Summary of Contents for Waters Autospec Premier

- Page 1 Autospec Premier Operator’s Guide 71500089202/Revision B Copyright © Waters Corporation 2005-2009 All rights reserved...

-

Page 2: Copyright Notice

Corporation assumes no responsibility for any errors that may appear in this document. This document is believed to be complete and accurate at the time of publication. In no event shall Waters Corporation be liable for incidental or consequential damages in connection with, or arising from, its use. -

Page 3: Customer Comments

Customer comments Waters’ Technical Communications department invites you to tell us of any errors you encounter in this document or to suggest ideas for otherwise improving it. Please help us better understand what you expect from our documentation so that we can continuously improve its accuracy and usability. -

Page 4: Contacting Waters

Contacting Waters ® Contact Waters with enhancement requests or technical questions regarding the use, transportation, removal, or disposal of any Waters product. You can reach us via the Internet, telephone, or conventional mail. Waters contact information Contacting medium Information Internet The Waters Web site includes contact information for Waters locations worldwide. -

Page 5: Considerations Specific To The Autospec Premier

Solvent leakage hazard The source exhaust system is designed to be robust and leak-tight. Waters recommends you perform a hazard analysis, assuming a maximum leak into the laboratory atmosphere of 10% LC eluate. -

Page 6: Flammable Solvents Hazard

Flammable solvents hazard To prevent the ignition of accumulated solvent vapors inside Warning: the source, maintain a continuous flow of nitrogen through the source whenever significant amounts of flammable solvents are used during instrument operation. Never let the nitrogen supply pressure fall below 400 kPa (4 bar, 58 psi) during analyses that require flammable solvents. -

Page 7: Pinch Hazard

Pinch hazard A pinch hazard exists at the front and rear of the instrument. Warning: Do not put your fingers between the air mount frame and top of the instrument’s cubicles (highlighted on the illustrations below). Pinch hazard at front of instrument Pinch hazard Pinch hazard at rear of instrument... -

Page 8: High Temperature Hazard

To avoid burn injuries, avoid touching the GC interface with Warning: your unprotected hand when operating or servicing the instrument (indicated in red on the figure below). Autospec Premier high temperature hazard GC interface High voltage hazard Warning: • To avoid electric shock, do not remove the instrument’s protective panels. -

Page 9: Hazards Associated With Removing An Instrument From Service

The need to decontaminate other vacuum areas of the instrument depends on the kinds of samples the instrument analyzed and their levels of concentration. Do not dispose of the instrument or return it to Waters for repair until the authority responsible for approving its removal from the premises specifies the extent of decontamination required and the level of residual contamination permissible. -

Page 10: High Magnetic Field Hazard

High magnetic field hazard Do not use the instrument if you have a cardiac pacemaker. Warning: Electromagnetic interference and magnetic fields disrupt a pacemaker’s operation. The magnetic field generated by the instrument is not Warning: quantified in terms of risk. When working with the instrument: •... -

Page 11: Operating This Instrument

Autospec Premier instrument. Intended use of the Autospec Premier Waters designed the Autospec Premier to use as a research tool to perform authenticated mass measurement. It is intended for use only by qualified laboratory personnel, installation engineers and field service engineers. -

Page 12: Calibrating

Calibrating When calibrating mass spectrometers, consult the calibration section of the operator’s guide for the instrument you are calibrating. In cases where an overview and maintenance guide, not operator’s guide, accompanies the instrument, consult the instrument’s online Help system for calibration instructions. -

Page 13: Ec Authorized Representative

EC Authorized Representative Waters Corporation (Micromass UK Ltd.) Floats Road Wythenshawe Manchester M23 9LZ United Kingdom Telephone: +44-161-946-2400 Fax: +44-161-946-2480 Contact: Quality manager xiii... -

Page 15: Table Of Contents

Trademarks ......................ii Customer comments .................... iii Contacting Waters ....................iv Safety considerations ..................iv Considerations specific to the Autospec Premier ..........v Solvent leakage hazard ................i-v Flammable solvents hazard ................ i-vi Pinch hazard ....................i-vii High temperature hazard ................. i-viii High voltage hazard .................. - Page 16 Probe sample introduction ................1-4 Vacuum system ....................1-4 MassLynx control system ................1-5 Controls and connections on the front of the instrument ...... 1-6 A.C. distribution panel ..................1-6 Status switch panel ..................1-8 Controls and connections on the top of the instrument ......1-10 Probe cooling water connections ..............

- Page 17 Setting the maximum retention time ............. 3-6 Setting up scanning functions ............... 3-7 Magnet Scan function ..................3-7 Voltage Scan function ..................3-10 B/E (product ion) function ................3-12 B2/E (precursor ion) function ................ 3-15 Constant Neutral Loss (CNL) function............3-18 MIKES Scan function ..................

- Page 18 Acquiring analog data ................... 4-14 5 Calibrating the instrument ..............5-1 Overview ......................5-1 Calibration files ....................5-2 Calibrating the instrument for SIR experiments ........5-2 Calibrating the instrument for MIKES and NRMS experiments ..5-5 Calibrating the instrument for scanning experiments ......5-5 Manually correcting a calibration ..............

- Page 19 7 Routine maintenance ................7-1 Maintenance schedule ..................7-1 Safety and handling ..................7-2 Vacuum pump maintenance ................7-3 GC interface maintenance ................7-3 Source maintenance ..................7-5 Inner source chamber assembly maintenance ..........7-6 Required materials ..................7-9 Withdrawing the inner source chamber assembly from the source ..7-10 Removing the chamber assembly from the source handle ......

- Page 20 Mass spectrometer shock hazard ............... A-4 Biohazard warning ..................A-4 Chemical hazard warning ................A-5 Caution symbol ....................A-5 Warnings that apply to all Waters instruments ......... A-5 Electrical and handling symbols ..............A-8 Electrical symbols .................... A-8 Handling symbols .................... A-9...

- Page 21 B Materials of construction and compliant solvents ....... B-1 Preventing contamination ................B-1 Items exposed to solvent ................B-1 Solvents used to prepare mobile phases ............ B-3 C Starting up and shutting down the instrument ......C-1 Starting up the instrument ................C-1 Shutting down the instrument ..............

- Page 22 Verifying VSIR experimental resolution ............D-24 Ramping the probe temperature..............D-26 The Linked Scanning Utility................. D-26 Configuring the magnet and MIKES and NMRS options ......D-28 Viewing the status of, and rebooting, the instrument’s embedded PC..D-28 Selecting the instrument name..............D-28 Customizing the Tune window..............

- Page 23 E Calibration reference information ........... E-1 Overview ......................E-1 Editing a calibration reference file .............. E-1 Calibration reference files ................E-2 F Performance specifications and file types ........F-1 Performance specifications ................F-1 File types ......................F-2 G Theory and principles of operation ..........G-1 Ionization techniques ..................

- Page 24 Rotate 3 lens ....................G-7 Z Deflect 3 lens .................... G-7 Z Focus 3 lens ....................G-7 NRMS gas cell (optional) ................G-7 MIKES gas cell (optional) ................G-7 MIKES slit (optional) .................. G-7 Second ESA assembly (ESA 2) ................ G-7 Collector slit plate assembly ................

- Page 25 Controls and connections on the top of the instrument 1-10 Controls and connections on the rear of the instrument 1-11 Overview This instrument uses Waters Micromass patented tri-sector (EBE) double-focusing geometry and a wide gap magnet to provide high sensitivity, high resolution, and low background noise. Overview...

