Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ABB IRBP

- Page 1 ROBOTICS Product manual IRBP /D2009...

- Page 2 Trace back information: Workspace 20A version a6 Checked in 2020-03-05 Skribenta version 5.3.033...

- Page 3 Product manual IRBP A IRBP B IRBP C IRBP D IRBP K IRBP R IRBP L IRC5 Document ID: 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. Specifications subject to change without notice.

- Page 4 The information in this manual is subject to change without notice and should not be construed as a commitment by ABB. ABB assumes no responsibility for any errors that may appear in this manual. Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind of guarantee or warranty by ABB for losses, damages to persons or property, fitness for a specific purpose or the like.

-

Page 5: Table Of Contents

3.4.2 Orienting and securing the manipulator ............3.4.3 Securing the controller ................3.4.4 Mounting of secondary shield on IRBP-K ............. 3.4.5 Dimensions of the tailstock IRBP L-5000 ............. Safety options positioning ................... 3.5.1 Safe positioning of the control equipment ............ - Page 6 Cut the paint or surface on the robot before replacing parts ......Frame parts ..................... 6.2.1 Replacing frame parts ................6.2.2 Lifting frame parts ................... Lower frame and base ..................6.3.1 Replacing stop lugs ................. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 7 When to calibrate ..................... Calibration marks ....................Updating revolution counters ................Manual setting of the calibration values ..............Recalibrating the axes ..................Calibration of the station interchange unit for positioner IRBP ........Multi-arc calibration (not IRBP C) ................. 8.7.1 Introduction .................... 8.7.2 Calibrating the multi-arc system ..............

- Page 8 Table of contents 10.6 Circuit diagrams ....................11 Lifting instructions 12 Spare parts 12.1 Spare part lists and illustrations ................Index Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 9: Overview Of This Manual

ABB and have the required knowledge of mechanical and electrical installation/repair/maintenance work. Product manual scope The manual covers covers all variants and designs of the IRBP. Some variants and designs may have been removed from the business offer and are no longer available for purchase. - Page 10 Revision Description First edition The following new sections added: • Securing the manipulator IRBP L using fixture laser on page 94 • Example of fixture laser aligning on page 95 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T...

- Page 11 SEROP -POF-110000 & CNAUS -POF- 510000. • Minor corrections. • Changed designations for IRBP R. 250 to 300, 500 to 600 and 750 to 1000. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T...

- Page 12 • Updated list of applicable standards. • Added information regarding removal/refitting of plates and protection plugs for access to lifting eye holes on the IRBP R frame. Published in release R18.1. This revision includes the following additions and/or changes: •...

- Page 13 External control units on page Published in release 19D. The following updates are made in this revision: • Added information about load data identification for IRBP C, see Identification of load data for positioners IRBP on page 289. Published in release 20A. The following updates are made in this revision: •...

-

Page 14: Product Documentation

Product documentation Categories for user documentation from ABB Robotics The user documentation from ABB Robotics is divided into a number of categories. This listing is based on the type of information in the documents, regardless of whether the products are standard or optional. - Page 15 The operating manuals describe hands-on handling of the products. The manuals are aimed at those having first-hand operational contact with the product, that is production cell operators, programmers, and troubleshooters. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 16: How To Read The Product Manual

Likewise, certain work methods or general information that is valid for several robot models, can be illustrated with illustrations that show a different robot model than the one that is described in the current manual. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 17: Safety

The installation and/or use of non-original spare parts and equipment can negatively affect the safety, function, performance, and structural properties of the robot. ABB is not liable for damages caused by the use of non-original spare parts and equipment. -

Page 18: Requirements On Personnel

The plant liable must make sure that the personnel is trained on the robot, and on responding to emergency or abnormal situations. Personal protective equipment Use personal protective equipment, as stated in the product manual. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 19: Safety Signals And Symbols

NOTE Signal word used to indicate important facts and conditions. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 20 1.2.1 Safety signals in the manual Continued Symbol Designation Significance Signal word used to indicate where to find additional information or how to do an operation in an easier way. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 21: Safety Symbols On Manipulator Labels

Prohibition Used in combinations with other symbols. xx0900000839 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 22 Brake release Pressing this button will release the brakes. This means that the robot arm can fall down. xx0900000808 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 23 Tip risk when loosening bolts The robot can tip over if the bolts are not securely fastened. xx0900000810 xx1500002402 Crush Risk of crush injuries. xx0900000817 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 24 Risk of heat that can cause burns. (Both signs are used) xx0900000818 xx1300001087 Moving robot The robot can move unexpectedly. xx0900000819 xx1000001141 xx1500002616 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 25 Lifting of robot xx0900000822 Can be used in combination with prohibition if oil is not allowed. xx0900000823 Mechanical stop xx0900000824 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 26 Shut off with handle Use the power switch on the controller. xx0900000827 Do not step Warns that stepping on these parts can cause damage to the parts. xx1400002648 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 27: Robot Stopping Functions

Protective stop and emergency stop The protective stops and emergency stops are described in the product manual for the controller. For more information see: • Product manual - IRC5 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 28: Installation And Commissioning

The power supply wiring to the robot must be sufficiently fused and if necessary, it must be possible to disconnect it manually from the mains power. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 29 The risk assessment should also consider other hazards, such as, but not limited • Water • Compressed air • Hydraulics Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 30 Always use the prescribed personal protective equipment. Welding fumes and any gases formed or used when welding can be dangerous to inhale. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 31 Before the robot system is put into operation, verify that the safety functions are working as intended and that any remaining hazards identified in the risk assessment are mitigated to an acceptable level. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 32: Maintenance And Repair

Possible pressure build-up in gearbox Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 33 Risk of fire or explosion. Operating temperatures are listed in Operating conditions on page Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 34 1 Safety 1.5.1 Maintenance and repair Continued Related information See also the safety information related to installation and operation. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 35: Brake Testing

3 Inspect and verify that the axis maintains its position. If the manipulator does not change position as the motors are switched off, then the brake function is adequate. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 36: Troubleshooting

The manipulator can move unexpectedly at any time. DANGER Troubleshooting on the controller while powered on must be performed by personnel trained by ABB or by ABB field engineers. A risk assessment must be done to address both robot and robot system specific hazards. -

Page 37: Decommissioning

1 Safety 1.7 Decommissioning 1.7 Decommissioning General See section Decommissioning on page 305. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 38 This page is intentionally left blank...

