Table of Contents

Summary of Contents for Siemens LMS14

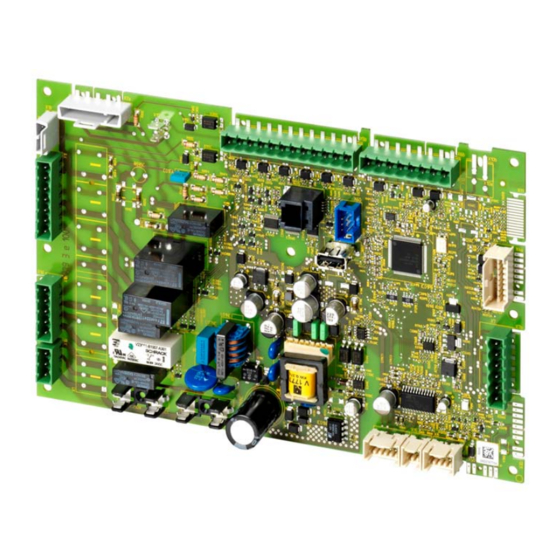

- Page 1 Albatros² Boiler management unit LMS14... User Manual The LMS14… and this User Manual are intended for use by OEMs which integrate the boiler management unit in their products. Release 6 Building Technologies Division CC1U7471en 28.01.2015...

- Page 2 2/617 Building Technologies Division User Manual LMS14… CC1U7471en 28.01.2015...

-

Page 3: Table Of Contents

Terminals of LMS14… complete (Basic) ............27 3.4.2 Assignment of terminal X30 ................28 3.4.3 List of terminals of LMS14… complete (Basic) ..........29 Basic unit LMS14... complete (Medium) ............30 3.5.1 Terminals of LMS14… complete (Medium) ........... 31 3.5.2 Assignment of terminal X30 ................ - Page 4 Overtemperature protection for the pump heating circuit ......161 6.5.24 Locking signals .................... 162 6.5.25 Forced signals ....................162 6.5.26 Overtemperature protection for the mixing heating circuit ......162 6.5.27 Pulse lock ..................... 163 4/617 Building Technologies Division User Manual LMS14… CC1U7471en Contents 28.01.2015...

- Page 5 Limitations of the flow temperature setpoint ..........196 6.10.2 Mixing valve control ..................197 6.10.3 Plant hydraulics ................... 198 6.11 Boiler ......................199 6.11.1 Release threshold Outside temperature ............199 5/617 Building Technologies Division User Manual LMS14… CC1U7471en Contents 28.01.2015...

- Page 6 Manual heat generation lock ................ 261 6.12.5 Generation of common flow temperature setpoint ........262 6.12.6 Generation of boiler temperature setpoint ........... 262 6.12.7 Boiler control ....................263 6.12.8 Heat output limits ..................264 6/617 Building Technologies Division User Manual LMS14… CC1U7471en Contents 28.01.2015...

- Page 7 Sensor error ....................304 6.17 Buffer storage tank ..................305 6.17.1 Release/control of heat source ..............305 6.17.2 Automatic locks ................... 305 6.17.3 Charging solar/solid fuel boiler ..............307 6.17.4 Recooling ..................... 308 7/617 Building Technologies Division User Manual LMS14… CC1U7471en Contents 28.01.2015...

- Page 8 6.20.3.1. Full charging of stratification storage tank ........... 349 6.20.3.2. Recharging the stratification storage tank ............ 351 6.21 Instantaneous water heater ................. 352 6.21.1 Control ......................352 6.21.2 DHW consumption (flow) ................352 8/617 Building Technologies Division User Manual LMS14… CC1U7471en Contents 28.01.2015...

- Page 9 6.23.29 External space heating ................468 6.23.30 Partial diagrams ................... 469 6.24 LPB system ....................470 6.24.1 Address/power supply ................. 470 6.24.2 Errors/maintenance/alarm ................472 6.24.3 Central functions ..................473 9/617 Building Technologies Division User Manual LMS14… CC1U7471en Contents 28.01.2015...

- Page 10 General notes on risks and problems ............496 6.28.7 Operation via the boiler ................497 6.28.8 Parameter setting state ................501 6.28.9 Conditions for the transfer of data between LMS14... and parameter stick . 502 6.29 Input/output test ................... 504 6.29.1 Output test relay ................... 505 6.29.2 Input test sensors ..................

- Page 11 Additional activation of remote reset capability ........... 580 6.42.2 Restrictions in connection with remote reset ..........580 6.43 Production ....................581 6.43.1 Monitoring mains voltage/mains frequency ..........583 Plant diagrams ..................... 584 Basic diagrams .................... 584 11/617 Building Technologies Division User Manual LMS14… CC1U7471en Contents 28.01.2015...

- Page 12 Extra functions ..................... 585 Technical data ....................586 LMS14… basic unit ..................586 8.1.1 General data ....................586 8.1.2 Environmental conditions ................586 8.1.3 Electrical connection data, mains voltage connections ........ 587 8.1.4 Electrical connection data, extra-low voltage connections (PELV) ....589 8.1.4.3.

-

Page 13: Summary

QAA55.110... Room unit basic CE1U2353 QAA75.610... Room unit wire CE1U2353 QAA75.611... Room unit wire, with backlit display CE1U2353 QAA78.610... Room unit wireless CE1U2353 QAC34/101 Outside sensor NTC 1k CC1Q1701 13/617 Building Technologies Division User Manual LMS14... CC1U7471en 1 Summary 28.01.2015... -

Page 14: Target Group Of Users

<10 kW to 1 MW in intermittent operation with direct ignition of the main flame. The OEM must make certain that the LMS14… are suited for the application in question. The LMS14... provide all supervisory and control functions required for burner operation, space heating and DHW heating. -

Page 15: Product Range Summary

AVS75... LMS... ( max. 3) OCI345... BSB : Boiler System Bus LPB : Local Process Bus Basic Unit LMS... / RVS... Figure 2: Product range summary – wireless 15/617 Building Technologies Division User Manual LMS14... CC1U7471en 1 Summary 28.01.2015... -

Page 16: Operating Options

Reset Reset Operation via operator unit Wired Wireless Clear-text (optionally with additional room unit) Basic unit LMS14... Room unit QAA55.../QAA75.../QAA78... Outside sensor AVS13... Operator unit AVS37.294... (Clear-text) Operator unit AVS37.390... (Basic) RF module AVS71... 16/617 Building Technologies Division User Manual LMS14... -

Page 17: Safety Notes

Safety notes 2.1 Notes on product liability The LMS14… may only be used in building services plant and only in compliance with the applications covered by this document When employing the products, all requirements specified in chapters Handling and Technical data must be satisfied ... -

Page 18: Use Of High-Efficiency Pumps

Siemens. 2.1.2 High-voltage test Caution! When making 100% inspections to DIN EN 60335-1, Addendum A, only AC voltage may be applied. If tests are conducted with DC voltage, the LMS14... might be damaged. 18/617 Building Technologies Division User Manual LMS14... -

Page 19: Environmental Compatibility

A summary of the conditions has been published by the European Control Manufacturers Association (Afecor) (www.afecor.org). The designed lifetime is based on usage of the LMS14… as specified in the manufacturer’s Data Sheet and User Manual. After reaching the designed lifetime in terms of the number of burner startup cycles, or the respective time of usage, the LMS14…... -

