Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Molecular Devices MultiWash+

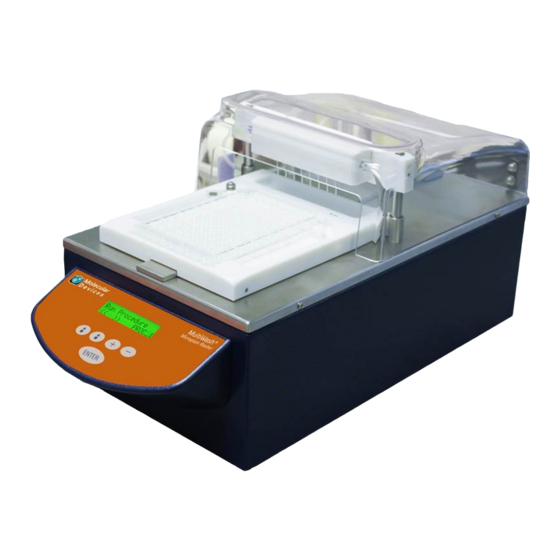

- Page 1 MultiWash+ Microplate Washer User Guide 5032022 C August 2019...

- Page 2 For research use only. Not for use in diagnostic procedures. The trademarks mentioned herein are the property of Molecular Devices, LLC or their respective owners. These trademarks may not be used in any type of promotion or advertising without the prior written permission of Molecular Devices, LLC.

-

Page 3: Table Of Contents

Contents Safety Information Warnings, Cautions, Notes, and Tips Chapter 1: Unpacking and Setting Up the Instrument Contents of the Package Unpacking the Washer Installing the Manifold Connecting the Fluid Bottles Installing the Microplate Carrier Connecting Power to the Instrument Chapter 2: Using the Instrument Using the Instrument Control Panel Software Overview Setting Up the Software... - Page 4 MicroWash+ Microplate Washer User Guide Selecting the Installed Manifold Selecting the Number of Installed Wash Bottles Scrolling Through the Detection Options Selecting the Display of the Liquid Level Warning Selecting the Display of the Waste Level Warning Selecting the Display of the Microplate Warning Selecting the Key Click Option Selecting the Emergency Stop Option Chapter 9: Maintenance and Troubleshooting...

-

Page 5: Safety Information

Follow the related safety information. The following user attention statements might be displayed in the text of Molecular Devices user documentation. Each statement implies the amount of observation or recommended procedure. - Page 6 For products under the requirement of the WEEE directive, contact your dealer or local Molecular Devices office for the procedures to facilitate the proper collection, treatment, recovery, recycling, and safe disposal of the device.

- Page 7 When Molecular Devices installs the instrument, part of the setup procedure is to provide training for the people in your company who are to be your company's service trained users. Contact Molecular Devices to arrange additional training.

- Page 8 MicroWash+ Microplate Washer User Guide Splashing of liquids can occur. Take applicable safety precautions, such as using safety glasses and wearing protective clothing, when working with potentially hazardous liquids. Observe the applicable cautionary procedures as defined by your safety officer when using hazardous materials, flammable solvents, toxic, pathological, or radioactive materials in or near a powered-up instrument.

-

Page 9: Chapter 1: Unpacking And Setting Up The Instrument

Chapter 1: Unpacking and Setting Up the Instrument Before unpacking and setting up the MultiWash+ Microplate Washer, prepare a dry, flat, vibration-free work area that has sufficient space for the instrument, the fluidics bottles and tubing, and the power cable. The instrument is 21.00 cm (8.27 in.) wide, 21.00 cm (8.27 in.) high, and 46.00 cm (18.11 in.) deep. -

Page 10: Contents Of The Package

MicroWash+ Microplate Washer User Guide Contents of the Package The package contains the instrument and the accessories that are required for installing the instrument as follows: MultiWash+ Microplate Washer Quick-Start Guide MultiWash+ Microplate Washer Power cord 2.5 L waste bottle 2.0 L rinse bottle 2.0 L wash bottles (3) Microplate carrier 8-channel manifold... -

Page 11: Unpacking The Washer

To unpack the washer: 1. Check the box for visible damage that occurred during transportation. In case of damage, immediately report it to your Molecular Devices representative and keep the damaged packaging. 2. With the box facing up as indicated on the packaging, use a box cutter to carefully cut open the top of the box. - Page 12 MicroWash+ Microplate Washer User Guide 5. Remove the accessories boxes. Figure 1-3: Accessories Boxes 6. Remove the cardboard dividers from each end of the box Figure 1-4: Cardboard Dividers 5032022 C...

- Page 13 Keep the instrument away from direct sunlight. 11. Visually inspect the instrument for loose, bent, or broken parts. If damage is found, immediately report it to your Molecular Devices representative. 12. Compare the serial number on the rear of the instrument with the instrument serial number on the shipping document and the packing list.

- Page 14 MicroWash+ Microplate Washer User Guide 14. Remove the adhesive tape from the clear cover and then open the cover. 15. Remove all packing material, foam, and adhesive tape from the instrument deck. Figure 1-6: Remove and keep all packing materials 16.

-

Page 15: Installing The Manifold

Chapter 1: Unpacking and Setting Up the Instrument Installing the Manifold There are three manifolds available for the MultiWash+ Microplate Washer. The standard 8-channel manifold works with 96-well plates in portrait orientation. The optional 12-channel manifold works with 96-well plates in landscape orientation. The optional 16-channel manifold works with 384-well plates in portrait orientation. - Page 16 MicroWash+ Microplate Washer User Guide 4. Connect the blue quick-fit connector on the dispense tubing to the blue connector on the top of the instrument. 5. Press down on the black top of the pinch valve and then slip the dispense tubing into the slot.