-

Page 39: System Description

2 System description 2.1 System overview 2 System description 2.1 System overview IRBP function package The IRBP function package consists of the following units: • Positioner(s) with one or two operator stations • Robot(s) with process equipment for e.g. arc welding •... - Page 40 2 System description 2.1 System overview Continued Manual jog Service door with gate switch Controller Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

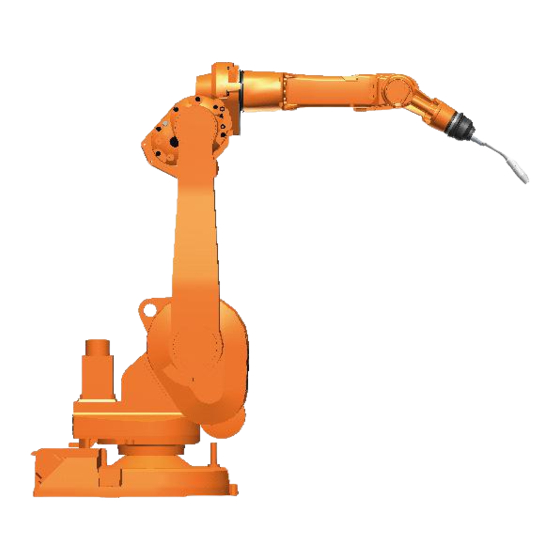

Page 41: Irbp Positioner

Positioner A positioner is used to position work pieces optimally for welding joints and robots. The IRBP positioner is equipped with maintenance-free AC motors with electro-magnetic brakes. The letter in the positioner name indicates the positioner type and the number indicates its maximum handling capacity in Kg. - Page 42 2 System description 2.2.1 IRB Positioner overview Continued IRBP Illustration IRBP B: • • • xx0900000840 IRBP C: • • 1000 xx0900000846 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 43 • • xx0900000837 IRBP K: • • • 1000 xx0900000832 IRBP L: • • • 1000 • 2000 • 5000 xx0900000845 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 44 2 System description 2.2.1 IRB Positioner overview Continued IRBP Illustration IRBP R: • • • 1000 xx0900000838 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 45: Station Interchange Unit Mid

The station interchange unit for two stations consists of the following: xx0900000834 Gear drive AC servo motor with integrated resolver and brake Limit switch with limit position disc Connection panel Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 46 2.2.2 Station interchange unit MID Continued Station interchange unit MID 1.1 xx0900000841 Gear drive AC servo motor with integrated resolver and brake Limit switch Limit position disc Connection panel Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 47: Rotary Units

The rotary unit MTD is a modular unit, developed specifically for robot applications and is intended for positioning the workpiece. MTD units xx0900000843 MTD 250 MTD 500/750 MTD 2000 MTD 5000 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 48 The motor is maintenance free. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 49: Support Collar

2.2.4 Support collar Components The support collar allows axial movement during rotation. xx0900000844 Support collar Shaft with the mounting flange Flange bearing with spherical bearing position. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 50: Control System

Single Cabinet Controller/Dual Cabinet Controller The Single Cabinet Controller/Dual Cabinet Controller (Drive Module DM1) contains control equipment (axis selector unit) for IRBP positioners. It is installed on a pivot frame in the Single Cabinet Controller/Dual Cabinet Controller (Drive module). In the Dual Controller, the Drive Module (DM1) and Control Module (CM) are jointly connected to incoming power supply. - Page 51 Main power switch (Circuit Breaker) on Drive Module) Stand by lamp indicates that electronic supply is switched on by the Control Module mains switch. Flex Pendant Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 52 2 System description 2.3.1 IRC5 controller Continued Block overview xx1000000227 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 53: Operator Panel

The hot plug button option makes it possible to disconnect the FlexPendant in automatic mode and continue running without it. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 54 Use the joystick to move the manipulator. This is called jogging the robot. There are several settings for how the joystick will move the manipulator. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 55 START button. Starts program execution. Step FORWARD button. Executes one instruction forward as button is pressed. STOP button. Stops program execution. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 56 If there is a need to enter safeguarded space, always bring the three-position enabling device. This is to enforce single point of control. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 57 A left-hander, however, can easily rotate the display through 180 degrees and use his right hand to support the device. en0400000913 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 58 • Production Window • Program Editor • Program Data • Backup and Restore • Calibration • Control Panel • Event Log Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 59 • System Info • etc. This is further described in section The ABB Menu in Operating manual - IRC5 with FlexPendant. Operator window The operator window displays messages from robot programs. This usually happens when the program needs some kind of operator response in order to continue.

-

Page 60: External Control Units

2 System description 2.4.2 External control units 2.4.2 External control units External control panel xx0900000860 Emergency stop Motors On button Operating mode selector Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 61 This variant applies to stations with one working area for the operator. xx0900000863 Emergency stop Entry permitted indication Start process, reset (toggle function) Program start Program stop Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 62 The variant for two working areas has one indicator per station. The variant for two working areas has one button per station. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 63 Manual Jog can be used for: • Positioner IRBP K/R • Positioner 2 x IRBP L Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 64 Press and hold the SafeBall during the whole op- eration. Press and hold the buttons for the desired direc- tion until the positioner has reached the desired position. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 65 Jog program task gets stuck. To recover, go into the Manual Jog program task on the FlexPendant and move the program pointer to the start of the task. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 66: Safety Equipment (Options)

Safety control equipment is located on the sidewall of the cabinet. The control equipment may also be located on the guard or on a stationary building wall. xx0900000796 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 67 2.5.1 Location of safety equipment Continued Safety block diagram xx0900000896 Controller Safety control equipment Gate switch Gate reset IRBP Manual jog panel Pre-reset Operating panel Light barrier Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 68: Customer Options

2 System description 2.6.1 Optional swivels 2.6 Customer options 2.6.1 Optional swivels Air swivel, 1 channel xx1000000177 Air swivel, 2 channel xx1000000179 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 69 2 System description 2.6.1 Optional swivels Continued Electrical swivel xx1000000178 Air swivel, 1 channel and 1 electrical channel xx1000000180 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 70 This page is intentionally left blank...