Page 20: Typographical Conventions

When using the unit in connection with third-party products or components, following must be noted: - The technical data of the LMS14… must be observed; in addition to static data, consideration must be given to dynamic data, such as switch-on and switch-off currents, surge currents, etc. -

Page 21: Mounting And Installation

Degree of protection IP40 as per DIN EN 60529 for burner controls must be ensured by the burner or boiler manufacturer through correct installation of the LMS14... 3.1.1 Electrical connection of ionization probe It is important to achieve practically disturbance- and loss-free signal transmission: ... -

Page 22: Electrical Connection On 2-Phase Systems

3.1.2 Electrical connection on 2-phase systems When operating the LMS14 on 2-phase systems, the following points must be observed: You must adhere to the mains voltage and mains frequency values specified in the technical data The components you connect to the LMS14 (gas valve, igniter, etc.) must be suitable for 2-phase operation ... -

Page 23: Boiler Management Unit Lms14

When mounted, the maximum permissible ambient temperature must never be exceeded Condensation water must not drip on the LMS14… or enter the unit, neither in operation nor when service work is carried out Ignition equipment Note! In terms of switching performance, any type of external ignition module used must be... - Page 24 Mains cables must be run completely separate from low-voltage cables (sensors), observing a minimum distance of 100 mm Mounting location The LMS14… has been designed for mounting inside the burner or inside a control panel. Protection against electric shock must be ensured! 24/617 Building Technologies Division User Manual LMS14...

-

Page 25: Basic Diagram Lms14

PC tool Line AUX1 (fuse) Line AUX2 (fuse) 7471a44e/1214 Figure 3: Basic diagram The diagram shows the full scope of functions of the LMS14… system. The actual functions are to be determined based on the respective execution/configuration. 25/617 Building Technologies Division User Manual LMS14... -

Page 26: Basic Unit Lms14

3.4 Basic unit LMS14… complete (Basic) Dimensions in mm 108,5 93,8 112,1 Figure 4: Dimensions of basic unit complete (Basic) 26/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 27: Terminals Of Lms14

3.4.1 Terminals of LMS14… complete (Basic) Fan PWM Fuel valve Ignition module Ionization Figure 5: Terminals of LMS14… complete 27/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 28: Assignment Of Terminal X30

3.4.2 Assignment of terminal X30 7471m22e/1214 Figure 6: Assignment of terminal X30 28/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 29: List Of Terminals Of Lms14

3.4.3 List of terminals of LMS14… complete (Basic) LMS14... standard (Basic) Terminal Mating connector marking Number Supplier Type/coding of pins Wieland 25.320.3353.0 green Lumberg 3636 04K02 Lumberg 3636 05K02 Lumberg 3636 02K10 Lumberg 3636 05K22 Lumberg 3515 08K20 Lumberg 3636 12K01... -

Page 30: Basic Unit Lms14

3.5 Basic unit LMS14... complete (Medium) Dimensions in mm 139,4 131,5 108,5 95,2 9,33 93,8 112,1 128,7 Figure 7: Dimensions of basic unit complete (Medium) 30/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 31: Terminals Of Lms14

3.5.1 Terminals of LMS14… complete (Medium) Fan PWM Ionization Fuel valve Ignition module Ionization Figure 8: Terminals of LMS14… complete 31/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 32: Assignment Of Terminal X30

3.5.2 Assignment of terminal X30 7471m22e/1214 Figure 9: Assignment of terminal X30 32/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 33: List Of Terminals Of Lms14

3.5.3 List of terminals of LMS14… complete (Medium) LMS14... standard (Medium) Terminal Mating connector marking Number Supplier Type/coding of pins Wieland 25.320.3353.0 green Wieland 25.320.3553.0 green Wieland 25.320.3753.0 green Stocko Housing: MKH 2805-1-0-500 Contact: RFB 7851 V 0,6-0,5 Uncoded Lumberg... -

Page 34: Basic Unit Lms14

3.6 Basic unit LMS14... complete (Deluxe) Dimensions in mm 135,2 131,5 108,5 93,8 112,1 128,7 142,2 Figure 10: Dimensions of basic unit complete (Deluxe) 34/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 35: Terminals Of Lms14

3.6.1 Terminals of LMS14… complete (Deluxe) Fan PWM Ionization Fuel valve Ignition module Ionization Figure 11: Terminals of LMS14… complete (Deluxe) 35/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 36: Assignment Of Terminal X30

3.6.2 Assignment of terminal X30 7471m22e/1214 Figure 12: Assignment of terminal X30 36/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 37: List Of Terminals Of Lms14

3.6.3 List of terminals of LMS14… complete (Deluxe) LMS14... standard (Deluxe) Terminal Mating connector marking Number Supplier Type/coding of pins Lumberg 3615-1 03K117P30 3618-1 03K19P5 3618-1-03K20P4 or 3618-1-05K129 3618-1 03K02P7 3618-1 03K10 3618-1 03K10 Stocko Housing: MKH 2805-1-0-500 Contact: RFB 7851 V 0,6-0,5... -

Page 38: Cable Agu2.110X109

3.7 Cable AGU2.110x109 Dimensions in mm Figure 13: Cable AGU2.110x109 38/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 39: Parameter Stick Agu2.56Xx109

3.8 Parameter stick AGU2.56xx109 Dimensions Dimensions in mm 7471m24/0112 (76) Figure 14: Dimension AGU2.56xx109 39/617 Building Technologies Division User Manual LMS14... CC1U7471en 3 Mounting and installation 28.01.2015... -

Page 40: Commissioning

Outside temp attenuated (8703)) Note! The boiler manufacturer assumes responsibility for the correct parameterization of the LMS14…, which must meet the requirements of the relevant standards and directives The connectors do not ensure total protection against false wiring. For this reason, the connections must be checked prior to commissioning ... -

Page 41: Handling

Enduser, heating engineer, OEM Connection ACS700… To AVS37... When setting the parameters via the LMS14… PC software, the unit runs to a special programming position. Before changed parameter are stored in EEPROM, the respective backup values (CRC, test values of the transmission programs, plausibility of parameters) –... -