-

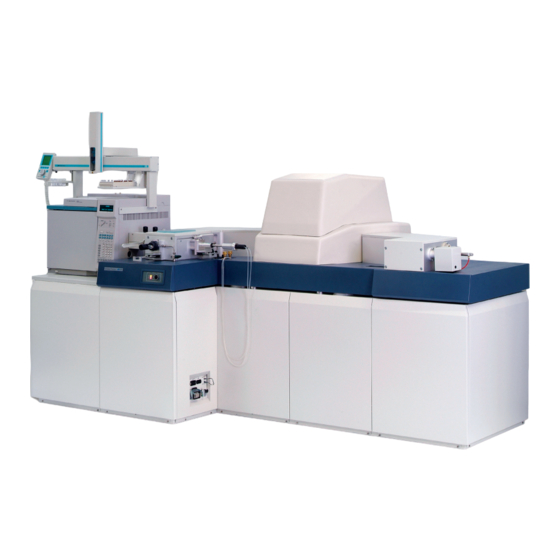

Page 26: Instrument Description

AutoSpec Premier mass spectrometer The EBE design has an electric sector (electrostatic analyzer [ESA]) on each side of the magnetic sector. The first electric sector (ESA1) has demagnifying optics, which give high resolution and sensitivity. The second electric sector (ESA2) improves abundance sensitivity, automatically rejects metastable ion interferences, and reduces background noise. -

Page 27: Sample Inlet

AutoSpec Premier schematic diagram Z Focus 2 lens assembly Z Focus 3 lens assembly First ESA assembly Second ESA (ESA 1) assembly (ESA Magnet Collector slit plate assembly Detector Source assembly The ion optics are supported by a pneumatic suspension bench to isolate the analyzer from floor vibrations and maximize the instrument’s performance. -

Page 28: Probe Sample Introduction

1-5, “A.C. distribution panel” on page 1-6, and “Controlling and monitoring the vacuum pumps” on page D-5. There are three main pumping regions in the AutoSpec Premier: • The source • The analyzer • The gas inlets, valves, and interface areas... -

Page 29: Masslynx Control System

Vent the source region prior to performing maintenance on the outer ion source. To minimize the time required to vent and pump the source, isolate the source fine pump from the source region by using the source isolation valve. The source fine pump is backed by a fore pump. The analyzer region usually remains under fine vacuum. -

Page 30: Controls And Connections On The Front Of The Instrument

• Acquiring data. • Processing data. See the MassLynx User’s Guide and MassLynx online Help for more information. Controls and connections on the front of the instrument A pinch hazard exists at the front of the instrument. Do not Warning: put your fingers between the air mount frame and top of the instrument’s cubicles. - Page 31 A.C. distribution panel ROTARY PUMPS The system power MCBs do not isolate the instrument from Warning: the main power supply. Isolate the instrument at the main power supply source. Miniature circuit breakers Supplies System Power Power to the whole system. (3-off) Magnet (3-off) The magnet power transformer.

-

Page 32: Status Switch Panel

Miniature circuit breakers (Continued) Supplies Analyser Fine The fine pumps for the analyzer region. Rotary Pumps Analyser The fore pump for the analyzer region. Inlets 1 The inlets fore pump, used to pump the gas inlets, valves, and interface regions. Source The fore pump for the source region. - Page 33 Appendix C for details of how to use the status switch when starting up or shutting down the instrument. Status switch positions and LED states Switch Vacuum Operate Instrument state position Isolate The system is totally isolated. You cannot turn on high voltages or operate valves.

-

Page 34: Controls And Connections On The Top Of The Instrument

Controls and connections on the top of the instrument Probe cooling water connections and gas flow valves CI gas flow valve Fine control FFR1 gas flow valve Coarse control Probe cooling water connections Probe cooling water connections The cooling water connections (one inlet and one outlet) provide cooling water for the solids sample introduction probe. -

Page 35: Controls And Connections On The Rear Of The Instrument

Controls and connections on the rear of the instrument A trip hazard exists at the rear of the instrument because of Warning: the large number of cable and pipe connections; take great care when working in this area. A pinch hazard exists at the rear of the instrument. Do not Warning: put your fingers between the air mount frame and top of the instrument’s cubicles. -

Page 36: Cooling Water Connections

Cooling water connections Cooling water connections MAGNET COOLING CIRCUIT DIFFUSION PUMP RESISTOR SLAVE COILS COOLING CIRCUIT These cooling circuits have four cooling water inlet and four corresponding outlet connections on the rear, left-hand panel of the instrument: • Magnet current reference resistor •... -

Page 37: Magnet Power Connection

Cooling water connections showing typical hose connections This figure shows a typical configuration for the cooling water Note: connections, with two separate water supplies; the actual configuration may differ on your instrument. Magnet power connection The magnet power connection is adjacent to the cooling water connections; it connects the magnet power transformer output to the instrument. -

Page 38: Electrical Power Outlets

Magnet power transformer Electrical power outlets Electrical power outlet connections 240V 10AMP MAX. SOURCE ANALYSER INLET 1 INLET 2 The following electrical power outlets appear on the rear of the instrument: • Two 240 V a.c. 10 A maximum • Power outlets for the following vacuum pumps: 1-14 Instrument description... -

Page 39: Vacuum Connections

– Source – Analyzer – Inlet 1 – Inlet 2 Vacuum connections To avoid toxic vapors, a suitable exhaust line must be fitted Warning: to the fore pumps. If the exhaust is not correctly filtered, environmental damage can occur. Ensure that each rotary fore pump contains oil and has been Caution: gas-ballasted before pumping. -

Page 40: Gas Inlet Panel

Gas inlet panel Gas inlet panel IMPORTANT INFLATE AIRMOUNTS CLEAR FFR.1 CI. 1 OF SPACERS BY 2MM MAX. First field-free CI gas region gas connection INLET connection connection Air mount regulator valves Inlet air regulator valve The gas inlet panel has these gas connections: •... -

Page 41: Soft-Vent Control Panel

To operate a regulator valve: Pull the handle toward you. Turn the handle clockwise to increase the air pressure, or counterclockwise to decrease the air pressure until you reach the desired setting. Push the handle away from you, to lock it. Soft-vent control panel Soft-vent control panel Soft-vent gas connection... -

Page 42: Epc Power Switch

pressure at the back of the diffusion (fine) pump. In the event of a loss of current to the fore pump (signifying a pump or power failure) or a critical increase of the pressure behind the diffusion pump to stalling level (indicating a fore pump failure), the soft-vent valve opens, admitting a slow flow of gas to the analyzer. -

Page 43: Tuning The Instrument

Tuning the instrument This chapter describes how to manually tune the instrument (that is, adjust the instrument’s parameters to achieve maximum performance) for both low and high resolution, and gives an example of using the AutoTune facility. Chapter 5 for details of how to calibrate the instrument, and Appendix B for full details of the Tune window The figures in this chapter show indicative parameter values only. - Page 44 To set up the Tune window peak display toolbar Ensure that the items described in the following table are present in the Tune window peak display toolbar. If necessary, add them to the toolbar. Item Function When enabled, the display scales to the value of the intensity of the highest peak, that is, the peak is normalized.

- Page 45 Vacuum Monitor window To switch on the magnet In the MassLynx Tune window, click Click Options > Instrument Setup. Alternative: In the Instrument Setup dialog box, select Magnet. To open the analyzer isolation valve On the MassLynx Tune window Vacuum tab, select Analyser. To look for an ion beam In the MassLynx Tune window, click Set the status switch (on the front of the instrument) to the Operate...

- Page 46 On the Control 1 tab, set both Source Slit and Collector Slit to 100.00 to open the slits fully. If you type the values into the text boxes, rather than using the Tip: sliders, press the keyboard return key after entering each value. In the Control 2 tab, set Alpha Slit to 100.00 to open the slit fully.

- Page 47 Tune window with initial nitrogen peak To calibrate the mass scale In the Tune window, click Options > Instrument Setup. On the Limits tab, drag the Magnet Limit slider until the peak is approximately centered at mass 28. Low resolution tuning...

- Page 48 Calibrating the mass scale Use the Span (ppm) slider to zoom in to the nitrogen peak. Tuning the instrument...

- Page 49 Zooming in to the nitrogen peak In the Control 1 tab, enter 7950 (that is, the maximum value minus 50) for accelerating V. Do not use the slider. Rationale • If you double-click in the peak display to center the peak in the display, the software tries to center the peak using the accelerating voltage.

- Page 50 Peak display showing centralized nitrogen peak On the Source tab, enter the following parameter values: Tune window Source page parameter values Parameter Value Electron Energy (eV) Enter 70 if a GC column is not Note: fitted, or standard scanning is being performed.

- Page 51 These are typical starting values for performing dioxin Rationale: analysis (the most common type of analysis performed on this instrument). Adjust the peak display gain and detector voltage to see the peak Tip: top, if necessary. On the Lenses 1 tab, enter 2500 for both Z Focus 2 and Z Focus 3. Setting these values sometimes saturates the instrument’s detector, Tip: that is.

- Page 52 To complete low resolution tuning of the instrument Use a syringe to inject approximately 0.5 µL of PFK into the injection port on the GC interface. See “The GC interface” on page 6-2. In the MassLynx Tune window, on the Control 1 tab, set Magnet Mass to A PFK peak appears in the Tune window peak display.

-

Page 53: Low Resolution Tuning

Tuning controls : Location in Tune Control Notes window Source tab Ion Repeller (V) Ion Repeller (V) and Focus 1 are interactive and must be tuned in Focus 1 conjunction with each other. Beam Centre Beam Centre, Focus 2, and Y Deflect 1 are interactive and must Focus 2 be tuned in conjunction with each... - Page 54 Flat-topped peak Set the collector slit to optimize the ion beam width and shape. Optimum transmission is achieved when the width of the collector Tip: slit is equal to the ion beam width. When this is the case, the ion beam is said to be triangulated.

