Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Keysight E5052B

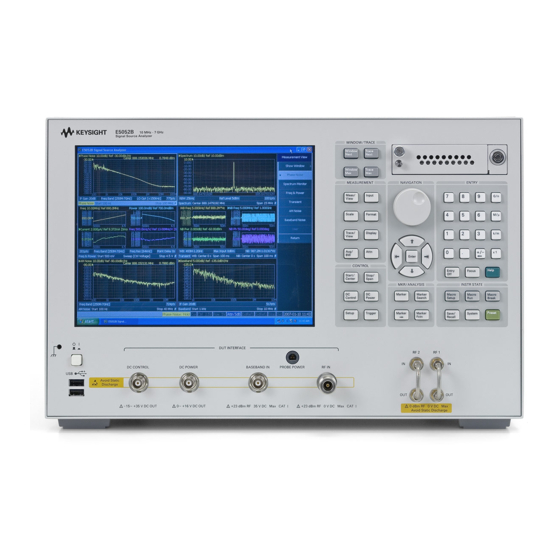

- Page 1 Keysight E5052B Signal Source Analyzer Service Guide...

- Page 4 The information contained in this document is subject to change without notice. This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of Keysight Technologies. ® ®...

- Page 5 The E5052B complies with INSTALLATION CATEGORY II as well as POLLUTION DEGREE 2 in IEC61010-1. The E5052B is an INDOOR USE product. NOTE The LEDs in the E5052B are Class 1 in accordance with IEC60825-1, CLASS 1 LED PRODUCT NOTE This equipment is MEASUREMENT CATEGORY I (CAT I).

- Page 6 Keysight Technologies Sales and Service Office for service and repair to ensure that safety features are maintained in operational condition. • Dangerous Procedure Warnings Warnings, such as the example below, precede potentially dangerous procedures throughout this manual. Instructions contained in the warnings must be followed.

- Page 7 Further, to the maximum extent permitted by applicable law, Keysight disclaims all warranties, either express or implied with regard to this manual and any information contained herein, including but not limited to the implied warranties of merchantability and fitness for a particular purpose.

- Page 8 Typeface Conventions Sample (bold) Boldface type is used when a term is defined or emphasised. Sample (Italic) Italic type is used for emphasis. Indicates a hardkey (key on the front panel or key / [Sample] key external keyboard) labeled “Sample.” “key” may be omitted.

-

Page 9: Table Of Contents

E5052B Performance Test Calculation Sheet ........ - Page 10 How to exit from the E5052B Measurement View ....... . .

- Page 11 Contents Replaceable Parts List..............87 Power Cables and Plug Configurations.

- Page 12 Contents Removal Procedure..............140 Removable Hard Disk Drive Replacement .

- Page 13 Contents A20 Digital Motherboard Replacement ........... 166 Tools Required .

- Page 14 How to make E5052B Firmware Installation Device ........

- Page 15 Contents Error Messages ..............249 A .

- Page 16 Contents...

-

Page 17: General Information

General Information The Service Guide is a guide to servicing the E5052B Signal Source Analyzer. The guide contains information requisite to do performance tests, adjustments, troubleshooting, and repairs. -

Page 18: Precautions

The E5052B does NOT have antivirus protection when shipped. Use of an antivirus program is strongly recommended if you connect the E5052B to the LAN (Internet). In addition, the use of a firewall could help to protect the E5052B from viruses. However, some firewalls could limit DCOM connectivity of the E5052B. -

Page 19: Organization Of Service Guide

This chapter provides the adjustment information for the E5052B to ensure that it is within its specifications. The adjustment must be performed Keysight’s qualified service personnel. If you need the adjustment for your E5052B, it should be sent to the nearest Keysight Technologies service office. - Page 20 Appendix D , “Power Requirement,” Appendix E, “Messages,” The E5052B can display error messages as well as messages that indicate the internal operating status of the equipment. This appendix explains what these messages mean. They are listed in alphabetical order.

-

Page 21: Instrument Covered By This Manual

Changes supplement. The supplement for this manual is identified by this manual's printing data and is available from Keysight Technologies. If the serial prefix or number of an instrument is lower than that on the title page of this manual, see Appendix A, Manual Changes. -

Page 22: Required Equipment

General Information Required Equipment Required Equipment Table 1-1 lists the recommended equipment for performing maintenance on the E5052B. Table 1-1 Recommended Test Equipment Equipment Critical specifications Recommended Model Qty. Signal Generator Frequency: 10 MHz to 7 GHz Keysight E8257D Low SSB Phase Noise with Opt. - Page 23 Recommended Model Qty. 50 Ω Termination 50 Ω (BNC) Keysight 11593A Handler I/O Test Kit No substitute Keysight p/n E5070-65001 Cable BNC(m)-BNC(m) Cable, 61 cm Keysight p/n 8120-1839 P,A,T BNC(m)-BNC(m) Cable, 122 cm Keysight p/n 8120-1840 Coaxial cable with Type-N (m)

- Page 24 Keysight 34411A Network Analyzer Frequency: 10 M to 3 GHz Keysight 8753ES Power Meter No Substitute Keysight E4419A Power Sensor No Substitute Keysight E9304A Opt. Step Attenuator No Substitute Keysight 8496H *1.P: Performance Tests, A: Adjustment, T: Troubleshooting Chapter 1...