Page 42: Overview Of Settings

Not available ¦ Ready to operate ¦ No Not available ¦ Ready to operate ¦ No reception ¦ Change battery reception ¦ Change battery Operator unit 2 Operator unit 2 Operator unit 2 42/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015... - Page 43 Switch prg HC2 Sa Time switch program HC2 Saturday 24:00 00:00 24:00 hh:mm 3rd phase off Switch prg HC2 Su Time switch program HC2 Sunday 24:00 00:00 24:00 hh:mm 43/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 44 2nd phase on TSP 5 Thu Time switch program 5 Thursday 24:00 00:00 24:00 hh:mm 2nd phase off TSP 5 Fri Time switch program 5 Friday 24:00 00:00 24:00 hh:mm 44/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 45 RoomTemp ComfSetp HC1 Room temperature Comfort setpoint 20.0 BZ 712 BZ 716 °C Reduced setpoint RmTmp RedSetp HC1 Room temp reduced setpoint heat BZ 714 BZ 710 °C circuit 1 45/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 46 Off ¦ Down to reduced setp ¦ Down to frost Off ¦ Down to reduced setp ¦ Down to frost prot setp prot setp Optimum start control max OptStartCtrl MaxTime1 Optimum start control max forward Min. shift HC1 46/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 47 Excess heat draw Overtemp drop HC1 Overtemperature drop heating Always circuit 1 Off ¦ Heating mode ¦ Always Off ¦ Heating mode ¦ Always Off ¦ Heating mode ¦ Always 47/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 48 - - - / 15 °C cooling circuit 1 Room temp limitation RT limitation CC1 Room temp limitation cooling circuit - - - / 0,5 °C Heating circuit 2 48/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 49 Heating limit room controller Heating limit RC HC2 Heating limit room control HC2 /0 1070 Boost heating RmTmp SetpBoost HC2 Room temp setpoint boost HC2 °C (boost heating) 49/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 50 Belegreif' + functional heating ¦ Manuell 1151 Floor curing setp manually FloorSetp man HC2 Floor setpoint manually HC2 °C 1155 Floor curing setp current FlowTmpSetFloorPlast2 Flow temp setpoint flooring plaster °C 50/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 51 - - -/0 Min. Heating circuit 3 1300 Operating mode HC3/P Operating mode HC3/P Automatic Protection ¦ Automatic ¦ Reduced ¦ Comfort Protection ¦ Automatic ¦ Reduced ¦ Comfort 51/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 52 Off ¦ Down to reduced setp ¦ Down to frost prot setp prot setp 1390 Optimum start control max OptStartMaxShift 3/P Optimum start control max forward Min. shift HC3/P 52/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 53 Flow temperature setpoint floor °C curing HC3/P 1456 Floor curing day current DHW TempActTop B3/BMU Floor curing day HC3/P 1461 Excess heat draw Overtemp drop HC3/P Overtemperature drop heating Always 53/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 54 BZ 1614 °C 1612 Reduced setpoint DHW RedSetp DHW temperature reduced setpoint 40 BZ 1610 °C 1614 Nominal setpoint max DHW NomSetp max DHW temperature nominal setpoint BZ 1610 °C 54/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 55 1 No ¦ Yes No ¦ Yes No ¦ Yes 1875 Excess heat draw Overtemp drop CC1 Overtemperature drop consumer circuit 1 Off ¦ On Off ¦ On 55/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 56 No ¦ Yes Swimming pool 2055 Setpoint solar heating Pool setpoint solar Pool setpoint solar heating °C 2056 Setpoint source heating Pool setp producer Pool setpoint producer heating °C 56/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 57 Setpoint max OEM BoilTmp MaxLimitn OEM Boiler temp max limitation OEM BZ 2212 °C 2214 Setpoint manual control BoilerSetp man Boiler temperature setpoint in BZ 2210 BZ 2212 °C 57/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 58 Heating mode only ¦ Heating and DHW Heating mode only ¦ Heating and DHW mode mode 2310 Limit thermostat function TR function TR function Off ¦ On Off ¦ On Off ¦ On 58/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 59 Heating and DHW mode ¦ Heating and DHW mode ¦ Heating and DHW mode 2452 Controller delay speed Contr delay speed Controller delay speed 2400 BZ 9525 BZ 9530 Min. 59/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 60 2494 Dyn superv press increase DynSupervPressInc Dyn superv press increase No ¦ Yes No ¦ Yes No ¦ Yes 2495 Dyn press superv time DynPressSupervTime Dyn press superv time 60/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 61 Numbr err, Tr>Tf 24h Numb of errors return above flow in 24 hours [3639.1] TempBoilerMaxSLTSec TempBoilerMaxSLTSec °C [3925.1] TempRetMaxSLTSec TempRetMaxSLTSec °C 2550 Gas energy metering Gas energy counting Gas energy metering 61/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 62 Power range, upper limit (Pmax) BZ 3511 3530 Release integral source seq RelLimit ProdSeq Release limit producer sequence °C*Min. 3531 Reset integral source seq ResetLimit ProdSeq Reset limit producer sequence °C*Min. 62/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 63 Temp diff off buffer TempDiffOFF buffer BZ 3813 °C / 8 3815 Charging temp min buffer MinChargTemp Buf Min charging temperature buffer °C 63/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 64 Pump speed min OEM Pump speed minOEM sol Pump speed min OEM solar BZ 3870 3876 Pump speed max OEM Pump speed max OEM Pump speed max OEM BZ 3871 64/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 65 / 8 4724 Min st tank temp heat mode MinBufferTempHeatMode °C 4750 Charging temp max Buffer Charg temp max Buffer charging temp max BZ 4751 °C 65/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 66 Off ¦ On Off ¦ On 5020 Flow setpoint boost DHW Flow Setp Boost DHW flow setpoint boost °C 5021 Transfer boost Dhw transfer boost Dhw transfer boost °C 66/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 67 Excess heat draw DHW overtemp drop DHW storage tank overtemperature drop Off ¦ On Off ¦ On Off ¦ On 5090 With buffer DHW buffer DHW storage tank with buffer 67/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 68 Min start temp diff Q33 MinStartTDiffQ33 Min start temp diff Q33 - - - / -20 °C 5151 Excess interm circ temp del T Char’cir’exc’supv Charg’ cir excess superv delay Instantaneous water heater 68/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 69 Instantaneous DHW heater 5536 Pump speed max OEM Pump speed max OEM Pump speed max OEM BZ 5531 5537 Starting speed Starting speed Starting speed - - - / 0 69/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 70 DHW outlet sensor B38 | Primary exch B9 | Primary contr sensor B15 | Room sensor B5 | sensor B26 | Boiler sensor B2 | Solar sensor B26 | Boiler sensor B2 | Solar 70/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 71 None | DHW sensor B31 | Collector sensor Return sensor B7 | DHW circulation sensor B39 | sensor B6 | Return sensor B7 | DHW B6 | Return sensor B7 | DHW circulation 71/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 72 | Room sensor B53 | Flow sensor HC1 B1 | Room sensor B53 | Flow sensor HC1 B1 | Flow sensor HC2 B12 | Flow sensor HC3 | Flow sensor HC2 B12 | Flow sensor HC3 72/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 73 Contact type DHW div valve Position on DHW Position on DHW ¦ Position on heating circuit Position on DHW ¦ Position on heating Position on DHW ¦ Position on heating circuit circuit 73/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 74 Solar actuating device Charging pump Charging pump ¦ Diverting valve Charging pump ¦ Diverting valve Charging pump ¦ Diverting valve 5841 External solar exchanger Ext solar exchanger External solar exchanger Commonly 74/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 75 Q1 ¦ Bypass pump Q12 ¦ Alarm output K10 pump speed HC2 Q22 ¦ 2nd pump speed HC3 Q23 ¦ 2nd pump speed HC1 Q21 ¦ 2nd pump ¦ 2nd pump speed HC1 Q21 ¦ 2nd pump 75/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 76 HC2 Q6 ¦ DHW ctrl elem Q3 ¦ Instant WH ctrl elem Q35 ¦ DHW interm circ pump Q33 ¦ Heat Q35 ¦ DHW interm circ pump Q33 ¦ Heat 76/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 77 B26 Solar flow sensor B63 ¦ Solar return Solar flow sensor B63 ¦ Solar return sensor B64 ¦ Primary exch sensor B26 sensor B64 ¦ Primary exch sensor B26 77/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 78 NC ¦ NO normal closed ¦ normal opened normal closed ¦ normal opened 5953 Voltage value 1 H1 Voltage value 1 H1 Voltage value 1 H1 Volt 78/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 79 HCs ¦ Optg mode changeover changeover HC2 ¦ Optg mode changeover HC3 ¦ HC1 ¦ Optg mode changeover HC2 ¦ Optg HC1 ¦ Optg mode changeover HC2 ¦ Optg 79/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 80 HC2 ¦ Room thermostat HC3 ¦ thermostat HC2 ¦ Room thermostat HC3 ¦ Boiler flow switch ¦ Boiler pressure switch DHW flow switch ¦ DHW thermostat ¦ DHW flow switch ¦ DHW thermostat ¦ 80/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 81 VK1 ¦ Consumer request VK2 ¦ discharge ¦ Release swi pool solar ¦ Operating level Release swi pool source heat ¦ Excess Release swi pool source heat ¦ Excess 81/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 82 None ¦ Circulating pump Q4 ¦ El imm K6 ¦ Collector pump Q5 ¦ Cons circuit pump VK1 heater DHW K6 ¦ Collector pump Q5 ¦ heater DHW K6 ¦ Collector pump Q5 ¦ 82/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 83 K9 ¦ Solar ctrl elem buffer K8 ¦ Solar DHW mixing pump Q35 ¦ DHW interm circ pump ctrl elem swi pool K18 ¦ Swimming pool ctrl elem swi pool K18 ¦ Swimming pool 83/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 84 K35 ¦ Status information K36 ¦ Fan shutdown K38 ¦ dT controller 1 K21 ¦ dT shutdown K38 ¦ dT controller 1 K21 ¦ dT controller 2 K22 controller 2 K22 84/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 85 K9 ¦ Solar ctrl elem buffer K8 ¦ Solar boiler pump Q10 ¦ Time program 5 K13 ¦ boiler pump Q10 ¦ Time program 5 K13 ¦ 85/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 86 Instant heater ctrl elem Q34 ¦ Water filling Instant heater ctrl elem Q34 ¦ Water filling K34 ¦ 2nd boiler pump speed Q27 ¦ Status K34 ¦ 2nd boiler pump speed Q27 ¦ Status 86/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 87 ¦ 2nd pump speed HC1 Q21 ¦ 2nd pump ¦ Heat circuit pump HC3 Q20 ¦ Cons circuit pump speed HC2 Q22 ¦ 2nd pump speed HC3 speed HC2 Q22 ¦ 2nd pump speed HC3 87/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 88 Q35 ¦ DHW interm circ pump Q33 ¦ Heat Q34 ¦ Water refill K34 ¦ 2nd boiler pump speed Q27 request K27 ¦ Refrigeration request K28 ¦ request K27 ¦ Refrigeration request K28 ¦ 88/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 89 B8 ¦ Segment flow sensor B22 ¦ DHW charging sensor B36 ¦ Buffer sensor B10 ¦ Solid fuel boiler sensor B22 ¦ DHW B10 ¦ Solid fuel boiler sensor B22 ¦ DHW 89/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 90 B36 ¦ Buffer sensor B42 ¦ sensor B70 ¦ Swimming pool sensor B13 ¦ Solar Segment return sensor B73 ¦ Cascade Segment return sensor B73 ¦ Cascade 90/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 91 HC1 ¦ Optg mode changeover HC2 ¦ Optg HC1 ¦ Optg mode changeover HC2 ¦ Optg Heat generation lock ¦ Error/alarm message ¦ mode changeover HC3 ¦ Heat generation mode changeover HC3 ¦ Heat generation 91/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 92 HC2 ¦ Room thermostat HC3 ¦ switch ¦ Boiler pressure switch ¦ Consumer request DHW flow switch ¦ DHW thermostat ¦ Limit DHW flow switch ¦ DHW thermostat ¦ Limit 92/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 93 DHW interm circ pump Q33 ¦ Heat circuit Heat circuit pump HC2 Q6 ¦ Heat circuit pump HC3 ¦ Heat circuit pump HC3 Q20 ¦ Collector pump HC1 Q2 ¦ Heat circuit pump HC2 Q6 93/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 94 Water Pressure 2 SD Water pressure 2 switching 10,0 differential / 0,0 6180 Water pressure 3 max Water Pressure 3 max Water pressure 3 max 10,0 94/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 95 Internally ¦ Externally 6357 Room controller HC3 Room controller HC3 Room controller HC3 Internally Internally ¦ Externally Internally ¦ Externally Internally ¦ Externally [1564.1] PartDiagram oil/gas Partial diagram oil/gas-fired boiler 95/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 96 No ¦ Yes No ¦ Yes No ¦ Yes 6611 Syst messages alarm relay SystemMessAlarmRelay System messages on alarm relay No ¦ Yes No ¦ Yes No ¦ Yes 96/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 97 Flow temp 1 alarm TimeFlowTempAlarm HC1 Time flow temperature alarm HC1 Min. / 10 6741 Flow temp 2 alarm TimeFlowTempAlarm HC2 Time flow temperature alarm Min. 97/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 98 No error ¦ Error 1 ... 6845 SW diagnostic code 5 StrDia5 5th past value of internal diagnostic 65535 code 6846 Burner control phase 5 StrPn5 5th past value of lockout phase 98/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 99 No error ¦ Error 1 ... No error ¦ Error 1 ... No error ¦ Error 1 ... 6915 SW diagnostic code 12 StrDia12 SW diagnostic code 12 65535 99/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 100 ErrorCode History 19 Error code history entry 19 No error 0 65535 No error ¦ Error 1 ... No error ¦ Error 1 ... No error ¦ Error 1 ... 100/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 101 Controller stop setpoint 7146 Deaeration function Deaeration function Deaeration function Off ¦ On Off ¦ On Off ¦ On 7147 Type of venting Type of venting Type of venting None 101/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 102 QX21 module 2 ¦ Relay output output QX21 module 3 ¦ Relay output QX22 QX22 module 2 ¦ Relay output QX23 QX22 module 2 ¦ Relay output QX23 102/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 103 Sensor temp BX21 module 3 Temp BX21 Module 3 Sensor temperature BX21 module 3 - °C 7835 Sensor temp BX22 module 3 Temp BX22 Module 3 Sensor temperature BX22 module 3 - °C 103/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 104 Status heating circuit 2 SLT has tripped ¦ Pumping off refrig, man ¦ ... SLT cut out ¦ Fault ¦ ... SLT cut out ¦ Pumping off refrig, man ¦ … 104/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 105 * Operator unit: Lines with priority of the source also show the state ACS420: Priority and state are not shown ACS700/ACS790: Priority and state are shown on different lines 105/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 106 Priority producer 5 Priority producer 5 * Operator unit: Lines with priority of the source also show the state ACS420: Priority and state are not shown ACS700/ACS790: Priority and state are 106/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 107 Priority/state source 8 Priority producer 8 Priority producer 8 * Operator unit: Lines with priority of the source also show the state ACS420: Priority and state are not shown 107/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 108 ¦ Released released ¦ Released 8120 * Priority/state source 11 Priority producer 11 Priority producer 11 * Operator unit: Lines with priority of the source also show the state 108/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 109 ¦ Outside temp limit active ¦ No released ¦ Released released ¦ Released 8126 * Priority/state source 14 Priority producer 14 Priority producer 14 * Operator unit: Lines with priority of 109/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 110 ¦ Outside temp limit active ¦ No unavailable ¦ Outside temp limit active ¦ No released ¦ Released released ¦ Released 8138 Cascade flow temp Cascade supply temp Cascade supply temperature actual 0 °C 110/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 111 Set point fan 10000 U/min 8325 Current fan control Current fan control Current fan control 8326 Burner modulation Boiler modulation Boiler modulation 8327 Water pressure Water pressure Water pressure 111/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 112 Collector temp 1 max CollTmp MaxActual 1 Collector temp max actual value 1 °C (B6) 8512 Collector temp 1 min CollTmp MinActual 1 Collector temp min actual value 1 °C (B6) 112/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 113 Ionization current limitation, lower 10000 speed limit [4379.1] IntegratDynWatPress Integrator dynamic water pressure [4380.1] BoilFlowTemp secure Boiler flow temp secure °C [4381.1] BoilReturnTemp secure Boiler return temp secure °C Diagnostics consumer 113/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 114 Room temperature setpoint 2 °C 8772 Room temp 2 model RoomTempModel 2 Room temperature model 2 °C 8773 Flow temp 2 FlowTmp act HeatCirc2 Flow temp actual value heat circuit - °C 114/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 115 DHW temperature actual value °C bottom (B31) 8835 DHW circulation temp DHW Circ temp DHW circulating temperature °C 8836 DHW charging temp DHW charging temp DHW charging temperature °C 115/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 116 Multifunct Relay QX4 State multifunctional relay (QX4) Off ¦ On Off ¦ On Off ¦ On 9050 Relay output QX21 module 1 Multi Relay QX21 Mod1 State multifunctional relay (QX21 116/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 117 Inactiv heating circuit 1 Inactive ¦ Active Inactive ¦ Active [2482.1] 2nd Speed HC Pump Q22 State 2nd speed heating circuit pump (Q22) Off ¦ On Off ¦ On 117/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 118 TSP 5 Relay K13 Status time program 5 relays (K13) Off ¦ On Off ¦ On [2776.1] Return temp valve Y15 Status return temp valve (Y15) Off ¦ On Off ¦ On 118/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 119 Status delta-T controller 1 K21 Off | On Off ¦ On [6197.1] Delta-T contr 2 K22 Status delta-T controller 2 K22 Off | On Off ¦ On Burner control 119/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 120 LP mode 1 ¦ LP mode 2 ¦ LP mode 3 ¦ LP LP mode 5 mode 4 ¦ LP mode 5 mode 4 ¦ LP mode 5 9612 GP configuration GP configuration GP configuration GP not connected 120/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 121 Fan PWM-Min Lower limit manipulated variable fan 0 [3998.1] Fan PWM-Max Upper limit manipulated variable fan 100 [4269.1] Ion curr lim, low Ionization current limitation low limit 0 µA 121/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 122 [4495.1] Remote reset SLT ParRemoteUnlockEnableStl No ¦ Yes No | Yes [4496.1] Remote reset air ParRemoteUnlockEnableAir No ¦ Yes No | Yes [4497.1] Rem res extran light ParRemoteUnlockEnableStraylignt No 122/617 Building Technologies Division User Manual LMS14... CC1U7471en 5 Handling 28.01.2015...

