Table of Contents

Advertisement

Quick Links

-7-Series AC Servo Drive

-7S SERVOPACK with

Analog Voltage/Pulse Train References

Product Manual

Model: SGD7S

MANUAL NO. SIEP S800001 26B

Basic Information on

SERVOPACKs

Selecting a SERVOPACK

SERVOPACK Installation

Wiring and Connecting

SERVOPACKs

Basic Functions That Require

Setting before Operation

Application Functions

Trial Operation and

Actual Operation

Tuning

Monitoring

Fully-closed Loop Control

Safety Functions

Maintenance

Panel Displays and

Panel Operator Procedures

Parameter Lists

Appendices

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for YASKAWA E-7-Series SGD7S

- Page 1 -7-Series AC Servo Drive -7S SERVOPACK with Analog Voltage/Pulse Train References Product Manual Model: SGD7S Basic Information on SERVOPACKs Selecting a SERVOPACK SERVOPACK Installation Wiring and Connecting SERVOPACKs Basic Functions That Require Setting before Operation Application Functions Trial Operation and Actual Operation Tuning Monitoring...

- Page 2 Yaskawa. No patent liability is assumed with respect to the use of the informa- tion contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is sub- ject to change without notice.

- Page 3 About this Manual This manual provides information required to select Σ-7S SERVOPACKs with Analog Voltage/Pulse Train References for Σ-7-Series AC Servo Drives, and to design, perform trial operation of, tune, operate, and maintain the Servo Drives. Read and understand this manual to ensure correct usage of the Σ-7-Series AC Servo Drives. Keep this manual in a safe place so that it can be referred to whenever necessary.

- Page 4 Related Documents The relationships between the documents that are related to the Servo Drives are shown in the following figure. The numbers in the figure correspond to the numbers in the table on the following pages. Refer to these documents as required. System Components Machine Controllers...

- Page 5 Classification Document Name Document No. Description Provides detailed information Machine Controller Machine Controller and Servo required to select MP3000-Series KAEP S800001 22 Machine Controllers and Σ-7-Series and Servo Drive Drive Solutions Catalog General Catalog AC Servo Drives. Provides detailed information on ...

- Page 6 Continued from previous page. Classification Document Name Document No. Description Σ-7-Series AC Servo Drive Provides detailed information on MECHATROLINK-II the MECHATROLINK-II communi- SIEP S800001 30 Communications cations commands that are used for a Σ-7-Series Servo System. Command Manual Σ-7-Series MECHATROLINK Σ-7-Series AC Servo Drive Communications Provides detailed information on...

- Page 7 Using This Manual Technical Terms Used in This Manual The following terms are used in this manual. Term Meaning A Σ-7-Series Rotary Servomotor, Direct Drive Servomotor, or Linear Servomotor. Servomotor A generic term used for a Σ-7-Series Rotary Servomotor (SGM7A, SGM7J, or SGM7G) or a Rotary Servomotor Direct Drive Servomotor (SGMCS or SGMCV).

- Page 8 Notation Used in this Manual Notation for Reverse Signals The names of reverse signals (i.e., ones that are valid when low) are written with a forward slash (/) before the signal abbreviation. Notation Example BK is written as /BK. ...

- Page 9 Trademarks • QR code is a trademark of Denso Wave Inc. • Other product names and company names are the trademarks or registered trademarks of the respective company. “TM” and the ® mark do not appear with product or company names in this manual.

- Page 10 Safety Precautions Safety Information To prevent personal injury and equipment damage in advance, the following signal words are used to indicate safety precautions in this document. The signal words are used to classify the hazards and the degree of damage or injury that may occur if a product is used incorrectly. Information marked as shown below is important for safety.

- Page 11 Safety Precautions That Must Always Be Observed General Precautions DANGER Read and understand this manual to ensure the safe usage of the product. Keep this manual in a safe, convenient place so that it can be referred to whenever necessary. Make sure that it is delivered to the final user of the product.

- Page 12 NOTICE Do not attempt to use a SERVOPACK or Servomotor that is damaged or that has missing parts. Install external emergency stop circuits that shut OFF the power supply and stops operation immediately when an error occurs. In locations with poor power supply conditions, install the necessary protective devices (such as AC reactors) to ensure that the input power is supplied within the specified voltage range.

- Page 13 NOTICE Do not hold onto the front cover or connectors when you move a SERVOPACK. There is a risk of the SERVOPACK falling. A SERVOPACK or Servomotor is a precision device. Do not drop it or subject it to strong shock. There is a risk of failure or damage.

- Page 14 NOTICE Do not install or store the product in any of the following locations. • Locations that are subject to direct sunlight • Locations that are subject to ambient temperatures that exceed product specifications • Locations that are subject to relative humidities that exceed product specifications •...

- Page 15 Whenever possible, use the Cables specified by Yaskawa. If you use any other cables, confirm the rated current and application environment of your model and use the wiring materials specified by Yaskawa or equivalent materials. Securely tighten cable connector screws and lock mechanisms.

- Page 16 Operation Precautions WARNING Before starting operation with a machine connected, change the settings of the switches and parameters to match the machine. Unexpected machine operation, failure, or personal injury may occur if operation is started before appropriate settings are made. ...

- Page 17 NOTICE When you adjust the gain during system commissioning, use a measuring instrument to monitor the torque waveform and speed waveform and confirm that there is no vibration. If a high gain causes vibration, the Servomotor will be damaged quickly. ...

- Page 18 We will update the document number of the document and issue revisions when changes are made. Any and all quality guarantees provided by Yaskawa are null and void if the customer modifies the product in any way. Yaskawa disavows any responsibility for damages or losses that are caused by modified products.

- Page 19 • Events for which Yaskawa is not responsible, such as natural or human-made disasters Limitations of Liability • Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer that arises due to failure of the delivered product.

- Page 20 • It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations that apply if the Yaskawa product is used in combination with any other products. • The customer must confirm that the Yaskawa product is suitable for the systems, machines, and equipment used by the customer.

-

Page 21: Servopacks

Compliance with UL Standards, EU Directives, and Other Safety Standards Certification marks for the standards for which the product has been certified by certification bodies are shown on nameplate. Products that do not have the marks are not certified for the standards. ... - Page 22 Only the SGMCV is certified. Certification is scheduled for April 2015. Note: We declared the CE Marking based on the harmonized standards in the above table. Safety Standards Product Model Safety Standards Standards EN ISO13849-1: 2008/AC: 2009 Safety of Machinery IEC 60204-1 IEC 61508 series SERVOPACKs...

-

Page 23: Table Of Contents

Contents About this Manual..........iii Outline of Manual . - Page 24 SERVOPACK Installation Installation Precautions ....... 3-2 Mounting Types and Orientation ......3-3 Mounting Hole Dimensions .

-

Page 25: Setting Before Operation

4.7.2 Computer Connector (CN7) ........4-43 4.7.3 Analog Monitor Connector (CN5) . - Page 26 5.14 Motor Stopping Methods for Servo OFF and Alarms..5-41 5.14.1 Stopping Method for Servo OFF ....... . .5-41 5.14.2 Servomotor Stopping Method for Alarms .

- Page 27 Torque Control ........6-37 6.7.1 Basic Settings for Torque Control .

- Page 28 6.15.3 Operating Procedure .........6-94 6.15.4 Related Parameters .

- Page 29 Tuning-less Function ....... . 8-11 8.4.1 Application Restrictions ........8-11 8.4.2 Operating Procedure .

- Page 30 8.11.3 Current Control Mode Selection ....... . .8-64 8.11.4 Current Gain Level Setting ........8-64 8.11.5 Speed Detection Method Selection .

- Page 31 Safety Functions 11.1 Introduction to the Safety Functions ....11-3 11.1.1 Safety Functions ..........11-3 11.1.2 Precautions for Safety Functions .

- Page 32 Panel Displays and Panel Operator Procedures 13.1 Panel Operator ........13-3 13.1.1 Panel Operator Key Names and Functions .

- Page 33 Parameter Lists 14.1 List of Parameters ........14-2 14.1.1 Interpreting the Parameter Lists .

- Page 34 Basic Information on SERVOPACKs This chapter provides information required to select SERVOPACKs, such as SERVOPACK models and combi- nations with Servomotors. The Σ-7 Series ..... . . 1-2 Interpreting the Nameplate .

-

Page 35: The Σ-7 Series

1.1 The Σ-7 Series Σ -7 Series The Σ-7-series SERVOPACKs are designed for applications that require frequent high-speed and high-precision positioning. The SERVOPACK will make the most of machine performance in the shortest time possible, thus contributing to improving productivity. The Σ-7-series SERVOPACKs include Σ-7S SERVOPACKs for single-axis control and Σ-7W SERVOPACKs for two-axis control. -

Page 36: Interpreting The Nameplate

1.2 Interpreting the Nameplate Interpreting the Nameplate The following basic information is provided on the nameplate. S_Ana - SERVOPACK model Protection class Surrounding air temperature Order number Serial number... -

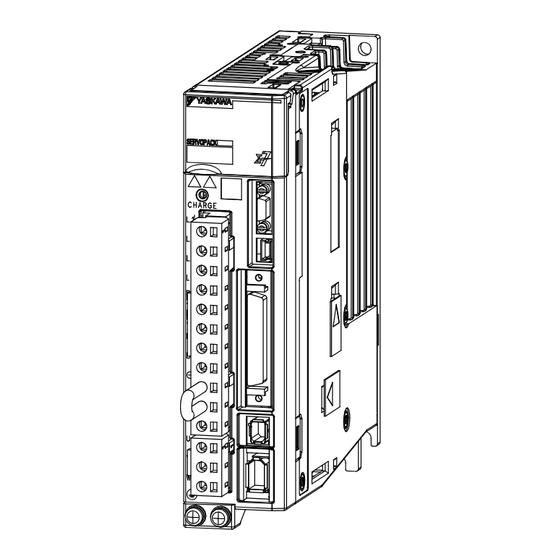

Page 37: Part Names

1.3 Part Names Part Names With Front Cover Open (on side of SERVOPACK) Main circuit terminals S_Analog Motor terminals Name Description Reference − − Front Cover Nameplate Indicates the SERVOPACK model and ratings. page 1-3 − Input Voltage –... - Page 38 1.3 Part Names Name Description Reference Used to display SERVOPACK status, alarm numbers, and Panel Display parameters. page 13-3 Panel Operator Keys Used to set parameters. − Panel Operator Analog Monitor Connector You can use a special cable (peripheral device) to monitor page 4-43 (CN5) the motor speed, torque reference, or other values.

