Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

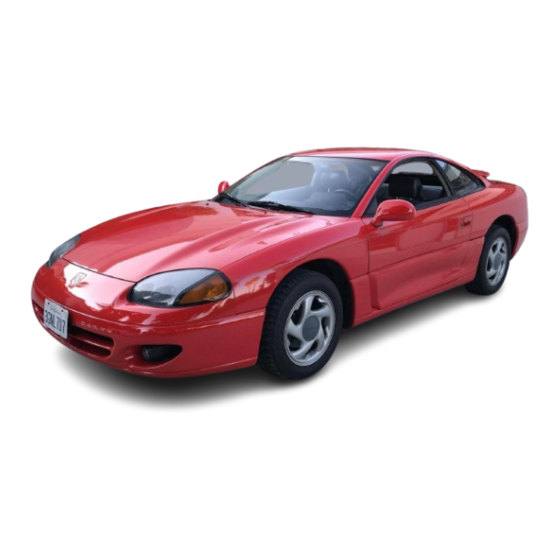

Summary of Contents for Mitsubishi Stealth 1994

- Page 1 IMPORT SERVICE MANUAL ENGINE, CHASSIS & BODY Volume - I...

-

Page 2: Safety Notice

SAFETY NOTICE CAUTION ALL SERVICE AND REBUILDING INSTRUCTIONS CONTAINED HEREIN ARE APPLICABLE TO, AND FOR THE CONVENIENCE OF, THE AUTOMOTIVE TRADE ONLY. All test and repair procedures on components or assemblies in non-automotive applications should be repaired in accordance with instructions supplied by the manufacturer of the total product. - Page 3 BackupServiceManual GROUP INDEX Introduction and Stealth Master Troubleshooting *****..***.**.***.*. Lubrication and Maintenance ..Front Suspension ....... . 1994 .

- Page 4 INTRODUCTION AND MASTER TROUBLESHOOTING WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES WARNING! (1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from rendering the SRS inoperative).

-

Page 5: How To Use This Manual

(3) Special tightening methods are used. SPECIAL TOOLS Only Mitsubishi special tool numbers are called out in the repair section of this manual. Please refer to the special tool cross reference chart, located at the beginning of each group for a cross reference from Mitsubishi special tool numbers to Miller special tool numbers. -

Page 6: Explanation Of Manual Contents

INTRODUCTION AND MASTER TROUBLESHOOTING - “0~ to “se this Manual EXPLANATION OF MANUAL CONTENTS Indicates procedures to be per- Maintenance and Servicing Procedures Removal steps: The part designation number corresponds to the number in the illustration to indicate removal near the front of each section in order to give the steps. - Page 7 INTRODUCTION AND MASTER TROUBLESHOOTING - “0~ to “se This Manua’ This number corresponds to the The title of the page (following the page on which the diagram of component parts is pre- sented) indicating the locations of lubrication and sealing proce- dures.

-

Page 8: Explanation Of The Troubleshooting Guide

INTRODUCTION AND MASTER TROUBLESHOOTING - How to Use This Manual EXPLANATION OF THE TROUBLESHOOTING GUIDE Indicates the circuit diagram for checking (including the inter- face of the ato;Foi ditioning unit). Indicates connec- tor’s terminal num- ber. Indicates the con- nector number. Numbers are used in the operation de- scriptions only as... -

Page 9: Explanation Of Circuit Diagrams

INTRODUCTION AND MASTER TROUBLESHOOTING EXPLANATION OF CIRCUIT DIAGRAMS The symbols used in circuit diagrams are used as NOTE described below. For detailed information concerning the reading of circuit diagrams, refer to GROUP 8 - Wiring Harness. The input/output (direction of cur- rent flow) relative to the electro- nic control unit is indicated by symbols (A, V). -

Page 10: Vehicle Identification

INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle Identification VEHICLE IDENTIFICATION VEHICLE IDENTIFICATION NUMBER LOCATION The vehicle identification number (V.I.N.) is located on a plate attached to the left top side of the instrument panel. VEHICLE IDENTIFICATION CODE CHART PLATE All vehicle identification numbers contain 17 digits. The vehicle number is a code which tells country, make, vehicle type, etc. -

Page 11: Vehicle Identification Number List

INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle lden*ifica*ion VEHICLE IDENTIFICATION NUMBER LIST VEHICLES FOR FEDERAL V.I.N. (except sequence number) Brand Engine displacement Models code Dodge Stealth 3.0 dm3 (181.4 cu.in.1 [SOHC-MFII Dodge Stealth 3.0 dm” (181.4 cu.in.) [DOHC-MFI-Turbo] VEHICLES FOR CALIFORNIA Brand Models code V.I.N. - Page 12 INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle lden*ifica*ion VEHICLE INFORMATION CODE PLATE Vehicle information code plate is riveted onto the bulkhead in the engine compartment. The place shows model code, engine model, transaxle model, and body color code. Vehicle model 2. ENGINE 3.

- Page 13 INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle identification ENGINE MODEL STAMPING 1. The engine model number is stamped at the front side on the top edge of the cylinder block as shown in the following: Engine model Engine displacement 3.0 dm3 (181.4 cu.in.1 2.

- Page 14 INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle Identification LOCATIONS DOHC Manual transaxle Automatic transaxle...

- Page 15 INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle Identification The replacement part label is attached to the inner side of the part shown in the illustration. The illustration indicates left hand side, outer. Right hand side is symmetrically opposite.

- Page 16 INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle identification Rear of vehicle...

-

Page 17: Precautions Before Service

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Service PRECAUTIONS BEFORE SERVICE SUPPLEMENTAL RESTRAINT SYSTEM (SRS) 1. Items to follow when servicing SRS System (SRS). For safe operations, please follow the directions and heed all warnings. (2) Always use the designated special tools and test equipment. - Page 18 INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Service SERVICING ELECTRICAL SYSTEM 1. Note the following before proceeding with work on the electrical system. Note that the following must never be done: Unauthorized modifications of any electrical device or wiring, because such modifications might lead to a vehicle malfunction, over-capacity or short-circuit that could result in a fire in the vehicle.

- Page 19 INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting TOWING AND HOISTING ing type WRECKER TOWING RECOMMENDATION FRONT TOWING PICKUP Caution This vehicle cannot be towed by a wrecker using sling-type heel lift type equipment to prevent the bumper from deformation. If this vehicle is towed, use wheel lift or flat bed equip- ment.

- Page 20 INTRODUCTION AND MASTER SAFETY PRECAUTIONS The following precautions should be taken when towing the vehicle. 1. DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING TO OR WRAPPING AROUND THE BUMPER. 2. Any loose or protruding parts of damaged vehicle such as hoods, doors, fenders, trim, etc., should be secured or removed prior to moving the vehicle.

- Page 21 INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting HOISTING Frame contact support location POST TYPE Special care should be taken when raising the vehicle on a frame contact type hoist. The hoist must be equipped with the proper adapters in order to support the vehicle at the proper locations.

- Page 22 INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting LIFTING, JACKING SUPPORT LOCATION Approximate center of gravity Frame contact hoist, twin post hoist or scissors lack (emergency) locations EMERGENCY JACKING Jack receptacles are located at the body sills to accept the scissors jack supplied with the vehicle for emergency road service.

-

Page 23: For Awd Models

Special Handling Instructions INTRODUCTION AND MASTER TROUBLESHOOTING Models SPECIAL HANDLING INSTRUCTIONS FOR AWD MODELS BRAKE TEST In order to stabilize the viscous coupling’s dragging force, the brake test should always be conducted after the speedometer test. FRONT WHEEL MEASUREMENTS 1. Place the front wheels on the brake tester. 2. -

Page 24: General Data And Specifications

INTRODUCTION AND MASTER TROUBLESHOOTING - General Data and Specifications GENERAL DATA AND SPECIFICATIONS GENERAL SPECIFICATIONS STEALTH STEALTH R/T STEALTH R/T STEALTH ES <SOHC> <DOHC> <DOHC> <DOHC> (Turbo) (Non-Turbo) (Non-Turbo) Vehicle dimensions mm (in.) Overall length 4,560 (179.5) 4,565 (179.7) 4,565 (179.7) 4,565 (179.7) Overall width 1,840 (72.4) -

Page 25: Engine Specifications

INTRODUCTION AND MASTER TROUBLESHOOTING - General Data and Specifications 23 Models STEALTH STEALTH ES STEALTH R/T STEALTH R/T <SOHC> <DOHC> <DOHC> <DOHC> (Non-Turbo) (Non-Turbo) (Turbo) Transaxle Model No. -Type Manual transaxle Automatic transaxle automatic automatic automatic Fuel system Fuel system Fuel supply system Fuel supply system Multiport... -

Page 26: Tightening Torque

INTRODUCTION AND MASTER TROUBLESHOOTING - Tiahtenincl Toraue TIGHTENING TORQUE Each torque value in the table is a standard value for tightening under the following conditions. (1) Bolts, nuts and washers are all mode of steel and plated with zinc. (2) The threads and bearing surface of bolts and nuts are all in dry condition. The values in the table are not applicable: (1) If toothed washers are inserted. -

Page 27: Master Troubleshooting

INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting MASTER TROUBLESHOOTING ENGINE OVERHEATS Symptom Probable cause Reference page Engine overheats Cooling system faulty Incorrect ignition timing 9-l 8 ENGINE WILL NOT CRANK OR CRANKS SLOWLY Symptom Probable cause Reference page Engine will not crank Starting system faulty 8-l 87 or cranks slowly... - Page 28 INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troub’eshootiw ROUGH IDLE OR ENGINE STALLS Symptom Probable cause Reference page or remedy Rough idle or engine stalls Vacuum leaks 25-3 Purge control valve hose Vacuum hoses Intake manifold Intake manifold plenum Throttle body EGR valve Ignition system problems 8-199...

- Page 29 INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting ENGINE DIESELING Probable cause Reference page Engine dieseling (runs after Incorrect ignition timing 9-18 ignition switch is turned off) EXCESSIVE OIL CONSUMPTION Symptom Probable cause Reference page or remedy Oil leak Repair as necessary Excessive oil consumption Positive crankcase ventilation line clogged 25-9...

- Page 30 INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting HARD STEERING Reference page or remedy Symptom Probable cause Hard steering Loose power steering oil pump belt Low fluid level Replenish Air in power steering system Low tire pressure 22-3 Excessive turning resistance of lower arm ball joint Excessively tightened steering gear box rack support cover...

