Lenze i55AE125B Manual

Cabinet 0.25 ... 90 kw

Hide thumbs

Also See for i55AE125B:

- Mounting and switch-on instructions (212 pages) ,

- Operating instructions manual (48 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lenze i55AE125B

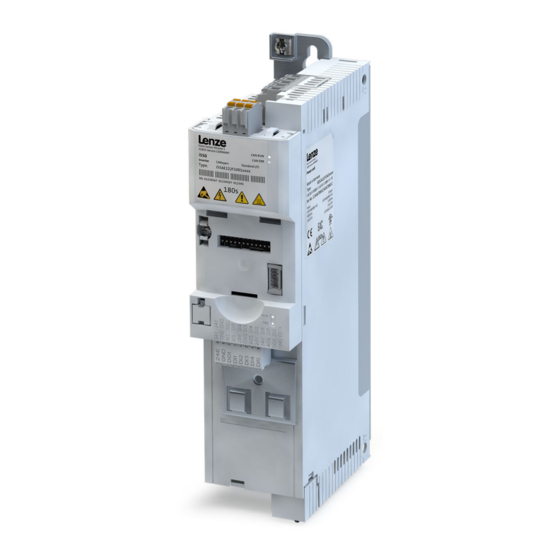

- Page 1 Commissioning | EN Inverter Inverter i550 Cabinet 0.25 ... 90 kW...

-

Page 3: Table Of Contents

Contents Contents 1 General information Read first, then start 2 Safety instructions Basic safety measures Residual hazards Application as directed 3 Mechanical installation Dimensions 4 Electrical installation Important notes Mains connection 4.2.1 1-phase mains connection 120 V 4.2.1.1 Connection plan 4.2.1.2 Fusing and terminal data 4.2.2... - Page 4 Contents 5 Commissioning Important notes Operating interfaces 5.2.1 Keypad 5.2.2 Engineering tool »EASY Starter« 5.2.2.1 Generate a connection between inverter and »EASY Starter« Parameter setting 5.3.1 General notes on parameters 5.3.2 Basic inverter settings 5.3.3 Basic motor settings 5.3.4 Function assignment of the inputs and outputs Keypad parameter list Save parameter settings in the memory module 5.5.1...

- Page 5 Contents 7 Basic setting Mains voltage Inverter load characteristic Control source selection Selection of setpoint source 7.4.1 Keypad setpoint default setting Starting/stopping performance 7.5.1 Starting performance 7.5.2 Stopping performance Frequency limits and ramp times Quick stop S-shaped ramps Optical device identification...

- Page 6 Contents 8 Motor control Motor data 8.1.1 Manual setting of the motor data Motor control selection 8.2.1 V/f characteristic control (VFC) 8.2.1.1 Linear V/f characteristic 8.2.1.2 Square-law V/f characteristic 8.2.1.3 User-definable V/f characteristic 8.2.1.4 V/f characteristic control - energy-saving (VFC Eco) 8.2.2 V/f characteristic control (VFC closed loop) 8.2.3...

- Page 7 Contents Motor protection 8.7.1 Motor overload monitoring (i²*t) 8.7.2 Motor temperature monitoring 8.7.3 Current limits 8.7.4 Overcurrent monitoring 8.7.5 Motor phase failure detection 8.7.6 Motor speed monitoring 8.7.7 Motor torque monitoring...

- Page 8 General network settings Predefined process data words 9.2.1 Device profile CiA 402 9.2.2 AC Drive Profile 9.2.3 Lenze LECOM profile 9.2.4 Further process data 9.2.5 Parameter access monitoring (PAM) 9.2.6 Process data handling in case of error Acyclic data exchange CANopen 9.4.1...

- Page 9 Contents PROFIBUS 9.6.1 Introduction 9.6.2 Communication time setting 9.6.3 Station address setting 9.6.4 Baud rate setting 9.6.5 Monitoring 9.6.6 LED status displays 9.6.7 Diagnostics 9.6.8 Functions 9.6.9 Data mapping 9.6.10 Parameter data transfer 9.6.11 Read parameter data 9.6.12 Write parameter data 9.6.13 Error codes for parameter data transfer 9.6.14...

- Page 10 Contents 9.10 EtherCAT 9.10.1 Device identification 9.10.2 EtherCAT configuration 9.10.3 LED status displays 9.10.4 Diagnostics 9.10.5 Monitoring 9.10.6 Objects 9.10.7 Process data transfer 9.10.8 Parameter data transfer 9.10.9 Short setup 9.11 POWERLINK 9.11.1 Introduction 9.11.2 Basic settings 9.11.3 LED status displays 9.11.4 Diagnostics 9.11.5...

- Page 11 11.4.1 Example 1: Automatic DC braking when the motor is started 11.4.2 Example 2: Automatic DC braking when the motor is stopped 11.4.3 Migration of Lenze Inverter Drives 8200/8400 11.5 Brake energy management 11.5.1 Use of a brake resistor 11.5.2 Stopping the deceleration ramp function generator 11.5.3...

- Page 12 Contents 11.14 Automatic restart 11.15 Mains failure control 11.15.1 Activating the mains failure control 11.15.2 Restart protection 11.15.3 Fast mains recovery 11.15.4 Commissioning the mains failure control 11.16 UPS operation 11.17 Process data 11.17.1 Position counter 11.18 Encoder settings 11.18.1 HTL encoder 11.18.2 Encoder monitoring...

- Page 13 Contents 14 Flexible I/O configuration 14.1 Control source change-over 14.1.1 Example 1: Change-over from terminal control to keypad control 14.1.2 Example 2: Change-over from terminal control to network control 14.2 Start / stop motor 14.2.1 Example 1: Start/stop (1 signal) and reversal 14.2.2 Example 2: Start forward/start reverse/stop (edge-controlled) 14.2.3...

- Page 14 Contents 14.15 Configuration of digital outputs 14.15.1 Relay 14.15.2 Digital output 1 14.15.3 Digital output 2 14.15.4 NetWordOUT1 status word 14.15.5 HTL output 14.15.5.1 Example 1: Pulse train 0 ... 10 kHz ≡ output frequency 0 ... 100 Hz 14.15.5.2 Example 2: Pulse train 2 ...

-

Page 15: General Information

Read first, then start WARNING! Read this documentation thoroughly before carrying out the installation and commissioning. ▶ Please observe the safety instructions! Information and tools with regard to the Lenze products can be found on the Internet: http://www.lenze.com à Download... -

Page 16: Safety Instructions

The procedural notes and circuit details described in this document are only proposals. It is up to the user to check whether they can be adapted to the particular applications. Lenze does not take any responsibility for the suitability of the procedures and circuit proposals descri- bed. -

Page 17: Residual Hazards

Safety instructions Application as directed Residual hazards The user must take the residual hazards mentioned into consideration in the risk assessment for his/her machine/system. If the above is disregarded, this can lead to severe injuries to persons and damage to material assets! Product Observe the warning labels on the product! -

Page 18: Mechanical Installation

Mechanical installation Mechanical installation Dimensions 0.25 kW ... 0.37 kW The dimensions in mm apply to: 0.25 kW I55AE125B I55AE125D 0.37 kW I55AE137B I55AE137D I55AE137F... - Page 19 Mechanical installation Dimensions 0.25 kW ... 0.37 kW The dimensions in mm apply to: 0.25 kW I55AE125A 0.37 kW I55AE137A...

- Page 20 Mechanical installation Dimensions 0.55 kW ... 0.75 kW The dimensions in mm apply to: 0.55 kW I55AE155B I55AE155D I55AE155F 0.75 kW I55AE175B I55AE175D I55AE175F...

- Page 21 Mechanical installation Dimensions 0.75 kW ... 1.1 kW The dimensions in mm apply to: 0.75 kW I55AE175A 1.1 kW I55AE211A...

- Page 22 Mechanical installation Dimensions 1.1 kW ... 2.2 kW The dimensions in mm apply to: 1.1 kW I55AE211B I55AE211D I55AE211F 1.5 kW I55AE215B I55AE215D I55AE215F 2.2 kW I55AE222B I55AE222D I55AE222F...

- Page 23 Mechanical installation Dimensions 3 kW ... 5.5 kW The dimensions in mm apply to: 3 kW I55AE230F 4 kW I55AE240C I55AE240F 5.5 kW I55AE255C I55AE255F...

- Page 24 Mechanical installation Dimensions 7.5 kW ... 11 kW The dimensions in mm apply to: 7.5 kW I55AE275F 11 kW I55AE311F...

- Page 25 Mechanical installation Dimensions 15 kW ... 22 kW The dimensions in mm apply to: 15 kW I55AE315F 18.5 kW I55AE318F 22 kW I55AE322F...

- Page 26 Mechanical installation Dimensions 30 kW ... 45 kW The dimensions in mm apply to: 30 kW I55AE330F 37 kW I55AE337F 45 kW I55AE345F...

- Page 27 Mechanical installation Dimensions 55 kW ... 75 kW The dimensions in mm apply to: 55 kW I55AE355F 75 kW I55AE375F...

