex verification error or duplex bus error occurs when the power is turned ON, the CPU Unit goes into “CPU standby” status. 2. The cause of the “CPU standby” is stored in A322 in the Auxiliary Area. Conditions for Mode Switching in a Duplex System (Reference)

-

Page 163: Duplex Power Supply Units

Backplane's power supply of 5 V DC and 26 V DC is provided in parallel from the two Power Supply Units. Even if the power is interrupted at one of the Power Supply Units, or if one of the Power Supply Units breaks down, power can still be provided to the Rack by the other Power Supply Unit alone. -

Page 164: Primary And Secondary Communications

Communications Unit, the other as the secondary Communications Unit. The same unit number and node address are set for both of the Units, but two unit numbers (twice the amount of memory) are allocated. The primary Communications Unit performs communications with the nodes on the primary network while confirming node participation in the primary net- work. - Page 165 CS1D CPU Units for Duplex CPU Systems with a unit version of 1.1 or later or a CS1D CPU Unit for Single CPU Systems with a unit version of 2.0 or later is required to use Duplex Communication Units using primary/secondary com- munications.

-

Page 166: Duplex Connecting Cables

Units for information on the settings that are required. Duplex Connecting Cables In a CS1D Duplex CPU, Dual I/O Expansion System, it is possible to duplex the Connecting Cables between the CPU Rack and Expansion Rack and the Connecting Cables between Expansion Racks. The system components... - Page 167 Section 3-4 Duplex Connecting Cables Unit CPU Rack The system will stop if there are problems in both Connecting Cables. Expansion Rack Units Expansion Rack...

- Page 168 Section 3-4 Duplex Connecting Cables...

-

Page 169: Operating Procedures

Basic Procedures ........ -

Page 170: Introduction

• Set the DPL USE/NO USE switch to USE (CS1D-DPL02D only). • Set the communications switch on the Duplex Unit. b) Set the DIP switches and rotary switches on the front of the CPU Unit and other Units. Refer to SECTION 2 Specifications, Nomenclature, and Functions for de- tails. - Page 171 Refer to SECTION 6 PLC Setup for details. 7. Registering the I/O Tables Check the Units to verify that they are installed in the right slots. With the PLC in PROGRAM mode, register the I/O tables from the Programming Device (CX-Programmer or Programming Console). (Another method is to create the I/O tables in CX-Programmer and transfer them to the CPU Unit.)

-

Page 172: Basic Procedures

1. Connect the power supply and I/O wiring. 2. Connect communications lines if required. !Caution When 200 to 240 V AC power is being supplied, be sure to remove the jumper bar that shorts the voltage selector terminals. The Power Supply Unit will be... - Page 173 Note For simplex operation, set the mode switch to SPL. b) Set the active-CPU Unit switch to ACT.RIGHT or ACT.LEFT depending on which CPU Unit is to be used as the active CPU Unit. DPL SW ON: The left-side CPU Unit will be active.

- Page 174 Confirm that both CPU Units are the same model. Settings for Single CPU The DIP switch on the front of the CPU Unit must be set, along with other set- Systems tings. Be particularly careful when setting the peripheral port and RS-232C port settings.

- Page 175 CPU Unit. 5. Checking Initial Operation !Caution When 200 to 240 V AC power is being supplied, be sure to remove the jumper bar that shorts the voltage selector terminals. The Power Supply Unit will be damaged if 200 to 240 V AC is supplied with the jumper bar connected.

- Page 176 Single CPU Systems Not supported CS1D-S 2. Edit the PLC Setup and transfer it to the CPU Unit. (It can be transferred separately or the CXP project can be saved and the PLC Setup can be transferred together with the program.) Note In a Duplex CPU System, transfer to PLC Setup to the active CPU Unit.

- Page 177 Note Supported for CPU Unit Ver. 1.1 or later. 7. Registering the I/O Tables in the CPU Unit Registering the I/O tables allocates I/O memory to the Units actually installed in the PLC. This operation is required in CS-series PLCs.