- Page 31 INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troub’eshooting POOR RIDING Reference page or remedy Probable cause Symptom 22-3 Poor riding Improper tire pressure Repair lmbalanced wheels Improper front or rear wheel alignment Malfunctioning shock absorber Broken or worn stabilizer Broken or worn coil spring Loose suspension securing bolt(s) Retighten Worn lower arm bushing...

-

Page 32: Vehicle Pulls To One Side

INTRODUCTION AND MASTER TROUBLESHOOTlNG VEHICLE PULLS TO ONE SIDE Probable cause Reference page or remedy Improper front or rear wheel alignment 17-5.22 lmbalanced or worn tires 22-3 Uneven tire pressure Excessive turning resistance of lower arm ball joint Wheel bearing seizure Replace Broken or worn coil spring , Bent front axle drive shaft... - Page 33 INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting WHEEL BEARING TROUBLESHOOTING Trouble Symptom Probable cause Pitting Pitting occurs because of uneven rotation of race Excessive bearing preload and bearing surfaces Excessive load Flaking The surface peels because of uneven rotation of End of bearing life the race and bearing surfaces Improper bearing assembly...

-

Page 35: Table Of Contents

LUBRICATION i MAINTENANCE CONTENTS GENERAL INFORMATION ..t..... Evaporative Emission Control System . MAINTENANCE SERVICE ....... Exhaust System . -

Page 36: General Information

LUBRICATION AND MAINTENANCE - General Information GENERAL INFORMATION Caution Test results submitted to EPA have shown that Maintenance and lubrication service recommenda- laboratory animals develop skin cancer after tions have been compiled to provide maximum prolonged contact with used engine oil. Accor- protection for the vehicle owner’s investment dingly, the potential exists for humans to de- against all reasonable types of driving conditions. - Page 37 LUBRICATION AND MAINTENANCE - General Information MATERIALS ADDED TO FUEL Cars equipped with DOHC engines Your car is designed to operate on premium Indiscriminate use of fuel system cleaning agents unleaded gasoline having a minimum octane rating should be avoided. Many of these materials in- of 91 or 95 RON (Research Octane Number).

-

Page 38: Scheduled Maintenance Table

LUBRICATION AND MAINTENANCE - Scheduled Maintenance Table SCHEDULED MAINTENANCE TABLE SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PROPER VEHICLE PERFORMANCE Inspection and services should be performed any time a malfunction is observed or suspected. Retain receipts for all vehicle emission services to protect your emission warranty. Kilometers in thousands 96 120 Emission control system... -

Page 39: Ball Joint And Steering Linkage Seals

LUBRICATION AND MAINTENANCE - Scheduled Maintenance Table Kilometers in thousands Service to be performed Mileage in thousands 16 Brake hoses Check deterioration leaks Every year Ball fount and steering linkage Inspect for grease leaks and damage seals Every 2 years Inspect for grease leaks and damage 18 Drive shaft boots Every year... -

Page 40: Engine Coolant

Recommended Lubricants and LUBRICATION AND MAINTENANCE RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLE RECOMMENDED LUBRICANTS Items Recommended lubricants Engine oil API classification SG ECII or SG/CD ECll (For further details, refer to SAE viscosity number) Manual transaxle MOPAR Hypoid Gear Oil/API classification GL-4, SAE 75W-90 or 75w - 85W Transfer Automatic transaxle... - Page 41 Recommended Lubricants and LUBRICATION AND MAINTENANCE LUBRICANT CAPACITIES TABLE Description Metric measure U.S. measure Engine oil 4.0 dm” 4.2 qts. Crankcase Oil filter 0.3 dm3 0.3 dm” 112 qt. Oil cooler (Turbo) Total 4.5 qts. <Non-Turbo> 4.3 dm3 <Turbo> 4.6 dm” 4.9 qts.

-

Page 42: Rear Axle

Recommended Lubricants and LUBRICATION AND MAINTENANCE Oil Identification Symbol A standard symbol appears on the top of oil containers and has three district areas for identifying various aspects of the oil. The top portion will indicate the quality of the oil. The center d portion will show the SAE viscosity grade, such as SAE indicates that the oil has fuel-saving capabilities. -

Page 43: Maintenance Service

LUBRICATION AND MAlNTENANCE - Maintenance Service MAINTENANCE SERVICE 1. FUEL SYSTEM (TANK, PIPE LINE, CONNEC- TIONS AND FUEL TANK FILLER TUBE CAP) (Check for leak) / 2. FUEL HOSES (Check condition) 1. Check for damage or leakage in the fuel lines and connections and looseness of the fuel tank filler tube cap. -

Page 44: Spark Plugs

LUBRICATION AND MAINTENANCE - Maintenance Service 4. EVAPORATIVE EMISSION CONTROL SYSTEM (Check for leaks and clogging) 1. If the fuel-vapor vent line is clogged or damaged, a fuel vapor mixture escapes into the atmosphere causing exces- sive emissions. Disconnect the line at both ends, and blow it clean with compressed air. - Page 45 LUBRICATION AND MAINTENANCE - Maintenance Service 8. TIMING BELT (Replace) Replace the belt with a new one periodically to assure proper engine performance. For removal and installation procedures, refer to GROUP 9 - Timing Belt. 9. DRIVE BELT (For Generator) (Check condition) Check the tension of the drive belt.

- Page 46 256 psi (1,765 kPa) (manufacturer’s specifications) to avoid filter and engine damage. The following is a high-quality filter and is strongly recommended for use on this vehicle: Mitsubishi Engine Oil Filter P/N MD136790.

- Page 47 o-13 LUBRICATION AND MAINTENANCE - Maintenance Service Any replacement oil filter should be installed in accordance with the oil filter manufacturer’s installation instructions. (2) Clean the oil filter mounting surface of the oil filter bracket. (3) Coat engine oil to the O-ring of new oil filter. (4) Screw in the oil filter by hand, and after the O-ring contacts the flange surface, tighten it another 3/4 turns with a filter wrench, etc.

- Page 48 o-14 LUBRICATION AND MAINTENANCE 13. AUTOMATIC TRANSAXLE (Inspect fluid level) 1. Drive until the fluid temperature reaches the usual tempera- 1 ture [70 - 80°C (160 - 18O”F)]. 2. Place vehicle on level floor. 3. Move selector lever sequentially to every position to fill torque converter and hydraulic circuit with fluid, then place lever in “N”...

- Page 49 LUBRICATION AND MAINTENANCE (8) Pour 4.5 dm3 (4.8 qts.) of specified ATF into case through dipstick hole. [Total quantity of ATF required is approx. 7.5 of fluid can be replaced because rest of fluid remains in torque converter.] Specified fluid: MOPAR ATF PLUS (Automatic Trans- mission Fluid Type 7176) / Dia ATF SP or equivalent (9) Start engine and allow to idle for at least two minutes.

- Page 50 O-16 LUBRICATION AND MAINTENANCE - Maintenance Service 9. Install the radiator cap securely. 11. Race the engine up to around 3,000 rpm several times, then stop the engine. 12. When the engine has cooled down, remove the radiator cap and add coolant up to the brim. Add coolant to the reserve tank up to the FULL line.

- Page 51 o-17 LUBRICATION AND MAINTENANCE - Maintenance Service 18. DRIVE SHAFT BOOTS (Inspect for grease leaks and damage) 1. These components, which are permanently lubricated at the factory, do not require periodic lubrication. Damaged boots should be replaced to prevent leakage or contamina- tion of the grease.

- Page 52 O-18 LUBRICATION AND MAINTENANCE - Maintenance ‘Service Maintenance Items SRS warning light “SRS” WARNING LIGHT CHECK When the ignition key is turned to “ON” or engine started, the “SRS” warning light will illuminate for about 7 seconds and then turn off. This means that the system is functioning properly.

- Page 53 LUBRICATION AND MAINTENANCE - Maintenance Service o-19 Check sensors to ensure the arrow marks face the front of the vehicle. (2) Check front upper frame lowers and sensor brackets for deformities or rust. Caution The SRS may not activate properly if a front impact sensor is not installed properly, which could result in serious injury or death to the vehicles driver and passenger.

- Page 54 LUBRICATION AND MAINTENANCE 2-3 Air Bag Module, Clock Spring Rotor Ring gear Screw Air bag module <Driver’s side> Steering shaft <Passenger’s side>...

- Page 55 o-21 LUBRICATION AND MAINTENANCE - Maintenance Service GROUP 23B - Air Bag Module and Clock Spring.) Caution When disconnecting the air bag module-clock spring connector, take care not to apply excessive force to it. (2) Check pad cover for dents, cracks or deformities. <Driver’s side>...

- Page 56 o-22 LUBRICATION AND MAINTENANCE - Maintenance Service (6) Remove the steering wheel by using the special tool. Caution Do not hammer on the steering wheel. Doing so may a damage the collapsible column mechanism. (7) Remove the steering column covers. (Refer to GROUP 23A Instrument Panel.) (8) Remove the clock spring.

- Page 57 O-23 LUBRICATION AND MAINTENANCE 2-4 Front Wiring Harness and Body Wiring Harness (2) Check harnesses for binds, connectors for damage, and terminals for deformities. REPLACE ANY CONNECTORS OR HARNESS THAT FAIL THE VISUAL INSPECTION. (Refer to GROUP 23B - SRS Service Precautions.) Caution The SRS may not activate properly if SRS harnesses or connectors are damaged or improperly connected, which...

- Page 59 FRONT SUSPENSION CONTENTS ....................2A FRONT SUSPENSION .

- Page 61 FRONT SUSPENSION CONTENTS DRIVE SHAFT ............SPECIFICATIONS .

- Page 62 FRONT SUSPENSION SPECIFICATIONS GENERAL SPECIFICATIONS Items DOHC SOHC Vehicles Vehicles without ECS with ECS Wheel bearing Double-row angular-contact ball bearing Unit ball bearing mm (in.) 84 x 45 (3.31 x 1.77) Drive shaft Joint type Outer B.J. Inner T.J. T.J. T.J.

- Page 63 FRONT SUSPENSION SERVICE SPECIFICATIONS Specifications Standard value Setting of T.J. boot length mm (in.) L.H. 85 + 3 (3.35 k .12) 85 + 3(3.35 + .12) No. 1 crossmember Bushing (B) projection mm (in.) Crossmember Bushing (A) projection mm (in.) Bushing (B) projection mm (in.) Camber...