-

Page 25: Performance Tests

Performance Tests This chapter provides information on how to verify the E5052B performance. -

Page 26: Introduction

Performance Tests Introduction Introduction This chapter provides the performance tests procedures for Keysight E5052B. The performance test names are listed in Table 2-1. NOTE Allow the analyzer to warm up for at least 30 minutes before you execute any of the performance tests. -

Page 27: Individual Test Description

Individual Test Description Individual Test Description 1. RF IN Port VSWR Test Description This test checks the VSWR of the E5052B’s RF IN port with a network analyzer. The VSWR is checked at 10 MHz to 3 GHz. Test equipment Network Analyzer... -

Page 28: Frequency Measurement Test

Performance Tests Individual Test Description 2. Frequency Measurement Test Description This test checks the frequency measurement accuracy of the E5052B. The frequency measurement is checked for each frequency band and each frequency resolution of the E5052B Test equipment Signal Generator Keysight E8257D with Opt. -

Page 29: Power Measurement Accuracy Test

Individual Test Description 3. Power Measurement Accuracy Test Description This test checks the RF power measurement accuracy of the E5052B. The measurement power level for this test is set at -20 dBm to 20 dBm in 10 dB step. Test equipment Signal Generator Keysight E8257D with Opt. -

Page 30: Phase Noise Accuracy Test

Individual Test Description 4. Phase Noise Accuracy Test Description This test checks the phase noise accuracy of the E5052B. The mixed signals generated by two signal generators are used, and the carrier frequencies for this test are 10 MHz and 1 GHz. -

Page 31: Ssb Phase Noise Sensitivity Test

Performance Tests Individual Test Description 5. SSB Phase Noise Sensitivity Test Description This test checks the SSB phase noise sensitivity of the E5052B. The carrier frequency for this test is 70 MHz. Test equipment Signal Generator Keysight E8257D with Opt. UNX, UNT, 1EA without Opt. -

Page 32: Sa Relative Level Accuracy Test

6. SA Relative Level Accuracy Test Description This test checks the relative level accuracy for the dpectrum monitor of the E5052B. The mixed signals generated by two signal generators are used, and the carrier frequencies for this test are 10 MHz, 1 GHz and 3 GHz. -

Page 33: Dc Power Voltage Test

7. DC Power Voltage Test Description This test checks the accuracy of the DC Power output voltage. Test Equipment Multimeter Keysight 3458A, Keysight 34401A, Keysight 34410A or Keysight 34411A BNC cable, 61 cm Keysight p/n 8120-1839 Dual Banana-BNC(f) adapter Keysight p/n 1251-2277... -

Page 34: Dc Power Current Measurement Test

141 Ω resistor to define the DC Power current. Test Equipment Multimeter Keysight 3458A, Keysight 34401A, Keysight 34410A or Keysight 34411A 141 Ω, 1 W (Keysight p/n 0698-3615 (47 Ω), 3ea) Resistor BNC cable, 61 cm, 2 ea. Keysight p/n 8120-1839 Dual Banana-BNC(f) adapter... -

Page 35: E5052B Performance Test Calculation Sheet

Performance Tests E5052B Performance Test Calculation Sheet E5052B Performance Test Calculation Sheet Introduction This section contains calculation sheets for each performance test that requires additional calculations to determine the final test result. Use the calculation sheet in this section as an aid for recording raw measurement data and calculating the performance test results. - Page 36 Performance Tests E5052B Performance Test Calculation Sheet Table 2-3 Sheet for Reference Frequency (1 GHz) Offset E5052B Power Meter reading Cal value of Test Result Test Result Frequency reading [dBm] Setp Att [dB] [dB] equation [Hz] [dBm] E5052B SATT Result...

-

Page 37: Sa Relative Level Accuracy Test

Performance Tests E5052B Performance Test Calculation Sheet SA Relative Level Accuracy Test Table 2-4 Sheet for Low Frequency (100 MHz) Frequency [Hz] Power meter E5052B reading Cal value Test Test result of Step Att Result reading [dBm] [dBm] equation [dB]... - Page 38 Performance Tests E5052B Performance Test Calculation Sheet Table 2-5 Sheet for High Frequency (1GHz) Frequency [Hz] Power meter E5052B reading Cal value Test Test result of Step Att Result reading [dBm] [dBm] equation [dB] [dB] SATT Result 992.5 M 993.5 M 994.5 M...

- Page 39 Performance Tests E5052B Performance Test Calculation Sheet Table 2-6 Sheet for High Frequency (3 GHz) Frequency [Hz] Power meter E5052B reading Cal value Test Test result of Step Att Result reading [dBm] [dBm] equation [dB] [dB] SATT Result 2992.5 M 2993.5 M...

-

Page 40: E5052B Performance Test Record

Performance Tests E5052B Performance Test Record E5052B Performance Test Record Keysight Technologies E5052B Signal Source Analyzer Serial Number: Option: ⋅C Temperature: Test Date: Humidity: % R.H. Tested by: F/W Revision: RF IN Port VSWR Test @ Input Attenuator = 0 dB... - Page 41 Performance Tests E5052B Performance Test Record @ Frequency Band: 10 MHz - 1.5 GHz, Power Level: -20 dBm Frequency Frequency Test Limit Test result Measurement Status [Hz] Resolution [Hz] [Hz] [Hz] uncertainty [Hz] ± 64 k ± 13.09 k 30 M...

-

Page 42: Power Measurement Accuracy Test

Performance Tests E5052B Performance Test Record @ Frequency Band: 250 MHz - 7 GHz, Power Level: +20 dBm Frequency Frequency Test Limit Test result Measurement Status [Hz] Resolution [Hz] [Hz] [Hz] uncertainty [Hz] ± 64 k ± 0.94 k 301 M 64 k 68.0... - Page 43 Performance Tests E5052B Performance Test Record Frequency Test limit [dB] Test result Measurement Status [Hz] [dB] uncertainty [dB] ± 1.0 ± 0.287 6.0125 G 3.79 PASS ± 1.0 ± 0.300 3.63 PASS @ 0 dBm Frequency Test limit [dB] Test result...

-

Page 44: Phase Noise Accuracy Test

Performance Tests E5052B Performance Test Record Frequency Test limit [dB] Test result Measurement Status [Hz] [dB] uncertainty [dB] ± 1.0 ± 0.158 3.30 PASS ± 1.0 ± 0.150 2.0125 G 3.47 PASS ± 1.0 ± 0.170 3.0125 G 6.49 PASS ±... -

Page 45: Ssb Phase Noise Sensitivity Test (For Standard)

Performance Tests E5052B Performance Test Record Offset Test limit [dB] Test result Measurement Status Frequency [Hz] [dB] uncertainty [dB] ± 3.0 ± 0.252 - 100 16.63 PASS ± 3.0 ± 0.253 16.62 PASS ± 2.0 ± 0.251 9.81 PASS ± 2.0 ±... - Page 46 Performance Tests E5052B Performance Test Record Offset Frequency Test limit [dB] Test result Measurement Status [Hz] [dB] uncertainty [dB] ± 1.5 ± 0.315 -2.5 M 5.47 PASS ± 1.5 ± 0.318 -1.5 M 5.43 PASS ± 1.5 ± 0.315 -0.5 M 5.47...

