Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Toyota 1 MZ–FE

- Page 1 EG2–1 1MZ–FE ENGINE – 1MZ–FE ENGINE...

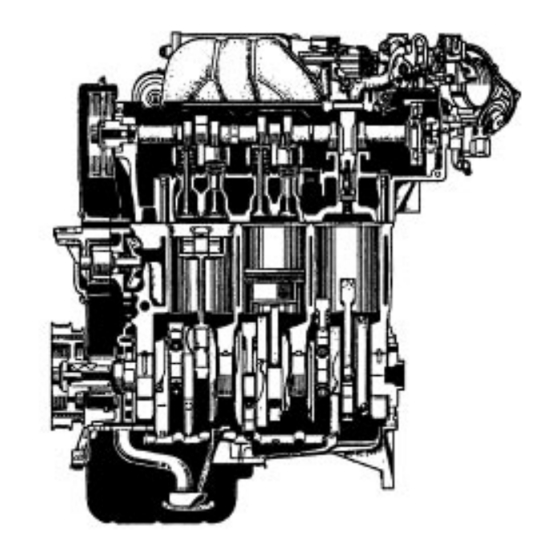

- Page 2 EG2–2 1MZ–FE ENGINE – ENGINE MECHANICAL ENGINE MECHANICAL DESCRIPTION The 1 MZ–FE engine is a V–6, 3.0 liter 24 valve DOHC engine. OPERATION...

- Page 3 EG2–3 1MZ–FE ENGINE – ENGINE MECHANICAL The 1 MZ–FE engine has 6 cylinders in a V arrangement at a bank angle of 602. From the front of the RH bank cylinders are numbered 1–3–5, and from the front of the LH bank cylinders are numbered 2–4–6.

- Page 4 EG2–4 1MZ–FE ENGINE – ENGINE MECHANICAL PREPARATION SST (SPECIAL SERVICE TOOLS) 09201–01055 Valve Guide Bushing Remover & Replacer 5.5 09201–41020 Valve Stem Oil Seal Replacer 09202–70010 Valve Spring Compressor 09213–54015 Crankshaft Pulley Holding Tool 09213–60017 Crankshaft Pulley & Gear Puller (09213–00020) Body With Bolt (09213–00030) Handle (09213–00050) Bolt set...

- Page 5 EG2–5 1MZ–FE ENGINE – ENGINE MECHANICAL (09248 –05410) Valve Lifter Press (09248–05420) Valve Lifter Stopper RH camshaft timing pulley 09249–63010 Torque Wrench Adaptor Crankshaft pulley 09330–00021 Companion Flange Holding Tool 09608–20012 Front Hub & Drive Pinion Bearing Tool Set (09608–03020) Handle Crankshaft rear oil seal Valve guide bushing (09608–03070) Replacer...

-

Page 6: Recommended Tools

EG2–6 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL RECOMMENDED TOOLS 09040–00010 Hexagon Wrench Set 09090–04010 Engine Sling Device For suspending engine 09200–00010 Engine Adjust Kit Plug for the vacuum hose, fuel 09258–00030 Hose Plug set hose etc. 09904–00010 Expander Set EQUIPMENT Battery specific gravity gauge Caliper gauge... - Page 7 EG2–7 1MZ–FE ENGINE – ENGINE MECHANICAL Soft brush Valve spring Spring tester Valve spring Steel square Thermometer Torque wrench Valve seat cutter Vernier calipers COOLANT Capacity Classification Item 8.7 liters (9.2 US qts, 7.7 Imp. qts) Ethylene–glycol base Engine coolant LUBRICANT Classification Capacity...

-

Page 8: Engine Coolant Inspection

EG2–8 1MZ–FE ENGINE – ENGINE MECHANICAL TUNE–UP ENGINE COOLANT INSPECTION 1. CHECK ENGINE COOLANT LEVEL AT RESERVOIR TANK The engine coolant level should be between the ”LOW” and ”FULL” lines. If low, check for leaks and add engine coolant up to the ”FULL”... -

Page 9: Engine Oil Inspection

EG2–9 1MZ–FE ENGINE – ENGINE MECHANICAL ENGINE OIL INSPECTION 1. CHECK OIL QUALITY Check the oil for deterioration, entry of water, dis– coloring or thinning. If oil quality is visibly poor, replace the oil. Oil grade: API grade SG or SH, Energy – Conserving H or ILSAC multigrade engine oil. -

Page 10: Battery Inspection

EG2–10 1MZ–FE ENGINE – ENGINE MECHANICAL BATTERY INSPECTION 1. Except Delco Battery: CHECK BATTERY ELECTROLYTE LEVEL Check the electrolyte quantity of each cell. A. Maintenance Free Battery If under the lower level, replace the battery (or add distilled water if possible). Check the charging system. B. -

Page 11: Air Filter Inspection And Cleaning

EG2–11 1MZ–FE ENGINE – ENGINE MECHANICAL B. Except Maintenance Free Battery Check the specific gravity of each cell. Standard specific gravity: 55D23L battery for GNB Incorporated 1.25 – 1.27 at 20°C (60°F) 5513231– battery for JOHNSON CONTROLS 1.26 – 1.28 at 27°C (81°F) 80D26L battery for GNB Incorporated 1.27 –... -

Page 12: Generator Drive Belt Inspection

EG2–12 1MZ–FE ENGINE – ENGINE MECHANICAL 2. INSPECT AND CLEAN AIR FILTER (a) Visually check that the air filter is not excessively dirty, damaged or oily. If necessary, replace the air filter. (b) Clean the air filter with compressed air. First blow from the inside thoroughly, then blow from the outside of the air filter. -

Page 13: Valve Clearance Inspection And Adjustment

EG2–13 1MZ–FE ENGINE – ENGINE MECHANICAL VALVE CLEARANCE INSPECTION AND ADJUSTMENT HINT: Inspect and adjust the valve clearance when the engine is cold. 1. DISCONNECT NEGATIVE (–) TERMINAL CABLE TO BATTERY CAUTION: Work must be started after 90 seconds from the time the ignition switch is turned to the ”LOCK”... - Page 14 EG2–14 1MZ–FE ENGINE – ENGINE MECHANICAL 8. REMOVE EMISSION CONTROL VALVE SET (a) Disconnect the following vacuum hoses: (1) Vacuum hose from fuel pressure control VSV (2) Vacuum hose from fuel pressure regulator (3) Vacuum hose from cylinder head rear plate (4) Vacuum hose from intake air control valve VSV (5) Vacuum hose from EGR vacuum modulator (6) Vacuum hose from EGR valve...

- Page 15 EG2–15 1MZ–FE ENGINE – ENGINE MECHANICAL (d) Remove the bolt and disconnect the hydraulic motor pressure hose from the air intake chamber. (e) Remove the bolt, and disconnect the ground strap. (f) Disconnect the RH oxygen sensor connector clamp from the PS pressure tube. (g) Remove the 2 nuts, and disconnect the PS pressure tube.

- Page 16 EG2–16 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL (I) Disconnect the following connectors: (1) Throttle position sensor connector (2) IAC valve connector (3) EGR gas temperature sensor connector (4) A/C idle–up connector (m) Disconnect the following vacuum hoses: (1) 2 vacuum hoses from TVV (2) Vacuum hose from cylinder head rear plate (3) Vacuum hose from charcoal canister (n) Disconnect the following hoses:...

- Page 17 EG2–17 1MZ–FE ENGINE – ENGINE MECHANICAL 10. DISCONNECT ENGINE WIRE FROM ENGINE LH SIDE (a) Disconnect the following connectors: (1) 3 injector connectors (2) 3 ignition coil connectors (b) Remove the 2 nuts, and disconnect the engine wire. 11. DISCONNECT ENGINE WIRE FROM NO.3 TIMING BELT COVER Remove the bolt and 3 clamps, and disconnect the engine wire.

-

Page 18: Remove Spark Plugs

EG2–18 1MZ–FE ENGINE – ENGINE MECHANICAL 14. REMOVE IGNITION COILS Remove the 6 bolts and 6 ignition coils from the RH and LH cylinder heads. HINT: Arrange the ignition coils in the correct order. 15. REMOVE SPARK PLUGS Using a 16 mm plug wrench, remove the 6 spark plugs from the RH and LH cylinder heads. -

Page 19: Inspect Valve Clearance

EG2–19 1MZ–FE ENGINE – ENGINE MECHANICAL 18. INSPECT VALVE CLEARANCE (a) Check only those valves indicated in the illustration. Using a feeler gauge, measure the clearance be– tween the valve lifter and camshaft. Record out of specification valve clearance mea– surements. -

Page 20: Adjust Valve Clearance

EG2–20 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Turn the crankshaft a further 2/3 of a revolution (2402), and check only the valves indicated in the illustration. Measure the valve clearance. (See procedure step (a)) 19. ADJUST VALVE CLEARANCE (a) Remove the adjusting shim. Turn the camshaft so that the cam lobe for the valve to be adjusted faces up. - Page 21 EG2–21 1MZ–FE ENGINE – ENGINE MECHANICAL Using a small screwdriver and a magnetic finger, remove the adjusting shim. (b) Determine the replacement adjusting shim size ac– cording to the following Formula or Charts on the next 2 pages: Using a micrometer, measure the thickness of the removed shim.

- Page 22 Adjusting Shim Selection Chart (Intake)

- Page 23 Adjusting Shim Selection Chart (Exhaust)

- Page 24 EG2–24 1MZ–FE ENGINE – ENGINE MECHANICAL 20. REINSTALL CYLINDER HEAD COVERS (a) Apply seal packing to the cylinder heads as shown in the illustration. Seal packing: Part No. 08826–00080 or equivalent (b) Install the gasket to the cylinder head cover. (c) Install the cylinder head cover with the 8 bolts.

- Page 25 EG2–25 1MZ–FE ENGINE – ENGINE MECHANICAL 23. RECONNECT ENGINE WIRE TO ENGINE RH SIDE (a) Connect the engine wire with the 5 nuts. (b) Connect the following connectors: (1) 3 injector connectors (2) 3 ignition coil connectors 24. RECONNECT ENGINE WIRE TO ENGINE REAR SIDE Connect the engine wire with the 2 nuts.

- Page 26 EG2–26 1MZ–FE ENGINE – ENGINE MECHANICAL 27. REINSTALL AIR INTAKE CHAMBER (a) Using an 8 mm hexagon wrench, install a new gasket and the air intake chamber with the 2 bolts and 2 nuts. Torque: 43 N–m (440 kgf–cm, 32 ft–lbf) (b) Connect the following hoses: (1) 2 water bypass hoses (2) Air assist hose...

- Page 27 EG2–27 1MZ–FE ENGINE – ENGINE MECHANICAL (e) Install 2 new gaskets and EGR pipe with the 4 nuts. Torque: 12 N–m (120 kgf–cm. 9 ft–lbf) (f) install the No. 1 engine hanger with the 2 bolts. Torque: 39 N–m (400 kgf–cm, 19 ft–lbf) (g) Install the air intake chamber stay with the 2 bolts.

- Page 28 EG2–28 1MZ–FE ENGINE – ENGINE MECHANICAL (m) Connect the following hoses: (1) Brake booster vacuum hose (2) PCV hose (3) Intake air control valve vacuum hose (n) Connect the data link connector 1. (o) Connect the 2 ground straps with the nut. 28.

- Page 29 EG2–29 1MZ–FE ENGINE – ENGINE MECHANICAL 29. REINSTALL AIR CLEANER CAP, VOLUME AIR FLOW METER AND AIR CLEANER HOSE (a) Connect the air cleaner hose, and install the air clean– er cap and volume air flow meter with the 4 clips. (b) Tighten the air cleaner hose clamp bolt.