-

Page 28: Electrical Installation

Electrical installation Important notes Electrical installation Important notes DANGER! Dangerous electrical voltage Possible consequence: death or severe injuries ▶ All work on the inverter must only be carried out in the deenergised state. ▶ After switching off the mains voltage, wait for at least 3 minutes before you start working. -

Page 29: Mains Connection

Electrical installation Mains connection 1-phase mains connection 120 V Mains connection 4.2.1 1-phase mains connection 120 V 4.2.1.1 Connection plan The connection plan is valid for the inverters I55AExxxA. Inverters I55AExxxA do not have an integrated RFI filter in the AC mains supply. In order to meet the EMC requirements according to EN 61800−3, an external EMC filter according to IEC EN 60939 must be used. -

Page 30: Fusing And Terminal Data

Electrical installation Mains connection 1-phase mains connection 120 V 4.2.1.2 Fusing and terminal data Fuse data Inverter I55AE125A I55AE175A I55AE137A I55AE211A Cable installation in compliance with EN 60204-1 Installation method operation without mains choke Fuse Characteristics gG/gL or gRL Max. rated current Circuit breaker Characteristics Max. - Page 31 Electrical installation Mains connection 1-phase mains connection 120 V Mains connection Inverter I55AE125A I55AE175A I55AE137A I55AE211A Connection X100 Connection type pluggable screw terminal Min. cable cross-section mm² Min. cable cross-section Max. cable cross-section mm² Max. cable cross-section Stripping length Stripping length inch 0.32 Tightening torque...

-

Page 32: 1-Phase Mains Connection 230/240 V

Electrical installation Mains connection 1-phase mains connection 230/240 V 4.2.2 1-phase mains connection 230/240 V 4.2.2.1 Connection plan The connection plan is valid for the inverters I55AExxxB. 3/N/ PE 3/N/ PE 2/N/ PE 400 V 208 V ... 240 V 208 V ... - Page 33 Electrical installation Mains connection 1-phase mains connection 230/240 V The connection plan is valid for the inverters I55AExxxD. Inverters I55AExxxD do not have an integrated RFI filter in the AC mains supply. In order to meet the EMC requirements according to EN 61800−3, an external EMC filter according to IEC EN 60939 must be used.

-

Page 34: Fusing And Terminal Data

Electrical installation Mains connection 1-phase mains connection 230/240 V 4.2.2.2 Fusing and terminal data Fuse data Inverter I55AE125B I55AE125D I55AE155B I55AE155D I55AE137B I55AE137D I55AE175B I55AE175D Cable installation in compliance with EN 60204-1 Installation method operation without mains choke Fuse Characteristics gG/gL or gRL Max. - Page 35 Electrical installation Mains connection 1-phase mains connection 230/240 V Fuse data Inverter I55AE125B I55AE125D I55AE211B I55AE211D I55AE137B I55AE137D I55AE215B I55AE215D I55AE155B I55AE155D I55AE222B I55AE222D I55AE175B I55AE175D Cable installation in compliance with US National Electrical Code NFPA 70 / Canadian Electrical Code C22.1...

- Page 36 Electrical installation Mains connection 1-phase mains connection 230/240 V PE connection Inverter I55AE125B I55AE125D I55AE137B I55AE137D I55AE155B I55AE155D I55AE175B I55AE175D I55AE211B I55AE211D I55AE215B I55AE215D I55AE222B I55AE222D Connection Connection type PE screw Min. cable cross-section mm² Min. cable cross-section Max. cable cross-section mm²...

-

Page 37: 3-Phase Mains Connection 230/240

Electrical installation Mains connection 3-phase mains connection 230/240 V 4.2.3 3-phase mains connection 230/240 V 4.2.3.1 Connection plan The connection plan is valid for the inverters I55AExxxC. Inverters I55AExxxC do not have an integrated RFI filter in the AC mains supply. In order to meet the EMC requirements according to EN 61800−3, an external EMC filter according to IEC EN 60939 must be used. - Page 38 Electrical installation Mains connection 3-phase mains connection 230/240 V The connection plan is valid for the inverters I55AExxxD. Inverters I55AExxxD do not have an integrated RFI filter in the AC mains supply. In order to meet the EMC requirements according to EN 61800−3, an external EMC filter according to IEC EN 60939 must be used.

-

Page 39: Fusing And Terminal Data

Electrical installation Mains connection 3-phase mains connection 230/240 V 4.2.3.2 Fusing and terminal data Fuse data Inverter I55AE211D I55AE125D I55AE155D I55AE240C I55AE215D I55AE137D I55AE175D I55AE255C I55AE222D Cable installation in compliance with EN 60204-1 Installation method operation without mains choke Fuse Characteristics gG/gL or gRL Max. - Page 40 Electrical installation Mains connection 3-phase mains connection 230/240 V Mains connection Inverter I55AE125D I55AE211D I55AE137D I55AE240C I55AE215D I55AE155D I55AE255C I55AE222D I55AE175D Connection X100 Connection type pluggable screw terminal Screw terminal Min. cable cross-section mm² Min. cable cross-section Max. cable cross-section mm²...

-

Page 41: 3-Phase Mains Connection 400 V

Electrical installation Mains connection 3-phase mains connection 400 V 4.2.4 3-phase mains connection 400 V 4.2.4.1 Connection plan The connection plan is valid for the inverters I55AExxxF. 3/N/ PE AC 400 V … 3/ PE 340 V ... 528 V 45 Hz ... -

Page 42: Fusing And Terminal Data

Electrical installation Mains connection 3-phase mains connection 400 V 4.2.4.2 Fusing and terminal data Fuse data Inverter I55AE137F I55AE211F I55AE230F I55AE275F I55AE155F I55AE215F I55AE240F I55AE311F I55AE175F I55AE222F I55AE255F Cable installation in compliance with EN 60204-1 Installation method operation without mains choke Fuse Characteristics gG/gL or gRL... - Page 43 Electrical installation Mains connection 3-phase mains connection 400 V Fuse data Inverter I55AE355F I55AE345F I55AE375F Cable installation in compliance with EN 60204-1 Installation method operation Fuse Characteristics Max. rated current Circuit breaker Characteristics Max. rated current operation with mains choke Fuse Characteristics gG/gL or gRL...

- Page 44 Electrical installation Mains connection 3-phase mains connection 400 V Fuse data Inverter I55AE315F I55AE322F I55AE330F I55AE337F I55AE318F Cable installation in compliance with US National Electrical Code NFPA 70 / Canadian Electrical Code C22.1 operation without mains choke Fuse Characteristics all acc. to UL 248 / Class J, T, R Max.

- Page 45 Electrical installation Mains connection 3-phase mains connection 400 V Mains connection Inverter I55AE137F I55AE155F I55AE230F I55AE315F I55AE330F I55AE175F I55AE275F I55AE355F I55AE240F I55AE318F I55AE337F I55AE211F I55AE311F I55AE375F I55AE255F I55AE322F I55AE345F I55AE215F I55AE222F Connection X100 Connection type pluggable Screw terminal screw terminal Min.

- Page 46 Electrical installation Mains connection 3-phase mains connection 400 V Motor connection Inverter I55AE137F I55AE155F I55AE230F I55AE315F I55AE330F I55AE175F I55AE275F I55AE355F I55AE240F I55AE318F I55AE337F I55AE211F I55AE311F I55AE375F I55AE255F I55AE322F I55AE345F I55AE215F I55AE222F Connection X105 Connection type pluggable Screw terminal screw terminal Min.

-

Page 47: 3-Phase Mains Connection 400 V "Light Duty

Electrical installation Mains connection 3-phase mains connection 400 V "light duty" 4.2.5 3-phase mains connection 400 V "light duty" 4.2.5.1 Connection plan See chapter "3-phase mains connection 400 V". ^ 41... -

Page 48: Fusing And Terminal Data

Electrical installation Mains connection 3-phase mains connection 400 V "light duty" 4.2.5.2 Fusing and terminal data Fuse data Inverter I55AE230F I55AE240F I55AE275F I55AE311F I55AE315F I55AE255F Cable installation in compliance with EN 60204-1 Installation method operation without mains choke without mains choke Fuse Characteristics gG/gL or gRL... - Page 49 Electrical installation Mains connection 3-phase mains connection 400 V "light duty" Fuse data Inverter I55AE355F I55AE390F I55AE375F Cable installation in compliance with EN 60204-1 Installation method operation Fuse Characteristics Max. rated current Circuit breaker Characteristics Max. rated current operation with mains choke Fuse Characteristics Max.

- Page 50 Electrical installation Mains connection 3-phase mains connection 400 V "light duty" Fuse data Inverter I55AE318F I55AE330F I55AE337F I55AE345F I55AE322F Cable installation in compliance with US National Electrical Code NFPA 70 / Canadian Electrical Code C22.1 operation Fuse Characteristics Max. rated current Circuit breaker Characteristics Max.

- Page 51 Electrical installation Mains connection 3-phase mains connection 400 V "light duty" Mains connection Inverter I55AE230F I55AE315F I55AE330F I55AE275F I55AE355F I55AE240F I55AE318F I55AE337F I55AE390F I55AE311F I55AE375F I55AE255F I55AE322F I55AE345F Connection X100 Connection type Screw terminal Min. cable cross-section mm² Min. cable cross-section Max.