-

Page 17: Connecting The Fluid Bottles

Chapter 1: Unpacking and Setting Up the Instrument Connecting the Fluid Bottles The waste, rinse, and wash bottles connect to the color-coded fittings on the rear of the MultiWash+ Microplate Washer. Figure 1-10: Fittings for Fluid Bottle Connections The 2.5 liter waste bottle connects to the fitting framed in red. The 2 liter rinse bottle connects to the fitting with the black label below it. -

Page 18: Installing The Microplate Carrier

MicroWash+ Microplate Washer User Guide 7. Locate a wash tubing with the blue marking. 8. Connect the wash tubing to the Wash 1 fitting with a blue label below it on the rear of the instrument. 9. Connect the other end of the wash tubing to the fitting on top of a 2 liter wash bottle. 10. -

Page 19: Connecting Power To The Instrument

Chapter 1: Unpacking and Setting Up the Instrument Connecting Power to the Instrument The power port and power switch are located on the rear of the instrument. Figure 1-12: Power Switch, Fuses, and Power Port Item Description 1 Power switch 2 ... - Page 20 MicroWash+ Microplate Washer User Guide 5032022 C...

-

Page 21: Chapter 2: Using The Instrument

Chapter 2: Using the Instrument The MultiWash+ Microplate Washer is a fully automated and programmable microplate washer for standard ANSI/SLAS footprint 96-well and 384-well microplates with flat-bottom or round-bottom wells. The standard 8-channel manifold works with 96-well plates in portrait orientation. The optional 12-channel manifold works with 96-well plates in landscape orientation. -

Page 22: Using The Instrument Control Panel

MicroWash+ Microplate Washer User Guide Using the Instrument Control Panel After you turn on the power to the instrument, the indicator light on the front of the instrument illuminates, and the LCD screen displays the Run Procedure menu. Figure 2-1: Instrument Control Panel You can control all instrument operations using the 5 keys and the 2-line LCD display on the front of the instrument. -

Page 23: Software Overview

Chapter 2: Using the Instrument Software Overview The top-level menus can be accessed by pressing the buttons on the control panel. Table 2-1: Top-Level Menus Menu Description From Run Procedure, select a previously defined wash or rinse procedure from the list. See Running a Procedure on page From Prime/Rinse, define and run a manual, automatic,... -

Page 24: Setting Up The Software

MicroWash+ Microplate Washer User Guide Setting Up the Software Before running procedures with the MultiWash+ Microplate Washer, select the instrument set up options, define the microplate types, define the wash or rinse cycles, and then define the procedures. Do the software set up procedures in the following order: Selecting Instrument Set Up Options, see page 113 Defining a Microplate Type, see page 77 Defining a Wash or Rinse Cycle, see page 65... -

Page 25: Chapter 3: Running A Procedure

Table 3-1: Actions of Control Panel Buttons Button Action Press this button to scroll to Service. The Service menu is intended to be used by Molecular Devices trained personnel only. On the left Press this button to scroll to Prime/Rinse. See Priming or Rinsing the Fluidics System on page On the right... -

Page 26: Running The Selected Procedure

MicroWash+ Microplate Washer User Guide Running the Selected Procedure After you have selected the procedure to run, the software displays a series of optional prompts to make sure that the instrument is ready for the procedure. Note: Before starting a procedure, make sure that the applicable wash and rinse bottles contain adequate liquid, and that the waste bottle is empty. - Page 27 Chapter 3: Running a Procedure Confirm the Level of the Wash Bottle If the Liquid Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the applicable wash bottles have sufficient liquid for the selected procedure.

- Page 28 MicroWash+ Microplate Washer User Guide Confirm the Level of the Waste Bottle If the Waste Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the waste bottle has sufficient room for aspirated liquid during the selected procedure.

- Page 29 Chapter 3: Running a Procedure Confirm That the Microplate is Loaded If the Plate Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the microplate has been loaded into the microplate carriage. See Loading a Microplate on page CAUTION! Running a procedure without a microplate loaded in the microplate carrier can cause spillage of the wash fluid.

- Page 30 MicroWash+ Microplate Washer User Guide Define the Number of Strips to Process If the Ask Strip Nr option is enabled for the selected procedure, then the software displays a prompt for you to define the number of strips to process. The strips are processed starting from row A.

-

Page 31: Chapter 4: Priming Or Rinsing The Fluidics System

Chapter 4: Priming or Rinsing the Fluidics System To prime or rinse the fluidics system, scroll the LCD display to Prime/Rinse. From Prime/Rinse, define and run a manual, automatic, or periodic prime or rinse process. A Manual prime or rinse lets you manually control the length of time for the prime or rinse process. -

Page 32: Running A Manual Prime Or Rinse Process

MicroWash+ Microplate Washer User Guide Running a Manual Prime or Rinse Process A Manual prime or rinse lets you manually control the length of time for the prime or rinse process. Figure 4-2: The Manual Prime/Rinse option Press the buttons to scroll through the options until Manual is displayed, and then press The software displays a series of prompts to prepare the instrument for the process. - Page 33 Chapter 4: Priming or Rinsing the Fluidics System Select the Bottle for the Prime or Rinse Process Before you can run the manual prime or rinse process, you must select the bottle to use. The labels above the fittings where the bottles connect to the rear of the instrument match the names of the bottles in the software.

- Page 34 MicroWash+ Microplate Washer User Guide Confirm the Level of the Wash or Rinse Bottle If the Liquid Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the applicable wash or rinse bottle has sufficient liquid for the process.

- Page 35 Chapter 4: Priming or Rinsing the Fluidics System Confirm the Level of the Waste Bottle If the Waste Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the waste bottle has sufficient room for aspirated liquid during the prime or rinse process.

- Page 36 MicroWash+ Microplate Washer User Guide Controlling the Manual Prime or Rinse Process After the instrument is prepared, the manual prime or rinse process can be run. Figure 4-7: The Manual Prime/Rinse option Table 4-5: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Prime/Rinse.

-

Page 37: Running An Automatic Prime Or Rinse Process

Chapter 4: Priming or Rinsing the Fluidics System Running an Automatic Prime or Rinse Process An Auto prime or rinse lets you define the prime or rinse process that then runs automatically. Figure 4-8: The Auto Prime/Rinse option Press the buttons to scroll through the options until Auto is displayed, and then press The software displays a series of prompts to prepare the instrument for the process. - Page 38 MicroWash+ Microplate Washer User Guide Select the Bottle for the Prime or Rinse Process Before you can run the automatic prime or rinse process, you must select the bottle to use. The labels above the fittings where the bottles connect to the rear of the instrument match the names of the bottles in the software.