-

Page 71: Installation And Commissioning

Safety on page 17 before performing any installation work. Note If the IRBP is connected to power, always make sure that the robot is connected to protective earth and a residual current device (RCD) before starting any installation work. For more information see: •... -

Page 72: Installation And Set-Up

Note Lifting eyes (standard as well as with swivel) are not delivered with the IRBP. Use lifting eyes and/or swiveled lifting eyes in the proper positions as described in the lifting instructions for each IRBP. Always use lifting eyes with the correct lifting capacity according to the part being lifted. -

Page 73: Unpacking And Handling

If the IRBP system is not installed directly, it must be stored. Before taking the IRBP system to its installation site, make sure the foundation con- forms to the requirements. Before moving the IRBP system, please observe and read the sections regarding lifting of the IRBP system. - Page 74 Manipulator IRBP C IP 42 Manipulator IRBP D IP 42 Manipulator IRBP L IP 65 Manipulator IRBP K IP 42 Manipulator IRBP R IP 42 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 75: Lifting The Irbp

Note Lifting eyes (standard as well as with swivel) are not delivered with the IRBP. Use lifting eyes and/or lifting eyes with swivel in the proper positions as described in the lifting instructions for each IRBP. Always use lifting eyes with the correct lifting capacity according to the part being lifted. - Page 76 IRBP L 1000 2000 5000 IRBP K 1090 1,515 1980 2,570 1000 1980 2,570 IRBP R 1285 1,380 1000 1285 1,380 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 77 3 Installation and commissioning 3.3.2 Lifting the IRBP Continued Lifting IRBP A xx0900000897 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 78 3 Installation and commissioning 3.3.2 Lifting the IRBP Continued Lifting IRBP B xx1000000089 Lifting IRBP D xx1000000090 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 79 3 Installation and commissioning 3.3.2 Lifting the IRBP Continued Lifting IRBP R, K xx1000000092 Lifting beam 4000 mm Fitting the lifting eyes on IRBP R Action Note Remove the plates to get access to the lifting eye holes in the frame. xx1700001322...

- Page 80 Remove the protection plugs from the lifting eye holes. Note Save the plugs for refit after installation. xx1700001324 Attach the lifting eyes. 2 pcs xx1700001323 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 81 3 Installation and commissioning 3.3.2 Lifting the IRBP Continued Lifting IRBP L xx1000000093 Lifting beam 4000 mm Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 82: Forces On Foundation

Endurance load in operation (N) Max load at emergency Screw dimen- unit stop (N) sion A-250 6300 1930 11500 A-500 3300 12900 6700 23200 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 83 Max load at emergency stop Screw dimen- unit sion K-300 1000 3100 1500 5000 K-600 2000 7000 2000 10200 K-1000 2000 7000 2000 10200 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 84 8900 L-600 1200 12000 2200 18800 L-1000 1200 12000 2200 18800 L-2000 1700 25700 3700 36700 L-5000 3000 35000 9000 44500 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 85 D-300 2500 10300 4500 15500 D-600 5000 20600 9000 30900 R-300 1380 5400 3000 7800 R-600 2700 15000 6400 22300 R-1000 2700 15000 6400 22300 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 86: Recommendations For Attachment Bolts And Screws

87. These instructions do not apply to screw joints composed of soft or brittle materials. For screws with a higher property class than 8.8, the data for 8.8 must be used unless otherwise specified. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 87: Screw Joints

3.3.5 Screw joints 3.3.5 Screw joints General This section describes how to tighten the various types of screw joints on ABB robots. The instructions and torque values are valid for screw joints comprised of metallic materials and do not apply to soft or brittle materials. - Page 88 A special torque specified in the repair, maintenance or installation procedure overrides the standard torque. Dimension Tightening torque (Nm) Tightening torque (Nm) Class 10.9, lubricated Class 12.9, lubricated Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 89 A special torque specified in the repair, maintenance or installation procedure overrides the standard torque. Dimension Tightening torque Nm - Tightening torque Nm - Tightening torque Nm - Nominal Min. Max. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 90: The Unit Is Sensitive To Esd

The mat must be grounded through a current-limit- ing resistor. Use a dissipative table mat. The mat should provide a controlled discharge of static voltages and must be grounded. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 91: On-Site Installation

The pedestal can be placed in different hole groups on the stand. Exercise care to ensure the robot and positioner do not collide during station switching. Recommended spacing, see the chapter for respective positioner. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 92 Use this procedure to secure the robot stand. Action Note Position the robot stand at the intended work site. See instructions in Orienting and securing the manipulator on page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 93: Orienting And Securing The Manipulator

3.4.2 Orienting and securing the manipulator 3.4.2 Orienting and securing the manipulator Illustration, positioning the manipulator Note The illustration shows IRBP A, but the principle for orienting and securing the positioner is the same for all variants. xx0900000914 Screws for fastening (floor bolts) - Page 94 Refit the protection plugs to the lifting eye holes. xx1700001324 Securing the manipulator IRBP L using fixture laser Use this procedure to secure the IRBP L using a fixture laser. Action Note Position the IRBP L at the intended work site.

- Page 95 NXA by Fixturlaser or TKSA41 from SKF, turning disc adapters and adjustment tool. For more information, see Example of adjusting the bearing units for IRBP L on page 96 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T...

- Page 96 This is an example on how to use the adjustment tool when adjusting the bearing units on the IRBP L positioner. The adjustment tool can be ordered from ABB as a spare part. Other equipment mentioned in this example, for example laser sensors and turning disc adapter, is to be considered generic and therefore not available as spare parts delivered by ABB.

- Page 97 Loosen the bearing screws from both sides of the bearing house. xx1700001365 Fasten the turning disc adapter on to the bearing disc using the adapter screws. xx1700001366 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 98 Pull the sensor as close as possible to the edge of the indentation. Tighten the sensor chain. Ensure that the adapter screws are tightened. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 99 If the values from the laser reading is not within the allowed deviation during calibration, then re- calibrate and measure again. If the problem re- main, please contact ABB. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 100 3 Installation and commissioning 3.4.2 Orienting and securing the manipulator Continued Action Note Remove any equipment fitted on the IRBP L posi- tioner. Fasten the bearing screws to the bearing house For more information about the using the correct torque.