-

Page 52: Connection Plan

Electrical installation Mains connection 3-phase mains connection 480 V 4.2.6 3-phase mains connection 480 V 4.2.6.1 Connection plan The connection plan is valid for the inverters I55AExxxF. 3/N/ PE AC 480 V … 3/ PE 340 V ... 528 V 45 Hz ... -

Page 53: Fusing And Terminal Data

Electrical installation Mains connection 3-phase mains connection 480 V 4.2.6.2 Fusing and terminal data Fuse data Inverter I55AE137F I55AE211F I55AE230F I55AE275F I55AE155F I55AE215F I55AE240F I55AE311F I55AE175F I55AE222F I55AE255F Cable installation in compliance with EN 60204-1 Installation method operation without mains choke Fuse Characteristics gG/gL or gRL... - Page 54 Electrical installation Mains connection 3-phase mains connection 480 V Fuse data Inverter I55AE355F I55AE375F Cable installation in compliance with EN 60204-1 Installation method operation Fuse Characteristics Max. rated current Circuit breaker Characteristics Max. rated current operation with mains choke Fuse Characteristics Max.

- Page 55 Electrical installation Mains connection 3-phase mains connection 480 V Fuse data Inverter I55AE315F I55AE318F I55AE330F I55AE337F I55AE345F I55AE322F Cable installation in compliance with US National Electrical Code NFPA 70 / Canadian Electrical Code C22.1 operation without mains choke Fuse Characteristics all acc.

- Page 56 Electrical installation Mains connection 3-phase mains connection 480 V Mains connection Inverter I55AE137F I55AE155F I55AE230F I55AE315F I55AE330F I55AE175F I55AE275F I55AE355F I55AE240F I55AE318F I55AE337F I55AE211F I55AE311F I55AE375F I55AE255F I55AE322F I55AE345F I55AE215F I55AE222F Connection X100 Connection type pluggable Screw terminal screw terminal Min.

- Page 57 Electrical installation Mains connection 3-phase mains connection 480 V Motor connection Inverter I55AE137F I55AE155F I55AE230F I55AE315F I55AE330F I55AE175F I55AE275F I55AE355F I55AE240F I55AE318F I55AE337F I55AE211F I55AE311F I55AE375F I55AE255F I55AE322F I55AE345F I55AE215F I55AE222F Connection X105 Connection type pluggable Screw terminal screw terminal Min.

-

Page 58: 3-Phase Mains Connection 480 V "Light Duty

Electrical installation Mains connection 3-phase mains connection 480 V "Light Duty" 4.2.7 3-phase mains connection 480 V "Light Duty" 4.2.7.1 Connection plan See chapter "3-phase mains connection 480 V". ^ 52... -

Page 59: Fusing And Terminal Data

Electrical installation Mains connection 3-phase mains connection 480 V "Light Duty" 4.2.7.2 Fusing and terminal data Fuse data Inverter I55AE230F I55AE240F I55AE275F I55AE311F I55AE315F I55AE255F Cable installation in compliance with EN 60204-1 Installation method operation without mains choke without mains choke Fuse Characteristics gG/gL or gRL... - Page 60 Electrical installation Mains connection 3-phase mains connection 480 V "Light Duty" Fuse data Inverter I55AE355F I55AE390F I55AE375F Cable installation in compliance with EN 60204-1 Installation method operation Fuse Characteristics Max. rated current Circuit breaker Characteristics Max. rated current operation with mains choke Fuse Characteristics Max.

- Page 61 Electrical installation Mains connection 3-phase mains connection 480 V "Light Duty" Fuse data Inverter I55AE318F I55AE330F I55AE337F I55AE345F I55AE322F Cable installation in compliance with US National Electrical Code NFPA 70 / Canadian Electrical Code C22.1 operation Fuse Characteristics Max. rated current Circuit breaker Characteristics Max.

- Page 62 Electrical installation Mains connection 3-phase mains connection 480 V "Light Duty" Mains connection Inverter I55AE230F I55AE315F I55AE330F I55AE275F I55AE355F I55AE240F I55AE318F I55AE337F I55AE390F I55AE311F I55AE375F I55AE255F I55AE322F I55AE345F Connection X100 Connection type Screw terminal Min. cable cross-section mm² Min. cable cross-section Max.

-

Page 63: Control Connections

Electrical installation Control connections Control connections Terminal description Relay output PTC input Control terminals Connection X109 Connection type pluggable screw terminal pluggable screw terminal pluggable spring terminal Min. cable cross-section mm² Min. cable cross-section Max. cable cross-section mm² Max. cable cross-section Stripping length Stripping length inch... -

Page 64: Networks

Electrical installation Networks CANopen Networks 4.4.1 CANopen Typical topologies Line X216 X216 X216 X216 Terminal description CANopen Connection X216 Connection type pluggable spring terminal Min. cable cross-section mm² Min. cable cross-section Max. cable cross-section mm² Max. cable cross-section Stripping length Stripping length inch 0.39... -

Page 65: Modbus Rtu

Electrical installation Networks Modbus RTU 4.4.2 Modbus RTU Typical topologies Line X216 X216 X216 X216 Terminal description Modbus RTU Connection X216 Connection type pluggable spring terminal Min. cable cross-section mm² Min. cable cross-section Max. cable cross-section mm² Max. cable cross-section Stripping length Stripping length inch... -

Page 66: Modbus Tcp

Electrical installation Networks Modbus TCP 4.4.3 Modbus TCP Typical topologies Line Tree Master Switch Slave Basic network settings The rotary encoder switch allows you to set the last byteof the IP address. Setting Value of last byte Resulting IP address 0x00 Value from parameter Value from parameter... -

Page 67: Profibus

Electrical installation Networks PROFIBUS 4.4.4 PROFIBUS Typical topologies Line with repeater Master Repeater Slave Activated bus terminating resistor Terminal description PROFIBUS Connection X226 Connection type Sub-D 9p Min. cable cross-section mm² Min. cable cross-section Max. cable cross-section mm² Max. cable cross-section Stripping length Stripping length inch... -

Page 68: Ethercat

Electrical installation Networks EtherNet/IP 4.4.5 EtherCAT Typical topologies Line Master Slave Device Basic network settings The rotary encoder switch allows you to set an EtherCAT identifier. Setting Identifier 0x00 Value from parameter 0x01 ... 0xFF Switch position 4.4.6 EtherNet/IP Typical topologies Line Tree Ring... -

Page 69: Profinet

Electrical installation Networks PROFINET 4.4.7 PROFINET Typical topologies Line Tree Ring IO controller Switch SCALANCE (MRP capable) IO device Redundant domain The rotary encoder switch has no function. -

Page 70: Powerlink

Electrical installation Connection of the safety module 4.4.8 POWERLINK Typical topologies Line CN1n CN11 CN12 CN2n CN21 CN22 Mrated Managing Node Controlled Node Basic network settings The rotary encoder switch allows you to set the node address (last byte of the IP address). Setting Node address Resulting IP address... -

Page 71: Commissioning

Commissioning Important notes Commissioning Important notes WARNING! Incorrect wiring can cause unexpected states during the commissioning phase. Possible consequence: death, severe injuries or damage to property Check the following before switching on the mains voltage: ▶ Is the wiring complete and correct? ▶... -

Page 72: Operating Interfaces

Commissioning Operating interfaces Keypad Operating interfaces Commissioning the inverter requires an operator-process interface. 5.2.1 Keypad The keypad is an easy means for the local operation, parameterisation, and diagnostics of the inverter. The keypad is simply connected to the diagnostic interface on the front of the inverter. •... -

Page 73: Engineering Tool »Easy Starter

Engineering tool »EASY Starter« The »EASY Starter« is a PC software that is especially designed for the commissioning and maintenance of the inverter. The »EASY Starter« PC software can be found on the Internet: http://www.lenze.com à Download à Software Downloads Sample screenshot:... -

Page 74: Generate A Connection Between Inverter And »Easy Starter

Commissioning Operating interfaces Engineering tool »EASY Starter« 5.2.2.1 Generate a connection between inverter and »EASY Starter« For commissioning the inverter with the »EASY Starter«, a communication link with the inver- ter is required. This can be established in a wired or wireless manner via WLAN. Preconditions For the wired communication with the inverter, the USB module and a USB 2.0 cable (A •... - Page 75 Commissioning Operating interfaces Engineering tool »EASY Starter« Details The following instructions describe the connection establishment via the USB module. Parameterising without motor operation does not require a mains voltage: If you connect • the inverter directly to the PC without a hub, The USB interface of the PC is sufficient for the voltage supply.

-

Page 76: Parameter Setting

Commissioning Parameter setting Parameter setting As a part of a machine with a speed-variable drive system, the inverter must be adapted to its drive task. The adaptation process of the inverter is carried out by changing parameters. Optionally these parameters can be accessed by means of the keypad or »EASY Starter«. If the inverter is provided with a network option, access can also be effected by a higher-level Con- troller via the corresponding network. -

Page 77: General Notes On Parameters

Commissioning Parameter setting General notes on parameters 5.3.1 General notes on parameters Each parameter features a 16-bit index as address. Under this address, the parameter is stored in the object directory of the inverter. Parameters that belong together functionally are combined in a data set. These parame- •... -

Page 78: Basic Inverter Settings

Commissioning Parameter setting Basic inverter settings 5.3.2 Basic inverter settings Check the following basic settings of the inverter and adapt them, if required. Parameter Name / value range / [default setting] Info 0x2540:001 Mains settings: Rated mains voltage Selection of the mains voltage for actuating the inverter. (P208.01) (Mains settings: Mains voltage) •... - Page 79 Commissioning Parameter setting Basic inverter settings Parameter Name / value range / [default setting] Info 0x2860:001 Frequency control: Default setpoint source Selection of the standard setpoint source for operating mode "MS: (P201.01) (Stnd. setpoints: Freq. setp. src.) Velocity mode". • The selected standard setpoint source is always active in the operat- ing mode 0x6060 (P301.00) = "MS: Velocity mode [-2]"...