- Page 39 Chapter 4: Priming or Rinsing the Fluidics System Confirm the Level of the Wash or Rinse Bottle If the Liquid Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the applicable wash or rinse bottle has sufficient liquid for the process.

- Page 40 MicroWash+ Microplate Washer User Guide Confirm the Level of the Waste Bottle If the Waste Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the waste bottle has sufficient room for aspirated liquid during the prime or rinse process.

- Page 41 Chapter 4: Priming or Rinsing the Fluidics System Defining the Liquid Volume for the Prime or Rinse Process Define the volume of liquid to dispense during the automatic prime or rinse process. Figure 4-13: The Volume prompt Table 4-9: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Prime/Rinse.

- Page 42 MicroWash+ Microplate Washer User Guide Starting the Automatic Prime or Rinse Process After the instrument is prepared, the automatic prime or rinse process can be run. Figure 4-14: The Start Prime/Rinse prompt Table 4-10: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Prime/Rinse.

-

Page 43: Running A Periodic Prime Or Rinse Process

Chapter 4: Priming or Rinsing the Fluidics System Running a Periodic Prime or Rinse Process A Periodic prime or rinse lets you define the prime or rinse process that can then be run repeatedly at a specified interval of time. Figure 4-16: The Periodic Prime/Rinse option Press the buttons to scroll through the options until Periodic is displayed,... -

Page 44: Select The Bottle For The Prime Or Rinse Process

MicroWash+ Microplate Washer User Guide Select the Bottle for the Prime or Rinse Process Before you can run the periodic prime or rinse process, you must select the bottle to use. The labels above the fittings where the bottles connect to the rear of the instrument match the names of the bottles in the software. -

Page 45: Confirm The Level Of The Wash Or Rinse Bottle

Chapter 4: Priming or Rinsing the Fluidics System Confirm the Level of the Wash or Rinse Bottle If the Liquid Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the applicable wash or rinse bottle has sufficient liquid for the process. -

Page 46: Confirm The Level Of The Waste Bottle

MicroWash+ Microplate Washer User Guide Confirm the Level of the Waste Bottle If the Waste Warning option is enabled in the Setup menu, then the software displays a prompt to make sure that the waste bottle has sufficient room for aspirated liquid during the prime or rinse process. -

Page 47: Defining The Liquid Volume For The Prime Or Rinse Process

Chapter 4: Priming or Rinsing the Fluidics System Defining the Liquid Volume for the Prime or Rinse Process Define the volume of liquid to dispense during the periodic prime or rinse process. Figure 4-21: The Volume prompt Table 4-14: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Prime/Rinse. -

Page 48: Defining The Interval Between Each Prime Or Rinse Process

MicroWash+ Microplate Washer User Guide Defining the Interval Between Each Prime or Rinse Process Define the number of minutes to wait before running each periodic prime or rinse process. The defined prime or rinse process repeats after the defined interval of time until the process is stopped. - Page 49 Chapter 4: Priming or Rinsing the Fluidics System Starting the Periodic Prime or Rinse Process After the instrument is prepared, the periodic prime or rinse process can be run. Figure 4-23: The Start Prime/Rinse prompt Table 4-16: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Prime/Rinse.

- Page 50 MicroWash+ Microplate Washer User Guide 5032022 C...

-

Page 51: Chapter 5: Defining A Procedure

Chapter 5: Defining a Procedure Before running procedures with the MultiWash+ Microplate Washer, select the instrument set up options, define the microplate types, define the wash or rinse cycles, and then define the procedures. To select the instrument set up options, see Selecting Instrument Set Up Options on page 113. -

Page 52: Defining The Procedure

MicroWash+ Microplate Washer User Guide Defining the Procedure The defined procedure can have up to eight previously defined cycles and one previously defined microplate type. If you have not defined the cycles and microplate type to use with this procedure, you must do so before you can continue with the procedure definition. To define the wash or rinse cycles, see Defining a Wash or Rinse Cycle on page To define the microplate type, see... -

Page 53: Confirm Or Change The Name Of The Procedure

Chapter 5: Defining a Procedure Confirm or Change the Name of the Procedure A name is displayed for the procedure. You can either confirm the displayed name or give the procedure a new name. Figure 5-2: The Name prompt Table 5-2: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Define Procedure without saving... - Page 54 MicroWash+ Microplate Washer User Guide Edit the Name of the Procedure You can give a short, descriptive name to the procedure, with up to eight alphanumeric characters. Figure 5-3: The Name edit prompt Table 5-3: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Define Procedure without saving...

-

Page 55: Select The Bottle For The Procedure

Chapter 5: Defining a Procedure Select the Bottle for the Procedure The procedure uses the wash or rinse bottle defined in this step. The labels above the fittings where the bottles connect to the rear of the instrument match the names of the bottles in the software. Figure 5-4: Fittings for Fluid Bottle Connections Figure 5-5: The Liquid prompt Table 5-4: Actions of Control Panel Buttons... -

Page 56: Select The Cycles For The Procedure

MicroWash+ Microplate Washer User Guide Select the Cycles for the Procedure The procedure definition must have at least one cycle selected, and can have up to eight cycles. If you have not defined the cycles to use with this procedure, you must do so before you can continue with the procedure definition. - Page 57 Chapter 5: Defining a Procedure Add More Cycles to the Procedure The procedure definition can have up to eight cycles. When you have finished adding cycles, select - - - as the name of the next cycle to stop adding cycles to the procedure definition. Figure 5-7: The Cycle2 prompt Table 5-6: Actions of Control Panel Buttons Button...

