Summary of Contents for Thermo Scientific 5030

- Page 1 Model 5030 Instruction Manual Synchronized Hybrid Ambient Real-time Particulate Monitor Part Number 102017-00 8Jan2013 USEPA Automated Equivalent PM Method: EQPM-0609-184...

- Page 2 © 2007 Thermo Fisher Scientific Inc. All rights reserved. Specifications, terms and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representative for details. Thermo Fisher Scientific Air Quality Instruments 27 Forge Parkway Franklin, MA 02038 1-508-520-0430 www.thermo.com/aqi...

- Page 3 WEEE Compliance This product is required to comply with the European Union’s Waste Electrical & Electronic Equipment (WEEE) Directive 2002/96/EC. It is marked with the following symbol: Thermo Fisher Scientific has contracted with one or more recycling/disposal companies in each EU Member State, and this product should be disposed of or recycled through them.

- Page 5 Preface Section This manual provides information about operating, maintaining, and servicing the Model 5030 SHARP Monitor. It also contains important alerts to ensure safe operation and prevent equipment damage. The manual is organized into the following chapters and appendices to provide direct access to specific operation and service information: Chapter 1 “Introduction”...

- Page 6 Service is available from exclusive distributors worldwide. Contact one of the phone numbers below for product support and technical information or visit us on the web at www.thermo.com/aqi. 1-866-282-0430 Toll Free 1-508-520-0430 International Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 7 Preface Section US NRC Exemption US NRC Exemption The Model 5030 SHARP Monitor is an exempt product in accordance with NRC license No. 20-23922-01E and SSD Registration Certificate No. AVR-1234-D-101-E. The user is exempt from any licensing requirements for this device. Laws may vary outside of the United States.

- Page 8 2. Inlet to sample tube connector. 3. Standard 1-meter heater. 4. SHARP monitor. 5. Pump kit. 6. Glass fiber filter tape. 7. Vertical stabilization of sample tube, as necessary. 8. Nephelometer zeroing kit viii Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 9: Table Of Contents

Analog Output Installation ............2-22 Serial Data Communications ............2-25 Filter Tape Installation..............2-26 Chapter 3 Operation ......................3-1 Operation and Service Menus ............. 3-1 Display..................... 3-1 Keypad..................... 3-1 Main User Screen................3-2 Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... - Page 10 Warning and Operating Detailed Status Reports......6-4 Structure of the Status Conception ..........6-5 Detailed Status Messages..............6-6 Overlay of Several Status Messages ..........6-10 Status Output by Potential Free Relay Contacts........ 6-11 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 11 Inlet Assemblies................... 8-1 Sampling Tube Extensions ..............8-1 Weather Enclosure ................8-1 Rack Mounting Accessories..............8-1 Appendix A Warranty ......................A-1 Appendix B RS-232 Commands ................... B-1 Appendix C Connector and Board Schematics..............C-1 Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual...

- Page 12 Contents Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 13 Figure 1–2. Model 5030 SHARP Flow Schematic ..........1-8 Figure 2–1. Model 5030 Front Panel and Component List......... 2-3 Figure 2–2. Model 5030 Rear Panel and Component List ......... 2-4 Figure 2–3. Vacuum Pump Assembly and Connectors........2-5 Figure 2–4. 1-Meter Heated Sample Tube............2-5 Figure 2–5.

- Page 14 Figures Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 15 Tables Table 1–1. Model 5030 Specifications............... 1-9 Table 2–1. EU and US Monitoring Protocols............2-9 Table 3–1. Model 5030 SHARP Parameter List..........3-6 Table 3–2. Parameter Change List..............3-7 Table 5–1. Recommended Spare Parts .............. 5-1 Table 6–1. Troubleshooting Guide..............6-1 Table 6–2.

- Page 16 Tables Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 17: Chapter 1 Introduction

Chapter 1 Introduction The Model 5030 Synchronized Hybrid Ambient Real-time Particulate (SHARP) Monitor is a hybrid nephelometric/radiometric particulate mass monitor capable of providing precise, one-minute, real-time measurements with a superior detection limit. The SHARP Monitor measures the mass concentration of ambient PM... -

Page 18: Principle Of Operation

Principle of The Model 5030 is based on the principles of aerosol light scattering (nephelometer) and beta attenuation to measure precise and accurate Operation ambient aerosol concentrations. -

Page 19: Calculation Of Particulate Mass On Filter Tape

The collected sample temperature is measured within the attenuation chamber. Calculation of The beta detector of the 5030 SHARP delivers a count rate, which is proportional to the intensity of the beta beam. The mass is calculated from Particulate Mass... - Page 20 (hPa), 20 , Δ P3 = P3 – P3 change in barometric pressure since filter change (hPa), temperature coefficient, sub-filter pressure coefficient barometric pressure coefficient Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 21: Calculation Of The Pm Concentration With Digital Filter And Fixed Time Constant