- Page 80 Commissioning Parameter setting Basic inverter settings Parameter Name / value range / [default setting] Info 0x2911:001 Frequency setpoint presets: Preset 1 Parameterisable frequency setpoints (presets) for operating mode "MS: (P450.01) (Freq. presets: Freq. preset 1) Velocity mode". 0.0 ... [20.0] ... 599.0 Hz 0x2911:002 Frequency setpoint presets: Preset 2 (P450.02)

-

Page 81: Basic Motor Settings

Commissioning Parameter setting Basic motor settings 5.3.3 Basic motor settings Check the following default settings for the motor and motor control and adapt them, if required. Drive behaviour by default By default, the V/f characteristic control with a linear characteristic is preset as motor control for asynchronous motors. -

Page 82: Function Assignment Of The Inputs And Outputs

Commissioning Parameter setting Function assignment of the inputs and outputs 5.3.4 Function assignment of the inputs and outputs The inverter control can be adapted individually to the respective application. This is basically effected by assigning digital control sources ("triggers") to functions of the inverter. By default, the inverter can be controlled via the I/O terminals as follows: Input signals Mains voltage... - Page 83 Commissioning Parameter setting Function assignment of the inputs and outputs Parameter Name / value range / [default setting] Info 0x2631:002 Function list: Run Assignment of a trigger to the "Run" function. (P400.02) (Function list: Run) • Setting can only be changed if the inverter is inhibi- Function 1: Start / stop motor (default setting) ted.

- Page 84 Commissioning Parameter setting Function assignment of the inputs and outputs Parameter Name / value range / [default setting] Info 0x2634:002 Digital outputs function: Digital output 1 Assignment of a trigger to digital output 1. (P420.02) (Dig.out.function: DO1 function) Trigger = FALSE: X3/DO1 set to LOW level. •...

-

Page 85: Keypad Parameter List

Commissioning Keypad parameter list Keypad parameter list For commissioning or diagnostics using the keypad, all parameters of the inverter that can also be accessed by means of the keypad are listed in the following "Keypad parameter list". The keypad parameter list is sorted in ascending order in compliance with the "display •... - Page 86 Commissioning Keypad parameter list How to read the keypad parameter list: Column Meaning Display code Parameter number on the keypad. Format: Number.Subindex Short designation Short keypad designation limited to 16 characters. Default setting Default setting of the parameter. Setting range Possible setting range for the parameter.

- Page 87 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P117.01 Heatsink temp. x.x °C - (Read only) 0x2D84:001 general P118.00 Digital inputs - (Read only) 0x60FD general P119.00 Keypad status - (Read only) 0x2DAC general P120.00 Int.

- Page 88 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P190.08 OBD version - (Read only) 0x2000:008 general └ P190.10 PU firmware ver. - (Read only) 0x2000:010 general └ P190.11 PU firmware type - (Read only) 0x2000:011 general └...

- Page 89 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category P301.00 Modes of op. MS: Velocitymode [-2] Selection list 0x6060 general P302.00 V/f charac.shape Linear [0] Selection list 0x2B00 general P303.xx V/f shape data └ P303.01 Base voltage 230 V * 0 ...

- Page 90 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category P324.00 Max current 200.0 % 0.0 ... 3000.0 % 0x6073 general P325.00 Motor torque 1.650 Nm * 0.001 ... 4294967.295 Nm 0x6076 MCTRL P326.00 Max torque 250.0 % 0.0 ...

- Page 91 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P351.03 Magn. current 0.96 A * 0.00 ... 500.00 A 0x2C02:003 MCTRL └ P351.04 Slip frequency x.x Hz - (Read only) 0x2C02:004 general P352.xx PSM motor par. └...

- Page 92 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P400.47 PID-I inhibited Not connected [0] Selection list 0x2631:047 general └ P400.48 PID-Inf ramp on TRUE [1] Selection list 0x2631:048 general └ P400.49 Release brake Not connected [0] Selection list 0x2631:049...

- Page 93 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P420.13 NetWordOUT1.03 Error [56] Selection list 0x2634:013 general └ P420.14 NetWordOUT1.04 Not connected [0] Selection list 0x2634:014 general └ P420.15 NetWordOUT1.05 Quick stop [54] Selection list 0x2634:015 general └...

- Page 94 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P431.07 AI2 dead band 0.0 % 0.0 ... 100.0 % 0x2637:007 general └ P431.08 AI2 monit.level 0.0 % -100.0 ... 100.0 % 0x2637:008 general └ P431.09 AI2 error resp.

- Page 95 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P500.01 Active module ID - (Read only) 0x231F:001 general └ P500.02 Module ID conn. - (Read only) 0x231F:002 general P505.xx NetWordIN1 fct. └ P505.01 NetWordIN1.00 Not active [0] Selection list 0x400E:001...

- Page 96 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P510.03 Data format Automatic [0] Selection list 0x2321:003 Modbus RTU └ P510.04 Min. resp. time 0 ms 0 ... 1000 ms 0x2321:004 Modbus RTU P510.xx MBTCP settings └...

- Page 97 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P512.01 Port 1 Auto-Negotiation [0] Selection list 0x23B4:001 Modbus TCP └ P512.02 Port 2 Auto-Negotiation [0] Selection list 0x23B4:002 Modbus TCP P512.xx PROFIBUS Config. └ P512.01 Ext.

- Page 98 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category P516.00 PROFINET status - (Read only) 0x2388 PROFINET P517.00 CAN contr.status - (Read only) 0x2309 CANopen P517.00 EtherCAT error - (Read only) 0x2369 EtherCAT P517.00 EtherN/IP status - (Read only) 0x23A9 EtherNet/IP...

- Page 99 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P551.02 Transm. type 0 ... 255 0x1801:002 CANopen └ P551.03 Inhibit time 0.0 ms 0.0 ... 6553.5 ms 0x1801:003 CANopen └ P551.05 Event timer 0 ms 0 ...

- Page 100 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P583.16 Last RxD byte14 - (Read only) 0x232E:016 Modbus RTU └ P583.17 Last RxD byte15 - (Read only) 0x232E:017 Modbus RTU P585.xx Tx data diagn. └...

- Page 101 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P593.08 Frequency 0.02Hz - (Read only) 0x400C:008 general └ P593.09 Freq. [+/-16384] - (Read only) 0x400C:009 general P595.xx PAM monitoring └ P595.02 Keep alive reg. 0 ...

- Page 102 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P700.08 Load par. set 2 Off / ready [0] Selection list 0x2022:008 general └ P700.09 Load par. set 3 Off / ready [0] Selection list 0x2022:009 general └...

- Page 103 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P712.15 Brake status - (Read only) 0x2820:015 general P718.xx Flying restart └ P718.01 Current 30 % 0 ... 100 % 0x2BA1:001 MCTRL └ P718.02 Start frequency 20.0 Hz -599.0 ...

- Page 104 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P740.35 Parameter 35 0x26311200 0x00000000 ... 0xFFFFFF00 0x261C:035 general └ P740.36 Parameter 36 0x26311300 0x00000000 ... 0xFFFFFF00 0x261C:036 general └ P740.37 Parameter 37 0x26311400 0x00000000 ... 0xFFFFFF00 0x261C:037 general └...

- Page 105 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category P790.00 Quick stop dec. 546000 pos. unit/s² 0 ... 2147483647 pos. unit/s² 0x6085 general P791.00 Fault reaction Coasting [0] Selection list 0x605E general P800.00 Sequencer mode Disabled [0] Selection list 0x4025...

- Page 106 Commissioning Keypad parameter list Display code Short designation Default setting Setting range Address Category └ P807.03 Time 0.0 s 0.0 ... 100000.0 s 0x402C:003 general └ P807.04 Digital outp. 0 ... 255 0x402C:004 general └ P807.05 Analog outp. 0.00 VDC 0.00 ...

-

Page 107: Save Parameter Settings In The Memory Module

Commissioning Save parameter settings in the memory module Save parameter settings with »EASY Starter« Save parameter settings in the memory module 5.5.1 Save parameter settings with keypad If one parameter setting has been changed with the keypad but has not been saved in the memory module with mains failure protection, the SET display is blinking. -

Page 108: Diagnostics And Fault Elimination

Diagnostics and fault elimination LED status display Diagnostics and fault elimination LED status display The "RDY" and "ERR" LED status displays on the front of the inverter provide some quick infor- mation about certain operating states. "RDY" LED (blue) "ERR" LED (red) Status/meaning No supply voltage. -

Page 109: Diagnostics Parameter

Diagnostics and fault elimination Diagnostics parameter Diagnostics parameter The inverter provides many diagnostic parameters which are helpful for operation, mainte- nance, error diagnosis, error correction, etc. In the following overview the most common diagnostic parameters are listed. For the key- •... -

Page 110: Logbook

Diagnostics and fault elimination Diagnostics parameter Logbook 6.2.1 Logbook For diagnostic purposes, the logbook contains the last 32 error messages and warning signals of the inverter, which have occurred during operation. Preconditions The logbook can only be accessed via the user interface of »EASY Starter« ("Diagnostics" tab) or •... -

Page 111: Error History Buffer

Diagnostics and fault elimination Diagnostics parameter Error history buffer 6.2.2 Error history buffer For purposes of diagnostics, the error history buffer contains the last 32 error and warning messages of the inverter, which have occurred during operation. The error history buffer can be read out using the keypad via P155.00 and provides a limited view on the logbook. - Page 112 Diagnostics and fault elimination Diagnostics parameter Error history buffer Parameter Name / value range / [default setting] Info 0x2006:002 Error history buffer: Latest message Display of the subindex of the most recent message. • Read only 0x2006:003 Error history buffer: Latest acknowledgement mes- 0 = delete all entries in the error history buffer.