-

Page 55: High Resolution Tuning

Optimized (triangulated) peak Click File > Save As to save the low resolution tuning parameters to a new instrument parameter file (*.ipr). The low resolution tuning is now finished; perform the high resolution tuning as described in High resolution tuning on page 2-13. - Page 56 The peak appears in the Tune window’s peak display near to, but not at, its correct value of 293. Calibrate the mass scale in order to correct this. To calibrate the mass scale In the Tune window, click Options > Instrument Setup. On the Limits tab, drag the Magnet Limit slider until the peak is centered at mass 293.

- Page 57 To perform initial high-resolution tuning In the Tune window’s Lenses 1 tab, set Z Focus 3 to 0. The Z Focus 3 lens is usually beneficial to low (less than Rationale: approximately 5000) resolution tuning only. When tuning to higher resolutions it is generally found that turning this lens off improves transmission.

- Page 58 To adjust the source slit for high resolution operation In the Tune window’s Control 2 tab, set Detector (V) to 250 V. On the Control 1 tab, set Collector Slit to 100. The peak becomes flat-topped, because the collector slit is wider Result: than the ion beam.

- Page 59 Flat-topped mass 293 peak, intensity 0.1 V To perform final high resolution tuning In the Tune window’s Control 2 tab, set Detector (V) to 350. Zoom in to the peak, and tune the instrument to center the displayed peak on mass 293 and to obtain the best peak shape (with minimum tailing) and intensity as described in step 2 on page 2-15.

-

Page 60: Additional Notes Concerning Manual Instrument Tuning

High resolution tuned peak: Click File > Save As to save the high resolution tuning parameters to a new instrument parameter file (*.ipr). Additional notes concerning manual instrument tuning The following controls on the Tune window’s Control 2 tab affect instrument tuning. -

Page 61: Alpha Slit

This section describes how to perform the basic autotuning procedure. Note: To perform more comprehensive autotuning using the controls available in the AutoSpecAutoTune dialog box, contact Waters for advice. To prepare for an autotune procedure On the Tune window’s Control 1 tab enter 7950 (that is, the maximum value minus 50 for Accelerating V). - Page 62 The AutoTune Progress window has a progress bar at the bottom which Tip: displays the target resolution and progress of the AutoTune. AutoTune Progress window and AutoSpecAutoTune dialog box To perform an autotune procedure In the AutoSpec AutoTune dialog box, specify the desired resolution in the yellow Target Resolution box.

- Page 63 Preliminary autotune in progress The following figure shows a successful autotune procedure, as shown in the AutoTune Progress window. Using the AutoTune facility 2-21...

- Page 64 Successful autotune procedure To stop an autotune procedure In the AutoSpecAutoTune dialog box, click Stop. The program stops after the current lens is tuned. Result: For a more detailed description of the AutoTune program, see the help document “AutoTuneHelp.doc” found in the directory MassLynx\AutoSpec. 2-22 Tuning the instrument...

-

Page 65: Scanning Techniques

Scanning techniques This chapter describes function lists, the MS method editor, the available scanning techniques, and selected ion recording (SIR) experiments. An example of how to set up the instrument to acquire voltage selected ion recording (VSIR) data (the most sensitive data acquisition mode), using PFK as a reference sample also appears. - Page 66 MS method editor with a single function You can save a function list in a MassLynx experiment file, and then reopen and edit it at any time. “The MassLynx experiment file” on page 3-4. figure “MS method editor with a single function” on page 3-2 shows a simple Function List containing only one function: a Magnet scan between 50 and 500 Da, using EI+ ionization.

-

Page 67: The Ms Method Editor Toolbar

The currently selected function is highlighted and enclosed in a rectangular frame. If the function list contains several functions, select a function by clicking on it or by using the keyboard arrow keys. The MS method editor toolbar The following table details the MS method editor toolbar buttons. MS method editor toolbar buttons Equivalent Tool... -

Page 68: The Masslynx Experiment File

MS method editor toolbar buttons Equivalent Tool Function menu item Functions > B/E Sets up a B/E function. Functions > Sets up a B /E function. Functions > Sets up a constant neutral loss (CNL) function. Functions > Sets up a Mass-analyzed Ion Kinetic MIKES Scan Energy Spectrometry (MIKES) function. -

Page 69: Editing The Function List

To save a function list to a new MassLynx experiment file In the MS method editor, click Click File > Save As. In the Save As dialog box, enter a new file name, or select an existing file from the displayed list. Click Save. -

Page 70: Setting The Maximum Retention Time

To copy an existing function in the list Click on the function. Click Edit > Copy. Click Edit > Paste. Modify the parameters as required. To delete a function from the list: Click on the function. Click Click Edit > Delete, or press the Del key. Alternative: To change the order of functions in the list Functions appear in ascending start and end time order;... -

Page 71: Setting Up Scanning Functions

Setting up scanning functions Magnet Scan function Use the Magnet Scan function editor to set up scans in which the magnet’s field strength varies, to scan from high to low mass over large mass ranges. Magnet scans are ideal for experiments that require a wide mass range. Magnet Scan function editor Setting up scanning functions... - Page 72 Magnet Scan function editor parameters Parameter Description AutoSpec Parameter Enter the required parameter file name and path in File the text box, or click Browse. Use Probe Ramping When selected, you can specify a probe ramping Method method (.prf) file name and path in the text box, or click Browse.

- Page 73 Magnet Scan function editor parameters (Continued) Parameter Description Inter-Scan Delay (s) The time between one scan’s end and the next scan’s start, in seconds. No data are collected during this time; the time is used to allow the magnet to settle, and to transfer collected data from the EPC to the MassLynx PC.

-

Page 74: Voltage Scan Function

Voltage Scan function The Voltage Scan function editor is used to set up scans in which the source’s accelerating voltage is varied, to scan from low to high mass. Use voltage scanning to scan over smaller mass ranges, but with higher accuracy than magnet scanning. - Page 75 Voltage Scan function editor parameters (Continued): Parameter Description Start Time (min) The retention time (in minutes) at which the function starts. End Time (min) The retention time (in minutes) at which the function stops. Resolution The resolution, used to determine scanning parameters.

-

Page 76: B/E (Product Ion) Function

B/E (product ion) function Use the B/E Scan function editor is used to set up scans in which the magnet’s field strength (B) is scanned (as for a Magnet Scan), but with the addition of a scan of ESA1 and ESA2. The electric fields (E) are scanned such that the ratio B/E remains constant. - Page 77 B/E Scan function editor parameters: Parameter Description AutoSpec Parameter Enter the required parameter file name and path in File the text box, or click Browse. Use Probe Ramping When selected, you can enter a probe ramping Method method (.prf) file name and path in the text box, or click Browse.

- Page 78 B/E Scan function editor parameters: Parameter Description Pre-Acquisition Enter a pre-acquisition calibration file name and Calibration File path in the text box, or click Browse. This file is used to calibrate the scan of ESA1 and ESA2 performed by the B/E scan. You must create it on standard Magnet Scan data, over exactly the same magnet mass range and scan time as the B/E scan.

-

Page 79: B2/E (Precursor Ion) Function

/E (precursor ion) function Use the B /E Scan function editor to set up scans in which ESA1 and ESA2 are scanned relative to the magnet, such that the ratio B /E remains constant. This function detects all the precursors whose fragmentation gives rise to a specific product ion. - Page 80 /E Scan function editor parameters Parameter Description AutoSpec Parameter Type the required parameter file name and path in File pane the text box, or click Browse to locate the file. Use Probe Ramping When selected, you can specify a probe ramping Method method (.prf) file name and path in the text box, or click Browse.

- Page 81 /E Scan function editor parameters (Continued) Parameter Description Pre-Acquisition Enter a pre-acquisition calibration file name and Calibration File path in the text box, or click Browse. This file is used to calibrate the scan of ESA1 and ESA2 performed by the B /E scan.

-

Page 82: Constant Neutral Loss (Cnl) Function

Constant Neutral Loss (CNL) function Use the Constant Neutral Loss Scan function editor to set up scans in which, ESA1 and ESA2 are scanned relative to the B field, following a complex relationship. This function detects all the product ions whose fragmentation from a precursor ion has yielded a specific neutral fragment. - Page 83 Constant Neutral Loss Scan function editor parameter (Continued) Parameter Description Use Probe Ramping When selected, you can specify a probe ramping Method method (.prf) file name and path in the text box, or click Browse. Low Mass (m/z) The magnet mass at which the scans in the function stop.