τ ν ∝ τ No matter what the constant, both N and C are passed through f_1n τv τv resulting in synchronized long-tern averages N and C14 , respectively. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 22: Calculation Of Concentration Averages

The Model 5030 retains 1 year of 30-minute concentration averages or 2- years of 60-minute averages via the internal 512 kilo-Byte memory. Each record is stored with a respective date, time, instrument status, and classification. - Page 23 "DISP". These data are also available via the serial interfaces (COM1, COM2) by remote commands and print format command. The Model 5030 airflow schematic is shown in Figure 1-2. This figure shows the general locations of the ambient, sample, and heater wall temperature sensors;...

-

Page 24: Figure 1-2. Model 5030 Sharp Flow Schematic

0-100 hPa Figure 1–2. Model 5030 SHARP Flow Schematic The Model 5030 SHARP provides an updated concentration every 4 seconds via the analog output, serial output, and user menu. User selected 30-minute or 60-minute concentrations are date and time stamped with any status/error conditions logged to the internal memory. -

Page 25: Specifications

Dimensions Instrument 19-inches (W) x 12.25-inches (H) x 13-inches (D) // 483mm(W) x 311mm(H) x 330mm(D) Pump 8.25-inches (W) x 8.75-inches (H) x 4.25-inches (D) / 210mm(W) x 222mm(H) x 108mm(D) Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 27: Chapter 2 Installation

“Optional Equipment” chapter. Packaging and The Model 5030 instrument, power cord, and operator manual are shipped Transport in an ISTA 2A-certified packaging and all other items/accessories are shipped separately. The Model 5030 ISTA 2A-certified packaging is comprised of the instrument within an inner box which is secured within an outer box using foam end-caps and corner bracing. -

Page 28: Acceptance Testing And Startup Procedures

2. Continue with the “Acceptance Testing and Startup Procedures” that follow. Acceptance Testing The Model 5030 has been bench tested and calibrated at the factory prior to and Startup shipping. The mass sensors, RH sensor, internal sample temperature sensor, flowmeter temperature sensor, external ambient/heater temperature sensors,... -

Page 29: Figure 2-7 Model 5030 Main Circuit Board

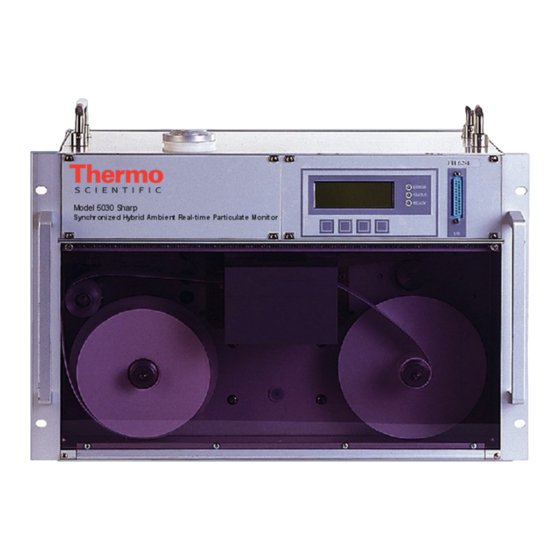

Acceptance Testing and Startup Procedures Figure 2-7 Model 5030 Main Circuit Board Figure 2-1. Model 5030 Front Panel and Component List 1. Inlet - Nephelometer connector (shown with inlet cap) 2. Nephelometer - Beta detection chamber connection 3. Beta Attenuation chamber 4. - Page 30 Installation Acceptance Testing and Startup Procedures Figure 2-2. Model 5030 Rear Panel and Component List 10. Vacuum pump hose connection 11. Power connection, fuse (2 x 6A), and main switch 12. 3A auxiliary pump connection (used on new Busch/Becker Pumps) 13.