-

Page 39: Model Designations

1.4 Model Designations 1.4.1 Interpreting SERVOPACK Model Numbers Model Designations 1.4.1 Interpreting SERVOPACK Model Numbers SGD7S - R70 S_Analog 1st+2nd+3rd 5th+6th 8th+9th+10th Σ-7-Series digit digit digits digits digits Σ-7S SERVOPACKs Hardware Options Maximum Applicable 1st+2nd+3rd digits 4th digit Voltage 8th+9th+10th digits Motor Capacity Specification Applicable... - Page 40 1.4 Model Designations 1.4.2 Interpreting Servomotor Model Numbers Direct Drive Servomotors SGMC - 02 1st+2nd Series digit digit digit digit digit digits Σ-7 Series Servomotors Series 1st+2nd digits 5th digit Rated Torque Design Revision Order Code Specification 3rd digit 6th digit Servomotor Outer Diameter Flange Specification Small capacity, coreless...

-

Page 41: Combinations Of Servopacks And Servomotors

1.5 Combinations of SERVOPACKs and Servomotors 1.5.1 Combinations of Rotary Servomotors and SERVOPACKs Combinations of SERVOPACKs and Servomotors 1.5.1 Combinations of Rotary Servomotors and SERVOPACKs SERVOPACK Model Rotary Servomotor Model Capacity SGD7S- SGM7A-A5A 50 W R70A SGM7A-01A 100 W R90A SGM7A-C2A 150 W 1R6A... -

Page 42: Combinations Of Linear Servomotors And Servopacks

1.5 Combinations of SERVOPACKs and Servomotors 1.5.3 Combinations of Linear Servomotors and SERVOPACKs Instantaneous SERVOPACK Model Rated Torque Direct Drive Servomotor Model Maximum Torque [N·m] SGD7S- [N·m] SGMCS-45M 7R6A SGMCS-80M 120A Medium Capacity, SGMCS-80N With Core SGMCS-1AM 180A (SGMCS) SGMCS-1EN 200A SGMCS-2ZN SGMCV-04B... -

Page 43: Combinations Of Linear Servomotors And Servopacks

1.5 Combinations of SERVOPACKs and Servomotors 1.5.3 Combinations of Linear Servomotors and SERVOPACKs Instantaneous SERVOPACK Model Rated Torque Linear Servomotor Model Maximum Torque SGD7S- SGLFW-20A090A SGLFW-20A120A 1R6A SGLFW-35A120A SGLFW-35A230A 3R8A SGLFW-50A200B 5R5A SGLFW-50A380B 1200 120A SGLFW-1ZA200B SGLFW-1ZA380B 1120 2400 200A SGLF SGLFW2-30A070A (Models with F-type... -

Page 44: Functions

1.6 Functions Functions This section lists the functions provided by SERVOPACKs. Refer to the reference pages for details on the functions. • Functions Related to the Machine Function Reference Power Supply Type Settings for the Main Circuit page 5-14 and Control Circuit Automatic Detection of Connected Motor page 5-16 Motor Direction Setting... - Page 45 1.6 Functions Function Reference Position Deviation Clear Input (CLR) Signal Func- page 6-30 tion and Settings Reference Pulse Input Multiplication Switching page 6-31 Positioning Completion (/COIN) Signal page 6-33 Near (/NEAR) Signal page 6-35 Reference Pulse Inhibition and Settings page 6-35 Torque Control page 6-37 Basic Settings for Torque Control...

- Page 46 1.6 Functions • Functions for Trial Operation during Setup Function Reference Software Reset page 6-91 Trial Operation of Servomotor without a Load page 7-7 Program Jogging page 7-20 Origin Search page 7-25 Test without a Motor page 7-26 Monitoring Machine Operation Status and Signal page 9-6 Waveforms •...

-

Page 47: Selecting A Servopack

Selecting a SERVOPACK This chapter provides information required to select SERVOPACKs, such as specifications, block diagrams, dimensional drawings, and connection examples. Ratings and Specifications ... . . 2-2 2.1.1 Ratings ....... . 2-2 2.1.2 Specifications . - Page 48 2.1 Ratings and Specifications 2.1.1 Ratings Ratings and Specifications This section gives the ratings and specifications of SERVOPACKs. 2.1.1 Ratings Three-Phase, 200 VAC Model SGD7S- R70A R90A 1R6A 2R8A 3R8A 5R5A 7R6A 120A 180A 200A Maximum Applicable Motor Capacity 0.05 0.75 [kW] Continuous Output Current [Arms]...

-

Page 49: Ratings And Specifications

2.1 Ratings and Specifications 2.1.2 Specifications 2.1.2 Specifications Item Specification Control Method IGBT-based PWM control, sine wave current drive Serial encoder: 20 bits or 24 bits (incremental encoder/absolute With Rotary encoder) Servomotor 22 bits (absolute encoder) • Absolute linear encoder (The signal resolution depends on the abso- Feedback lute linear encoder.) With Linear... -

Page 50: Ratings

2.1 Ratings and Specifications 2.1.2 Specifications Continued from previous page. Item Specification Encoder Divided Phase A, phase B, phase C: Line-driver output Pulse Output Number of divided output pulses: Any setting is allowed. Linear Servomotor Number of input points: 1 Overheat Protection Input voltage range: 0 V to +5 V Signal Input... -

Page 51: Ratings And Specifications

2.1 Ratings and Specifications 2.1.2 Specifications Continued from previous page. Item Specification Digital Operator (JUSP-OP05A-1-E) and personal computer (with Sig- Inter- faces maWin+) RS-422A Communi- Commu- Up to N = 15 stations possible for RS-422A port cations nications (CN3) Axis Communi- Address Set with parameters. -

Page 52: Ratings

2.1 Ratings and Specifications 2.1.2 Specifications Continued from previous page. Item Specification Soft Start Time Set- 0 s to 10 s (Can be set separately for acceleration and deceleration.) ting • Maximum input voltage: ±12 V (forward motor rotation for positive ref- Refer- erence). -

Page 53: Block Diagrams

2.2 Block Diagrams 2.2.1 SGD7S-R70A, -R90A, and -1R6A Block Diagrams 2.2.1 SGD7S-R70A, -R90A, and -1R6A Servomotor Varistor Main circuit power − supply Dynamic brake circuit Voltage Voltage Relay Temperature Gate drive Current Gate drive sensor sensor drive sensor overcurrent protection sensor Varistor Control... -

Page 54: Sgd7S-3R8A, -5R5A, And -7R6A

2.2 Block Diagrams 2.2.3 SGD7S-3R8A, -5R5A, and -7R6A 2.2.3 SGD7S-3R8A, -5R5A, and -7R6A S_Analog Servomotor Varistor Main circuit − power supply Dynamic brake circuit Voltage Relay Temperature Gate drive Current Voltage Gate drive sensor drive sensor overcurrent protection sensor sensor Varistor Control Control... -

Page 55: Sgd7S-120A

2.2 Block Diagrams 2.2.4 SGD7S-120A 2.2.4 SGD7S-120A S_Analog Servomotor Varistor Main circuit − power supply Overheat/ Dynamic overcurrent brake circuit protection Relay Current Voltage Voltage Temperature Gate drive Gate drive drive sensor sensor sensor sensor Varistor Control Analog monitor Analog Control voltage power... -

Page 56: Sgd7S-180A And -200A

2.2 Block Diagrams 2.2.5 SGD7S-180A and -200A 2.2.5 SGD7S-180A and -200A S_Analog Servomotor Varistor Main circuit − power supply Overheat/overcurrent Dynamic protection brake circuit Voltage Voltage Relay Temperature Current Gate drive sensor sensor sensor drive sensor Varistor Control Analog Analog monitor Control voltage power... -

Page 57: External Dimensions

2.3 External Dimensions 2.3.1 Front Cover Dimensions and Connector Specifications External Dimensions 2.3.1 Front Cover Dimensions and Connector Specifications The front cover dimensions and panel connector section are the same for all models. Refer to the following figures and table. •... - Page 58 2.3 External Dimensions 2.3.2 SERVOPACK External Dimensions • Three-phase, 200 VAC: SGD7S-2R8A 2×M4 Exterior 20 ±0.5 (mounting pitch) Ground terminals (75) 2 × M4 Mounting Hole Diagram S_Analog Approx. mass: 1.0 kg Unit: mm • Three-phase, 200 VAC: SGD7S-3R8A, -5R5A, and -7R6A 3×M4 Exterior 58 ±0.5 (mounting pitch)

- Page 59 2.3 External Dimensions 2.3.2 SERVOPACK External Dimensions • Three-phase, 200 VAC: SGD7S-180A and -200A 3×M4 Exterior Terminals 75 ±0.5 (mounting pitch) Ground 14 × M4 12.5 82.5 ±0.5 (mounting pitch) terminals (75) 2 × M4 Terminal Details Mounting Hole Diagram S_Analog Approx.