- Page 123 Under the most unfavorable conditions, it may take up to 40 seconds for signal H2 from the extension modules via BSB to become refreshed in the LMS14… This can lead to functional limitations with the DHW flow switch and to crucial situations in connection with limit functions! For such functions, use inputs H1 and inputs H3…H7.

-

Page 124: The Settings In Detail

Year Line no. Operating line Year Start of summertime Line no. Operating line Start of summertime End of summertime Line no. Operating line End of summertime 124/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 125: Rf Link

Line no. Operating line Test mode Test mode is used for checking the wireless communication. The test should be made when the installation is fully completed. 125/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 126: List Of Wireless Devices

Change batt Operator unit 3 Missing In operation No recept'n Change batt Service unit Line no. Operating line Service unit Missing In operation No recept'n Change batt 126/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 127 Line no. Operating line Delete all devices The RF link to all devices is canceled. If wireless communication is required again, set up a new binding. 127/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 128: Time Programs

All time programs can be reset to their default settings. Each time program has its own operating line to make the reset. Note! In that case, individual settings will be lost! 128/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 129: Holidays

(Reduced or Protection). The impact of a currently active holiday period can only be canceled by switching to non-automatic operation or by deleting the programmed holiday period. 129/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 130 DHW heating assigned to these heating circuits will be switched off. Note! The LMS14… offers 8 holiday periods per year: Setting several holiday periods: Use parameter Preselection (641/651/661) to select the required holiday period (1 - 8).

-

Page 131: Heating Circuits

Automatic operation at the Comfort, Reduced or Frost protection level in accordance with the switching program, the presence button, the holiday program, optimum start/stop control and the ECO function. 131/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 132: Compensation Variants

132/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 133 Generation of the compensation variant is possible for each heating circuit and can be set accordingly. 133/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 134: Occupancy Button (Presence Button)

* Selectable whether the holiday program shall switch to Reduced or Frost Note! The operating level can also be changed via input H (refer to chapter Operating level changeover via input H). 134/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 135: Setpoints

Meaning 1010 1310 Room temperature Comfort setpoint 1012 1312 Room temperature Reduced setpoint 1014 1314 Frost protection setpoint 1016 1316 TRKmax Maximum room temperature Comfort setpoint 135/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 136: Heating Curve

The set heating curve is based on a room temperature setpoint of 20 °C. If this setpoint is changed, the heating curve adapts automatically to the new value. Figure 17: Heating curve – heating curve slope 136/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 137 °C °C 8700 7471d48/0910 Figure 18: Heating curve – heating curve displacement Line no. Meaning 8700 Outside temperature Room temperature setpoint Flow temperature 137/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 138 If the attenuated outside temperature exceeds 12 °C, the learning process is stopped. These reference values apply when the comfort setpoint = 20 °C and the heating curve displacement = 0 °C (no extraneous heat). 138/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 139: Eco Function

730 / 1030 / 1330 -1 K Figure 19: ECO function – summer/winter heating limit Line no. Meaning 1030 1330 SWHG Summer/winter heating limit 8703 TAged Attenuated outside temperature Days Temperature 139/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 140 Changeover temperature (room temperature setpoint – setpoint of 24- = 19 °C hour heating limit), heating Off Switching differential (fixed) -1 K Changeover temperature, heating On = 18 °C 140/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 141 The 24-hour heating limit takes effect solely depending on the current outside temperature. The 24-hour heating limit takes effect as described under 24-hour heating limit, depending on both the current and the composite outside temperature. 141/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 142: Flow Temperature Setpoint Limits

Flow temp setpoint min The flow temperature setpoint is limited according to the setting made. This also applies to heat requests made to the heat sources. 142/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 143: Room Thermostat

For that purpose, the required cycling ratio of the room thermostat must be parameterized Flow temperature setpoint as parameterized: adaption of setpoint Flow temperature setpoint according to the heating curve: adaption of heating curve 143/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 144 If no outside sensor is connected, the backup outside temperature of 0 º C is used (refer to chapters Flow temperature setpoint according to the heating curve and Adaption with flow temperature setpoint according to the heating curve.) 144/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 145 If, at midnight, the room thermostat is in the Warm state, the setpoint readjustment is not made until the room thermostat switches to the Cold state. 145/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 146 In that case, the heat request is continuously matched to varying conditions in accordance with the composite outside temperature. Adaption can be deactivated (---). 146/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 147: Delay Heat Request