- Page 178 Basic Procedures Section 4-2 Note The I/O tables, user program, and PLC Setup data in CS1D CPU Units is backed up in the built-in flash memory. The BKUP indicator will light on the front of the CPU Unit when the backup operation is in progress. Do not turn OFF the power supply to the CPU Unit when the BKUP indicator is lit.

- Page 179 CPU Unit. The I/O tables will automatically be copied to the standby CPU Unit as well. Note The first word allocated to each Rack can be set in the PLC Setup under the Options menu. Using a Programming Console Use the following procedure to register the I/O table with a Programming Con- sole.

- Page 180 D32000 to D32099 (100 words 1 Board) After writing the initial settings to the DM Area, be sure to restart the Units by turning the PLC OFF and then ON again or turning ON the Restart Bits for the affected Units.

- Page 181 Operating mode changed IOM Hold Bit Status at Startup When the IOM Hold Bit has been turned ON and the PLC Setup is set to pro- tect the status of the IOM Hold Bit at startup (PLC Setup address 80 bit 15...

- Page 182 PLC turned ON. Output OFF Bit (A50015) Turning ON the Output OFF Bit causes all outputs on Basic I/O Units and Special I/O Units to be turned OFF. The outputs will be turned OFF regardless of the PLC’s operating mode.

- Page 183 When a Programming Console is being used, monitor the bits with Bit/Word Monitor or 3-word Monitor. Press the SHIFT+SET Keys to force-set a bit or press the SHIFT+RESET Keys to force-reset a bit. The forced status can be cleared by pressing the NOT Key.

- Page 184 Basic Procedures Online Editing When a few lines of the program in the CPU Unit have to be modified, they can be edited online with the PLC in MONITOR mode or PROGRAM mode. When more extensive modifications are needed, upload the program from the CPU Unit to the host computer, make the necessary changes, and transfer the edited program back to the CPU Unit.

-

Page 185: Installation And Wiring

Mounting Height........ -

Page 186: Fail-Safe Circuits

Note When a fatal error occurs, all outputs from Output Units will be turned OFF even if the IOM Hold Bit has been turned ON to protect the contents of I/O memory. (When the IOM Hold Bit is ON, the outputs will retain their previous status after the PLC has been switched from RUN/MONITOR mode to PRO- GRAM mode.) -

Page 187: Installation

PLC RUN output Surge suppressor Note Do not latch the RUN output and use it in a circuit to stop a controlled object. Chattering of the relay contacts used in the output may cause incorrect opera- tion. Interlock Circuits... - Page 188 • To ensure safe access for operation and maintenance, separate the PLC as much as possible from high-voltage equipment and moving machinery. • The PLC will be easiest to install and operate if it is mounted at a height of about 1.0 to 1.6 m.

- Page 189 • Ground the mounting plate between the PLC and the mounting surface. • When I/O Connecting Cables are 10 m or longer, connect the control pan- els in which Racks are mounted with heavier power wires (3 wires at least 2 mm in cross-sectional area).

-

Page 190: Installation In A Control Panel

Note If the CS1D-PA207R Power Supply Unit is to be used at an ambient tempera- ture of 50 C or higher, provide a minimum space of 80 mm between the top of the Unit and any other objects, e.g., ceiling, wiring ducts, structural supports, devices, etc. - Page 191 • Whenever possible, route I/O wiring through wiring ducts or raceways. Install the duct so that it is easy to fish wire from the I/O Units through the duct. It is handy to have the duct at the same height as the Racks.