-

Page 31: Figure 2-4. 1-Meter Heated Sample Tube

Installation Acceptance Testing and Startup Procedures Figure 2-3. Vacuum Pump Assembly and Connectors Figure 2-4. 1-Meter Heated Sample Tube Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... - Page 32 Installation Acceptance Testing and Startup Procedures Figure 2-5. Roof/Shelter Flange Installation HEPA Filter Flow Audit Adapter Inlet Adapter Sample Inlet Adapter Figure 2-6. Zero Test Assembly Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 33: Bench Acceptance Test

2. Following a sufficient equilibration period, connect the power cord to the rear of the instrument and to a properly grounded power supply. If the Model 5030 turns ON at this point, set the power switch to the “OFF” position and then proceed. -

Page 34: Establishing Monitor Protocol

The third screen informs the user that the Model 5030 is zeroing the mass of the filter tape and air column, and will begin measuring the accumulated mass on the filter tape. -

Page 35: Menu Tutorial

Once there, the user can scroll through the sub-menu by pressing NEXT. These are the following screens that should be seen upon startup: This is the main User Screen showing a combined STATUS Code, combined ERROR Code, and PM Concentration. Press DISP. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... - Page 36 “Operation” chapter for changing these values. Press NEXT. By pressing NEXT, from the last screen within the main User Screen, the following screen will appear: This is the Operation menu. Press NEXT. 2-10 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 37 T3: Orifice Temperature (deg C), T4: Heater External Wall Temperature (deg C), P1: Orifice Pressure Drop (hPa), P2: Vacuum under sample filter tape (hPa), P3: Barometric Pressure (hPa), RH: Sample Relative Humidity (% RH). Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual 2-11...

-

Page 38: One-Point Temperature Verification

Support at (866) 282-0430 or your local sales representative. Temperature sensor calibration is covered in the “Calibration” chapter. One-Point RH Sensor Record the RH sensor reading from the Model 5030 and compare to your NIST-traceable Hygrometer. The Model 5030 RH sensor should compare Verification within ±2% RH tolerance of your NIST-traceable Hygrometer. -

Page 39: One-Point Barometric Pressure Verification

RH-sensor verification due to a thermal compensation applied to the RH-sensor. If the Model 5030 RH sensor is slightly out of tolerance, ±3% RH, the acceptance test should be classified as marginal. If the sensor performance is less than marginal, please contact Thermo Fisher Scientific’s Technical Support at (866) 282-0430 or your local sales representative. -

Page 40: Nephelometer Zero

FTS may require. Allow 60 seconds to stabilize the flow. Note Keep this inlet assembly for nephelometer zero. Record the Model 5030 Volumetric Flow Rate as Qm and the FTS flow rate as Qi, assuring that both are being recorded in units of L/h. Take three (3) readings each from Qm and Qi and average the respective values. - Page 41 ( ). The third μ value (2.5) is the long-term beta attenuation derived aerosol concentration in units of . The fourth value (0.7) is the Model 5030 hybrid μ real-time aerosol concentration in units of μ Thermo Fisher Scientific...

-

Page 42: Background Zero

A HEPA filter is provided with each Model 5030 for this purpose. Furthermore, by introducing a known concentration of aerosol to the Model 5030, a span calibration can be performed on the nephelometer. However, for the purpose of this step only the zero of the nephelometer should be performed. -

Page 43: 24-Hour Zero And Detection Limit

24-Hour Zero and Perform the following steps to thoroughly evaluate the absolute zero and detection limit of the Model 5030. Detection Limit 1. Keep the instrument in the Calibration Mode (Status = 0070). 2. Maintain the HEPA filter at the inlet. -

Page 44: Heated Sample Tube Sensor Calibration

–22 to 60 ° Through the use of a flange kit, the Model 5030 may be installed on a flat building or shelter roof surface. Depending upon the inlet height, additional vertical bracing may be required. The Model 5030 can be either rack mounted or tabletop mounted. -

Page 45: Heated Sample Tube Lengths

Review the following installation steps prior to field installation. 1. Mount the Model 5030 to the rack using a set of FH132 sliding rail hardware. 2. Determine the location of the Model 5030 inlet tube on the roof enclosure (ambient shelters are already provided with this location cleared). - Page 46 10. Place the inlet tubing through the roof flange and onto the top of the Model 5030. Note PLEASE PAY EXTRA CARE TO THE INTEGRATED AMBIENT/HEATER TEMPERATURE SENSOR CABLE ASSEMBLY THAT MUST PASS THROUGH WITH THE HEATED TUBE. 2-20 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 47 90 degrees apart or employ the use of a tripod attachment as available. 17. Connect the power cord to the rear of the Model 5030 and to a properly grounded power supply of the appropriate voltage and frequency.

-

Page 48: Establishing Communications

9-pin connector labeled “sensors” on the rear of the monitor. 22. Place the heater control unit on top of the Model 5030 with the green power switch facing forward. 23. Connect the brass resistance-heater connectors to the upper-most exposed copper tubing and the lower-most exposed stainless sample tube. - Page 49 Installation Establishing Communications The Model 5030 analog output of measured aerosol concentrations can be accessed from the rear I/O socket on the central unit. Pin numbers 12 and 13 from the I/O socket are used as the (+) 0-20mA/0-10V concentration signal and as the (-) 20mA/ground connectors, respectively.