-

Page 60: Examples Of Standard Connections Between Servopacks And Peripheral Devices

Rotary Servomotor External Regenerative Resistors are not provided by Yaskawa. The power supply for the holding brake is not provided by Yaskawa. Select a power supply based on the hold- ing brake specifications. If you use a 24-V brake, install a separate power supply for the 24-VDC power supply from other power sup- plies, such as the one for the I/O signals of the CN1 connector. - Page 61 I/O Signal Cable External External Regenerative Regenerative * Resistor Cable Resistor Safety Function Device Cable Serial Converter Unit Cable Serial Converter Unit Ground cable Sensor Cable Linear Encoder Cable Linear encoder Linear Servomotor External Regenerative Resistors are not provided by Yaskawa. 2-15...

-

Page 62: Servopack Installation

SERVOPACK Installation This chapter provides information on installing SERVO- PACKs in the required locations. Installation Precautions ....3-2 Mounting Types and Orientation ..3-3 Mounting Hole Dimensions . -

Page 63: Installation Precautions

3.1 Installation Precautions Installation Precautions Refer to the following section for the ambient installation conditions. 2.1.2 Specifications on page 2-3 Installation Near Sources of Heat Implement measures to prevent temperature increases caused by radiant or convection heat from heat sources so that the ambient temperature of the SERVOPACK meets the ambient conditions. -

Page 64: Mounting Types And Orientation

3.2 Mounting Types and Orientation Mounting Types and Orientation The SERVOPACKs come in the following mounting types: base-mounted, rack-mounted, and duct-ventilated types. Regardless of the mounting type, mount the SERVOPACK vertically, as shown in the following figures. Also, mount the SERVOPACK so that the front panel is facing toward the operator. Note: Prepare two to four mounting holes for the SERVOPACK and mount it securely in the mounting holes. -

Page 65: Mounting Hole Dimensions

3.3 Mounting Hole Dimensions Mounting Hole Dimensions Use mounting holes to securely mount the SERVOPACK to the mounting surface. Note: To mount the SERVOPACK, you will need to prepare a screwdriver that is longer than the depth of the SER- VOPACK. -

Page 66: Mounting Interval

3.4 Mounting Interval 3.4.1 Installing One SERVOPACK in a Control Panel Mounting Interval 3.4.1 Installing One SERVOPACK in a Control Panel Provide the following spaces around the SERVOPACK. 40 mm min. 30 mm min. 30 mm min. 40 mm min. For this dimension, ignore items protruding from the main body of the SERVOPACK. -

Page 67: Monitoring The Installation Environment

3.5 Monitoring the Installation Environment Monitoring the Installation Environment You can use the SERVOPACK Installation Environment Monitor parameter to check the operat- ing conditions of the SERVOPACK in the installation environment. You can check the SERVOPACK installation environment monitor with either of the following methods. -

Page 68: Derating Specifications

3.6 Derating Specifications Derating Specifications If you use the SERVOPACK at a surrounding air temperature of 55°C to 60°C or at an altitude of 1,000 m to 2,000 m, you must apply the derating rates given in the following graphs. •... -

Page 69: Emc Installation Conditions

The EMC installation conditions that are given here are the conditions that were used to pass testing criteria at Yaskawa. The EMC level may change under other conditions, such as the actual installation structure and wiring conditions. These Yaskawa products are designed to be built into equipment. -

Page 70: Wiring And Connecting Servopacks

Wiring and Connecting SERVOPACKs This chapter provides information on wiring and connecting SERVOPACKs to power supplies and peripheral devices. Wiring and Connecting SERVOPACKs ..4-3 4.1.1 General Precautions ..... . 4-3 4.1.2 Countermeasures against Noise . - Page 71 Connecting Safety Function Signals ..4-41 4.6.1 Pin Arrangement of Safety Function Signals (CN8) . . 4-41 4.6.2 I/O Circuits ......4-41 Connecting the Other Connectors .

-

Page 72: Wiring And Connecting Servopacks

4.1 Wiring and Connecting SERVOPACKs 4.1.1 General Precautions Wiring and Connecting SERVOPACKs 4.1.1 General Precautions DANGER Do not change any wiring while power is being supplied. There is a risk of electric shock or injury. WARNING Wiring and inspections must be performed only by qualified engineers. There is a risk of electric shock or product failure. - Page 73 To ensure safe, stable application of the servo system, observe the following precautions when wiring. • Use the cables specified by Yaskawa. Design and arrange the system so that each cable is as short as possible. Refer to the following manual for information on the specified cables.

-

Page 74: Countermeasures Against Noise

4.1 Wiring and Connecting SERVOPACKs 4.1.2 Countermeasures against Noise 4.1.2 Countermeasures against Noise The SERVOPACK is designed as an industrial device. It therefore provides no measures to pre- vent radio interference. The SERVOPACK uses high-speed switching elements in the main circuit. Therefore peripheral devices may be affected by switching noise. - Page 75 4.1 Wiring and Connecting SERVOPACKs 4.1.2 Countermeasures against Noise Noise Filters You must attach Noise Filters in appropriate places to protect the SERVOPACK from the adverse effects of noise. The following is an example of wiring for countermeasures against noise. SERVOPACK Noise Filter Servomotor...

- Page 76 4.1 Wiring and Connecting SERVOPACKs 4.1.2 Countermeasures against Noise Noise Filter Wiring and Connection Precautions Always observe the following precautions when wiring or connecting Noise Filters. • Separate input lines from output lines. Do not place input lines and output lines in the same duct or bundle them together.

-

Page 77: Grounding

4.1 Wiring and Connecting SERVOPACKs 4.1.3 Grounding • If a Noise Filter is located inside a control panel, first connect the Noise Filter ground wire and the ground wires from other devices inside the control panel to the grounding plate for the control panel, then ground the plate. -

Page 78: Basic Wiring Diagrams

4.2 Basic Wiring Diagrams Basic Wiring Diagrams This section provide the basic wiring diagrams. Refer to the reference sections given in the diagrams for details. SERVOPACK S_Analog R S T Main circuit Motor terminals terminals 4.4 Wiring Ser- 1FLT vomotors on page 4-19 PG5V PG0V... - Page 79 You can enable this function with a parameter setting. The 24-VDC power supply is not provided by Yaskawa. Use a 24-VDC power supply with double insulation or reinforced insulation. Refer to the following chapter if you use a safety function device.

-

Page 80: Wiring The Power Supply To The Servopack

4.3 Wiring the Power Supply to the SERVOPACK 4.3.1 Terminal Symbols and Terminal Names Wiring the Power Supply to the SERVOPACK 4.3.1 Terminal Symbols and Terminal Names Use the main circuit connector on the SERVOPACK to wire the main circuit power supply and control circuit power supply to the SERVOPACK. -

Page 81: Wiring Procedure For Main Circuit Connector

4.3 Wiring the Power Supply to the SERVOPACK 4.3.2 Wiring Procedure for Main Circuit Connector Continued from previous page. Terminal Terminal Name Specifications and Reference Symbols 4.3.5 Wiring Regenerative Resistors on page 4-17 For SGD7S-R70A, -R90A, -1R6A, and -2R8A If the regenerative capacity is insufficient, connect an Exter- nal Regenerative Resistor between B1/ and B2. -

Page 82: Power On Sequence

4.3 Wiring the Power Supply to the SERVOPACK 4.3.3 Power ON Sequence Remove the main circuit connector and motor connector from the SERVOPACK. S_Analog Enlarged View 1. Press in on the lock. 2. Press in on the locks to remove Main circuit the connectors. -

Page 83: Power Supply Wiring Diagrams

4.3 Wiring the Power Supply to the SERVOPACK 4.3.4 Power Supply Wiring Diagrams Power ON Control power supply Main circuit power supply Servo Alarm (ALM) Alarm Alarm cleared. output signal Up to 5.0 s • Design the power ON sequence so that main circuit power supply is turned OFF when an ALM (Servo Alarm) signal is output. - Page 84 4.3 Wiring the Power Supply to the SERVOPACK 4.3.4 Power Supply Wiring Diagrams • Wiring Example for Single-Phase, 200-VAC Power Supply Input S_Analog SERVOPACK 1FLT +24 V (For servo alarm display) − Servo power Servo power 1QF: Molded-case circuit breaker 1Ry: Relay 1FLT: Noise Filter 1PL: Indicator lamp...

- Page 85 4.3 Wiring the Power Supply to the SERVOPACK 4.3.4 Power Supply Wiring Diagrams Using More Than One SERVOPACK Connect the ALM (Servo Alarm) output for these SERVOPACKs in series to operate the alarm detection relay (1RY). When a SERVOPACK alarm is activated, the ALM output signal transistor turns OFF. The following diagram shows the wiring to stop all of the Servomotors when there is an alarm for any one SERVOPACK.

-

Page 86: Wiring Regenerative Resistors

4.3 Wiring the Power Supply to the SERVOPACK 4.3.5 Wiring Regenerative Resistors 4.3.5 Wiring Regenerative Resistors This section describes how to connect External Regenerative Resistors. Refer to the following manual to select External Regenerative Resistors. Σ-7-Series Peripheral Device Selection Manual (Manual No.: SIEP S800001 32) WARNING ... -

Page 87: Wiring Dc Reactors

4.3 Wiring the Power Supply to the SERVOPACK 4.3.6 Wiring DC Reactors Connect the External Regenerative Resistor between the B1/⊕ and B2 terminals. Enlarged View S_Analog Set Pn600 (Regenerative Resistor Capacity) and Pn603 (Regenerative Resistor Resis- tance). Refer to the following section for details on the settings. 5.19 Setting the Regenerative Resistor Capacity on page 5-57 4.3.6 Wiring DC Reactors... -

Page 88: Wiring Servomotors

4.4 Wiring Servomotors 4.4.1 Terminal Symbols and Terminal Names Wiring Servomotors 4.4.1 Terminal Symbols and Terminal Names The SERVOPACK terminals or connectors that are required to connect the SERVOPACK to a Servomotor are given below. Terminal/Connector Terminal/Connector Name Remarks Symbols Refer to the following section for the wiring proce- dure. -

Page 89: Wiring The Servopack To The Encoder

4.4 Wiring Servomotors 4.4.3 Wiring the SERVOPACK to the Encoder 4.4.3 Wiring the SERVOPACK to the Encoder When Using an Absolute Encoder If you use an absolute encoder, use an Encoder Cable with a JUSP-BA01-E Battery Case or install a battery on the host controller. Refer to the following section for the battery replacement procedure. - Page 90 4.4 Wiring Servomotors 4.4.3 Wiring the SERVOPACK to the Encoder When Using an Incremental Encoder SERVOPACK Incremental encoder PG5V PG0V Connector shell (Shell) Shield The incremental encoder pin numbers for wiring the connector depend on the Servomotor that you use. represents a shielded twisted-pair cable.

