Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Manual

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric FR-F700PJ

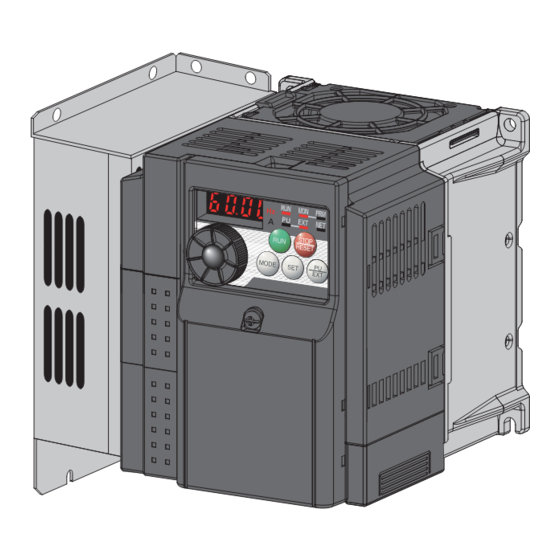

- Page 1 INVERTER FR-F700PJ INSTRUCTION MANUAL (Applied) Air-conditioning inverter FR-F720PJ-0.4K to 15K (F) FR-F740PJ-0.4K to 15K (F) OUTLINE WIRING PRECAUTIONS FOR USE OF THE INVERTER PARAMETERS TROUBLESHOOTING PRECAUTIONS FOR MAINTENANCE AND INSPECTION SPECIFICATIONS...

- Page 2 Thank you for choosing this Mitsubishi Inverter. This Instruction Manual (Applied) provides instructions for advanced use of the FR-F700PJ series inverters. Incorrect handling might cause an unexpected fault. Before using the inverter, always read this Instruction Manual and the Instruction Manual (Basic) [IB-0600425ENG] packed with the product carefully to use the equipment to its optimum performance.

- Page 3 2. Fire Prevention (2) Wiring CAUTION CAUTION Inverter (Filterpack) must be installed on a nonflammable Do not install a power factor correction capacitor or surge wall without holes (so that nobody touches the inverter suppressor/capacitor type filter on the inverter output heatsink on the rear side, etc.).

- Page 4 (7) Disposal CAUTION CAUTION The electronic thermal relay function does not guarantee The inverter must be treated as industrial waste. protection motor from overheating. recommended to install both an external thermal and PTC General instruction thermistor for overheat protection. Many of the diagrams and drawings in this Instruction ...

-

Page 5: Table Of Contents

CONTENTS OUTLINE Product checking and parts identification......... 2 Inverter and peripheral devices ............4 1.2.1 Peripheral devices .......................... 5 Removal and reinstallation of the cover ..........6 1.3.1 Front cover............................6 1.3.2 Wiring cover............................ 8 Installation of the inverter and enclosure design......9 1.4.1 Installation environment for the inverter (Filterpack)............... - Page 6 3 PRECAUTIONS FOR USE OF THE INVERTER EMC and leakage currents ..............42 3.1.1 Leakage currents and countermeasures ..................42 3.1.2 EMC measures ..........................45 3.1.3 Power supply harmonics ......................47 3.1.4 Harmonic suppression guideline in Japan ..................48 Installation of power factor improving reactor ........ 50 Power-OFF and magnetic contactor (MC).........

- Page 7 V/F pattern..................103 4.6.1 Base frequency, voltage (Pr. 3, Pr. 19, Pr. 47) <V/F> ............... 103 4.6.2 Load pattern selection (Pr. 14) ....................105 Frequency setting by external terminals ........106 4.7.1 Operation by multi-speed operation (Pr. 4 to Pr. 6, Pr. 24 to Pr. 27, Pr. 232 to Pr. 239)... 106 4.7.2 Jog operation (Pr.

- Page 8 4.12.3 Reference of the terminal FM (pulse train output) (Pr. 55, Pr. 56) ..........157 4.12.4 Terminal FM calibration (calibration parameter C0 (Pr. 900)) ........... 158 4.12.5 How to calibrate the terminal FM when using the operation panel ..........159 4.13 Operation selection at power failure and instantaneous power failure....................

- Page 9 4.19.4 Setting the frequency by analog input (voltage input)..............212 4.19.5 Operation mode at power-ON (Pr. 79, Pr. 340) ................. 213 4.19.6 Start command source and frequency command source during communication operation (Pr. 338, Pr. 339, Pr. 551)..................214 4.20 Communication operation and setting .......... 218 4.20.1 Wiring and configuration of PU connector .................

- Page 10 5 TROUBLESHOOTING Reset method of protective function ..........296 List of fault or alarm indications............. 297 Causes and corrective actions ............298 Correspondences between digital and actual characters ..... 308 Check first when you have a trouble ..........309 5.5.1 Motor does not start........................

- Page 11 6.2.8 Insulation resistance test using megger ..................328 6.2.9 Pressure test..........................328 SPECIFICATIONS Rating ....................330 Common specifications ..............331 Outline dimension drawings ............333 Specification of the premium high-efficiency IPM motor [MM-EFS (1500r/min) series] ................339 7.4.1 Motor specification........................339 Specification of dedicated IPM motor [MM-EF(1800r/min) series] 340 7.5.1 Motor specification........................

- Page 12 <Abbreviation> PU ...........Operation panel and parameter unit (FR-PU04 /FR-PU07 Inverter ..........Mitsubishi inverter FR-F700PJ series F700PJ ........Mitsubishi inverter FR-F700PJ series Pr.............Parameter number (Number assigned to function) PU operation ........Operation using the PU (operation panel/FR-PU04/FR-PU07) External operation ......Operation using the control circuit signals Combined operation......Operation using both the PU (operation panel/FR-PU04/FR-PU07) and External...

- Page 13 MEMO...

- Page 14 OUTLINE This chapter explains the "OUTLINE" for use of this product. Always read the instructions before using the equipment. Product checking and parts identification ......... 2 Inverter and peripheral devices........... 4 Removal and reinstallation of the cover ........6 Installation of the inverter and enclosure design ...... 9 Inverter placement (Installation of Filterpack) ......

-

Page 15: Product Checking And Parts Identification

Product checking and parts identification Product checking and parts identification Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side face to ensure that the product agrees with your order and the inverter is intact. Inverter Inverter model F740PJ -... -

Page 16: Inverter Placement (Installation Of Filterpack)

RATED installation screw hole SERIAL number SERIAL MITSUBISHI ELECTRIC CORPORATION Crimping terminals for the inverter connection Terminal block cover Black cable: connect to terminal R, S and T of the inverter Red cable: connect to terminal P and P1 of the inverter... -

Page 17: Inverter And Peripheral Devices

0.5MHz to 5MHz. Inverter A wire should be wound four turns at a FR-F700PJ Earth (Ground) maximum. EMC filter (ferrite core) * Contactor (FR-BSF01, FR-BLF) Example) No-fuse R/L1 S/L2T/L3... -

Page 18: Peripheral Devices

Inverter and peripheral devices 1.2.1 Peripheral devices Check the inverter model of the inverter you purchased. Appropriate peripheral devices must be selected according to the capacity. Refer to the following list and prepare appropriate peripheral devices. Moulded Case Circuit Breaker (MCCB) or Earth Leakage Circuit Breaker (ELB) ... -

Page 19: Removal And Reinstallation Of The Cover

Removal and reinstallation of the cover Removal and reinstallation of the cover 1.3.1 Front cover 3.7K or lower Removal (Example of FR-F740PJ-1.5K) 1) Loosen the installation screws of the front cover. (The screws cannot be removed.) 2) Remove the front cover by pulling it like the direction of arrow. Installation screw Reinstallation (Example of FR-F740PJ-1.5K) 1) Place the front cover in front of the inverter, and install it straight. - Page 20 Removal and reinstallation of the cover 5.5K or higher Removal (Example of FR-F740PJ-7.5K) 1) Loosen the installation screws of the front cover. (The screws cannot be removed.) 2) Remove the front cover by pulling it like the direction of arrow with holding the installation hook on the front cover. Installation hook Installation screw...

-

Page 21: Wiring Cover

Removal and reinstallation of the cover 1.3.2 Wiring cover Removal and reinstallation 3.7K or lower Hold the side of the wiring cover, and pull it downward for Also pull the wiring cover downward by holding a removal. frontal part of the wiring cover. To reinstall, fit the cover to the inverter along the guides. -

Page 22: Installation Of The Inverter And Enclosure Design

Installation of the inverter and enclosure design Installation of the inverter and enclosure design When an inverter enclosure is to be designed and manufactured, heat generated by contained equipment, etc., the environment of an operating place, and others must be fully considered to determine the enclosure structure, size and equipment layout. - Page 23 Installation of the inverter and enclosure design Dust, dirt, oil mist Dust and dirt will cause such faults as poor contact of contact points, reduced insulation or reduced cooling effect due to moisture absorption of accumulated dust and dirt, and in-enclosure temperature rise due to clogged filter. In the atmosphere where conductive powder floats, dust and dirt will cause such faults as malfunction, deteriorated insulation and short circuit in a short time.