- Page 84 Constant Neutral Loss Scan function editor parameter (Continued) Parameter Description High Mass Precursor Displays the actual high mass of the returned data. Ion (m/z) This is a function of the neutral fragment mass and the magnet high mass. Pre-Acquisition Enter a pre-acquisition calibration file name and Calibration File path in the text box, or click Browse.

-

Page 85: Mikes Scan Function

MIKES Scan function Use the MIKES Scan function editor to set up mass-analyzed ion kinetic energy spectrometry (MIKES) scans. In this type of acquisition, a parent ion is selected by ESA1 and the magnet. It is fragmented in the third field-free region (FFR3, between the magnet and ESA2). -

Page 86: Nrms Scan Function

MIKES Scan function editor parameters (Continued): Parameter Description Start Time (min) The retention time (in minutes) at which the function starts. End Time (min) The retention time (in minutes) at which the function stops. Resolution The resolution, used to determine scanning parameters. - Page 87 the NRMS gas cell [located in the third field-free region (FFR3), between the magnet and ESA2]. The charged species are filtered out, leaving the neutral fragments to pass through the MIKES slit into the MIKES gas cell. They are re-ionized here, using a collision gas. A kinetic energy spectrum is then acquired by scanning the ESA2 energy.

-

Page 88: Sir Function Editors

NRMS Scan function editor parameters (Continued) Parameter Description Start Time (min) The retention time (in minutes) at which the function starts. End Time (min) The retention time (in minutes) at which the function stops. Resolution The resolution, used to determine scanning parameters. -

Page 89: The Voltage Sir Function Editor

The voltage SIR function editor Use the voltage SIR function editor is used to set up voltage selected ion recording (VSIR) experiments. VSIR is the most sensitive data acquisition mode, used for trace analysis. A specified number of masses are monitored, by setting the magnet’s field strength (B) to a fixed value and changing the accelerating voltage (V) between values corresponding to the specified masses. - Page 90 Voltage SIR function editor 3-26 Scanning techniques...

- Page 91 Voltage SIR function editor parameters : Parameter Description AutoSpec Parameter Type the required parameter file name and path in File the text box, or click Browse. Use Probe Ramping When selected, you can specify a probe ramping Method method (.prf) file name and path in the text box, or click Browse.

- Page 92 Voltage SIR function editor parameters (Continued): Parameter Description FI Set up Opens the FI Set up dialog box so you can specify that an inter-scan current be applied to an field ionization (FI) emitter. This option is enabled only when you select FI+ Tip: or FI- selected as the ionization mode.

-

Page 93: The Sir Mass Dialog Box

The SIR Mass dialog box Use the SIR Mass dialog box to add an entry to, or edit an entry in, the voltage SIR function editor mass table. SIR Mass dialog box parameters Parameter Description Mass (m/z) The mass to be monitored by the function. Channel Time (ms) The time for which this mass is to be monitored, typically 50 to 150 ms (the higher values can give a... -

Page 94: The Mrm Function Editor

To edit an entry to the Voltage SIR Scan function editor mass table: In the Voltage SIR Scan function editor, click Change. In the mass table, double-click on the mass to be edited. Alternative: In the SIR Mass dialog box, enter the required parameters. Click OK. - Page 95 MRM function editor MRM function editor parameters : Parameter Description AutoSpec Parameter Enter the required parameter file name and path in File pane the text box, or click Browse. Use Probe Ramping When selected, you can specify a probe ramping Method method (.prf) file name and path in the text box, or click Browse.

- Page 96 MRM function editor parameters (Continued): Parameter Description Mass table Contains a table of MRM masses to jump between during the MRM function. Opens the MRM Mass dialog box so you can add an MRM mass to the mass table. Change Opens the MRM Mass dialog box so you can edit the selected mass table entry.

-

Page 97: The Mrm Mass Dialog Box

To set up an MRM Scan function: In the MS method editor, click Click Functions > MRM. Alternative: In the MRM function editor, enter the required parameters. Click OK. The MRM Mass dialog box Use the MRM Mass dialog box to add an entry to, or edit an entry in, the MRM function editor mass table. -

Page 98: Example Of Vsir Experiment Set Up

To add an entry to the MRM function editor mass table In the MRM function editor, click Add. In the MRM Mass dialog box, enter the required parameters. Click OK. To edit an entry to the MRM function editor mass table In the MRM function editor, click Change. -

Page 99: Creating The Vsir Function

Creating the VSIR function To open the VSIR function editor In the MassLynx window, click the MS Method icon. In the MS method editor, click The default function is deleted from the function list. Result: Click Click Functions > Voltage SIR. Alternative: Voltage SIR function editor Example of VSIR experiment set up... - Page 100 To enter the parameters in the VSIR function editor Enter the required instrument parameter file name and path in the AutoSpec Parameter File text box, or click Brows. Delete the default mass in the SIR Masses list by clicking on it and then clicking Delete.

- Page 101 Example voltage SIR function editor for TCDD 13. Select the required Ionization Mode. This mode must be the same as the ionization mode in the selected Rule: AutoSpec parameter file. 14. Set Primary Lock Span (pw) to 2. Doing so allows the instrument to compensate for an Rationale: approximate 100 ppm mass drift between calibration and acquisition.

- Page 102 Doing so prevents nearby interfering masses from being Rationale: accidentally locked on to. 16. Set Lock Mass Threshold (mV) to 10. If the lock-mass intensity falls below the threshold value you Rationale: specify, the instrument does not apply the threshold for correction until the intensity recovers.

-

Page 103: Example Of Mrm Experiment Set Up

Example of MRM experiment set up Multiple Reaction Monitoring (MRM) is used for monitoring high energy ion fragmentation reactions. You can monitor a specified number of fragmentation reactions by setting the magnet’s field strength to a fixed value and changing the ESA voltages with the accelerating voltage at close to its maximum. - Page 104 MRM function editor: To enter the parameters in the MRM function editor Enter the required instrument parameter file name and path in the AutoSpec Parameter File text box, or click Browse for a file. Delete the default mass in the MRM Masses list by clicking on it, and then clicking Delete.

- Page 105 In the Channel Time (ms) text box, set the time for which this mass is to be monitored, typically 50 to 150 ms. In the Delay Time (ms) text box, set the time delay between finishing monitoring the previous mass and starting monitoring this mass (in the MRM Masses list).

- Page 106 11. Type an appropriate value, for example 20 minutes, in the End Time (min) text box. 12. Type an appropriate value, for example 10000, in the Resolution text box. Example of MRM function editor 13. Select the required Ionization Mode. You must select the same mode as in the selected AutoSpec Rule: parameter file.

-

Page 107: Applying An Inter-Scan Current In Fi Ionization Mode

To save the experiment file In the MS method editor, click File > Save As. In the Save As dialog box, save the file as MRM Experiment.exp Applying an inter-scan current in FI ionization mode All the scan function editors have an FI Set up button, that opens the FI Set up dialog box, so you can apply a specified inter-scan current to the FI emitter. - Page 108 3-44 Scanning techniques...

- Page 109 Acquiring data This chapter describes how to start data acquisition (from both the Tune window and MassLynx window), and how to monitor, stop, or pause data acquisition. Instrument calibration is also described for various types of experiment. Contents Topic Page Starting data acquisition Stopping data acquisition 4-11...

-

Page 110: Acquiring Data

• You cannot synchronize acquisitions with a GC injection. • You cannot acquire multiple sample sequences. The AutoSpec Tune Acquisition dialog box is opens when you start data acquisition from the Tune window; use it to define the parameters used during the data acquisition. -

Page 111: Starting Data Acquisition

AutoSpec Tune Acquisition dialog box parameters (Continued) Parameter Description Data File Name Specifies the name of the data file to be created in this text box. Text Provide a brief description of the sample. The description can be displayed on any output of the acquired data. - Page 112 AutoSpec Tune Acquisition dialog box parameters (Continued) Parameter Description Inter Scan Delay (s) The time between one scan’s end and the next scan’s start, in seconds. No data are stored in this period. This value is typically 10% of Scan Time. Tip: Linked scanning options are available only if you select B/E scan, Note:...

-

Page 113: Starting Multiple-Sample Data Acquisition From The Masslynx Window

To start a single sample acquisition In the Tune window, click Click Acquire; this button changes to Stop when an Alternative: acquisition is running. In the Acquisition Setup dialog box, enter the required parameters. Click Start. To change the project into which data are saved Stop the acquisition. - Page 114 Typical MassLynx window Sample List menu bar Menu bar Toolbar Information bar Status bar MassLynx bar Sample List editor Acquiring data...

- Page 115 Start Sample List Run dialog box Start Sample List Run dialog box parameters Parameter Description Project Specifies the current project. To send acquired data to a different project, close this dialog box, open the other project, and restart the acquisition. Acquire Sample Acquires data from the selected samples in the Data...