- Page 91 4.4 Wiring Servomotors 4.4.3 Wiring the SERVOPACK to the Encoder Connections to Absolute Linear Encoder from Magnescale Co., Ltd. SR77 and SR87 Absolute linear encoder from Magnescale Co., Ltd. SERVOPACK PG5V PG0V Connector Connector shell shell Shield represents a shielded twisted-pair cable. 4-22...

- Page 92 4.4 Wiring Servomotors 4.4.3 Wiring the SERVOPACK to the Encoder When Using an Incremental Linear Encoder The wiring depends on the manufacturer of the linear encoder. Connections to Linear Encoder from Heidenhain Corporation Linear encoder from Heidenhain Corporation Serial Converter Unit SERVOPACK /COS /SIN...

- Page 93 4.4 Wiring Servomotors 4.4.3 Wiring the SERVOPACK to the Encoder Connections to Linear Encoder from Magnescale Co., Ltd. If you use a linear encoder from Magnescale Co., Ltd., the wiring will depend on the model of the linear encoder. ...

-

Page 94: Wiring The Servopack To The Holding Brake

4.4 Wiring Servomotors 4.4.4 Wiring the SERVOPACK to the Holding Brake SL700, SL710, SL720, and SL730 • MJ620-T13 Interpolator Linear encoder Interpolator SERVOPACK Head Cable from Magnescale Co., Ltd. 12, 14, 16 PG0V +5 V Connector Connector External power supply shell shell Shield... - Page 95 4.4 Wiring Servomotors 4.4.4 Wiring the SERVOPACK to the Holding Brake Servomotor with SERVOPACK Holding Brake Power supply +24 V BK-RY (/BK+) Surge Absorber (/BK-) DC side Brake power supply BK-RY BK-RY: Brake control relay 1D: Flywheel diode Install the surge absorber near the brake terminals on the Servomotor. 4-26...

-

Page 96: I/O Signal Connections

Allowable voltage range: 24 VDC ±20% − +24VIN Signal Power Supply Input The 24-VDC power supply is not provided by Yaskawa. Absolute Data page 6-70 Inputs the position data request signal for 4 (2) Request Input an absolute encoder. - Page 97 4.5 I/O Signal Connections 4.5.1 I/O Signal Connector (CN1) Names and Functions Control Reference Signal Name Function Method Page PULS Pulse Reference One of the following input pulse forms is set. /PULS Input • Sign + pulse train page 6-28 •...

- Page 98 4.5 I/O Signal Connections 4.5.1 I/O Signal Connector (CN1) Names and Functions Output Signals Default settings are given in parentheses. Control Reference Signal Pin No. Name Function Method Page ALM+ Servo Alarm Turns OFF (opens) when an error is page 6-8 Output detected.

-

Page 99: I/O Signal Connector (Cn1) Pin Arrangement

4.5 I/O Signal Connections 4.5.2 I/O Signal Connector (CN1) Pin Arrangement 4.5.2 I/O Signal Connector (CN1) Pin Arrangement The following figure gives the pin arrangement of the of the I/O signal connector (CN1) for the default settings. General- Signal /SO1- purpose General- Ground... -

Page 100: I/O Signal Wiring Examples

You can enable this function with a parameter setting. The 24-VDC power supply is not provided by Yaskawa. Use a 24-VDC power supply with double insulation or reinforced insulation. Always use line receivers to receive the output signals. - Page 101 Connect these when using an absolute linear encoder. You can enable this function with a parameter setting. The 24-VDC power supply is not provided by Yaskawa. Use a 24-VDC power supply with double insulation or reinforced insulation. Always use line receivers to receive the output signals.

- Page 102 Connect these when using an absolute encoder. If the Encoder Cable with a Battery Case is connected, do not connect a backup battery. The 24-VDC power supply is not provided by Yaskawa. Use a 24-VDC power supply with double insulation or reinforced insulation.

- Page 103 Frame ground represents twisted-pair wires. Connect when using an absolute linear encoder. The 24-VDC power supply is not provided by Yaskawa. Use a 24-VDC power supply with double insulation or reinforced insulation. Always use line receivers to receive the output signals.

- Page 104 You can enable this function with a parameter setting. The 24-VDC power supply is not provided by Yaskawa. Use a 24-VDC power supply with double insulation or reinforced insulation. Always use line receivers to receive the output signals.

- Page 105 Connect when using an absolute linear encoder. You can enable this function with a parameter setting. The 24-VDC power supply is not provided by Yaskawa. Use a 24-VDC power supply with double insulation or reinforced insulation. Always use line receivers to receive the output signals.

-

Page 106: I/O Circuits

4.5 I/O Signal Connections 4.5.4 I/O Circuits 4.5.4 I/O Circuits Reference Input Circuits Analog Input Circuits This section describes CN1 connector terminals 5-6 (Speed Reference Input) and 9-10 (Torque Reference Input). The analog signals are used as either speed or torque reference signals. The input impedance is as follows: •... - Page 107 4.5 I/O Signal Connections 4.5.4 I/O Circuits • Precaution When Host Controller Uses Open-Collector Output with User-Supplied Power Sup- The SERVOPACK may fail depending on the relationship between the pull-up voltage (Vcc) and Important the pull-up resistance (R1). Before you wire the circuits, confirm that the specifications of the host controller satisfy the values shown in the following table.

- Page 108 4.5 I/O Signal Connections 4.5.4 I/O Circuits Sink Circuits Source Circuits 24 V 24 V − − SERVOPACK input side SERVOPACK input side Photocoupler Photocoupler Internal Internal signal signal Switch Switch level level Photocoupler Photocoupler Internal Internal signal signal Switch Switch level level...

- Page 109 4.5 I/O Signal Connections 4.5.4 I/O Circuits Photocoupler Output Circuits Photocoupler output circuits are used for the ALM (Servo Alarm), /S-RDY (Servo Ready), and other sequence output signals. Connect a photocoupler output circuit to a relay or line-receiver circuit. Example for Relay Circuit Example for Line-Receiver Circuit SERVOPACK...

-

Page 110: Connecting Safety Function Signals

4.6 Connecting Safety Function Signals 4.6.1 Pin Arrangement of Safety Function Signals (CN8) Connecting Safety Function Signals This section describes the wiring required to use a safety function. Refer to the following chapter for details on the safety function. Chapter 11 Safety Functions 4.6.1 Pin Arrangement of Safety Function Signals (CN8) Pin No. - Page 111 4.6 Connecting Safety Function Signals 4.6.2 I/O Circuits Input (HWBB) Signal Specifications Connector Type Signal Status Meaning Pin No. ON (closed) Does not activate the HWBB (normal operation). CN8-4 /HWBB1 Activates the HWBB (motor current shut-OFF CN8-3 OFF (open) request).

-

Page 112: Connecting The Other Connectors

Measuring probe Black Probe ground The measuring instrument is not provided by Yaskawa. Refer to the following section for information on the monitoring methods for an analog monitor. 9.3 Monitoring Machine Operation Status and Signal Waveforms on page 9-6 4-43... - Page 113 Basic Functions That Require Setting before Operation This chapter describes the basic functions that must be set before you start servo system operation. It also describes the setting methods. Manipulating Parameters (Pn) ..5-4 5.1.1 Parameter Classification .

- Page 114 Selecting the Phase Sequence for a Linear Servomotor . 5-24 5.10 Polarity Sensor Setting ....5-26 5.11 Polarity Detection ....5-27 5.11.1 Restrictions .

- Page 115 5.19 Setting the Regenerative Resistor Capacity . . . 5-57...

-

Page 116: Manipulating Parameters (Pn)

5.1 Manipulating Parameters (Pn) 5.1.1 Parameter Classification Manipulating Parameters (Pn) This section describes the classifications, notation, and setting methods for the parameters given in this manual. 5.1.1 Parameter Classification There are the following two types of SERVOPACK parameters. Classification Meaning Parameters for the basic settings that are Setup Parameters required for operation. -

Page 117: Notation For Parameters

5.1 Manipulating Parameters (Pn) 5.1.2 Notation for Parameters Tuning Parameters Normally the user does not need to set the tuning parameters individually. Use the various SigmaWin+ tuning functions to set the related tuning parameters to increase the response even further for the conditions of your machine. Refer to the following sections for details. 8.6 Autotuning without Host Reference on page 8-23 8.7 Autotuning with a Host Reference on page 8-35 8.8 Custom Tuning on page 8-42... -

Page 118: Parameter Setting Methods

5.1 Manipulating Parameters (Pn) 5.1.3 Parameter Setting Methods 5.1.3 Parameter Setting Methods You can use the SigmaWin+, a Digital Operator, or the Panel Operator to set parameters. A sample operating procedure is given below. Setting Parameters with the SigmaWin+ Select Parameters - Edit Parameters from the menu bar of the Main Window of the Sig- maWin+. -

Page 119: Write Prohibition Setting For Parameters

5.1 Manipulating Parameters (Pn) 5.1.4 Write Prohibition Setting for Parameters Click the Write Button. Writing will start. This concludes the procedure to edit the parameter. Proceed to step 7 only when the dialog box shown in step 7 is displayed. Click the OK Button. - Page 120 5.1 Manipulating Parameters (Pn) 5.1.4 Write Prohibition Setting for Parameters Operating Procedure Use the following procedure to prohibit or permit writing parameter settings. Select Setup - Write Prohibited Setting from the menu bar of the Main Window of the SigmaWin+. Press the for the rightmost digit and set one of the following.