-

Page 192: Mounting Height

5-2-3 Mounting Height The mounting height of CPU Racks and Expansion Racks is 123 to 153 mm, depending on I/O Units mounted. If Programming Devices or connecting cables are attached, the additional dimensions must be taken into account. -

Page 193: Backplane Mounting Dimensions

1,2,3... 1. Mount the Unit to the Backplane by hooking the top of the Unit into the slot on the Backplane and rotating the I/O Unit downwards. 2. Make sure that the connector on the back of the Unit is properly inserted into the connector in the Backplane. -

Page 194: I/O Connecting Cables

20 mm min. Duct Phillips screwdriver 4. To remove a Unit, use a phillips-head screwdriver to loosen the screw at the bottom of the Unit, rotate the Unit upward, and remove it. 5-2-6 I/O Connecting Cables I/O Connecting Cables are used to connect the CPU Rack and Expansion Racks. - Page 195 • When connecting Expansion Racks with Long-distance Expansion Rack I/O Connecting Cables, install the Racks and select I/O Connecting Cables so that the total length of all I/O Connecting Cables in one system does not exceed 50 m. Example 1: CS-series I/O Connecting Cables...

- Page 196 2. A maximum of seven Long-distance Expansion Racks can be connected (including all Racks in both series). 3. Each series of Long-distance Expansion Racks must be 50 m max. with a total of 100 m max. for both series. 4. Expansion Racks and Long-distance Expansion Racks cannot be con- nected at the same time.

- Page 197 The connecting port for each CS-series I/O Connecting Cable depends on the system configuration and the Rack being connected, as shown in the follow- ing diagrams. The PLC will not operate properly if the Racks are not con- nected as shown in the following diagrams.

- Page 198 2. Always turn OFF the power supply to the PLC before connecting Cables. 3. An I/O bus error will occur and the PLC will stop if an I/O Connecting Ca- ble’s connector separates from the Rack. Be sure that the connectors are...

-

Page 199: Inner Board Installation

Long-distance Expansion Rack and a 63-mm hole will be required for Cables connecting other Racks. 5. I/O Connecting Cables cannot be cut or rejoined. Be sure to use I/O Con- necting Cables of the proper length, particularly when wiring inside panels or wiring ducts. - Page 200 CPU Unit to malfunction, damage internal components, or cause com- munications errors. 3. Before installing the Inner Board, be sure to first touch a grounded metallic object, such as a metal water pipe, in order to discharge any static build- up from your body.

-

Page 201: Power Supply Wiring

Provide an emergency stop circuit to control the power supply to the con- trolled system so that power is supplied to the controlled system only when the PLC is operating and the RUN output is ON. Connect an external relay to the RUN output from the Power Supply Unit. - Page 202 2A RESISTIVE 2A RESISTIVE Note 1. Wire the Power Supply Units so that they can be replaced safely and with- out interrupt the power supply to other Racks or devices in the event that a Power Supply Unit fails. 2. Branching wiring at a Power Supply Unit terminal block will create a dan- gerous situation if a Unit must be replaced.

-

Page 203: Wiring Methods

INCORRECT! (Unit will be damaged.) Note If 100 to 120 V AC power is supplied but the jumper bar has been removed to select 200 to 220 V AC, the Unit will not operate because the power supply voltage will be below the 85% minimum level. - Page 204 120 V AC supply voltage. For 200 to 240 V AC leave them open. !Caution The Power Supply Unit will be damaged if 200 to 240 V AC power is supplied and the voltage selector terminals are connected with the jumper bar.

- Page 205 16 to 14) V2-M3(RAV2-3.5) Round terminal with sleeve Note 1. Use crimp terminals for wiring. 2. Do not connect bare stranded wires directly to terminals. 7 mm max. 20 mm max. M3.5 self-raising terminals Torque to 0.8 N m...

- Page 206 This label prevents wire strands and other foreign matter from entering the Unit during wiring procedures. Do not forget to remove the label from the top of the Unit after wiring the Unit. The label will block air circu- lation needed for cooling.

- Page 207 Supply power to all of the Power Supply Units from the same source. 4. Do not forget to remove the label from the top of the Unit after wiring the Unit. The label will block air circulation needed for cooling.