-

Page 47: Dc Power Voltage Test

Performance Tests E5052B Performance Test Record Offset Frequency Test limit [dB] Test result Measurement Status [Hz] [dB] uncertainty [dB] ± 1.5 ± 0.287 +7.5 M 6.05 PASS CW Frequency: 3 GHz Offset Frequency Test limit [dB] Test result Measurement Status... -

Page 48: Dc Current Measurement Test

Performance Tests E5052B Performance Test Record DC POWER Test limit [mV] Test result Measurement Status Voltage [V] [mV] uncertainty [mV] ± 34.0 ± 0.533 63.78 PASS DC Current Measurement Test DC Current [mA] Test limit [μA] Test result Measurement Status [μA]... -

Page 49: Adjustment

This chapter provides the adjustment information for the E5052B to ensure that it is within its specifications. The adjustment must be performed Keysight’s qualified service personnel. If you need the adjustment for your E5052B, it should be sent to the nearest Keysight Technologies service office. -

Page 50: Safety Considerations

Intentional interruption of the protective ground system for any reason is prohibited. Warm-up for Adjustment Warm-up the E5052B for at least 30 minute before performing any of the following Adjustment procedures to ensure proper results and correct instrument operation. Required Equipment... -

Page 51: Required Adjustment After Replacing Assembly

Table 3-1 must be required. The adjustment must be performed by Keysight’s qualified service personnel. If you need the adjustment for your E5052B, it should be sent to the nearest Keysight Technologies service office. Table 3-1 Required Adjustment Item after Replacing Assembly... -

Page 52: Dc Control Voltage Adjustment

Required equipment for the DC power current adjustment Description Recommended Model Multimeter Keysight 3458A, Keysight 34401A, Keysight 34410A or Keysight 34411A Keysight p/n 0698-3615 (47 Ω), 3ea 141 ohm Load BNC(f)-Banana Adapter Keysight p/n 1251-2277 BNC Tee Adapter Keysight p/n 1250-0781... -

Page 53: Reference Frequency Adjustment

Required equipment for reference frequency adjustment Description Recommended Model Signal Generator Keysight E8257D with Opt. UNX, UNT, 1EA without Opt. UNW, 1EH N(m)-N(m) Cable Keysight N6314A (p/n 8120-8862) Pre-LO Sampler PLL BW Adjustment The purpose of this procedure is to pre-adjust the LO sampler PLL BW of the A4/A5 local synthesize modules. -

Page 54: Pm Offset Adjustment

The purpose of this procedure is to adjust the PM offset of the A1 freq/power detector module. Required equipment for the PM offset adjustment Description Recommended Model Signal Generator Keysight E8257D with Opt. UNX, UNT, 1EA without Opt. UNW, 1EH Power Amplifier (35dB) R & K A3000-2H-R Step Attenuator Keysight 8496H Attenuator (3dB) Keysight 8491A Opt. -

Page 55: Pm Linearity Adjustment

The purpose of this procedure is to adjust the PM linearity of the A1 freq/power detector module. Required equipment for the PM linearity adjustment Description Recommended Model Signal Generator Keysight E8257D with Opt. UNX, UNT, 1EA without Opt. UNW, 1EH Power Amplifier (35dB) R & K A3000-2H-R Step Attenuator Keysight 8496H Attenuator (3dB) Keysight 8491A Opt. -

Page 56: Pm Flatness Adjustment

The purpose of this procedure is to adjust the PM flatness of the A1 freq/power detector module. Required equipment for the PM flatness adjustment Description Recommended Model Signal Generator Keysight E8257D with Opt. UNX, UNT, 1EA without Opt. UNW, 1EH Power Splitter Keysight 11667A Power Sensor Keysight E9304A Opt. H18 or Keysight E9304A Opt. -

Page 57: Receiver If Gain/Flatness Adjustment

Required equipment for the receiver IF gain/flatness adjustment Description Recommended Model Signal Generator Keysight E8257D with Opt. UNX, UNT, 1EA without Opt. UNW, 1EH 50 ohm Termination Keysight 909C opt.012 Power Sensor Keysight E9304A Opt. H18 or Keysight E9304A Opt. -

Page 58: Receiver If Gain/Flatness Dir Adjustment

50 ohm Termination Keysight 909C Opt. 012 Multimeter Keysight 3458A, Keysight 34401A, Keysight 34410A or Keysight 34411A Power Sensor Keysight E9304A Opt. H18 or Keysight E9304A Opt. H19 Power Meter Keysight E4419A/B Power Splitter Keysight 11667A BNC(m)-BNC(m) Cable, 61 cm... -

Page 59: Phase Noise Bw Adjustment

The purpose of this procedure is to adjust the phase noise BW of the phase detector board. Required equipment for the phase noise BW adjustment Description Recommended Model Signal Generator Keysight E8257D with Opt. UNX, UNT, 1EA without Opt. UNW, 1EH N(m)-N(m) Cable Keysight N6314A (p/n 8120-8862) FLL BW Adjustment The purpose of this procedure is to adjust the frequency lock loop BW of the phase detector board. - Page 60 Adjustment Required Adjustment after Replacing Assembly Chapter 3...