- Page 64 FRONT SUSPENSION LUBRICANTS Quantity Items Specified lubricants T.J. boot grease Repair kit grease Dust seal inner MOPAR Multi-mileage Lubricant Part No. 2525035 or equivalent 8 - 12 g (.28 - .42 oz) Dust seal outer As required MOPAR Multi-mileage Lubricant Spider assembly Part No.

- Page 65 FRONT SUSPENSION - SPECIAL TOOLS the knuckle and tie rod M B990767 remover and M B990326 General service tool Measurement of the wheel bearing starting Preload socket of the lower arm ball joint of the stabilizer link rotation- gauge attachment...

- Page 66 FRONT SUSPENSION Press-fitting of the dust seal inner Press-fitting of the wheel bearing Press-fitting of the oil-seal (drive shaft side)

- Page 67 FRONT SUSPENSION Oil seal installer remover...

- Page 68 FRONT SUSPENSION TROUBLESHOOTING Symptom Probable cause Remedy Steering wheel is heavy, Suspension malfunction Adjust or replace vibrates or pulls to Ball joint one side Coil spring Wheel alignment Unbalanced or worn tires Adjust or replace Excessive vehicle Broken or deteriorated stabilizer Replace rolling Shock absorber malfunction...

- Page 69 FRONT SUSPENSION SERVICE ADJUSTMENT PROCEDURES HUB END PLAY INSPECTION 1. Jack up the vehicle and remove the front wheels. 2. Remove the disc brake caliper and suspend it with a wire. (Refer to GROUP 5 - Service Adjustment Procedures.) 3. Attach a dial indicator as shown in the illustration, and then measure the axial play while moving the hub back and forth.

- Page 70 FRONT SUSPENSION - Right Member, Left Member and Crossmember RIGHT MEMBER, LEFT MEMBER AND CROSSMEMBER REMOVAL AND INSTALLATION CAUTION: SRS Before removal of steering gear box, Pre-removal Operation refer to GROUP 23B - SRS, center front Removal of Under Cover wheels and remove ignition key.

- Page 71 FRONT SUSPENSION - Right Member, Left Member and Crossmember Crossmember 45 Nm 33 ft.lbs. Removal steps of crossmember 13. Self-locking nut 14. Clamp installation bolt (short) 15. Clamp installation bolt (long) 16. Clamp 17. Lower arm mounting bolt 18. Stopper 19.

- Page 72 FRONT SUSPENSION - Right Member, Left Member and Crossmember Press in bushings A and B so that the arrows on their bottom Front surfaces may be directed in the crosswise direction (except those on No. 1 crossmember of FWD vehicles). Caution Shifting of the arrow in the direction of rotation shall be within k5”...

-

Page 73: 11. Drive Shaft

FRONT SUSPENSION HUB AND KNUCKLE REMOVAL AND INSTALLATION 65 - 76 ftlbs. 43 - 52 ft.lbs. 166 ft.lbs. 5 - 76 ft.lbs. 11 NO029 Removal steps 9. Cotter pin <Vehicles with A.B.S.> 2. Cotter pin 3. Drive shaft nut 12. Front strut mounting bolt 13. - Page 74 FRONT SUSPENSION SERVICE POINTS OF REMOVAL 1. DISCONNECTION OF FRONT SPEED SENSOR Remove the mounting bolts which hold the speed sensor ‘{J bracket to the knuckle, and then remove the speed sensor. Caution Be careful when handling the pole piece at the tip of the speed sensor and the toothed edge of the rotor so as not to damage them by striking against other parts.

- Page 75 FRONT SUSPENSION INSPECTION Check the hub for cracks and spline for wear. Check the oil seal for damage. Check the knuckle for cracks. Check for defective bearing. NOTE If the meshing of the wheel bearing outer race and the knuckle, or of the wheel bearing inner race and the hub, is loose, replace the bearing or damaged parts.

- Page 76 FRONT SUSPENSION - Hub and Knuckle DISASSEMBLY AND REASSEMBLY Disassembly steps 2. Hub and rotor Adjustment of wheel bearing starting torque 3. Hub 4. Rotor <Vehicles with A.B.S.> 5. Dust shield 6. Oil seal (hub side) 7 ftlbs. 7. Snap ring 8.

- Page 77 FRONT SUSPENSION (3) Remove the snap ring from the knuckle. M B990938 (4) Remove the bearing by using the special tools. M B 9 9 0 9 3 2 / ‘NOTE Removal is easier if the outer side inner race removed from the hub is placed on the bearing and the wheel bearing is then removed.

- Page 78 FRONT SUSPENSION (5) Measure to determine whether the end play of the hub is within the specified limit or not. MB990998 Limit: 0.05 mm (.002 in.) (6) If the starting torque and hub end play are not within the limit range while the nut is tightened to 200 - 260 Nm (145 - 188 ft.lbs.), the bearing, hub and/or knuckle have probably not been installed correctly.

- Page 79 FRONT SUSPENSION SERVICE POINTS OF REMOVAL REMOVAL OF DRIVE SHAFT NUT Loosen the drive shaft nut while the vehicle is on the floor with the brakes applied. Caution Do not apply vehicle load to the wheel bearing loosing the drive shaft nut. If, however, vehicle load must be applied to the bearing in moving the vehicle, temporari- ly secure the wheel bearing by using the special tools, DISCONNECTION OF LOWER ARM BALL JOINT...

- Page 80 FRONT SUSPENSION (3) To remove the drive shaft (R.H.) from the transaxle, pry off the shaft using a lever against the protrusion of the drive shaft. Caution Pulling the drive shaft can cause damage to the T.J. Be sure to use a lever. INSPECTION Check the drive shaft boot for damage or deterioration.

- Page 81 FRONT SUSPENSION <Left side> T.J. Boot Repair Kit Bearing Dust Seal Repair Kit Bracket Assembly Repair Kit T.J. Repair Kit Disassembly steps 12. Center bearing bracket 2. T.J. boot band (small) 13. Circlip 3. T.J. case and inner shaft assembly 14.

- Page 82 FRONT SUSPENSION Grease: Multipurpose greas- g (.49 - .71 oz.) Dust seal outer 160 g (5.64 oz.) The grease in the repair kit should be the joint and inside the boot. joint. Do not mix old and new grease o different types of grease.

- Page 83 FRONT SUSPENSION SERVICE POINTS OF DISASSEMBLY 6. REMOVAL OF INNER SHAFT bly, together with the seal plate, from the T.J. case. NOTE Press the tool directly against the seal plate. The tool under pressure will puncture and deform the seal plate, and push out the inner shaft underneath.

- Page 84 FRONT SUSPENSION INSPECTION Check the drive shaft for damage, bending or corrosion. Check the inner shaft for damage, bending or corrosion. Check the drive shaft splines for wear or damage. Check the inner shaft splines for wear or damage. Check for entry of water and/or foreign material into B.J. Check the spider assembly for roller rotation, wear or corrosion.

- Page 85 FRONT SUSPENSION 11. INSTALLATION OF CENTER BEARING (1) Apply multipurpose grease to the center bearing and inside the center bearing bracket. Grease: MOPAR Multi-mileage Lubricant Part No. 2525035 or equivalent llLO064 (2) Use the special tools to press-fit the center bearing into the center bearing bracket.

- Page 86 FRONT SUSPENSION 6. INSTALLATION OF INNER SHAFT Use the special tool to hold the inner race of the center bearing and force the inner shaft into place. 3. INSTALLATION OF T.J. CASE AND INNER SHAFT ASSEMBLY then press fit it into the T.J. case. Grease: MOPAR Multi-mileage Lubricant Part No.

- Page 87 FRONT SUSPENSION STRUT ASSEMBLY REMOVAL AND INSTALLATION 33 ft.lbs. Removal steps clamp mounting bolt 2. Brake hose tube clamp 3. Front speed sen sor clamp mounting nut 5. Strut lower mounting bolt 6. Strut upper mounting bolt 7. ECS connector <ECS> 8.

- Page 88 FRONT SUSPENSION DISASSEMBLY AND REASSEMBLY 78Nm 56 ftlbs. Grease: MOPAR Multi-mileage Lubricant Part No. 2525035 or equivalent Caution When applying the grease, take care that grease does not adhere to the insulator’s rubber part. Disassembly steps 1. Dust shield 2. Self-locking nut 3.

- Page 89 FRONT SUSPENSION SERVICE POlNiS OF REASSEMBLY 4. INSTALLATION OF SPRING UPPER SEAT ASSEMBLY the notch in the rod to the shaped hole in spring seat. (2) Using a pipe, line up the holes in the strut assembly spring lower seat with the hole in the spring upper seat. NOTE’...

-

Page 90: Lower Arm

FRONT SUSPENSION LOWER ARM REMOVAL AND INSTALLATION - 7 2 100 Nm 40 Nm 40 Nm 29 ft.lbs. 72 - 87 ftlbs. Adjustment of Wheel Alignment shield Removal steps 1. Stabilizer link mounting nut (stabilizer bar side) 2. Stabilizer link mounting nut (lower arm side) 3. - Page 91 FRONT SUSPENSION SERVICE POINT OF REMOVAL 4. REMOVAL OF LOWER ARM BALL JOINT Using the special tool, disconnect the knuckle from the lower arm ball joint. NOTE loosen it. (2) Suspend the special tool with a rope to prevent it from dropping.

- Page 92 FRONT SUSPENSION STABILIZER BAR REMOVAL AND INSTALLATION Pre-removal and Post-installation Operation Removal and Installation of the Front Exhaust Pipe (Refer to GROUP 11 - Exhaust Pipe and Main Muffler.) Removal and Installation of the Under Cover Removal and Installation of the Left Member and Right Member (Refer to P.2A-IO.) 40 Nm 29 ftlbs.

- Page 93 FRONT SUSPENSION CHECKING STABILIZER LINK BALL JOINT BREAKAWAY TORQUE Install the nut to the stud, and use the special tool to measure the ball joint breakaway torque. Standard value: 1.7 - 3.2 Nm (15 - 28 in.lbs.) BALL JOINT DUST SHIELD REPLACEMENT Clip ring (2) Apply multipurpose grease to the lip and inside of shield.