-

Page 58: Select The Duration Of The Final Aspiration For The Procedure

MicroWash+ Microplate Washer User Guide Select the Duration of the Final Aspiration for the Procedure Define the duration time for the final aspiration of the procedure from 0.1 second to 10.0 seconds. The aspiration duration is the amount of time that the aspiration needle on the manifold stays inside a well during aspiration. -

Page 59: Select The Speed Of The Final Aspiration For The Procedure

Chapter 5: Defining a Procedure Select the Speed of the Final Aspiration for the Procedure Define the speed, or power, of the final aspiration of the procedure. Figure 5-9: The Final Aspiration Speed prompt Table 5-8: Actions of Control Panel Buttons Button Action Press this button to return to the previous step. -

Page 60: Select The Processing Mode For The Procedure

MicroWash+ Microplate Washer User Guide Select the Processing Mode for the Procedure Define the processing mode for the procedure as either Plate or Strip. Figure 5-10: The Processing Mode prompt Table 5-9: Actions of Control Panel Buttons Button Action Press this button to return to the previous step. See Select the Speed of the Final Aspiration for the Procedure on page On the left... -

Page 61: Select The Microplate Type For The Procedure

Chapter 5: Defining a Procedure Select the Microplate Type for the Procedure Select a previously defined microplate type for the procedure. If you have not defined the microplate type to use with this procedure, you must do so before you can continue with the procedure definition. -

Page 62: Enable The Number Of Strips Prompt For The Procedure

MicroWash+ Microplate Washer User Guide Enable the Number of Strips Prompt for the Procedure Enable or disable the prompt to define the number of strips to process during the procedure. This can be useful to process a partial microplate or only a few strips in the procedure. -

Page 63: Delay The Final Aspiration For Strips In The Procedure

Chapter 5: Defining a Procedure Delay the Final Aspiration for Strips in the Procedure For Strip processing mode only, you can select to delay the final aspiration until after the last cycle for the last strip is complete and the soak time has expired. Figure 5-13: The Delay Final Aspiration prompt Table 5-12: Actions of Control Panel Buttons Button... - Page 64 MicroWash+ Microplate Washer User Guide 5032022 C...

-

Page 65: Chapter 6: Defining A Wash Or Rinse Cycle

Chapter 6: Defining a Wash or Rinse Cycle Before running procedures with the MultiWash+ Microplate Washer, select the instrument set up options, define the microplate types, define the wash or rinse cycles, and then define the procedures. To select the instrument set up options, see Selecting Instrument Set Up Options on page 113. -

Page 66: Defining The Cycle

MicroWash+ Microplate Washer User Guide Defining the Cycle One or more defined cycles are required before a procedure can be defined. The software displays the prompts for the cycle definition in the following order: Confirm or Change the Name of the Cycle, see page 67 Select the Duration of the Aspiration for the Cycle, see page 69 Select the Speed of the Aspiration for the Cycle, see page 70 Define the Dispense Volume for the Cycle, see page 71... -

Page 67: Confirm Or Change The Name Of The Cycle

Chapter 6: Defining a Wash or Rinse Cycle Confirm or Change the Name of the Cycle A name is displayed for the cycle. You can either confirm the displayed name or give the cycle a new name. Figure 6-2: The Name prompt Table 6-2: Actions of Control Panel Buttons Button Action... - Page 68 MicroWash+ Microplate Washer User Guide Edit the Name of the Cycle You can give a short, descriptive name to the cycle, with up to eight alphanumeric characters. Figure 6-3: The Name edit prompt Table 6-3: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Define Cycle without saving any...

-

Page 69: Select The Duration Of The Aspiration For The Cycle

Chapter 6: Defining a Wash or Rinse Cycle Select the Duration of the Aspiration for the Cycle Define the duration time for the aspiration in the cycle from 0 seconds to 10.0 seconds. The aspiration duration is the amount of time that the aspiration needle on the manifold stays inside a well during aspiration. -

Page 70: Select The Speed Of The Aspiration For The Cycle

MicroWash+ Microplate Washer User Guide Select the Speed of the Aspiration for the Cycle Define the speed, or power, of the aspiration in the cycle. Figure 6-5: The Aspiration Power prompt Table 6-5: Actions of Control Panel Buttons Button Action Press this button to return to the previous step. -

Page 71: Define The Dispense Volume For The Cycle

Chapter 6: Defining a Wash or Rinse Cycle Define the Dispense Volume for the Cycle Define the dispense volume in the cycle from 0 µL to 2000 µL. Figure 6-6: The Dispense Volume prompt Table 6-6: Actions of Control Panel Buttons Button Action Press this button to return to the previous step. -

Page 72: Select The Dispense Speed For The Cycle

MicroWash+ Microplate Washer User Guide Select the Dispense Speed for the Cycle Define the speed, or power, of the dispense in the cycle. Figure 6-7: The Dispense Power prompt Table 6-7: Actions of Control Panel Buttons Button Action Press this button to return to the previous step. See Define the Dispense Volume for the Cycle on page On the left... -

Page 73: Select The Wash Mode For The Cycle

The wash solution is aspirated only after it reaches the aspiration needles on the manifold. When using the Overflow wash mode, Molecular Devices recommends that you use a dispense volume that is slightly more than the well volume. For information on defining the Bottom and Overflow positions for a microplate, see... -

Page 74: Define The Microplate Shake Time For The Cycle

MicroWash+ Microplate Washer User Guide Define the Microplate Shake Time for the Cycle Define the duration of time to shake the microplate from 0 seconds to 10 seconds. Figure 6-9: The Shaking Time prompt Table 6-9: Actions of Control Panel Buttons Button Action Press this button to return to the previous step. -

Page 75: Select The Microplate Shake Intensity For The Cycle

Chapter 6: Defining a Wash or Rinse Cycle Select the Microplate Shake Intensity for the Cycle Define the intensity for shaking the microplate in the cycle. Figure 6-10: The Shaking Intensity prompt Table 6-10: Actions of Control Panel Buttons Button Action Press this button to return to the previous step. -

Page 76: Define The Minimum Soak Time For The Cycle

MicroWash+ Microplate Washer User Guide Define the Minimum Soak Time for the Cycle Define the minimum duration of time to soak the wells, between dispense and aspirate, from 0 seconds to 1000 seconds. Figure 6-11: The Minimum Soak Time prompt Table 6-11: Actions of Control Panel Buttons Button Action Press this button to return to the previous step. -

Page 77: Chapter 7: Defining A Microplate Type

Chapter 7: Defining a Microplate Type Before running procedures with the MultiWash+ Microplate Washer, select the instrument set up options, define the microplate types, define the wash or rinse cycles, and then define the procedures. To select the instrument set up options, see Selecting Instrument Set Up Options on page 113. -

Page 78: Defining Microplate Types

MicroWash+ Microplate Washer User Guide Defining Microplate Types Molecular Devices recommends that you load the plate in the plate carrier before creating or editing a plate type definition. Different options are available for round-bottom and flat-bottom microplates. For round-bottom microplates, define the center of the well for aspiration. - Page 79 Chapter 7: Defining a Microplate Type For flat-bottom microplates, you can define the outside edges of the well for crosswise aspiration. Table 7-3: Flat-Bottom Microplate Item Description 1 Dispense needle 2 Aspiration needle 3 Vertical "zero" point for setting the vertical position of the manifold. 4 ...