-

Page 61: Troubleshooting

Troubleshooting This chapter provides the procedure to isolate a faulty assembly in the E5052B. -

Page 62: Introduction

Troubleshooting Introduction Introduction WARNING These servicing instructions are for use by qualified personnel only. To avoid possible electrical shock, do not perform any servicing unless you are qualified to do so. WARNING The opening of covers or removal of parts is likely to expose dangerous voltages. Disconnect the instrument from its power supply beforehand. -

Page 63: How To Exit From The E5052B Measurement View

If you wish to return to the Measurement View, double-click "E5052B" icon. NOTE If you need to shut down the E5052B and again turn on, perform in accordance with the following procedure. a. To get "Start" menu bar displayed, move the pointer to the bottom of the screen with mouse. -

Page 64: To Troubleshoot The Instrument

Step 1. Turn the instrument power on About a few minutes after the E5052B is turned on, the measurement view is displayed on the screen. The display on the screen should be similar to Figure 4-7, “Measurement view,”... - Page 65 Troubleshooting To Troubleshoot the Instrument Figure 4-1 Primary trouble isolation flowchart Chapter 4...

-

Page 66: No Display Troubleshooting

Troubleshooting No Display troubleshooting No Display troubleshooting If the E5052B displays nothing despite it is powered from proper ac power line, isolate the failure in accordance with the procedure shown in Figure 4-2. Connect the keyboard to the E5052B rear panel connector, turn the power on and start trouble isolation. - Page 67 DMM. Step 2. Check system fans inside. If the system fans on the chassis inside the E5052B don't run, problem seems in the A22 power distribution board. In this case, remove the E5052B outer cover and make sure whether the fans run or not.

-

Page 68: Booting Process Troubleshooting

Troubleshooting Booting Process Troubleshooting Booting Process Troubleshooting Figure 4-3 represents the booting process flow in the E5052B. If the E5052B stops in the booting process, troubleshoot using the following step-by-step procedure. Figure 4-3 Booting process flowchart Power On Splash Screen... - Page 69 Troubleshooting Booting Process Troubleshooting Step 1. Splash Screen The splash screen is displayed with Keysight logo as shown in Figure 4-4. If the splash screen is displayed, you can assume that the A20 digital motherboard is functioning correctly. NOTE While the splash screen is displayed, if you want to run the BIOS setup utility, press F2 key as soon as in the screen.

- Page 70 The operating system automatically checks the device drivers, which are necessary to use the E5052B functions and are installed in the system before the E5052B is shipped from Keysight factory. If the operating system doesn't detect them, a message box is displayed.

- Page 71 Troubleshooting Booting Process Troubleshooting NOTE If a message of "Will Shut Down in Five Seconds" is displayed in place of "Initializing.." and the shutdown occurs, the A21 PCI DSP card fails in starting up. The following message may be displayed before the shutdown occurs: "Fatal Error: Failed to Initialize DSP Driver": or "Fatal Error: Failed to Initialize DSP": This message indicates that the A21 PCI DSP card doesn't work or is not properly...

-

Page 72: Troubleshooting Using Service Function

Power On Test. Power On Test Power-on self-test always takes place once the E5052B is turned on. When a failure is detected, a message "Power on self test failed" is displayed. The content of the power-on self-test includes the dc power supply voltage, source PLL synthesizer and level controller (ALC) tests. -

Page 73: Contents Of The Power On Test Results

Troubleshooting Troubleshooting Using Service Function Contents of the power on test results The power on test contains 6 test results shown in Figure 4-8. Each test result can display various operating characteristics of the analog measurement section. You can identify a failure section with the test results. - Page 74 Troubleshooting Troubleshooting Using Service Function Figure 4-11 A3 Result example e5052bse1008 A4 Result Figure 4-12 is an example of the A4 Result. Figure 4-12 A4 Result example e5052bse1009 A5 Result Figure 4-13 is an example of the A5 Result. Chapter 4...

-

Page 75: Power On Test Failure Troubleshooting

Troubleshooting Troubleshooting Using Service Function Figure 4-13 A5 Result example e5052bse1010 A6 Result Figure 4-14 is an example of the A6 Result. Figure 4-14 A6 Result example e5052bse1011 Power On Test Failure Troubleshooting Table 4-1 represents the contents of the test results and the relationships of failed tests to probable faulty board assemblies. - Page 76 Troubleshooting Troubleshooting Using Service Function Table 4-1 Power on test failure troubleshooting information Test result Probable faulty board assembly A1 F/P A2 DC A3 ADC/ A4 Local A5 Local A6 Phase Detect Source Synth Synth Detect A2 Result A3 Result A4 Result A5 Result A6 Result...

-

Page 77: Function Specific Troubleshooting

Function Specific Troubleshooting Function Specific Troubleshooting If the E5052B exhibits a failure symptom that is related to a specific function or control such as a front panel key control, display, data storage, remote control interface, printer interface, external trigger, external keyboard or mouse, isolate the trouble using the Function Specific Troubleshooting procedures described below. -

Page 78: To Check The Device Driver

Card” on page To Check the Device Driver Make sure first whether the E5052B device drivers are installed properly or not by the following procedure, if a function of specific device in the E5052B doesn't work. Step 1. Exit from the E5052B measurement view in accordance with the procedure described in “How to exit from the E5052B Measurement View”... - Page 79 Troubleshooting Function Specific Troubleshooting Figure 4-16 System Properties Window (General) e5052bse1013 Step 3. Click Hardware tab and Device Manager button. The operating system detects all the necessary device drivers and displays the device names as shown in Figure 4-17. Figure 4-17 System Properties Window (Hardware) e5052bse1014 Right-click the icon and select Property to show the detail of the status as shown in...