- Page 50 Output Jumper Configuration X24 Jumper X25 Jumper Volt Jumper Configuration 0-10 VDC Concentration Analog Output Jumper Configuration Front of Instrument Rear of Instrument Figure 2–7. Model 5030 Main Circuit Board 2-24 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 51: Serial Data Communications

Any information regarding Serial Data Output is discussed in Chapter 3 and RS-232 Commands are provided in Appendix B. Serial Data There are two RS-232 serial data ports on the Model 5030. Referencing Figure 2-2, these two com-ports are labeled COM1 (No 23) and COM2 Communications (No 22) and are a 25-pin and 9-pin female connectors, respectively. -

Page 52: Filter Tape Installation

It is recommended that COM2 be used for remote dial-up connection and COM1 be reserved as either an onsite interface or for scheduled data printouts. One COM1 cable is provided with each Model 5030. A full explanation of serial communication is provided in the “Operation” chapter. - Page 53 Consequently, the filter tape needs to be checked. After investigation, another filter change cycle has to be initialized by pressing the key “FC+Z” again. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual 2-27...

- Page 54 Installation Filter Tape Installation 2-28 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 55: Chapter 3 Operation

Keypad The keypad of the Model 5030 consists of 4 keys to operate the instrument. Together with the display unit, these keys form the interactive user surface. The functions that are covered by the single keys are described in the lowest line of the display. -

Page 56: Main User Screen

Press NEXT. This screen shows the individual text codes in relation to the combined status codes that are expected at startup, press TEXT for additional information. Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 57: Operation Menu

NEXT to enter the Service menu. To toggle between the operation via keypad and serial interface, press the SET key. Please remember that the parameters cannot be changed without having enabled the keypad. Press SET. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... - Page 58 632 Kbytes. At a bit transmission rate of 9600, the transmission process will need approximately 10 minutes. The transmission of hourly values will take less space and time. Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 59 172 21.0 18.5 0.492 14562 8) Parameter list Print Format 8 provides the Parameter List for the Model 5030 SHARP. The parameter list provides all internally stored parameters for the operation and calibration of the Model 5030 SHARP. It is recommended upon receipt of the Model 5030 SHARP that Print Format 8 (Parameter List) be downloaded and kept as a record of the manufacturer’s default...

-

Page 60: Table 3-1. Model 5030 Sharp Parameter List

Parameter List should be performed and kept for record keeping. Should a warning or error status condition occur, download the Parameter List for review. Table 3-1. Model 5030 SHARP Parameter List Themo Fisher Scientific SHARP v1.21 SERIAL NUMBER 19 05-03-03 PRINT FORMAT:... -

Page 61: Table 3-2. Parameter Change List

Operation Operation and Service Menus Table 3-1. Model 5030 SHARP Parameter List, continued Themo Fisher Scientific SHARP v1.21 SERIAL NUMBER 19 05-03-03 ANALOG OUTPUTS OUTPUT ZERO 0 mA CONC -100 1000 GESYSTEC PROTOCOL STATUS VERSION STANDARD NUMBER OF VARIABLES CONC 9) Parameter Change list: 22 entries Print Format 9 provides a Parameter Change List. - Page 62 Print Format 31 is represented below. Print Formats 30 and 39 are usually preferred for later data reduction via spreadsheet applications. Print Format 39 provides data from the expanded memory, over one year of 30-minute average data. Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 63 22.4 Filter Change Frequency The Model 5030 SHARP comes with a filter change cycle of 0-hours, a filter change hour of 24 (midnight), and a mass limit of 1500 micrograms. The Model 5030 SHARP will automatically perform a filter change when the mass on the filter spot reaches 1500 micrograms, when the filter change cycle has been reached, and when the filter change hour has been reached.

- Page 64 Operation Operation and Service Menus Flow Rate Setpoint The Model 5030 SHARP has a fixed flow rate of 1000 L/h (16.67 L/min). Dynamic Heating System The temperature control system that is used on the Model 5030 SHARP Monitor is the Dynamic Heating System (DHS). A relative humidity sensor is placed downstream of the optical sensing volume and upstream of the beta attenuation sample chamber.

- Page 65 Here the user can choose the analog output of the default channel by using the +/- keypad. Press NEXT. User-selected concentration for the zero point of the analog output range. Possible settings: -100 to 1000 μg/m . Press NEXT. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual 3-11...