-

Page 30: Ignition Timing Inspection

EG2–30 1MZ–FE ENGINE – ENGINE MECHANICAL IGNITION TIMING INSPECTION 1. WARM UP ENGINE Allow the engine to warm up to normal operating temperature. 2. CONNECT TACHOMETER TO ENGINE Connect the tester probe of a tachometer to terminal IG(–) of the data link connector 1. NOTICE: Never allow the tachometer terminal to touch ground as it could result In damage to the igniter... - Page 31 EG2–31 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Check the idle speed. Idle speed: 60 rpm 5. INSPECT IGNITION TIMING (a) Using SST, connect terminals TE1 and E1 of the data link connector 1. SST 09843–18020 (b) Using a timing light, check the ignition timing. Ignition timing: 8 –...

- Page 32 EG2–32 1MZ–FE ENGINE – ENGINE MECHANICAL 7. DISCONNECT TIMING LIGHT FROM ENGINE (a) Remove the timing light. (b) Using a 5 mm hexagon wrench, install the V–bank cover with the 2 cap nuts. 8. DISCONNECT TACHOMETER FROM ENGINE...

-

Page 33: Idle Speed Inspection

EG2–33 1MZ–FE ENGINE – ENGINE MECHANICAL IDLE SPEED INSPECTION 1. INITIAL CONDITIONS (a) Engine at normal operating temperature (b) Air cleaner installed (c) All pipes and hoses of air induction system connected (d) All accessories switched OFF (e) All vacuum lines properly connected HINT: All vacuum hoses for EGR system, etc. - Page 34 EG2–34 1MZ–FE ENGINE – ENGINE MECHANICAL IDLE AND OR 2500 RPM CO HC CHECK HINT: This check is used only to determine whether or not the idle CO/HC complies with regulations. 1. INITIAL CONDITIONS (a) Engine at normal operating temperature (b) Air cleaner installed (c) All pipes and hoses of air induction system connected (d) All accessories switched OFF...

- Page 35 EG2–35 1MZ–FE ENGINE – ENGINE MECHANICAL Troubleshooting If the CO/HC concentration does not comply with regulations, perform troubleshooting in the order given below. See the table below for possible causes, and then inspect and correct the applicable causes if neces– sary.

-

Page 36: Compression Check

EG2–36 1MZ–FE ENGINE – ENGINE MECHANICAL COMPRESSION CHECK HINT: If there is lack of power, excessive oil consump– tion or poor fuel economy, measure the compression pressure. 1. WARM UP AND STOP ENGINE Allow the engine to warm up to normal operating temperature. -

Page 37: Remove Spark Plugs

EG2–37 1MZ–FE ENGINE – ENGINE MECHANICAL 4. REMOVE SPARK PLUGS Using a 16 mm plug wrench, remove the 6 spark plugs from the RH and LH cylinder heads. 5. CHECK CYLINDER COMPRESSION PRESSURE (a) Insert a compression gauge into the spark plug hole. (b) Fully open the throttle. - Page 38 EG2–38 1MZ–FE ENGINE – ENGINE MECHANICAL 7. INSTALL IGNITION COILS (a) Install the 6 ignition coil to the RH and LH cylinder heads with the 6 bolts. Torque: 8 N–m (80 kgf–cm, 69 in.–lbf) (b) Connect the 6 ignition coil connectors. 8.

- Page 39 EG2–39 1MZ–FE ENGINE – ENGINE MECHANICAL TIMING BELT COMPONENTS FOR REMOVAL AND INSTALLATION...

- Page 40 EG2–40 1MZ–FE ENGINE – ENGINE MECHANICAL...

-

Page 41: Timing Belt Removal

EG2–41 1MZ–FE ENGINE – ENGINE MECHANICAL TIMING BELT REMOVAL (See Components for Removal and Installation) 1. DISCONNECT NEGATIVE (–) TERMINAL CABLE FROM BATTERY CAUTION: Work must be started after 90 seconds from the time the ignition switch is turned to the ’LOCK’ position and the negative (–) terminal cable is discon–... - Page 42 EG2–42 1MZ–FE ENGINE – ENGINE MECHANICAL 6. REMOVE PS DRIVE BELT Loosen the 2 bolts, and remove the drive belt. 7. DISCONNECT GROUND STRAPS Disconnect the 2 straps. 8. REMOVE RH ENGINE MOUNTING STAY Remove the 3 bolts and RH engine mounting stay. 9.

- Page 43 EG2–43 1MZ–FE ENGINE – ENGINE MECHANICAL 11. REMOVE CRANKSHAFT PULLEY (a) Using SST, remove the pulley bolt. SST 09213–54016, 09330–00021 (b) Using SST, remove the pulley. SST 09213–00060 12. REMOVE No.1 TIMING BELT COVER Remove the 4 bolts and timing belt cover. 13.

- Page 44 EG2–44 1MZ–FE ENGINE – ENGINE MECHANICAL 15. REMOVE ENGINE RH MOUNTING BRACKET Remove the 2 bolts, nut and mounting bracket. 16. REMOVE TIMING BELT GUIDE 17. SET NO.1 CYLINDER TO TDC/COMPRESSION (a) Temporarily install the crankshaft pulley bolt to the crankshaft.

-

Page 45: Remove Timing Belt

EG2–45 1MZ–FE ENGINE – ENGINE MECHANICAL 18. IF REUSING TIMING BELT, CHECK INSTALLATION MARKS ON TIMING BELT Check that there are 3 installation marks and front mark on the timing belt. If the installation and front marks have disappeared, before removing the timing belt, place new installation and front marks on the timing belt to the following position: Timing mark of RH camshaft timing pulley... - Page 46 EG2–46 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Using SST, remove the LH timing pulley. SST 09960–10010 (09962–01000) HINT: Arrange the camshaft timing pulleys (RH and LH sides). 22. REMOVE NO.2 IDLER PULLEY Remove the bolt and idler pulley. 23. REMOVE No.1 IDLER PULLEY Using a 10 mm hexagon wrench, remove the bolt, idler pulley and plate washer.

-

Page 47: Timing Belt Inspection

EG2–47 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Using SST, remove the crankshaft timing pulley. SST 09213–60017 (09213–00020, 09213–00030, 09213–00050) NOTICE: Do not scratch the sensor part of the crankshaft timing pulley. TIMING BELT INSPECTION 1. INSPECT TIMING BELT NOTICE: Do not bend, twist or turn the timing belt inside out. Do not allow the timing belt to come into contact with oil, water or steam. - Page 48 EG2–48 1MZ–FE ENGINE – ENGINE MECHANICAL (d) If there is wear or damage on only one side of the belt, check the belt guide and the alignment of each pulley. (e) If there is noticeable wear on the belt teeth, check timing cover for damage and check gasket has been installed correctly and for foreign material on the pulley teeth.

-

Page 49: Timing Belt Installation

EG2–49 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Measure the protrusion of the push rod from the housing end. Protrusion: 10.0 – 10.8 mm (0.394 – 0.425 In.) If the protrusion is not as specified, replace the tensi– oner. TIMING BELT INSTALLATION (See Components for Removal and Installation) 1. - Page 50 EG2–50 1MZ–FE ENGINE – ENGINE MECHANICAL 3. INSTALL No.2 IDLER PULLEY (a) Install the idler pulley with the bolt. Torque: 43 N–m (440 kgf–cm, 32 ft–lbf) (b) Check that the idler pulley moves smoothly. 4. INSTALL RH CAMSHAFT TIMING PULLEY (a) Install the timing pulley, facing the flange side out–...

- Page 51 EG2–51 1MZ–FE ENGINE – ENGINE MECHANICAL 6. SET NO.1 CYLINDER TO TDC/COMPRESSION (a) Crankshaft Timing Pulley Position: Temporarily install the crankshaft pulley bolt to the crankshaft. Turn the crankshaft and align the crankshaft timing pulley groove with the oil pump alignment mark.

- Page 52 EG2–52 1MZ–FE ENGINE – ENGINE MECHANICAL 8. SET TIMING BELT TENSIONER (a) Using a press, slowly press in the push rod using 981 –9,807 N (1100–1,000 kgf, 200–2,205 Ibf) of pres– sure. (b) Align the holes of the push rod and housing, pass a 1.27 mm hexagon wrench through the holes to keep the setting position of the push rod.

- Page 53 EG2–53 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL (b) Check that the timing marks of the RH and LH timing pulleys with the timing marks of the No.3 timing belt cover as shown in the illustration. If the marks do not align, remove the timing belt and reinstall it.

- Page 54 EG2–54 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Install the belt cover with the 5 bolts. Torque: 8.5 N–m (85 kgf–cm. 74 in.–lbf) 14. CONNECT ENGINE WIRE (a) Connect the engine wire with the clamp. (b) Install the bolt holding the engine wire to the No.3 timing belt cover.

- Page 55 EG2–55 1MZ–FE ENGINE – ENGINE MECHANICAL 16. INSTALL CRANKSHAFT PULLEY (a) Align the pulley set key with the key groove of the pulley, and slide the pulley. (b) Using SST, install and torque the bolt. SST 09213–54015, 09330–00021 Torque: 216 N–m (2,200 kgf–cm, 159 ft–lbf) 17.

- Page 56 EG2–56 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL 21. INSTALL AND ADJUST PS DRIVE BELT Install the drive belt with the pivot and adjusting bolts. Drive belt tension: New belt 185 I bf Used belt 20 lbf 22. INSTALL GENERATOR DRIVE BELT Adjust the drive belt.

- Page 57 EG2–57 1MZ–FE ENGINE – ENGINE MECHANICAL CYLINDER HEAD COMPONENTS FOR REMOVAL AND INSTALLATION...

- Page 58 EG2–58 1MZ–FE ENGINE – ENGINE MECHANICAL...

- Page 59 EG2–59 1MZ–FE ENGINE – ENGINE MECHANICAL...

- Page 60 EG2–60 1MZ–FE ENGINE – ENGINE MECHANICAL...

- Page 61 EG2–61 1MZ–FE ENGINE – ENGINE MECHANICAL...

-

Page 62: Cylinder Heads Removal

EG2–62 1MZ–FE ENGINE – ENGINE MECHANICAL CYLINDER HEADS REMOVAL (See Components for Removal and Installation) 1. REMOVE BATTERY AND TRAY CAUTION: Work must be started after 90 seconds from the time the ignition switch is turned to the ’LOCK’ position and the negative (–) terminal cable is discon– nected from the battery. - Page 63 EG2–63 1MZ–FE ENGINE – ENGINE MECHANICAL 8. REMOVE RH ENGINE MOUNTING STAY Remove the 3 bolts and RH engine mounting stay. 9. DISCONNECT RADIATOR HOSES 10. DISCONNECT HEATER HOSES Disconnect the 2 hoses. 11. DISCONNECT FUEL HOSES Disconnect the fuel inlet and return hoses. CAUTION: Catch leaking fuel in a container.

- Page 64 EG2–64 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL 13. REMOVE V – BANK COVER Using a 5 mm hexagon wrench, remove the 2 nuts and V–bank cover. 14. REMOVE EMISSION CONTROL VALVE SET (a) Disconnect the following vacuum hoses: (1) Vacuum hose from fuel pressure control VSV (2) Vacuum hose from fuel pressure regulator (3) Vacuum hose from cylinder head rear plate...

- Page 65 EG2–65 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL (d) Remove the bolt and disconnect the hydraulic motor pressure hose from the air intake chamber. (e) Remove the bolt, and disconnect the ground strap. (f) Disconnect the RH oxygen sensor connector clamp from the PS pressure tube.