(e.g. charging pump) – both heating circuit and DHW are being served simultaneously. But function Overtemperature protection continues to be active for this heating circuit, provided it is parameterized. 147/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 148 If the heat request results from a special function of the heat source (e.g. Chimney sweep function), the delay becomes inactive. In this case, parameter Delay heat request special op (2470) must be set as well. 148/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 149: Room Model

The heat up gradient is available for every heating circuit and can be set. Additional parameters Line no. Meaning 1094 1394 Heat up gradient 6110 Time constant building 8703 Outside temp attenuated 149/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 150: Room Influence

TRw = TR * room influence/10 Line no. Meaning TR Room deviation (room temperature setpoint – actual value of room temperature) TRw Resulting room temperature setpoint readjustment 150/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 151 No thermostatic radiator valves should be used in the reference room where the room sensor is located (if installed, such valves must be fully opened and locked in that position) 151/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 152: Room Temperature Control And Limitation

Note! If an outside sensor is available, functions 24-hour heating limit and Summer/winter changeover – if parameterized – can shut down the heating as well. 152/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 153: Boost Heating

Boost heating is possible with or without room sensor. Figure 24: Boost heating Line no. Meaning DTRSA Room temperature setpoint increase Room temperature setpoint Actual value of room temperature 153/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 154: Quick Setback

Duration of quick setback in hours Duration of quick setback when Comfort setpoint – Reduced setpoint = 4 °C (e.g. Comfort setpoint = 20 °C, Reduced setpoint =16 °C) 154/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 155 The function can be activated/deactivated and it can be parameterized whether quick setback shall be active down to the Reduced or the Frost protection level Quick setback is possible with or without room sensor 155/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 156: Optimum Start/Stop Control

When setting the time of optimization to 0, the function is deactivated. Optimum start/stop control is possible with or without room sensor. 156/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 157: Heating Up Gradient Room Model

Start of Reduced setpoint increase 1001 1401 TRwA2 End of Reduced setpoint increase 8704 TAgem Composite outside temperature Room temperature setpoint – heat gains + room influence 157/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 158 Line no. Meaning 1010 1310 Room temperature Comfort setpoint 1012 1312 Room temperature Reduced setpoint 8704 TAgem Composite outside temperature Room temperature setpoint TRRw+ Increased Reduced setpoint 158/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 159: Continuous Pump Operation

8 °C – even in the case of continuous pump operation. To prevent this, Overtemp prot pump circuit (820, 1120, 1420) must be deactivated. 159/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 160: Frost Protection For The Room

Frost protection for the heating circuit should be switched off only if adequate measures are taken (e.g. antifreeze in the heating circuit water), ensuring that external frost protection is provided. 160/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 161: Overtemperature Protection For The Pump Heating Circuit

Therefore, if overtemperature protection is active, you must ensure that the boiler flow rate is correct, because there may not be any other consumer pumps still running except this one. 161/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 162: Locking Signals

15%, the mixing heating circuit pump is deactivated. The pump is activated again when the flow temperature drops below the maximum flow temperature setpoint. Note! This function is active only if the Temperature limiter function is not activated. 162/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 163: Pulse Lock

The function can be deactivated. Additional parameters Line no. Operating line 6740 Flow temp 1 alarm 6741 Flow temp 2 alarm 6742 Flow temp 3 alarm 163/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 164: Locking Signals

Mixing heating circuits receive forced signals from the heat source (Boiler overtemperature protection or Chimney sweep function). This means that heat consumers can make use of forced signals to extend or enforce heat consumption. 164/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 165: Mixing Valve Control

Operating line 2-pos 1133 1433 Switching differential 2-pos With 2-position actuators, the 2-position switching differential must be adapted also. This is not required with 3-position actuators. 165/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 166 The mixing valve's integral action time Tn can be adjusted, thereby matching the control behavior of the valve's actuator to that of the plant (controlled system). The integral action time influences the controller's I-control action. 166/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 167: Floor Curing Function

(hydraulic system, electrical installation, settings)! If not observed, the floor might be damaged The function can be aborted by selecting Off Maximum limitation of flow temperature remains active 167/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 168 During Floor curing, the profile temperature (TVEp) is limited within the 2 values Flow temp setpoint max (TVmax) and Flow temp setpoint min (TVmin). The function is ended when the functional days have elapsed or when deactivated via parameterization. 168/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 169 Floor curing day current Line no. Operating line 1156 1456 Floor curing day current Shows the current weekday of the Floor curing function in progress. 169/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 170: Forced Signal And Locking Signal

Enter whether the heating circuit receives its heat via the primary controller or with the help of the system pump (depending on the type of plant). 170/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 171: Speed-Controlled Pump

When DHW operation is active, the heating circuit pump is controlled using the set minimum speed. When the floor curing function is active, the heating circuit pump is controlled using the set maximum speed. 171/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 172 Readjustment of the flow temperature setpoint when the pump speed is reduced by 50%. This readjustment is calculated based on the differential of flow temperature setpoint according to the heating curve and current room temperature setpoint. 172/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 173 The request for heat remains unchanged. The calculated readjustment is not added. The request for heat gives consideration to the calculated readjustment of the flow temperature setpoint. 173/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 174: Operating Level Changeover Via Input H

DHW heating of the other basic units connected to LPB. Additional parameters Line no. Operating line 6620 Action changeover functions 174/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 175: Behavior In The Case Of Burner Cycling

Relay 2nd speed State (1st speed) Q2/Q6/Q20 Q21/Q22/Q23 Low-fire High-fire Note! If the second speed needs a potential-free or inverted relay output, an intermediate relay is required. 175/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 176: 2-Speed Boiler Pump

Boiler pump Q1. This parameterization is not required for the 2-speed boiler pump function If the second speed needs a potentialfree or inverted relay output, an intermediate relay is required 176/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 177: Cooling Circuit 1

Protection setpoint The room temperature ensured by the Protection setpoint prevents the room from overheating, provided the LMS14… is in Standby mode. Cooling is automatically switched on when the room temperature exceeds this value by Room temp limitation (932) and is switched off again when the room temperature drops below the protection setpoint. -

Page 178: Room Temperature Limitation

Figure 30: Room temperature limitation Line no. Meaning TRKw Room temperature setpoint cooling Actual value of room temperature Room temperature limitation Relay: Cooling request K28 Time 178/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 179: Dhw Heating

6.7 DHW heating The LMS14… makes possible the following types of DHW heating: 1. Charging with oil- or gas-fired boiler 2. Charging with electric immersion heater 3. Charging with solar collectors 4. Charging with solid fuel boiler Charging with Heat generation with an oil- or gas-fired boiler or electric immersion heater can be controllable heat controlled. -

Page 180: Dhw Mode

Keep hot function is generally enabled in On mode, it is deactivated in ECO mode. In connection with the aqua booster, ECO mode is always disabled. 180/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 181: Setpoints

Backup temperature outside release times. Nominal setpoint max Line no. Operating line 1614 Nominal setpoint max This setting ensures maximum limitation of the Nominal setpoint (1610). 181/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 182: Holiday Program

If the Legionella function was not effected because of a holiday period, it will be performed the next time DHW is heated to the Nominal setpoint. 182/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 183: Dhw Release

When selecting Once/day, the forward shift for the release of DHW heating is 2.5 hours. When selecting Several times/day, the forward shift for the release of DHW heating is 1.0 hour. 183/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 184 Setting Once/day or Several times/day has no impact. When DHW heating is Off, the Frost Protection setpoint applies. Example: 24 h Figure 34: DHW release – time program 4/DHW 184/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 185: Priority