-

Page 101: Securing The Controller

Space requirements See installation description in Product manual - IRC5. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 102: Mounting Of Secondary Shield On Irbp-K

3 Installation and commissioning 3.4.4 Mounting of secondary shield on IRBP-K 3.4.4 Mounting of secondary shield on IRBP-K Location of the shield The secondary shield is located as shown in the figure. xx1700000439 Secondary shield Primary shield Required tools and equipment... - Page 103 3 Installation and commissioning 3.4.4 Mounting of secondary shield on IRBP-K Continued Action Note Fit the six screws with washers (A) through the pre-mounted bracket (B). xx1700000440 Screw: M8x25 (6 pcs) Washer: 8.4x21x4 (6 pcs) Tighten the screws. Tightening torque: 25 Nm Tighten the screws (A) with nuts (6 pcs) on the pre-mounted shield brackets.

-

Page 104: Dimensions Of The Tailstock Irbp L-5000

3.4.5 Dimensions of the tailstock IRBP L-5000 3.4.5 Dimensions of the tailstock IRBP L-5000 Tailstock dimensions The tailstock on the IRBP L-5000 has a centered hole to be able to, for example, pull cable harness through. 12x M 24 FAS 3 x 45... -

Page 105: Safety Options Positioning

Repairs, especially those concerning optics and circuit cards, must only be carried out by the manufacturer or by persons appointed by the manufacturer. Interference or modifications to safety equipment are not permitted. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 106 Positioned on SC/DC or on Fence xx0900000916 Control equipment for safety placed on fence Control equipment for safety placed on SC/DC Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 107 3 Installation and commissioning 3.5.1 Safe positioning of the control equipment Continued Control equipment fastening xx0900000923 Bracket Hole for M8 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 108 3.5.1 Safe positioning of the control equipment Continued Safety block diagram xx0900000896 Controller Safety control equipment Gate switch Gate reset IRBP Manual jog panel Pre-reset Operating panel Light barrier Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 109: Positioning Of Light Barrier

Light barriers are an optoelectronics protective device intended to secure dangerous areas. xx0900000989 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 110 Adjust to the optimal horizontal position us- ing the set screws (1) if necessary. xx1000000036 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 111 3 Installation and commissioning 3.5.2 Positioning of light barrier Continued Action Information Check that the receiver unit is correctly adjus- ted. xx1000000034 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 112: Positioning Of Gate Switch

Mount the safety switch and the safety lock in a suitable position. Mount the cable using straps. Attache the cable according to section Connections safety equipment on page 128 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 113: Electrical Connections

Pre-reset STN1 Pre-reset STN2 Activation unit STN1 Activation unit STN2 Gate reset External cables IRBP A/L Cables shown in figure IRBP A/L Connector Length (m) Cable signal IRBP STN1 7/10/15 Cable motor IRBP STN1 7/10/15 Cable signal IRBP STN2... - Page 114 Cable activation unit “Programming from operator area” STN2 Cable pre-reset STN1 Cable pre-reset STN2 Cable protective earth 7/10/15 Cable protective earth 7/10/15 IRBP B/C/D/K/R xx1000000226 Gate reset Pre-reset Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 115 3 Installation and commissioning 3.6.1 Electrical connectors Continued External cables IRBP B/C/D/K/R Cables shown in figure IRBP B/C/D/K/R Connector Length (m) CAN bus + cable safety signals + cable position switches Cable CAN bus + cable operator panel Cable control panel manual jog...

-

Page 116: Electrical Assembly Irbp

Electrical signals Ground connection, weld negative Air connection (4 pcs) Current collectors xx0900000990 Current collector connection 1 Current collector connection 2 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 117 3.6.2 Electrical assembly IRBP Continued Customer connections xx1200000067 CP1.Customer Power 1 CP2.Customer Power 2 R1.SMB.Resolversignals. CS1.Customer Signals 1. CS2.Customer Signals 2. XS50/XP50.Motor Power Earth connection point Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 118: Connections For Sc/Dc (Dm)

XS41.2 Resolver signals IRBP 2 XS41 Resolver signals IRBP 1 XP41.2 Jumper connector if only using one IRBP Cover hood if only using one IRBP Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 119 3 Installation and commissioning 3.6.3 Connections for SC/DC (DM) Continued Outputs for positioner C, K, R, B, D xx0900001005 XS 101 Motor power XS 41 Resolver signals Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 120: Open And Close The Pivot Frame

Opening the pivot frame xx0900001051 Action Information Open the controller cabinet. Disconnect the cables on the axis selector unit. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 121 Secure the pivot frame with the axis selector plate by tightening the two locking screws (pos. A). Fit the cables on the axis selector unit. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 122: Retrofit An Interface To The Irc5 Controller

Note If the standalone controller was ordered without the option Prepared for IRBP, then one mounting rail is missing. One extra rail is delivered with the positioner interface and it is necessary to remove the axis computer and the main drive module to attach the rail. - Page 123 The bushings are often tight so it is re- commended to carefully use a plastic hammer. Lock the shaft with a screw. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 124 1, 2 or 3 drive units depending on the type of the positioner. xx1600000456 Attach the SMB2 cable to the X5 connector on the axis computer. xx1600000457 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 125 Assemble the attachment plate in the cabinet front left corner. xx1700001273 Attach the hinge to the attachment plate. xx1600000460 Attach the axis selector to the hinge. xx1700001274 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 126 Note If the standalone controller was ordered without the option Prepared for IRBP, then one mounting rail is missing. One extra rail is delivered with the positioner interface and it is necessary to remove the axis computer and the main drive module to attach the rail.

- Page 127 Item 26: Cable I/O RS485 (3HEA802201-001) Attach the connectors X1, X2 and A111.TB1 to the axis selector. Attach the ground cable from the axis selector to the chassis. xx1600000465 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 128: Safety Installations

3.7.1 Connections safety equipment 3.7 Safety installations 3.7.1 Connections safety equipment Connections in SC/DC (DM) The tables below show the configuration for the specific IRBP, (x) = not used. The safety unit has the following tasks: • To monitor the station interchange unit •... - Page 129 3 Installation and commissioning 3.7.1 Connections safety equipment Continued IRBP A IRBP B IRBP C IRBP D IRBP K IRBP R IRBP L Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 130 Button for gate reset, (A13.X2.2) Gate switch, (A13.X2.1) Button for gate reset, (A13.X2.2) CAN IN, (A131.TB6) Positioner signals, (A131.TB2) Safety signals, (A13.X8) CAN OUT, (A13.A35.J1) Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 131 Button for gate reset, (A13.X2.2) Supervision of contactors in drive module, (A131.TB2) CAN OUT, (A13.A35.J1) Safety signals, (A13.X8) Positioners safety signals CAN IN, (A131.TB6) Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 132 Button for pre-reset, station 2 Home position/transport position indication Button for activation unit, station 1 Button for activation unit, station 2 Gate switch Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 133 Cable connections B, C, D, K, R xx0900001015 Light barrier 1, (A13.X3) Push-button for pre reset station 1, (A13.X4) Gate switch, (A13.X2.1) Push-button for resetting gate, (A13.X2.2) Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 134: Connection Of Cable For Manipulator Signals