- Page 208 To prevent noise from entering on the GR (ground) terminal as a result of a difference in potential, wire the system as shown below. • Connect all of the GR terminals on the Racks and ground them at one point only to 100 or less.

- Page 209 Wiring Communications Lines When using communications from one or more Rack in the system, ground the entire system so that only one point is grounded. (Refer to user documen- tation for the devices connected.) For detailed connection methods, refer to the Operation Manual for the Communications Unit.

-

Page 210: Wiring Cs-Series Basic I/O Units With Terminal Blocks

The following wire gauges are recommended. Wire Size AWG 22 (0.32 mm Note The current capacity of electric wire depends on factors such as the ambient temperature and insulation thickness as well as the gauge of the conductor. Wiring Terminal screws M3.5 self-rising screws... - Page 211 • In addition, make sure that the I/O indicators are not covered by the wir- ing. • Do not place the wiring for I/O Units in the same duct or raceway as power lines. Inductive noise can cause errors in operation.

-

Page 212: Wiring Cs-Series Basic I/O Units With Connectors

The I/O Units are equipped with removable terminal blocks. The lead wires do not have to be removed from the terminal block to remove it from an I/O Unit. The terminal block can be removed by taking out the terminal block mounting screws. -

Page 213: Wiring Procedure

1. Check that each Unit is installed securely. Note Do not apply excessive force on the cables. 2. Do not remove the protective label from the top of the Unit until wiring has been completed. This label prevents wire strands and other foreign matter from entering the Unit during wiring. - Page 214 Wire (0.2 to 0.13 mm Note Double-check to make sure that the Output Unit’s power supply leads haven’t been reversed. If the leads are reversed, the Unit’s internal fuse will blow and the Unit will not operate. 4. Assemble the connector (included or purchased separately) as shown in the following diagram.

- Page 215 After wiring Remove label after wiring. Connector lock screws Tighten the connector-attaching screws to a torque of 0.2 N m. The following examples show applications for preassembled OMRON Cables. Contact your OMRON dealer for more details. Connecting to a Terminal Two sets of the following Cables and Conversion Units are required.

- Page 216 CS1W-ID291 (96 input points) CS1W-OD291 (96 output points) CS1W-OD291 (96 output points) CS1W-OD292 (96 output points) CS1W-OD292 (96 output points) CS1W-MD291 (48 inputs, 48 outputs) CS1W-MD291 (48 inputs, 48 outputs) CS1W-MD292 (48 inputs, 48 outputs) CS1W-MD292 (48 inputs, 48 outputs) XW2Z-@@@H-3 Connecting...

-

Page 217: Connecting I/O Devices

Section 5-4 Wiring Methods Connecting to a Relay Two sets of the following Cables and Relay Terminals are required. Terminal CS1 Basic I/O Unit CS1 Basic I/O Unit CS1W-ID231 CS1W-ID291 (96 input points) CS1W-ID261 CS1W-OD291 (96 output points) CS1W-MD261 (inputs) - Page 218 Sensor Power Supply Output AC/DC Input Unit 7 mA • Voltage current output Output DC Input Unit Sensor Power Supply The circuit below should NOT be used for I/O devices having a voltage output. Sensor Power Supply DC Input Unit Output...

- Page 219 Note When using a reed switch as the input contact for an AC Input Unit, use a switch with an allowable current of 1 A or greater. If Reed switches with smaller allowable currents are used, the contacts may fuse due to surge cur- rents.

- Page 220 : PLC input impedance 4. Precautions on Sensor Surge Current An incorrect input may occur if a sensor is turned ON after the PLC has started up to the point where inputs are possible. Determine the time re- quired for sensor operation to stabilize after the sensor is turned ON and take appropriate measures, such as inserting into the program a timer de- lay after turning ON the sensor.

-

Page 221: Reducing Electrical Noise

In-floor duct Conduits Suspended duct If the I/O wiring and power wiring must be routed in the same duct, use shielded cable and connect the shield to the GR terminal to reduce noise. Inductive Loads When an inductive load is connected to an I/O Unit, connect a surge suppres-... - Page 222 Power cables Power lines Ground to 100 or less If the I/O wiring and power cables must be placed in the same duct, they must be shielded from each other using grounded steel sheet metal. PLC power supply and general...