- Page 116 Start Sample List Run dialog box parameters (Continued) Parameter Description Auto Process Processes acquired data (new or existing) as Samples specified in the Sample List Process column. See “Verifying VSIR experimental resolution” on page D-24 Auto Quantify Quantifies the acquired data using the method Samples specified in the Quantify Samples dialog box.

-

Page 117: Automatic Quantification Of The Sample List

To start data acquisition: Create a sample list in the MassLynx window. Click Click Run > Start. Alternative: In the Start Sample List Run dialog box, enter the appropriate parameters. Click OK. Repeat steps 1 to 4 as required. Sample lists are added to a queue and run sequentially unless Result: you select Priority or Night Time Process. - Page 118 Quantify Samples dialog box Quantify Samples dialog box parameters Parameter Description Update Method Updates the retention times specified in the Times TargetLynx method, using a specified sample. Available during a run or during reprocessing. See the QuanLynx User’s Guide and TargetLynx Software User’s Guide.

-

Page 119: Stopping Data Acquisition

Quantify Samples dialog box parameters (Continued) Parameter Description Export Results to Produces a text file containing the quantitation LIMS results for use with a laboratory information management system (LIMS). If selected you can specify a file in the LIMS export text box. Project Displays the name of the current project. -

Page 120: Pausing Data Acquisition

Pausing data acquisition You can pause an acquisition from the Tune window or the MassLynx window. Pausing during a GC data acquisition can disturb the Caution: retention time data, because the GC ramp continues. To pause data acquisition • In the Tune window, click •... -

Page 121: Viewing A Chromatogram In Real-Time

Viewing a chromatogram in real-time To view a chromatogram in real-time In the MassLynx window’s Sample List menu bar, click Chromatogram. In the Chromatogram window, click Click Display > Real-Time Update. Alternative: The chromatogram display updates as the acquisition proceeds. Viewing a spectrum in real-time To view a spectrum in real-time In the MassLynx window’s Sample List menu bar, click Spectrum. -

Page 122: Acquiring Analog Data

Real-Time Update dialog box, real-time updating can also be turned on and off by clicking in the Spectrum window. Acquiring analog data Contact Waters if you need to acquire analog data. Analog data Requirement: acquisition is optional and requires additional hardware. “Waters contact information” on page i-iv. - Page 123 Analog Data dialog box Provide a textual description for each selected channel. Tip: This description appears on the analog Chromatogram dialog box as the channel description (see the MassLynx User’s Guide). If required, specify an Offset (mins) to align the external unit with the mass spectrometer.

- Page 124 4-16 Acquiring data...

- Page 125 Calibrating the instrument This chapter describes how to calibrate the instrument (that is, to ensure that the peaks displayed in a spectrum are in their correct locations). The figures in this chapter show indicative parameter values only. Note: Contents Topic Page Overview Calibration files...

-

Page 126: Calibrating The Instrument

Calibration files Two types of calibration file exist: • .sircal files are used for SIR experiments. They comprise the actual and apparent reference masses for all the functions in the SIR experiment. “Calibrating the instrument for SIR experiments” on page 5-2. - Page 127 Experiment Calibration dialog box Click Browse to select the PFK reference file (Pfk.ref). Click Start. In the Tune window peak display toolbar, click to normalize the display. If necessary, use the Span (ppm) slider to locate the ion beam. Each mass peak in the experiment appears sequentially.

- Page 128 In the Experiment Calibration dialog box, select Centroid to center the peaks within the peak display. Use the Span (ppm) slider to zoom in on the reference peaks when centered on the display to allow more accurate calibration. Each mass must be a similar shape, have a similar Requirement: resolution, and be in the center of the display.

-

Page 129: Calibrating The Instrument For Mikes And Nrms Experiments

10. When the peaks are acceptable, in the Experiment Calibration dialog box, click Continue to end the calibration and create a calibration file (*.sircal) for the experiment. If you are using a multi-function experiment for the calibration, Note: clicking Continue advances you to the next function. Calibrating the instrument for MIKES and NRMS experiments Use the experiment calibration dialog box to calibrate MIKES and NRMS... - Page 130 If the experiment mass range extends below 44 Da and the Tip: reference compound has no masses below this value, you can improve the calibration by selecting Air references. Make new calibration dialog box Click OK. The Calibration report window opens displaying these four Result: panes: •...

-

Page 131: Manually Correcting A Calibration

Calibration report window Manually correcting a calibration If you manually correct a calibration but open and close the Caution: Calibration Parameters dialog box with the “Perform auto peak matching option” selected, the spectrum is automatically recalibrated; any manual corrections are lost. “Editing the calibration parameters”... - Page 132 Calibration report window with large residual errors To manually adjust the large residual error peaks Zoom in on the mass region of a mismatched peak by clicking and dragging over the region. Click Default to zoom out. Tip: Right-click just to the right of, and just below, the top of the mismatched reference peak in the reference spectrum pane.

-

Page 133: Editing The Calibration Parameters

Calibration report window with residual errors corrected Editing the calibration parameters For any type of experiment, you can edit the calibration parameters in the Calibration Parameters dialog box. To do so, in the calibration report window, Edit > Calibration Parameters. Editing the calibration parameters... - Page 134 Calibration Parameters dialog box Calibration Parameters dialog box parameters Parameter Description If performing an automatic calibration, the Peak Match parameters determine the limits within which the acquired data must lie for the software to recognize the calibration masses and result in a successful calibration.

- Page 135 Calibration Parameters dialog box parameters (Continued) Parameter Description Peak window (Da) Specifies the maximum mass difference between the reference peaks and the expected position of the corresponding peaks in the acquired calibration spectrum. The normal operating range for this Note: parameter is 0.3 to 1.5 Da.

-

Page 136: Saving A Calibration

Saving a calibration To save a calibration In the Calibration report window, click File > Save As. Applying the calibration To apply the calibration Close the Calibration report window. Click Yes. Calibration is automatically applied to the active data file. Result: To apply the calibration to new data acquired using an existing experiment: Select the data. -

Page 137: Associating A Calibration File With An Experiment

Associating a calibration file with an experiment To associate a calibration file with an experiment In the MS method editor, click Options > Calibration. See “Function lists and the MS method editor” on page 3-1. Scope Calibration dialog box In the Scope Calibration dialog box, select Use Positive Calibration File. Negative calibration files are intended for use in negative ion mode. - Page 138 5-14 Calibrating the instrument...

- Page 139 Inlets and probes This chapter describes how to operate the GC interface, how to install the GC column and the solids sample introduction probe, and how to ramp the probe’s temperature. Contents Topic Page The GC interface Installing the GC column The solids sample introduction probe Ramping the probe temperature 6-14...

-

Page 140: Inlets And Probes

The GC interface The GC interface Reference inlet valve Pump valve Injection port To avoid burns, take care when working with the GC Warning: interface. To inject a reference sample Open the reference inlet and pump valves. Wait for 10 minutes, to allow any previous sample to clear from the injection port. -

Page 141: Installing The Gc Column

Open the pump valve, to remove any remaining sample from between the reference inlet valve and the instrument’s source. Reference sample will remain in the injection port. Installing the GC column To avoid contamination from samples, always wear lint-free Warning: cotton gloves when handling the column. -

Page 142: The Solids Sample Introduction Probe

To determine this position, look into the outer source from above; the end Tip: of the GC column will be visible as it enters the outer source housing, as shown in the following figure. Positioning the end of the GC column GC interface Source probe port GC transfer line... -

Page 143: Making The Probe Cooling Water Connections

“Loading sample into the sample cup” on page 6-6 “Fitting the sample cup to the probe tip” on page 6-8. Attach the probe to the ion source by means of the source side lock. Probe in position in the source side lock Making the probe cooling water connections To make the cooling water connections between the probe and instrument Connect the probe’s two male cooling water connectors to the female cooling... -

Page 144: Fitting The Probe Tip To The Probe

Fitting the probe tip to the probe The probe components can be contaminated with toxic Warning: materials. Wear nitrile gloves at all times while handling the components. To fit the probe tip to the probe With the probe in the vertical position, fit the probe tip over the end of the probe. - Page 145 Sample cups Type C Type D You can load the sample cup with the sample before or after inserting the cup into the probe. Clean used sample cups in a hot flame and/or in solvent before reuse. To load sample into a sample cup The sample can comprise toxic materials.