-

Page 66: Service Menu

Otherwise the device assumes that the pump is defective or the tubing was pulled off and consequently sets a corresponding error status. 3-12 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 67: Mass Display

(R ), the βø real-time beta counts (R ), the alpha counts β ), and the reference setting (Rref ) are all α being measured by the proportional detector. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual 3-13... - Page 68 β α Sensor Signals The following screen will display digital signals of the Model 5030 SHARP sensors. Note Should one of the values within this screen blink repeatedly this is an indication that a sensor malfunction is occurring. Should this occur, please see the “Troubleshooting”...

- Page 69 4 mA = 2V and 20 mA = 10V. When quitting this menu by pressing either the BACK or NEXT key, the measured value will be again output to the analog interface. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual 3-15...

- Page 70 Operation Service Menu 3-16 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 71: Chapter 4 Calibration

“Operation” chapter. Equipment Required The Model 5030 SHARP comes with a HEPA filter and adapter for zeroing the instrument. Optional mass transfer standards are available from Thermo Fisher Scientific for performing an annual mass calibration. However,... -

Page 72: Pre-Calibration

Calibration Pre-Calibration Pre-Calibration Prior to calibration, be sure the Model 5030 is operating properly. The Model 5030’s internal diagnostics makes this a quick and simple process. Turn on the instrument and allow it to stabilize for one hour prior to calibrating. - Page 73 The T1 calibration procedure above is also valid for the T2 HEAD Temperature (also referred to as, sample temperature) and can be referenced to shelter temperature if the Model 5030 has been equilibrated for approximately one hour while sampling room or shelter air. Press NEXT.

-

Page 74: Sample Flow Rate Calibration

(FTS). The volumetric flow rate is initially indicated as measured by the Model 5030. Press CAL to adjust the air flow rate calibration coefficient. Thereafter, adjust the volumetric air flow rate measured by a FTS using the +, - keys and press NEXT. -

Page 75: Theoretical Adjustment Of The High Voltage And The Thresholds

Only in case of a detector error or instrument status condition should this readjustment be done. The Model 5030 SHARP - detector is a proportional counter, which depends on the operating High Voltage (HV). Figure 4-1a shows the relation of count rate versus HV. - Page 76 This is described in the “Automated Detector Adjustment” procedure described previously. Press START. The display of the Model 5030 will automatically proceed through the HV and threshold adjustments necessary to bring the detector within operating specifications. During this automatic procedure, the beta counts (R ), the β...

-

Page 77: Mass Foil Calibration

Calibration Menu Mass Foil Calibration The Model 5030 SHARP is calibrated for mass in the factory using a series of null and span foils. The mass transfer standard foil sets are available from Thermo Fisher Scientific, and should be used as part of a QA Program for performing a QC check on the mass measurements. - Page 78 IMR heating system turned off, and the instrument should be allowed to equilibrate to shelter or ambient temperature. If the Model 5030 SHARP is mounted within an ambient shelter, then the most stable time of day to perform a mass calibration would be either early morning or late afternoon.

-

Page 79: Nephelometer Zero And Calibration

Mechanic Control in the Service menu can be used. Press NEXT to proceed. Nephelometer Zero and The Model 5030 SHARP has a nephelometer (aerosol light scattering sensor) built-in upstream of the beta attenuation measurement chamber Calibration and downstream of the instrument sample delivery tube. - Page 80 Model 5030 SHARP. During calibration the test dust is delivered to the test assembly, and once a stable concentration is achieved the technician will press SPAN on the Model 5030 menu. During this period, the Model 5030 will calculate a one-minute average from the nephelometer while the display counts down from 60-seconds to zero.

-

Page 81: Configuration Menu

100% scaling of the beta attenuation derived aerosol concentration. Should any site-specific issues require a change in the response in the accuracy (slope) of the Model 5030 SHARP, compared to a reference measurement, the response can be adjusted in this screen by pressing the +/- keys. -

Page 82: German Networking Protocol

These data are reloaded, either in case an error is detected in the battery-buffered RAM when switching the main switch or by simply giving the respective command via keyboard entry in the next screen. 4-12 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 83: Reloading From Eeprom

SAVE-RAM has been found. After all calibrations are completed, the keypad may be disabled, and normal operation should continue. Normally, a filter change and zero (FC+Z) is usually activated after a calibration. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual 4-13... - Page 84 Calibration Reloading from EEPROM 4-14 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 85: Chapter 5 Preventive Maintenance

Preventive Maintenance Chapter 5 The Model 5030 SHARP has been designed to operate unattended for a period of up to one year. However, monitoring program requirements can vary and sometimes depend upon the application and the regulations that the sampling method must meet. -