- Page 113 Diagnostics and fault elimination Diagnostics parameter Error history buffer Parameter Name / value range / [default setting] Info 0x2006:028 Error history buffer: Message 22 Error history buffer entry 23 • Read only 0x2006:029 Error history buffer: Message 23 Error history buffer entry 24 •...

-

Page 114: Inverter Diagnostics

Diagnostics and fault elimination Diagnostics parameter Inverter diagnostics 6.2.3 Inverter diagnostics The following parameters supply some information about the current operating status of the inverter. This includes the following information: Active access protection after log-in by means of PIN1/PIN2 • Currently loaded parameter settings •... - Page 115 Diagnostics and fault elimination Diagnostics parameter Inverter diagnostics Parameter Name / value range / [default setting] Info 0x282A:002 Status words: Cause of quick stop Bit coded display of the cause(s) of quick stop. (P126.02) (Status words: Cause of QSP) • Read only Bit 0 Flexible I/O configuration 1 ≡...

- Page 116 Diagnostics and fault elimination Diagnostics parameter Inverter diagnostics Parameter Name / value range / [default setting] Info 0x282B:002 Inverter diagnostics: Active setpoint source Display of the setpoint source that is currently active. (P125.02) (Inverter diag.: Active setpoint) • Read only 0 Not selected 1 Analog input 1 2 Analog input 2...

- Page 117 Diagnostics and fault elimination Diagnostics parameter Inverter diagnostics Parameter Name / value range / [default setting] Info 0x282B:004 Inverter diagnostics: Active drive mode Display of the active drive mode. (P125.04) (Inverter diag.: Drive mode) • Read only 0 Velocity mode "Velocity mode"...

-

Page 118: Network Diagnostics

Diagnostics and fault elimination Diagnostics parameter Inverter diagnostics Parameter Name / value range / [default setting] Info 0x2DAD Internal hardware states Bit-coded display of internal hardware states. (P120.00) (Int. HW states) • Read only Bit 0 Relay 0 ≡ X9/NO-COM open and NC-COM closed. 1 ≡... -

Page 119: Canopen Diagnostics

Diagnostics and fault elimination Diagnostics parameter Network diagnostics Parameter Name / value range / [default setting] Info 0x231F:001 Module ID: Active module ID Display of the network options currently configured in the inverter. (P500.01) (Module ID: Active module ID) • With the help of this module ID, the keypad only shows the communi- •... - Page 120 0x1018:001 Identity object: Vendor ID Display of the manufacturer's identification number. • Read only • The identification number allocated to Lenze by the organisation "CAN in Automation e. V." is "0x0000003B". 0x1018:002 Identity object: Product ID Display of the product code of the inverter.

- Page 121 Diagnostics and fault elimination Diagnostics parameter Network diagnostics Parameter Name / value range / [default setting] Info 0x2308 CANopen status Display of the current fieldbus state (P516.00) (CANopen status) • Read only 0 Initialisation Fieldbus initialisation active. • The initialisation is started automatically at mains connection. During this phase, the inverter us not involved in the data exchange process on the CAN bus.

-

Page 122: Modbus Diagnostics

Diagnostics and fault elimination Diagnostics parameter Network diagnostics 6.2.4.2 Modbus diagnostics The following parameters serve to diagnose the Modbus interface and communication via Modbus. Preconditions Control unit (CU) of the inverter is provided with Modbus. Parameter Name / value range / [default setting] Info 0x2322:001 Active Modbus settings: Active node ID... - Page 123 Diagnostics and fault elimination Diagnostics parameter Network diagnostics Parameter Name / value range / [default setting] Info 0x2342:002 Active PROFIBUS settings: Active baud rate Display of the active baud rate. (P511.02) (PROFIBUS diag.: Active baud rate) • Read only 0 12 Mbps 1 6 Mbps 2 3 Mbps 3 1.5 Mbps...

- Page 124 Diagnostics and fault elimination Diagnostics parameter Network diagnostics Parameter Name / value range / [default setting] Info 0x2349 PROFIBUS error Bit-coded display of PROFIBUS errors. (P517.00) (PROFIBUS error) • Read only Bit 0 Watchdog elapsed Communication with the PROFIBUS master is continuously interrupted, e.

-

Page 125: Ethernet/Ip Diagnostics

Diagnostics and fault elimination Diagnostics parameter Network diagnostics 6.2.4.4 EtherNet/IP diagnostics The following parameters serve to diagnose the EtherNet/IP interface and the communication via EtherNet/IP. Preconditions Control unit (CU) of the inverter is provided with EtherNet/IP. Parameter Name / value range / [default setting] Info 0x23A2:001 Active EtherNet/IP settings: IP address... -

Page 126: Profinet Diagnostics

Diagnostics and fault elimination Diagnostics parameter Network diagnostics Parameter Name / value range / [default setting] Info 0x23A9 EtherNet/IP status Display of the active network status. (P517.00) (EtherN/IP status) • Read only • From version 02.00 Related topics 4EtherNet/IP ^ 316 6.2.4.5 PROFINET diagnostics The following parameters serve to diagnose the PROFINET interface and the communication... -

Page 127: Ethercat Diagnostics

Diagnostics and fault elimination Diagnostics parameter Network diagnostics Parameter Name / value range / [default setting] Info 0x2389:001 PROFINET error: Error 1 The parameter currently contains the error detected on the network. (P517.01) (PROFINET error: Error 1) • The error values may occur in combination with the error values from •... -

Page 128: Powerlink Diagnostics

Diagnostics and fault elimination Diagnostics parameter Network diagnostics Parameter Name / value range / [default setting] Info 0x1018:002 Identity object: Product ID Display of the product code of the inverter. • Read only • From version 02.00 0x1018:003 Identity object: Revision number Display of the main and subversion of the firmware. -

Page 129: Diagnostics Of The Inputs And Outputs

Diagnostics and fault elimination Diagnostics parameter Network diagnostics Parameter Name / value range / [default setting] Info 0x1008 NMT_ManufactDevName_VS Display of the manufacturer device name. • Read only 0x1009 NMT_ManufactHwVers_VS Display of the manufacturer hardware version. • Read only 0x100A NMT_ManufactSwVers_VS Display of the manufacturer software version. -

Page 130: Analog Inputs And Outputs

Diagnostics and fault elimination Diagnostics parameter Diagnostics of the inputs and outputs Parameter Name / value range / [default setting] Info 0x4016:005 Digital output 1: Terminal state Display of the logic state of output terminal X3/DO1. • Read only 0 FALSE 1 TRUE 0x4016:006 Digital output 1: Trigger signal state... - Page 131 Diagnostics and fault elimination Diagnostics parameter Diagnostics of the inputs and outputs Parameter Name / value range / [default setting] Info 0x2DA4:016 Diagnostics of analog input 1: Status Bit-coded display of the status of analog input 1 (X3/AI1). (P110.16) (AI1 diagnostics: AI1 status) •...

-

Page 132: Wireless-Lan Diagnostics

Diagnostics and fault elimination Diagnostics parameter Wireless-LAN diagnostics Related topics 4Configuration of analog inputs ^ 597 4Configuration of analog outputs ^ 617 6.2.6 Wireless-LAN diagnostics The following parameters serve to diagnose the WLAN module and the WLAN communica- tion. Preconditions WLAN module has been plugged onto the interface X16 on the front of the inverter. -

Page 133: Setpoint Diagnostic

Diagnostics and fault elimination Diagnostics parameter Setpoint diagnostic 6.2.7 Setpoint diagnostic The following parameters show the current setpoints of different setpoint sources. Parameter Name / value range / [default setting] Info 0x282B:007 Inverter diagnostics: Default frequency setpoint Display of the frequency setpoint of the standard setpoint source set in •... -

Page 134: Sequencer Diagnostics

Diagnostics and fault elimination Diagnostics parameter Process controller status Parameter Name / value range / [default setting] Info 0x401F:003 Status Bit-coded status display of the process controller. (P121.03) (PID status) • Read only Bit 0 Process controller off Bit 1 PID output set to 0 Bit 2 PID I-component inhibited Bit 3 PID influence active Bit 4 Setpoint = actual value... -

Page 135: Device Identification

Diagnostics and fault elimination Diagnostics parameter Sequencer diagnostics Parameter Name / value range / [default setting] Info 0x2DAE:008 Sequencer diagnostics: Relative sequence time Display of the residual time of the sequence in [%]. (P140.08) remaining (Sequencer diag: SeqTime remain %) •... -

Page 136: Device Overload Monitoring (I*T)

Diagnostics and fault elimination Diagnostics parameter Device identification Parameter Name / value range / [default setting] Info 0x2000:016 Device data: Bootloader revision number Bootloader version of the network option. (P190.16) (Device data: Bootloader revNo) • Read only 0x2001 Device name Any device name (e.g. -

Page 137: Heatsink Temperature Monitoring

Diagnostics and fault elimination Diagnostics parameter Heatsink Temperature Monitoring Parameter Name / value range / [default setting] Info 0x2D40:005 Device utilisation (i*t): Error response Selection of the response to be executed when the device overload (P135.05) (Device utilisat.: Error response) monitoring function is triggered. - Page 138 Diagnostics and fault elimination Diagnostics parameter Life-diagnosis Parameter Name / value range / [default setting] Info 0x2D81:008 Life-diagnosis: Clamp active Display of the number of "Imax: Clamp responded too often" errors that (P151.08) (Life-diagnosis: Clamp active) have occurred. • Read only •...