- Page 66 EG2–66 1MZ–FE ENGINE – ENGINE MECHANICAL (I) Disconnect the following connectors: (1) Throttle position sensor connector (2) IAC valve connector (3) EGR gas temperature sensor connector (4) A/C idle–up connector (m) Disconnect the following vacuum hoses: (1) 2 vacuum hoses from TVV (2) Vacuum hose from cylinder head rear plate (3) Vacuum hose from charcoal canister (n) Disconnect the following hoses:...

- Page 67 EG2–67 1MZ–FE ENGINE – ENGINE MECHANICAL 16. REMOVE INTAKE AIR CONTROL VALVE FROM AIR INTAKE CHAMBER (a) Disconnect the A/C air hose. (b) Remove the 3 nuts and data link connector 1 clamp. (c) Remove the intake air control valve by prying a screw– driver between the intake air control valve and air intake chamber.

- Page 68 EG2–68 1MZ–FE ENGINE – ENGINE MECHANICAL 21. DISCONNECT ENGINE WIRE FROM NO.3 TIMING BELT COVER Disconnect the 2 clamps and engine wire. 22. DISCONNECT ENGINE WIRE FROM ENGINE REAR SIDE (a) Disconnect the following connectors: (1) LH oxygen sensor (2) Engine coolant temperature sensor (3) Camshaft position sensor (b) Disconnect the 3 clamps.

- Page 69 EG2–69 1MZ–FE ENGINE – ENGINE MECHANICAL 24. REMOVE IGNITION COILS Remove the6 bolts and6 ignition coils from the RH and LH cylinder heads. HINT: Arrange the ignition coils in the correct order. 25. REMOVE SPARK PLUGS Using a 16 mm plug wrench, remove the6 spark plugs from the RH and LH cylinder heads.

- Page 70 EG2–70 1MZ–FE ENGINE – ENGINE MECHANICAL 27. REMOVE TIMING BELT (See steps 2 to 20 on pages EG2–41 to 45) 28. REMOVE CAMSHAFT TIMING PULLEYS (a) Using SST, remove the bolt and RH timing pulley. SST 09249–63010, 09960–10010 (09862–01000) (b) Using SST, remove the LH timing pulley. SST 09960–10010 (09962–01000) HINT: Arrange the camshaft timing pulleys (RH and LH sides).

- Page 71 EG2–71 1MZ–FE ENGINE – ENGINE MECHANICAL 30. REMOVE NO.3 TIMING BELT COVER Remove the 6 bolts and belt cover. 31. REMOVE CYLINDER HEAD REAR PLATE (a) Disconnect the vacuum hose from the vacuum tank. (b) Remove the nut, and disconnect the ground strap. (c) Remove the bolt and rear plate.

- Page 72 EG2–72 1MZ–FE ENGINE – ENGINE MECHANICAL 35. REMOVE FUEL PRESSURE REGULATOR FROM LH DELIVERY PIPE (a) Remove the 2 bolts, and pull out the pressure regula– tor. (b) Remove the 0–ring from the pressure regulator. 36. REMOVE TVV FROM INTAKE MANIFOLD 37.

- Page 73 EG2–73 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Pull out the 6 injectors from the delivery pipes. Remove the 0–ring and grommet from each injector. 40. REMOVE WATER OUTLET (a) Remove the 2 bolts, 2 nuts and 2 plate washers. (b) Disconnect the water bypass hose and remove the water outlet.

- Page 74 EG2–74 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Remove the 6 nuts, exhaust manifold and gasket. 43. REMOVE OIL DIPSTICK AND GUIDE (a) Remove the bolt holding the dipstick guide to the LH cylinder head. (b) Pull out the dipstick guide together with the dipstick from the No.1 oil pan.

- Page 75 EG2–75 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Remove the bolts, 2 nuts, exhaust manifold stay and exhaust manifold plate. (d) Remove the 6 nuts, exhaust manifold and gasket. 46. REMOVE CYLINDER HEAD COVERS Remove the 8 bolts, cylinder head cover and gasket. Remove the 2 cylinder head covers.

- Page 76 EG2–76 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL A. Remove intake camshaft of RH cylinder head (a) Align the timing marks (2 dot marks) of the camshaft drive and driven gears by turning the camshaft with a wrench. (b) Secure the exhaust camshaft sub–gear to the main gear with a service bolt.

- Page 77 EG2–77 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Secure the exhaust camshaft sub–gear to the main gear with a service bolt. Recommended service bolt: Thread diameter 6 mm Thread pitch 1.0 mm Bolt length 16–20 mm HINT: When removing the camshaft, make sure that the torsional spring force of the sub–gear has been eliminated by the above operation.

- Page 78 EG2–78 1MZ–FE ENGINE – ENGINE MECHANICAL 49. DISASSEMBLE EXHAUST CAMSHAFTS (a) Mount the hexagonal wrench head portion of the camshaft in a vise. NOTICE: Be careful not to damage the camshaft. (b) Using SST, turn the sub–gear counterclockwise, and remove the service bolt. SST 09960–10010 (09962–0100) (c) Using snap ring pliers, remove the snap ring.

-

Page 79: Remove Cylinder Heads

EG2–79 1MZ–FE ENGINE – ENGINE MECHANICAL 50. REMOVE CYLINDER HEADS (a) Using a 8 mm hexagon wrench, remove the cylinder head (recessed head) bolt on each cylinder head, then repeat for the other side, as shown. (b) Uniformly loosen and remove the 8 cylinder head (12 pointed head) bolts on each cylinder head, in several passes, in the sequence shown, then repeat for the other side, as shown. -

Page 80: Cylinder Head Disassembly

EG2–80 1MZ–FE ENGINE – ENGINE MECHANICAL CYLINDER HEAD DISASSEMBLY (See Components for Removal and Installation) 1. REMOVE VALVE LIFTERS AND SHIMS HINT: Arrange the valve lifters and shims in the cor– rect order. 2. REMOVE VALVES (a) Using SST, compress the valve spring and remove the 2 keepers. -

Page 81: Cylinder Head Components Inspection And Repair

EG2–81 1MZ–FE ENGINE – ENGINE MECHANICAL (d) Using compressed air and a magnetic finger, remove the spring seat by blowing air. HINT: Arrange the valves, valve springs, spring seats and spring retainers in the correct order. CYLINDER HEAD COMPONENTS INSPECTION AND REPAIR 1. -

Page 82: Inspect Cylinder Head

EG2–82 1MZ–FE ENGINE – ENGINE MECHANICAL B. Clean combustion chambers Using a wire brush, remove all the carbon from the combustion chambers. NOTICE: Be careful not to scratch the cylinder block contact surface. C. Clean cylinder head Using a soft brush and solvent, thoroughly clean the cylinder head. - Page 83 EG2–83 1MZ–FE ENGINE – ENGINE MECHANICAL B. Inspect for cracks Using a dye penetrant, check the combustion cham– ber, intake ports, exhaust ports and cylinder block surface for cracks. If cracked, replace the cylinder head. 4. CLEAN VALVES (a) Using a gasket scraper, chip off any carbon from the valve head.

- Page 84 EG2–84 1MZ–FE ENGINE – ENGINE MECHANICAL Maximum oil clearance: Intake 0.08 mm (0.0031 in.) Exhaust 0.10 mm (0.0039 in.) If the clearance is greater than maximum, replace the valve and guide bushing. 6. IF NECESSARY, REPLACE VALVE GUIDE BUSHINGS (a) Gradually heat the cylinder head to 80 – 1002 C (176 –...

- Page 85 EG2–85 1MZ–FE ENGINE – ENGINE MECHANICAL HINT: Different bushings are used for the intake and exhaust. (e) Gradually heat the cylinder head to 80 – 1002C (176 – 2122F). (f) Using SST and a hammer, tap in a new guide bushing to the specified protrusion height.

- Page 86 EG2–86 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Check the valve head margin thickness. Standard margin thickness: 1.0 mm (0.039 in.) Minimum margin thickness: 0.5 mm (0.020 in.) If the margin thickness is less than minimum, replace the valve. (d) Check the valve overall length. Standard overall length: Intake 95.45 mm (3.5779 in.)

- Page 87 EG2–87 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Check the valve seating position. Apply a light coat of prussian blue (or white lead) to the valve face. Lightly press the valve against the seat. Do not rotate valve. (c) Check the valve face and seat for the following: If blue appears 3602 around the face, the valve is concentric.

- Page 88 EG2–88 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Using a vernier caliper, measure the free length of the valve spring. Free length: 45.50 mm (1.7913 in.) If the free length is not as specified, replace the valve spring. (c) Using a spring tester, measure the tension of the valve spring at the specified installed length.

- Page 89 EG2–89 1MZ–FE ENGINE – ENGINE MECHANICAL C. Inspect camshaft journals Using a micrometer, measure the journal diameter. Journal diameter: 26.949 – 26.965 mm (1.0610 – 1.061 6 in.) If the journal diameter is not as specified, check the oil clearance. D.

- Page 90 EG2–90 1MZ–FE ENGINE – ENGINE MECHANICAL (f) Measure the Plastigage at its widest point. Standard oil clearance: 0.035 – 0.072 mm (0.0014 – 0.0028 in.) Maximum oil clearance: 0.10 mm (0.0039 fn.) If the oil clearance is greater than maximum, replace the camshaft.

- Page 91 EG2–91 1MZ–FE ENGINE – ENGINE MECHANICAL H. Inspect camshaft gear spring Using a vernier caliper, measure the free distance between the spring ends. Free distance: 18.2 – 18.8 mm (0.712 – 0.740 in.) If the free distance is not as specified, replace the gear spring.

- Page 92 EG2–92 1MZ–FE ENGINE – ENGINE MECHANICAL 13. INSPECT INTAKE MANIFOLD Using a precision straight edge and feeler gauge, mea– sure the surface contacting the cylinder head and air intake chamber for warpage. Maximum warpage: Air Intake Chamber Side 0.15 mm (0.0059 in.) Cylinder Head Side 0.08 mm (0.0031 in.) If warpage is greater than maximum, replace the man–...

-

Page 93: Cylinder Head Assembly

EG2–93 1MZ–FE ENGINE – ENGINE MECHANICAL 16. IF NECESSARY, REPLACE SPARK PLUG TUBE GASKETS (a) Bend up the tab on the ventilation baffle plate which prevents the gasket from the slipping out. (b) Using a screwdriver and hammer, tap out the gasket. (c) Using needle–nose pliers, ply out the gasket. -

Page 94: Install Valves

EG2–94 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Using a press, press in a new spark plug tube until there is 42.4 – 43.4 mm (1.669 – 1.749) protruding from the camshaft bearing cap installation surface of the cylinder head. NOTICE: Avoid pressing a new spark plug tube In too far by measuring the amount of the protrusion while press–... - Page 95 EG2–95 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Using SST, compress the valve spring and place the 2 keepers around the valve stem. SST 09202 – 70010 (d) Using a plastic–faced hammer, lightly tap the valve stem tip to ensure a proper fit. 4.

-

Page 96: Cylinder Head Installation

EG2–96 1MZ–FE ENGINE – ENGINE MECHANICAL CYLINDER HEAD INSTALLATION (See Components for Removal and Installation) 1. INSTALL CYLINDER HEADS A. Place cylinder head on cylinder block (a) Place 2 new cylinder head gaskets in position on the cylinder block. NOTICE: Be careful of the installation direction. (b) Place the 2 cylinder heads in position on the cylinder head gaskets. - Page 97 EG2–97 1MZ–FE ENGINE – ENGINE MECHANICAL C. Install cylinder head (recessed head) bolts (a) Apply a light coat of engine oil on the threads and under the heads of the cylinder head bolts. (b) Using a 8 mm hexagon wrench, install the cylinder head bolt on each cylinder head, then repeat for the other side, as shown.