-

Page 80: To Check The Front Panel

Troubleshooting Function Specific Troubleshooting Figure 4-18 Opening Device Driver Property e5052bse1015 To Check the Front Panel Procedure Randomly press the front panel keys and rotate the knob to verify that they work normally. Step 1. Press key. Step 2. Click and, then, in the softkeys. -

Page 81: To Check The Touch Panel

White and Black every 2 seconds and returns to the measurement view. If the color test screen doesn't appear correctly, perform step 4. Step 4. Connect an external XGA monitor to the VIDEO output port on the E5052B rear panel. •... -

Page 82: To Check The External Keyboard

To Check the Video output Procedure Step 1. Connect an external XGA color monitor to the Video output port on the E5052B rear panel. Step 2. Turn the external monitor on. Step 3. Verify that the monitor screen view is the same as the display on the LCD. If the monitor screen view is abnormal, a failure seems in the A21 PCI DSP Board. -

Page 83: To Check The Gpib

Function Specific Troubleshooting To Check the GPIB Procedure Perform the E5052B performance test program. If the controller cannot detect the E5052B, the problem seems in the A24 GPIB card or the connection of the GPIB cable. To Check the 24-bit I/O port... -

Page 84: To Check The Oven Ch2

The number of averaging times is displayed in the averaging status (lower right) of the measurement windows. Step 4. Press [Trigger] Hold of the E5052B to make a measurement. Step 5. Note the E5052B reading as Frequency value. Step 6. Set the E5052B as follow. E5052B settings Key strokes Service Function : Ch2 [System]... -

Page 85: To Check The Usb (Usbtmc) Interface Card

Connect the USB cable between the controller PC and the E5052B. Turn the controller PC on. If the E5052B cannot detect the controller PC, the problem seems in the A32 USB (USBTMC) Interface Card or the A20 digital motherboard is suspected. -

Page 86: Performance Test Failure Troubleshooting

This section describes the adjustment and troubleshooting procedures used when the E5052B fails the performance tests. If the performance of the instrument is critical for the test limits and seems to be adjustable, perform first the adjustment(s) related to the failed test. -

Page 87: Adjustment Failure Troubleshooting

Troubleshooting Performance test failure troubleshooting Adjustment failure troubleshooting Table 4-4 represents the relationships between the failed adjustment and probably faulty assembly. Note that this table lists some typical cases. There are possibilities that another assembly may be faulty. Table 4-4 Adjustment failure troubleshooting information First failed adjustment Probable faulty board assembly... - Page 88 Troubleshooting Performance test failure troubleshooting NOTE When RF IN Port VSWR test fails, check first whether the connections of the RF semi-rigid cables between the suspicious assembly and others are tight or loose. Also check for possible disconnection (impairment) of the cables and connectors. Table 4-5 Performance test failure troubleshooting information Test...

-

Page 89: To Configure The A20 Digital Motherboard And Bios

Step 1. Connect the external keyboard and mouse to the E5052B rear panel connectors. Step 2. Turn the instrument on. Wait until the E5052B boots up. Do not press any key until the E5052B measurement view appears. -

Page 90: To Confirm Or Set The Bios Options

BIOS involves the system BIOS, start-up program and BIOS setup utility. The E5052B starts up first with the BIOS when the power is turned on. Use the following procedure to confirm or set the BIOS options, known as the BIOS setup utility. - Page 91 Troubleshooting To configure the A20 Digital Motherboard and BIOS Step 6. The BIOS setup utility has primary menus, most of which have sub-menus. Brief descriptions for these menus are provided in Table 4-6. It is recommended not to change any value except for the case of replaceing A20 digital motherboard assembly. Step 7.

- Page 92 Setup Defaults into the BIOS ROM. As a result, almost all of the BIOS options are automatically configured to the optimal settings for the E5052B. Exit Without Saving If you cancel the changes in the BIOS option settings, select "Exit Discarding Change"...

-

Page 93: Replaceable Parts

Replaceable Parts This chapter contains information for ordering replacement parts for the E5052B. -

Page 94: Ordering Information

Replaceable Parts Ordering Information Ordering Information To order a part in the replaceable parts lists, quote the Keysight Technologies part number, indicate the quantity required, and address the order to the nearest Keysight Technologies Sales Office. To order a part not listed in the replaceable parts lists, include the instrument model number, the description and function of the part, and the quantity of parts required. -

Page 95: Replaceable Parts List

Replaceable Parts Replaceable Parts List Replaceable Parts List Power Cables and Plug Configurations Figure 5-1 Power Cables and Plug Configurations Chapter 5... -

Page 96: Top View (Major Assemblies)

Replaceable Parts Replaceable Parts List Top View (Major Assemblies) Figure 5-2 Top View (Major Assemblies) e5052bse1034 Chapter 5... - Page 97 Replaceable Parts Replaceable Parts List Table 5-1 Top View (Major Assemblies) Ref. Keysight Part Qty. Description Desig. Number 0950-4899 POWER SUPPLY E5052-66625 A23 24BIT I/O BOARD Table 5-18 A26 PCA DIGITAL BOARD Table 5-16 A21 PCI DSP CARD ASSY Table 5-16...

-

Page 98: Top View (Cables)

Replaceable Parts Replaceable Parts List Top View (Cables) Figure 5-3 Top View (Cables) 13 14 15 e5052bse1035 Chapter 5... - Page 99 Replaceable Parts Replaceable Parts List Table 5-2 Top View (Cables) Ref. Keysight Part Qty. Description Desig. Number E5052-61685 FLAT CABLE ASSY E5071-61614 FLAT CABLE ASSY E5071-61615 WIRE ASSY E5052-61634 WIRE ASSY (6PIN) E5052-61628 FLAT CABLE ASSY E5070-61616 FLAT CABLE ASSY...

-

Page 100: Top View (Miscellaneous Parts)

Replaceable Parts Replaceable Parts List Top View (Miscellaneous Parts) Figure 5-4 Top View (Miscellaneous Parts) e5052bse1036 Chapter 5... - Page 101 Replaceable Parts Replaceable Parts List Table 5-3 Top View (Miscellaneous Parts) Ref. Keysight Part Qty. Description Desig. Number E5052-01264 ANGLE 0515-1382 SCREW-MACH M3.5 x L6 FL T15 5041-9176 TRIM STRIP 0515-2113 SCREW-MACH M4.0 x L8 PN T20 E5052-01265 BRACKET FAN L...

-

Page 102: Top View (Under Power Supply)

Replaceable Parts Replaceable Parts List Top View (Under Power Supply) Figure 5-5 Top View (Under Power Supply) e5052bse1037 Chapter 5... - Page 103 Replaceable Parts Replaceable Parts List Table 5-4 Top View (Under Power Supply) Ref. Keysight Part Qty. Description Desig. Number 0515-2032 SCREW-MACH M3.0 x L8 FL T10 E5052-01262 ANGLE PS E5071-61649 FLAT CABLE ASSY E5071-61606 WIRE ASSY 5041-9174 TRIM-FR FR SIDE...