-

Page 80: Defining A Round-Bottom Microplate Type

Define the Dispense Position, see page 89 Define the Bottom Dispense Height, see page 91 Define the Overflow Dispense Height, see page 93 Note: Molecular Devices recommends that you load the plate in the plate carrier before creating or editing a plate type definition. 5032022 C... -

Page 81: Confirm Or Change The Name Of The Microplate Type

Chapter 7: Defining a Microplate Type Confirm or Change the Name of the Microplate Type A name is displayed for the microplate type. You can either confirm the displayed name or give the microplate type a new name. Figure 7-3: The Name prompt Table 7-4: Actions of Control Panel Buttons Button Action... - Page 82 MicroWash+ Microplate Washer User Guide Edit the Name of the Microplate Type You can give a short, descriptive name to the microplate type, with up to eight alphanumeric characters. Figure 7-4: The Name edit prompt Table 7-5: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Define Plate without saving any...

-

Page 83: Select The Format Of The Microplate Type

Chapter 7: Defining a Microplate Type Select the Format of the Microplate Type You can select the 8-strip, 12-strip, or 16-strip format for the microplate type. The strip formats correspond to the number of channels in the manifold. The standard 8-channel manifold works with 96-well plates in portrait orientation. The optional 12-channel manifold works with 96-well plates in landscape orientation. -

Page 84: Select The Well Shape Of The Microplate Type

MicroWash+ Microplate Washer User Guide Select the Well Shape of the Microplate Type Different options are available for round-bottom and flat-bottom microplates. To define a flat-bottom microplate type, see Defining a Flat-Bottom Microplate Type on page Figure 7-6: The Well Shape prompt Table 7-7: Actions of Control Panel Buttons Button Action... -

Page 85: Define The Center Of The Well For Aspiration

Chapter 7: Defining a Microplate Type Define the Center of the Well for Aspiration This option is available only for round-bottom microplates. Molecular Devices recommends positioning the aspiration needle in the center of the well for round-bottom microplates. Figure 7-7: The center of a round-bottom microplate You can define the center by editing the offset value, or by using the "teach-in"... - Page 86 MicroWash+ Microplate Washer User Guide Teach-In the Center of the Well for Aspiration Use the "teach-in" method to define the center of the well for aspiration. Figure 7-9: The Center Position "teach-in" prompt Table 7-9: Actions of Control Panel Buttons Button Action With ...

-

Page 87: Define The Height For Aspiration

Chapter 7: Defining a Microplate Type Define the Height for Aspiration Define the height of the manifold during aspiration for the microplate type. Figure 7-10: Aspiration height You can define the aspiration height by editing the offset value, or by using the "teach-in" method. - Page 88 MicroWash+ Microplate Washer User Guide Teach-In the Height for Aspiration Use the "teach-in" method to define the height for aspiration. Figure 7-12: The Aspiration Height "teach-in" prompt Table 7-11: Actions of Control Panel Buttons Button Action With displayed on the left, press this button to detect and move the aspiration needle to the bottom of the well.

-

Page 89: Define The Dispense Position

Chapter 7: Defining a Microplate Type Define the Dispense Position The dispense position defines the horizontal position of the microplate below the manifold needles. For washing, the dispense needle is placed above the microplate well. The aspiration needle aspirates overflow to prevent spillage into adjacent wells. Figure 7-13: Dispense position You can define the dispense position by editing the offset value, or by using the "teach-in"... - Page 90 MicroWash+ Microplate Washer User Guide Teach-In the Dispense Position Use the "teach-in" method to define the dispense position. Figure 7-15: The Dispense Position "teach-in" prompt Table 7-13: Actions of Control Panel Buttons Button Action With displayed on the left, press this button to detect and move the aspiration needle to the bottom of the well.

-

Page 91: Define The Bottom Dispense Height

Chapter 7: Defining a Microplate Type Define the Bottom Dispense Height The bottom dispense height defines the height of the manifold during a dispense for a Bottom wash. The dispense height must be higher or equal to the height for aspiration. Figure 7-16: Bottom dispense height You can define the bottom dispense height by editing the offset value, or by using the "teach-in"... - Page 92 MicroWash+ Microplate Washer User Guide Teach-In the Bottom Dispense Height Use the "teach-in" method to define the dispense height for a Bottom wash. Figure 7-18: The Bottom Dispense Height "teach-in" prompt Table 7-15: Actions of Control Panel Buttons Button Action With ...

-

Page 93: Define The Overflow Dispense Height

The overflow dispense height defines the height of the manifold during a dispense for an Overflow wash. The dispense height must be higher or equal to the height for aspiration. When using the Overflow wash mode, Molecular Devices recommends that you use a dispense volume that is slightly more than the well volume. - Page 94 MicroWash+ Microplate Washer User Guide Teach-In the Overflow Dispense Height Use the "teach-in" method to define the dispense height for an Overflow wash. Figure 7-21: The Overflow Dispense Height "teach-in" prompt Table 7-17: Actions of Control Panel Buttons Button Action With ...