-

Page 24: Cooling System Types For Inverter Enclosure

Inverter placement (Installation of Filterpack) 1.4.2 Cooling system types for inverter enclosure From the enclosure that contains the inverter, the heat of the inverter and other equipment (transformers, lamps, resistors, etc.) and the incoming heat such as direct sunlight must be dissipated to keep the in-enclosure temperature lower than the permissible temperatures of the in-enclosure equipment including the inverter. -

Page 25: Installation Of The Inverter And Filterpack (For Rear Panel Installation)

Inverter placement (Installation of Filterpack) NOTE When encasing multiple inverters, install them in parallel as a cooling measure. Install the inverter vertically. For heat dissipation and maintenance, allow minimum clearance shown in the figures below from the inverter to the other devices and to the inner surface of the enclosure. -

Page 26: Installation Of Filterpack

Inverter placement (Installation of Filterpack) NOTE When encasing multiple inverters, install them in parallel as a cooling measure. Install the inverter (Filterpack) vertically. When installing the Filterpack to the inverter, use the included installation screws for the inverter rear panel. Using a longer screw may damage the Filterpack. - Page 27 Inverter placement (Installation of Filterpack) Underneath installation 10cm or more Filterpack NOTE Install Filterpack with the wiring portion facing right. Underneath installation is not available for 11K and 15K. To release heat, leave clearance of 10cm or more between the inverter and Filterpack. ...

-

Page 28: Installation Precautions

Inverter placement (Installation of Filterpack) 1.5.4 Installation precautions Above inverter Heat is blown up from inside the inverter by the small fan built in the unit. Any equipment placed above the inverter should be heat resistant. Arrangement of multiple inverters (Filterpacks) When multiple inverters (Filterpacks) are placed in the same enclosure, generally arrange them horizontally as shown in the right figure (a). - Page 29 MEMO...

-

Page 30: Wiring

WIRING This chapter describes the basic "WIRING" for use of this product. Always read the instructions before using the equipment. Wiring..................... 18 Main circuit terminal specifications ..........19 Control circuit specifications ............25 Connection of stand-alone option unit ........34... -

Page 31: Terminal Connection Diagram

Wiring Wiring 2.1.1 Terminal connection diagram Sink logic Main circuit terminal Control circuit terminal With Filterpack *1 Remove the jumper Filterpack . DC reactor (FR-HEL) across the terminals P1 FR-BFP2 Inverter and P/+ to install When connecting a DC reactor, remove the Filterpack. -

Page 32: Main Circuit Terminal Specifications

Main circuit terminal specifications Main circuit terminal specifications 2.2.1 Specification of main circuit terminal Inverter Refer Terminal Terminal Name Description Symbol page R/L1, Connect to the commercial power supply. S/L2, AC power input Do not connect anything to these terminals when using the high power factor T/L3 converter (FR-HC2) or power regeneration common converter (FR-CV). -

Page 33: Terminal Arrangement Of The Main Circuit Terminal, Power Supply And The Motor Wiring

Main circuit terminal specifications 2.2.2 Terminal arrangement of the main circuit terminal, power supply and the motor wiring Three-phase 200V class FR-F720PJ-0.4K to 0.75K FR-F720PJ-1.5K to 3.7K Jumper Jumper N/- P/+ R/L1 S/L2 T/L3 R/L1 S/L2 T/L3 Motor Power supply Power supply Motor FR-F720PJ-5.5K, 7.5K... -

Page 34: Wiring Of The Inverter And Filterpack

Main circuit terminal specifications Three-phase 400V class FR-F740PJ-0.4K to 3.7K FR-F740PJ-5.5K, 7.5K Jumper Jumper N/- P/+ R/L1 S/L2 T/L3 R/L1 S/L2 T/L3 P/+ PR Power supply Motor Power supply Motor FR-F740PJ-11K, 15K NOTE For the inverters without Filterpacks, make sure P/+ PR R/L1 S/L2 T/L3 the power cables are connected to R/L1, S/L2, and T/L3. -

Page 35: Cables And Wiring Length

Main circuit terminal specifications 2.2.4 Cables and wiring length Applicable wire size Select the recommended cable size to ensure that a voltage drop will be 2% or less. If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor torque to decrease especially at the output of a low frequency. - Page 36 Main circuit terminal specifications Earthing (Grounding) precautions Always earth (ground) the motor and inverter (Filterpack). 1) Purpose of earthing (grounding) Generally, an electrical apparatus has an earth (ground) terminal, which must be connected to the ground before use. An electrical circuit is usually insulated by an insulating material and encased. However, it is impossible to manufacture an insulating material that can shut off a leakage current completely, and actually, a slight current flows into the case.

- Page 37 Main circuit terminal specifications Total wiring length Under general-purpose motor control Connect one or more general-purpose motors within the total wiring length shown in the following table. 200V class Pr. 72 PWM frequency selection Setting 1.5K 0.4K 0.75K (carrier frequency) or higher 1 (1kHz) or less 300m...

-

Page 38: Control Circuit Specifications

Control circuit specifications Control circuit specifications 2.3.1 Control circuit terminal indicates that terminal functions can be selected using Pr. 178 to Pr. 182, Pr. 190, and Pr. 192 (I/O terminal function selection). (Refer to page 134.) Input signal Refer Terminal Terminal Name Description Rated Specifications... -

Page 39: Connection Of Stand-Alone Option Unit

Control circuit specifications Output signal Terminal Reference Terminal Name Description Rated Specifications Symbol Page 1 changeover contact output indicates that the inverter Contact capacity:230VAC Relay output (fault protective function has activated and the output stopped. 0.3A A, B, C output) Fault: discontinuity across B-C (continuity across A-C), (power factor =0.4) Normal: continuity across B-C (discontinuity across A-C) -

Page 40: Changing The Control Logic

Control circuit specifications 2.3.2 Changing the control logic The input signals are set to sink logic (SINK) when shipped from the factory. To change the control logic, the jumper connector above the control terminal must be moved to the other position. Change the jumper connector in the sink logic (SINK) position to source logic (SOURCE) position using tweezers, a pair of long-nose pliers etc. - Page 41 Control circuit specifications (1) Sink logic type and source logic type In sink logic, a signal switches ON when a current flows from the corresponding signal input terminal. Terminal SD is common to the contact input signals. Terminal SE is common to the open collector output signals. In source logic, a signal switches ON when a current flows into the corresponding signal input terminal.

-

Page 42: Wiring Of Control Circuit

Control circuit specifications 2.3.3 Wiring of control circuit Control circuit terminal layout Recommend wire size: 0.3mm to 0.75mm RUN SE S1 S2 SC STF STR NOTE Do not remove the shortening wires across the terminals S1 and SC and the terminals S2 and SC. Removing either shortening wire disables the inverter operation. - Page 43 Control circuit specifications 3) Insert the wire into a socket. When using a single wire or a stranded wire without a blade terminal, push an open/close button all the way down with a flathead screwdriver, and insert the wire. Open/close button Flathead screwdriver NOTE ...

- Page 44 Control circuit specifications Signal inputs by contactless switches The contacted input terminals of the inverter (STF, STR, RH, RM, AU) can be controlled using a transistor +24V instead of a contacted switch as shown on the right. STF, etc. Inverter External signal input using transistor Wiring instructions 1) It is recommended to use the cables of 0.3mm...

-

Page 45: Connection To The Pu Connector

Control circuit specifications 2.3.4 Connection to the PU connector Using the PU connector, you can perform communication operation from the parameter unit (FR-PU07), enclosure surface operation panel (FR-PA07), or a personal computer, etc. Remove the inverter front cover when connecting. When connecting the parameter unit or enclosure surface operation panel using a connection cable Use the optional FR-CB2... - Page 46 Pins No. 2 and 8 provide power to the parameter unit. Do not use these pins for RS-485 communication. When making RS-485 communication with a combination of the FR-F700PJ series, FR-F500J series, FR-E500 series and FR-S500 series, incorrect connection of pins No.2 and 8 (parameter unit power supply) of the above PU connector may result in the inverter malfunction or failure.

-

Page 47: Connection Of Stand-Alone Option Unit

Connection of stand-alone option unit Connection of stand-alone option unit The inverter accepts a variety of stand-alone option units as required. Incorrect connection will cause inverter damage or accident. Connect and operate the option unit carefully in accordance with the corresponding option unit manual. 2.4.1 Connection of a dedicated external brake resistor (MRS type, MYS type, FR-ABR) Install a dedicated brake resistor (MRS type, MYS type, FR-ABR) outside when the motor driven by the inverter is made to run... - Page 48 Connection of stand-alone option unit It is recommended to configure a sequence, which shuts off power in the input side of the inverter by the external thermal relay as shown below, to prevent overheat and burnout of the brake resistor (MRS type, MYS type) and high duty brake resistor (FR-ABR) in case the regenerative brake transistor is damaged.

-

Page 49: Connection Of The Brake Unit (Fr-Bu2)

Connection of stand-alone option unit 2.4.2 Connection of the brake unit (FR-BU2) Connect the brake unit (FR-BU2) as shown below to improve the braking capability at deceleration. If the transistors in the brake unit should become faulty, the resistor can be unusually hot. To prevent unusual overheat and fire, install a magnetic contactor on the inverter's input side to configure a circuit so that a current is shut off in case of fault. - Page 50 Connection of stand-alone option unit Connection example with the FR-BR(-H) type resistor FR-BR MCCB Motor R/L1 Three-phase AC S/L2 power supply T/L3 FR-BU2 Inverter 5m or less Connect the inverter terminals (P/+ and N/-) and brake unit (FR-BU2) terminals so that their terminal names match with each other.