- Page 121 5.1 Manipulating Parameters (Pn) 5.1.4 Write Prohibition Setting for Parameters SigmaWin+ Panel Operator or Digital Operator When Writ- ing Is Pro- Reference Menu Bar SigmaWin+ Function Fn No. Utility Function Name hibited Button Name Cannot be Origin Search Fn003 Origin Search page 7-25 executed.

-

Page 122: Initializing Parameter Settings

5.1 Manipulating Parameters (Pn) 5.1.5 Initializing Parameter Settings SigmaWin+ Panel Operator or Digital Operator When Writ- ing Is Pro- Reference Menu Bar SigmaWin+ Function Fn No. Utility Function Name hibited Button Name Cannot be Jogging Fn002 page 7-7 executed. Test Opera- tion Cannot be Program Jogging... - Page 123 5.1 Manipulating Parameters (Pn) 5.1.5 Initializing Parameter Settings Click the Initialize Button. Click the OK Button. Click the Cancel Button to cancel initialization. The Parameter Editing Dialog Box will return. Click the Initialize Button. Click the Cancel Button to cancel initialization. The Parameter Editing Dialog Box will return. Click the OK Button.

- Page 124 5.1 Manipulating Parameters (Pn) 5.1.5 Initializing Parameter Settings Turn the power supply to the SERVOPACK OFF and ON again after the parameter set- tings have been initialized. This concludes the procedure to initialize the parameter settings. 5-12...

-

Page 125: Control Method Selection

5.2 Control Method Selection Control Method Selection You can use the SERVOPACK for speed control, position control, or torque control. You set the control method in Pn000 = n.X (Control Method Selection). Control Method Selection Pn000 = Control Method Outline Reference ... -

Page 126: Power Supply Type Settings For The Main Circuit And Control Circuit

5.3 Power Supply Type Settings for the Main Circuit and Control Circuit 5.3.1 AC Power Supply Input/DC Power Supply Input Setting Power Supply Type Settings for the Main Circuit and Control Circuit A SERVOPACK can operated on either an AC power supply input or DC power supply input to the main and control circuits. -

Page 127: Single-Phase Ac Power Supply Input/Three-Phase Ac Power Supply Input Setting

5.3 Power Supply Type Settings for the Main Circuit and Control Circuit 5.3.2 Single-phase AC Power Supply Input/Three-phase AC Power Supply Input Setting 5.3.2 Single-phase AC Power Supply Input/Three-phase AC Power Supply Input Setting Some models of Three-phase 200-VAC SERVOPACKs can also operate on a single-phase 200-VAC power supply. -

Page 128: Automatic Detection Of Connected Motor

5.4 Automatic Detection of Connected Motor Automatic Detection of Connected Motor You can use a SERVOPACK to operate either a Rotary Servomotor or a Linear Servomotor. If you connect the Servomotor encoder to the CN2 connector on the SERVOPACK, the SER- VOPACK will automatically determine which type of Servomotor is connected. -

Page 129: Functions And Settings For The /S-On (Servo On) Signal

5.5 Functions and Settings for the /S-ON (Servo ON) Signal 5.5.1 Function of the /S-ON (Servo ON) Signal Functions and Settings for the /S-ON (Servo ON) Signal The /S-ON (Servo ON) signal is used to enable Servomotor operation. This section describes the function of and settings for the /S-ON signal. 5.5.1 Function of the /S-ON (Servo ON) Signal Type... -

Page 130: Motor Direction Setting

5.6 Motor Direction Setting Motor Direction Setting You can reverse the direction of Servomotor rotation by changing the setting of Pn000 = n.X (Direction Selection) without changing the polarity of the speed or position reference. This causes the rotation direction of the motor to change, but the polarity of the signals, such as encoder output pulses, output from the SERVOPACK do not change. -

Page 131: Setting The Linear Encoder Pitch

5.7 Setting the Linear Encoder Pitch Setting the Linear Encoder Pitch If you connect a linear encoder to the SERVOPACK through a Serial Converter Unit, you must set the scale pitch of the linear encoder in Pn282. If a Serial Converter Unit is not connected, you do not need to set Pn282. Serial Converter Unit The Serial Converter Unit converts the signal from the linear encoder into a form that can be read by the SERVOPACK. -

Page 132: Writing Linear Servomotor Parameters

5.8 Writing Linear Servomotor Parameters Writing Linear Servomotor Parameters If you connect a linear encoder to the SERVOPACK without going through a Serial Converter Unit, you must use the SigmaWin+ to write the motor parameters to the linear encoder. The motor parameters contain the information that is required by the SERVOPACK to operate the Linear Servomotor. - Page 133 5.8 Writing Linear Servomotor Parameters Operating Procedure Use the following procedure to write the motor parameters to the linear encoder. You can download the motor parameter file to write to the linear encoder from our web site (http://www.e-mechatronics.com/). Select Setup - Motor Parameter Scale Write from the menu bar of the Main Window of the SigmaWin+.

- Page 134 5.8 Writing Linear Servomotor Parameters Confirm that the motor parameter file information that is displayed is suitable for your motor, and then click the Next Button. Displays an exterior view of the motor. Click the image to enlarge it. Click the Cancel Button to cancel writing the motor parameters to the linear encoder. The Main Win- dow will return.

- Page 135 5.8 Writing Linear Servomotor Parameters Click the No Button to cancel writing the motor parameters to the linear encoder. If you click the Yes Button, writing the motor parameter scale will start. Click the Complete Button. Click the OK Button. Turn the power supply to the SERVOPACK OFF and ON again.

-

Page 136: Selecting The Phase Sequence For A Linear Servomotor

5.9 Selecting the Phase Sequence for a Linear Servomotor Selecting the Phase Sequence for a Linear Servomotor You must select the phase sequence of the Linear Servomotor so that the forward direction of the Linear Servomotor is the same as the encoder’s count-up direction. Before you set the Linear Servomotor phase sequence (Pn080 = n.X), check the follow- ing items. - Page 137 5.9 Selecting the Phase Sequence for a Linear Servomotor If the correct value is not displayed for the feedback pulse counter, the following condi- Information tions may exist. Check the situation and correct any problems. • The linear encoder pitch is not correct. If the scale pitch that is set in Pn282 does not agree with the actual scale pitch, the expected number of feedback pulses will not be returned.

-

Page 138: Polarity Sensor Setting

5.10 Polarity Sensor Setting 5.10 Polarity Sensor Setting The polarity sensor detects the polarity of the Servomotor. You must set a parameter to specify whether the Linear Servomotor that is connected to the SERVOPACK has a polarity sensor. Specify whether there is a polarity sensor in Pn080 = n.X (Polarity Sensor Selection). If the Linear Servomotor has a polarity sensor, set Pn080 to n.0 (Use polarity sensor) (default setting). -

Page 139: Polarity Detection

5.11 Polarity Detection 5.11.1 Restrictions 5.11 Polarity Detection If you use a Linear Servomotor that does not have a polarity sensor, then you must detect the polarity. Detecting the polarity means that the position of the electrical phase angle on the electrical angle coordinates of the Servomotor is detected. -

Page 140: Using The /S-On (Servo On) Signal To Perform Polarity Detection

5.11 Polarity Detection 5.11.2 Using the /S-ON (Servo ON) Signal to Perform Polarity Detection • There must be no alarms except for an A.C22 alarm (Phase Information Disagreement). • The parameters must not be write prohibited. (This item applies only when using the Sig- maWin+ or Digital Operator.) •... -

Page 141: Using A Tool Function To Perform Polarity Detection

5.11 Polarity Detection 5.11.4 Using a Tool Function to Perform Polarity Detection Signal Type Signal Connector Pin No. Meaning Status Turns ON the servo (supplies power to the motor) and (closed) enables operation. CN1-40 /S-ON (default setting) Turns OFF the servo (stops power supply to the (open) motor) and disables operation. - Page 142 5.11 Polarity Detection 5.11.4 Using a Tool Function to Perform Polarity Detection Click the Continue Button. Click the Cancel Button to cancel polarity detection. The Main Window will return. Click the Start Button. Polarity detection will be executed. This concludes the procedure to execute polarity detection. 5-30...

-

Page 143: Overtravel And Related Settings

5.12 Overtravel and Related Settings 5.12 Overtravel and Related Settings Overtravel is a safety function of the SERVOPACK that forces the Servomotor to stop in response to a signal input from a limit switch that is activated when a moving part of the machine exceeds the safe range of movement. -

Page 144: Overtravel Signals

5.12 Overtravel and Related Settings 5.12.1 Overtravel Signals 5.12.1 Overtravel Signals The overtravel signals include the P-OT (Forward Drive Prohibit) and the N-OT (Reverse Drive Prohibit) signals. Type Signal Connector Pin No. Signal Status Meaning Forward drive is enabled (actual operation). P-OT CN1-42 Forward drive is prohibited... -

Page 145: Motor Stopping Method For Overtravel

5.12 Overtravel and Related Settings 5.12.3 Motor Stopping Method for Overtravel 5.12.3 Motor Stopping Method for Overtravel You can set the stopping method of the Servomotor when overtravel occurs in Pn001 = n.XX (Servo OFF or Alarm Group 1 Stopping Method and Overtravel Stopping Method). Motor Stopping Status after Parameter... -

Page 146: Overtravel Warnings

5.12 Overtravel and Related Settings 5.12.4 Overtravel Warnings Maximum speed Operating speed × Deceleration time (Pn30A) Actual deceleration time Maximum speed Operating speed Actual deceleration time Pn30A 5.12.4 Overtravel Warnings You can set the system to detect an A.9A0 warning (Overtravel) if overtravel occurs while the servo is ON. - Page 147 5.12 Overtravel and Related Settings 5.12.4 Overtravel Warnings 1. Warnings are detected for overtravel in the same direction as the reference. Information 2. Warnings are not detected for overtravel in the opposite direction from the reference. Example: A warning will not be output for a forward reference even if the N-OT signal turns 3.