Make the cable gland in the separable panel on the SC or DC drive mod- ule (POSITIONER SIG- NALS) (1). xx0900001026 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 135 3 Installation and commissioning 3.7.2 Connection of cable for manipulator signals Continued Action Illustration Connect the cable to connector A11.X3 or A11.X4 in SCC/DCC (1). xx0900001032 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 136: Connection Of Cable For Safety Signals

(SAFETY SIGNALS) (1). xx0900001035 Connect the cable to con- nector A13.X8 in the control equipment for safety (2). xx0900001036 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 137 Add a cable gland to the separable panel on the SCC or DCC control module (SAFETY SIGNALS) (3). xx0900001037 Connect the cable to con- nector A13.X9 in SCC/DCC xx0900001039 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 138: Drive System

Axis computer • Main Drive Unit • Rectifier • Drive unit for positioner • Cables and contactors for connecting rotary unit. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 139 Axis computer • Main Drive Unit (Rectifier included) • Drive unit for positioner • Cables and contactors for connecting rotary unit. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 140 Main Drive Unit (MDU) A42.X5 Axis computer A41.3 Additional Drive Unit (ADU) for positioner A41.4 Additional Drive Unit (ADU) for positioner A41.5 Additional Drive Unit (ADU) for positioner Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 141: Axis Computer

Serial measurement board, located in the external distribution box • Resolver connection cable Connections xx1000000046 A42.X4 Measurement Link 1 A42.X5 Measurement Link 2 A42.X9 Console port Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 142: Software Installation

3.8 Software installation 3.8.1 Starting the system for the first time General An IRBP function package delivered by ABB has a customized configuration installed at delivery. The system is preconfigured and will start up with the options and settings that were ordered. -

Page 143: Upgrading The Software

The folder can also be unzipped elsewhere, but will then need to be located manually in the System Builder wizard. Verify that the folder is created: ...\ABB Industrial IT\Robotics IT\MediaPool\\3HEA-<system serial number>\ Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 144 Update the revolution counters, see Updating revolution counters on page 269. For more detailed instructions on using the Installation Manager, see Operating manual - RobotStudio. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 145: Installing Fixtures And Testing With Corresponding Workpieces

Note The values for Max load difference between sides 1 and 2 are listed in the technical data in Product specification - IRBP /D2009. Load difference sides 1 and 2 does not exceed specified maximum value If the positioner is in a horizontal position or not at the end of the working range when installing fixtures, make sure that the value of Max load difference sides 1 and 2 is not exceeded. - Page 146 3 Installation and commissioning 3.9.1 Installing fixtures Continued xx1100000143 Brake testing After installing fixtures, always test the brakes, see Brake testing on page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 147: Removing Or Changing Fixtures

Note The values for Max load difference between sides 1 and 2 are listed in the technical data in Product specification - IRBP /D2009. Load difference sides 1 and 2 does not exceed specified maximum value If the positioner is in a horizontal position or not at the end of the working range when removing or changing fixtures, make sure that the value of Max load difference sides 1 and 2 is not exceeded. - Page 148 3 Installation and commissioning 3.9.2 Removing or changing fixtures Continued xx1100000143 Brake testing After installing fixtures, always test the brakes, see Brake testing on page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 149: Configuration

4 Configuration 4.1 Positioner Interface IRBP A 4 Configuration 4.1 Positioner Interface IRBP A General This section describes the I/O configuration for positioner IRBP A. I/O board Configuration for positioner Address Name Type Digit- Digit- Ana- Ana- al/Input al/Out- log/In-... - Page 150 Mechanical unit 2 activated Positioner diK3_ACT Mechanical unit 3 activated Positioner diK4_ACT Mechanical unit 4 activated Positioner 0 V input 1-7 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 151 4 Configuration 4.1 Positioner Interface IRBP A Continued Configuration cross-connections xx1000000130 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 152: Positioner Interface Irbp B/D

4 Configuration 4.2 Positioner Interface IRBP B/D 4.2 Positioner Interface IRBP B/D General This section describes the I/O configuration for positioner IRBP B/D. I/O board Configuration for positioner Address Name Type Digit- Digit- Ana- Ana- al/Input al/Out- log/In- log/Out- lay/Out-... - Page 153 Mechanical unit 3 activated Positioner diK4_ACT Mechanical unit 4 activated Positioner diK5_ACT Mechanical unit 5 activated Positioner 0 V input 1-7 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 154 4 Configuration 4.2 Positioner Interface IRBP B/D Continued Configuration cross-connections xx1000000131 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 155: Positioner Interface Irbp C

4 Configuration 4.3 Positioner Interface IRBP C 4.3 Positioner Interface IRBP C General This section describes the I/O configuration for positioner IRBP C I/O board Configuration for positioner Address Name Type Digit- Digit- Ana- Ana- al/Input al/Out- log/In- log/Out- lay/Out-... - Page 156 Positioner ated diLS_1_INPOS Limit switch station 1 Station interchange unit diLS_2_INPOS Limit switch station 2 Station interchange unit 0 V input 1-7 Configuration cross-connections xx1000000134 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 157: Positioner Interface Irbp K/R

4 Configuration 4.4 Positioner Interface IRBP K/R 4.4 Positioner Interface IRBP K/R General This section describes the I/O configuration for positioner IRBP K/R. I/O board Configuration for positioner Address Name Type Digit- Digit- Ana- Ana- al/Input al/Out- log/In- log/Out- lay/Out-... - Page 158 Limit switch station 1 Station interchange unit diLS_2_INPOS Limit switch station 2 Station interchange unit 0 V input 1-7 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 159 4 Configuration 4.4 Positioner Interface IRBP K/R Continued Configuration cross-connections xx1000000135 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 160: Positioner Interface Irbp L