– if the DHW temperature is lower – the charging pump is activated. When the forced signal becomes invalid, the charging pump is deactivated again and the DHW setpoint will be reset to the normal setpoint. 185/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 186: Pump Overrun

In connection with DHW storage tanks, the Legionella function is started 1 hour after power ON at the earliest. Warning! During the time the Legionella function is performed, there is a risk of scalding when opening the taps. 186/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 187 If DHW heating is Off (DHW operating mode button = Off, or holidays), the Legionella function is effected whenever DHW heating is switched on again (DHW operating mode button = On, and end of holiday period). 187/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 188 Legionella function is performed the moment the Legionella funct setpoint is reached. Note! If the Legionella function cannot be performed within a 48-hour period, an error message is delivered. 188/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 189 Legionella funct duration commences again. Warning! During the time the Legionella function is effected, there is a risk of scalding when opening the taps. 189/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 190: Circulating Pump

Time program 4/DHW The circulating pump is released according to Time program 4/DHW. Time program 5 The circulating pump is released according to Time program 5. 190/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 191: Frost Protection For The Circulation Pipe

Frost protection level of 5 °C is reached. The minimum on time is 10 minutes. Note! This function is only available if a circulation sensor is connected. 191/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 192: Operating Mode Changeover Via Input H

None Function is deactivated. No changeover of operating mode. Operating mode is changed to Off. Operating mode is changed to On. 192/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 193: Consumer Circuit And Swimming Pool Circuit

The setting made here defines whether the consumer circuit or the swimming pool circuit shall receive heat via the primary controller or the system pump (depending on the type of plant). 193/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 194: Swimming Pool

Swimming pool charging is effected without priority (after the buffer storage tank, the DHW storage tank, the heating circuits, and the consumer circuits). Note! Release and priority can also be influenced via inputs Hx. 194/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 195: Overtemperature Protection

With solar integration Line no. Operating line 2080 With solar integration The setting made here decides whether the swimming pool can be heated by solar energy. 195/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 196: Primary Controller/System Pump

Locks other heat sources (4102) is set to On. In that case, consumers downstream from the system pump do not receive any heat. 196/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 197: Mixing Valve Control

By setting the right proportional band Xp, the control action of the mixing valve’s actuator is matched to the behavior of the plant (controlled system). The proportional band influences the controller’s P-control action. 197/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 198: Plant Hydraulics

If the plant is equipped with a buffer storage tank, it must be entered here whether – hydraulically speaking – the primary controller or the system pump is located upstream of or downstream from the buffer storage tank. 198/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 199: Boiler

Heat sources that are not in operation are not switched on because full charging is required. 199/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 200: Setpoints

8 °C Normal operating mode Figure 37: Boiler setpoints Line no. Meaning 2210 Setpoint minimum 2211 Setpoint minimum OEM 2212 Setpoint maximum 2213 Setpoint maximum OEM 200/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 201 Cutout temperature limit thermostat 8311 TKSoll Boiler temperature setpoint TKAus Switch-off threshold boiler TKEin Switch-on threshold boiler SdAus Dynamic switch-off threshold (heating circuit/DHW) SdEin Switch-on threshold (heating circuit/DHW) 201/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 202: Setpoint Manual Control

Dynamic switching differential when setpoint changes 2465 Minimum setpoint change with dynamic switching differential 2466 Dynamic switching differential changeover heating circuit/DHW 2467 Dynamic switching differential when burner On 202/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 203: Frost Protection For The Boiler

-20 °C. Additional parameters Line no. Meaning 2454 SdHkEin Switch-on differential heating circuits 2455 SdHkAusMin Minimum switch-off differential heating circuits 5774 Control boiler pump/DHW diverting valve 203/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 204: Pid Control Algorithm

The derivative action time Tv determines the extent of after-effect of a spontaneous change of control offset. A short Tv only has a short-time impact on the manipulated variable. 204/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 205: Boiler/Burner Control

Heating mode. The 2-position controller initiates new startups resulting from space heating requests only when this period of time has elapsed. 205/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 206: Overtemperature Protection

Pump overrun time after Heating mode and external requests for heat. Pump overr time after Line no. Operating line 2253 Pump overr time after DHW Pump overrun time after DHW heating. 206/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 207: Minimum Limitation Of Boiler Temperature

When protective startup is activated, the consumers with mixing valve are restricted in their heat consumption in accordance with the locking signal value. The function can be deactivated. Function is deactivated. Function is activated. 207/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 208 ] + (TKgradient * t aktuell voraus Eventually, the difference of anticipated boiler temperature and minimum boiler temperature determines the value of the locking signal (0…100%). 208/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 209: Minimum Limitation Of Return Temperature

DHW charging pump, external load), the consumer pumps are deactivated, or stay deactivated, if the locking signal exceeds the relevant threshold value Function is deactivated. Function is activated. 209/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 210: Boiler Pump

Only space heating requests are locked. DHW heating requests continue to be met. Heating and DHW mode All space heating and DHW heating requests are locked. 210/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 211: Electronic Temperature Controller

When the Limit thermostat function is activated, maximum switch-off point and maximum setpoint are limited to the limit thermostat’s cutout temperature –3 K. Additional parameters Line no. Operating line 2531 Cutout temp LT 211/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 212: Limitation Of Boiler Temperature Increase

Limitation of boiler temperature increase 2316 2317 Filter time constant speed control Time Pump PWM PWM-Max PWM-Min 7471d70e/0911 Time Figure 39: Limitation of boiler temperature increase 212/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 213 In connection with a speed-controlled heating circuit pump and pure Heating mode, the nominal boiler temperature differential is maintained as long as the heating circuit pump is not controlled at the maximum permissible speed. 213/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 214: Speed Control

5774 Ctrl boiler pump/DHW valve Note! This function is only for use with single-boiler plants. For cascaded systems, one of the other functions must be selected. 214/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 215 Figure 40: Speed control – boiler setpoint Additional parameters Line no. Operating line 2324 Speed Xp 2325 Speed Tn 2326 Speed Tv 2329 Pump setpoint reduction 215/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 216 Boiler setpoint function. Additional parameters Line no. Operating line 2324 Speed Xp 2325 Speed Tn 2326 Speed Tv 216/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 217 2334 Output at pump speed minimum 2335 Output at pump speed maximum PWM-min Parameterized minimum speed of boiler pump PWM-max Parameterized maximum speed of boiler pump 217/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 218 The minimum value should be selected such that the pump is reliably activated when controlled. Pump speed max Line no. Operating line 2323 Pump speed max Power consumption can be limited via the maximum value. 218/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 219 Also, when the burner is switched on, the pump’s minimum modulation is limited to 100% for 10 seconds, thus setting modulation to the maximum. The function can be deactivated. Function is deactivated. Function is activated. 219/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 220: Output Data

Output at pump speed max (2335). If the burner’s output lies between these 2 values, the boiler pump’s speed is calculated through linear conversion. 220/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 221: Fan

Fan shutdown heating mode (2445) can be used to select whether the fan’s power supply shall also be released when there are requests for space heating, independent of PWM control. Function is deactivated. Function is activated. 221/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 222 Fan shutdown heating mode (2445) can be used to select whether the fan’s power supply shall also be released when there are requests for space heating, independent of PWM control. 222/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 223: Controller Delay