-

Page 51: Connection Of The High Power Factor Converter (Fr-Hc2)

Connection of stand-alone option unit 2.4.3 Connection of the high power factor converter (FR-HC2) When connecting the high power factor converter (FR-HC2) to suppress power harmonics, perform wiring securely as shown below. Incorrect connection will damage the FR-HC2 and the inverter. After making sure that the FR-HC2 is properly connected, set the following parameters. -

Page 52: Connection Of The Power Regeneration Common Converter (Fr-Cv)

Connection of stand-alone option unit 2.4.4 Connection of the power regeneration common converter (FR-CV) When connecting the power regeneration common converter (FR-CV), connect the inverter terminals (P/+ and N/-) and power regeneration common converter (FR-CV) terminals as shown below so that their symbols match with each other. R/L1 S/L2 T/L3... -

Page 53: Connection Of A Dc Reactor (Fr-Hel)

Connection of stand-alone option unit 2.4.5 Connection of a DC reactor (FR-HEL) (1) Keep the surrounding air temperature within the permissible range (-10C to +50C). Keep enough clearance around the reactor because it heats up. (Take 10cm or more clearance on top and bottom and 5cm or more on left and right regardless of the installation direction.) 10cm or more 5cm or more... -

Page 54: Precautions For Use Of The Inverter

PRECAUTIONS FOR USE OF THE INVERTER This chapter explains the "PRECAUTIONS FOR USE OF THE INVERTER" for use of this product. Always read the instructions before using the equipment. EMC and leakage currents ............42 Installation of power factor improving reactor ......50 Power-OFF and magnetic contactor (MC) ......... -

Page 55: Emc And Leakage Currents

EMC and leakage currents EMC and leakage currents 3.1.1 Leakage currents and countermeasures Capacitances exist between the inverter I/O cables, other cables and earth and in the motor, through which a leakage current flows. Since its value depends on the static capacitances, carrier frequency, etc., low acoustic noise operation at the increased carrier frequency of the inverter will increase the leakage current. - Page 56 EMC and leakage currents Line-to-line leakage currents Harmonics of leakage currents flowing in static capacitances between the inverter output cables may operate the external thermal relay unnecessarily. When the wiring length is long (50m or more) for the 400V class small-capacity model (7.5kW or less), the external thermal relay is likely to operate unnecessarily because the ratio of the leakage current to the rated motor current increases.

-

Page 57: Inverter-Driven 400V Class Motor

EMC and leakage currents Selection of rated sensitivity current of earth (ground) leakage current breaker When using the earth leakage current breaker with the inverter circuit, select its rated sensitivity current as follows, independently of the PWM carrier frequency. Breaker designed for harmonic and Ig1, Ig2: Leakage currents in wire path during commercial surge suppression... -

Page 58: Emc Measures

EMC and leakage currents 3.1.2 EMC measures Some electromagnetic noises enter the inverter to malfunction it, and others are radiated by the inverter to malfunction peripheral devices. Though the inverter is designed to have high immunity performance, it handles low-level signals, so it requires the following basic techniques. - Page 59 EMC and leakage currents Propagation Path Measures When devices that handle low-level signals and are liable to malfunction due to electromagnetic noises, e.g. instruments, receivers and sensors, are contained in the enclosure that contains the inverter or when their signal cables are run near the inverter, the devices may malfunction due to air-propagated electromagnetic noises.

-

Page 60: Power Supply Harmonics

EMC and leakage currents 3.1.3 Power supply harmonics The inverter may generate power supply harmonics from its converter circuit to affect the power generator, power capacitor etc. Power supply harmonics are different from noise and leakage currents in source, frequency band and transmission path. Take the following countermeasure suppression techniques. -

Page 61: Harmonic Suppression Guideline In Japan

Harmonic suppression measures necessary Equal to or less than upper limit Harmonic suppression measures unnecessary Table 2 Conversion Factors for FR-F700PJ Series Class Circuit Type Conversion Factor (Ki) Without reactor K31= 3.4 With reactor (AC side) K32 = 1.8... - Page 62 EMC and leakage currents Table 4 Harmonic Contents (Values at the fundamental current of 100%) Reactor 11th 13th 17th 19th 23rd 25th Not used Used (AC side) 14.5 Three-phase bridge Used (DC side) or with (Capacitor smoothing) Filterpack Used (AC, DC sides) 1) Calculation of equivalent capacity (P0) of harmonic generating equipment The "equivalent capacity"...

-

Page 63: Installation Of Power Factor Improving Reactor

Installation of power factor improving reactor Installation of power factor improving reactor When the inverter is connected near a large-capacity power transformer (500kVA or more) or when a power capacitor is to be switched over, an excessive peak current may flow in the power input circuit, damaging the converter circuit. To prevent this, always install a Filterpack or an optional AC reactor (FR-HAL). -

Page 64: Power-Off And Magnetic Contactor (Mc)

Power-OFF and magnetic contactor (MC) Power-OFF and magnetic contactor (MC) Inverter input side magnetic contactor (MC) On the inverter input side, it is recommended to provide an MC for the following purposes. (Refer to page 5 for selection.) 1) To release the inverter from the power supply when the fault occurs or when the drive is not functioning (e.g. emergency stop operation). -

Page 65: Inverter-Driven 400V Class Motor

Inverter-driven 400V class motor Inverter-driven 400V class motor In the PWM type inverter, a surge voltage attributable to wiring constants is generated at the motor terminals. Especially for a 400V class motor, the surge voltage may deteriorate the insulation. When the 400V class motor is driven by the inverter, consider the following measures: Measures ... -

Page 66: Precautions For Use Of The Inverter

Precautions for use of the inverter Precautions for use of the inverter The FR-F700PJ series is a highly reliable product, but incorrect peripheral circuit making or operation/handling method may shorten the product life or damage the product. Before starting operation, always recheck the following items. - Page 67 Precautions for use of the inverter (12) Do not apply a voltage higher than the permissible voltage to the inverter I/O signal circuits. Application of a voltage higher than the permissible voltage to the inverter I/O signal circuits or opposite polarity may damage the I/O devices.

-

Page 68: Failsafe Of The System Which Uses The Inverter

Failsafe of the system which uses the inverter Failsafe of the system which uses the inverter When a fault occurs, the inverter trips to output a fault signal. However, a fault output signal may not be output at an inverter fault occurrence when the detection circuit or output circuit fails, etc. - Page 69 Failsafe of the system which uses the inverter 4)Checking the motor operating status by the start signal input to the inverter and inverter output current detection signal. The output current detection signal (Y12 signal) is output when the inverter operates and currents flows in the motor. Check if Y12 signal is output when inputting the start signal to the inverter (forward signal is STF signal and reverse signal is STR signal).

-

Page 70: Parameters

PARAMETERS This chapter explains the "PARAMETERS" for use of this product. Always read the instructions before using the equipment. The following marks are used to indicate the controls as below. (Parameters without any mark are valid for all controls.) Mark Control method Applied motor (control) V/F control... -

Page 71: Operation Panel

Operation panel Operation panel 4.1.1 Names and functions of the operation panel The operation panel cannot be removed from the inverter. (g) Operation status indicator (a) Unit indicator (h) Parameter setting mode indicator (b) Monitor (4-digit LED) (i) Monitor indicator (c) Setting dial (j) Operation mode indicator (d) Start command... -

Page 72: Basic Operation (Factory Setting)

Operation panel 4.1.2 Basic operation (factory setting) Operation mode switchover At power-ON (External operation mode) PU Jog operation mode (Example) Value change and frequency flicker alternately. PU operation mode Frequency setting has been (output frequency monitor) written and completed!! (After 1s) General-purpose Set frequency Keep pressing... -

Page 73: Easy Operation Mode Setting (Easy Setting Mode)

Operation panel 4.1.3 Easy operation mode setting (easy setting mode) Setting of Pr. 79 Operation mode selection according to combination of the start command and speed command can be easily made. Changing Start command: external (STF/STR), frequency command: operate with example Operation Display... -

Page 74: Changing The Parameter Setting Value

Operation panel 4.1.4 Changing the parameter setting value Changing Change the Pr. 1 Maximum frequency setting. example Operation Display Screen at power-ON The monitor display appears. Changing the operation mode PU indicator is lit. Press to choose the PU operation mode. PRM indicator is lit. -

Page 75: Displaying The Control Method And The Set Frequency

Operation panel 4.1.5 Displaying the control method and the set frequency Press the setting dial ( ) to display the present control method. Keep pressing the setting dial in the PU operation mode or in the External/PU combined operation mode 1 (Pr. 79 = "3") to show the presently set frequency. - Page 76 MEMO...