- Page 98 EG2–98 1MZ–FE ENGINE – ENGINE MECHANICAL (d) Using SST, align the holes of the camshaft main gear and sub–gear by turning camshaft sub–gear coun– terclockwise, and install a service bolt. SST 09960–10010 (09962–0100) HINT: Align the pins on the gears with the gear spring ends.

- Page 99 EG2–99 1MZ–FE ENGINE – ENGINE MECHANICAL (e) Remove any old packing (FIPG) material. (f) Apply seal packing to the No. 1 bearing cap as shown. Seal packing: Part No. 08826–00080 or equivalent (g) Install the 5 bearing caps in their proper locations. (h) Apply a light coat of engine oil on the threads and under the heads of the bearing cap bolts.

- Page 100 EG2–100 1MZ–FE ENGINE – ENGINE MECHANICAL (e) Apply a light coat of engine oil on the threads and under the heads of the bearing cap bolts. (f) Install and uniformly tighten the 10 bearing cap bolts, in several passes, in the sequence shown. Torque: 16 N–m (160 kgf–cm, 12 ft–Ibf) (g) Remove the service bolt C.

- Page 101 EG2–101 1MZ–FE ENGINE – ENGINE MECHANICAL (d) Install the oil seal to the camshaft. (e) Remove any old packing (FIPG) material. (f) Apply seal packing to the No. 1 bearing cap as shown. Seal packing: Part No. 08826–00080 or equivalent (g) Install the 5 bearing caps in their proper locations.

-

Page 102: Check And Adjust Valve Clearance

EG2–102 1MZ–FE ENGINE – ENGINE MECHANICAL (d) Install the 5 bearing caps in their proper locations. (e) Apply a light coat of engine oil on the threads and under the heads of bearing cap bolts. (f) Install and uniformly tighten the 10 bearing cap bolts, in several passes, in the sequence shown. - Page 103 EG2–103 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Install the 4 semi–circular plugs to the cylinder heads. 6. INSTALL CAMSHAFT POSITION SENSOR (a) Install a new gasket to the position sensor. (b) Install the positron sensor with the bolt. Torque: 8 N–m (80 kgf–cm, 69 in.–lbf) 7.

- Page 104 EG2–104 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Install the gasket to the cylinder head cover. (c) Install the cylinder head cover with the 8 bolts. Uni– formly tighten the bolts in several passes. Install the 2 cylinder head covers. Torque: 8 N–m (80 kgf–cm, 69 in.–lbf) 8.

- Page 105 EG2–105 1MZ–FE ENGINE – ENGINE MECHANICAL 9. INSTALL PS BRACKET Install the PS bracket with the 3 bolts. Torque: 43 N–m (440 kgf–cm, 32 ft–lbf) 10. INSTALL OIL DIPSTICK AND GUIDE (a) Install a new O–ring to the dipstick guide. (b) Apply soapy water to the 0–...

- Page 106 EG2–106 1MZ–FE ENGINE – ENGINE MECHANICAL 12. INSTALL No.2 ENGINE HANGER Install the engine hanger with the 2 bolts. Torque: 19.5 N–m (200 kgf–cm, 14 ft–lbf) 13. INSTALL WATER OUTLET (a) Connect the water outlet to the bypass hose. (b) Install 2 new gaskets and the water outlet with the 2 bolts, 2 nuts and 2 plate washers.

- Page 107 EG2–107 1MZ–FE ENGINE – ENGINE MECHANICAL (f) Place the delivery pipes together with the 6 injectors in position on the intake manifold. (g) Temporarily install the 4 bolts holding the delivery pipes to the intake manifold. (h) Check that the injectors rotate smoothly. HINT: If injectors do not rotate smoothly, the probable cause is incorrect installation of O–rings.

- Page 108 EG2–108 1MZ–FE ENGINE – ENGINE MECHANICAL 17. INSTALL TVV (a) Apply adhesive to 2 or 3 threads. Adhesive: Part No. 08833–00070, THREE BOND 1324 or equivalent (b) Install the TVV. Torque: 30 N–m (305 kgf–cm, 22 ft–lbf) 18. INSTALL FUEL PRESSURE REGULATOR (a) Apply a light coat of gasoline to a new 0–ring, and install it to the pressure regulator.

-

Page 109: Install Intake Manifold

EG2–109 1MZ–FE ENGINE – ENGINE MECHANICAL (d) Install the pressure regulator with the 2 bolts. Torque: 8 N–m (80 kgf–cm, 69 in.–lbf) 19. INSTALL INTAKE MANIFOLD Install the intake manifold with the 9 bolts, 2 nuts and 2 plate washers. Torque: 15 N–m (150 kgf–cm, 11 ft–lbf) 20. - Page 110 EG2–110 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Connect the water inlet pipe to the water inlet. (d) Install the bolt holding the water inlet pipe to the cylinder head. Torque: 19.5 N–m (200 kgf–cm, 14 ft–lbf) 23. INSTALL CYLINDER HEAD REAR PLATE (a) Install the rear plate and grand strap with the bolt and nut.

- Page 111 EG2–111 1MZ–FE ENGINE – ENGINE MECHANICAL 25. INSTALL NO.2 IDLER PULLEY (a) Install the idler pulley with the bolt. Torque: 43 N–m (440 kgf–cm, 32 ft–lbf) (b) Check that the idler pulley moves smoothly. 26. INSTALL RH CAMSHAFT TIMING PULLEY (a) Install the timing pulley, facing the flange side out–...

- Page 112 EG2–112 1MZ–FE ENGINE – ENGINE MECHANICAL 28. INSTALL TIMING BELT (See steps 6 to 27 on pages EG2–51 to 66) 29. INSTALL FRONT EXHAUST PIPE (a) Temporarily install 3 new gaskets and the front ex– haust pipe with the 2 bolts and 6 nuts. (b) Tighten the 4 nuts holding the exhaust manifolds to the front exhaust pipe.

- Page 113 EG2–113 1MZ–FE ENGINE – ENGINE MECHANICAL 32. CONNECT ENGINE WIRE TO ENGINE RH SIDE (a) Connect the following connectors: (1) 3 injector connectors (2) 3 ignition coil connectors (3) Water temperature sender gauge connector (4) Water temperature sensor connector (5) RH oxygens sensor connector (b) Connect the engine wire with the 5 nuts.

- Page 114 EG2–114 1MZ–FE ENGINE – ENGINE MECHANICAL 35. CONNECT ENGINE WIRE TO ENGINE LH SIDE (a) Connect the following connectors: (1) 3 injector connectors (2) 3 ignition coil connectors (b) Connect the engine wire with the 2 nuts. 36. INSTALL EGR VALVE AND VACUUM MODULATOR TO AIR INTAKE CHAMBER Install a new gasket, the EGR valve and vacuum mod–...

- Page 115 EG2–115 1MZ–FE ENGINE – ENGINE MECHANICAL 39. INSTALL INTAKE AIR CONTROL VALVE TO AIR INTAKE CHAMBER (a) Install a new gasket to the air intake chamber. (b) Apply a light coat of engine oil to the rubber portions. (c) Apply seal packing to the positions of the intake air control valve as shown in the illustration.

- Page 116 EG2–116 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL (3) Vacuum hose to charcoal canister (d) Connect the following connectors: (1) Throttle position sensor connector (2) IAC valve connector (3) EGR gas temperature sensor connector (4) A/C idle–up connector (e) Install 2 new gaskets and EGR pipe with the 4 nuts. Torque: 12 N–m (120 kgf–cm, 9 ft–lbf) (f) Install the No.1 engine hanger with the 2 bolts.

- Page 117 EG2–117 1MZ–FE ENGINE – ENGINE MECHANICAL (j) Connect the RH oxygen sensor connector clamp to the PS pressure tube. (k) Connect the ground strap with the bolt. (1) Connect the hydraulic pressure pipe to the air intake chamber with the bolt. (m) Connect the following hoses: (1) Brake booster vacuum hose (2) PCV hose...

- Page 118 EG2–118 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Connect the following vacuum hoses: (1) Vacuum hose to fuel pressure control VSV (2) Vacuum hose to fuel pressure regulator (3) Vacuum hose to cylinder head rear plate (4) Vacuum hose to intake air control valve VSV (5) Vacuum hose to EGR vacuum modulator (6) Vacuum hose to EGR valve 42.

- Page 119 EG2–119 1MZ–FE ENGINE – ENGINE MECHANICAL 46. CONNECT RADIATOR HOSES Connect the 2 hoses. 47. INSTALL RH ENGINE MOUNTING STAY Install the mounting stay with the 3 bolts. Torque: 31.4 N–m (320 kgf–cm, 23 ft–lbf) 48. CONNECT GROUND STRAPS Connect the 2 straps. 49.

- Page 120 EG2–120 1MZ–FE ENGINE – ENGINE MECHANICAL 51. CONNECT THROTTLE CABLE 52. CONNECT ACCELERATOR CABLE 53. FILL WITH ENGINE COOLANT Capacity: 8.7 liters (9.2 US qts, 7.7 Imp. qts) 54. INSTALL BATTERY TRAY AND BATTERY 55. START ENGINE AND CHECK FOR LEAKS 56.

- Page 121 EG2–121 1MZ–FE ENGINE – ENGINE MECHANICAL CYLINDER BLOCK COMPONENTS FOR ENGINE REMOVAL AND INSTALLATION...

- Page 122 EG2–122 1MZ–FE ENGINE – ENGINE MECHANICAL...

- Page 123 EG2–123 1MZ–FE ENGINE – ENGINE MECHANICAL...

-

Page 124: Engine Removal

EG2–124 1MZ–FE ENGINE – ENGINE MECHANICAL ENGINE REMOVAL (See Components for Engine Removal and Installation) 1. REMOVE BATTERY AND TRAY CAUTION: Work must be started after 90 seconds from the time the ignition switch is turned to the ”LOCK” position and the negative (–) terminal cable is discon– nected from the battery. -

Page 125: Remove Radiator

EG2–125 1MZ–FE ENGINE – ENGINE MECHANICAL 9. REMOVE RADIATOR (See page EG2–336) 10. DISCONNECT ENGINE WIRE (a) Remove the 2 bolts and disconnect the engine relay box. (b) Disconnect the following wires and connectors: (1) 5 connectors from relay box (2) 2 igniter connectors (3) Noise filter connector (4) Connector from LH fender apron... - Page 126 EG2–126 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL (2) Vacuum hose from charcoal canister (3) Brake booster vacuum hose from air intake cha– mber 12. DISCONNECT HEATER HOSES Disconnect the 2 hoses. 13. DISCONNECT FUEL HOSES Disconnect the fuel inlet and return hoses. CAUTION: Catch leaking fuel in a container.

- Page 127 EG2–127 1MZ–FE ENGINE – ENGINE MECHANICAL 15. DISCONNECT ENGINE WIRE FROM CABIN (a) Remove the following parts: (1) Under cover (2) Lower instrument panel (3) Glove compartment door (4) Glove compartment (b) Disconnect the following connectors: (1) 3 ECM connectors (2) 5 cowl wire connectors (3) Cooling fan ECU connector (c) Disconnect the wire clamp.

- Page 128 EG2–128 1MZ–FE ENGINE – ENGINE MECHANICAL 17. REMOVE FRONT EXHAUST PIPE (a) Remove the 2 bolts and exhaust pipe clamp. (b) Remove the 2 bolts, and disconnect the bracket. (c) Remove the 2 bolts and 2 nuts holding the front exhaust pipe to the three–way catalytic converter.