-

Page 104: Top View (Motherboard And Other Parts)

Replaceable Parts Replaceable Parts List Top View (Motherboard and Other Parts) Figure 5-6 Top View (Motherboard and Other Parts) e5052bse1038 Chapter 5... - Page 105 Replaceable Parts Replaceable Parts List Table 5-5 Top View (Motherboard and Other Parts) Ref. Keysight Part Qty. Description Desig. Number 0515-0430 SCREW-MACH M3.0 x L6 PN T10 1400-0249 CABLE TIE 0515-0430 SCREW-MACH M3.0 x L6 PN T10 1420-0356 BATTERY LITHIUM (CR2032), 3V,.22A-HR...

-

Page 106: Bottom View

Replaceable Parts Replaceable Parts List Bottom View Figure 5-7 Bottom View e5052bse1039 Table 5-6 Bottom View Ref. Keysight Part Qty. Description Desig. Number 0515-1382 SCREW-MACH M3.5 x L6 FL T15 0515-0430 SCREW-MACH M3.0 x L6 PN T10 Chapter 5... -

Page 107: Front View (Analog Boards)

Replaceable Parts Replaceable Parts List Front View (Analog Boards) Figure 5-8 Front View (Analog Boards) e5052bse1040 Table 5-7 Front View (Analog Boards) Ref. Keysight Part Qty. Description Desig. Number E5052-62121 A1 FREQ/POWER DETECTOR MODULE E5052-69121 RSTRD E5052-62121 FREQ/POWER Table 5-26... -

Page 108: Front View (Cables)

Replaceable Parts Replaceable Parts List Front View (Cables) Figure 5-9 Front View (Cables) e5052bse1041 Table 5-8 Front View (Cables) Ref. Keysight Part Qty. Description Desig. Number E5052-61681 RF CABLE ASSY SRGD E5052-61619 RF CABLE ASSY SRGD E5052-61678 RF CABLE ASSY SRGD... -

Page 109: Front View (Miscellaneous)

Replaceable Parts Replaceable Parts List Front View (Miscellaneous) Figure 5-10 Front View (Miscellaneous) e5052bse1042 Table 5-9 Front View (Miscellaneous) Ref. Keysight Part Qty. Description Desig. Number 0515-0430 SCREW-MACH M3.0 x L6 PN T10 1400-3156 CLAMP-CABLE NYLON 1400-1391 CLAMP-CABLE STL E5052-24009... -

Page 110: Front Panel

Replaceable Parts Replaceable Parts List Front Panel Figure 5-11 Front Panel e5052bse1043 Chapter 5... - Page 111 Replaceable Parts Replaceable Parts List Table 5-10 Front Panel Ref. Keysight Part Qty. Description Desig. Number 5182-7594 KNOB E5052-00211 PANEL FRONT 04191-08000 SPRING E5052-00212 PANEL SUB E5052-25124 KEYPAD RUBBER E5070-66652 FRONT PANEL KEYBOARD E5070-60112 LCD-TPANEL ASSY Table 5-32 A52 INVERTER LS700...

-

Page 112: Rear View

N10149 personnel. I/O PANEL Not Auto-MDIX Serial Label PRINTER Ref In 1 ETHERNET (PARALLEL) Windows Label RESERVED RESERVED VIDEO E5052B 10 MHz Ref In 2 Ref Out e5052bse1044 Table 5-11 Rear View Ref. Keysight Part Qty. Description Desig. Number 0515-0372 SCREW-MACH M3.0 x L8 PN T10... -

Page 113: Cover Assembly

Replaceable Parts Replaceable Parts List Cover Assembly Figure 5-13 Cover Assembly e5052bse1045 Table 5-12 Cover Assembly Ref. Keysight Part Qty. Description Desig. Number E5052-60022 COVER ASSY 5041-9186 STRAP HANDLE FRT 0515-2049 SCREW-MACH M5.0 x L16 FL T20 5041-9174 TRIM-FR FR SIDE... -

Page 114: Left Side View

Replaceable Parts Replaceable Parts List Left Side View Figure 5-14 Left Side View e5052bse1046 Table 5-13 Left Side View Ref. Keysight Part Qty. Description Desig. Number 0515-0372 SCREW-MACH M3.0 x L8 PN T10 0515-0372 SCREW-MACH M3.0 x L8 PN T10... -

Page 115: Right Side View

Replaceable Parts Replaceable Parts List Right Side View Figure 5-15 Right Side View e5052bse1047 Table 5-14 Right Side View Ref. Keysight Part Qty. Description Desig. Number 0515-0430 SCREW-MACH M3.0 x L6 PN T10 0515-0372 SCREW-MACH M3.0 x L8 PN T10... -

Page 116: Removable Hard Disk Drive Assembly

Replaceable Parts List Removable Hard Disk Drive Assembly Figure 5-16 Removable Hard Disk Drive Assembly e5052bse1104 Table 5-15 Removable Hard Disk Drive Assembly Ref. Keysight Part Qty. Description Desig. Number E5052-60101 REMOVABLE HDD 2.5INCH RECEIVING FRAME ASSY E5070-66638 CONNECTOR BD PCA (S/N prefix : MY471) - Page 117 Replaceable Parts Replaceable Parts List Table 5-15 Removable Hard Disk Drive Assembly Ref. Keysight Part Qty. Description Desig. Number 0515-1946 SCREW-MACH M3.0 x L6 FL T10 E5070-00655 PLATE FRONT 0515-2146 SCREW-MACH M3.0 x L4 FL T10 E5070-87301 LABEL 5188-4426 HDD KEYS...