-

Page 146: Fitting The Sample Cup To The Probe Tip

Evaporate any solvent used in loading by placing the sample cup(s) in a warm location. Fitting the sample cup to the probe tip The probe components can be contaminated with toxic Warning: materials. Wear nitrile gloves at all times while handling the components. -

Page 147: Removing The Sample Cup From The Probe Tip

To adjust the grip of the sample cup holder Use tweezers to squeeze the sample cup holder prongs together, or use a jeweler’s screwdriver to gently pry the prongs apart. Removing the sample cup from the probe tip The probe components can be contaminated with toxic Warning: materials. - Page 148 Tilt the source side lock slider assembly so that the probe handle is horizontal. While holding the side lock slider assembly and probe handle, push the side lock slider assembly forward until it butts against the side lock housing. Close the lock latch, by turning it clockwise. Ensure that it is fully in line with the probe handle.

- Page 149 Close the vent valve (to the right-hand side of the source side lock) by turning it fully clockwise. Vent valve Pump valve Open the source side lock pump valve (on the right-hand side of the source side lock). The source side lock pump valve is open when its handle is in line Tip: with the associated pipework.

- Page 150 The source side lock isolation valve is open when its handle is in line Tip: with the probe handle. Close the source lock pump valve. The probe assembly now appears, as in the following figure. Tip: 10. Rotate the probe handle so that its guide slot is correctly oriented with the guide pin.

-

Page 151: Removing The Probe From The Ion Source

11. Push the probe handle forwards until it reaches its stop, insert the probe sample cup into the source. Removing the probe from the ion source The source and probe components can be contaminated with Warning: toxic materials. Wear nitrile gloves at all times while handling the components. -

Page 152: Ramping The Probe Temperature

Close the source side lock isolation valve (on the top of the source side lock). Tip: The source side lock isolation valve is closed when its handle is at right angles to the probe handle. Open the vent valve (to the right-hand side of the source side lock) by turning it counterclockwise. - Page 153 Probe Control dialog box Options tab Probe Control dialog box’s Options tab tools Tool Function Opens a Save As dialog box, so you can crete a new probe ramping method file. Opens an existing probe ramping method file. Saves the probe ramping method file. Ramping the probe temperature 6-15...

-

Page 154: The Probe Control Dialog Box's Ramps Tab

Probe Control dialog box’s Options tab parameters Parameter Description Use Ramps Enables probe ramp control. Use Base Peak Enables probe regulation based on the base peak intensity. The base peak is the most intense peak within the scanned mass range. Use TIC control Enables probe regulation based on the Total Ion Current (TIC). - Page 155 Probe control dialog box’s Ramps tab Probe Control dialog box’s Ramps tab parameters Parameter Description Ramp The ramp identifying number. Rate The rate of the ramp, in units of Value/minute. Value Displays the ramp’s final target value, in units appropriate to the probe type. Hold The time (in minutes) for which to hold the Value, once it is reached.

-

Page 156: The Probe Control Dialog Box's Control Tab

In the Rate text box specify the required value and then press Enter key. Repeat step 3 for the Value and Hold text boxes. When the Enter key is pressed for the Hold text box, a new row (Ramp 2) is created. Repeat steps 3 and 4 as required to create further probe ramps. - Page 157 Probe Control dialog box’s Control tab displays Display Description Ramps Display Shows a graph of the current probe ramp against time. Both the target value and actual value appear to indicate how accurately the ramp profile is being followed. Probe State Displays the current state of the probe ramp.

- Page 158 6-20 Inlets and probes...

-

Page 159: Routine Maintenance

Routine maintenance This chapter provides maintenance guidelines and procedures that are required to maintain the instrument’s performance. Keep to the maintenance schedule and perform maintenance as required and described in this chapter. Contents Topic Page Maintenance schedule Safety and handling Vacuum pump maintenance GC interface maintenance Source maintenance... -

Page 160: Safety And Handling

Maintenance schedule (Continued) Procedure Frequency Replace scroll pump seals. Annually (see the Edwards document XDS 35i Instruction Manual A730-01-880). Clean all source components. When sensitivity decreases to unacceptable levels. Measure the instrument’s EI Monthly. sensitivity. Safety and handling Remember the following safety considerations when performing maintenance procedures. -

Page 161: Vacuum Pump Maintenance

• Use tweezers and pliers whenever possible. • If nitrile or lint-free cotton gloves are used, take care not to leave fibers in sensitive areas. • Avoid touching sensitive parts with fingers. • Before reassembling and replacing dismantled components, inspect O-rings and other vacuum seals for damage. - Page 162 GC interface Reference inlet valve Pump valve Injection port Thumbscrew To renew the injection port septum The GC interface components can be contaminated Warning: with toxic materials. Wear nitrile gloves at all times while handling the components. To avoid burns, take care when working with the GC Warning: interface, because it can be hot.

-

Page 163: Source Maintenance

Remove the septum from the injection port. When fitting the new septum, note the color and orientation, Caution: because an incorrectly-fitted septum causes air leakage. ® Fit the new septum to the injection port, with the gray Teflon side facing downward and the yellow rubber side facing upward. Refit and loosely tighten the injection port thumbscrew. -

Page 164: Inner Source Chamber Assembly Maintenance

Source housing GC interface View port Solids sample introduction probe Source lock Source side lock Inner source handle Inner source chamber assembly maintenance Inner source chamber assembly Routine maintenance... - Page 165 Inner source chamber assembly components Key to inner source chamber assembly components Item Description Ion exit plate Ion exit plate securing screw Filament terminal block Filament terminal block securing screw Filament Filament securing screw Washer Bayonet support Bayonet support securing screw Source maintenance...

- Page 166 Key to inner source chamber assembly components (Continued) Item Description Ceramic spacer Locating dowel (shouldered) Locating dowel (plain) Ceramic spacer Ion block Trap Trap securing nut Washer Trap contact Ceramic spacer Ceramic spacer Ceramic spacer Repeller contact Repeller contact ceramic spacer Repeller contact securing nut Washer Repeller shaft...

-

Page 167: Required Materials

“Component hardware troubleshooting” on page 8-2. If cleaning the inner source chamber assembly fails to increase signal sensitivity, also clean the outer source assembly. See “Outer source maintenance” on page 7-38. Cleaning the chamber assembly involves these tasks: • Withdrawing the chamber assembly from the instrument (see page 7-10). -

Page 168: Withdrawing The Inner Source Chamber Assembly From The Source

• Ultrasonic bath. • Source of oil-free, inert gas (nitrogen or helium) for drying (air-drying optional). • Lint-free paper towels. Withdrawing the inner source chamber assembly from the source To withdraw the chamber assembly from the source The source and chamber assembly components can be Warning: contaminated with toxic materials. - Page 169 Hold the source handle and loosen the security lock thumbscrew on the right-hand side of the source handle. Source handle Security lock thumbscrew Retract the source handle until it reaches its stop. Rotate the source handle so that the guide slot is no longer aligned with the guide pin.

- Page 170 Hold the probe handle and open the source lock vent valve (on the left side of the source lock) by turning counterclockwise, to vent the lock volume. Source lock Source lock vent valve 10. Release the source lock latch, by turning it counterclockwise. Source lock latch 7-12 Routine maintenance...

- Page 171 11. Hold the source lock slider assembly collar. 12. While holding the lock slider assembly and source handle, withdraw the source lock slider until it reaches its stop. Source maintenance 7-13...

-

Page 172: Removing The Chamber Assembly From The Source Handle

13. Tilt the lock slider assembly so that the chamber assembly is vertical. Chamber assembly Removing the chamber assembly from the source handle To remove the chamber assembly from the source handle The source and chamber assembly components can be Warning: contaminated with toxic materials. -

Page 173: Disassembling The Chamber Assembly

Turn the chamber assembly 45 degrees counterclockwise. Lift the chamber assembly off the bayonet connector. Disassembling the chamber assembly The chamber assembly components can be contaminated Warning: with toxic materials. Wear nitrile gloves at all times while handling the components. To remove the ion exit plate Remove the 4 screws securing the ion exit plate to the ion block. - Page 174 Remove the ion exit plate from the ion block. To remove the filament assembly Remove the screw and washer securing the filament assembly to the ion block. Filament assembly 7-16 Routine maintenance...

- Page 175 Remove the filament assembly from the ion block. Remove the screws securing the filament terminal blocks to the filament. Filament terminal block Remove the filament terminal blocks from the filament. To remove the bayonet support Remove 1 of the 4 screws securing the bayonet support to the ion block. Source maintenance 7-17...

- Page 176 These screws are located within cylindrical ceramic spacers, and are Tip: screwed into locating dowels passing through the ion block. Ceramic Bayonet Remove the associated ceramic spacer. Remove the corresponding locating dowel from the opposite end of the the ion block. Ceramic spacer Locating dowel...

- Page 177 To remove the trap Using the 1/8-inch wrench, remove the nut and washer securing the trap contact to the trap’s shaft. Trap contact Remove the trap contact. Remove the trap and 2 associated ceramic spacers from the bottom of the ion block. Remove the ceramic spacers from the trap’s shaft.