Page 86: Maintaining The Sample Vacuum Pump

Power to the pump in the Main Display sub-menu. If the flow rate of the Model 5030 SHARP is below the nominal set point and the pump power is very high (>95%), then the user should check and tighten all external fittings, and if necessary tighten the internal fittings surrounding the flow path. -

Page 87: Checking The Air Flow

“Calibration” chapter. For this purpose, a flow transfer standard (FTS) is needed to determine and calibrate the air flow (preferred flow meters can be supplied by Thermo Fisher Scientific as maintenance accessories). Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 88: Temperature Sensors

Flow audits can be done once per quarter. If the flow rate of the Model 5030 SHARP does not deviate by more than ±5% of the auditing standard then no calibration is required except for an annual calibration. -

Page 89: Pressure Sensors

P2 measures the vacuum under the filter tape, relative to barometric pressure. P3 directly measures the barometric pressure. Although the Model 5030 SHARP should hold a valid calibration for up to one year, typically it is recommended by the USEPA to visit the monitoring site biweekly to perform a flow check for control charting. -

Page 90: Inlet Assemblies

Preventive Maintenance Inlet Assemblies Although the Model 5030 SHARP should hold a valid calibration for up to one year, typically it is recommended by the USEPA to visit the monitoring site biweekly for the QC checks referenced above. However, during these visits it is also a convenient time to check the optical background of the nephelometric stage (as described in the “Installation”... -

Page 91: Cyclone Maintenance

SCC assembly should be inspected and cleaned, O-rings checked for distortion, cracks, fraying, or other problems. Replace O-rings as necessary. Inlet Dust Pot Outlet Figure 5-4. PM Sharp-Cut-Cyclone Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 92: Usepa Pm

Completely dry all components. Also monthly, check the O-rings for distortion, cracks, fraying, or other problems and replace as necessary. Apply small amounts of grease to the rings before assembling the unit. Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 93: Inlet

Standard tube connection: d = 16 mm for connecting a continuous monitor • Easy converting to PM using the PM nozzle plate (8 nozzles) • Easy converting to PM using the PM nozzle plate (8 nozzles) Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 94: Weather Proofing

LCA and calculate the difference. It is normal for the 5030 to have a lower flow rate approximately 0.8 alpm when the LCA is attached compared to without the LCA. If the difference is less than 0.80 L/min (80 ml/min) the the leack check passes. -

Page 95: Chapter 6 Troubleshooting

Troubleshooting Chapter 6 The Model 5030 SHARP has been designed to achieve a high level of reliability. Only premium components are used, thus complete failure is rare. In the event of problems or failure, the troubleshooting guidelines presented in this chapter should be helpful in isolating the fault(s). - Page 96 Run output noisy Recorder noise Replace or repair recorder and/or leads. Sample concentration varying Run Model 5030 on a zero filter - if quiet, there is no malfunction Foreign material in Clean optical bench optical bench...

-

Page 97: Status Messages

Global status: 6 characters, each one consisting of 4 bits, characters 0 thorough F. In the following section is a list of the most important status displays. The status, however, can occur also in various other combinations. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 98: Warning And Operating Detailed Status Reports

Troubleshooting Status Messages Status Concept and This section interprets the Operational, Warning and Error Status codes that may be indicated by the Model 5030. Structure Warning and Operating Detailed Status Reports Warning Status Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 99: Structure Of The Status Conception

Power supply switched on Structure of the Status Note The detailed status messages are a result of added status codes and thus form the warning as well as the operating status. Conception Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 100: Detailed Status Messages

Being able to recognize these subtleties will allow the user to easily define and troubleshoot the Model 5030 as necessary. Below is a matrix of alphanumeric combinations. Status Codes - Alphanumeric Combinations... -

Page 101: Table 6-4. Global Error Status

The following break down of the Global Error Status Definitions to a Detailed Error Status can be obtained by pressing the DISP key once and the NEXT key four times from the Main Menu. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 102: Table 6-5. Data And Program Memory

(do not block the air intake!) lift sensor: “open” position not noticed filter break ≥ Plateau Flag (Counter pump was switched off when nominal air flow could not be reached Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 103: Table 6-7. Pressure Sensors

> 5 % 0000 00 0000 0000 E Sum status of the sample heater (Table 6-9). Table 6-9. Sample Heater Code Definition ° T4 exceeds max-heater temp > 2 RH Sensor Over Range Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 104: Overlay Of Several Status Messages

Lifting position: opening of the filter tape gap has not been recognized Filter tape fissure: no filter tape transport has been recognized 04: 0000 0000 0001 0000 Differential pressure sensor 6-10 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 105: Status Output By Potential Free Relay Contacts