-

Page 118: Pci Dsp Card And Gpib Card Assembly

Replaceable Parts List PCI DSP Card and GPIB Card Assembly Figure 5-17 PCI DSP Card and GPIB Card Assembly e5052bse1048 Table 5-16 PCI DSP Card and GPIB Card Assembly Ref. Keysight Part Qty. Description Desig. Number 82350-66512 PCI GPIB CARD E5070-66651... -

Page 119: Usb Card Assembly

Replaceable Parts Replaceable Parts List USB Card Assembly Figure 5-18 USB Card Assembly e5052bse1049 Table 5-17 USB Card Assembly Ref. Keysight Part Qty. Description Desig. Number 0960-2357 USB ADAPTER CARD 0515-0430 SCREW-MACH M3.0 x L6 PN T10 E5071-01218 BRACKET USB... -

Page 120: Pca Digital Board Assembly

Replaceable Parts Replaceable Parts List PCA Digital Board Assembly Figure 5-19 PCA Digital Board Assembly e5071cse1088 Table 5-18 PCA Digital Board Assembly Ref. Keysight Part Qty. Description Desig. Number E5070-66653 PCI DIGITAL BRIDGE 0515-0430 SCREW-MACH M3.0 x L6 PN T10... -

Page 121: Oven Ch1 Assembly

Replaceable Parts Replaceable Parts List Oven Ch1 Assembly Figure 5-20 Oven Ch1 Assembly e5052bse1083 Table 5-19 Oven Ch1 Assembly Ref. Keysight Part Qty. Description Desig. Number 2200-0239 SCREW-MACH 4-40 0.25-IN-LG PN T10 3050-0105 WASHER-FL 1520-0205 GROMMET E8251-00041 L BRACKET E5052-81005... -

Page 122: Oven Ch2 Assembly

Replaceable Parts Replaceable Parts List Oven Ch2 Assembly Figure 5-21 Oven Ch2 Assembly e5052bse1084 Table 5-20 Oven Ch2 Assembly Ref. Keysight Part Qty. Description Desig. Number 0515-0665 SCREW-MACH 4-40 0.625-IN-LG PN T10 3050-1628 WASHER-SPR 0380-1402 SPACER-RND 8MM-LG 0400-0356 GROMMET-RND E5052-60102... -

Page 123: Dc Block Unit Assembly

Replaceable Parts Replaceable Parts List DC Block Unit Assembly Figure 5-22 DC Block Unit Assembly e5052bse1050 Table 5-21 DC Block Unit Assembly Ref. Keysight Part Qty. Description Desig. Number E5052-61067 DC BLOCK 0515-0430 SCREW-MACH M3.0 x L6 PN T10 E5052-25005... -

Page 124: Analog Mother Board Assembly

Replaceable Parts Replaceable Parts List Analog Mother Board Assembly Figure 5-23 Analog Mother Board Assembly e5052bse1051 Table 5-22 Analog Mother Board Assembly Ref. Keysight Part Qty. Description Desig. Number E5052-66650 ANALOG MOTHER PCA 0515-0372 SCREW-MACH M3.0 x L8 PN T10 0515-1946 SCREW-MACH M3.0 x L6 FL T10... -

Page 125: Freq/Power Detector Module Attachment Assembly

Replaceable Parts List Freq/Power Detector Module Attachment Assembly Figure 5-24 Freq/Power Detector Module Attachment Assembly e5052bse1052 Table 5-23 Freq/Power Detector Module Attachment Assembly Ref. Keysight Part Qty. Description Desig. Number E5052-62121 A1 FREQ/POWER DETECTOR MODULE E5052-61611 RF CBL ASSY SRGD... -

Page 126: Dc Source Board Attachment Assembly

Replaceable Parts Replaceable Parts List DC Source Board Attachment Assembly Figure 5-25 DC Source Board Attachment Assembly e5052bse1053 Table 5-24 DC Source Board Attachment Assembly Ref. Keysight Part Qty. Description Desig. Number E5052-61642 CABEL ASSY E5052-61692 RF CABLE ASSY 1250-0252... -

Page 127: Local Synthesize Module Assembly

Replaceable Parts Replaceable Parts List Local Synthesize Module Assembly Figure 5-26 Local Synthesize Module Assembly Table 5-25 Local Synthesize Module Assembly Ref. Keysight Part Qty. Description Desig. Number E5052-62034 A4 LOCAL SYNTHESIZE MODULE ASSY E5052-69034 RSTRD E5052-62034 SYNTHESIZE E5052-62035 A5 LOCAL SYNTHESIZE MODULE ASSY... -

Page 128: Phase Detector Board Assembly

Replaceable Parts Replaceable Parts List Phase Detector Board Assembly Figure 5-27 Phase Detector Board Assembly e5052bse1055 Table 5-26 Phase Detector Board Assembly Ref. Keysight Part Qty. Description Desig. Number E5052-62026 A6 PAHSE DETECTOR BOARD ASSY E5052-69026 RSTRD E5052-62026 PHASE DET... - Page 129 Replaceable Parts Replaceable Parts List Table 5-26 Phase Detector Board Assembly Ref. Keysight Part Qty. Description Desig. Number 0515-0430 SCREW-MACH M3.0 x L6 PN T10 E5052-61694 RF CABLE ASSY Chapter 5...

-

Page 130: Chassis Assembly

Replaceable Parts Replaceable Parts List Chassis Assembly Figure 5-28 Chassis Assembly e5052bse1056 Table 5-27 Chassis Assembly Ref. Keysight Part Qty. Description Desig. Number 5022-7129 FRONT FRAME 8160-0641 RFI BRAID STRIP 1.35 M 0515-2113 SCREW-MACH M4.0 x L8 PN T15 Chapter 5... - Page 131 Replaceable Parts Replaceable Parts List Table 5-27 Chassis Assembly Ref. Keysight Part Qty. Description Desig. Number 0403-0285 BUMPER E5071-24007 SPACER E5052-60021 CHASSIS ASSY 1520-0685 DAMPER 8160-1677 I/O SHIELD Chapter 5...