-

Page 77: Parameter List

Parameter list Parameter list Parameter list 4.2.1 Parameter list For simple variable-speed operation of the inverter, the initial setting of the parameters may be used. Set the necessary parameters to meet the load and operational specifications. Parameter setting, change and check can be made from the operation panel. - Page 78 Parameter list Parameter list Control Mode-based Instruction Code Parameter Minimum Refer Correspondence Table Func- Initial Customer Parameter Name Setting Range Setting Parameter Remarks tion Value Setting Increments Page Read Write Extended Copy Clear MFVC MFVC MFVC clear Multi-speed setting (speed 4) 0 to 400Hz, 9999 0.01Hz 9999...

- Page 79 Parameter list Parameter list Control Mode-based Instruction Code Parameter Minimum Refer Correspondence Table Func- Initial Customer Parameter Name Setting Range Setting Parameter Remarks tion Value Setting Increments Page Read Write Extended Copy Clear MFVC MFVC MFVC clear Motor capacity 0.4 to 15kW, 9999 0.01kW 9999...

- Page 80 Parameter list Parameter list Control Mode-based Instruction Code Parameter Minimum Refer Correspondence Table Func- Initial Customer Parameter Name Setting Range Setting Parameter Remarks tion Value Setting Increments Page Read Write Extended Copy Clear MFVC MFVC MFVC clear Output current detection signal 0 to 10s, 9999 0.1s 0.1s...

- Page 81 Parameter list Parameter list Control Mode-based Instruction Code Parameter Minimum Refer Correspondence Table Func- Initial Customer Parameter Name Setting Range Setting Parameter Remarks tion Value Setting Increments Page Read Write Extended Copy Clear MFVC MFVC MFVC clear Life alarm status display (0 to 15) ...

- Page 82 Parameter list Parameter list Control Mode-based Instruction Code Parameter Minimum Refer Correspondence Table Func- Initial Customer Parameter Name Setting Range Setting Parameter Remarks tion Value Setting Increments Page Read Write Extended Copy Clear MFVC MFVC MFVC clear Current average time 0.1 to 1s 0.1s ...

- Page 83 Parameter list Parameter list Control Mode-based Instruction Code Parameter Minimum Refer Correspondence Table Func- Initial Customer Parameter Name Setting Range Setting Parameter Remarks tion Value Setting Increments Page Read Write Extended Copy Clear MFVC MFVC MFVC clear FM terminal calibration —...

- Page 84 Parameter list Parameter list Control Mode-based Instruction Code Parameter Minimum Refer Correspondence Table Func- Initial Customer Parameter Name Setting Range Setting Parameter Remarks tion Value Setting Increments Page Read Write Extended Copy Clear MFVC MFVC MFVC clear Pr.CL Parameter clear 0, 1 Pr.CL —...

-

Page 85: Ipm Motor Control

Parameters according to purposes IPM motor control <IPM> 4.3.1 Setting procedure of IPM motor control <IPM> ................83 4.3.2 Initializing the parameters required to drive an IPM motor (Pr.998) <IPM>........85 4.3.3 IPM motor test operation (Pr.800) <IPM>..................88 4.3.4 Adjusting the speed control gain (Pr.820, Pr.821) <IPM>... - Page 86 4.11.4 Start signal operation selection (STF, STR, STOP signal, Pr. 250) ........... 138 4.11.5 Output terminal function selection (Pr. 190, Pr. 192)..............140 4.11.6 Detection of output frequency (SU, FU signal, Pr. 41 to Pr. 43, Pr. 870) ........144 4.11.7 Output current detection function (Y12 signal, Y13 signal, Pr.

- Page 87 4.18.4 Extended parameter display (Pr. 160) ..................197 4.18.5 Password function (Pr. 296, Pr. 297)..................198 4.19 Selection of operation mode and operation location 4.19.1 Operation mode selection (Pr. 79)....................200 4.19.2 Setting the frequency by the operation panel ................209 4.19.3 Setting the frequency by the operation panel (Pr.

-

Page 88: Ipm Motor Control

When parameter copy is performed from an FR-F700PJ series inverter, which is set to use MM-EFS under IPM motor control, check that IPM motor control is selected on the operation panel after the copy. (Refer to page 62) ... -

Page 89: Parameter Setting

IPM motor control <IPM> IPM motor control setting by the operation panel (parameter setting mode) POINT The parameters required to drive an IPM motor are automatically changed as a batch. (Refer to page 85) Initialize the parameter setting for a premium high-efficiency IPM motor (MM-EFS 1500r/min specification) in the Operation example parameter setting mode. -

Page 90: Initializing The Parameters Required To Drive An Ipm Motor (Pr.998)

IPM motor control <IPM> Parameters referred to Pr.60 Energy saving control selection Refer to page 174 Pr.72 PWM frequency selection Refer to page 181 Pr.190 or Pr.192 (Output terminal function selection) Refer to page 140 Pr. 261 Power failure stop selection Refer to page 168 Pr.653 Speed smoothing control Refer to page 182... - Page 91 IPM motor control <IPM> IPM parameter initialization list By selecting IPM motor control from the parameter setting mode or with Pr.998 IPM parameter initialization, the parameter settings in the following table change to the settings required to drive an IPM motor. The changed settings differ according to the IPM motor specification (capacity).

- Page 92 IPM motor control <IPM> Setting General- IPM motor IPM motor Increment purpose (rotations per Name (frequency) motor minute) 1(MM-EF), 101(MM-EF), 0,101, 1,12 Pr.998 (Initial setting) 12(MM-EFS) 112(MM-EFS) Current average value monitor signal Rated Rated motor current 0.01A output reference current inverter current 10r/min 0.5Hz...

-

Page 93: Ipm Motor Test Operation (Pr.800)

IPM motor control <IPM> 4.3.3 IPM motor test operation (Pr.800) < I P M > Without connecting an IPM motor, the frequency movement can be checked by the monitor or analog signal output. Two types of operation can be selected using this parameter: an actual operation by connecting an IPM motor, or a test operation without connecting an IPM motor to simulate a virtual operation. - Page 94 IPM motor control <IPM> Valid/invalid statuses of I/O terminal functions during the test operation 1)Input terminal function selection (Pr.178 to Pr.182) All assignable functions are valid. 2)Output terminal function selection (Pr. 190 and Pr. 192) Some functions have restrictions. For details, refer to the table below. : invalid : Valid, Signal...

-

Page 95: Adjusting The Speed Control Gain (Pr.820, Pr.821)

IPM motor control <IPM> 4.3.4 Adjusting the speed control gain (Pr.820, Pr.821) < I P M > Manual adjustment of gain is useful to exhibit the optimum performance of the machine or to improve unfavorable conditions such as vibration and acoustic noise during the operation with high load inertia or gear backlashes. Parameter Initial Setting... - Page 96 IPM motor control <IPM> Adjust in the following procedure: 1) Change the Pr.820 setting while checking the conditions. 2) If it can not be adjusted well, change Pr.821 setting, and perform 1) again. · Movement condition Adjustment method Set Pr.820 and Pr.821 higher. If acceleration is slow, raise the setting by 10%s and set a value that satisfies the Pr.820 following condition: The setting immediately before vibration/noise starts...

-

Page 97: Adjustment Of The Output Torque (Current) Of The Motor

Adjustment of the output torque (current) of the motor Adjustment of the output torque (current) of the motor Purpose Parameter that should be Set Refer to Page Set starting torque manually Manual torque boost Pr. 0, Pr. 46 Automatically control output current General-purpose magnetic Pr. -

Page 98: Acquiring Large Starting Torque And Low Speed Torque (General-Purpose Magnetic Flux Vector Control (Pr. 71, Pr. 80))

Adjustment of the output torque (current) of the motor 4.4.2 Acquiring large starting torque and low speed torque (General-purpose magnetic flux vector control (Pr. 71, Pr. 80)) MFVC MFVC MFVC General-purpose magnetic flux vector control is available. Large starting torque and low speed torque are available with General-purpose magnetic flux vector control. ... - Page 99 Adjustment of the output torque (current) of the motor Selection method of General-purpose magnetic flux vector control Perform secure wiring. (Refer to page 18) Display the extended function parameters. (Pr. 160) (Refer to page 197) Set "0" in Pr. 160 to display the extended function parameters. Set the motor.

-

Page 100: Slip Compensation (Pr. 245 To Pr. 247)

Adjustment of the output torque (current) of the motor 4.4.3 Slip compensation (Pr. 245 to Pr. 247) MFVC MFVC MFVC <V/F><GP MFVC> Inverter output current may be used to assume motor slip to keep the motor speed constant. Parameter Name Initial Value Setting Range Description... -

Page 101: Stall Prevention Operation (Pr. 22, Pr. 23, Pr. 48, Pr. 66, Pr. 154, Pr. 156, Pr. 157)

Adjustment of the output torque (current) of the motor 4.4.4 Stall prevention operation (Pr. 22, Pr. 23, Pr. 48, Pr. 66, Pr. 154, Pr. 156, Pr. 157) This function monitors the output current and automatically changes the output frequency to prevent the inverter from coming to trip due to overcurrent, overvoltage, etc. - Page 102 Adjustment of the output torque (current) of the motor Setting of stall prevention operation level (Pr. 22) For Pr. 22, set the output current level where the stall prevention is activated. Set the output current level in ratio to Output current the rated inverter current (rated IPM motor current under IPM Pr.