-

Page 139: Error Handling

Diagnostics and fault elimination Error handling Error types Error handling Many functions integrated in the inverter can detect errors and thus protect inverter and motor from damages, • detect an operating error of the user, • output a warning or information if desired. •... -

Page 140: Error Configuration

Diagnostics and fault elimination Error handling Keypad error messages 6.3.2 Error configuration The errors can be divided into two types: Errors with predefined error type • Errors with configurable error type • Especially critical errors are permanently set to the "Fault" error type in order to protect inver- ter and motor from damages. -

Page 141: Data Handling

Diagnostics and fault elimination Data handling Data handling In the following, the behaviour of the inverter is described if the data on the memory module do not match the inverter hardware or firmware, for whatever reason. The following points are described in detail here: Automatic loading of the parameter settings when the inverter is switched on •... - Page 142 Diagnostics and fault elimination Data handling Manual loading of the OEM data via device command Device command: "Load OEM data" 0x2022:005 (P700.05) If the OEM memory contains invalid parameter settings, the user parameter settings are • loaded automatically. If the OEM memory is empty, the status feedback "Action cancelled" takes place. The cur- •...

-

Page 143: Basic Setting

Basic setting Basic setting This chapter contains the most frequently used functions and settings to adapt the inverter to a simple application based on the default setting. Mains voltage • ^ 144 Inverter load characteristic • ^ 146 Control source selection •... -

Page 144: Mains Voltage

Basic setting Mains voltage Mains voltage The rated mains voltage set for the inverter has an impact on the operating range of the inver- ter. Details By default, the rated mains voltage in 0x2540:001 (P208.01) is set according to the product code of the inverter. - Page 145 Basic setting Mains voltage Parameter Name / value range / [default setting] Info 0x2540:001 Mains settings: Rated mains voltage Selection of the mains voltage for actuating the inverter. (P208.01) (Mains settings: Mains voltage) • Setting can only be changed if the inverter is inhibi- ted.

-

Page 146: Inverter Load Characteristic

Basic setting Inverter load characteristic Inverter load characteristic The inverter has two different load characteristics: "Light Duty" and "Heavy Duty". The load characteristic "Light Duty" enables a higher output current with restrictions regarding over- load capacity, ambient temperature and switching frequency. This enables the motor required for the application to be driven by a less powerful inverter. -

Page 147: Control Source Selection

Basic setting Control source selection Control source selection The selected "control source" serves to provide the inverter with its start, stop, and reversal commands. Possible control sources are: Digital inputs • Keypad • Network • Irrespective of the control source selection, stop commands are always active from each source connected! If, for instance, the network control is active and a keypad is connected for diagnostic purposes, the motor is also stopped if the keypad key... -

Page 148: Selection Of Setpoint Source

Basic setting Selection of setpoint source Selection of setpoint source The selected "setpoint source" serves to provide the inverter with its setpoint. The setpoint source can be selected individually for each operating mode. Possible setpoint sources are: Analog inputs • Keypad •... - Page 149 Basic setting Selection of setpoint source Parameter Name / value range / [default setting] Info 31 Segment preset 1 For the setpoint selection, the segment presets parameterised for the (from version 03.00) "sequencer" function can be selected as well. 32 Segment preset 2 (from version 03.00) 4Sequencer ^ 504...

- Page 150 Basic setting Selection of setpoint source Parameter Name / value range / [default setting] Info 0x2860:002 PID control: Default setpoint source Selection of the standard setpoint source for the reference value of the (P201.02) (Stnd. setpoints: PID setp. src.) PID control. •...

-

Page 151: Keypad Setpoint Default Setting

Basic setting Selection of setpoint source Keypad setpoint default setting Parameter Name / value range / [default setting] Info 0x2860:003 Torque control: Default setpoint source Selection of the standard setpoint source for operating mode "MS: Tor- (P201.03) (Stnd. setpoints: Torque setp.src.) que mode". - Page 152 Basic setting Selection of setpoint source Keypad setpoint default setting Parameter Name / value range / [default setting] Info 0x2601:003 Keypad setpoints: Torque setpoint Default setting of the keypad setpoint for the operating mode 0x6060 (P202.03) (Keypad setpoints: KP torq.setpoint) (P301.00) = "MS: Torque mode [-1]".

-

Page 153: Starting/Stopping Performance

Basic setting Starting/stopping performance Starting performance Starting/stopping performance 7.5.1 Starting performance The start can be optionally made with DC braking or flying restart circuit. Moreover, an auto- matic start can be activated after switch-on. Details The start method can be selected in 0x2838:001 (P203.01). - Page 154 Basic setting Starting/stopping performance Starting performance Automatic start after switching on the mains voltage The automatic start can be activated in 0x2838:002 (P203.02). Preconditions for the automatic start: Flexible I/O configuration is selected: 0x2824 (P200.00) = "Flexible I/O configuration [0]" •...

-

Page 155: Stopping Performance

Basic setting Starting/stopping performance Stopping performance 7.5.2 Stopping performance In the default setting, the motor is brought to a standstill after a stop command with standard ramp. Alternatively, coasting or ramping down with quick stop ramp can be selected. Details The stop method can be selected in 0x2838:003 (P203.03). -

Page 156: Frequency Limits And Ramp Times

Basic setting Frequency limits and ramp times Frequency limits and ramp times The frequency range can be limited by setting a minimum and maximum frequency. For the frequency setpoint, two different ramps can be parameterised. Change-over to ramp 2 can be carried out manually or automatically. - Page 157 Basic setting Frequency limits and ramp times Parameter Name / value range / [default setting] Info 0x2917 Acceleration time 1 Acceleration time 1 for the operating mode "MS: Velocity mode". (P220.00) (Accelerat.time 1) • The acceleration time set refers to the acceleration from standstill to 0.0 ...

- Page 158 Basic setting Frequency limits and ramp times Example for operating mode Parameter Name Setting for this example 0x2631:001 (P400.01) Enable inverter Constant TRUE [1] 0x2631:002 (P400.02) Digital input 1 [11] 0x2915 (P210.00) Minimum frequency 15 Hz 0x2916 (P211.00) Maximum frequency 40 Hz 0x2917 (P220.00) Acceleration time 1...

-

Page 159: Quick Stop

Basic setting Quick stop Quick stop The "quick stop" function is an alternative stop method if the motor has to be stopped faster than normal. Cancelling the quick stop causes a restart of the motor if the start command is still active and the inverter is enabled! Details Possible triggers to be selected for the "quick stop"... - Page 160 Basic setting Quick stop Example for operating mode Parameter Name Setting for this example 0x2631:001 (P400.01) Enable inverter Constant TRUE [1] 0x2631:002 (P400.02) Digital input 1 [11] 0x2631:003 (P400.03) Activate quick stop Digital input 2 [12] 0x2838:003 (P203.03) Stop method Standard ramp [1] 0x2916 (P211.00) Maximum frequency...

-

Page 161: S-Shaped Ramps

Basic setting S-shaped ramps S-shaped ramps In order to reduce the jerk and to therefore prevent the drive components from damage, a smoothing factor can be set for the acceleration/deceleration ramps. Details In the default setting, the motor is accelerated and decelerated with linear ramps since this is the most used configuration. -

Page 162: Optical Device Identification

Basic setting Optical device identification Optical device identification For applications including several interconnected inverters it may be difficult to locate a device that has been connected online. The "Optical device identification" function serves to locate the inverter by means of blinking LEDs. Details In order to start the visual tracking, click the button in the toolbar of the »EASY Starter«... -

Page 163: Motor Control

Whether a setting can be applied or not depends on the motor (Lenze motor yes/no) and the application. If possible, always use the possible setting listed first in the following diagram since this one leads to the most accurate results. -

Page 164: Motor Data

(star or delta connection). Only enter the data applying to the connec- tion type selected. Possible settings If a Lenze motor is connected to the inverter, you can simply select the used motor in the engineering tool from the "motor catalog". For details see chapter "Motor selection from motor... -

Page 165: Motor Control Selection

Motor control Motor control selection Motor control selection Setting of motor data Motor control selection Optimisation of motor control Optimisation of the control loops The inverter supports different modes for closed-loop/open-loop motor control. Parameter Name / value range / [default setting] Info 0x2C00 Motor control mode... -

Page 166: V/F Characteristic Control (Vfc)