-

Page 95: Service Adjustment Procedures

ELECTRONIC CONTROL SUSPENSION (ECS) CONTENTS CIRCUIT DIAGRAM ..............SPECIAL TOOLS ................ DAMPING FORCE CHANGEOVER SPECIFICATIONS ..............ACTUATOR ................General Specifications ........................ Service Specifications ECS CONTROL UNIT ..............ECS INDICATOR LIGHT ............STEERING ANGULAR VELOCITY ................................ECS SWITCH STOP LIGHT SWITCH ............ -

Page 96: Specifications

SPECIFICATIONS GENERAL SPECIFICATIONS FRONT SUSPENSION Items SOHC DOHC Suspension system McPherson strut type 15.2 x 170 x 301.6 Wire dia. x center dia. x 14.2 x 170 x 316 14.4 x 170 x 322.7 14.5 x 170 x 329.3 free length mm (in.) Brown x 1 Coil spring identification... - Page 97 REAR SUSPENSION Items SOHC DOHC Suspension system Multi-link type Double-wishbone type Coil spring Wire dia. x center dia. x 11.6 x 105 x 350.0 11.5 x 105 x 379.3 free length mm (in.) Coil spring identification Green x 1 Brown color Spring constant 34 (190)

-

Page 98: Troubleshooting

Tool number and tool name Replaced by Miller Application tool number MB991 529 MB991 529 Inspection of electronic control suspension system using a voltmeter Diagnostic trouble code check harness TROUBLESHOOTING QUICK REFERENCE CHART FOR TROUBLESHOOTING Associated components Pages to refer to Symptoms When diagnostic trouble code No. - Page 99 ECS - Troubleshootincl When diagnostic trouble code No. 11 is output Check by entering simulated vehicle speed from scan tool to simulate pitching and bouncing controls. (Refer to P.2B-16.) Good? Disconnect G sensor connector. No. 1 terminal voltage and continuity between No.

- Page 100 When diagnostic trouble code No. 21 is output, or when anti-roll control only stops. Using scan tool, check service Check by entering simulated vehicle speed to simulate anti-roll controls. (Refer to P.2B-17.) Disconnect steering angular velocity Replace ECS control unit. sensor connector.

- Page 101 ECS - Troubleshooting When diagnostic trouble code No. 24 is output Check by entering simulated vehicle speed from scan tool to data on vehicle ‘speed sensor. Good? simulate high speed-sensitive control. (Refer to P.2B-17.) Good? Disconnect vehicle speed sensor con- Replace ECS control unit.

- Page 102 ECS - Troubleshootina Using scan tool, check actuator. (Refer to P.2B-15.) Good? Remove cap at top of shock absorber associated with diagnostic trouble connected to shock absorber, and No. 1 and 3 terminal voltages up Is continuity provided across the following areas of shock to specification? absorber associated with diagnostic trouble code No.? Standard: 5 V...

- Page 103 ECS - Troubleshooting Does ECS indicator light flash? Read diagnostic trouble code and check area associated with diagnostic trouble code. Disconnect ECS switch connector and check harness connector with (ignition switch at 0,N. Is continuity provided betwen No. 10 terminal of ECS switch No.

- Page 104 6 Anti-dive control only stops. Using scan tool, check service Check by entering simulated vehicle speed from scan tool data on stop light switch. Good? to simulate anti-dive control. (Refer to P.2B-16.) Good? Replace ECS control unit Is continuity provided between No. 3 terminal of stop light switch and No.

- Page 105 Anti-squat control only stops. Using scan tool, check service data Check by entering simulated vehicle speed from scan tool on throttle position sensor. Good? to simulate anti-squat control. (Refer to P.2B-16.) Good? Replace ECS control unit. Does check engine/malfunction Is continuity provided between No. 2 terminal of throttle indicator lamp illuminate? position sensor and No.

- Page 106 ON-VEHICLE INSPECTION WARNING INDICATION BY ECS INDICATOR LIGHT If a problem associated with the following items occurs, the ECS indicator light (Tour Sport) in the combination light flashes at intervals of 0.5 sec. At the same time, the diagnostic trouble code associated with the problem is output to the data link connector.

- Page 107 Fail Safe and Diagnosis List Output Code Fail Safe Diagnostic Item Indication Pattern [Good] [Good] Ride controls (pinching and bouncing G sensor defective* control, bad road detection control) stop. Anti-roll control stops. Steering angular velocity sensor open- circuited* Vehicle speed sensor open-circuited* speed sensitive controls) and attitude controls (anti-dive, anti-squat) stop.

- Page 108 On-board Diagnostic Determination Conditions Code No. What is defective On-board diagnostic determination conditions G sensor defective When sensor input of 0.5 or less or 4.5 V or more lasts for more than 10 seconds. Steering angular velocity Open circuit detected on the basis of difference in voltage level of sensor open-circuited sensor signal.

- Page 109 ECS - Service Adiustment Procedures Item No. Check Check Condition Soundness Determination Value Point Vehicle Check by actually operating Speedometer indication and speed vehicle. scan tool indication coincide. sensor stop Depress brake pedal. light switch Do not depress brake pedal. F.R.

- Page 110 ECS - Service Adjustment Procedures CONTROL FUNCTION SIMULATION CHECK Using the scan tool, check all control functions during operation with the vehicle in stationary condition. Anti-Roll Control Function Check (1) Raise the front wheels on a jack and have them supported by rigid racks.

- Page 111 ECS - Service Adjustment Procedures (4) Check that when the accelerator pedal is operated, the indications of service data items No. 61 through 64 on the scan tool change as shown in the following table. (5) With the simulated vehicle speed at 60 km/h (37 mph) and 90 km/h (56 mph), similarly operate the accelerator pedal and check that the scan tool indications change over.

- Page 112 Service Adjustment Procedures I ECS Switch I ECS - s ACTUATOR OPERA ON CHECK ACTUATOR OPERATING SOUND CHECK (1) Set the ignition switch (2) Bring your ear near the top of the shock absorber. NOTE In the case of the rear shock absorbers, remove the trim cover at the top of the shock absorber before bringing your ear near the shock absorber.

-

Page 113: Damping Force Changeover Actuator

G Sensor I Vehicle Speed Sensor I Throttle Position Sensor I Stop Light Switch I To mount or remove the G sensor, refer to the section on front seats in GROUP 23A - Body. Remove the front seat (L.H.) before removing or mounting the sensor. To mount or remove the vehicle speed sensor, refer to the section on meters and gauges in GROUP 8 -Chassis Electrical. -

Page 114: Ecs Control Unit

To remove or mount the ECS indicator lights, refer to the \ section on meters and gauges in GROUP 8 - Chassis Electrical. vi REMOVAL AND INSTALLATION Removal steps 1. Cargo floor box (R.H.) 2. Lid 3. ECS control unit... -

Page 115: Ecs Switch

FUSIBLE LINK@ TAILLIG 1 C-68 * c-70 ‘5 2 c-77 IOD OR C - 6 9 STORAGE CONNECTOR 1 2 9 4 ELECTRONIC CONTROL SUSPENSION F-13 62 ----------- CONTROL UNIT 1 F-12 SWITCH D-03 D-41 DATA LINK CONNECTOR c-79 NOTE... -

Page 116: G Sensor

CIRCUIT DIAGRAM (CONTINUED) THROTTLE B-05 STOP LIGHT SWITCH ---------- ~ - - - - - - - - - - - - - - - - - - - - - 54 5 C-60 G SENSOR STEERING SPEED SENSOR... - Page 117 FRONT SHOCK ABSORBERtL FRONT Sl-iOCK ABSORBER(I; 1 ‘1 4 L-- 1 --- _ --- -- 4 --- SUSPENSION CONTROL UN11 14 F-20 F-07...

- Page 119 CONTENTS AXLE SHAFT ............TROUBLESHOOTING .

- Page 120 REAR AXLE - Specifications GENERAL SPECIFICATIONS Specifications Semi-floating type mm (in.) 35 (1.38) Outer bearing portion dia. Inner bearing portion dia. 34.5 (1.36) Center portion dia. 245.4 (9.7) Overall length Bearing mm (in.) O.D. x I.D. 72 x 35 (2.83 x 1.38) Outer Inner Drive shaft...

- Page 121 REAR AXLE SERVICE SPECIFICATIONS Items Specifications Standard value Setting of T.J. boot length mm (in.) 85 + 3 (3.35 + .I 2) Final drive gear backlash mm (in.) 0.11 -0.16(.004-,006) Differential gear backlash (Limited slip differential) mm (in.) 0.03 - 0.09 LOO1 2 -.0035) Drive pinion rotation torque Nm (in.lbs.) With oil seal...

- Page 122 REAR AXLE Rear axle shaft Removal of axle shaft inner bearing (Use universal driver Installation of axle shaft inner bearing Installation of drive pinion rear bearing Installation of drive pinion front bearing Installation of differential side oil seal MB990938 (Use in conjunction with Removal of drive pinion front bearing and drive pinion rear bearing outer race Adjustment of differential final gear tooth...

- Page 123 REAR AXLE - Special Tools and remover A Removal of the side bearing inner race, drive pinion rear bearing inner race and companion flange M B990339 C-293PA Removal of drive pinion rear bearing inner race...

- Page 124 REAR AXLE - Special Tools junction with MB991366) Preload socket Oil seal installer M B990728 Oil seal installer...

-

Page 125: Troubleshooting

REAR AXLE Symptom Probable cause Remedy AXLE SHAFT Brake drag Replace Noise while wheels are rotating Bent axle shaft Worn or scarred axle shaft bearing Grease leakage Worn or damaged oil seal Replace Malfunction of bearing seal DRIVE SHAFT Replace Noise Wear, play or seizure of ball joint Excessive drive shaft spline looseness... - Page 126 REAR AXLE - Troubleshootina Symptom Probable cause Remedy Gear oil leakage Worn or damaged front oil seal, or an improperly Replace installed oil seal Damaged gasket Loose companion flange self-locking nut Retighten or replace Loose filler or drain plug Retighten or apply adhesive Clogged or damaged vent plug Clean or replace Seizure...

- Page 127 REAR AXLE REAR AXLE TOTAL BACKLASH CHECK If the vehicle vibrates and produces a booming sound due to an imbalance of the driving system, measure the rear axle total backlash by the following procedures to see if the differential carrier assembly required removal. parking brake and jack up the vehicle.