- Page 129 EG2–129 1MZ–FE ENGINE – ENGINE MECHANICAL 22. DISCONNECT LH ENGINE MOUNTING INSULATOR Remove the 4 bolts, and disconnect the mounting insulator. 23. DISCONNECT RR ENGINE MOUNTING INSULATOR (a) Remove the 2 hole plugs. (b) Remove the 4 nuts, and disconnect the mounting insulator.

- Page 130 EG2–130 1MZ–FE ENGINE – ENGINE MECHANICAL 27. REMOVE COOLANT RESERVOIR TANK (a) Disconnect the reservoir hose. (b) Using a screwdriver, remove the reservoir tank. 28. DISCONNECT GROUND STRAPS Disconnect the 2 straps. 29. REMOVE RH ENGINE MOUNTING STAY Remove the 3 bolts and RH engine mounting stay. 30.

- Page 131 EG2–131 1MZ–FE ENGINE – ENGINE MECHANICAL 31. REMOVE ENGINE AND TRANSAXLE ASSEMBLY PROM VEHICLE (a) Lift the engine out of the vehicle slowly and carefully. NOTICE: Be careful not to hit the PS gear housing or park/neutral position switch. (b) Make sure the engine is clear of all wiring, hoses and cables.

- Page 132 EG2–132 1MZ–FE ENGINE – ENGINE MECHANICAL COMPONENTS FOR ENGINE & TRANSAXLE SEPARATION AND ASSEMBLY ENGINE & TRANSAXLE SEPARATION (See Components for Engine & Transaxle Separation and Assembly) 1. DISCONNECT ENGINE WIRE (a) Disconnect the following connector: (1) O/D solenoid connector (2) PNP switch speedometer (3) Starter 50 terminal (4) Starter B terminal...

-

Page 133: Remove Starter

EG2–133 1MZ–FE ENGINE – ENGINE MECHANICAL 2. REMOVE OIL DIPSTICK GUIDE AND DIPSTICK FOR TRANSAXLE (a) Remove the mounting bolt. (b) Pull out the dipstick guide and dipstick from the port of transaxle. (c) Remove the 0–ring from the dipstick guide. 3. - Page 134 EG2–134 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Remove the bolt, nut and No.2 manifold stay. (c) Remove the 2 bolts holding the No.2 oil pan to the transaxle. (d) Remove the 6 bolts holding the engine to the trans– axle. (e) Remove the transaxle together with the torque con–...

- Page 135 EG2–135 1MZ–FE ENGINE – ENGINE MECHANICAL COMPONENTS FOR PREPARATION AND AFTER ASSEMBLY...

-

Page 136: Preparation For Disassembly

EG2–136 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL PREPARATION FOR DISASSEMBLY (See Components for Cylinder Block Preparation of Disassembly and After Assembly) 1. INSTALL ENGINE TO ENGINE STAND FOR DISASSEMBLY 2. REMOVE TIMING BELT AND PULLEYS (See pages EG2–42 to 47) 3. -

Page 137: Remove Water Pump

EG2–137 1MZ–FE ENGINE – ENGINE MECHANICAL 8. REMOVE KNOCK SENSORS (a) Disconnect the 2 knock sensor connectors. (b) Remove the wire band. (c) Disconnect the engine wire clamp. (d) Using SST, remove the 2 knock sensors. SST 09816 – 30010 9. - Page 138 EG2–138 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Insert the blade of SST between the No. 1 and No.2 oil pans, and cut off applied sealer and remove the No. 1 oil pan. SST 09032 – 00100 NOTICE: Be careful not to the damage the No.2 oil pan con– tact surface of the No.1 oil pan.

-

Page 139: Remove Oil Pump

EG2–139 1MZ–FE ENGINE – ENGINE MECHANICAL 14. REMOVE OIL PUMP (a) Remove the 9 bolts. (b) Remove the oil pump by prying a screwdriver between the oil pump and main bearing cap. (c) Remove the 0–ring. 15. REMOVE OIL FILTER Using SST, remove the oil filter. - Page 140 EG2–140 1MZ–FE ENGINE – ENGINE MECHANICAL 18. REMOVE ENGINE COOLANT DRAIN COCK 19. REMOVE OIL PRESSURE SWITCH Using SST, remove the oil pressure switch. SST 09816 – 30010 20. REMOVE EGR COOLER Remove the 3 bolts, 2 nuts, EGR cooler and gasket.

-

Page 141: Components For Cylinder Block Disassembly And Assembly

EG2–141 1MZ–FE ENGINE – ENGINE MECHANICAL COMPONENTS FOR CYLINDER BLOCK DISASSEMBLY AND ASSEMBLY... -

Page 142: Cylinder Block Disassembly

EG2–142 1MZ–FE ENGINE – ENGINE MECHANICAL CYLINDER BLOCK DISASSEMBLY (See Components for Disassembly and Assembly) 1. REMOVE REAR OIL SEAL RETAINER (a) Remove the 6 bolts. (b) Using a screwdriver, remove the oil seal retainer by prying the portions between the oil seal retainer and main bearing cap. - Page 143 EG2–143 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Using the 2 removed connecting rod cap bolts, remove the connecting rod cap and lower bearing by wiggling the connecting rod cap right and left. HINT: Keep the lower bearing inserted with the con– necting rod cap.

- Page 144 EG2–144 1MZ–FE ENGINE – ENGINE MECHANICAL Measure the Plastigage at its widest point. Standard oil clearance: 0.038 – 0.064 mm (0.0015 – 0.0025 in.) Maximum oil clearance: 0.08 mm (0.0031 in.) If the oil clearance is greater than maximum, replace the bearings.

- Page 145 EG2–145 1MZ–FE ENGINE – ENGINE MECHANICAL HINT: Keep the bearings, connecting rod and cap to– gether. Arrange the piston and connecting rod assembl– ies in correct order. 5. CHECK CRANKSHAFT THRUST CLEARANCE Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

- Page 146 EG2–146 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Uniformly loosen and remove the 16 main bearing cap bolts, in several passes, in the sequence shown. (c) Using a screwdriver, pry out main bearing caps, remove the 4 main bearing caps, lower bearings and (No.2 main bearing cap only) 2 lower thrust washers.

- Page 147 EG2–147 1MZ–FE ENGINE – ENGINE MECHANICAL (i) Install the 4 main bearing caps. (See step 4 on pages EG2–165) 12 Pointed Head Bolts: Torque: 1 st 22 N–m (225 kgf–cm, 16 ft–lbf) 2nd Turn extra 902 Hexagon Head Bolts: Torque: 27 N–m (275 kgf–cm, 20 ft–lbf) NOTICE: Do not turn the crankshaft.

- Page 148 EG2–148 1MZ–FE ENGINE – ENGINE MECHANICAL Reference: Cylinder block main journal bore diameter (A): Mark ”00’ 66.000 mm (2.5984 in.) Mark ’01’ 66.001 mm (2.5985 in.) Mark ”02” 66.002 mm (2.5985 in.) Mark ’03’ 66.003 mm (2.5985 in.) Mark ”04’ 66.004 mm (2.5986 in.) Mark ’05’...

- Page 149 EG2–149 1MZ–FE ENGINE – ENGINE MECHANICAL Crankshaft main journal diameter (B): Mark ’00” 61.000 mm (2.401 6 in.) Mark ”01’ 60.999 mm (2.4015 in.) Mark ’02’ 60.998 mm (2.4015 in.) Mark ”03” 60.997 mm (2.4015 in.) Mark ’04’ 60.996 mm (2.4014 in.) Mark ’05’...

-

Page 150: Remove Crankshaft

EG2–150 1MZ–FE ENGINE – ENGINE MECHANICAL Standard sized Bearing Selection Chart Cylinder block number mark Crankshaft number mark EXAMPLE: Cylinder block ”06”, Crankshaft ”08” = Use bearing ”3” (l) Completely remove the Plastigage. 7. REMOVE CRANKSHAFT (a) Lift out the crankshaft. (b) Remove the 4 upper main bearings and 2 upper thrust washers from the cylinder block. -

Page 151: Cylinder Block Inspection And Repair

EG2–151 1MZ–FE ENGINE – ENGINE MECHANICAL CYLINDER BLOCK INSPECTION AND REPAIR 1. CLEAN CYLINDER BLOCK A. Remove gasket material Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block. B. Clean cylinder block Using a soft brush and solvent, thoroughly clean the cylinder block. - Page 152 EG2–152 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL 4. INSPECT CYLINDER BORE DIAMETER Using a cylinder gauge, measure the cylinder bore diameter at positions A, B and C in the thrust and axial directions. Standard diameter: 87.500 – 87.512 mm (3.4449 – 3.4453 in.) Maximum diameter: 87.52 mm (3.4457 in.) If the diameter is greater than maximum, replace the...

-

Page 153: Piston And Connecting Rod Disassembly

EG2–153 1MZ–FE ENGINE – ENGINE MECHANICAL PISTON AND CONNECTING ROD DISASSEMBLY 1. CHECK FIT BETWEEN PISTON AND PISTON PIN Try to move the piston back and forth on the piston pin. If any movement is felt, replace the piston and pin as a set. -

Page 154: Piston And Connecting Rod Inspection

EG2–154 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Using a plastic–faced hammer and brass bar, lightly tap out the piston pin and remove the connecting rod. HINT: The piston and pin are a matched set. Arrange the pistons, pins, rings, connecting rods and bearings in correct order. -

Page 155: Inspect Piston

EG2–155 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Using solvent and a brush, thoroughly clean the piston. NOTICE: Do not use a wire brush. 2. INSPECT PISTON A. Inspect piston oil clearance (a) Using a micrometer, measure the piston diameter at ring angles to the piston pin center line, 23.2 mm (0.913 in.) from the piston head. -

Page 156: Inspect Connecting Rod

EG2–156 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL C. Inspect piston ring end gap (a) Insert the piston ring into the cylinder bore. (b) Using a piston, push the piston ring a little beyond the bottom of the ring travel, 105 mm (4.13 in.) from the top of the cylinder block. - Page 157 EG2–157 1MZ–FE ENGINE – ENGINE MECHANICAL Check for twist Maximum twist: 0.15 mm (0.0059 in.) per 100 mm (3.94 in.) If twist is greater than maximum, replace the connect– ing rod assembly. B. Inspect piston pin oil clearance (a) Using a caliper gauge, measure the inside diameter of the connecting rod bushing.

- Page 158 EG2–158 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Align the oil holes of a new bushing and the connect– ing rod. (c) Using SST and a press, press in the bushing. SST 09222–30010 (d) Using a pin hole grinder, hone the bushing to obtain the standard specified clearance (see step B above) between the bushing and piston pin.

-

Page 159: Crankshaft Inspection

EG2–159 1MZ–FE ENGINE – ENGINE MECHANICAL CRANKSHAFT INSPECTION 1. INSPECT CRANKSHAFT FOR CIRCLE RUNOUT (a) Place the crankshaft on V–blocks. (b) Using a dial indicator, measure the circle runout, as shown in the illustration. Maximum circle runout: 0.06 mm (0.0024 in.) If the circle runout is greater than maximum, replace the crankshaft. - Page 160 EG2–160 1MZ–FE ENGINE – ENGINE MECHANICAL CRANKSHAFT OIL SEALS REPLACEMENT HINT: There are 2 methods (A and B) to replace the oil seal which are as follows: 1. REPLACE CRANKSHAFT FRONT OIL SEAL A. If oil pump is removed from cylinder block: (a) Using a screwdriver, pry out the oil seal.