- Page 103 Adjustment of the output torque (current) of the motor Setting of stall prevention operation in high frequency range (Pr. 22, Pr. 23, Pr. 66) MFVC MFVC MFVC Setting example (Pr. 22 = 120%, Pr. 23 = 100%, Pr. 66 = 60Hz) Pr.

- Page 104 Adjustment of the output torque (current) of the motor To further prevent a trip (Pr.154) Set Pr.154 = "11" when the overvoltage protective function (E.OV ) activates during stall prevention operation in an application with large load inertia. Note that turning OFF the start signal (STF/STR) or varying the frequency signal during stall prevention operation may delay the acceleration/deceleration start.

- Page 105 Adjustment of the output torque (current) of the motor CAUTION Do not set a small value as the stall prevention operation current. Otherwise, torque generated will reduce. Test operation must be performed. Stall prevention operation during acceleration may increase the acceleration time. Stall prevention operation performed during constant speed may cause sudden speed changes.

-

Page 106: Limiting The Output Frequency

Limiting the output frequency Limiting the output frequency Purpose Parameter that should be Set Refer to Page Set upper limit and lower limit of Maximum/minimum Pr. 1, Pr. 2, Pr. 18 output frequency frequency Perform operation by avoiding Frequency jump Pr. -

Page 107: Avoiding Mechanical Resonance Points (Frequency Jumps) (Pr. 31 To Pr. 36, Pr. 552)

Limiting the output frequency 4.5.2 Avoiding mechanical resonance points (frequency jumps) (Pr. 31 to Pr. 36, Pr. 552) When it is desired to avoid resonance attributable to the natural frequency of a mechanical system, these parameters allow resonant frequencies to be jumped. Parameter Name Initial Value... -

Page 108: V/F Pattern

V/F pattern V/F pattern Purpose Parameter that should be Set Refer to Page Base frequency, Set motor ratings Pr. 3, Pr. 19, Pr. 47 Base frequency voltage Select a V/F pattern according to Load pattern selection Pr. 14 applications. 4.6.1 Base frequency, voltage (Pr. - Page 109 V/F pattern Base frequency voltage setting (Pr. 19) Use Pr. 19 Base frequency voltage to set the base voltage (e.g. rated motor voltage). If the setting is less than the power supply voltage, the maximum output voltage of the inverter is as set in Pr. 19. ...

-

Page 110: Load Pattern Selection (Pr. 14)

V/F pattern 4.6.2 Load pattern selection (Pr. 14) Optimum output characteristic (V/F characteristic) for the application and load characteristics can be selected. Parameter Name Initial Value Setting Range Description Number For constant-torque load Load pattern selection For variable-torque load The above parameters can be set when Pr. 160 Extended function display selection = "0". (Refer to page 197) Constant-torque load application (setting "0") Pr. -

Page 111: Frequency Setting By External Terminals

Frequency setting by external terminals Frequency setting by external terminals Purpose Parameter that should be Set Refer to Page Make frequency setting by Pr. 4 to Pr. 6, Pr. 24 to Pr. 27, Multi-speed operation combination of terminals Pr. 232 to Pr. 239 Perform Jog operation Jog operation Pr. - Page 112 Frequency setting by external terminals Multi-speed setting for 4 or more speeds (Pr. 24 to Pr. 27, Pr. 232 to Pr. 239) Frequency from 4th speed to 15th speed can be set according to the combination of the RH, RM, RL and REX signals. Set the running frequencies in Pr.

-

Page 113: Jog Operation (Pr. 15, Pr. 16)

Frequency setting by external terminals 4.7.2 Jog operation (Pr. 15, Pr. 16) The frequency and acceleration/deceleration time for Jog operation can be set. Jog operation can be performed in either of the external and the PU operation mode. This operation can be used for conveyor positioning, test operation, etc. Parameter Initial Name... - Page 114 Frequency setting by external terminals Jog operation from PU Select Jog operation mode from the operation panel and PU (FR-PU04/FR-PU07). Operation is performed only while the start button is pressed. Inverter R/L1 Three-phase AC S/L2 Motor power supply T/L3 Operation panel Operation Display Confirmation of the operation status indicator...

-

Page 115: Remote Setting Function (Pr. 59)

Frequency setting by external terminals NOTE The Pr. 15 setting should be equal to or higher than the Pr. 13 Starting frequency. Changing the terminal assignment using Pr.178 to Pr.182 (input terminal function selection) may affect other functions. Set parameters after confirming the function of each terminal. - Page 116 Frequency setting by external terminals Remote setting function Use Pr. 59 to select whether the remote setting function is used or not and whether the frequency setting storage function in the remote setting mode is used or not. When Pr. 59 is set to any of "1 to 3" (remote setting function valid), the functions of the RH, RM and RL signals are changed to acceleration (RH), deceleration (RM) and clear (RL).

- Page 117 Frequency setting by external terminals REMARKS The RH and RM signals are assigned to the terminals RH and RM in the initial setting. By setting "1 (RM)" or "2 (RH)" in any of Pr. 178 to Pr. 182 (input terminal function selection), you can assign the signals to other terminals. During Jog operation or PID control operation, the remote setting function is invalid.

-

Page 118: Setting Of Acceleration/Deceleration Time And Acceleration/ Deceleration Pattern

Setting of acceleration/deceleration time and acceleration/ deceleration pattern Setting of acceleration/deceleration time and acceleration/ deceleration pattern Purpose Parameter that should be Set Refer to Page Pr. 7, Pr. 8, Pr. 20, Pr. 44, Pr. 45, Motor acceleration/deceleration time Acceleration/deceleration setting times Pr. - Page 119 Setting of acceleration/deceleration time and acceleration/ deceleration pattern Deceleration time setting (Pr. 8, Pr. 20) Use Pr. 8 Deceleration time to set the deceleration time required to reach 0Hz from Pr. 20 Acceleration/deceleration reference frequency. Set the deceleration time according to the following formula. Deceleration Pr.

- Page 120 Setting of acceleration/deceleration time and acceleration/ deceleration pattern (4) Setting the acceleration/deceleration time in the low-speed range (Pr.791, Pr.792) If torque is required in the low-speed range (rated motor frequency/10), set the Pr.791 Acceleration time in low-speed range and Pr.792 Deceleration time in low-speed range settings higher than the Pr.7 Acceleration time and Pr.8 Deceleration time (When the second function is enabled, the setting is applied.) settings so that the slow acceleration/deceleration is performed in the low-speed range.

-

Page 121: Starting Frequency And Start-Time Hold Function (Pr. 13, Pr. 571)

Setting of acceleration/deceleration time and acceleration/ deceleration pattern 4.8.2 Starting frequency and start-time hold function (Pr. 13, Pr. 571) MFVC MFVC MFVC <V/F><GP MFVC> You can set the starting frequency and hold the set starting frequency for a certain period of time. Set these functions when you need the starting torque or want to smooth motor drive at a start. -

Page 122: Minimum Motor Rotation Frequency (Pr.13)

Setting of acceleration/deceleration time and acceleration/ deceleration pattern 4.8.3 Minimum motor rotation frequency (Pr.13) <IPM> Set the frequency where the motor starts running. Set the deadband in the low-speed range to eliminate noise and offset deviation when setting a frequency with analog input. -

Page 123: Acceleration/Deceleration Pattern (Pr. 29)

Setting of acceleration/deceleration time and acceleration/ deceleration pattern 4.8.4 Acceleration/deceleration pattern (Pr. 29) You can set the acceleration/deceleration pattern suitable for application. Parameter Name Initial Value Setting Range Description Number Linear acceleration/ deceleration Acceleration/deceleration S-pattern acceleration/deceleration A pattern selection S-pattern acceleration/deceleration B The above parameters can be set when Pr. -

Page 124: Selection And Protection Of A Motor

Selection and protection of a motor Selection and protection of a motor Purpose Parameter that should be Set Refer to Page Electronic thermal O/L relay Motor protection from overheat Pr. 9, Pr. 51, Pr. 561 PTC thermistor protection Use the constant-torque motor Applied motor Pr. - Page 125 Selection and protection of a motor (2) Electronic thermal O/L relay operation under IPM motor control (Pr.9) This function detects the overload (overheat) of the motor and trips the inverter by stopping the operation of the transistor at the inverter output side. (The operation characteristic is shown below.) ...

- Page 126 Selection and protection of a motor Set two different electronic thermal O/L relays (Pr. 51) MFVC MFVC MFVC Use this function when running two motors of different rated currents individually by a single inverter. (When running two motors together, use external thermal relays.) Set the rated current of the second motor to Pr.

- Page 127 Selection and protection of a motor PTC thermistor protection (Pr. 561) Inverter Motor Terminal 2 and terminal 10 are available for inputting of motor built-in PTC thermistor output. When the PTC thermistor input reaches to the resistance value set in Pr. 561 PTC thermistor protection level, inverter outputs PTC thermistor operation error PTC thermistor input connection signal (E.PTC) and trips.

-

Page 128: Applied Motor (Pr. 71, Pr. 450)

Selection and protection of a motor 4.9.2 Applied motor (Pr. 71, Pr. 450) Setting of the used motor selects the thermal characteristic appropriate for the motor. Setting is required when using a constant-torque motor or IPM motor. Thermal characteristic of the electronic thermal relay function suitable for the motor is set. - Page 129 Selection and protection of a motor To use two types of motors (Pr. 450) MFVC MFVC MFVC Set Pr. 450 Second applied motor to use two different motors with one inverter. When "9999" (initial value) is set, no function is selected. ...