- Page 128 REAR AXLE - Service Adjustment Procedures R E A R W H E E L B E A R I N G R O T A R Y - S L I D I N G RESISTANCE CHECK 1. Remove the drive shaft from the companion flange. 2.

-

Page 129: Axle Shaft

REAR AXLE - Axle Shaft REMOVAL AND INSTALLATION 12 Nm 40 - 47 ftlbs. 9 ftlbs. 36 - 43 I ft.lbs. 260 - 3’00 Nm Removal steps 1. Rear speed sensor <Vehicles with A.B.S.> 2. Brake caliper assembly 3. Brake disc 4. - Page 130 REAR AXLE 5. REMOVAL OF SELF-LOCKING NUT With the special tool, secure the axle shaft and remove the companion flange self-locking nut. 8. REMOVAL OF AXLE SHAFT ASSEM.pLY With the special tool, remove the axle shaft from the axle housing. MB990242 (use three puller) l l N 0 0 4 0...

- Page 131 REAR AXLE SERVICE POINTS OF INSTALLATION Axle housing 15. INSTALLATION OF INNER BEARING MB990938 With the tool, press fit the inner bearing onto the axle housing. MB990931 14. INSTALLATION OF OIL SEAL housing with the depression in the oil seal facing upward, and until it contacts the shoulder on the inside of the axle housing.

-

Page 132: Differential Carrier

REAR AXLE 9. INSTALLATION OF REAR ROTOR <VEHICLES WITH With the special tool, press fit the rear rotor to the axle shaft \ with the rear rotor groove surface toward the axle shaft flange. 5. INSTALLATION OF SELF-LOCKING NUT With the special tool, secure the axle shaft and tighten the companion flange self-locking nut. - Page 133 REAR AXLE - Drive Shaft INSPECTION Check the drive shaft boots for damage or deterioration. Check the ball joints for excessive play or check operation. Check the drive shaft spline for wear or damage. SERVICE POINTS OF INSTALLATION 4. INSTALLATION OF OIL SEAL it in by using the special tool.

- Page 134 REAR AXLE - Drive Shaft DISASSEMBLY AND REASSEMBLY T.J. boot repair kit B.J. boot repair kit T.J. repair kit B.J. repair kit Disassembly steps 7. B.J. boot band (large) 8. B.J. boot band (small) 2. T.J. boot band (small) l * l 9.

- Page 135 REAR ,AXLE - Drive Shaft Lubrication Points Grease: Repair kit grease Quantity to use: 135 g (4.76 oz.) Caution Apply all of the grease from the repair kit to the joint and boot, a half to each as a rule. Special grease is used for the joint.

- Page 136 REAR AXLE SERVICE POINTS OF DISASSEMBLY 4. REMOVAL OF SNAP RING / 5. SPIDER ASSEMBLY (1) Remove the snap ring from the drive shaft with the d snap ring pliers. (2) Take out the spider assembly from the drive shaft. (3) Clean the spider assembly.

- Page 137 REAR AXLE - Drive Shaft grease. 125 g (4.4102.) Specified grease: Repair kit grease Caution The grease in the repair kit should be divided in half for use, respectively, at the joint and inside the boot. A special type of grease is used on the joint. Be cautious to ensure that not other grease is allowed to come in contact with the joint.

- Page 138 REAR AXLE - Differential Carrier REMOVAL AND INSTALLATION Pre-removal and Post-installation Operation Draining and Filling of Differential Gear Oil (Refer to Group O- Maintenance Service.) Removal and Installation of Main Muffler (Refer to Group 11 - Exhaust Pipe and Muffler.) 24 Nm 17 ftlbs.

- Page 139 REAR AXLE - Differential Carrier SERVICE POINTS OF REMOVAL 1. REMOVAL OF DRIVE SHAFT With a tire lever, etc., remove the drive shaft from the differential carrier. NOTE Be cautious to ensure that the differential carrier oil seal is not damaged by the drive shaft spline. 3.

- Page 140 REAR AXLE FINAL DRIVE GEAR BACKLASH With the drive pinion locked in place, measure the final drive gear backlash with a dial indicator on the drive gear. NOTE Measure at four points or more on the circumference of the drive gear. Standard value: 0.11 - 0.16 mm (.004 - .006 in.) DRIVE GEAR RUNOUT t at the shoulder on the reverse...

- Page 141 REAR AXLE Standard tooth contact pattern 1 Narrow tooth side 2 Drive-side tooth surface (the side applying power during forward movement) 3 Wide tooth side 4 Coast-side tooth surface (the side applying power during reverse movement) Solution Problem Tooth contact pattern resulting from exces- sive pinion height The drive pinion is positioned too far from the center of Increase the thickness of the pinion height adjusting...

- Page 142 REAR AXLE DISASSEMBLY Inspection Before Disassembly Final Drive Gear Backlash (Refer to P.3-2’2.) Drive Gear Runout (Refer to P.3-22.) Final Drive Gear Tooth Contact (Refer to P.3-22.) Disassembly steps 15. Drive pinion assembly 16. Companion flange 2. Vent plug 17. Drive pinion front shim 3.

- Page 143 REAR AXLE 6. REMOVAL OF SIDE BEARING OUTER RACE pressed against the carrier. (2) Remove the differential case from the press. Insert two spacers in diagonally opposed positions between the side bearing outer race to be removed and the inner race.

- Page 144 REAR AXLE 15. REMOVAL OF DRIVE PINION ASSEMBLY Mating marks companion flange. NOTE Mating marks should not be made to the contact surfaces of companion flange and propeller shaft. (2) Drive out the drive pinion together with the drive pinion spacer and drive pinion front shims.

- Page 145 REAR AXLE REASSEMBLY 36 Nm 26 ft.lbs. 137 ft.lbs. 58 - 65 ft.lbs.* 22 23 Reassembly steps 1. Spring pin 15. Washer + 2. Drivegear 16. Self-locking nut 3. Differential carrier LSD case (Refer to P.3-34.) 4. Drive pinion rear bearing outer race 18.

- Page 146 REAR AXLE Lubrication, Sealing and Adhesion Points Sealant: Semi-drying sealant Part No. 2525035 or equivalent l l F O 0 3 2 Grease: MOPAR Multi-Mileage Lubricant Adhesive: MOPAR Part No. 4318031 or Part No. 2525035 or equivalent 4318032, or equivalent SERVICE POINTS OF REASSEMBLY 1.

- Page 147 REAR AXLE 2. PRESS-IN OF THE DRIVE GEAR drive gear at the inner side, press in the drive gear (by using the special tool) until the drive gear contacts the M B990890 end surface of the differential case. (2) Check to ensure that the drive gear and the spring pin are flush.

- Page 148 REAR AXLE (4) Position the special tool in the side bearing seat of the gear carrier, and then select a drive pinion rear shim of a thickness which corresponds to the gap between the special tools. NOTE Clean the side bearing seat thoroughly. When selecting the drive pinion rear shims, keep the number of shims to a minimum.

- Page 149 REAR AXLE (5) Remove the companion flange and drive pinion once again. Drive the oil seal into the gear carrier front lip by using the special tool. Apply multipurpose grease to the oil seal lip. Specified grease: MOPAR Multi-Mileage Lubricant Part No.

- Page 150 REAR AXLE (3) Apply multipurpose adhesive to the threaded holes of the drive gear. Specified adhesive: MOPAR Part No. 4318031 or ‘d ~ 4318032, or equivalent (4) Install the drive gear onto the differential case with the mating marks properly aligned. Tighten the bolts to the specified torque in a diagonal sequence.

- Page 151 REAR AXLE (4) Using the special tool, to apply the preload, turn down both right and left side bearing nuts on half the distance between centers of two neighboring holes. (5) Fit the snap ring at either position shown to lock the side bearing nut.

-

Page 152: Lsd Case Assembly

REAR AXLE DISASSEMBLY AND REASSEMBLY Disassembly steps l l F O 0 3 3 * I)+ 3. Thrustwasher(L.H.) 4. Viscous unit 7. Differential pinion shaft 8. Differential side gear (R.H.) 9. Thrust washer (R.H.) INSPECTION BEFORE DISASSEMBLY Feeler gauge 1. CHECKING THE DIFFERENTIAL GEAR BACKLASH the differential side gear (right) is facing upward. - Page 153 REAR AXLE (3) Insert the special tool at the spline part of differential case B (right) and check to be sure the side gear (right) rotates. Feeler gauge (4) Then insert a 0.09 mm (.0035 in.) feeler gauge to replace a 0.03 mm (.0012 in.) gauge. (5) Insert the special tool at the spline part of the differential side gear (right) and check to be sure the side gear (right) does not rotate.

- Page 154 REAR AXLE - LSD Case Assembly (5) Check the spline part of the viscous unit for stepped wear Contact surface or damage, and check the contact surface with differential case B. (6) Check the side gear (left) of the viscous unit for unusual Id wear or damage.

- Page 155 REAR AXLE (5) Insert the special tool at the spline part of differential side gear (right) and check to be sure the side gear (right) rotates. Feeler gauge (6) Then insert a 0.09 mm (.0035 in.) feeler gauge to replace a 0.03 mm (.0012 in.) gauge.

-

Page 157: Service Adjustment Procedures

CONTENTS ANTI-LOCK BRAKING SYSTEM TROUBLESHOOTING ..7 Brake Fluid Level Sensor Check ........46 Brake Lining and Brake Drum Connection Check .... Actuator Test Function ............ 12, 30 Brake Lining Thickness Check ..........Check Using On-board Diagnostic ........ 1 1, 29 Brake Pedal Inspection and Adjustment ...... -

Page 158: Specifications

BRAKES GENERAL SPECIFICATIONS Items Master cylinder Tandem type Tandem type (with level sensor) (with level sensor) I.D. mm (in.) 25.4 (I) or 26.9 26.9 (1 l/16) Brake booster Vacuum type, tandem Vacuum type, tandem Effective dia. of power cylinder mm (in.) 203 (8.0) + 230 (9.0) 203 (8.0) + 230 (9.0)* Boosting ratio... - Page 159 BRAKES - Specifications SPECIFICATIONS lter ndard value 3rake pedal height mm (in.) 177 - 182 (7.0 - 7.2) 3rake pedal free play mm (in.) 3 - 8 (.I - .3) 3rake pedal to floorboard clearance mm (in.) 80 (3.1) or more 80 (3.1) or more mm (in.) mm (in.)