Motor control Motor control selection V/f characteristic control (VFC) 8.2.1 V/f characteristic control (VFC) The V/f characteristic control is a motor control for conventional frequency inverter applica- tions. It is based on a simple and robust control mode for the operation of asynchronous motors with a linear or square-law load torque characteristic (e.g. -

Page 167: Linear V/F Characteristic

Motor control Motor control selection V/f characteristic control (VFC) 8.2.1.1 Linear V/f characteristic The linear V/f characteristic is the most used characteristic shape for general applications since they cause a torque that is largely constant. Details Select V/f characteristic control with linear characteristic: 1. -

Page 168: Square-Law V/F Characteristic

Motor control Motor control selection V/f characteristic control (VFC) 8.2.1.2 Square-law V/f characteristic The square-law V/f characteristic is typically used in heating, ventilation and climate applica- tions to control the speed of fans and pumps. Details Each application that is provided with the features according to the affinity laws may possibly benefit from a square-law V/f characteristic. -

Page 169: User-Definable V/F Characteristic

Motor control Motor control selection V/f characteristic control (VFC) 8.2.1.3 User-definable V/f characteristic The user-definable V/f characteristic is based on the linear V/f characteristic. An additional medium characteristic point, however, enables the adaptation to applications with special tor- que properties. Details An application case for this characteristic shape are applications that require a higher torque at lower speeds. -

Page 170: V/F Characteristic Control - Energy-Saving (Vfc Eco)

Motor control Motor control selection V/f characteristic control (VFC) 8.2.1.4 V/f characteristic control - energy-saving (VFC Eco) In case of the energy-saving V/f characteristic control (VFCplusEco). the motor voltage of the inverter is detected by means of a linear characteristic as a function of the rotating field fre- quency or motor speed to be generated. - Page 171 Motor control Motor control selection V/f characteristic control (VFC) Parameter Name / value range / [default setting] Info 0x2B00 V/f characteristic shape Selection of the V/f characteristic shape for the adaptation to different (P302.00) (V/f charac.shape) load profiles. • Setting can only be changed if the inverter is inhibi- ted.

-

Page 172: V/F Characteristic Control (Vfc Closed Loop)

Motor control Motor control selection V/f characteristic control (VFC closed loop) 8.2.2 V/f characteristic control (VFC closed loop) The V/f characteristic control with feedback (VFC closed loop) can be used if an asynchronous motor with motor encoder is connected to the inverter. The speed feedback leads to the following advantages: Stationary speed accuracy •... -

Page 173: Sensorless Vector Control (Slvc)

Motor control Motor control selection Sensorless vector control (SLVC) 8.2.3 Sensorless vector control (SLVC) Sensorless (field-oriented) vector control for asynchronous motors is based on a decoupled, separate control for the torque-producing and the field-producing current component. In addition, the actual speed is reconstructed by means of a motor model so that a speed sensor is not required. - Page 174 Motor control Motor control selection Sensorless vector control (SLVC) Parameter Name / value range / [default setting] Info 0x2949:001 Positive torque limit source Selection of the source for the positive torque limit source. (P337.01) (Pos. torqlim src) • From version 03.00 0 Max torque Positive torque limit source = Max torque 0x6072...

- Page 175 Motor control Motor control selection Sensorless vector control (SLVC) Parameter Name / value range / [default setting] Info 0x6060 Modes of operation Selection of the operating mode. (P301.00) (Modes of op.) • Setting can only be changed if the inverter is inhibi- ted.

-

Page 176: Servo Control For Asynchronous Motors (Sc-Asm)

Motor control Motor control selection Servo control for asynchronous motors (SC-ASM) 8.2.4 Servo control for asynchronous motors (SC-ASM) The field-oriented servo control is based on a decoupled, separated control of the torque-pro- ducing and field-producing current share. The motor control is based on a feedback, field-ori- ented and cascaded controller structure and enables a dynamic and stable operation in all four quadrants. - Page 177 Motor control Motor control selection Servo control for asynchronous motors (SC-ASM) Parameter Name / value range / [default setting] Info 0x2949:002 Negative torque limit source Selection of the source for the negative torque limit source. (P337.02) (Neg. torqlim src) • From version 03.00 0 (-) Max torque Negative torque limit source = (-) Max torque 0x6072...

-

Page 178: Sensorless Control For Synchronous Motors (Sl-Psm)

Motor control Motor control selection Sensorless control for synchronous motors (SL-PSM) 8.2.5 Sensorless control for synchronous motors (SL-PSM) The sensorless control for synchronous motors is based on a decoupled, separated control of the torque-producing current and the current in field direction. In contrast to the servo con- trol, the actual speed value and rotor position are reconstructed via a motor model. - Page 179 Motor control Motor control selection Sensorless control for synchronous motors (SL-PSM) SL-PSM parameters The parameters for this motor control type are calculated and set automatically while optimis- ing the control loops. 4Optimisation of the control loops ^ 193 Parameter Name / value range / [default setting] Info 0x2C03:001 Back EMF constant...

- Page 180 Motor control Motor control selection Sensorless control for synchronous motors (SL-PSM) Parameter Name / value range / [default setting] Info 0x2949:002 Negative torque limit source Selection of the source for the negative torque limit source. (P337.02) (Neg. torqlim src) • From version 03.00 0 (-) Max torque Negative torque limit source = (-) Max torque 0x6072...

-

Page 181: Stall Monitoring

Motor control Motor control selection Sensorless control for synchronous motors (SL-PSM) 8.2.5.1 Stall monitoring The stalling monitoring for the sensorless control for synchronous motors (SL-PSM) switches off the drive if the motor is about to "stall". A possible cause may be an overload of the motor. Preconditions The stalling monitoring only works in the controlled area and if the motor is not operated in the field weakening range. -

Page 182: Optimisation Of Motor Control

Motor control Optimisation of motor control Optimisation of motor control Setting of motor data Motor control selection Optimisation of motor control Optimisation of the control loops The inverter provides different functions by means of which the drive behaviour can be fur- ther optimised. -

Page 183: V/F Voltage Boost

Motor control Optimisation of motor control V/f voltage boost 8.3.1 V/f voltage boost The parameterisable voltage boost makes it possible to improve the starting performance for applications requiring a high starting torque. Preconditions The function is only effective in the following motor control types: V/f characteristic control (VFC open loop) •... -

Page 184: Skip Frequencies

Motor control Optimisation of motor control Skip frequencies 8.3.2 Skip frequencies By means of the three parameterisable skip frequencies, critical frequencies can be sup- pressed which lead to mechanical resonances in the system. Details A blocking zone is active as soon as the frequency for this blocking zone is set to value unequal to "0 Hz". - Page 185 Motor control Optimisation of motor control Skip frequencies Valid and invalid ranges: Example on the left: Skip frequency = 5 Hz, bandwidth = 10 Hz • à Valid range (starts at ≥ 0) Example on the right: Skip frequency = 4 Hz, bandwidth = 10 Hz •...

-

Page 186: Optimising The Stalling Behaviour

Motor control Optimisation of motor control Optimising the stalling behaviour 8.3.3 Optimising the stalling behaviour If the motor is driven with frequencies above the rated motor frequency, the operating point is shifted to the "field weakening range". In this range, the motor voltage does not increase proportionately to the output frequency anymore. - Page 187 Motor control Optimisation of motor control Optimising the stalling behaviour Details The operating range of an asynchronous motor consists of the voltage range and the field ① weakening range. The field weakening range again is divided into two ranges: In the first range , the power can be kept constant without the motor stalling.

-

Page 188: Slip Compensation

Motor control Optimisation of motor control Slip compensation 8.3.4 Slip compensation In case of a load, the speed of an asynchronous motor decreases. This load-dependent speed drop is called slip. The slip compensation serves to counteract the load-dependent speed loss. Preconditions The function is only effective in the motor control type "V/f characteristic control (VFC open loop)". - Page 189 Motor control Optimisation of motor control Slip compensation Parameter Name / value range / [default setting] Info 0x2C02:004 Slip frequency Display of the rated slip determined. (P351.04) (Slip frequency) • Read only: x.x Hz 0x2C01:001 Motor parameters: Number of pole pairs Display of the number of pole pairs calculated from the rated speed and •...

-

Page 190: Oscillation Damping

Motor control Optimisation of motor control Oscillation damping 8.3.5 Oscillation damping The oscillation damping serves to reduce the oscillations during no-load operation which are caused by energy oscillating between the mechanical system (mass inertia) and the electrical system (DC bus). Furthermore, the oscillation damping can also be used to compensate for resonances. -

Page 191: Pole Position Identification Without Movement

Motor control Optimisation of motor control Pole position identification without movement 8.3.6 Pole position identification without movement If a permanent-magnet synchronous motor is driven by the inverter, a "pole position identifi- cation (PLI)" is required for an optimum and jerk-free starting torque. In the default setting, a pole position identification is executed after each inverter enable. - Page 192 Motor control Optimisation of motor control Pole position identification without movement Parameter Name / value range / [default setting] Info 0x2C63:001 PPI without movement: Execution Starting performance (without or with pole position identification before • Setting can only be changed if the inverter is inhibi- the start).