- Page 161 EG2–161 1MZ–FE ENGINE – ENGINE MECHANICAL 2. REPLACE CRANKSHAFT REAR OIL SEAL A. If rear oil seal retainer is removed from cylinder block: (a) Using a screwdriver and hammer, tap out the oil seal. (b) Using SST and a hammer, tap in a new oil seal until its surface is flush with the rear oil seal retainer edge.

-

Page 162: Piston And Connecting Rod Assembly

EG2–162 1MZ–FE ENGINE – ENGINE MECHANICAL PISTON AND CONNECTING ROD ASSEMBLY 1. ASSEMBLE PISTON AND CONNECTING ROD (a) Using a small screwdriver, install a new snap ring at one end of the piston pin hole. HINT: Be sure that end gap of the snap ring is not aligned with the pin hole cutout portion of the piston. -

Page 163: Install Piston Rings

EG2–163 1MZ–FE ENGINE – ENGINE MECHANICAL 2. INSTALL PISTON RINGS (a) Install the oil ring expander and 2 side rails by hand. (b) Using a piston ring expander, install the 2 compres– sion rings with the code mark facing upward. Code mark: No.1 1RorT... -

Page 164: Cylinder Block Assembly

EG2–164 1MZ–FE ENGINE – FE ENGINE – ENGINE MECHANICAL CYLINDER BLOCK ASSEMBLY (See Components for Disassembly and Assembly) HINT: Thoroughly clean all parts to be assembled. Before installing the parts, apply new engine oil to all sliding and and rotating surfaces. Replace all gaskets, 0–rings and oil seals with new parts. - Page 165 EG2–165 1MZ–FE ENGINE – ENGINE MECHANICAL 3. PLACE CRANKSHAFT ON CYLINDER BLOCK 4. INSTALL MAIN BEARING CAPS AND LOWER THRUST WASHERS A. Place main bearing caps and lower thrust washers on cylinder block (a) Install the 2 thrust washers on the No.2 bearing cap with the grooves facing outward.

- Page 166 EG2–166 1MZ–FE ENGINE – ENGINE MECHANICAL B. Install main bearing cap bolts (for 12 Pointed Head Bolts) HINT: The main bearing cap bolts are tightened in 2 progressive steps (steps (b) and (d)). If any of the main bearing cap bolts is broken or deformed, replace it.

-

Page 167: Install Connecting Rod Caps

EG2–167 1MZ–FE ENGINE – ENGINE MECHANICAL 5. CHECK CRANKSHAFT THRUST CLEARANCE Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver. Standard thrust clearance: 0.04 – 0.24 mm (0.0016 – 0.0095 in.) Maximum thrust clearance: 0.30 mm (0.0118 in.) If the thrust clearance is greater than maximum, re–... - Page 168 EG2–168 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Check that the protrusion of the connecting rod cap is facing in the correct direction. B. Install connecting rod cap bolts HINT: The connecting rod cap bolts are tightened in 2 progressive steps (steps (b) and (d)). If any of the connecting rod cap bolts is broken or deformed, replace it.

- Page 169 EG2–169 1MZ–FE ENGINE – ENGINE MECHANICAL 8. CHECK CONNECTING ROD OIL CLEARANCE Using a dial indicator, measure the thrust clearance while moving the connecting rod back and forth. Standard thrust clearance: 0.15 – 0.30 mm (0.0059 – 0.0118 in.) Maximum thrust clearance: 0.35 mm (0.0138 in.) If the thrust clearance is greater than maximum, re–...

-

Page 170: After Assembly

EG2–170 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Install the oil seal retainer with the 6 bolts. Torque: 8 N–m (80 kgf–cm, 69 in.–lbf) AFTER ASSEMBLY (See Components for Cylinder Block Preparation of Disassembly and After Assembly) 1. INSTALL EGR COOLER Install a new gasket and the EGR cooler with the 3 bolts and 2 nuts. - Page 171 EG2–171 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Install the drain cock. Torque: 39 N–m (400 kgf–cm, 29 ft–lbf) HINT: After applying the specified torque, rotate the drain cock clockwise until it is in the position shown. 4. INSTALL WATER SEAL PLATE (a) Remove any old packing (FIPG) material and be care–...

-

Page 172: Install Oil Filter

EG2–172 1MZ–FE ENGINE – ENGINE MECHANICAL 5. INSTALL OIL FILTER UNION Using a 12 mm hexagon wrench, install the oil filter union. Torque: 13 N–m (130 kgf–cm, 9 ft–lbf) 6. INSTALL OIL FILTER (a) Apply clean engine oil to the gasket of anew oil filter. (b) Lightly screw the oil filter into place, and tighten it until the gasket contacts the seat. - Page 173 EG2–173 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Apply seal packing to the oil pump as shown in the illustration. Seal packing: Part No. 08826–00080 or equivalent Install a nozzle that has been cut to a 2–3 mm (0.08–0.12 in.) opening. HINT: Avoid applying an excessive amount to the surface.

- Page 174 EG2–174 1MZ–FE ENGINE – ENGINE MECHANICAL 8. INSTALL N0.1 OIL PAN (a) Remove any old packing (FIPG) material and be care– ful not to drop any oil on the contact surface of the No.1 oil pan and cylinder block. Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing grooves.

-

Page 175: Install Water Pump

EG2–175 1MZ–FE ENGINE – ENGINE MECHANICAL 10. INSTALL NO.2 OIL PAN (a) Remove any old packing (FIPG) material and be care– ful not to drop any oil on the contact surface of the No.1 and No.2 oil pans. Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing grooves. - Page 176 EG2–176 1MZ–FE ENGINE – ENGINE MECHANICAL 12. INSTALL WATER INLET HOUSING (a) Remove any old packing (FIPG) material and be care– ful not to drop any oil on the contact surfaces of the water inlet housing and cylinder block. Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing grooves.

- Page 177 EG2–177 1MZ–FE ENGINE – ENGINE MECHANICAL (b) Connect the 2 knock sensor connectors. (c) Install the wire band. (d) Connect the engine wire clamp. 14. INSTALL NO.2 IDLER PULLEY BRACKET Install the pulley bracket with the 2 bolts. Torque: 28 N–m (290 kgf–cm, 21 ft–lbf) 15.

- Page 178 EG2–178 1MZ–FE ENGINE – ENGINE MECHANICAL ENGINE & TRANSAXLE ASSEMBLY (See Components for Engine & Transaxle Separation and Assembly) 1. INSTALL DRIVE PLATE (a) Install the front spacer on the crankshaft with the chamfered end facing the shaft. (b) Install the drive pate and rear spacer on the crank– shaft.

- Page 179 EG2–179 1MZ–FE ENGINE – ENGINE MECHANICAL 3. INSTALL TRANSAXLE TO ENGINE A. Install transaxle (a) Attach the transaxle to the engine. (b) Install the6 bolts. Torque: 64 N–m (650 kgf–cm, 47 ft–lbf) (c) Install the 2 bolts holding the No.2 oil pan to the transaxle.

- Page 180 EG2–180 1MZ–FE ENGINE – ENGINE MECHANICAL (c) Hold the crankshaft pulley bolt with a wrench, and install the 6 bolts evenly. Torque: 41 N–m (420 kgf–cm, 30 ft–lbf) HINT: First install the dark green colored bolt, then install the other bolts. (d) Install the flywheel housing under cover with the 2 bolts.

-

Page 181: Engine Installation

EG2–181 1MZ–FE ENGINE – ENGINE MECHANICAL ENGINE INSTALLATION (See Components for Engine Removal and Installation) 1. INSTALL FRONT EXHAUST PIPE STAY Install the pipe stay with the 2 bolts. Torque: 21 N–m (210 kgf–cm, 16 ft–lbf) 2. INSTALL RR ENGINE MOUNTING INSULATOR Install the mounting insulator with the 4 bolts. - Page 182 EG2–182 1MZ–FE ENGINE – ENGINE MECHANICAL 5. INSTALL N0.2 ENGINE MOUNTING BRACKET AND ENGINE MOVING CONTROL ROD Install the engine moving control rod and No.2 engine mounting bracket with the 3 bolts. Torque: 63.7 N–m (650 kgf–cm, 47 ft–lbf) 6. INSTALL RH ENGINE MOUNTING STAY Install the RH mounting stay with the 3 bolts.

- Page 183 EG2–183 1MZ–FE ENGINE – ENGINE MECHANICAL 10. INSTALL ENGINE MOUNTING ABSORBER Install the engine mounting absorber with the 4 bolts. Torque: 48 N–m (490 kgf–cm, 35 ft–lbf) 11. CONNECT RR ENGINE MOUNTING INSULATOR (a) Connect the mounting insulator with the 4 nuts. Torque: 65.7 N–m (670 kgf–cm, 48 ft–lbf) (b) Install the 2 hole plugs.

- Page 184 EG2–184 1MZ–FE ENGINE – ENGINE MECHANICAL 16. CONNECT PS PRESSURE TUBE (a) Connect the PS pressure tube with the 2 nuts. (b) Connect the 2 PS air hoses. 17. INSTALL DRIVE SHAFTS (See SA section) 18. INSTALL FRONT EXHAUST PIPE (a) Temporarily install 3 new gaskets and the front ex–...

- Page 185 EG2–185 1MZ–FE ENGINE – ENGINE MECHANICAL 20. CONNECT ENGINE WIRE TO CABIN (a) Push in the engine wire through the cowl panel. Install the 2 nuts. (b) Connect the wire clamp. (c) Connect the following connectors: (1) 3 engine ECM connectors (2) 5 cowl wire connectors (3) Cooling fan ECU connector (d) Install the following parts:...

- Page 186 EG2–186 1MZ–FE ENGINE – ENGINE MECHANICAL 22. CONNECT FUEL HOSES (a) Connect the fuel return hose to the fuel pipe. (b) Connect the fuel inlet hose to the fuel filter. Torque: 30 N–m (300 kgf–cm, 22 ft–lbf) 23. CONNECT HEATER HOSES Connect the 2 hoses.

-

Page 187: Install Radiator

EG2–187 1MZ–FE ENGINE – ENGINE MECHANICAL 25. CONNECT ENGINE WIRE (a) Connect the wire clamps. (b) Connect the ground strap with the bolt. (c) Connect the connector to the LH fender apron. (d) Connect the wire clamps (e) Connect the following wires and connectors: (1) 2 igniter connectors (2) Noise filter connector (3) Connector to LH fender apron... - Page 188 EG2–188 1MZ–FE ENGINE – ENGINE MECHANICAL 28. INSTALL AIR CLEANER CAP, VOLUME AIR FLOW METER AND AIR CLEANER HOSE (a) Connect the air cleaner hose, and install the air clean– er cap and volume air flow meter with the 4 clips. (b) Tighten the air cleaner hose clamp bolt.

-

Page 189: Exhaust System Components

EG2–189 1MZ–FE ENGINE – ENGINE MECHANICAL EXHAUST SYSTEM COMPONENTS... - Page 190 EG2–190 1MZ–FE ENGINE – – ENGINE MECHANICAL SERVICE SPECIFICATIONS SERVICE DATA Engine tune – up Intake manifold vacuum Compression pressure Tinning belt tensioner...

- Page 191 EG2–191 1MZ–FE ENGINE – ENGINE MECHANICAL Cylinder head Valve guide bushing Valve Valve spring Valve lifter Camshaft Air intake chamber...

- Page 192 EG2–192 1MZ–FE ENGINE – ENGINE MECHANICAL Intake manifold Exhaust manifold Cylinder block Piston and piston ring Connecting...