-

Page 160: Lubricants

BRAKES LUBRICANTS Items Specified lubricant Brake fluid MOPAR Brake Fluid/Conforming to DOT3 or DOT4 Brake pedal bushing inner surface MOPAR Multi-mileage Lubricant Part No. 2525035 or equivalent Clevis pin and washer Inside of shim A and shim B, or inside of inner shim A, MOPAR Multi-Purpose Grease inner shim B, and outer shim Part No. -

Page 161: Troubleshooting

BRAKES - Special Tools / Troubleshootinn power Bleed air from system Increased pedal stroke Air in brake system (Reduced pedal to floorboard clearance) Worn pad Replace Replace Broken vacuum hose Brake fluid leaks Correct Excessive push rod to master cylinder clearance Adjust Faulty master cylinder Replace... - Page 162 BRAKES - Troubleshootina Probable cause Remedy Symptom Brake drag Incomplete release of parking brake Correct Incorrect parking brake adjustment Adjust Worn brake pedal return spring Replace Adjust Incorrect push rod to master cylinder clearance Replace Defective master cylinder piston return spring Correct Clogged master cylinder return port Worn brake pad...

- Page 163 BRAKES - Anti-lock Brakina Svstem Troubleshootina ‘PARTICULAR P H E N O M E N A O F T H E For problems in the electrical system, the on-board diagnostic is built into the electronic control unit ANTI-LOCK BRAKING SYSTEM (E.C.U.) causing the ABS warning light to illuminate Models equipped with the anti-lock braking system as a warning to the driver.

- Page 164 BRAKES TROUBLESHOOTING (ABS - FWD) Confirm condition in the following way and diagnosis accordingly, Does the ABS warning light illuminate as described (2) With the ignition key in the “START” position, below up to the time the engine starts? power to the ABS ECU is interrupted and the (1) When the ignition key is turned to the “ON”...

- Page 165 BRAKES Trouble condition Major causes Remedy After the ignition key is turned to the Break in harness for ECU warning Check, using flow “ON” position, it blinks once and then light drive circuit chart D (Refer to illuminates when it is turned to the Malfunction of ECU “START”...

- Page 166 BRAKES NOTE more than 30 seconds. diagnostic to check (Refer to P.5-13.). No on-board diagnostic output Check and repair the har- No diagnostic trouble codes output Diagnostic trouble codes are output ness between the ABS and normal codes are displayed? ECU serial/on-board diag- nostic output terminals and the diagnosis check...

- Page 167 BRAKES - Anti-lock Braking System Troubleshooting CHECK USING ON-BOARD DIAGNOSTIC Caution Turn off the ignition switch beforehand whenever the scan tool is connected or disconnected. Turn the ignition ON and select the ABS system. (The ABS warning light lights up, it goes into the scan tool mode. the scan tool mode, ABS does not function.) If it does not go into the scan tool mode, check the ECU power circuit and the harness between the ECU and...

- Page 168 BRAKES METHOD OF CLEARING DIAGNOSTIC ACTUATOR TEST FUNCTION TROUBLE CODE MEMORY The actuator can be forcibly driven in the following Caution way by using the scan tool. When servicing is finished, clear the diagnos- NOTE tic trouble code memory. The actuator test cannot be carried out when the ABS ECU system is in fail safe.

- Page 169 BRAKES A ABS warning light does not light at all. [Explanation] [Hint] When it does not light up at all, there is a strong if other warning lights do not light up either, fuse is possibility that there is trouble with ABS warning IGNITION i&R RELAY COMBINATION...

- Page 170 BRAKES Does voltage between harness connector terminal combination meter from No. 14 and ground indicate fuse No. 11 is broken. battery positive voltage? Repair harness. Circuit in combination meter is broken. combination meter. Turn the ignition switch OFF and meter No. 58 and No. 59 terminals? Broken wire in ECU, valve relay or both drive circuits.

- Page 171 BRAKES Remove the ECU connector and check. Does the voltage between ECU harness connector terminal No. 25 and ground warning light and ECU indicate battery positive voltage while the ignition key is in the “ON” position? Check valve relay. Remove valve relay and check. Is valve relay normal? (Refer to P.5-58.) Valve relay malfunction Replace valve relay.

- Page 172 BRAKES warning light stays on when the ignition key is in the “ON” position. [ H i n t ] [Explanation] Check the on-board diagnostic output and if there is This is the symptom when the ABS ECU does not no output voltage or if the scan tool and ABS ECU power up due to broken ECU power circuit, etc., cannot communicate, there is a good possibility that...

- Page 173 CONTINUED FROM PREVIOUS PAGE Is power relay normal? (Refer to P.5-69.) Replace power relay. With the ignition key in the power relay and ECU “ON” position, does voltage between ECU connector terminal No. 18 and ground indicate the battery positive voltage? Is there continuity between body harness terminals No.

- Page 174 BRAKES ABS warning light does not illuminate when ignition key is in “START” position. [Explanation] The ABS ECU uses the IG2 power source which is and the ECU turns the valve relay OFF. If the turned off in the “START” position. The ABS warning light does not illuminate at this time, there warning light uses the IG1 power source which is is trouble in the warning light circuit on the valve...

- Page 175 BRAKES ABS warning light blinks once after the ignition key is turned to the “ON” position. It illuminates in the “START” position and blinks once again when turned to the “ON” position. [Explanation] When power flows, the ABS ECU turns on the harness between the ECU and the warning light, the warning light for approximately 1 sec.

- Page 176 BRAKES When the following diagnostic trouble codes are displayed “11 FL SNSR. OPEN” “12 FR SNSR. OPEN” “13 RL SNSR. OPEN” “14 RR SNSR. OPEN” [Hint] [Explanation] The ABS ECU detects breaks in the wheel speed In addition to a broken wire/short circuit in the wheel speed sensor, also check whether the sensor gap is sensor wire.

- Page 177 BRAKES Check flow connected with wheel NOTE speedsensor When checking with an oscilloscope, first measure voltage variations in the wheel speed sensor output. (Refer to P.5-58.) o ~- Is the resistance value of the wheel speed sensor part normal? sensor Standard value: Front 0.8 - 1.2 k0 Rear 0.6 - 0.8 kR...

- Page 178 BRAKES When diagnostic trouble code “22 STOP LAMP SW” is displayed [Explanation] [Hint] The ABS ECU outputs this diagnostic trouble code If the stop light operates normal, the harness for the in the following cases. stop light switch input circuit is broken or there is a Stop light switch may remain on for more than malfunction in the ABS ECU.

- Page 179 BRAKES When diagnostic trouble codes “41 FL SOL. VALVE”, “42 FR SOL. VALVE” or “43 REAR SOL. V.” are displayed. [Explanation] The ABS ECU normally monitors the solenoid valve when turned OFF, the ECU determines the solenoid drive circuit. coil wire is broken/short-circuited or the harness is If no current flows in the solenoid even if the ECU broken/short-circuited, and then these diagnostic turns the solenoid ON or if it continues to flow even...

- Page 180 BRAKES When diagnostic trouble code “51 VALVE RELAY” is displayed [Explanation] When the ignition switch is turned ON, the ABS not there is power in the valve power monitor line ECU switches the valve relay OFF and ON for an since the valve relay is normally ON.

- Page 181 BRAKES When diagnostic trouble code “52 MOTOR RELAY” is displayed [Explanation] The ABS ECU outputs this diagnostic trouble code When the motor continues to revolve for the motor relay and motor in the following cases. [Hint] When the motor relay does not function If there is motor operation noise during scan tool When there is trouble with the motor itself and it forced drive mode, there is a broken or short...

- Page 182 BRAKES TROUBLESHOOTING (ABS - AWD) Confirm condition in the following way and diagnosis accordingly. Does the ABS warning light illuminate as described (2) With the ignition key in the “START” position, below up to the time the engine starts? power to the ABS ECU is interrupted and the ABS warning light remains lit because the valve position, the ABS ECU causes the ABS warning relay is OFF.

- Page 183 BRAKES Trouble condition Major causes Remedy After the ignition key is turned to the Break in harness for ECU warning Check, using flow “ON” position, it blinks once and then light drive circuit chart D (Refer to illuminates when it is turned to the Malfunction of ECU “START”...

- Page 184 BRAKES CONTINUED FROM PREVIOUS PAGE After a test drive, use on-board diagnostic to check (Refer to P.5-33.). No on-board diagnostic output No diagnostic trouble codes output Check and repair the har- Diagnostic trouble codes are output and normal codes are displayed? ness between the ABS There was trouble in Referring to the diagnostic...

- Page 185 BRAKES CHECK USING ON-BOARD DIAGNOSTIC Caution Turn off the ignition switch beforehand whenever the scan tool is connected or disconnected. Turn the ignition ON and select the ABS system. (The ABS warning light lights up, it goes into the scan tool mode. the scan tool mode, ABS does not function.) If it does not go into the scan tool mode, check the ECU tool...

- Page 186 BRAKES METHOD OF CLEARING DIAGNOSTIC ACTUATOR TEST FUNCTION TROUBLE CODE MEMORY The actuator can be forcibly driven in the following way by using the scan tool. Caution When servicing is finished, clear the diagnos- NOTE tic trouble code memory The actuator test cannot be carried out when the ABS ECU system is in fail safe mode.

- Page 187 BRAKES warning A ABS light does not light at all. [Explanation] [Hint] When it does not light up at all, there is a strong If other warning lights do not light up either, fuse is possibility that there is trouble with ABS warning probably blown.

- Page 188 BRAKES With the ignition key in the “ON” posi- Check fuse No. 1 I. If it is tion, do other warning lights (except blown, correct the cause of door-ajar warning light, seat belt warning the blown fuse and then light) illuminate? replace the fuse.

- Page 189 BRAKES Check ABS ECU. Remove the ECU connector and check. Does the voltage between ECU harness connector terminal No. 25 and ground warning light and ECU indicate battery positive voltage while the ignition key is in the “ON” position? Check valve relay. Remove valve relay and check.

- Page 190 BRAKES ABS warning light stays on when the ignition key in the “ON” position. [Explanation] [Hint] This is the symptom when the ABS ECU does not Check the on-board diagnostic output and if there is power up due to broken ECU power circuit, etc., no output voltage or if the scan tool and ABS ECU when the fail safe function operates and isolates the cannot communicate, there is a good possibility that...