- Page 178 To remove the repeller Using the 1/8-inch wrench, remove the nut and washer securing the repeller contact to the ion block. Repeller contact Remove the repeller contact from the ion block. Remove the repeller contact ceramic spacer, located below the repeller contact, from the ion block.

-

Page 179: Cleaning Ion Burn From The Inner Source Chamber Assembly Components

Cleaning ion burn from the inner source chamber assembly components The chamber assembly components can be contaminated Warning: with toxic materials. Wear nitrile gloves at all times while handling the components. To clean the ion exit plate Using 12- lapping paper, rub all the ion exit plate surfaces, including mµ... - Page 180 To clean the repeller Using 12- lapping paper laid on a flat surface, and using a mµ “figure-eight” motion”, rub the repeller flat surface until it is free of visible ion burn. Using 9- lapping paper laid on a flat surface, and using a mµ...

-

Page 181: Ultrasonically Cleaning The Chamber Assembly Components

To clean the ion volume Use a cotton bud to rub a mixture of lapping paste and methanol on all the surfaces (inner and outer) of the ion volume until they are free of visible ion burn. To clean the locating dowels Using 9- lapping paper, clean all the surfaces of the locating dowels. -

Page 182: Assembling The Inner Source Chamber Assembly

Place the vessel in the ultrasonic bath for 30 minutes. Depending on the nature of the contamination, Recommendation: repeat steps 1 and 2 with different solvents, to achieve thorough cleaning of the components. To avoid re-contaminating the chamber assembly Caution: components following cleaning, use clean, lint-free cotton gloves during assembly. - Page 183 Fit the trap and 2 associated ceramic spacers into the bottom of the ion block. At the top of the ion block, fit the ceramic spacer to the trap’s shaft. Fit the trap contact to the trap’s shaft. Source maintenance 7-25...

- Page 184 Fit the nut and washer securing the trap contact to the trap. Do not tighten the nut fully at this stage. Use the “clutch pencil” tool to place the nut on the trap’s thread. Tip: To fit the repeller Fit the long ceramic spacer to the repeller’s shaft. Fit the two 2-mm ceramic spacers over the long spacer.

- Page 185 Using a ceramic spacer as a support for the repeller, fit the ion block over the repeller’s shaft. Fit the remaining ceramic spacer over the ceramic spacer on the repeller shaft, at the top of the ion block. Fit the repeller contact ceramic spacer over the repeller shaft, onto the ion block.

- Page 186 This spacer is shaped, and will fit only one way round. Tip: Repeller contact ceramic spacer Fit the repeller contact over the repeller shaft. Repeller shaft Repeller contact Fit the nut and washer securing the repeller contact to the repeller. Do not tighten the nut fully at this stage.

- Page 187 Ensure that the repeller plate is not touching any part of the ion block. Ion block Repeller plate Trap Using the 1/8-inch wrench, tighten the nut securing the repeller contact to the repeller, while ensuring that the repeller plate does not come into contact with the ion block.

- Page 188 Fit and tighten the screw and washer securing the filament assembly to the ion block, while ensuring that the filament coils are centered in the ion block aperture. Filament coil To fit the bayonet support Fit the shouldered locating dowels in the holes on opposite sides of the trap, with the shouldered end on the front side of the ion block.

- Page 189 Fit a ceramic spacer, with the stepped portion uppermost, over each of the locating dowels. You must fit the bayonet support so that the connector slit is Caution: parallel to the repeller contact. Fit the bayonet support to the ceramic spacers. Connector slit Repeller contact Source maintenance...

-

Page 190: Fitting The Inner Source Chamber Assembly To The Source Handle

Fit a small ceramic spacer over 1 of the spacers projecting through the bayonet support, and fit and tighten the securing screw. Repeat step 6 for the other 3 ceramic spacers and securing screws. To fit the ion exit plate to the ion block Fit the ion exit plate to the ion block. -

Page 191: Inserting The Inner Source Chamber Assembly Into The Outer Source

With the filament contacts facing away from the instrument, fit the chamber assembly to the bayonet connector, pushing down against the spring. Turn the chamber assembly 45 degrees clockwise to lock it in place. Inserting the inner source chamber assembly into the outer source To insert the chamber assembly into the outer source To avoid re-contaminating the chamber assembly Caution:... - Page 192 Tilt the lock slider assembly so that the chamber assembly is horizontal. While holding the lock slider assembly and source handle, push the source lock slider assembly forward until it butts against the outer source housing. 7-34 Routine maintenance...

- Page 193 Close the source lock latch, by turning it clockwise. Ensure that it is fully in line with the source handle. Close the vent valve, on the left-hand side of the source lock, by turning it fully clockwise. Open the source lock pump valve, on the right-hand side of the source lock.

- Page 194 The source lock pump valve is open when its handle is in line with Tip: the associated pipework. Wait a few seconds to allow the interlock to roughly pump-down (evacuate). On the MassLynx Vacuum Monitor window, ensure that the Source display is <...

-

Page 195: Degassing The Ion Source Assembly

12. Push the source handle forward to its stop, to insert the chamber assembly in the outer source. 13. Tighten the security lock thumbscrew. Degassing the ion source assembly After performing maintenance on the chamber assembly, you must degas the ion source assembly. -

Page 196: Outer Source Maintenance

Outer source maintenance The outer source assembly Clean the outer source assembly when either of these conditions applies: • It is visibly fouled. • When cleaning the inner source chamber assembly fails to increase signal sensitivity. “Inner source chamber assembly maintenance” on page 7-6. -

Page 197: Required Materials

Required materials • Lint-free cotton gloves. • Nitrile gloves. • Needle-nose pliers or tweezers. • 1/8-inch (3.2-mm) wrench. • 1.5-mm Allen wrench. • 1-mm Allen wrench. • Jeweler’s screwdriver. • “Clutch pencil” tool (provided in the tool kit). • Vernier caliper. •... -

Page 198: Removing The Outer Source Assembly From The Instrument

Removing the outer source assembly from the instrument To remove the outer source assembly from the instrument The source components can be contaminated with toxic Warning: materials. Wear nitrile gloves at all times while handling the components. In the MassLynx Tune window, click Press for Standby and confirm that the adjacent instrument status indicator shows red. - Page 199 11. Withdraw the inner source chamber assembly from the source as described on page 7-10. 12. Lift the viewing port glass plate from the top of the source housing. See figure “Source housing” on page 7-6. 13. Loosen the outer source locating screw. Locating screw 14.

-

Page 200: Disassembling The Outer Source

15. Lift the outer source assembly vertically out of the source housing. Disassembling the outer source The source components can be contaminated with toxic Warning: materials. Wear nitrile gloves at all times while handling the components. At all stages of disassembly, note the location and orientation of Tip: components;... - Page 201 Re-entrant coupling mechanism Ion block Mounting bracket Tee-block and spring When removing the mounting bracket from the ion block, be Caution: careful not to lose the spring, which is located between the tee block and ion block. To remove the re-entrant coupling mechanism The re-entrant coupling mechanism connects the GC interface and the outer source.

- Page 202 To remove the probe contact assembly Use needle-nose pliers or tweezers to disconnect the 4 push-on connectors connecting the leads to the right-hand side contact rail assembly. Probe contact assembly securing screw Probe contact assembly Right-hand side contact rail assembly Remove the 2 screws securing the probe contact assembly, spacer and adaptor block to the ion chamber.

- Page 203 Remove the spacer and adaptor block from the outer source assembly. Spacer Adaptor block To disconnect the internal connecting leads Disconnect the filament, heater, and repeller wire push-on connectors on the right-hand side contact rail assembly. Filament, heater, and repeller connections Ion chamber connection Ion chamber Source maintenance...

- Page 204 Disconnect the ion chamber push-on connection. On the left-hand side contact rail assembly, disconnect these parts: • Focus 1 plate push-on connection. Focus 1 plate connection • Ion chamber accelerating voltage push-on connection. Ion chamber accelerating voltage connection 7-46 Routine maintenance...

- Page 205 • Remaining heater push-on connections. End plate securing screw End plate Heater connections End plate securing nut To remove the end plate Remove two 5.5-mm nuts and washers, and 2 screws and washers securing the end plate to the contact rail assemblies and metal pillars respectively.

- Page 206 Carefully remove the end plate from the outer source assembly. To remove the inner source contact support assembly Remove the wavy washers from the ceramic rods. The number of wavy washers fitted to the ceramic rods varies from Tip: source to source. Note this number, because you must replace these exactly when reassembling the outer source assembly.