-

Page 130: Exhibiting The Best Performance For The Motor (Offline Auto Tuning)

Selection and protection of a motor 4.9.3 Exhibiting the best performance for the motor (offline auto tuning) (Pr. 71, Pr. 80, Pr. 82 to Pr. 84, Pr. 90, Pr. 96) MFVC MFVC MFVC <GP MFVC> The motor performance can be maximized with offline auto tuning. What is offline auto tuning? When performing General-purpose magnetic flux vector control, the motor can be run with the optimum operating characteristics by automatically measuring the motor constants (offline auto tuning) even when each motor constants... - Page 131 Selection and protection of a motor Before performing offline auto tuning Check the following before performing offline auto tuning. Make sure General-purpose magnetic flux vector control (Pr. 80) is selected. A general-purpose motor (three-phase induction motor) should be connected. Note that the motor should be at a stop at a tuning start.

- Page 132 Selection and protection of a motor Execution of tuning POINT Before tuning, check the monitor display of the operation panel or parameter unit (FR-PU04/FR-PU07) to confirm that the inverter is in the suitable condition for tuning. (Refer to 2) below.) Turning ON the start command in a tuning-disabled status starts the motor running.

- Page 133 Selection and protection of a motor 3) When offline auto tuning ends, press of the operation panel during PU operation. For External operation, turn OFF the start signal (STF signal or STR signal) once. This operation resets the offline auto tuning and the PU's monitor display returns to the normal indication. (Without this operation, next operation cannot be started.) REMARKS ...

-

Page 134: Motor Brake And Stop Operation

Motor brake and stop operation 4.10 Motor brake and stop operation Purpose Parameter that should be Set Refer to Page DC Injection brake of general- Pr. 10 to Pr. 12 purpose motor control Motor braking torque adjustment DC injection brake of IPM Pr. -

Page 135: Dc Injection Brake Of Ipm Motor Control (Pr.10, Pr.11)

Motor brake and stop operation CAUTION Install a mechanical brake to make an emergency stop or to stay stopped for a long time. Parameters referred to Pr. 13 Starting frequency Refer to page 116 Pr. 71 Applied motor Refer to page 123 4.10.2 DC injection brake of IPM motor control (Pr.10, Pr.11) <... -

Page 136: Selection Of A Regenerative Brake (Pr. 30, Pr. 70)

Motor brake and stop operation 4.10.3 Selection of a regenerative brake (Pr. 30, Pr. 70) When making frequent starts/stops, use the optional brake resistor (MRS type, MYS type), high-duty brake resistor (FR-ABR) and brake unit (FR-BU2) to increase the regenerative brake duty. ... - Page 137 Motor brake and stop operation When a high power factor converter (FR-HC2) is used and automatic restart after instantaneous power failure function is valid When automatic restart after instantaneous power failure function of both the FR-HC2 and inverter is valid (when a value other than "9999"...

-

Page 138: Stop Selection (Pr. 250)

Motor brake and stop operation 4.10.4 Stop selection (Pr. 250) Used to select the stopping method (deceleration to a stop or coasting) when the start signal turns OFF. Used to stop the motor with a mechanical brake, etc. together with switching OFF of the start signal. You can also select the operations of the start signals (STF/STR). -

Page 139: Function Assignment Of External Terminal And Control

Function assignment of external terminal and control 4.11 Function assignment of external terminal and control Purpose Parameter that should be Set Refer to Page Input terminal function Assign function to input terminal Pr. 178 to Pr. 182 selection Set MRS signal (output shutoff) to MRS input selection Pr. - Page 140 Function assignment of external terminal and control Input terminal function assignment Using Pr. 178 to Pr. 182, set the functions of the input terminals. Refer to the following table and set the parameters: Refer to Setting Signal Function Related Parameters Page Pr.

-

Page 141: Inverter Output Shutoff Signal (Mrs Signal, Pr. 17)

Function assignment of external terminal and control 4.11.2 Inverter output shutoff signal (MRS signal, Pr. 17) The inverter output can be shut off by the MRS signal. Also, logic for the MRS signal can be selected. Parameter Name Initial Value Setting Range Description Number... -

Page 142: Condition Selection Of Function Validity By Second Function Selection Signal (Rt)

Function assignment of external terminal and control 4.11.3 Condition selection of function validity by second function selection signal (RT) You can select the second function using the RT signal. When the RT signal turns ON, the second function becomes valid. ... -

Page 143: Start Signal Operation Selection (Stf, Str, Stop Signal, Pr. 250)

Function assignment of external terminal and control 4.11.4 Start signal operation selection (STF, STR, STOP signal, Pr. 250) You can select the operation of the start signal (STF/STR). Used to select the stopping method (deceleration to a stop or coasting) when the start signal turns OFF. Used to stop the motor with a mechanical brake, etc. - Page 144 Function assignment of external terminal and control Three-wire type (STF, STR, STOP signal) The three-wire connection is shown below. Turning the STOP signal ON makes start self-holding function valid. In this case, the forward/reverse rotation signal functions only as a start signal. If the start signal (STF or STR) is turned ON and then OFF, the start signal is held and makes a start.

-

Page 145: Output Terminal Function Selection (Pr. 190, Pr. 192)

Function assignment of external terminal and control 4.11.5 Output terminal function selection (Pr. 190, Pr. 192) You can change the functions of the open collector output terminal and relay output terminal. Parameter Initial Name Initial Signal Setting Range Number Value 0, 1, 3, 4, 7, 8, 11 to 16, 25, 26, 46 RUN terminal Open collector... - Page 146 Function assignment of external terminal and control Setting Refer Related Signal Function Operation Positive Negative Parameter Page logic logic Pr. 71, Pr. 80, IPM motor control Output during IPM motor control. Pr. 998 Pr. 65 to During retry Output during retry processing. Pr.

- Page 147 Function assignment of external terminal and control Inverter operation ready signal (RY signal) and inverter running signal (RUN signal) Power supply DC injection brake operation point DC injection brake operation Pr. 13 Starting frequency Time Reset processing When the inverter is ready to operate, the output of the operation ready signal (RY) is ON. (It is also ON during inverter running.) ...

- Page 148 Function assignment of external terminal and control Fault output signal (ALM signal) Inverter fault occurrence If the inverter trips, the ALM signal is output. (Trip) Output frequency Time ON OFF Reset processing (about 1s) Reset ON REMARKS The ALM signal is assigned to the ABC contact in the initial setting. By setting "99 (positive logic) or 199 (negative logic) in Pr.190 or Pr.192 (output terminal function selection), the ALM signal can be assigned to the other signal.

-

Page 149: Detection Of Output Frequency (Su, Fu Signal, Pr. 41 To Pr. 43, Pr. 870)

Function assignment of external terminal and control 4.11.6 Detection of output frequency (SU, FU signal, Pr. 41 to Pr. 43, Pr. 870) The inverter output frequency is detected and output at the output signals. Parameter Name Initial Value Setting Range Description Number Up-to-frequency... - Page 150 Function assignment of external terminal and control (3) Speed detection hysteresis (Pr.870) Output This function prevents chattering of the speed detection frequency (Hz) signals. When an output frequency fluctuates, the up to frequency Pr.42 Pr.870 signal (SU) and output frequency detection signals (FU) may repeat ON/OFF (chatters).

-

Page 151: Output Current Detection Function (Y12 Signal, Y13 Signal, Pr. 150 To Pr. 153, Pr. 166, Pr. 167)

Function assignment of external terminal and control 4.11.7 Output current detection function (Y12 signal, Y13 signal, Pr. 150 to Pr. 153, Pr. 166, Pr. 167) The output current during inverter running can be detected and output to the output terminal. Parameter Setting Name... - Page 152 Function assignment of external terminal and control Zero current detection (Y13 signal, Pr. 152, Pr. 153) If the output current remains lower than the Pr. 152 setting during inverter operation for longer than the time set in Pr. 153, the zero current detection (Y13) signal is output from the inverter's open collector or relay output terminal.

-

Page 153: Remote Output Selection (Rem Signal, Pr. 495, Pr. 496)

Function assignment of external terminal and control 4.11.8 Remote output selection (REM signal, Pr. 495, Pr. 496) You can utilize the ON/OFF of the inverter's output signals instead of the remote output terminal of the programmable logic controller. Parameter Initial Setting Name Description... -

Page 154: Pulse Train Output Of Output Power (Y79 Signal, Pr. 799)

Function assignment of external terminal and control 4.11.9 Pulse train output of output power (Y79 signal, Pr. 799) After power ON or inverter reset, output signal (Y79 signal) is output in pulses every time accumulated output power, which is counted after the Pr.799 Pulse increment setting for output power is set, reaches the specified value (or its integral multiples). -

Page 155: Monitor Display And Monitor Output Signal

Monitor display and monitor output signal 4.12 Monitor display and monitor output signal Refer to Purpose Parameter that should be Set Page Display motor speed Speed display and speed setting Pr. 37, Pr. 144, Pr. 505 Set speed Monitor display/PU main display Pr. - Page 156 Monitor display and monitor output signal NOTE Under V/F control, the output frequency of the inverter is displayed in terms of synchronous speed, and therefore, displayed value = actual speed + motor slip. The display changes to the actual speed (estimated value calculated based on the motor slip) when slip compensation was valid.