-

Page 95: Defining A Flat-Bottom Microplate Type

Define the Dispense Position, see page 107 Define the Bottom Dispense Height, see page 109 Define the Overflow Dispense Height, see page 111 Note: Molecular Devices recommends that you load the plate in the plate carrier before creating or editing a plate type definition. 5032022 C... -

Page 96: Confirm Or Change The Name Of The Microplate Type

MicroWash+ Microplate Washer User Guide Confirm or Change the Name of the Microplate Type A name is displayed for the microplate type. You can either confirm the displayed name or give the microplate type a new name. Figure 7-23: The Name prompt Table 7-18: Actions of Control Panel Buttons Button Action... - Page 97 Chapter 7: Defining a Microplate Type Edit the Name of the Microplate Type You can give a short, descriptive name to the microplate type, with up to eight alphanumeric characters. Figure 7-24: The Name edit prompt Table 7-19: Actions of Control Panel Buttons Button Action Press this button to end the process and return to Define Plate without saving any...

-

Page 98: Select The Format Of The Microplate Type

MicroWash+ Microplate Washer User Guide Select the Format of the Microplate Type You can select the 8-strip, 12-strip, or 16-strip format for the microplate type. The strip formats correspond to the number of channels in the manifold. The standard 8-channel manifold works with 96-well plates in portrait orientation. The optional 12-channel manifold works with 96-well plates in landscape orientation. -

Page 99: Select The Well Shape Of The Microplate Type

Chapter 7: Defining a Microplate Type Select the Well Shape of the Microplate Type Different options are available for round-bottom and flat-bottom microplates. To define a round-bottom microplate type, see Defining a Round-Bottom Microplate Type on page Figure 7-26: The Well Shape prompt Table 7-21: Actions of Control Panel Buttons Button Action... -

Page 100: Select Whether To Use Crosswise Aspiration

After the defined aspiration time, the needle moves to the opposite side of the well for the second aspiration step. Figure 7-27: Crosswise Aspiration Molecular Devices recommends using crosswise aspiration for flat-bottom microplates. Crosswise aspiration is available only for flat-bottom microplates. Figure 7-28: The Crosswise Aspiration prompt... -

Page 101: Define The Side For Aspiration

This option defines the position of a flat-bottom microplate for aspiration. If crosswise aspiration is enabled, then this option defines the position for the first step of a crosswise aspiration. Molecular Devices recommends that you place the aspiration needle close to the edge the well in a flat-bottom microplate. - Page 102 MicroWash+ Microplate Washer User Guide Teach-In the Side for Aspiration Use the "teach-in" method to define the side of the well for aspiration, or the first side of the well for crosswise aspiration. Figure 7-31: The Side Position Front "teach-in" prompt Table 7-24: Actions of Control Panel Buttons Button Action...

-

Page 103: Define The Second Side For Crosswise Aspiration

This option is available only for flat-bottom microplates with crosswise aspiration enabled. This option defines the position of the microplate for the second step of a crosswise aspiration. Molecular Devices recommends that you place the aspiration needle close to the edge that is opposite from the first aspiration position. - Page 104 MicroWash+ Microplate Washer User Guide Teach-In the Second Side for Crosswise Aspiration Use the "teach-in" method to define the second side of the well for crosswise aspiration. Figure 7-34: The Side Position Rear "teach-in" prompt Table 7-26: Actions of Control Panel Buttons Button Action With ...

-

Page 105: Define The Height For Aspiration

Chapter 7: Defining a Microplate Type Define the Height for Aspiration Define the height of the manifold during aspiration for the microplate type. Figure 7-35: Aspiration height You can define the aspiration height by editing the offset value, or by using the "teach-in" method. - Page 106 MicroWash+ Microplate Washer User Guide Teach-In the Height for Aspiration Use the "teach-in" method to define the height for aspiration. Figure 7-37: The Aspiration Height "teach-in" prompt Table 7-28: Actions of Control Panel Buttons Button Action With displayed on the left, press this button to detect and move the aspiration needle to the bottom of the well.

-

Page 107: Define The Dispense Position

Chapter 7: Defining a Microplate Type Define the Dispense Position The dispense position defines the horizontal position of the microplate below the manifold needles. For washing, the dispense needle is placed above the microplate well. The aspiration needle aspirates overflow to prevent spillage into adjacent wells. Figure 7-38: Dispense position You can define the dispense position by editing the offset value, or by using the "teach-in"... - Page 108 MicroWash+ Microplate Washer User Guide Teach-In the Dispense Position Use the "teach-in" method to define the dispense position. Figure 7-40: The Dispense Position "teach-in" prompt Table 7-30: Actions of Control Panel Buttons Button Action With displayed on the left, press this button to detect and move the aspiration needle to the bottom of the well.

-

Page 109: Define The Bottom Dispense Height

Chapter 7: Defining a Microplate Type Define the Bottom Dispense Height The bottom dispense height defines the height of the manifold during a dispense for a Bottom wash. The dispense height must be higher or equal to the height for aspiration. Figure 7-41: Bottom dispense height You can define the bottom dispense height by editing the offset value, or by using the "teach-in"... - Page 110 MicroWash+ Microplate Washer User Guide Teach-In the Bottom Dispense Height Use the "teach-in" method to define the dispense height for a Bottom wash. Figure 7-43: The Bottom Dispense Height "teach-in" prompt Table 7-32: Actions of Control Panel Buttons Button Action With ...

-

Page 111: Define The Overflow Dispense Height

The overflow dispense height defines the height of the manifold during a dispense for an Overflow wash. The dispense height must be higher or equal to the height for aspiration. When using the Overflow wash mode, Molecular Devices recommends that you use a dispense volume that is slightly more than the well volume. - Page 112 MicroWash+ Microplate Washer User Guide Teach-In the Overflow Dispense Height Use the "teach-in" method to define the dispense height for an Overflow wash. Figure 7-46: The Overflow Dispense Height "teach-in" prompt Table 7-34: Actions of Control Panel Buttons Button Action With ...

