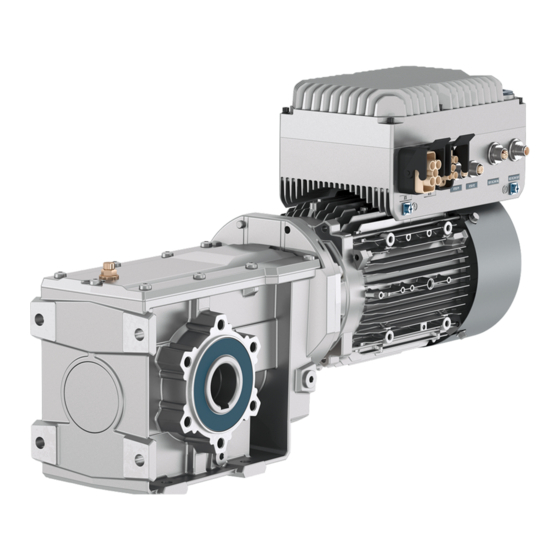

Siemens SINAMICS G115D Drive System Manuals

Manuals and User Guides for Siemens SINAMICS G115D Drive System. We have 2 Siemens SINAMICS G115D Drive System manuals available for free PDF download: Operating Instructions Manual

Siemens SINAMICS G115D Operating Instructions Manual (600 pages)

Distributed drive for conveyor applications

Table of Contents

-

Preface5

-

Connectors37

-

Mounting41

-

Wiring51

-

Line System56

-

Overview62

-

Overview77

-

Commissioning107

-

Factory Settings109

-

Overview135

-

Digital Inputs136

-

Digital Outputs137

-

Telegrams145

-

Dual Slave Mode177

-

Jogging186

-

Conveyors188

-

Turntables196

-

Motor Standard232

-

System of Units233

-

Setpoints257

-

Overview257

-

Overview267

-

Invert Setpoint268

-

Speed Limitation271

-

Motor Control284

-

U/F Control286

-

Torque Control310

-

DC Braking312

-

Dynamic Braking315

-

Load Monitoring329

-

Licensing344

-

Memory Cards354

-

Write Protection363

-

System Runtime375

-

Repair Switch400

-

Technical Data413

-

Derating Data420

-

Rating Plate430

-

Painted Version431

-

Primed Version433

-

Incoming Goods433

-

Unpacking435

-

Operation439

-

Disposal440

-

Technical Data441

-

Weight446

-

Spare Parts447

-

Spares on Web448

-

Cooling451

-

Storage452

-

Terminal Box456

-

Terminal Marking457

-

Lubrication467

-

Circuit Diagrams474

-

Brake480

-

Shaft Seals483

-

Cooling484

-

Storage486

-

Removing SIMOLOC505

-

Draining the Oil520

-

Filling in Oil522

-

Replace Bearings526

-

Bevel Gearbox545

-

Oil Quantities563

-

Helical Gearbox563

-

Bevel Gearbox565

-

Appendix583

-

Fundamentals583

-

Product Support592

-

Index595

Advertisement

Siemens SINAMICS G115D Operating Instructions Manual (552 pages)

Distributed drive for conveyor technology control

Table of Contents

-

Preface

5 -

Mounting

37 -

Wiring

47-

Line System52

-

Overview74

-

Commissioning

101-

Factory Settings103

-

-

Overview127

-

Digital Inputs128

-

Digital Outputs129

-

Telegrams137

-

Dual Slave Mode167

-

Jogging175

-

Conveyors177

-

Turntables184

-

Motor Standard216

-

System of Units217

-

Setpoints232

-

Overview232

-

Overview241

-

Invert Setpoint241

-

Speed Limitation245

-

Motor Control256

-

U/F Control257

-

Torque Control277

-

DC Braking279

-

Dynamic Braking282

-

-

Memory Cards307

-

Write Protection316

-

-

Repair Switch349

-

Technical Data

361-

Derating Data368

-

Derating Data379

-

Temperature381

-

-

Rating Plate388

-

Painted Version389

-

Primed Version391

-

Incoming Goods392

-

Unpacking393

-

Operation397

-

Disposal398

-

Technical Data399

-

Weight403

-

Spare Parts404

-

Spares on Web405

-

Cooling409

-

Storage410

-

Terminal Box414

-

Terminal Marking415

-

Lubrication426

-

Circuit Diagrams432

-

Brake437

-

Shaft Seals442

-

Cooling443

-

Storage444

-

Removing SIMOLOC462

-

Draining the Oil475

-

Filling in Oil477

-

Replace Bearings482

-

Bevel Gearbox500

-

Oil Quantities518

-

Helical Gearbox518

-

Bevel Gearbox520

-

Appendix

537-

Fundamentals537

-

Product Support546

-

Index

547

Advertisement