-

Page 193: Torque Specifications

EG2–193 1MZ–FE ENGINE – ENGINE MECHANICAL Connecting rod (Cont’d) Crankshaft TORQUE SPECIFICATIONS Part tightened Cylinder head cover x Cylinder head Spark plug x Cylinder head Ignition coil x Cylinder head cover Air intake chamber x Intake manifold EGR pipe x Exhaust manifold EGR pipe x Air intake chamber No.1 engine hanger x Air intake chamber No.1 engine hanger x Cylinder heed... - Page 194 EG2–194 1MZ–FE ENGINE – ENGINE MECHANICAL Camshaft timing pulley x Camshaft (For use with SST) Camshaft timing pulley x Camshaft Timing belt tensioner x Oil pump Engine RH mounting bracket x Cylinder block No.2 timing belt cover x No.3 timing belt cover No.1 timing belt cover x Oil pump Crankshaft pulley x Crankshaft No.2 generator bracket x Engine RH mounting bracket...

- Page 195 EG2–195 1MZ–FE ENGINE – ENGINE MECHANICAL Oil pressure switch x Cylinder block Engine coolant drain cock x Cylinder block Water seal plate x Cylinder block Oil filter union x Cylinder block Oil pump x Cylinder block (10 mm head bolt) Oil pump x Cylinder block (12 mm head bolt) No.1 oil pan x Cylinder block No.1 oil pan x Oil pump...

- Page 196 EG2–196 1MZ–FE ENGINE – FE ENGINE – EMISSION CONTROL SYSTEMS EMISSION CONTROL SYSTEMS DESCRIPTION The emission control systems are installed to reduce the amount of HC, CO and NOx emitted from the engine, and to also prevent release of evaporated fuel from the gasoline tank and prevent atmospheric release of blow–by gas.

-

Page 197: Component Layout

EG2–197 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS COMPONENT LAYOUT... -

Page 198: Schematic Drawing

EG2–198 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS SCHEMATIC DRAWING... -

Page 199: Recommended Tools

1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS PREPARATION SST (SPECIAL SERVICE TOOL) 09843–18020 Diagnosis Check Wire RECOMMENDED TOOLS 09082–00050 TOYOTA Electrical Tester Set EQUIPMENT Tachometer Torque wrench Vacuum gauge SSM (SPECIAL SERVICE MATERIALS) 08833–00070 Adhesive 1311, THREE BOND 1311 or equivalent... -

Page 200: Operation

EG2–200 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM DESCRIPTION To reduce HC emission, crankcase blow–by gas is routed through the PCV valve to the air intake chamber for combustion in the cylinders. OPERATION Normal Operation Engine not Running Idling or Deceleration Acceleration or High Load... - Page 201 EG2–201 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS PCV VALVE INSPECTION 1. REMOVE PCV VALVE (a) Disconnect the PCV hose from the PCV valve. (b) Remove the PCV valve. 2. INSTALL CLEAN HOSE TO PCV VALVE 3. INSPECT PCV VALVE OPERATION (a) Blow air into the cylinder head side, and check that air passes through easily.

- Page 202 EG2–202 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM DESCRIPTION To reduce HC emission, evaporated fuel from the fuel tank is routed through the charcoal canister to the intake manifold for combustion in the cylinders. OPERATION Engine Check Canister Check Valve Throttle Valve...

- Page 203 EG2–203 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS FUEL VAPOR LINES, FUEL TANK AND TANK CAP INSPECTION 1. VISUALLY INSPECT LINES AND CONNECTIONS Look for loose connections, sharp bends or damage. 2. VISUALLY INSPECT FUEL TANK Look for deformation, cracks or fuel leakage. 3.

- Page 204 EG2–204 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS 4. CLEAN FILTER IN CANISTER Clean the filter by blowing 294 kPa (3 kgf/cm , 43 psi) of compressed air into port A while holding port B closed. NOTICE: Do not attempt to wash the canister. No activated carbon should come out.

-

Page 205: Check Valve Inspection

EG2–205 1MZ–FE ENGINE – FE ENGINE – EMISSION CONTROL SYSTEMS CHECK VALVE INSPECTION 1. REMOVE CHECK VALVE 2. INSPECT CHECK VALVE (a) Check that air flows from the yellow port to the black port. (b) Check that air does not flow from the black port to the yellow port. - Page 206 EG2–206 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS EXHAUST GAS RECIRCULATION (EGR) SYSTEM DESCRIPTION To reduce NOx emission, part of the exhaust gases are recirculated through the EGR valve to the intake manifold to lower the maximum combustion temperature. OPERATION...

- Page 207 EG2–207 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS Engine Exhaust EG R EG R Vacuum Throttle Valve Pressure in the EGR Coolant Modulator Position Valve Valve Pressure Chamber Temp. Below CLOSED 55°C OPENS passage recirculated (131°F) to atmosphere Positioned below CLOSED port E recirculated OPENS passage...

- Page 208 EG2–208 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS 5. INSPECT VSV OPERATION WITH COLD ENGINE (a) The engine coolant temperature should be below 552 C (11312F). (b) Check that the vacuum gauge indicates zero at 2,800 rpm. (c) Check that the EGR pipe is not hot. 6.

- Page 209 EG2–209 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS 8. REMOVE VACUUM GAUGE Remove the vacuum gauge, and reconnect the vacuum hoses to their proper locations. 9. INSPECT EGR VALVE (a) Apply vacuum directly to the EGR valve with the engine idle. (b) Check that the engine runs rough or dies.

- Page 210 EG2–210 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS C. Inspect VSV operation (a) Check that the air flows from ports E to G. (b) Apply battery voltage across the terminals. (c) Check that the air flows from port E to the gas filter. If operation is not as specified, replace the VSV.

- Page 211 EG2–211 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS 3. RECONNECT VACUUM HOSES TO EGR VACUUM MODULATOR Connect the following vacuum hoses: (1) Vacuum hose to P port (2) Vacuum hose to Q port (3) Vacuum hose to R port EGR VALVE INSPECTION 1.

- Page 212 EG2–212 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS 4. SEPARATE EGR VALVE AND VACUUM MODULATOR (a) Remove the nut and disconnect the EGR vacuum modulator. (b) Disconnect the pressure hose from the EGR valve and remove the EGR vacuum modulator. 5. REMOVE EGR GAS TEMPERATURE SENSOR 6.

- Page 213 EG2–213 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS 7. REINSTALL EGR GAS TEMPERATURE SENSOR Torque: 20 N–m (200 kgf–cm, 14 ft–lbf) 8. REASSEMBLE EGR VALVE AND VACUUM MODULATOR (a) Connect the pressure hose to the EGR valve. (b) Install the EGR vacuum modulator with the nut. Torque: 12 N–m (120 kgf–cm, 9 ft–lbf) 9.

- Page 214 EG2–214 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS (b) Install and torque the 3 nuts. Torque: 12 N–m (120 kgf–cm, 9 ft–lbf) (c) Connect the following vacuum hoses: (1) Vacuum hose to P port of EGR vacuum modula– (2) Vacuum hose to a port of EGR vacuum modula– (3) Vacuum hose to R port of EGR vacuum modula–...

- Page 215 EG2–215 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS THREE–WAY CATALYTIC CONVERTER (TWC) SYSTEM DESCRIPTION To reduce HC. CO and NOx emissions, they are oxidized, reduced and converted to nitrogen (N carbon dioxide (C0 ) and water (H 0) by the three–way catalytic converter. OPERATION Exhaust Gas Exhaust port...

-

Page 216: Torque Specifications

EG2–216 1MZ–FE ENGINE – EMISSION CONTROL SYSTEMS HEAT INSULATOR INSPECTION 1. CHECK HEAT INSULATOR FOR DAMAGE 2. CHECK FOR ADEQUATE CLEARANCE BETWEEN CATALYTIC CONVERTER AND HEAT INSULATOR THREE–WAY CATALYTIC CONVERTER REPLACEMENT 1. REMOVE CONVERTER (a) Jack up the vehicle. (b) Check that the converter is cool. (c) Remove the 4 bolts and nuts holding the pipes to the converter. -

Page 217: Sfi System

EG2–217 1MZ–FE ENGINE – SFI SYSTEM SFI SYSTEM DESCRIPTION... - Page 218 The air induction system provides sufficient air for engine operation. ELECTRONIC CONTROL SYSTEM The 1 MZ–FE engine is equipped with a TOYOTA Computer Controlled System (TCCS) which centrally controls the SFI, ESA, IAC, diagnosis systems etc. by means of ECM–formerly SFI computer employing a microcomputer.

-

Page 219: System Circuit

EG2–219 1MZ–FE ENGINE – SFI SYSTEM SYSTEM CIRCUIT... - Page 220 EG2–220 1MZ–FE ENGINE – SFI SYSTEM OPERATION FUEL SYSTEM Fuel is pumped up by the fuel pump, which flows through the fuel filter under pressure through the fuel pipe to the delivery pipe where it is distributed to each injector. The fuel pressure regulator adjusts the pressure of the fuel from the fuel line (high pressure side) to a pressure 284 kPa (2.9 kgf/cm , 41 psi) higher than the pressure inside the intake manifold,...

-

Page 221: Air Induction System

EG2–221 1MZ–FE ENGINE – SFI SYSTEM AIR INDUCTION SYSTEM Air filtered through the air cleaner passes through the MAF meter and the amount flowing to the air intake chamber is determined by the throttle valve opening in the throttle body and the engine speed. -

Page 222: Electronic Control System

EG2–222 1MZ–FE ENGINE – SFI SYSTEM ELECTRONIC CONTROL SYSTEM The control system consists of sensors which detect various engine conditions, and an ECM which determines the injection volume (timing) based on the signals from the sensors. The various sensors detect the intake air volume, engine speed, oxygen density in the exhaust gas, engine coolant temperature and intake air temperature etc. -

Page 223: Recommended Tools

Fuel line flare nut 14 x 17 mm Wrench Set 09842–30070 Wiring ”F” EFI Inspection 09843–18020 Diagnosis Check Wire RECOMMENDED TOOLS 09082–00050 TOYOTA Electrical Tester Set 09200–00010 Engine Adjust Kit Plug for the vacuum hose, fuel 09258–00030 Hose Plug Set hose etc. - Page 224 EG2–224 1MZ–FE ENGINE – SFI SYSTEM EQUIPMENT Graduated cylinder Injector Carburetor cleaner Throttle body Sound scope Injector Tachometer Torque wrench Vacuum gauge Soft brush Throttle body SSM (SPECIAL SERVICE MATERIALS) 08826–00080 Seal packing or equivalent Intake air control valve COOLANT Item Capacity Classification...

-

Page 225: Maintenance Precautions

EG2–225 1MZ–FE ENGINE – SFI SYSTEM PRECAUTION 1. Before working on the fuel system, disconnect the negative (–) terminal cable from the battery. HINT: Any diagnostic trouble code retained by the computer will be erased when the battery terminal is removed. - Page 226 EG2–226 1MZ–FE ENGINE – SFI SYSTEM IF VEHICLE IS EQUIPPED WITH MOBILE RADIO SYSTEM (HAM, CB, ETC.) If the vehicle is equipped with a mobile communica– tion system, refer to the precaution in the IN section. AIR INDUCTION SYSTEM 1. Separation of the engine oil dipstick, oil filler cap, PCV hose, etc.

-

Page 227: Fuel System

EG2–227 1MZ–FE ENGINE – SFI SYSTEM 8. Care is required when pulling out and inserting wiring connectors. (a) Release the lock and pull out the connector, pulling on the connectors. (b) Fully insert the connector and check that it is locked. 9. - Page 228 EG2–228 1MZ–FE ENGINE – SFI SYSTEM Flare Nut Type: (a) Apply a light coat of engine oil to the flare nut, and tighten the flare nut by hand. M Using SST, tighten the flare nut to specified torque. SST 09631– 22020 NOTICE: Do not rotate the fuel pipe, when tightening the flare nut.