-

Page 223: Plc Setup

6-2-11 CPU Duplex Tab Page ........ -

Page 224: Overview Of Plc Setup

2. CS1D CPU Unit Ver. 1.1 or later and CX-Programmer version 4.0 or later only. 3. CX-Programmer version 3.1 or higher. 4. This function is supported only by Duplex CPU Units with Unit Ver. 1.2 or later and CX-Programmer version 6.1 or higher. -

Page 225: Settings Other Than Those For Duplex Systems

Startup Mode Console’s mode switch setting at startup. • You want the PLC to go into RUN mode or MONITOR mode and start oper- ating immediately after startup. • You want the operating mode to be other than PROGRAM mode when the power is turned ON. - Page 226 Set the peripheral port or the RS-232C port communications port baud rate to “high- speed NT Link.” You want the intervals for scheduled interrupts to be set in units of 1 ms Schedules Interrupt Time Units (See note.) rather than 10 ms.

-

Page 227: Specific Plc Setup Settings

PLC Setup when using a Programming Console or the Programming Console function of an NS-series Programming Terminal. The PLC Setup is stored in the Parameter Area, which can be accessed only from a Programming Device. Do not use the Programming Console addresses as operands in programming instructions. - Page 228 Console isn’t connected, startup mode will sole: be RUN mode. Programming Console’s mode switch Default: Program Execution Settings (Single CPU Systems Only) Setting to Start Program without Waiting for Specific Units/Inner Board (Single CPU Systems Only) Address in Settings Function Related New set- Programming flags and ting’s effec-...

-

Page 229: Cpu Unit Tab Page

Section 6-2 Specific PLC Setup Settings Enable Setting in Word 83 for Inner Boards (Single CPU Systems Only) Address in Settings Function Related New set- Programming flags and ting’s effec- Console words tiveness Word Bit(s) 0: Wait for Boards. To start the CPU Unit in MONITOR or PRO-... - Page 230 FAL(006) is in error log. toring for FPD(269) will be recorded in the executed error log (A100 to A199). Set it to 1 so pre- (every cycle) 1: Don’t record user- vent these errors from being recorded. defined FAL errors in error log.

- Page 231 Word Bit(s) 0 to 3 0 to C hex (0 to 12) If bit 7 (above) is set to 1, the setting here A344 (EM After initial- specifies the EM bank where file memory File Memory ization from Default: 0 begins.

-

Page 232: Timings Tab Page

(i.e., processed in the background). 1: Executed in back- ground Default: 0 Note This setting cannot be used with Duplex CPU Systems. Communications Port Number for Background Execution Address in Settings Function Related... - Page 233 Set to 1 to enable the Watch Cycle Time A40108 At the start of 1: Bits 0 to 14 Setting in bits 0 to 14. Leave this setting at 0 (Cycle Time operation for a maximum cycle time of 1 s.

-

Page 234: Siou Refresh Tab Page

(1-ms units) power interruption (approximately 10 to operation. 25 ms for AC power and 2 to 5 ms for DC Default: 00 hex (Can’t be power after the power supply voltage drops changed dur-... -

Page 235: Unit Settings Tab Page

Special I/O Units are being used and to 47 you don’t want to extend the cycle Default: 0 time or the cycle time is so short that Cyclic Refresh- 0 to 15 0: Enabled the Special I/O Unit’s internal pro-... -

Page 236: Host Link Port Tab Page

With a Duplex CPU System, these settings are valid when the COMM pin on the DIP switch on the Duplex Unit is turned OFF. With a Single CPU System, these settings are valid when the pin 5 on the DIP switch on the CPU Unit is turned OFF. - Page 237 Bit(s) 0: Default (stan- *The default settings are for 1 start bit, 7 A61902 Takes effect dard)* data bits, even parity, 2 stop bits, and a baud (RS-232C the next rate of 9,600 bps. Port Settings cycle. 1: PLC Setup (cus-...