-

Page 148: Holding Brake

5.13 Holding Brake 5.13.1 Brake Operating Sequence 5.13 Holding Brake A holding brake is used to hold the position of the moving part of the machine when the SER- VOPACK is turned OFF so that moving part does not move due to gravity or an external force. You can use the brake that is built into a Servomotor with a Brake, or you can provide one on the machine. -

Page 149: Bk (Brake) Signal

5.13 Holding Brake 5.13.2 /BK (Brake) Signal Time Required to Time Required to Model Voltage Release Brake [ms] Brake [ms] SGM7J-A5 to 04 SGM7J-06 to 10 24 VDC SGM7G-03 to 20 SGM7A-15 Linear Servomotors: The brake delay times depend on the brake that you use. Set the parameters related to /BK signal output timing according to the delay times for the brake that you will actually use. -

Page 150: Output Timing Of /Bk (Brake) Signal When The Servomotor Is Stopped

5.13 Holding Brake 5.13.3 Output Timing of /BK (Brake) Signal When the Servomotor Is Stopped 1. Signals other than the /BK signal are allocated to the connector pins by default. To allocate connector pins to the /BK signal, you must clear the allocations for the originally allocated sig- nals. -

Page 151: Output Timing Of /Bk (Brake) Signal When The Servomotor Is Operating

5.13 Holding Brake 5.13.4 Output Timing of /BK (Brake) Signal When the Servomotor Is Operating 5.13.4 Output Timing of /BK (Brake) Signal When the Servomotor Is Operating If an alarm occurs while the Servomotor is operating, the Servomotor will start stopping and the /BK signal will be turned OFF. - Page 152 5.13 Holding Brake 5.13.4 Output Timing of /BK (Brake) Signal When the Servomotor Is Operating • When the Time Set In Pn508 Elapses after the Power Supply to the Motor Is Stopped Analog /S-ON input, alarm, or power OFF Rotary Servomotor: Pn507 Linear Servomotor: Pn583 Motor speed Motor stopped with dynamic...

-

Page 153: Motor Stopping Methods For Servo Off And Alarms

5.14 Motor Stopping Methods for Servo OFF and Alarms 5.14.1 Stopping Method for Servo OFF 5.14 Motor Stopping Methods for Servo OFF and Alarms You can use the following methods to stop the Servomotor when the servo is turned OFF or an alarm occurs. -

Page 154: Servomotor Stopping Method For Alarms

5.14 Motor Stopping Methods for Servo OFF and Alarms 5.14.2 Servomotor Stopping Method for Alarms 5.14.2 Servomotor Stopping Method for Alarms There are two types of alarms, group 1 (Gr. 1) alarms and group 2 (Gr. 2) alarms. A different parameter is used to set the stopping method for alarms for each alarm type. - Page 155 5.14 Motor Stopping Methods for Servo OFF and Alarms 5.14.2 Servomotor Stopping Method for Alarms Parameter Status after Servomotor When Servomotor Classification Stopping Method Enabled Pn00B Pn00A Pn001 Stops Dynamic brake (default setting) Zero-speed stop- (default – ...

-

Page 156: Motor Overload Detection Level

5.15 Motor Overload Detection Level 5.15.1 Detection Timing for Overload Warnings (A.910) 5.15 Motor Overload Detection Level The motor overload detection level is the threshold used to detect overload alarms and over- load warnings when the Servomotor is subjected to a continuous load that exceeds the Servo- motor ratings. -

Page 157: Detection Timing For Overload Alarms (A.720)

5.15 Motor Overload Detection Level 5.15.2 Detection Timing for Overload Alarms (A.720) 5.15.2 Detection Timing for Overload Alarms (A.720) If Servomotor heat dissipation is insufficient (e.g., if the heat sink is too small), you can lower the overload alarm detection level to help prevent overheating. To reduce the overload alarm detection level, change the setting of Pn52C (Base Current Der- ating at Motor Overload Detection). -

Page 158: Electronic Gear Settings

5.16 Electronic Gear Settings 5.16 Electronic Gear Settings The minimum unit of the position data that is used to move a load is called the reference unit. The reference unit is used to give travel amounts, not in pulses, but rather in distances or other physical units (such as μm or °) that are easier to understand. -

Page 159: Electronic Gear Ratio Settings

5.16 Electronic Gear Settings 5.16.1 Electronic Gear Ratio Settings When the Electronic Gear Is Not Used When the Electronic Gear Is Used To move the load 10 mm: To use reference units to move the load 10 mm: 10 × 1000 ÷ 20 × 256 = 128,000 If we set the reference unit to 1 μm, the travel distance is 1 μm per pulse. - Page 160 5.16 Electronic Gear Settings 5.16.1 Electronic Gear Ratio Settings SGM7A, SGM7J, SGM7G - Specification Code Encoder Resolution 24-bit multiturn absolute encoder 16,777,216 24-bit incremental encoder 16,777,216 SGMCS - Code Specification Encoder Resolution 20-bit single-turn absolute encoder 1,048,576 20-bit incremental encoder 1,048,576 SGMCV - Specification...

- Page 161 5.16 Electronic Gear Settings 5.16.1 Electronic Gear Ratio Settings Linear Type of Model of Serial Con- Linear Encoder Encoder Linear Manufacturer verter Unit or Model of Resolution Resolution Model Pitch Encoder Head with Interpolator [μm] Heidenhain 0.005 μm LIC4100 Series 20.48 4,096 EIB3391Y...

-

Page 162: Electronic Gear Ratio Setting Examples

5.16 Electronic Gear Settings 5.16.2 Electronic Gear Ratio Setting Examples 5.16.2 Electronic Gear Ratio Setting Examples Setting examples are provided in this section. • Rotary Servomotors Machine Configuration Ball Screw Rotary Table Belt and Pulley Reference unit: 0.005 mm Reference unit: 0.01° Reference unit: 0.001 mm Load shaft Step... -

Page 163: Resetting The Absolute Encoder

5.17 Resetting the Absolute Encoder 5.17.1 Precautions on Resetting 5.17 Resetting the Absolute Encoder In a system that uses an absolute encoder, the multiturn data must be reset at startup. An alarm related to the absolute encoder (A.810 or A.820) will occur when the absolute encoder must be reset, such as when the power supply is turned ON. -

Page 164: Operating Procedure

5.17 Resetting the Absolute Encoder 5.17.3 Operating Procedure 5.17.3 Operating Procedure Use the following procedure to reset the absolute encoder Confirm that the servo is OFF. Select Setup - Reset Absolute Encoder from the menu bar of the Main Window of the SigmaWin+. - Page 165 5.17 Resetting the Absolute Encoder 5.17.3 Operating Procedure Click the OK Button. The absolute encoder will be reset. When Resetting Fails If you attempted to reset the absolute encoder when the servo was ON in the SERVOPACK, the fol- lowing dialog box will be displayed and processing will be cancelled. Click the OK Button.

-

Page 166: Setting The Origin Of The Absolute Encoder

5.18 Setting the Origin of the Absolute Encoder 5.18.1 Setting the Origin of the Absolute Linear Encoder 5.18 Setting the Origin of the Absolute Encoder 5.18.1 Setting the Origin of the Absolute Linear Encoder You can set any position as the origin in the following Linear Encoders. •... - Page 167 5.18 Setting the Origin of the Absolute Encoder 5.18.1 Setting the Origin of the Absolute Linear Encoder Click the Continue Button. Click the Execute setting Button. Click the Continue Button. Click the Cancel Button to cancel setting the origin of the absolute linear encoder. The previous dia- log box will return.

- Page 168 5.18 Setting the Origin of the Absolute Encoder 5.18.1 Setting the Origin of the Absolute Linear Encoder Click the OK Button. Turn the power supply to the SERVOPACK OFF and ON again. If you use a Linear Servomotor that does not have a polarity sensor, perform polarity detection.

-

Page 169: Setting The Regenerative Resistor Capacity

20% = 20 W). Note: 1. An A.320 alarm will be displayed if the setting is not suitable. 2. The default setting of 0 specifies that the SERVOPACK’s built-in regenerative resistor or Yaskawa’s Regen- erative Resistor Unit is being used. -

Page 170: Application Functions

Application Functions This chapter describes the application functions that you can set before you start servo system operation. It also describes the setting methods. I/O Signal Allocations ....6-4 6.1.1 Input Signal Allocations . - Page 171 6.6.5 /COIN (Positioning Completion) Signal ..6-33 6.6.6 /NEAR (Near) Signal ..... .6-35 6.6.7 Reference Pulse Inhibition Function .

- Page 172 6.12.8 Multiturn Limit Setting ....6-79 6.12.9 Multiturn Limit Disagreement Alarm (A.CC0) ....... 6-80 6.13 Absolute Linear Encoders .

-

Page 173: I/O Signal Allocations

6.1 I/O Signal Allocations 6.1.1 Input Signal Allocations I/O Signal Allocations Functions are allocated to the pins on the I/O signal connector (CN1) in advance. You can change the allocations and the polarity for some of the connector pins. Function allocations and polarity settings are made with parameters. - Page 174 6.1 I/O Signal Allocations 6.1.1 Input Signal Allocations Changing Input Signal Allocations • If you change the default polarity settings for the /S-ON (Servo ON), P-OT (Forward Drive Pro- hibit), or N-OT (Reverse Drive Prohibit) signal, the main circuit power supply will not be turned OFF and the overtravel function will not operate if there are signal line disconnections or other Important problems.