-

Page 157: Monitor Display Selection Of Du/Pu And Terminal Fm (Pr. 52, Pr. 54, Pr. 170, Pr. 171, Pr. 268, Pr. 563, Pr. 564, Pr. 891)

Monitor display and monitor output signal 4.12.2 Monitor display selection of DU/PU and terminal FM (Pr. 52, Pr. 54, Pr. 170, Pr. 171, Pr. 268, Pr. 563, Pr. 564, Pr. 891) The monitor to be displayed on the main screen of the operation panel and parameter unit (FR-PU04/FR-PU07) can be selected. - Page 158 Monitor display and monitor output signal Pr. 52 Setting Operation Pr. 54 (FM) Terminal FM Types of Monitor Unit Description panel main Setting Full Scale Value monitor Regenerative brake 0.1% Brake duty set in Pr. 30, Pr. 70 Pr. 70 duty Displays the thermal cumulative value on Electronic thermal...

- Page 159 Monitor display and monitor output signal Pr. 52 Setting Operation Pr. 54 (FM) Terminal FM Types of Monitor Unit Description panel main Setting Full Scale Value monitor Displays the PTC thermistor resistance at PTC thermistor terminal 2 when PTC thermistor protection ...

- Page 160 Monitor display and monitor output signal Operation panel I/O terminal monitor (Pr. 52) When Pr. 52 = "55", the I/O terminal status can be monitored on the operation panel. The I/O terminal monitor is displayed on the third monitor. The LED is ON when the terminal is ON, and the LED is OFF when the terminal is OFF. The center line of LED is always On the I/O terminal monitor (Pr.

- Page 161 Monitor display and monitor output signal Cumulative energization time and actual operation time monitor (Pr. 171, Pr. 563, Pr. 564) Cumulative energization time monitor (Pr. 52 = "20") accumulates energization time from shipment of the inverter every one hour. On the actual operation time monitor (Pr. 52 = "23"), the inverter running time is added up every hour. (Time is not added up during a stop.) If the monitored value exceeds 65535, it is added up from 0.

-

Page 162: Reference Of The Terminal Fm (Pulse Train Output) (Pr. 55, Pr. 56)

Monitor display and monitor output signal 4.12.3 Reference of the terminal FM (pulse train output) (Pr. 55, Pr. 56) The pulse train output terminal FM is available for monitor output. Set the reference of the signal output from terminal FM. Parameter Name Initial Value... -

Page 163: Terminal Fm Calibration (Calibration Parameter C0 (Pr. 900))

Monitor display and monitor output signal 4.12.4 Terminal FM calibration (calibration parameter C0 (Pr. 900)) By using the operation panel or parameter unit, you can calibrate terminal FM to full scale deflection. Parameter Name Initial Value Setting Range Description Number Calibrates the scale of the meter C0 (900) FM terminal calibration... -

Page 164: How To Calibrate The Terminal Fm When Using The Operation Panel

Monitor display and monitor output signal 4.12.5 How to calibrate the terminal FM when using the operation panel Perform the following procedure to calibrate terminal FM using the operation panel FR-DU07. Refer to page 158 for the details of parameters. Operation Display (When Pr. - Page 165 Monitor display and monitor output signal REMARKS Calibration can also be made for External operation. Set the frequency in the External operation mode, and make calibration in the above procedure. Calibration can be made even during operation. For operation from the parameter unit (FR-PU04/FR-PU07), refer to the Instruction Manual of the parameter unit. Parameters referred to Pr.

-

Page 166: Operation Selection At Power Failure And Instantaneous Power Failure

Operation selection at power failure and instantaneous power failure 4.13 Operation selection at power failure and instantaneous power failure Purpose Parameter that should be Set Refer to Page At instantaneous power failure Pr. 30, Pr. 57, Pr. 58, Pr. 96, Automatic restart operation occurrence, restart inverter without after instantaneous power... - Page 167 Operation selection at power failure and instantaneous power failure When Pr. 162 = 1, 11 (without frequency search) Automatic restart operation selection (Pr. 30, Pr. 162, Pr. 299) Instantaneous (power failure) time Without frequency search Power supply When Pr. 162 = "1 (initial value) or 11", automatic restart (R/L1, S/L2, T/L3) operation is performed in a reduced voltage system, where the voltage is gradually risen with the output...

- Page 168 Operation selection at power failure and instantaneous power failure Restart operation at every start When Pr. 162 = "10 or 11", automatic restart operation is also performed every start, in addition to the automatic restart after instantaneous power failure. When Pr. 162 = "0", automatic restart operation is performed at the first start after power supply ON, but not performed at the second time or later.

- Page 169 Operation selection at power failure and instantaneous power failure Setting 1) Set "21" in Pr. 96 Auto tuning setting/status. Tuning is performed without motor running. 2) Set the rated motor current (initial value is rated inverter current) in Pr. 9 Electronic thermal O/L relay. (Refer to page 119) 3) Set Pr.

- Page 170 Operation selection at power failure and instantaneous power failure 3) When offline auto tuning ends, press of the operation panel during PU operation. For External operation, turn OFF the start signal (STF signal or STR signal) once. This operation resets the offline auto tuning and the PU's monitor display returns to the normal indication. (Without this operation, next operation cannot be started.) 4) If offline auto tuning ended in error (see the table below), frequency search gain are not set.

-

Page 171: Automatic Restart After Instantaneous Power Failure/Flying Start Under Ipm

Operation selection at power failure and instantaneous power failure 4.13.2 Automatic restart after instantaneous power failure/flying start under IPM motor control (Pr. 57, Pr. 162, Pr. 611) <IPM> You can restart the inverter without stopping the motor in the following cases: When power comes back ON after an instantaneous power failure ... - Page 172 Operation selection at power failure and instantaneous power failure (3) Automatic restart operation adjustment (Pr. 611) Using Pr. 611, the acceleration time to reach Pr. 20 Acceleration/deceleration reference frequency can be set. This can be set separately from the normal acceleration time. REMARKS Even if the Pr.

-

Page 173: Power-Failure Deceleration Stop Function (Pr. 261)

Operation selection at power failure and instantaneous power failure 4.13.3 Power-failure deceleration stop function (Pr. 261) MFVC MFVC MFVC <V/F><GP MFVC> When a power failure or undervoltage occurs, the inverter can be decelerated to a stop or can be decelerated and re- accelerated to the set frequency. - Page 174 Operation selection at power failure and instantaneous power failure Operation continuation at instantaneous power failure function (Pr. 261 = "2") When power is restored during deceleration after a power failure, acceleration is made again up to the set frequency. ...

-

Page 175: Operation Setting At Fault Occurrence

Operation setting at fault occurrence 4.14 Operation setting at fault occurrence Purpose Parameter that should be Set Refer to Page Recover by retry operation at fault Retry operation Pr. 65, Pr. 67 to Pr. 69 occurrence Do not output input/output phase Input/output phase failure Pr. - Page 176 Operation setting at fault occurrence During a retry, the Y64 signal is ON. For the Y64 signal, assign the function by setting "64 (positive operation)" or "164 (negative operation)" to Pr. 190 or Pr. 192 (output terminal function selection) . ...

-

Page 177: Input/Output Phase Loss Protection Selection (Pr. 251, Pr. 872)

Operation setting at fault occurrence 4.14.2 Input/output phase loss protection selection (Pr. 251, Pr. 872) You can choose whether to make Input/output phase loss protection valid or invalid. Output phase loss protection is a function to stop the inverter output if one of the three phases (U, V, W) on the inverter's output side is lost. -

Page 178: Overspeed Detection Function (Pr.374)

Operation setting at fault occurrence 4.14.4 Overspeed detection function (Pr.374) Inverter outputs are stopped when the motor speed exceeds the Pr.374 Overspeed detection level under IPM motor control. Parameter Name Initial value Setting range Description Number When the motor speed exceeds the speed set in Pr.374, overspeed (E.OS) 0 to 400Hz Overspeed detection level... -

Page 179: Energy Saving Operation And Energy Saving Monitor

Energy saving operation and energy saving monitor 4.15 Energy saving operation and energy saving monitor Purpose Parameter that should be Set Refer to Page Energy saving operation Optimum excitation control Pr. 60 Pr. 52, Pr. 54, Pr. 158, How much energy can be saved Energy saving monitor Pr. -

Page 180: Energy Saving Monitor (Pr. 891 To Pr. 899)

Energy saving operation and energy saving monitor 4.15.2 Energy saving monitor (Pr. 891 to Pr. 899) From the power consumption estimated value during commercial power supply operation, the energy saving effect by use of the inverter can be monitored/output. Parameter Name Initial Value Setting Range... - Page 181 Energy saving operation and energy saving monitor (1) Energy saving monitor list Energy Saving Category Description Remarks Monitored Item Displays the real-time energy savings based on the following calculation: The (estimated) power consumption during the 1) Power saving Real-time energy saving commercial power supply operation - the input power 2) Power saving rate to the inverter...