- Page 238 Word Bit(s) 0 to 1 00: Even These settings are valid only when the com- A61902 Takes effect 01: Odd munications mode is set to host link or no- (RS-232C the next 10: None protocol. Port Settings cycle. Changing (Also can be...

- Page 239 “PLC Setup” and set the baud rate to Changing (Also can be Default: 00 hex 9,600 bps. Flag) changed with STUP (237).) NT Link Max. (Maximum Unit Number in NT Link Mode) Address in Settings Function Related New set- Programming flags and ting’s effec-...

- Page 240 With a setting of 0, the amount of data being 2 hex: CR+LF received must be specified. A setting of 1 enables the end code in bits 0 to 7 of 164. A Default: 0 hex setting of 2 enables an end code of CR+LF.

-

Page 241: Peripheral Port Tab Page

With a Duplex CPU System, these settings are valid when the PRPHL pin on the DIP switch on the Duplex Unit is turned ON. With a Single CPU System, these settings are valid when the pin 4 on the DIP switch on the CPU Unit is turned ON. - Page 242 0 to 7 00 hex: 9,600 This setting is valid only when the communi- A61901 Takes effect 01 hex: 300 cations mode is set to the Host Link mode. (Peripheral the next 02 hex: 600 Port Settings cycle. These settings are also valid only when the...

- Page 243 NT Link* Port Settings cycle. Changing (Also can be Default: 00 hex Flag) changed with STUP (237).) NT Link Max. (Maximum Unit Number in NT Link Mode) Address in Settings Function Related New set- Programming flags and ting’s effec- Console...

-

Page 244: Peripheral Service Tab Page

New set- Programming flags and ting’s effec- Console words tiveness Word Bit(s) 0: Default (stan- *The default settings are for a baud rate of A61901 Takes effect dard)* 9,600 bps (Peripheral the next 1: PLC Setup (cus- Port Settings cycle. - Page 245 Access) tion.) Note 1. This setting cannot be used with Duplex CPU Systems. The default setting will be used even if the setting is changed. 2. A PLC Setup error will occur if any non-specified value is set. Set Time to All Events (Fixed Peripheral Servicing Time)

- Page 246 Default: 00 (hex) (5 to 255 ms in 1-ms increments) (Can’t be changed dur- ing opera- tion.) Note This setting cannot be used with Duplex CPU Systems. Peripheral Service Execution Time Address in Settings Function Related New set- Programming flags and ting’s effec-...

-

Page 247: Fins Protection Tab Page (Single Cpu Systems Only)

A maximum of 32 nodes can be set. If these settings are not made (i.e., if the total number of nodes is 0), write operations will be disabled for all nodes but the local node. -

Page 248: Comms Unit Duplex Tab Page

Section 6-2 6-2-10 Comms Unit Duplex Tab Page There are two methods that can be used for duplex communications: Active- standby and primary-secondary. There are options available for both in the PLC Setup. The methods that are used depends on the Communications Units. -

Page 249: Cpu Duplex Tab Page

Commu- nications Unit is mounted. Note This setting is supported only for CS1D CPU Units Ver. 1.1 or later. CX-Pro- grammer version 4.0 or higher must be used to make the setting. 6-2-11 CPU Duplex Tab Page... - Page 250 Use this setting to reduce startup time when the power is turned ON. When an operation switching error occurs in the Active CPU Unit, the Standby CPU Unit will become the Active CPU Unit and start operating. Address in...

- Page 251 Memory Cards. Note Data read from the Memory Card mounted in the active CPU Unit is used by both the active and standby CPU Units. Note Memory Card duplex operation can be selected with CX-Programmer Ver. 3.1 or higher.