-

Page 113: Chapter 8: Selecting Instrument Set Up Options

Defining a Microplate Type on page On the left Press this button to scroll to Service. The Service menu is intended to be used by Molecular Devices trained personnel only. On the right The button has no function for this option. The button has no function for this option. -

Page 114: Selecting The Language For The Display

MicroWash+ Microplate Washer User Guide Selecting the Language for the Display You can choose to display the text on the LCD display in English or German. Figure 8-2: The Language option Table 8-2: Actions of Control Panel Buttons Button Action Press this button to return to Setup. See Selecting Instrument Set Up Options on page 113. - Page 115 Chapter 8: Selecting Instrument Set Up Options Selecting the Installed Manifold This option is very important to let the software know the size of the manifold that is installed on the instrument. A procedure will not run if a different manifold is defined here than the size defined for the procedure.

- Page 116 MicroWash+ Microplate Washer User Guide Selecting the Number of Installed Wash Bottles Up to three wash bottles can be connected to the instrument. Figure 8-4: The Wash Liquids option Table 8-4: Actions of Control Panel Buttons Button Action Press this button to return to Manifold. See Selecting the Installed Manifold on page 115.

- Page 117 Chapter 8: Selecting Instrument Set Up Options Scrolling Through the Detection Options Liquid-level detection is not available for the instrument. To prevent messages, make sure that Off is selected for each of the following options. Figure 8-5: The Waste Full Detection option Press to go to the Rinse Empty Detection option.

- Page 118 MicroWash+ Microplate Washer User Guide Selecting the Display of the Liquid Level Warning Before starting a wash procedure or rinse process, the software can display a message for the operator to make sure that the required wash or rinse bottles contain enough liquid for the procedure or process.

- Page 119 Chapter 8: Selecting Instrument Set Up Options Selecting the Display of the Waste Level Warning Before starting a wash procedure or rinse process, the software can display a message for the operator to make sure that the waste bottle is empty. Figure 8-11: The Waste Warning option Table 8-6: Actions of Control Panel Buttons Button...

- Page 120 MicroWash+ Microplate Washer User Guide Selecting the Display of the Microplate Warning Before starting a wash procedure or rinse process, the software can display a message for the operator to make sure that a microplate is loaded in the microplate carrier. Figure 8-12: The Plate Warning option Table 8-7: Actions of Control Panel Buttons Button...

- Page 121 Chapter 8: Selecting Instrument Set Up Options Selecting the Key Click Option You can turn the audible key click on or off. Figure 8-13: The Key Click option Table 8-8: Actions of Control Panel Buttons Button Action Press this button to return to Plate Warning. See Selecting the Display of the Microplate Warning on page 120.

- Page 122 MicroWash+ Microplate Washer User Guide Selecting the Emergency Stop Option If a microplate or microplate strip is installed incorrectly, the process in progress stops immediately if the aspirate needle touches the bottom of the well. Figure 8-14: The Emergency Stop option Table 8-9: Actions of Control Panel Buttons Button Action...

-

Page 123: Preventive Maintenance

Chapter 9: Maintenance and Troubleshooting Chapter 9: Maintenance and Troubleshooting Perform only the maintenance tasks described in this guide. Contact a Molecular Devices service engineer to inspect and perform a preventive maintenance service on the instrument each year. See Obtaining Support on page 142. -

Page 124: Clean The Instrument

MicroWash+ Microplate Washer User Guide Clean the Instrument Observe the following general tips when cleaning the instrument: WARNING! BIOHAZARD. Always wear gloves when operating the instrument and during cleaning procedures that could involve contact with either hazardous or biohazardous materials or fluids. CAUTION! Do not use abrasive cleaners. - Page 125 When you need to disinfect or decontaminate the instrument, use the policies and procedures defined by your laboratory. Molecular Devices recommends that you disinfect the fluidics system after the washer has not been used for more than a day or when changing the manifold. If the instrument is used regularly, disinfect it at least once each week.

-

Page 126: Maintaining The Fluidics System And Manifold

Cleaning the Manifold Needles, see page 129 Replacing the Fluidics Tubing, see page 129 Perform only the maintenance tasks described in this guide. Contact a Molecular Devices service engineer to inspect and perform a preventive maintenance service on the instrument each year. - Page 127 Chapter 9: Maintenance and Troubleshooting To replace the manifold: 1. Open the clear cover. 2. Remove the dispense tube from the blue connector on the manifold. 3. Make sure that the dispense tube remains in the pinch valve on the top of the instrument Figure 9-1: Manifold and Hydraulic Tubing Item...

- Page 128 MicroWash+ Microplate Washer User Guide 6. Place the new manifold on the horizontal manifold holder with the needles pointing down and the mounting pins pointing to the rear of the instrument. Figure 9-2: Placing the Manifold on the Manifold Holder 7.

- Page 129 Chapter 9: Maintenance and Troubleshooting Cleaning the Manifold Needles Some buffers solutions can crystallize on contact with air, blocking the tubing, fittings, and manifold needles. Clean the manifold needles using the provided manifold needle cleaning tools. Figure 9-3: Manifold Needle Cleaning Tools Rub the brush on the outside areas of the needles and manifold to remove build up, deposits, or staining.

-

Page 130: Replacing Fuses

If these checks fail to remedy the loss of power, replace the fuses. You can obtain replacement fuses from Molecular Devices. For fuse specifications, see Physical Specifications on page 145. - Page 131 8. Plug the power cord into the power port. 9. Turn on power to the instrument. Note: If the instrument still does not power on after changing the fuses, contact Molecular Devices technical support. See Obtaining Support on page 142.