- Page 207 Remove the 10-mm ceramic spacer from each ceramic rod. Remove the 2-mm ceramic spacer from each top ceramic rod. 2-mm ceramic spacer Inner source contact support assembly Hold down the ceramic rods when removing the inner source Caution: contact support assembly, so that the source lens plates and supporting ceramics do not fall apart Remove the inner source contact support assembly.

- Page 208 To remove the ion chamber Remove two 12-mm ceramic spacers from each top ceramic rod. 14-mm metal spacer 12-mm ceramic spacer Remove two 14-mm metal spacers from each bottom ceramic rod. Hold down the ceramic rods when removing the ion chamber, Caution: so that the source lens plates and supporting ceramics do not fall apart.

- Page 209 Remove the ion chamber from the outer source assembly. Ion chamber “Disassembling the ion chamber” on page 7-60. To disassemble the lens stack Remove the shield from each ceramic rod. Shield Source maintenance 7-51...

- Page 210 Remove the 12-mm ceramic spacer from each ceramic rod. 12-mm ceramic spacer Remove the Focus 1 plate from the ceramic rods. Focus 1 plate 7-52 Routine maintenance...

- Page 211 Remove three 2-mm ceramic spacers from each ceramic rod. 2-mm ceramic spacers First Y half-plate 6-mm metal spacer Remove the first Y half-plate from the left-hand side ceramic rods. Remove the 6-mm metal spacer from each left-hand side ceramic rod. Remove the second Y half-plate from the left-hand side ceramic rods.

- Page 212 11. Remove the left-hand side ceramic rods. Focus plate 12. Repeat steps 5 to 11 for the right-hand side ceramic rods. 13. Remove the focus plate. 7-54 Routine maintenance...

- Page 213 To complete disassembling the outer source assembly Remove the screws that secure the metal pillars to the source locating plate. Metal pillar Source locating plate Remove the metal pillars from the source locating plate. Remove the 2 screws that secure the contact rail assemblies to the source locating plate.

-

Page 214: Disassembling The Re-Entrant Coupling Mechanism

Disassembling the re-entrant coupling mechanism To disassemble the re-entrant coupling mechanism Slide the peg out of the mounting bracket. Remove the two screws that secure the tee-block to the U-bracket. Remove the nut that secures the peg to the U-bracket. Remove the peg from the U-bracket. - Page 215 Key to probe contact assembly components Item Description Probe contact mounting plate Contact 6-mm ceramic spacer 2-mm ceramic spacer Screw M1.6 × 6-mm Screw M1.6 × 10-mm 7.5-mm ceramic spacer 3.5-mm ceramic spacer To disassemble the probe contact assembly For each contact, remove the screw and washer securing the connecting lead to the contact.

-

Page 216: Disassembling The Inner Source Contact Support Assembly

Disassembling the inner source contact support assembly Inner source contact support assembly components Hole for ceramic support Key to inner source contact support assembly components Item Description Inner source contact support plate Filament contact Repeller contact 2-mm ceramic spacer 3.5-mm ceramic spacer Trap contact 7-58 Routine maintenance... - Page 217 Key to inner source contact support assembly components (Continued) Item Description Screw M1.6 × 8 Washer To disassemble the inner source contact support assembly To avoid damage, take great care when handling the inner Caution: source contact plate; it is very fragile. Remove the nut, screw, washer and spacers that secure the trap contact and connecting lead to the inner source contact support plate, and separate these components.

-

Page 218: Disassembling The Ion Chamber

Disassembling the ion chamber To remove the thermocouple To avoid damage, handle the thermocouple leads with great Caution: care; they are very fragile. Use a 1-mm hexagonal wrench to remove the set screw securing the thermocouple to the ion chamber. Set screw To avoid damage, take great care when handling the Caution:... - Page 219 To remove the source heaters To avoid damage, handle the source heaters with great care; Caution: they are very fragile. Remove the screw, washer, and 2-mm ceramic spacer, securing the first lead (with small insulating ceramic) of one of the source heaters to the ion block insulated heater terminal.

-

Page 220: Disassembling The Contact Rail Assemblies

Repeat steps 1 to 4 for the second source heater. To remove the accelerating voltage lead Remove the screw and washer securing the accelerating voltage lead to the ion block. Remove the accelerating voltage lead from the ion block. To remove the source magnets Use a 1.5-mm hexagonal wrench to remove the set screw securing the first magnet to the ion block. - Page 221 Contact rail assembly components Left-hand side Right-hand side Key to contact rail assembly components Item Description Contact Support rod Adjusting nut 5-mm ceramic spacer Insulator tube Washer Contact Contact Source maintenance 7-63...

-

Page 222: Cleaning Ion Burn From The Outer Source Assembly Components

To disassemble the contact rail assemblies For each contact rail assembly remove the following parts: • Adjusting nut from the support rod. • Locknut from the support rod. • Securing nut and washer from the support rod. • Ceramic spacers and contacts from the central spacer tube. Cleaning ion burn from the outer source assembly components The outer source assembly components can be contaminated Warning:... -

Page 223: Ultrasonically Cleaning The Outer Source Assembly Components

To clean metal components If any metal part has ion burn, use a glass-fiber pencil or 9-mµ lapping paper to clean the burnt areas. On a clean, lint-free cloth, mix a little aluminum oxide powder into a paste with methanol. Use a cotton bud to apply the paste to clean all the metal parts. -

Page 224: Assembling The Re-Entrant Coupling Mechanism

Blow-dry the components using inert, oil-free gas. Place the components on lint-free towels, and allow them to Alternative: air dry. Wipe off any water spots with a lint-free cloth. Assembling the re-entrant coupling mechanism To assemble the re-entrant coupling mechanism Fit the peg to the U-bracket. -

Page 225: Assembling The Inner Source Contact Support Assembly

12. Repeat steps 7 to 11 for the final contact. 13. For each contact, fit the washer and appropriate connecting lead to the screw that secures the lead to the contact mounting plate. 14. Fit and tighten the screw to the contact mounting plate. Assembling the inner source contact support assembly To assemble the trap contact Fit a washer to a M1.6 ×... -

Page 226: Assembling The Ion Chamber

Fit a 2-mm ceramic spacer over each 3.5-mm ceramic spacer. Fit the screws, spacers, and contact to the contact support plate. Fit a 2-mm ceramic spacer over each 3.5-mm ceramic spacer. Fit a washer to each screw. Fit and tighten a nut to each screw. 10. - Page 227 Use a 1.5-mm hexagonal wrench to fit and tighten the set screw securing the magnet to the ion block. Test the polarity of the second magnet by checking that it is attracted to the outer end of the first magnet in the ion block; turn the magnet around (end-to-end) if necessary.

- Page 228 To fit the source heaters To avoid damage, handle the source heaters with great care; Caution: they are very fragile. Slide the first source heater into the ion block. Source heater Insulating ceramic Ensure that the small insulating ceramic is in place on one lead of the source heater.

- Page 229 Wrap the heater lead, fitted with the insulating ceramic, around the shaped ceramic spacer. Heater terminal Heater lead Fit the 2-mm ceramic spacer over the shaped ceramic spacer, ensuring that the heater lead is trapped between the spacer and the heater terminal.

-

Page 230: Assembling The Contact Rail Assemblies

To fit the thermocouple To avoid damage, handle the thermocouple leads with great Caution: care; they are very fragile. Fit the thermocouple to the ion chamber, ensuring that it is correctly orientated. Thermocouple Use a 1-mm hexagonal wrench to fit the grub screw securing the thermocouple to the ion chamber. -

Page 231: Assembling The Outer Source Assembly

Fit the 5-mm ceramic spacers and contacts, in the correct order, over the insulator tube. The terminal contacts on the right-hand side contact rail Caution: assembly must be aligned at approximately 60 degrees to avoid fouling the inner source contact support assembly. The terminal contacts on the left-hand side contact rail assembly must be aligned slightly away from vertical, facing outwards. - Page 232 Fit the focus plate over the ceramic rods. Fit the 2-mm metal spacers to the left-hand side ceramic rods. Fit the first Y half-plate to the left-hand side ceramic rods. Fit the 6-mm metal spacers to the left-hand side ceramic rods. Fit the second Y half-plate to the left-hand side ceramic rods.

- Page 233 To fit the wavy washers to a ceramic rod, stack the washers onto a Tip: leg of a pair of tweezers, then carefully feed the washers onto the ceramic rod directly from the tweezers. Tweezers Wavy washers Ceramic rod 10-mm ceramic spacer To fit the end plate Fit the end plate to the outer source assembly.

- Page 234 Use a vernier caliper to measure the length of the outer source assembly over the metal rods. Repeat step 3 to measure the length of the outer source assembly over the contact rail assemblies. Locknut Adjusting nut 7-76 Routine maintenance...