- Page 252 1 to 63 Normally, the default setting for 4,906 words Default: 00 is used. Note If either the Transfer Program or Transfer EM option is selected the specified division size will be transferred each cycle. Transfer Program Address in...

- Page 253 Area Boards. operation 1: Do not transfer Default: 0 Note As of October 2006, there are no Inner Boards to which this setting applies. Use the default setting. Transfer Variable Area of Inner Board Address in Settings Function...

- Page 254 Device. Default: 0000 Note 1. This setting can be used only in Duplex CPU Units with Unit Ver. 1.2 and later. 2. This setting can be selected with CX-Programmer version 6.1 or higher. Enabling Unit Removal/Addition of Units without a Programming Device...

-

Page 255: Other Settings

PLC (CPU Unit) will not stop operating even if a Basic I/O Unit, Special I/O Unit, or CPU Bus Unit fails. If there are any Units that will adversely affect the system if an I/O bus error occurs, do not enable the Unit Removal without a Programming Device or Removal/Addi- tion of Units without a Programming Device function in the PLC Setup. - Page 256 Section 6-2 Specific PLC Setup Settings...

-

Page 257: I/O Allocations

Creating I/O Tables........ -

Page 258: I/O Allocations

I/O tables containing the models and locations of all Units and the allocations made to each must be created and these I/O tables must be registered in the CPU Unit. When the power supply is turned ON, the I/O tables are compared against the mounted Units to verify their accuracy. -

Page 259: Creating I/O Tables

Units that are mounted. • Create the I/O tables offline without basing them directly on the mounted Units and then transfer the I/O tables to the PLC. This is done offline on the CX-Programmer. - Page 260 When I/O memory is allocated automatically, words are automatically allo- cated to Units in the order they are mounted to the Racks. Words are allo- cated to Units from left to right starting on Rack 0 and then left to right on each Rack through Rack 7.

- Page 261 CPU Unit. Standby CPU Unit Active CPU Unit I/O Table Creation with CX-Programmer Use the following procedure to create the I/O tables offline with the CX-Pro- grammer and then transfer them to the CPU Unit. Once the Units that are to...

- Page 262 The first word for slot 00 on the Rack is set. Words Rack 1 are then allocated in order to Units from left to right. Note The first words for Racks cannot be set at the same time as the first words for slots. Setting the First Word for a Slot The first word allocated to the Unit in any slot on any Rack can be set regard- less of the order of the Rack or the position of the slot.

- Page 263 A word is set for slot 02 on the CPU Rack for group 01. Rack 0 Rack 1 A word is set for slot 02 on Rack 1 for group 02. Note The first words for Racks cannot be set at the same time as the first words for slots. Overview Method...

-

Page 264: I/O Allocation Methods

CIO 0000 and each Unit is allocated as many words as it requires. Note 1. Units that have 1 to 16 I/O points are allocated 16 bits (1 word) and Units that have 17 to 32 I/O points are allocated 32 bits (2 words). - Page 265 I/O allocation to Basic I/O Units continues from the CPU Rack to the Expan- sion Rack connected to the CPU Rack. Words are allocated from left to right and each Unit is allocated as many words as it requires, just like Units in the CPU Rack.

- Page 266 The CPU Rack is rack 0, the CS-series Expansion Rack (if there is one) is Rack 1. Rack numbers are then assigned in order to the Racks in series A of CS-series Long-distance Expansion Racks and finally to the Racks in series B of CS- series Long-distance Expansion Racks, to a maximum rack number of 7.

- Page 267 Dummy item from under the Basic I/O Unit with the correct number of I/O points. • CX-Programmer Ver. 6.0 or Later Right-click the slot for which a word is to be reserved and select Add Unit (alternatively, double-click the empty slot).

- Page 268 I/O Allocation Methods Section 7-2 The following Select Unit Dialog Box will be displayed. Click the expansion button (+) to the left of Basic I/O, select one of the Dummy Units (CS_Dummy_016/032/048/064/096/128), and click the OK Button. Note Do not execute the I/O table creation operation after completing the above...