100% value. In DHW mode, the maximum output is used as the 100% value. Another parameter defines for what period of time the controller delay shall be active. 223/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 224 Line no. Operating line duration 2453 Controller delay duration Duration of controller delay. This delay time is started the moment a flame is definitively detected after ignition. 224/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 225: Dynamic Switching Differentials

But the switch-off threshold is always limited at the bottom: Switch-off threshold boiler > = temperature setpoint + minimum switch-off threshold. The switch-on differential is ready parameterized. 225/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 226 Switch-on differential heating circuits 8311 TKSoll Boiler temperature setpoint SdHkAus Switch-off differential heating circuits Note! The dynamic switching differentials can only be parameterized with positive values. 226/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 227 The switch-off threshold is calculated from the required setpoint plus the switch-off differential. The parameter represents the switch-off differential used for DHW heating requests. The maximum switch-off differential is only used during the settling out process. 227/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 228 The dynamic switching thresholds can also be activated when the request for heat changes from DHW mode to Heating mode. This function is activated/deactivated via parameter Dyn SD with HC/DHW (2466). Function is deactivated. Function is activated. 228/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 229: Delay Heat Request Special Operation

So the system pump works against the fully closed heating circuit valve until it opens. 229/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 230: Flue Gas Supervision

The filter is used to delay the release of output when output limitation is active. Plausibility check of If a configuration with flue gas sensor is selected, the LMS14… must read in a valid flue sensor gas temperature value. Otherwise, either start prevention with message code or lockout will be initiated (Flue gas superv shutdown (2476)). - Page 231 Depending on the parameter setting (Flue gas superv shutdown (2476)), start prevention takes effect for at least 10 minutes (Flue gas superv st prev tme (2477)) or the LMS14… goes to lockout. The boiler is released again only when the flue gas temperature has dropped.

- Page 232 Flue gas temperature flue gas temperature switch-off limit. Output reduction or shutdown is canceled when: Flue gas temperature < Flue gas temp output red (2473) – Switching diff on HCs (2454) 232/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 233 Info/diagnostics Line no. Operating line 8318 Flue gas temp max Note! This slave pointer value cannot be reset! 233/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 234: Static Pressure Supervision

Start prevention Lockout position Basics of static supervision Function: Water pressure supervision overrides boiler control. When the water pressure exceeds or drops below certain thresholds, the LMS14... responds as follows: Shutdown (water pressure Hx maximum), Reduction of output (water pressure Hx minimum), or ... - Page 235 235/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 236 H1, H2 EM1, H2 EM2, H2 EM3, H3. Info/diagnostics Line no. Operating line Water pressure 9005 Water pressure 1 9006 Water pressure 2 9007 Water pressure 3 236/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 237: Dynamic Pressure Supervision

Dyn press superv time Line no. Operating line 2495 Dyn press superv time Dyn press superv tme Line no. Operating line const 2496 Dyn press superv tme const 237/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 238 Dyn superv press diff min (2491)/Dyn superv press diff max (2492), the LMS14… must read in a valid value for the water pressure. Otherwise, either startup is prevented and a status code is delivered, or the unit goes to lockout Dyn press superv sh’down (2490).

- Page 239 During the measuring time Dyn press superv time (2495), the current measured value of the differential pressure ∆P is compared with limit value Dyn superv diff press max (2492) at 200-ms intervals and, if necessary, the LMS14… responds to the fault. Caution!

- Page 240 Due to strong filtering of the measuring signal, intermediate values of the quantization stages may dynamically occur. For this reason, always wait until the settling state is reached (Tdelay). 240/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 241: Water Pressure Sensor

Due to the special requirements placed on the read in and filter algorithms, the pressure sensor for dynamic pressure measurements must always be configured at one of the local terminals of the LMS14… (H1/H3). Otherwise, the pressure sensor is to be configured the same way as it is for static pressure measurements. - Page 242 Voltage at Hx U2 = 3.5 V U1 = 0.5 V Figure 47: Water pressure sensor Function value 1 Function value 2 Voltage value 1 Voltage value 2 242/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 243: Filling/Flow Supervision

Depending on parameter Flow switch shutdown (2502), a change to start prevention or lockout is made, including the respective diagnostics. Warning! Start prevention/lockout via this input is not implemented as a safety-related function. 243/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 244 When the contacts of the flow switch are closed, the burner can immediately be started up. When the contacts are open, the LMS14… locks startup after an adjustable waiting time (parameter Min on time switch). When the contacts make on completion of this period of time, start prevention –...

-

Page 245: Quick Shutdown Of Burner

Prerequisites for quick shutdown: - Quick shutdown on the local boiler is active - The contacts of the last local room thermostat are open 245/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 246: Limitation Of Output

The burner is switched on again only after the boiler flow temperature has dropped by the switching differential (Swi diff output red (2528)) below this value. 246/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... - Page 247 Output limitation works with absolute values. This means that with a limitation set to 50% absolute output, for instance, the resulting relative burner output differs from 50%. 7471d58e/1210 Figure 48: Limitation of output – switching differential output reduction 247/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

-

Page 248: Electronic Limit Thermostat

Current boiler temperature 2531 Cutout temperature limit thermostat Temperature Switching differential boiler Burner operation (0 = Off, 1 = On) Additional parameters Line no. Operating line [3639.1] TempBoilerMaxSLTSec 248/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014... -

Page 249: Electronic Safety Limit Thermostat (Slt)

Electronic safety limit thermostat (SLT) Warning! If the safety limit thermostat (SLT) has the bridge resistor fitted (with LMS14…: R13SC), an external limit thermostat (LT) must not be connected since its cutting out in the case of overtemperature would not lead to shutdown so there would be a risk of excessive boiler temperatures. - Page 250 [3914.1] Numbr err, SLT 24h temperature temperature > activated by Residual heat temp in 24 h Numbr err, SLT exceeded limit thermostat TempBoilerMaxSLTSec 250/617 Building Technologies Division User Manual LMS14... CC1U7471en 6 The settings in detail 07.05.2014...

- Page 251 () than flow in 24 h higher than flow Switching differential return higher than flow ¹) Function must be separately activated by Siemens Legend Line no. Meaning T TKIst 251/617 Building Technologies Division User Manual LMS14...

- Page 252 Numbre err, Tdiff 24h Line no. Operating line [3921.1] Numbre err, Tdiff 24h Counter limit for triggering lockout in the event of a delta T error. 252/617 Building Technologies Division User Manual LMS14… CC1U7471en 6 The settings in detail 28.01.2015...

- Page 253 (DHW or space heating) can trigger the supervisory functions and lead to safety shutdown or even lockout of the LMS14... The Don’t care transition can be reactivated only when the sum of the elapsed time represents 4 times the Don’t care transition time.

- Page 254 [3924.1] Numbr err, Tr>Tf 24h [3639.1] TempBoilerMaxSLTSec [3925.1] TempRetMaxSLTSec 9541 Postpurge time TL max Info/diagnostics Line no. Operating line 8310 Boiler temp 8314 Boiler return temp 254/617 Building Technologies Division User Manual LMS14… CC1U7471en 6 The settings in detail 28.01.2015...

-

Page 255: Energy Meter

Total gas energy heating 8379 Total gas energy DHW 8380 Total gas energy 8381 Gas energy heating 8382 Gas energy DHW 8383 Gas energy 9626 Fan output/speed slope 255/617 Building Technologies Division User Manual LMS14… CC1U7471en 6 The settings in detail 28.01.2015... -

Page 256: Deaeration Function