- Page 229 EG2–229 1MZ–FE ENGINE – SFI SYSTEM (b) With engine stopped, turn the ignition switch ON. (c) Pinch the fuel return hose. The pressure in the high pressure line will rise to approx. 392 kPa (4 kgf/cm 57 psi). In this state, check to see that there are no leaks from any part of the fuel system.

- Page 230 EG2–230 1MZ–FE ENGINE – SFI SYSTEM FUEL PUMP ON–VEHICLE INSPECTION 1. CHECK FUEL PUMP OPERATION (a) Using SST, connect terminals +B and FP of the DLC SST 09843–18020 (b) Turn the ignition switch ON. NOTICE: Do not start the engine. (c) Check that there is pressure in the fuel inlet hose from the fuel filter.

- Page 231 EG2–231 1MZ–FE ENGINE – SFI SYSTEM (e) Remove the SST from the DLC1. SST 09843–18020 2. CHECK FUEL PRESSURE (a) Check the battery voltage is above 12 V. (b) Disconnect the negative (–) terminal cable from the battery. CAUTION: Work must be started after 90 seconds from the time the ignition switch Is turned to the ”LOCK”...

- Page 232 EG2–232 1MZ–FE ENGINE – SFI SYSTEM (f) Using SST, connect terminals +B and FP of the DLC (g) Reconnect the negative (–) terminal cable to the battery. (h) Turn the ignition switch ON. (i) Measure the fuel pressure. Fuel pressure: 266 –...

- Page 233 EG2–233 1MZ–FE ENGINE – SFI SYSTEM (m) Measure the fuel pressure at idle. Fuel pressure: 265 – 304 kPa (2.7 – 3.1 kgf/cm , 39 – 44 psi) (n) Reconnect the vacuum sensing hose to the fuel pres– sure regulator. (o) Measure the fuel pressure at idle.

-

Page 234: Fuel Pump Inspection

EG2–234 1MZ–FE ENGINE – Sf=I SYSTEM (s) Connect the fuel inlet hose with 2 new gaskets and the union bolt. Torque: 29 N–m (300 kgf–cm, 22 ft–lbf) (t) Reconnect the negative (–) terminal cable to the battery. (u) Check for fuel leakage. (See page EG2–228) FUEL PUMP INSPECTION 1. -

Page 235: Fuel Pump Removal

EG2–235 1MZ–FE ENGINE – SFI SYSTEM COMPONENTS FOR REMOVAL AND INSTALLATION FUEL PUMP REMOVAL (See Components for Removal and Installation) CAUTION: Do not smoke or work near an open flame when working on the fuel pump. 1. DISCONNECT NEGATIVE (–) TERMINAL CABLE FROM BATTERY CAUTION: Work must be started after 90 seconds from the time the ignition switch is turned to the ’LOCK’... - Page 236 EG2–236 1MZ–FE ENGINE – SFI SYSTEM 3. REMOVE FLOOR SERVICE HOLE COVER (a) Disconnect the fuel pump connector. (b) Remove the 5 screws and service hole cover. 4. REMOVE FUEL PUMP LEAD WIRE NOTICE: Do not lift the fuel pump up with the wire harness picking.

-

Page 237: Fuel Pump Disassembly

EG2–237 1MZ–FE ENGINE – SFI SYSTEM COMPONENTS FOR DISASSEMBLY AND ASSEMBLY FUEL PUMP DISASSEMBLY (See Components for Disassembly and Assembly) 1. REMOVE FUEL PUMP FROM FUEL PUMP BRACKET (a) Remove the fuel pump lead wire. (b) Pull off the lower side of the fuel pump from the pump bracket. -

Page 238: Fuel Pump Assembly

EG2–238 1MZ–FE ENGINE – SFI SYSTEM 3. REMOVE FUEL PUMP FILTER FROM FUEL PUMP (a) Using a small screwdriver, remove the clip. (b) Pull out the pump filter. 4. REMOVE CONNECTOR Remove the 2 screws, connector support, connector and gasket. FUEL PUMP ASSEMBLY (See Components for Disassembly and Assembly) 1. -

Page 239: Fuel Pump Installation

EG2–239 1MZ–FE ENGINE – SFI SYSTEM FUEL PUMP INSTALLATION (See Components for Removal and Installation) 1. INSTALL FUEL PUMP BRACKET ASSEMBLY TO FUEL TANK (a) Install a new gasket to the pump bracket. (b) Insert the pump bracket assembly into the fuel tank. NOTICE: Do not damage the fuel pump filter. -

Page 240: Fuel Pressure Regulator

EG2–240 1MZ–FE ENGINE – SFI SYSTEM FUEL PRESSURE REGULATOR ON–VEHICLE INSPECTION CHECK FUEL PRESSURE (See page EG2–231) COMPONENTS FOR REMOVAL AND INSTALLATION... -

Page 241: Fuel Pressure Regulator Removal

EG2–241 1MZ–FE ENGINE – SFI SYSTEM FUEL PRESSURE REGULATOR REMOVAL (See Components for Removal and Installation) 1. DISCONNECT NEGATIVE (–) TERMINAL CABLE FROM BATTERY CAUTION: Work must be started after 90 seconds from the time the ignition switch is turned to the ’LOCK’ position and the negative (–) terminal cable is discon–... - Page 242 EG2–242 1MZ–FE ENGINE – SFI SYSTEM (b) Attach the pressure regulator to the delivery pipe. (c) Check that the pressure regulator rotates smoothly. NOTICE: If it does not rotate smoothly, the O–ring may be pinched, so remove the pressure regulator and repeat steps (a) to (e) above.

- Page 243 EG2–243 1MZ–FE ENGINE – SFI SYSTEM INJECTOR ON–VEHICLE INSPECTION 1. DISCONNECT NEGATIVE (–) TERMINAL CABLE FROM BATTERY CAUTION: Work must be started after 90 seconds from the time the ignition switch is turned to the ’LOCK’ position and the negative (–) terminal cable is discon– nected from the battery.

- Page 244 EG2–244 1MZ–FE ENGINE – SFI SYSTEM 3. INSPECT INJECTOR OPERATION Check operation sound from each injector. (a) With the engine running or cranking, use a sound scope to check that there is normal operating noise in proportion to engine speed. (b) If you have no sound scope, you can check the injec–...

- Page 245 EG2–245 1MZ–FE ENGINE – SFI SYSTEM COMPONENTS FOR REMOVAL AND INSTALLATION...

-

Page 246: Injectors Removal

EG2–246 1MZ–FE ENGINE – SFI SYSTEM INJECTORS REMOVAL (See Components for Removal and Installation) 1. DISCONNECT NEGATIVE (–) TERMINAL CABLE FROM BATTERY CAUTION: Work must be started after 90 seconds from the time the Ignition switch is turned to the ’LOCK’ position and the negative (–) terminal cable is discon–... - Page 247 EG2–247 1MZ–FE ENGINE – SFI SYSTEM (b) Disconnect the following connectors: (1) VSV connector for ACIS (2) VSV connector for EGR (3) VSV connector for fuel pressure control (c) Remove the 2 nuts and emission control valve set. 8. REMOVE No.2 EGR PIPE Remove the 4 nuts, EGR pipe and 2 gaskets.

- Page 248 EG2–248 1MZ–FE ENGINE – SFI SYSTEM (c) Disconnect the following connectors: (1) A/C idle–up valve connector (2) EGR gas temperature sensor connector (3) Throttle position sensor connector (4) IAC valve connector (d) Disconnect the following vacuum hoses: (1) Vacuum hose from charcoal canister (2) Vacuum hose from air intake chamber (3) 2 vacuum hoses from throttle body (e) Disconnect the following hoses:...

- Page 249 EG2–249 1MZ–FE ENGINE – SFI SYSTEM (i) Remove the nut and disconnect the PS pressure tube. (j) Remove the bolt holding the No.1 engine hanger to the air intake chamber. (k) Remove the bolt, and disconnect the ground strap. Using a 8 mm hexagon wrench, remove the 2 bolts, 2 nuts, air intake chamber assembly and gasket.

-

Page 250: Injectors Inspection

EG2–250 1MZ–FE ENGINE – SFI SYSTEM 14. REMOVE DELIVERY PIPES AND INJECTORS NOTICE: Be careful not to drop the injectors when rem– oving the delivery pipes. (a) Loosen the 2 union bolts holding the No.2 fuel pipe to the delivery pipes. (b) Disconnect the fuel return hose from the fuel pressure regulator. - Page 251 EG2–251 1MZ–FE ENGINE – SFI SYSTEM (a) Disconnect the fuel hose from the fuel filter outlet. (b) Connect SST (union an hose) to the fuel filter outlet with 2 new gaskets and the union bolt. SST 09268–41045 (90405–09015) HINT: Use the vehicle’s fuel filter. (c) Remove the fuel pressure regulator.

-

Page 252: Injectors Installation

EG2–252 1MZ–FE ENGINE – FE ENGINE – SFI SYSTEM (k) Connect SST (wire) to the injector and battery for 15 seconds, and measure the injection volume with a graduated cylinder. Test each injector 2 or 3 times. SST 09842–30070 Volume: 54 –... - Page 253 EG2–253 1MZ–FE ENGINE – FE ENGINE – SFI SYSTEM (e) Place the 4 spacers in position on the intake manifold. (f) Place the RH delivery pipe and No.1 fuel pipe together with the 3 injectors in position on the intake manifold. (g) Temporarily install the 2 bolts holding the RH delivery pipe to the intake manifold.

- Page 254 EG2–254 1MZ–FE ENGINE – SFI SYSTEM 2. CONNECT FUEL INLET AND RETURN HOSES (a) Connect the fuel inlet hose to the fuel filter with the 2 new gaskets and union bolt. Torque: 30 N–m (300 kgf–cm, 22 ft–lbf) (b) Connect the fuel return hose to the No.1 fuel pipe. HINT: Pass the fuel return hose under the heater hoses.

- Page 255 EG2–255 1MZ–FE ENGINE – SFI SYSTEM (e) Connect the following hoses: (1) Brake booster vacuum hose (2) PCV hose (3) Actuator vacuum hose (f) Connect the DLC1. (g) Connect the 2 ground straps with the nut. Torque: 14.5 N–m (145 kgf–cm. 10 ft–lbf) (h) Connect the following hoses: (1) 2 water bypass hoses to throttle body (2) Air assist hose to throttle body...

- Page 256 EG2–256 1MZ–FE ENGINE – FE ENGINE – SFI SYSTEM (k) Install the bolt holding the air intake chamber stay to the air intake chamber. Torque: 19.5 N–m (200 kgf–cm. 14 ft–lbf) (1) Connect the 2 PS air hoses. 6. CONNECT HYDRAULIC MOTOR PRESSURE PIPE Connect the pressure pipe to the air intake chamber and water inlet with the 2 bolts.

- Page 257 EG2–257 1MZ–FE ENGINE – SFI SYSTEM (c) Connect the following vacuum hoses: (1) Vacuum hose to VSV for ACIS (2) Vacuum hose to EGR vacuum modulator (3) Vacuum hose to EGR valve (4) Vacuum hose (from cylinder head rear plate) (5) Vacuum hose from air intake chamber (6) Vacuum hose to fuel pressure regulator 9.

- Page 258 EG2–258 1MZ–FE ENGINE – SFI SYSTEM FUEL TANK AND LINE COMPONENTS...