4 Configuration 4.5 Positioner Interface IRBP L 4.5 Positioner Interface IRBP L General This section describes the I/O configuration for positioner IRBP L. I/O board Configuration for positioner Address Name Type Digit- Digit- Ana- Ana- al/Input al/Out- log/In- log/Out- lay/Out-... - Page 161 UnitMap Name Description Connected to unit diK1_ACT Mechanical unit 1 activated Positioner diK2_ACT Mechanical unit 2 activated Positioner 0 V input 1-7 Configuration cross-connections xx1000000136 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 162: Operator Panel Irbp

4 Configuration 4.6 Operator panel IRBP 4.6 Operator panel IRBP General This chapter describes the I/O configurations for operator panels delivered by ABB. I/O board configuration Address Name Type Digital/In- Digital/Out- Analog/In- Ana- log/Output B_OP_SIM Simulated digit- al I/O B_OP_21... - Page 163 Program start (only used when two operat- or panels are used) diPROG_STOP Program stop diPROG_STOP2 Program stop (only used when two operat- or panels are used) Configuring cross connections xx1100000160 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 164: Safety Interface Sib V For Positioner A/L

Type 3 *) Used as board No 2 in multi-station applications or combinations between different types of positioners. Example: Robot welding station with one positioner type IRBP 250K and one positioner type IRBP 250L. I/O signals configuration for SIB_V_B3 Digital inputs... - Page 165 Home position switch TB112:8,TB3 3:9 diRL402 Channel 2 active Home position switch TB112:11*), diRL403 Reset/control of function Home position switch TB112:12*) safety circuits Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 166 4 Configuration 4.7 Safety interface SIB V for positioner A/L Continued Configuration cross-connections xx1000000137 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 167: Safety Interface Sib V For Positioner B/C/D/K/R

Safety Interface Board Type 3 *) Used as board No 2 in multi-station applications or combinations between different types of positioners. Example: Robot welding station with one positioner type IRBP 250K and one positioner type IRBP 250L. I/O signals configuration for SIB_V_B1 Digital inputs... - Page 168 Reset/control of func- Safety switch service tion safety circuits door TB111:13, diRL204 Activate safety circuits Push button service door TB31:6 service door Configuration cross-connections xx1000000138 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 169: Maintenance

Safety on page 17 before performing any service work. Note If the IRBP is connected to power, always make sure that the IRBP is connected to protective earth and a residual current device (RCD) before starting any maintenance work. For more information see: •... -

Page 170: Specification Of Maintenance Intervals

5.2 Specification of maintenance intervals Introduction The intervals are specified in different ways depending on the type of maintenance activity to be carried out and the working conditions of the IRBP: • Calendar time: specified in months regardless of whether the system is running or not. -

Page 171: Maintenance Schedule And Expected Component Life

5.3 Maintenance schedule and expected component life 5.3.1 Maintenance schedule General This chapter details all maintenance activities recommended for the IRBP. It is based on the maintenance schedule located at the beginning of the chapter. The schedule contains information about required maintenance activities including intervals, and refers to procedures for the activities. -

Page 172: Inspection Activities

SMB 2 signals axis 2 Current collector rotary unit 2 Current collector rotary unit 1 Motor power axis 1 SMB 1 signals axis 1 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 173 Motor power axis 2 Current collector connection point Current collector rotary unit 1 SMB signals axis 1 Motor power axis 1 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 174 SMB signals axis 5/ Motor power axis 5 Current collector rotary unit 5 SMB signals axis 1 Motor power axis 1 Current collector rotary unit 1 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 175 SMB signals axis 1/ Motor power axis 1 Current collector rotary unit 2 SMB signals axis 2/ Motor power axis 2 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 176 Make an overall visual inspection of the cable harness, in order to detect wear and damage. Replace the cable harness if wear, cracks or damage is detected. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 177: Inspection, Current Collector

Inspection procedure xx1000000043 Current Collector Action Information Remove the Current Collector cable. Remove the Current Collector. Open key 46 mm Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 178 5 Maintenance 5.4.2 Inspection, current collector Continued Action Information Check the collector surface for damage. xx1000000113 For assemble see Replacing support collar axis on page 226. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 179: Inspection, Gearbox Oil Leak

See also Safety on page Location xx1000000250 Axis sealing Axis sealing Motor sealing Inspection procedure Action Information Check all sealing areas for oil leak. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 180: Cleaning Activities

General To secure high uptime it is important that the IRBP is cleaned regularly. The frequency of cleaning depends on the environment in which the product works. Different cleaning methods are allowed depending on the type of protection of the IRBP. - Page 181 Clean the cables if they have a crusty surface, for example from dry release agents. Mechanical stops Regularly clean the contact surface of the mechanical stops. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 182: Lubrication Activities

Equipment Note Grease Grease type: P34 from Nies. Article number: 0501869002. Standard tools Standard tools IRBP on page 312 Grease gun Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 183 5.6.1 Lubricating the current collector Continued Lubricate xx1000000024 Lubrication nipple Action Information Lubricate the current collector using a grease gun. Note Amount of grease: 12 ml. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 184: Oil In Gearboxes

Before starting any inspection, maintenance, or changing activities of lubrication, always contact the local ABB Service organization for more information. For ABB personnel: Always check ABB Library for the latest revision of the manual Technical reference manual - Lubrication in gearboxes, in order to always get the latest information of updates about lubrication in gearboxes. -

Page 185: Replacement And Changing Activities

Standard tools Standard tools IRBP on page 312 Cable strap (outdoors) 4.8 x 290, 2 pcs SMB battery See Product manual, spare parts - IRBP /D2009 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 186 Disconnect the connection cable (3) in figure and remove the battery. Fit the new battery in the reverse order. Use 2 cable straps. Mount the cover. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 187: Repair

Repair activities not described in this chapter must only be carried out by ABB. Report replaced units Note When replacing a part on the IRBP, report to your local ABB the serial number, the article number, and the revision of both the replaced unit and the replacement unit. -

Page 188: Mounting Instructions For Bearings

Make sure the bearing is properly aligned as this will directly affect the durab- ility of the bearing. Greasing of bearings Note This instruction is not valid for solid oil bearings. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 189 Grooved ball bearings must be filled with grease from both sides. • Tapered roller bearings and axial needle bearings must be greased in the split condition. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 190: Mounting Instructions For Sealings

Do not try to grind or polish the shaft surface to get rid of the defect. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 191 Mount the sealing correctly with a mounting tool. Never hammer directly on the sealing as this may result in leakage. xx2000000072 A Gap Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 192 If the flange surfaces are defective, the parts may not be used because leakage could occur. Clean the surfaces properly in accordance with the recommendations of ABB. Distribute the sealing compound evenly over the surface, preferably with a brush. Tighten the screws evenly when fastening the flange joint.