Contacts Each relay has one potential free change contact. The self-surveillance routine of the Model 5030 SHARP is executed every second and the relays are set or reset according to the actual status. Status Reports of the standard relays on the main board include: Relay 0: signals the “Operation Status”... -

Page 106: Print Formats

The first two figures represent the “Global Error Status,” the two in the middle represent the “Warning and Limit Statesman the last two represent the “Operation-Status.” Example: Print format 3: 03-11-16 14:48:18 0200CA 10.3 129.7 1000.7 6-12 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 107: Status Concepts For Quality-Assured Measurement

00 00 00 normal operation 14:35 00 00 40 Nephelometer calibration stabilizing 14:49 00 00 00 normal operation 14:55 00 00 10 keypad enabled 15:10 00 00 00 normal operation Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual 6-13... - Page 108 It contains the 60 latest values (standard). With the option “512 Kbyte RAM-expansion” it is extended to 18560 entries (more than one year). The entry happens at every finished half hour. 6-14 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 109: Chapter 7 Servicing

Neither the C source nor the detector are field serviceable. The Model 5030 SHARP must be returned to the factory for servicing or it can be serviced by an authorized Thermo Fisher Scientific field service technician. CAUTION Carefully observe the instructions in each procedure. -

Page 110: Filter Tape Replacement

7-1). Nephelometer and Servicing of the Nephelometer and Beta Attenuation Chambers should be Beta Attenuation performed by a trained technician. A technical bulletin is available via the internet at http://www.thermo.com/air. Servicing Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific... -

Page 111: Figure 7-1. Pump Parts Location

WARNING Avoid inhaling carbon particulate. Use an approved particle filter or respirator. When installing new vanes, be sure the beveled side points outwards (see Figure 7-2). Reassemble the parts in the reverse order. Figure 7-2. Carbon Vane Installation Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... -

Page 112: Firmware Update

Nephelometer and Beta Attenuation Servicing Firmware Update Firmware for the Model 5030 SHARP can be updated by exchanging its FLASH-EEPROM. However, it is more easily accomplished through the transmission of a new program code via the COM1 serial interface. During transmission the program is saved in RAM. -

Page 113: Firmware Update Procedure

Use the following procedure to update the Model 5030 SHARP firmware. Procedure 1. Connect COM1 of the PC to COM1 of Model 5030 and switch on both instruments. 2. Unlock the keypad in the Operations menu and configure the Model 5030 to: •... - Page 114 Servicing Nephelometer and Beta Attenuation Servicing 5. Select Device type for 5030 SHARP. 6. Click on the Select source file button to choose the software file you want to load into the dust monitor. Model 5030 SHARP Monitor Instruction Manual...

- Page 115 Servicing Nephelometer and Beta Attenuation Servicing 7. Click on the Program button. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual...

- Page 116 EEPROM did not work correctly, the instrument starts with the old firmware version. Note The parameters of the Model 5030 SHARP are not changed when the firmware is updated. As a precaution, however, the parameters should be compared with the values that existed before the update was made. This can be done by using Print Format 8 before and after the update.

-

Page 117: Service Locations

For additional assistance, service is available from exclusive distributors worldwide. Contact one of the phone numbers below for product support and technical information or visit us on the web at www.thermo.com/aqi. 1-866-282-0430 Toll Free 1-508-520-0430 International Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... - Page 118 Servicing Service Locations 7-10 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 119: Chapter 8 Optional Equipment

Sampling Tube Often the most compatible way to install the Model 5030 at air quality Extensions monitoring sites is to collocate the inlet at the same height as other similar-use inlets. The “Installation” chapter discusses specific siting criteria. - Page 120 Protective Housing for Ambient Temperature Sensor Enclosure Rack Mounting 425451065 Telescope Plate Accessories KT149140871 Telescope Mount Bars, 1 pair, for 19-inch Rack Mounting Analog 425451029 Printed Circuit Board(s) Potential-Free Separation Extension 425451026 Bit I/O Expansion Board Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 121: Appendix A Warranty

(i) normal wear and tear, (ii) accident, disaster or event of force majeure, (iii) misuse, fault or negligence of or by Buyer, (iv) use of the Products in a manner for which Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual... - Page 122 OR WRITTEN, WITH RESPECT TO THE PRODUCTS, INCLUDING WITHOUT LIMITATION ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. SELLER DOES NOT WARRANT THAT THE PRODUCTS ARE ERROR-FREE OR WILL ACCOMPLISH ANY PARTICULAR RESULT. Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 123: Appendix Brs-232 Commands

Consequently, several commands can be received immediately one after the other. For example; a complete set of parameters (approximately 20 commands) can be sent to the Model 5030 as one contiguous string of commands. The entire systems structure allows for operating several measuring instruments being connected to a common bus line (RS485). - Page 124 (such as, parameters that are no longer within the admissible range), the respective command will not be executed and the error counter will increment by 1. The MODEL 5030 monitor incorporates two serial interfaces which can be operated simultaneously: •...