-

Page 175: Output Signal Allocations

6.1 I/O Signal Allocations 6.1.2 Output Signal Allocations Parameter Pin No. Description Setting +24 V A reverse signal (a signal with “/” before the signal abbreviation, such as the / S-ON signal) is active when the contacts are OFF (open). A signal that does not have “/”... - Page 176 6.1 I/O Signal Allocations 6.1.2 Output Signal Allocations Interpreting the Output Signal Allocation Tables Analog These columns give the parameter settings to use. Signals are allocated to CN1 pins according to the settings. : Default settings. CN1 Pin No. Output Signal Name Disabled Output and Parameter...

-

Page 177: Alm (Servo Alarm) Signal

6.1 I/O Signal Allocations 6.1.3 ALM (Servo Alarm) Signal Example of Changing Output Signal Allocations The following example shows disabling the /COIN (Positioning Completion) signal allocated to CN1-25 and CN1-26 and allocating the /BK (Brake) signal. Pn50E = n. -

Page 178: Warn (Warning) Signal

6.1 I/O Signal Allocations 6.1.5 /WARN (Warning) Signal ALO1 to ALO3 (Alarm Code) Signals The ALO1 to ALO3 signals are allocated to the following output signal terminals (CN1) by default. Type Signal Name Pin No. ALO1 CN1-37 ALO2 Alarm Code Output CN1-38 Output ALO3... -

Page 179: Tgon (Rotation Detection) Signal

6.1 I/O Signal Allocations 6.1.6 /TGON (Rotation Detection) Signal 6.1.6 /TGON (Rotation Detection) Signal The /TGON signal indicates that the Servomotor is operating. This signal is output when the shaft of the Servomotor rotates at the setting of Pn502 (Rotation Detection Level) or faster or the setting of Pn581 (Zero Speed Level) or faster. - Page 180 6.1 I/O Signal Allocations 6.1.7 /S-RDY (Servo Ready) Signal The /S-RDY signal is allocated to CN1-29 and CN1-30 by default. Type Signal Connector Pin No. Signal Status Meaning ON (closed) Ready to receive the /S-ON (Servo ON) signal. CN1-29 and CN1- Output /S-RDY Not ready to receive the /S-ON (Servo ON) sig-...

-

Page 181: Operation For Momentary Power Interruptions

6.2 Operation for Momentary Power Interruptions Operation for Momentary Power Interruptions Even if the main power supply to the SERVOPACK is interrupted momentarily, power supply to the motor (servo ON status) will be maintained for the time set in Pn509 (Momentary Power Interruption Hold Time). -

Page 182: Semi F47 Function

6.3 SEMI F47 Function SEMI F47 Function The SEMI F47 function detects an A.971 warning (Undervoltage) and limits the output current if the DC main circuit power supply voltage to the SERVOPACK drops to a specified value or lower because the power was momentarily interrupted or the main circuit power supply voltage was temporarily reduced. - Page 183 6.3 SEMI F47 Function Setting for A.971 Warnings (Undervoltage) You can set whether or not to detect A.971 warnings (Undervoltage). Parameter Meaning When Enabled Classification n.0 Do not detect undervoltage warning. (default setting) Detect undervoltage warning and limit Pn008 After restart Setup...

-

Page 184: Setting The Motor Maximum Speed

6.4 Setting the Motor Maximum Speed Setting the Motor Maximum Speed You can set the maximum speed of the Servomotor with the following parameter. • Rotary Servomotors Speed Position Torque Maximum Motor Speed Setting Range Setting Unit Default Setting When Enabled Classification Pn316 0 to 65,535... -

Page 185: Speed Control

6.5 Speed Control 6.5.1 Basic Settings for Speed Control Speed Control There are two types of speed control: speed control with an analog voltage reference and speed control with internal set speeds. This section describes speed control with an analog voltage reference. - Page 186 6.5 Speed Control 6.5.1 Basic Settings for Speed Control If you will use a host controller, such as a programmable controller, for position control, connect the above output pins to the speed reference output terminals on the host controller. SERVOPACK Host controller V-REF Analog...

- Page 187 6.5 Speed Control 6.5.1 Basic Settings for Speed Control Adjusting the Speed Reference Offset With speed control, the Servomotor may sometimes rotate at a very low speed for a speed ref- erence of 0 V (with a reference speed of 0 or when the speed reference is stopped). This occurs because the internal reference in the SERVOPACK has a slight offset.

- Page 188 6.5 Speed Control 6.5.1 Basic Settings for Speed Control Input a 0-V reference voltage from the host controller or an external circuit. Servomotor Analog 0-V speed reference or 0-V torque reference Host controller Slight rotation (when servo is ON) Servo OFF SERVOPACK Select Setup - Adjust Offset - Adjust the Speed and Torque Reference Offset from the menu bar of the Main Window of the SigmaWin+.

- Page 189 6.5 Speed Control 6.5.1 Basic Settings for Speed Control Manually Adjusting the Speed Reference Offset You can directly input a speed reference offset to adjust the speed reference. The offset is adjusted manually in the following cases. • When a position loop is created with the host computer and the position deviation when the Servomotor is stopped by a servo lock is to be set to 0 •...

- Page 190 6.5 Speed Control 6.5.1 Basic Settings for Speed Control Use the +1 and -1 Buttons to adjust the value in the Speed Reference Box to 0. 6-21...

-

Page 191: Soft Start Settings

6.5 Speed Control 6.5.2 Soft Start Settings 6.5.2 Soft Start Settings The soft start function takes a stepwise speed reference input and applies the specified accel- eration/deceleration rates to convert it to a trapezoidal speed reference. You specify the acceleration/deceleration rates in Pn305 (Soft Start Acceleration Time) and Pn306 (Soft Start Deceleration Time). -

Page 192: Speed Reference Filter

6.5 Speed Control 6.5.3 Speed Reference Filter 6.5.3 Speed Reference Filter The speed reference filter is a first order lag filter that is applied to the V-REF (Speed Reference Input) signal. You set the speed reference filter in Pn307 (Speed Reference Filter Time Constant). It is normally not necessary to change this parameter. - Page 193 6.5 Speed Control 6.5.4 Zero Clamping /ZCLAMP (Zero Clamping) Signal Use the /ZCLAMP signal to enable zero clamping. When Using the Default Input Signal Allocations (Pn50A = n.0) The /ZCLAMP signal is allocated to pin CN1-41 on the I/O signal connector by default. Type Signal Connector Pin No.

-

Page 194: V-Cmp (Speed Coincidence Detection) Signal

6.5 Speed Control 6.5.5 /V-CMP (Speed Coincidence Detection) Signal Related Parameters You set the speed at which to apply zero clamping as the zero clamping level (Pn501 or Pn580). If you set a value that exceeds the maximum speed of the Servomotor, the actual speed will be limited to the maximum speed of the Servomotor. - Page 195 6.5 Speed Control 6.5.5 /V-CMP (Speed Coincidence Detection) Signal • Linear Servomotors Speed Speed Coincidence Signal Detection Width Pn582 Setting Range Setting Unit Default Setting When Enabled Classification 0 to 100 1 mm/s Immediately Setup The signal is output when the difference between the reference speed and motor speed is equal or less than the setting.

-

Page 196: Position Control

6.6 Position Control Position Control Position control is used to input a pulse train reference from the host controller to the SERVO- PACK to move to a target position. The position is controlled with the number of input pulses, and the speed is controlled with the input pulse frequency. Use position control when position- ing is required. -

Page 197: Basic Settings For Position Control

6.6 Position Control 6.6.1 Basic Settings for Position Control 6.6.1 Basic Settings for Position Control This section describes the reference pulse forms and input filters. Reference Pulse Forms To perform speed control, you must specify how the reference is input from the host controller (i.e., the reference pulse form). - Page 198 6.6 Position Control 6.6.1 Basic Settings for Position Control Electrical Specifications for Pulse Train Reference The following table describes the forms for pulse train references. Pulse Train Reference Form Electrical Specifications Remarks Sign and pulse train t1 t2 (SIGN and PLUS signals) SIGN SIGN is high for t1, t2, t3, t7 ≤...

-

Page 199: Clr (Position Deviation Clear) Signal Function And Settings

6.6 Position Control 6.6.2 CLR (Position Deviation Clear) Signal Function and Settings 6.6.2 CLR (Position Deviation Clear) Signal Function and Set- tings The CLR (Position Deviation Clear) signal is used to clear the deviation counter in the SERVO- PACK. As long as the CLR signal is ON, the deviation counter will be 0, so a position loop will not be formed. -

Page 200: Reference Pulse Input Multiplication Switching

6.6 Position Control 6.6.3 Reference Pulse Input Multiplication Switching Setting the Clear Operation (Pn200 = n.X) This parameter determines when the position error should be set to zero according to the con- dition of the SERVOPACK. Set Pn200 = n.X (Clear Operation). Parameter Meaning When Enabled... -

Page 201: Smoothing Settings

6.6 Position Control 6.6.4 Smoothing Settings CAUTION Always use the /PSELA signal to confirm that the reference pulse input multiplier has been switched and make sure that there are no position reference pulses before you input a posi- tion reference. Unexpected operation may occur if position reference pulses are input before the reference pulse input multiplier changes. -

Page 202: Coin (Positioning Completion) Signal

6.6 Position Control 6.6.5 /COIN (Positioning Completion) Signal Position Position Reference Acceleration/Deceleration Time Constant Setting Range Setting Unit Default Setting When Enabled Classification Pn216 Immediately after 0 to 65,535 0.1 ms Setup the motor stops Position Average Position Reference Movement Time Setting Range Setting Unit Default Setting... - Page 203 6.6 Position Control 6.6.5 /COIN (Positioning Completion) Signal Setting the Positioning Completed Width The /COIN signal is output when the difference between the reference position and the current position (i.e., the position deviation as given by the value of the deviation counter) is equal to or less than the setting of the positioning completed width (Pn522).