-

Page 193: Cut The Paint Or Surface On The Robot Before Replacing Parts

Carefully grind the paint edge that is left on the structure to a smooth surface. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 194: Frame Parts

Required equipment Equipment Note Standard tools For more information, see Standard tools IRBP on page 312. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 195 6 Repair 6.2.1 Replacing frame parts Continued Frame parts xx1000000019 Base frame screws Station frame screws Rotary units screws Turning disc screws Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 196 10x40 MTD 500 Turning axis 16x70 MTD 750 Turning axis 16x70 MTD 2000 Turning axis 20x90 MTD 5000 Turning axis 24x110 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 197 Described in section Lifting frame parts on page 205. Mount the attachment screws Tightening torque according to table in Screw joints MTD axis. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 198 Screws Base frame Station shield Attachment screws M20x90 Steel 12.9 Washers Action Note Remove the screws holding the station shield. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 199 MTD axis. Remove the lifting accessories from the frame. Valid for IRBP R Refit the plates at the frame ends. xx1700001322 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 200 Continued Action Note Valid for IRBP R Refit the protection plugs to the lifting eye holes. xx1700001324 Refit the station shield. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 201 Remove the frame and covers xx1000000020 Side cover Rotary Unit Attachment screw M20x90 Steel 12.9 Frame Screw M6x10 Bottom plate Washer 21x31/ 4 mm Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 202 4 Screw M6x10 Unscrew (2) and remove the bottom plate (1). xx1000000007 1 Bottom plate 2 Screw M6x10 Remove the electrical connec- tion. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 203 1 Attachment screw M20x90 Steel 12.9 2 Guide pin Mount all electrical connections. Mount the bottom plate. Mount the side plates and cover. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 204 Refit the MTD turning disc Action Note Refit the screws by holding the turning disc. Tightening torque according to the table in Screw joints MTD axis. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 205: Lifting Frame Parts

224. Note Lifting eyes (standard as well as with swivel) are not delivered with the IRBP. Use lifting eyes and/or lifting eyes with swivel in the proper positions as described in the lifting instructions for each IRBP. Always use lifting eyes with the correct lifting capacity according to the part being lifted. - Page 206 Attach the lifting eyes with swivel, as shown in the figure. Stretch the lifting chains. Remove the attachment screws. Lift the gearbox and the frame. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 207 Attach the lifting eyes as shown in the figure. Stretch the lifting chains Remove the attachment screws Lift the gearbox and the frame Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 208 Stretch the lifting chains Remove the attachment screws Lift the gearbox and the frame Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 209 Attach the lifting eyes as shown in the figure. Stretch the lifting chains Remove the attachment screws Lift the gearbox and the frame Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 210 Attach the lifting eyes as shown in the figure. Stretch the lifting chains Remove the attachment screws Lift the gearbox and the frame Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 211 394 kg 600/1000R, D=1000, L=1600 828 kg 600/1000R, D=1000, L=2000 853 kg 600/1000R, D=1200, L=1600 884 kg 600/1000R, D=1200, L=2000 909 kg Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 212 Attach the lifting eyes. 2 pcs xx1700001323 Stretch the lifting chains Remove the attachment screws Lift the gearbox and the frame Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 213 MID 2.2 285 kg Action Note Attach the lifting eyes as shown in the figure. Stretch the lifting chains Remove the attachment screws Lift the gearbox Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 214: Lower Frame And Base

Standard tools For more information, see Standard tools IRBP on page 312. Stop lug See Product manual, spare parts - IRBP /D2009 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 215 6 Repair 6.3.1 Replacing stop lugs Continued Remove stop lug xx1000000082 Stop lug Attachment screw M12 x 50/12.9 Washer Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 216 Always use the two locking pins Mount the attachment screws. Use standard tools, Tightening torque 140 Nm. Mount the cover (1) Standard tightening torque see Tightening torque on page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 217: Motors

Required equipment Equipment Note Standard tools For more information, see Standard tools IRBP on page 312. Spareparts Product Manual Sparepart IRBP /D2009 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 218 Remove motor rotary units axis 1 xx1000000017 Screws Cover plate Attachment screws Plain washers Insulating washer Motor Insulating tube O-ring Insulating material Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 219 Refit the insulating material and insulating tubes (7- Refit the o-ring (8) on the motor. Replace the o-ring if necessary. See superport in the spare parts manual. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 220 Refit all the covers on the manipulator foot. Only Detailed in the section Replacing axis one. frame parts on page 194. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 221 Remove the cable gland cover at the cable exit by unscrewing its the attachment screws. Disconnect all connectors. Remove the motor by unscrewing the attachment screws and washers (3-4). Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 222 1 Attachment screw 2 Insulating washer 3 Plane washer Connect all connectors. Refit the cable gland cover at the cable exit. Refit the cover plate (2). Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 223: Checking Insulation

1 kVolt AC 50/60 Hz - 1 sec. between the output shaft (gearbox body) and the ground point in the AC motor. The test voltage is to be supplied from a transformer with a minimum rating of 500 VA. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 224: Rotary Units

Screw dim. Qty. Tightening torque (Nm) MTD 250 12.9 MTD 500 12.9 MTD 750 12.9 MTD 2000 12.9 MTD 5000 12.9 1150 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 225 213. Refit the attachment screws and wash- Use standard tools, For Tightening torque ers. see table Screw joints on page 224 Assemble the cable harness. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 226: Support Collar

Required equipment Equipment Note Standard tools Standard tools IRBP on page 312 Spare parts Product manual, spare parts - IRBP /D2009 Replacing support collar xx1000000028 Action Note Remove screw (12) to loosen the current collector Standard tools. - Page 227 10, 11). Refit the screw (12) and attach the current collector cable. Lubricate the current collector. Lubricating the current collect- or on page 182 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 228: Electrical

Equipment Note Standard tools See section Standard tools IRBP on page 312. Current collector See Product Manual Spareparts IRBP / D2009 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 229 Assemble the lubrication nipple and the Lubricate the current collector, see section current collector cable. Lubricating the current collector on page 182. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 230: Replacing Smb Board