- Page 125 (273K, 1013hPa) air flow rate regulation 0...100% power of external heating 0...100% relative humidity value (%RH) non filtered mass in μg mass on LCD with RC-filter (μg) mass, filtered with Quick-Lock filter Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual...

- Page 126 β-concentration low pass filtered optics-concentration Instrument model and software version[Number] are given out. read date/time of day answer: jj-mm-tt hh:mm:ss read date/time Answer: jjmmddhhmmss Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 127 22 characters. Each character represents 4 status bits with hexadecimal display. The first 16 characters show the detailed error status, the last 6 characters the global error -, warning -/alarm – and operating status. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual...

- Page 128 Establishes the Range 1 Optical Offset KR[number] Establishes the Range 2 Optical Offset KS[number] Establishes the Range 1 Optical Calibration KT[number] Nephelometer temperature (factory) compensation factor KU[number] Establishes the RH Target Value Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 129 PARAMETER file (print format 47) y> write PARAMETER file (print format 47) offline online Output commands for file output: Auto stop ON; single line output Auto stop OFF Stop Continue Terminate Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual...

- Page 130 Data Protocols with Once the character <STX> (usually: Ctrl-B) has been received, the Measuring Network monitoring instrument MODEL 5030 starts processing the data received at the serial line according to the protocol that has been agreed upon for Connection devices operating in a measuring network.

- Page 131 (1). The format will be as follows (here in this case with 2 variables): <STX>MD0[n]<SP> [Address]<SP>[measured value 1]<SP>[Status]<SP>[Serial no.]<SP>[SFKT]<SP> [Address+1]<SP>[Measured value 2]<SP>[Status]<SP>[Serial no.]<SP>[SFKT]<SP> <ETX><BCC1><BCC2> [n]: Number of variables [Address]: Device address set, 3 characters, leading zeros are transmitted <SP>: Space character Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual...

- Page 132 02 : Breach or end of the filter tape 04 : Detector error 08: Heater error 10: Any error occurred <ETX>[BCC1][BCC2] is replaced by <CR><LF>, if the data inquiry has been terminated by <CR>. B-10 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 133 In case that the control command is accepted by the measuring instrument (the characters ST follow the <STX>, correct address, correct block check), then the command will be executed. It is allowed to replace <ETX>[BCC1][BCC2] by <CR>. Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual B-11...

- Page 134 (incl. <STX>, <ETX>) (based on 00hex). The bit that results is sent as hexadecimal number with two ASCII characters. Example: BCC binary: 01011010 Is transmitted by the ASCII characters: 5A B-12 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

-

Page 135: Appendix C Connector And Board Schematics

Loading capacity of the contacts: -12V max 60V/ 0.5A Rest: Relay picked-up -12V Analog outputs 0..10V: Ω Internal resistance : < 1 Maximum output current: 5 mA Analog outputs 0..20mA: Ω Maximum load: 500 Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual C-1... - Page 136 37 -20mA Mass 7 -20mA B (Temp. PM10-head) 19 -20mA Concentration 3 +20mA C (Channel 5) 8 -20mA C (Channel 5) 4 +20mA D (Channel 6) 9 -20mA D (Channel 6) C-2 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 137 Switched voltage output maximum 3 A Designation protective conductor switched voltage Pump neutral conductor Plug HEATER Switched voltage output maximum 3 A Designation protective conductor switched voltage Heating neutral conductor Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual C-3...

- Page 138 Switch Standard etting Sensor Type S1/1 S1/2 T2: KTY 10 S1/1 S1/2 T2: PT 100 S1/3 S1/4 FH 62-1 T3: KTY 10 S1/3 S1/4 FH 62 I-R T3: PT 100 C-4 Model 5030 SHARP Monitor Instruction Manual Thermo Fisher Scientific...

- Page 139 X11 Jumper mA Jumper Configuration 0-20 mA Concentration Analog Output Jumper Configuration X24 Jumper X25 Jumper Volt Jumper Configuration 0-10 VDC Concentration Analog Output Jumper Configuration Front of Instrument Rear of Instrument Thermo Fisher Scientific Model 5030 SHARP Monitor Instruction Manual...

Need help?

Do you have a question about the 5030 and is the answer not in the manual?

Questions and answers