-

Page 204: Near (Near) Signal

6.6 Position Control 6.6.6 /NEAR (Near) Signal 6.6.6 /NEAR (Near) Signal The /NEAR (Near) signal indicates when positioning completion is being approached. The host controller receives the NEAR signal before it receives the /COIN (Positioning Comple- tion) signal, it can start preparations for the operating sequence to use after positioning has been completed. - Page 205 6.6 Position Control 6.6.7 Reference Pulse Inhibition Function When Using the Default Input Signal Allocations (Pn50A = n.0) Type Signal Connector Pin No. Signal Status Meaning ON (closed) Counting the reference pulses is stopped. CN1-41 Input /INHIBIT (default setting) OFF (open) The reference pulses are counted.

-

Page 206: Torque Control

6.7 Torque Control 6.7.1 Basic Settings for Torque Control Torque Control Torque control is performed by inputting a torque reference with an analog voltage reference to the SERVOPACK to control the Servomotor with a torque that is proportional to the input volt- age. -

Page 207: Adjusting The Torque Reference Offset

6.7 Torque Control 6.7.2 Adjusting the Torque Reference Offset Output torque (%) Analog (Rated torque) Torque reference voltage (V) 10 12 Default Setting -100 -200 -300 Setting range (1.0 V to 10.0 V) Input voltage range (0 to 12 V) Note: You can input a torque reference that exceeds the rated torque, but A.710 (Instantaneous Overload) or A.720 (Continuous Overload) alarms may occur if the reference is maintained for a long time or the motor outputs a torque that exceeds the rated torque. - Page 208 6.7 Torque Control 6.7.2 Adjusting the Torque Reference Offset Applicable Tools The following table lists the tools that you can use to automatically adjust the torque reference offset and the applicable tool functions. Tool Function Operating Procedure Reference 13.4.8 Autotune Analog (Speed/Torque) Reference Off- Panel Operator Fn009 set (Fn009) on page 13-17...

- Page 209 6.7 Torque Control 6.7.2 Adjusting the Torque Reference Offset Analog Note: You cannot automatically adjust the reference offset if a position loop is created with the host controller. Man- ually adjust the torque reference offset. Manually Adjusting the Torque Reference Offset You can directly input a torque reference offset to adjust the torque reference.

- Page 210 6.7 Torque Control 6.7.2 Adjusting the Torque Reference Offset Operating Procedure Use the following procedure to manually adjust the torque reference offset. Input a 0-V reference voltage from the host controller or an external circuit. Servomotor Analog 0-V speed reference or 0-V torque reference Host controller Slight rotation...

-

Page 211: Torque Reference Filter Settings

Torque Control 6.7.3 Torque Reference Filter Settings 6.7.3 Torque Reference Filter Settings The torque reference filter is a first order lag filter that is applied to the T-REF (Torque Reference Input) signal. The torque reference input filter is set in Pn415 (T-REF Filter Time Constant). If the setting is too high, the response to the torque reference may be slowed down. - Page 212 Torque Control 6.7.4 Speed Limit during Torque Control Internal Speed Limiting If you select internal speed limiting for the torque control option (Pn002 = n.0), set the speed limit for the motor in Pn407 (Speed Limit during Torque Control) or Pn480 (Speed Limit during Force Control).

-

Page 213: Encoder Divided Pulse Output

6.8 Encoder Divided Pulse Output 6.8.1 Encoder Divided Pulse Output Signals Encoder Divided Pulse Output The encoder divided pulse output is a signal that is output from the encoder and processed inside the SERVOPACK. It is then output externally in the form of two phase pulse signals (phases A and B) with a 90°... - Page 214 6.8 Encoder Divided Pulse Output 6.8.1 Encoder Divided Pulse Output Signals Output Phase Forms Forward rotation or movement Reverse rotation or movement (phase B leads by 90°) (phase A leads by 90°) 90° 90° Phase A Phase A Phase B Phase B Phase C Phase C...

- Page 215 6.8 Encoder Divided Pulse Output 6.8.1 Encoder Divided Pulse Output Signals When Passing the First Origin Signal (Ref) in the Forward Direction and Returning after Turning ON the Power Supply Machine position (forward) No origin signal (Ref) is output by the external encoder. However, a phase-C pulse will be output from the SERVOPACK when the motor moves in the Origin detection reverse direction, because this is the same position from which a phase-C...

- Page 216 6.8 Encoder Divided Pulse Output 6.8.1 Encoder Divided Pulse Output Signals Observe the following precaution if you set Pn081 to n.0 (Output phase-C pulses only in the forward direction). When a linear incremental encoder from Magnescale Co., Ltd. is used, the count direction of the encoder determines how the phase-C pulse (CN1-19 and CN1-20) is output.

- Page 217 6.8 Encoder Divided Pulse Output 6.8.1 Encoder Divided Pulse Output Signals When Using a Linear Encoder with Multiple Origins and First Passing the Origin Posi- tion in the Forward Direction and Returning after Turning ON the Power Supply The encoder’s phase-C pulse is output when the origin detection position is passed for the first time in the forward direction after the power supply is turned ON.

-

Page 218: Setting For The Encoder Divided Pulse Output

6.8 Encoder Divided Pulse Output 6.8.2 Setting for the Encoder Divided Pulse Output 6.8.2 Setting for the Encoder Divided Pulse Output This section describes the setting for the encoder divided pulse output for a Rotary Servomotor or Linear Servomotor. Encoder Divided Pulse Output When Using a Rotary Servomotor If you will use a Rotary Servomotor, set the number of encoder output pulses (Pn212). - Page 219 6.8 Encoder Divided Pulse Output 6.8.2 Setting for the Encoder Divided Pulse Output Encoder Divided Pulse Output When Using a Linear Servomotor If you will use a Linear Servomotor, set the encoder output resolution (Pn281). Speed Position Force Encoder Output Resolution Pn281 Setting Range Setting Unit...

-

Page 220: Internal Set Speed Control

6.9 Internal Set Speed Control 6.9.1 Input Signals for Internal Set Speed Control Internal Set Speed Control You can set motor speeds in three parameters in the SERVOPACK and then perform speed control by using external input signals to select the motor speed and direction. Because the speed is controlled with parameters in the SERVOPACK, an external pulse generator or a refer- ence generator is not required to control the speed. -

Page 221: Setting The Control Method To Internal Set Speed Control

6.9 Internal Set Speed Control 6.9.2 Setting the Control Method to Internal Set Speed Control 6.9.2 Setting the Control Method to Internal Set Speed Con- trol Set Pn000 to n.X (Control Method Selection) to 3 to specify internal set speed control. Parameter Meaning When Enabled... -

Page 222: Changing Internal Set Speeds With Input Signals

6.9 Internal Set Speed Control 6.9.4 Changing Internal Set Speeds with Input Signals 6.9.4 Changing Internal Set Speeds with Input Signals You can select the internal set speed and direction with the ON/OFF combinations of the /SPD- D (Motor Direction) signal and the /SPD-A and /SPD-B (Internal Set Speed Selection) signals. •... - Page 223 6.9 Internal Set Speed Control 6.9.4 Changing Internal Set Speeds with Input Signals Motor speed Analog Speed 3 +SPEED3 The acceleration/deceleration rates Speed 2 are set in Pn305 and Pn306. +SPEED2 Speed 1 +SPEED1 Stopped Stopped Stopped -SPEED1 Speed 1 -SPEED2 Speed 2 -SPEED3...

-

Page 224: Selecting Combined Control Methods

6.10 Selecting Combined Control Methods 6.10.1 Setting Pn000 = n.X (Control Method Selection) to 4, 5, or 6 6.10 Selecting Combined Control Methods You can specify switching the SERVOPACK between two control methods. To combine control methods, set Pn000 = n.X (Control Method Selection) to between 4 and B. This section describes how to switch between the methods and the switching conditions. - Page 225 6.10 Selecting Combined Control Methods 6.10.1 Setting Pn000 = n.X (Control Method Selection) to 4, 5, or 6 • Linear Servomotors Input Pins Operation for Setting of Pn000 = n.X Motor /SPD-D /SPD-A /SPD-B Direction ...

- Page 226 6.10 Selecting Combined Control Methods 6.10.1 Setting Pn000 = n.X (Control Method Selection) to 4, 5, or 6 When Changing Input Signal Allocations (Pn50A = n.1) The following four signals are assigned to CN1-40 to CN1-46 on the I/O signal connector: /C- SEL (Control Selection), /SPD-A and /SPD-B (Internal Set Speed Selection) signals, and /SPD- D (Motor Direction) signal.

-

Page 227: Setting Pn000 = N.X (Control Method Selection) To 7, 8, Or 9

6.10 Selecting Combined Control Methods 6.10.2 Setting Pn000 = n.X (Control Method Selection) to 7, 8, or 9 6.10.2 Setting Pn000 = n.X (Control Method Selection) to 7, 8, or 9 You can set Pn000 = n.X (Control Method Selection) to switch between the following control methods. - Page 228 6.10 Selecting Combined Control Methods 6.10.3 Setting Pn000 = n.X (Control Method Selection) to A or B When Changing Input Signal Allocations (Pn50A = n.1) Control Method for Setting of Pn000 = n.X Connector Type Signal Signal Status Pin No. ...

-

Page 229: Selecting Torque Limits

6.11 Selecting Torque Limits 6.11.1 Internal Torque Limits 6.11 Selecting Torque Limits You can limit the torque that is output by the Servomotor. There are four different ways to limit the torque. These are described in the following table. Limit Method Outline Control Method Reference... -

Page 230: External Torque Limits