Remove the screws holding the plate. Pull out the plate. Loosen the three screws holding the SMB board. Pull out the SMB board. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 231 Cross tighten the screws to make sure the sealing is tight. Connect the cables and close the cover. Update the revolution counters. Calibration information on page 265. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 232: Station Changing Indication

Standard tools This is detailed in section Standard tools IRBP on page 312. Spareparts in Product Manual Spareparts IRBP / D2009 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 233 • air pressure supply to the robot, before entering the safe- guarded space. Remove the side Use standard tools cover. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 234 Information Loosen the cable connection (1) on the station sync cable. xx1000000299 Remove the sta- tion breaker. xx1000000075 1 Station indication 2 Screw 3 Nut Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 235: Controller

6 Repair 6.8.1 Overview of the controller 6.8 Controller 6.8.1 Overview of the controller Location of parts xx1000000230 Drive module Contactor Auxiliary contact Relay Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 236: Replacing Drive Module I/O

The unit is sensitive to ESD. Before handling the unit read the safety information in section The unit is sensitive to ESD on page Required equipment Equipment Note Spare parts Product manual, spare parts - IRBP /D2009 Standard tools Contents, standard toolkit, IRC5 on page 311. Drive module xx1000000231 Drive module I/O... - Page 237 Before any work inside the cabinet, read the safety information in section Electrical safety on page Turn the main power switch to OFF. xx1000000212 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 238 Press the two mounting foots upper ends (A). Press the drive module on to the mounting rail. Mount the cable harness to the drive module. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 239: Replacing Contactor

Required equipment Equipment Note Standard tools Contents, standard toolkit, IRC5 on page 311. Spare parts Product manual, spare parts - IRBP /D2009 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 240 6 Repair 6.8.3 Replacing contactor Continued Location of contactors xx1000000234 Contactor Auxiliary contact Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 241 Turn the main power switch to OFF. xx1000000212 Remove the cable harness from the auxiliary contact and the contactor Press the contactor down. Remove the contactor. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 242 6.8.3 Replacing contactor Continued Refitting xx1000000236 Action Information Press the contactor down. Press in the contactor. Refit the cable harness to the auxiliary contact and the contactor. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 243: Replacing Auxiliary Contact

Required equipment Equipment Note Standard tools Contents, standard toolkit, IRC5 on page 311. Auxiliary contact Product manual, spare parts - IRBP /D2009 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 244 6 Repair 6.8.4 Replacing auxiliary contact Continued Location xx1000000241 Auxiliary contact Contactor Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 245 Remove the cable harness from the auxiliary con- tact. Push the auxiliary contact towards the center of the contactor. Remove the auxiliary contact. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 246 Action Note Fit the attachment legs on the auxiliary contact into the locking rail in the contactor. Push the auxiliary contact to the locked position. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 247: Replacing Auxiliary Relays For Breaker

The unit is sensitive to ESD on page Prerequisites Equipment Note Standard tools Standard tools IRBP on page 312 Auxiliary relay Product manual, spare parts - IRBP /D2009 Location xx1000000243 Auxiliary relay Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T... - Page 248 Turn the main power switch to OFF. xx1000000212 Remove the cable harness from the auxiliary relay. Remove the auxiliary relay using a screw driver. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 249 6 Repair 6.8.5 Replacing auxiliary relays for breaker Continued Refitting Refit the auxiliary relay using a screw driver. xx1000000244 Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 250 This page is intentionally left blank...

-

Page 251: Operation

Check that the service gate (optional) is closed. Press the service gate's reset button (option- al). Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 252 1 Mode selector (100% optional) 2 Auto mode 3 Motors On button See section Control system with control panel at front on page Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 253 Press the Start button on the FlexPendant. xx1000000215 1 Start button Press Program Start on the operator's panel See section Operator panel on page to start the robot program. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 254: Loading The Workpiece

Action Information Load the positioner or the stationary table. Note Loading an IRBP B positioner in a position that is not calibration position can cause vibration on the opposite station side. Make sure that the robot, positioner, and travel track working areas are clear before the system starts. -

Page 255: Stop During Loading/Unloading

Leave the operator area of the station. Press the Start Process button on the operator panel. xx1000000213 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 256 Press OK when asked Is it OK to switch to auto- matic operation?. Press the Motors On button on the control module's control panel (3). Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 257 Do not go back to the original station side. Run the setting procedure to verify the positioner's station positions. See Drivers on page 289. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 258: Program Stop And Restart Of Program

Press the Program Stop button on the The FlexPendant on page FlexPendant. Press the Program Stop button on the Operator panel on page operator panel. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 259 Press the Program Stop button on the The FlexPendant on page FlexPendant. Press the Program Stop button on the Operator panel on page operator panel. Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 260 Turn the operating mode selector on the control module's external control panel. Result: Motors off. xx1000000220 A mode selector Switch off the welding power source. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 261: Restarting The System

Press Program Start on the operator panel to start See section Operator panel on the robot program. page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 262: Restarting After An Emergency Stop

Press Program Start on the operator panel to start See section Operator panel on the robot program. page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. -

Page 263: Measures In The Event Of Disturbances In The Operating Sequence

CAUTION All work carried out on the system shall be performed in a professional manner and conform to applicable safety regulations. Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 264 This page is intentionally left blank...

-

Page 265: Calibration Information

The resolver values are changed If resolver values are changed, the robot must be re-calibrated using the calibration methods supplied by ABB. Calibrate the robot carefully with standard calibration, according to information in this manual. The resolver values will change when parts affecting the calibration position are replaced on the robot, for example motors or parts of the transmission. -

Page 266: Calibration Marks

8 Calibration information 8.2 Calibration marks 8.2 Calibration marks Synchronization mark MID station foot xx1000000121 Synchronization mark MID 2.1 Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved. - Page 267 8 Calibration information 8.2 Calibration marks Continued Synchronization mark MTD station unit xx1000000122 Synchronization mark MTD Continues on next page Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

- Page 268 8 Calibration information 8.2 Calibration marks Continued Synchronization mark MTD rotary unit xx1000000117 Synchronization mark MTD Product manual - IRBP /D2009 3HAC037731-001 Revision: T © Copyright 2010-2020 ABB. All rights reserved.

-

Page 269: Updating Revolution Counters