-

Page 132: Packing The Instrument For Storage Or Service

MicroWash+ Microplate Washer User Guide Packing the Instrument for Storage or Service To minimize the possibility of damage during storage or shipment, the instrument should be repacked only in the original packaging materials. Before repacking the instrument, follow the applicable decontamination and cleaning procedures. -

Page 133: Disconnecting Power From The Instrument

Chapter 9: Maintenance and Troubleshooting Disconnecting Power From the Instrument The power port and power switch are located on the rear of the instrument. Figure 9-7: Power Switch, Fuses, and Power Port Item Description 1 Power switch 2 Fuse carrier 3 ... -

Page 134: Removing The Microplate Carrier

MicroWash+ Microplate Washer User Guide Removing the Microplate Carrier The removable microplate carrier has a very strong magnet permanently mounted to its base. When the microplate carrier is removed from the instrument, keep the carrier away from magnet-sensitive items or devices. Figure 9-8: Installed Microplate Carrier To remove the microplate carrier, carefully slide it off the front of the instrument. -

Page 135: Disconnecting The Fluid Bottles

Chapter 9: Maintenance and Troubleshooting Disconnecting the Fluid Bottles The waste, rinse, and wash bottles connect to the color-coded fittings on the rear of the MultiWash+ Microplate Washer. Figure 9-9: Fittings for Fluid Bottle Connections Before removing the bottles from the instrument, follow the applicable decontamination and cleaning procedures. -

Page 136: Removing The Manifold And Fluidics Tubing

MicroWash+ Microplate Washer User Guide Removing the Manifold and Fluidics Tubing There are three manifolds available for the MultiWash+ Microplate Washer. The standard 8-channel manifold works with 96-well plates in portrait orientation. The optional 12-channel manifold works with 96-well plates in landscape orientation. The optional 16-channel manifold works with 384-well plates in portrait orientation. - Page 137 Chapter 9: Maintenance and Troubleshooting 3. Press down on the black top of the pinch valve and then slide the dispense tubing out of the slot. Figure 9-11: Dispense Tubing in Pinch Valve 4. Disconnect the blue quick-fit connector on the dispense tubing from the blue connector on the top of the instrument.

-

Page 138: Packing The Instrument In Its Original Container

To minimize the possibility of damage during storage or shipment, the instrument should be repacked only in the original packaging materials. If you do not have the original packing materials, contact Molecular Devices. CAUTION! When transporting the instrument, warranty claims are void if improper packing results in damage to the instrument. - Page 139 Chapter 9: Maintenance and Troubleshooting 5. Place the slotted foam blocks under the manifold holder to secure it in position for shipping. 6. Close the clear cover. 7. Wrap the instrument in plastic. 8. Place the cardboard packing sheet on top of the clear cover with the foam resting against the rear of the cover, and then secure it with adhesive tape.

- Page 140 MicroWash+ Microplate Washer User Guide 12. Place the accessories boxes in their designated areas. Figure 9-16: Inserting Accessories Boxes 13. Place the waste, wash, and rinse bottles in their designated areas. Figure 9-17: Inserting Wash, Rinse, and Waste Bottles 14. Insert the power cable. 15.

-

Page 141: Status Messages And Error Messages

The following status and error messages can be displayed by the instrument. To close a status or error message, press any button on the instrument control panel. If an error condition persists, contact Molecular Devices. See Obtaining Support on page 142. - Page 142 If you still need assistance after consulting the Knowledge Base, you can submit a request to Molecular Devices Technical Support. You can contact your local representative or Molecular Devices Technical Support at 800-635-5577 (North America only) or +1 408-747-1700. In Europe, call +44 (0) 118 944 8000.

- Page 143 Table A-1: Parts and Accessories Part Number Description 5032337 8-channel manifold 5032336 12-channel manifold 5032338 16-channel manifold 5032339 Washer maintenance kit 5032340 External tubing kit 5032341 2-liter wash bottle 5032342 2-liter rinse bottle To order parts and accessories, contact your Molecular Devices representative. 5032022 C...

- Page 144 MicroWash+ Microplate Washer User Guide 5032022 C...

- Page 145 Appendix B: Instrument Specifications This appendix provides specifications for the MultiWash+ Microplate Washer. Physical Specifications The following table lists the physical specifications of the MultiWash+ Microplate Washer. Table B-1: Physical Specifications of the Instrument Item Description Environment Indoor use only Power requirements, power 115V~/230V~ 50/60 Hz autosensing, 2.5 amps, maximum power adapter...

- Page 146 MicroWash+ Microplate Washer User Guide Measurement Specifications The following table lists the measurement specifications of the MultiWash+ Microplate Washer. Table B-2: Measurement Specifications of the Instrument Item Description Dispense The wash liquid volume is adjustable from 50 µl to 2000 µl in 50 µl increments volume Dispensing ±5% at 300 µl across the microplate...

- Page 147 Appendix C: System Dimensions In the following drawings, the dimensions are shown in centimeters and inches. Figure C-1: Front View of the Instrument with Dimensions Item Description 1 Width: 21.00 cm (8.27 in.) 2 Height: 21.00 cm (8.27 in.) 5032022 C...

- Page 148 MicroWash+ Microplate Washer User Guide Figure C-2: Side View of the Instrument with Dimensions Item Description 1 Depth: 46.00 cm (18.11 in.) 2 Height: 21.00 cm (8.27 in.) 5032022 C...

- Page 149 Index delay final aspiration 63 disinfection 125 dispense position 89, 107 accessories 143 dispense power 72 ask strip number 62 dispense volume 71 aspiration height 87, 105 aspiration power 70 aspiration time 69 emergency stop? 122 error messages 141 bottom dispense height 91, 109 final aspiration speed 59 final aspiration time 58 center position 85...

- Page 150 MicroWash+ Microplate Washer User Guide number of strips 30 key click 121 ordering information 143 overflow dispense height 93, 111 language 114 LCD screen 22 packing instrument 132 liquid 33, 38, 44, 55 parts ordering 143 liquid warning 118 periodic rinse 49 plate 61 plate format 83, 98 maintenance...

- Page 151 Index overview 23 set up 24 spare parts 143 specifications instrument measurements 146 start prime/rinse 42, 49 start the instrument 19 status messages 141 top-level menus 23 unpacking 11 volume 41, 47 wash liquid OK? 27, 34, 39, 45 wash liquids 116 wash mode 73 waste empty? 28, 35, 40, 46 waste warning 119...

- Page 152 The trademarks used herein are the property of Molecular Devices, LLC or their respective owners. ©2019 Molecular Devices, LLC. Specifications subject to change without notice. Patents: www.moleculardevices.com/productpatents All rights reserved. FOR RESEARCH USE ONLY. NOT FOR USE IN DIAGNOSTIC PROCEDURES...

Need help?

Do you have a question about the MultiWash+ and is the answer not in the manual?

Questions and answers