- Page 191 BRAKES CONTINUED FROM PREVIOUS PAGE IGNITION POWER RELAY Is power relay normal? "3 (Refer to P.35-63.) Replace power relay. DIODE ABS-ECU With the ignition key in the “ON” position, does voltage power relay and ECU between ECU connector G N D GND terminal No.

- Page 192 BRAKES ABS warning light does not illuminate when ignition key is in “START” position. [Explanation] The ABS ECU uses the IG2 power source which is and the ECU turns the valve relay OFF. If the turned off in the “START” position. The ABS warning light does not illuminate at this time, there warning light uses the IG1 power source which is is trouble in the warning light circuit on the valve...

- Page 193 BRAKES - Anti-lock Braking System Troubleshooting ABS warning light blinks once after the ignition key is turned to the “ON” position. It illuminates in the “START” position and blinks once again when turned to the “ON” position. [Explanation] When power flows, the ABS ECU turns on the harness between the ECU and the warning light, the warning light for approximately 1 sec.

- Page 194 BRAKES When the following diagnostic trouble codes are displayed “11 FL SNSR. OPEN” “12 FR SNSR. OPEN” “13 RL SNSR. OPEN” “14 RR SNSR. OPEN” [Explanation] [Hint] The ABS ECU detects breaks in the wheel speed In addition to a broken wire/short circuit in the wheel sensor wire.

- Page 195 BRAKES When checking with an oscilloscope, first check the connections of the speed sensor harnesses and connectors. speed sensor part normal? sensor Standard value: 0.8 - 1.2 kfl connector normal? Standard value: 0.8 - 1.2 kfl I Yes Is the front wheel speed sensor-to-rotor clearance normal? Standard value:...

- Page 196 BRAKES When diagnostic trouble code “21 G SNSR.” is displayed [Explanation] The ABS ECU outputs this diagnostic trouble code vehicle is stopped or when there is stop light in the following cases. switch input. G sensor OFF trouble (It is judged that the G When there is a broken wire or short circuit in sensor continues to be OFF for more than the harness for the G sensor system.

- Page 197 BRAKES When diagnostic trouble code “22 STOP LAMP SW” is displayed [Explanation] [Hint] The ABS ECU outputs this diagnostic trouble code If the stop light operates normal, the harness for the in the following cases. stop light switch input circuit is broken or there is a Stop light switch may remain on for more than 15 minutes without ABS operation.

- Page 198 BRAKES When diagnostic trouble codes “41 FL SOL. VALVE”, “42 FR SOL. VALVE” “43 VALVE DRIFT” are displayed. [Explanation] The ABS ECU normally monitors the solenoid valve coil wire is broken/short-circuited or the harness is drive circuit. broken/short-circuited, and then these diagnostic If no current flows in the solenoid even if the ECU trouble codes are output.

- Page 199 BRAKES When diagnostic trouble code “51 VALVE RELAY” is displayed [Explanation] When the ignition switch is turned ON, the ABS not there is power in the valve power monitor line ECU switches the valve relay OFF and ON for an since the valve relay is normally ON.

- Page 200 BRAKES When diagnostic trouble code “52 MOTOR RELAY” is displayed [Explanation] The ABS ECU outputs this diagnostic trouble code When the motor ground line is disconnected and for the motor relay and motor in the following cases. the motor does not revolve When the motor relay does not function When the motor continues to revolve When there is trouble with the motor itself and it...

- Page 201 5-45 BRAKES - Service Adjustment Procedures SERVICE ADJUSTMENT PROCEDURES BRAKE PEDAL INSPECTION AND ADJUSTMENT 1. Measure the brake pedal height as illustrated. If the brake pedal height is not within the standard value, adjust as follows. Standard value (A): 177 - 182 mm (7.0 - 7.2 in.) lock nut, and move the stop light switch to a position Pedal where it does not contact the brake pedal arm.

- Page 202 5-46 BRAKES - Service Adjustment Procedures BRAKE FLUID LEVEL SENSOR CHECK 1. Connect a circuit tester to the brake fluid level sensor. 2. Move the float from top to bottom and check for continuity. ‘d 3. The brake fluid level sensor is in good condition if there is no continuity when the float surface is above “A”, and if there is continuity when the float surface is below “A“.

- Page 203 5-47 BRAKES PARKING BRAKE SWITCH CHECK 1. Disconnect the connector of the parking brake switch, and connect an ohmmeter to the parking brake switch and the switch installation bolt. 2. The parking brake switch is good if there is continuity when the parking brake lever is pulled and there is no continuity when it is returned.

- Page 204 5-48 BRAKES Check the operation of the check valve by using a vacuum Valve Spring Vacuum pump connection Accept/reject criteria Connection at the brake A negative pressure (vacuum) is booster side @ created and held. Connection at the intake A negative pressure (vacuum) is not manifold side @ created.

- Page 205 5-49 BRAKES BLEEDING Caution Use the specified brake fluid. Don’t use a mixture of the specified brake fluid and another non-specified fluid. Specified brake fluid: MOPAR Brake Fluid/ Conforming to DOT3 or DOT4 BLEEDING THE MASTER CYLINDER If the master cylinder is empty of brake fluid, bleed the cylinder as follows.

- Page 206 BRAKES - Service Adjustment Procedures tion hole in the caliper body. Standard value: 10.0 mm (.39 in.) Limit: 2.0 mm (.08 in.) Caution Replace the pad if worn beyond the limit. At this time, replace the pads on right and left wheels as a set. 2.

- Page 207 5-51 BRAKES - Service Adjustment Procedures 6. Clean the piston and, using the special tool, push the piston into the cylinder (caliper). 7. With care not to allow the piston boot to be wedged, lower the caliper assembly and fit the lock pin. 8.

- Page 208 5-52 BRAKES - Service Adiustment Procedures 3. Using a screwdriver, remove the pads and shims. Using the following method, measure the drag force of the disc brake after installation of the brake assembly. 4. With the brake assembly removed, use a spring scale to measure the rotary sliding resistance of the hub in the forward direction.

- Page 209 5-53 BRAKES - Service Adiustment Procedures 7. Start the engine, depress the brake pedal firmly two to three times and stop the engine. 8. Give the brake disc ten turns in the forward direction. 9. Using a spring scale, measure the rotary sliding resistance of the hub in the forward direction.

- Page 210 5-54 BRAKES FRONT BRAKE DISC RUN-OUT CORRECTION 1. If the run-out of the brake disc is equivalent to or exceeds the limit specification, change the phase of the disc and hub, and then measure the run-out again. (1) Before removing the brake disc, chalk both sides of the wheel stud on the side at which run-out is greatest.

- Page 211 5-55 BRAKES - Service Adjustment Procedures 4. Remove the following parts from caliper support Using the following method, measure the drag force of the disc brake after installation of the brake assembly. 5. With the brake assembly removed, use a spring scale to measure the rotary sliding resistance of the hub in the forward direction.

- Page 212 5-56 BRAKES REAR BRAKE DISC THICKNESS CHECK 1. Remove dirt and rust from brake disc surface. 2. Measure disc thickness at 4 locations or more. Standard value: <FWD> 18.0 mm (.71 in.) 20.0 mm (.79 in.) Limit: <FWD> 16.4 mm (.65 in.) 18.4 mm (.72 in.) Replace the discs and pad assembly for both sides left and right of the vehicle if they are worn beyond the specified...

- Page 213 5-57 BRAKES BRAKE LINING THICKNESS CHECK 1. Remove the rear brake assembly, and support it by a wire, etc. 2. Remove the brake disc. 3. Measure the wear of the brake lining at the place worn the most. Standard value: 2.8 mm (.I1 in.) Limit: 1.0 mm (.04 in.) Replace the shoe and lining assembly if any location of the brake lining thickness is less than the limit.

- Page 214 5-58 BRAKES - Service Adjustment Procedures 3. Drive the vehicle at a constant speed of 35 - 50 km/h (22 - 31 mph) for 100 m (328 ft.) 4. Release the parking brake and let the brakes cool for 5 - 10 minutes.

- Page 215 5-59 BRAKES - Service Adjustment Procedures POINTS IN WAVEFORM MEASUREMENT Symptom Probable causes Remedy Replace sensor Too small or zero waveform Faulty wheel speed sensor amplitude Adjust clearance Incorrect pole piece-to-rotor clearance Replace hub Waveform amplitude fluctuates Axle hub eccentric or with large runout excessively (this is no problem if the minimum amplitude is 100 mV or more)

- Page 216 BRAKES - Service Adjustment Procedures Scan tool actuator test start 3 sec. 3 sec. Pressure decrease Pedal operation Pedal operation pattern @ pattern @ Release 6 sec. Drag force when - - - - - --_- - - - - - - - - - - - - - - - - - - - - - - - - pedal is released (7) If any abnormality is found in the check, take corrective action according to the following “Judgement in Inspection...

- Page 217 5-61 BRAKES - Service Adiustment Procedures INSPECTION BY USING BRAKE FORCE TESTER NOTE (1) The brake force tester roller and tire must be dry during the test. (2) When testing the front brakes, apply the parking brake and when testing the rear brakes, apply chocks to the front wheels to lock them.

- Page 218 Judgement in Inspection by Using Brake Force Tester Scan tool Judgement (reading of brake force tester) display Operation Probable cause Remedy Normal Abnormal After brake force When the actuator is driven by scan Brake force in Incorrect HU Connect tester indication tool, brake force changes as shown Step 1 shows brake tube...

- Page 219 5-63 BRAKES - Service Adjustment Procedures INSPECTION OF POWER RELAY 1. Remove the relay box cover in the engine compartment and remove the power relay. 2. Apply the battery voltage to the terminal @ and check for continuity between the following terminals when the terminal @ is short-circuited to ground.

- Page 220 5-64 BRAKES - Service Adjustment Procedures INSPECTION OF VALVE RELAY AND MOTOR RELAY (ABS) cover by inserting a screwdriver between the hydraulic unit and cover to pry off the lock. 2. Remove the relays. The one closest to you (larger one) is the motor relay and the one farthest from you (smaller one) is the valve relay.