- Page 182 Energy saving operation and energy saving monitor Details of the energy saving monitors (Pr. 52 and Pr. 54 = "50") Parameter Setting Energy Saving Description and Formula Unit Monitored Item Pr. 895 Pr. 896 Pr. 897 Pr. 899 Difference between the estimated value of power necessary for commercial power supply operation Power saving and the input power calculated by the inverter...

- Page 183 Energy saving operation and energy saving monitor (2) Power saving instantaneous monitor ( 1) power savings, 2) power saving rate ) On the power saving monitor ( 1)), an energy saving effect as compared to the power consumption during commercial power supply operation (estimated value) is calculated and displays on the main monitor.

- Page 184 Energy saving operation and energy saving monitor (5) Power estimated value of commercial power supply operation (Pr. 892, Pr. 893, Pr. 894) Select the commercial power supply operation pattern from among the four patterns of discharge damper control (fan), inlet damper control (fan), valve control (pump) and commercial power supply drive, and set it to Pr.

- Page 185 Energy saving operation and energy saving monitor (6) Annual power saving amount, power cost (Pr. 899) By setting the operation time rate [%] (ratio of time when the motor is actually driven by the inverter during a year) in Pr. 899, the annual energy saving effect can be predicted.

-

Page 186: Motor Noise, Emi Measures, Mechanical Resonance

Motor noise, EMI measures, mechanical resonance 4.16 Motor noise, EMI measures, mechanical resonance Purpose of Use Parameter that should be Set Refer to Page Reduction of the motor noise Carrier frequency and Measures against EMI and leakage Pr. 72, Pr. 240, Pr. 260 Soft-PWM selection currents Reduce mechanical resonance... -

Page 187: Speed Smoothing Control (Pr. 653)

Motor noise, EMI measures, mechanical resonance 4.16.2 Speed smoothing control (Pr. 653) MFVC MFVC MFVC <V/F><GP MFVC> Vibration due to mechanical resonance influences the inverter control, causing the output current (torque) unstable. In this case, the output current (torque) fluctuation can be reduced to ease vibration by changing the output frequency. Parameter Name Initial Value... -

Page 188: Frequency Setting By Analog Input (Terminal 2, 4)

Frequency setting by analog input (terminal 2, 4) 4.17 Frequency setting by analog input (terminal 2, 4) Purpose Parameter that should be Set Refer to Page Selection of voltage/current input (terminal 2, 4) Analog input selection Pr. 73, Pr. 267 Perform forward/reverse rotation by analog input. - Page 189 Frequency setting by analog input (terminal 2, 4) NOTE Set Pr. 267 and a voltage/current input switch correctly, then input an analog signal in accordance with the setting. Incorrect setting as in the table below could cause component damage. Incorrect settings other than below can cause abnormal operation.

- Page 190 Frequency setting by analog input (terminal 2, 4) Perform operation by analog input selection Inverter The frequency setting signal inputs 0 to 5VDC (or 0 to 10VDC) across Forward rotation the terminals 2 and 5. The 5V (10V) input is the maximum output. The power supply 5V can be input by either using the internal power 0 to 5VDC supply or preparing an external power supply.

-

Page 191: Setting The Frequency By Analog Input (Voltage Input)

Frequency setting by analog input (terminal 2, 4) 4.17.2 Setting the frequency by analog input (voltage input) POINT Switch ON the STF (STR) signal to give a start command. Use the (frequency setting) potentiometer to give a frequency command. [Connection diagram] Inverter (The inverter supplies 5V power to the frequency... -

Page 192: Response Level Of Analog Input And Noise Elimination (Pr. 74)

Frequency setting by analog input (terminal 2, 4) REMARKS Pr. 178 STF terminal function selection must be set to "60" (or Pr. 179 STR terminal function selection must be set to "61"). (All are initial values.) The motor will not rotate ... Why? Check that [EXT] is lit. -

Page 193: Bias And Gain Of Frequency Setting Voltage (Current) (Pr. 125, Pr. 126, Pr. 241, C2 (Pr. 902) To C7 (Pr. 905))

Frequency setting by analog input (terminal 2, 4) 4.17.4 Bias and gain of frequency setting voltage (current) (Pr. 125, Pr. 126, Pr. 241, C2 (Pr. 902) to C7 (Pr. 905)) You can set the magnitude (slope) of the output frequency as desired in relation to the frequency setting signal (0 to 5VDC, 0 to 10VDC or 4 to 20mADC). - Page 194 Frequency setting by analog input (terminal 2, 4) Change frequency maximum analog input (Pr. 125, Pr. 126) Initial value 60Hz Set Pr. 125 (Pr. 126) when changing frequency setting (gain) of the maximum analog input voltage (current) only. (C2 (Pr. 902) to C7 (Pr.905) setting need not be changed) Gain Pr.

-

Page 195: Frequency Setting Signal (Current) Bias/Gain Adjustment Method

Frequency setting by analog input (terminal 2, 4) 4.17.5 Frequency setting signal (current) bias/gain adjustment method Follow the following procedure to adjust the bias and gain of the frequency setting voltage (current) using the operation panel. Refer to page 188 for the details of parameters. (a) Method to adjust any point by application of a voltage (current) across terminals 2 and 5 (4 and 5). - Page 196 Frequency setting by analog input (terminal 2, 4) (b) Method to adjust any point without application of a voltage (current) across terminals 2 5 (4 (To change from 4V (80%) to 5V (100%)) Operation Display Confirm the operation status indicator and operation mode indicator ...

- Page 197 Frequency setting by analog input (terminal 2, 4) (c) Adjusting only the frequency without adjusting the gain voltage (current). (When changing the gain frequency from 60Hz to 50Hz) Operation Display Turn until (Pr. 125) or Terminal 2 input Terminal 4 input is (Pr.

-

Page 198: Misoperation Prevention And Parameter Setting Restriction

Misoperation prevention and parameter setting restriction 4.18 Misoperation prevention and parameter setting restriction Purpose Parameter that should be Set Refer to Page Limits reset function Reset selection/disconnected PU Trips when PU is disconnected Pr. 75 detection/PU stop selection Stops from PU Prevention of parameter rewrite Parameter write disable selection Pr. - Page 199 Misoperation prevention and parameter setting restriction Disconnected PU detection This function detects that the PU (FR-PU04/FR-PU07) has been disconnected from the inverter for longer than 1s and causes the inverter to provide a fault output (E.PUE) and come to trip. When Pr.

- Page 200 Misoperation prevention and parameter setting restriction Restart (PS reset) method when PU stop (PS display) is made during PU operation PU stop (PS display) is made when the motor is stopped from the unit where control command source is not selected (operation panel, parameter unit (FR-PU04/FR-PU07, operation panel for FR-E500 (PA02)) in the PU operation mode.

-

Page 201: Parameter Write Disable Selection (Pr. 77)

Misoperation prevention and parameter setting restriction 4.18.2 Parameter write disable selection (Pr. 77) You can select whether write to various parameters can be performed or not. Use this function to prevent parameter values from being rewritten by misoperation. Parameter Name Initial Value Setting Range Description... -

Page 202: Reverse Rotation Prevention Selection (Pr. 78)

Misoperation prevention and parameter setting restriction 4.18.3 Reverse rotation prevention selection (Pr. 78) This function can prevent reverse rotation fault resulting from the incorrect input of the start signal. Parameter Initial Name Setting Range Description Number Value Both forward and reverse rotations allowed Reverse rotation prevention Reverse rotation disabled selection... -

Page 203: Password Function (Pr. 296, Pr. 297)

Misoperation prevention and parameter setting restriction 4.18.5 Password function (Pr. 296, Pr. 297) Registering a 4-digit password can restrict parameter reading/writing. Parameter Name Initial Value Setting Range Description Number Select restriction level of parameter reading/ 1 to 6, 101 to 106 writing when a password is registered. - Page 204 Misoperation prevention and parameter setting restriction Password lock/unlock (Pr. 296, Pr. 297 ) <Lock> 1) Set parameter reading/writing restriction level.(Pr. 296 9999) Pr. 296 Setting Restriction of Password Pr. 297 Display Unlock Error Value 1 to 6 No restriction Always 0 Displays error count 101 to 106 Restricted at fifth error...

-

Page 205: Selection Of Operation Mode And Operation Location

Selection of operation mode and operation location 4.19 Selection of operation mode and operation location Purpose Parameter that should be Set Refer to Page Operation mode selection Operation mode selection Pr. 79 Started in Network operation mode Operation mode at power-on Pr. - Page 206 Selection of operation mode and operation location Operation mode basics The operation mode specifies the source of the start command and the frequency command for the inverter. Basically, there are following operation modes. External operation mode: For inputting start command and frequency command with an external potentiometer and switches which are connected to the control circuit terminal.

- Page 207 Selection of operation mode and operation location Operation mode switching method External operation When "0 or 1" is set in Pr. 340 Switching with the PU Switching through the network Press Switch to External the PU to light operation mode through Press the network.

- Page 208 Selection of operation mode and operation location Operation mode selection flow In the following flowchart, select the basic parameter setting and terminal connection related to the operation mode. START Connection Parameter setting Operation Where is the start command source? From outside (STF/STR terminal) Where is the frequency command source?