-

Page 269: I/O Allocations To Special I/O Units

(CIO 2000 to CIO 2959) according the unit number set on the Unit. Special I/O Units can be mounted to the CPU Rack, CS-series Expansion Racks (see note). Note Refer to 2-14 I/O Table Settings for more details on the available Special I/O Units. Word Allocation The following table shows which words in the Special I/O Unit Area are allo- cated to each Unit according to unit number. -

Page 270: Allocating First Words To Racks

CIO 0100; the next Rack, words starting with CIO 0200; etc. This can make it easier to check word allocations to Units without calculating all the way from the CPU Rack. Note The first words for Racks cannot be set at the same time as the first words for slots. - Page 271 Example: Setting the First Words for Racks In this example, the first words have been set for Racks 0 (the CPU Rack), 2, and 3. For simplicity, only 16-bit Units have been used.

- Page 272 1. Press the FUN, SHIFT, and CH Keys to start the I/O table creation opera- tion. If the first work for a Rack has been set, a message saying so will ap- pear on the second line of the display.

-

Page 273: Allocating First Words To Slots (Single Cpu Systems Only)

Word Allocations When setting first words for slots, the first word must be set for slot 00 on the CPU Rack. The first word can then be set for any slot on any Rack for up to 63 other slots. -

Page 274: Setting First Slot Words

Rack 4 CIO 0600 Note Group 00 must start at slot 00 on the CPU Rack. Any word can be set. Any slot can be set on any Rack for groups 01 to 63. Setting First Slot Words from the CX-Programmer First slot words can be set from the CX-Programmer. - Page 275 Section 7-4 2. Select the Slot Start Addresses Settings Option and click the OK Button. 3. In the dialog box that will appear, set the first word for slot 00 on the CPU Rack. 4. To change the setting from CIO 0000, click the Edit Button. The follow di- alog box will appear.

-

Page 276: Detailed Information On I/O Table Creation Errors

Units mounted to the PLC. If there are any duplications, and error will occur and it will be no longer possible to edit the I/O tables. If this happens, the I/O tables will have to be deleted and recreated or retransferred from a Programming Devices. -

Page 277: Data Exchange With Cpu Bus Units

The 100 words allocated to each Unit are transferred from the DM Area to the Unit when the PLC is turned on or the Unit is restarted. Some C200H Special I/O Units do not use any of the allocated DM words and others use only a part of the allocated words. -

Page 278: Disabling Special I/O Unit Cyclic Refreshing

Ten words are allocated to each Special I/O Unit in the Special I/O Unit Area (CIO 2000 to CIO 2959) based on the unit number set on the front of each Unit. The data in the Special I/O Unit Area is refreshed in the CPU Unit every cycle during I/O refreshing (just after execution of the END(001) instruction). -

Page 279: Cpu Bus Units

CIO Area words allocated to the CPU Bus Unit of a specified unit number. Transfer of Words Allocated in the DM Area Each CPU Bus Unit is allocated 100 words in the DM Area in the range of D30000 to D31599 (100 words 16 Units). There are three times that data may be transferred through the words allocated to each Unit. -

Page 280: Fins Commands

Section 7-6 Some models transfer data in both directions, from the DM Area to the Unit and from the Unit to the DM Area. See the Unit’s Operation Manual for details on data transfers. These 100 words are generally used to hold initial settings for the CPU Bus Unit. -

Page 281: Online Addition Of Units And Backplanes

Both Units and Expansion Racks can be added during oper- ation. Note A Duplex CPU Unit with unit version 1.3 or later is required to add Units online. CPU Bus Units cannot be added online. Expansion Racks can be added online only in a Duplex CPU, Dual I/O Expansion System. - Page 282 Special I/O Units that are already mounted. Add the new Unit to a slot position so that the allocated words will not be duplicated. There are no other restrictions on the slot position.

-

Page 283: Online Addition Procedure