-

Page 221: Brake Pedal

5-65 BRAKES - Brake Pedal BRAKE PEDAL Pre-removal Operation Assembly (Refer to GROUP 19AASteering Wheel and Shaft.) Post-installation Operation Assembly (Refer to GROUP 19A-Steering Wheel and Shaft.) Clutch Pedal Adjustment (Refer to GROUP 6-Clutch Pedal.) Brake Pedal Adjustment (Refer to P.5-45.) 9 ft.lbs. - Page 222 BRAKES - Brake Pedal 5-66 30 Nm 22 ft.lbs. 13 Nm 9 ft.lbs. 22 ftlbs. Grease: MOPAR Multi-Mileage Lubricant Part No. 2525035 or equivalent 13 Nm Stop light switch removal steps 9 ft.lbs. 1. Stop light switch connector 2. Stop light switch 30 Nm 22 ftlbs.

- Page 223 BRAKES - Brake Pedal INSPECTION Check the bushing for wear. Check the brake pedal for bend or twisting. Check the brake pedal return spring for damage. STOP LIGHT SWITCH (2) The stop light switch is in good condition if there is no continuity when the plunger is pushed in to a depth of within 4 mm (.I 6 in.) from the outer case edge surface, and if there is continuity when it is released.

-

Page 224: Master Cylinder And Brake Booster

5-68 BRAKES - Master Cylinder and Brake Booster MASTER CYLINDER AND BRAKE BOOSTER REMOVAL AND INSTALLATION Pre-removal Operation Brake tube flare nut Draining Brake Fluid 15 Nm 11 ft.lbs. Post-installation Operation Supplying Brake Fluid Bleeding (Refer to P.5-49.) Adjustment of Brake Pedal (Refer to P.5-45.) 11 - 13 ft.lbs. - Page 225 BRAKES - Master Cylinder and Brake Booster SERVICE POINTS OF REMOVAL 1. MOVING LOW-PRESSURE HOSE Remove the nuts and bolts securing low-pressure hose shown in the illustration, and using a wire, suspend the hose from the hood to a position where it does not hamper the removal and installation of the brake booster.

- Page 226 BRAKES - Master Cylinder and Brake Booster (3) Measure the dimension (D) between the master cylin- der mounting surface on brake booster and the push rod end. NOTE To obtain (D), first take measurement with a square placed on the brake booster. Then, subtract the thick- ness of the square to arrive at (D).

- Page 227 5-71 BRAKES - Master Cylinder and Brake Booster SERVICE POINTS OF DISASSEMBLY Remove the piston stopper bolt, while depressing the piston. 12. DISASSEMBLY OF PISTON STOPPER RING Remove the piston stopper ring, while depressing the piston. 14. DISASSEMBLY OF SECONDARY PISTON ASSEMBLY NOTE If it is hard to remove the secondary piston from the cylinder, gradually apply compressed air from the outlet...

- Page 228 5-72 BRAKES - Brake Line BRAKE LINE REMOVAL AND INSTALLATION <Vehicles without ABS> 2. Brake tube (strut) 3. Brake tube (A) 4. Brake tube (B) 5. Brake tube (front, R.H.) 6. Brake tube (front, L.H.) 7. Brake tube (main, R.H.) 8.

- Page 229 BRAKES - Brake Line <Vehicles with ABS> Post-installation Operation Supplying Brake Fluid Bleeding (Refer to P.5-49.1 Flared brake line nuts 15 Nm 11 ftlbs. Connecting part of hydraulic unit 1. Brake hose 2. Brake tube 3. Brake tube (A) 4. Brake tube (B) 5.

-

Page 230: Front Disc Brake

BRAKES - Brake Line / Front Disc Brake INSPECTION Check the brake tubes for cracks, crimps and corrosion. Check the brake hoses for cracks, damage and leakage. s& Check the flared brake line nuts for damage and leakage. SERVICE POINT OF INSTALLATION Connect the tubes to the hydraulic unit as shown in the i l l u s t r a t i o n . - Page 231 5-75 BRAKES - Front Disc Brake INSPECTION Check disc for wear. (Refer to P.5-53.) Check disc for runout. (Refer to P.5-53, 54.) Check disc for damage. SERVICE POINTS OF INSTALLATION 2. INSTALLATION OF FRONT BRAKE ASSEMBLY Using the following method, measure the drag force of the disc brake after installation of the brake assembly.

- Page 232 BRAKES - Front Disc Brake 5-76 DISASSEMBLY AND REASSEMBLY Brake caliper kit Caliper assembly disassembly steps 1. Guide pin 3. Bushing 4. Caliper support (pad, clip, shim) 5. Pin boot 6. Boot ring 7. Piston boot 8. Piston 9. Piston seal Pad assembly disassembly steps 2.

- Page 233 BRAKES - Front Disc Brake Lubrication points Grease: Repair kit grease (orange) Brake fluid. MOPAR Brake Fluid/ Grease: Repair kit grease (orange) Grease: Repair kit grease (orange)

- Page 234 5-78 BRAKES - Front Disc Brake SERVICE POINTS OF DISASSEMBLY When disassembling the front disc brakes, disassemble both sides (left and right) as a set. 7. REMOVAL OF PISTON BOOT / 8. PISTON Send compressed air from the port to which brake hose is installed and remove the pistons and piston boots.

- Page 235 5-79 BRAKES - Front Disc Brake SERVICE POINTS OF REASSEMBLY Identification. 2. INSTALLATION OF LOCK PIN / 1. GUIDE PIN Install the guide pin and lock pin mating the head markings on the guide and lock pins with the identification markings on the caliper body.

- Page 236 BRAKES - Front Disc Brake DISASSEMBLY AND REASSEMBLY Caution The piston seal contained in the seal and boot kit is coated with special grease. Do not wipe off the grease. Brake fluid: MOPAR Brake Fluid/ Conforming to DOT3 or DOT4 Brake caliper kit Grease: MOPAR Multi-Purpose Grease Grease: Repair kit grease (orange)

- Page 237 5-81 BRAKES - Front Disc Brake SERVICE POINTS OF DISASSEMBLY 2. REMOVAL OF PAD PIN Holding the cross spring with hand, remove the pad pin. spring 4. REMOVAL OF PAD ASSEMBLY Using a screwdriver, remove the pad assembly 11. REMOVAL OF PISTONS Install a wood block as shown and send compressed air through the port, to which brake hose is attached, to remove the pistons.

-

Page 238: Rear Disc Brake

5-82 BRAKES REAR DISC BRAKE REMOVAL AND INSTALLATION Flared brake line nuts 15 Nm 11 ft.lbs. 50-60 Nm 36 - 43 ft.lbs. Removal steps 1. Brake hose 2. Rear brake assembly 3. Brake disc INSPECTION INSPECTING THE BRAKE DISC Check disc for wear. (Refer to P.5-56.) Check disc for runout. - Page 239 5-83 BRAKES - Rear Disc Brake Grease: MOPAR Multi-Purpose Grease Part No. 2932524 or equivalent Brake caliper kit Caliper assembly disassembly steps 6. Pad pin 7. Retaining ring. 8. Piston boot Seal and boot kit Pad kit 9. Piston 11. Caliper body Pad assembly disassembly steps 6.

- Page 240 BRAKES - Rear Disc Brake 5-84 27 Nm 20 ft.lbs. Brake caliper kit Part No. 2932524 or equivaleni Caliper disassembly steps 1. Lock pin 2. Caliper support (pad, clip, shim) 3. Sleeve Lock pin boot 5. Guide pin boot 6. Boot ring 8.

- Page 241 BRAKES - Rear Disc Brake Lubrication Points Grease: Repair kit grease (orange) Caution The piston seal contained in the seal and boot kit is coated with special grease. Do not wipe off the grease. Grease: Repair kit grease (orange) Brake fluid: Conforming to DOT3 or DOT4 Grease: Repair kit grease (orange) Caution...

- Page 242 5-86 BRAKES SERVICE POINTS OF DISASSEMBLY 8. REMOVAL OF PISTON BOOT / 9. PISTON Protect caliper body with cloth. Blow compressed air through brake hose to remove piston boot and piston. Caution Blow compressed air gently. Insert a piece of wooden plate as shown and blow compressed air through the brake hose connecting hole to remove the pistons.

- Page 243 5-87 BRAKES - Hydraulic Unit (ABS) HYDRAULIC UNIT (ABS) REMOVAL AND INSTALLATION Flared brake line nuts 15 Nm 11 ftlbs. 14FO38 Removal steps Pre-removal Operation Removal of Splash Shield Draining of Brake Fluid 2. Harness connector connection Removal of Relay Box 3.

- Page 244 BRAKES - Hydraulic Unit (ABS) SERVICE POINTS OF REMOVAL 1. REMOVAL OF BRAKE LINE Pull up the relay box with harness attached and inserting a ‘d hand under the relay box, remove the brake tubes using the flare nut wrench. 4.

- Page 245 5-89 BRAKES - Wheel Speed Sensor (ABS) WHEEL SPEED SENSOR (ABS) REMOVAL AND INSTALLATION 12 Nm 9 ft.lbs. Pre-removal Operation Removal of Splash Shield Front speed sensor removal steps (Refer to Group 23A - Fender.) Clip 3. Front speed sensor 4.

- Page 246 BRAKES - Wheel Speed Sensor (ABS) 12 Nm - z @ - - - 9 ft.lbs. 1. Front rotor Removal of Splash Shield (Front Only) Front speed sensor removal steps 2. Clip. 3. Front speed sensor 5. Rear rotor Installation of Splash Shield (Front Only) Rear speed sensor removal steps 6.

- Page 247 5-91 BRAKES - Wheel Speed Sensor (ABS) SERVICE POINTS OF REMOVAL 1. REMOVAL OF FRONT ROTOR / 5. REMOVAL OF REAR ROTOR Caution Do not damage rotor teeth and never drop the rotor. If the rotor has missing teeth or is deformed, accurate wheel speed detection cannot be expected and the system may fail to function normally.

- Page 248 5-92 BRAKES - Wheel Speed Sensor (ABS) (3) Check the speed sensor cable for open circuit and replace if faulty. NOTE Remove the cable clamp from the body and, while flexing the cable near the clamp, check for temporary open circuit. Also check connector connection and terminal insertion.

- Page 249 BRAKES G SENSOR (AWD - ABS) REMOVAL AND INSTALLATION Pre-removal/Post-installation Operation Removal/Installation of Front and Rear Console Assemblies (Refer to Group 23A-Console Box.) CAUTION: SRS When installing or removing the instrument panel, don’t allow any impact or shock to the SRS diagnosis unit. 4 ft.lbs.