-

Page 193: Optimisation Of The Control Loops

Motor control Optimisation of the control loops Optimisation of the control loops Setting of motor data Motor control selection Optimisation of motor control Optimisation of the control loops If there is a need to improve the total power of the system, different options are available: a) Select motor from motor catalogue b) Tuning of the motor and the speed controller c) Automatic motor identification (energized) - Page 194 Optimisation of the control loops Performing optimisation with engineering tool The following flow diagram shows the optimisation process with an engineering tool (e. g. »EASY Starter«): Start Lenze motor connected? Set manually: • Motor data (e.g. according to data on the motor nameplate) Engineering tool •...

- Page 195 4Man- ual setting of the motor data ^ 164 The following flow diagram shows the optimisation process with the keypad: Start Lenze motor connected? Set manually: • Motor data (e.g. according to data on the motor nameplate) Engineering tool •...

-

Page 196: Options For Optimized Motor Tuning

Motor control Optimisation of the control loops Options for optimized motor tuning 8.4.1 Options for optimized motor tuning The option to be selected depends on the respective application. Depending on the selected option, different procedures become active and thus different parameter groups are influ- enced: Rated motor data •... -

Page 197: Motor Selection From Motor Catalogue

Optimisation is possible online or offline (with or without connected motor). • Required steps 1. Open the Lenze engineering tool that provides for the functionality of a "Lenze motor cata- logue". 2. Click the Select motor... button. In case of the »EASY Starter«, you find the Select motor... -

Page 198: Tuning Of The Motor And The Speed Controller

Motor control Optimisation of the control loops Options for optimized motor tuning 8.4.1.2 Tuning of the motor and the speed controller The following describes in general how to optimise the speed controller. This may be required if some parameters have on the load side of the drive system have changed or have not been set yet, such as: Motor moment of inertia •... -

Page 199: Automatic Motor Identification (Energized)

Motor control Optimisation of the control loops Options for optimized motor tuning 8.4.1.3 Automatic motor identification (energized) The automatic identification of the motor results in the best possible parameter settings. If the application enables you to energise the system during the optimisation, carry out this optimisation. -

Page 200: Automatic Motor Calibration (Non-Energized)

Motor control Optimisation of the control loops Inverter Characteristics 8.4.1.4 Automatic motor calibration (non-energized) If the application does not enable you to energise the system during the optimisation, carry out this optimisation. Preconditions All rated motor data are known and set in the inverter, either by selecting the motor from •... -

Page 201: Motor Equivalent Circuit Diagram Data

Motor control Optimisation of the control loops Motor equivalent circuit diagram data 8.4.3 Motor equivalent circuit diagram data The motor equivalent circuit diagram data are automatically set if one of the following optimi- sations is carried out: 4Motor selection from motor catalogue ^ 197 4Automatic motor identification (energized) ^ 199... -

Page 202: Motor Controller Settings

Motor control Optimisation of the control loops Motor controller settings 8.4.4 Motor controller settings After the motor settings have been made, the different control loops must be set. For a quick commissioning, the calculations and settings are made automatically if one of the following optimisations is carried out: 4Motor selection from motor catalogue ^ 197... -

Page 203: Field Controller

Motor control Optimisation of the control loops Motor controller settings 8.4.4.2 Field controller For a quick commissioning, the calculations and settings are made automatically during the optimisation. Preconditions The field controller is only effective in the following motor control types: Servo control (SC ASM) •... -

Page 204: Imax Controller

Motor control Optimisation of the control loops Motor controller settings 8.4.4.5 Imax controller For a quick commissioning, the calculations and settings are made automatically during the optimisation. For typical applications, a manual adaptation of the parameters of the Imax con- troller is not recommended. -

Page 205: Flying Restart Controller

Motor control Optimisation of the control loops Motor controller settings 8.4.4.6 Flying restart controller For a quick commissioning, the calculations and settings are made automatically during the optimisation. Preconditions The flying restart controller is only effective in the following motor control types: V/f characteristic control (VFC open loop) •... -

Page 206: Torque Control W/ Freq. Limit

Motor control Optimisation of the control loops Motor controller settings 8.4.4.8 Torque control w/ freq. limit In general, the inverter is operated in a mode that controls the motor frequency. Alternatively, the inverter can be configured in such a way that it controls a motor torque within a defined frequency range. - Page 207 Motor control Optimisation of the control loops Motor controller settings Parameterisation required 1. Set the operating mode "MS: Torque mode [-1]" in 0x6060 (P301.00). 2. Set the rated motor torque in 0x6076 (P325.00). 3. Set the permissible maximum torque in 0x6072 (P326.00).

- Page 208 Motor control Optimisation of the control loops Motor controller settings Diagnostic parameters: 0x2DD5: Torque setpoint • 0x2949:003 (P337.03): Actual positive torque limit • 0x2949:004 (P337.04): Actual negative torque limit • 0x2946:007 (P340.07): Speed limitation: Actual upper speed limit • 0x2946:008 (P340.08): Speed limitation: Actual lower speed limit •...

- Page 209 Motor control Optimisation of the control loops Motor controller settings Parameter Name / value range / [default setting] Info 0x2946:004 Speed limitation: Lower speed limit source Selection of the source for the lower speed limit. (P340.04) (Speed limitation: Lowspeed lim src) •...

-

Page 210: Slip Controller

Motor control Optimisation of the control loops Motor controller settings Parameter Name / value range / [default setting] Info 0x2949:002 Negative torque limit source Selection of the source for the negative torque limit source. (P337.02) (Neg. torqlim src) • From version 03.00 0 (-) Max torque Negative torque limit source = (-) Max torque 0x6072... -

Page 211: Speed Controller

Motor control Optimisation of the control loops Speed controller 8.4.5 Speed controller The speed controller is automatically set if one of the following optimisations is carried out: 4Motor selection from motor catalogue ^ 197 4Automatic motor identification (energized) ^ 199 4Automatic motor calibration (non-energized) ^ 200 For typical applications, a manual adaptation of the parameters of the speed... -

Page 212: Motor Rotating Direction

Motor control Motor rotating direction Motor rotating direction In the default setting, both directions of motor rotation are enabled. Optionally, the direction of rotation can be restricted so that only a clockwise rotation (CW) of the motor is possible. Preconditions Wiring of the motor phases must be carried out correctly with regard to the direction of motor rotation. -

Page 213: Switching Frequency Changeover

Motor control Switching frequency changeover Switching frequency changeover The output voltage of the inverter is a DC voltage with sine-coded pulse width modulation (PWM). This corresponds by approximation to a AC voltage with variable frequency. The fre- quency of the PWM pulses is adjustable and is called "switching frequency". Details The switching frequency has an impact on the smooth running performance and the noise generation in the motor connected as well as on the power loss in the inverter. -

Page 214: Motor Protection

Motor control Motor protection Motor protection Many monitoring functions integrated in the inverter can detect errors and thus protect the device or motor from being destroyed or overloaded. Motor overload monitoring (i²*t) • ^ 215 Motor temperature monitoring • ^ 219 Current limits •... -

Page 215: Motor Overload Monitoring (I²*T)

Motor control Motor protection Motor overload monitoring (i²*t) 8.7.1 Motor overload monitoring (i²*t) This function monitors the thermal utilisation of the motor, taking the motor currents recor- ded and a mathematical model as a basis. DANGER! Fire hazard by overheating of the motor. Possible consequences: Death or severe injuries ▶... - Page 216 Motor control Motor protection Motor overload monitoring (i²*t) The following two diagrams show the relation between the motor load and release time of the monitoring under the following conditions: Maximum utilisation 0x2D4B:001 (P308.01) = 150 % • Speed compensation 0x2D4B:002 (P308.02) = "Off [1]"...

- Page 217 Motor control Motor protection Motor overload monitoring (i²*t) Speed compensation for protecting motors at low speed The inverter comes with an implemented compensation for low speed. If the motor is driven with frequencies lower than 40 Hz, the speed compensation in 0x2D4B:002 (P308.02)should be set to "On [0]"...

- Page 218 Motor control Motor protection Motor overload monitoring (i²*t) Parameter Name / value range / [default setting] Info 0x2D4B:002 Motor overload monitoring (i²*t): Speed compensa- Use this function to protect motors that are actuated at a speed below (P308.02) tion 40 Hz. (Motor overload: Speed comp.) •...

-

Page 219: Motor Temperature Monitoring

Motor control Motor protection Motor temperature monitoring 8.7.2 Motor temperature monitoring In order to record and monitor the motor temperature, a PTC thermistor (single sensor according to DIN 44081 or triple sensor according to DIN 44082) or thermal contact (normally- closed contact) can be connected to the terminals T1 and T2. -

Page 220: Current Limits

Motor control Motor protection Current limits 8.7.3 Current limits For the purpose of current limitation, a maximum overload current can be set for the inverter. If the current consumption of the motor exceeds this current limit, the inverter changes its dynamic behaviour, in order to counteract this exceedance. - Page 221 Motor control Motor protection Current limits Parameter Name / value range / [default setting] Info 0x6073 Max current Maximum overload current of the inverter. (P324.00) (Max current) • 100 % ≡ Motor rated current 0x6075 (P323.00) 0.0 ... [200.0] ... 3000.0 % •...

-

Page 222: Overcurrent Monitoring

Motor control Motor protection Overcurrent monitoring 8.7.4 Overcurrent monitoring This function monitors the instantaneous value of the motor current and serves as motor pro- tection. NOTICE With an incorrect parameterisation, the maximum permissible motor current may be excee- ded in the process. Possible consequence: irreversible damage of the motor. -