-

Page 132: Front Cover Assembly

Replaceable Parts Replaceable Parts List Front Cover Assembly Figure 5-29 Front Cover Assembly e5052bse1057 Table 5-28 Front Cover Assembly Ref. Keysight Part Qty. Description Desig. Number 0515-0430 SCREW-MACH M3.0 x L6 PN T10 8160-0619 GASKET 3-UNITS 1400-3156 CLAMP-CABLE NYLON 6/6 0515-0430 SCREW-MACH M3.0 x L6 PN T10... -

Page 133: Front Assembly (Lcd)

Replaceable Parts Replaceable Parts List Front Assembly (LCD) Figure 5-30 Front Assembly (LCD) e5052bse1058 Table 5-29 Front Assembly (LCD ) Ref. Keysight Part Qty. Description Desig. Number 0515-1402 SCREW-MACH M3.5 x L8 PN T15 1400-3361 CLAMP-CABLE 16MM E5070-61628 WIRE ASSY... -

Page 134: Front Assembly (Standby Switch And Pca Prove Power)

Front Assembly (Standby Switch and PCA Prove Power) Figure 5-31 Front Assembly (Standby Switch and PCA Prove Power) e5052bse1059 Table 5-30 Front Assembly (Standby Switch and PCA Prove Power) Ref. Keysight Part Qty. Description Desig. Number 0515-0430 SCREW-MACH M3.0 x L6 PN T10... -

Page 135: Front Assembly (Front Keyboard )

Replaceable Parts List Front Assembly (Front Keyboard ) Figure 5-32 Front Assembly (Front Keyboard ) e5052bse1060 Table 5-31 Front Assembly (Front Keyboard ) Ref. Keysight Part Qty. Description Desig. Number 0515-0430 SCREW-MACH M3.0 x L6 PN T10 E5070-66652 PCA FRONT KEY... -

Page 136: Front Assembly (Inverter)

Replaceable Parts Replaceable Parts List Front Assembly (Inverter) Figure 5-33 Front Assembly (Inverter) e5052bse1061 Table 5-32 Front Assembly (Inverter) Ref. Keysight Part Qty. Description Desig. Number 0361-1898 RIVET-PUSH-IN 4.2 MM 0950-4420 INVERTER DC-AC E5052-00603 SPACER E5052-01299 BRACKET INVERTER Chapter 5... -

Page 137: Label On Front Face

Replaceable Parts Replaceable Parts List Label on Front Face Figure 5-34 Label on Front Face E5052B 10 MHz - 7 GHz Signal Source Analyzer WINDOW/TRACE Window Window Trace Trace Next Next Next Next Window Window Trace Trace MEASUREMENT NAVIGATION ENTRY... -

Page 138: Label On Rear Face

N10149 I/O PANEL Not Auto-MDIX Serial Label PRINTER Ref In 1 ETHERNET (PARALLEL) Windows Label RESERVED RESERVED VIDEO E5052B OPTION 011 10 MHz Ref In 2 Ref Out e5052bse1063 Table 5-34 Label on Rear Face Ref. Keysight Part Qty. Description Desig. -

Page 139: Other Parts

Replaceable Parts Replaceable Parts List Other Parts Table 5-35 Other Parts Keysight Part Number Qty. Description SERVICE GUIDE E5052-901x0 5012-8615 MOUSE 5188-4463 KEYBOARD *1.The number indicated by “x” in the part number of each manual, or CD-ROM, 0 for the first edition, is incre- mented by 1 each time a revision is made. - Page 140 Replaceable Parts Replaceable Parts List Chapter 5...

-

Page 141: Replacement Procedure

Replacement Procedure This chapter provides procedure for removing and replacing the major assemblies in the E5052B. -

Page 142: Replacing An Assembly

Replacement Procedure Replacing an Assembly Replacing an Assembly The following steps show the sequence for replacing an assembly in a E5052B Signal Source Analyzer. 1. Identify the faulty group. Refer to Chapter 4, “Troubleshooting.” 2. Order a replacement assembly. Refer to Chapter 5, “Replaceable Parts.”... -

Page 143: Required Tools

Replacement Procedure Required Tools Required Tools The following tools are required for repair of the E5052B. Table 6-1 Required Tools Assembly TORX screwdriver flat edge 10 mm cutting hex key open-end torque wrench screwdriver torque Plier wrench T10 T15 T20 1.5 mm 9/16... -

Page 144: Outer Cover Removal

Refer to Figure 6-1 for this procedure. Step 1. Disconnect the power cable from the E5052B. Step 2. Remove the four bottom feet (item 1). Step 3. Remove the four TORX T10 screws (item 2) from the bottom. Step 4. Remove the four TORX T20 screws (item 3) fastening the side strap handles. - Page 145 Replacement Procedure Outer Cover Removal Figure 6-1 Outer Cover Removal e5052bse1064 Chapter 6...

-

Page 146: Front Panel Removal

Replacement Procedure Front Panel Removal Front Panel Removal Tools required • TORX screwdriver T10, T15 and T20 • Flat edge screwdriver • Open torque wrench, 5/16 inch (set to 10 in-lb) (for reconnecting SMA connector) Procedure Refer to Figure 6-2 for this procedure. - Page 147 Replacement Procedure Front Panel Removal Figure 6-2 Front Panel Removal Bottom Bottom e5052bse1065 Chapter 6...

-

Page 148: A27 Removable Hard Disk Assembly Removal

Replacement Procedure A27 Removable Hard Disk Assembly Removal A27 Removable Hard Disk Assembly Removal Tools Required • TORX screwdriver T10, T15 and T20 Removal Procedure Refer to Figure 6-3 for this procedure. Step 1. Remove the outer cover as described in “Outer Cover Removal”... - Page 149 Replacement Procedure A27 Removable Hard Disk Assembly Removal Figure 6-3 A27 Removable Hard Disk Assembly Removal e5052bse1105 Chapter 6...

-

Page 150: Removable Hard Disk Drive Replacement

Replacement Procedure Removable Hard Disk Drive Replacement Removable Hard Disk Drive Replacement Tools Required • TORX screwdriver, T10 • Torque screwdriver, TORX T10 Save Backup Files to the PC When the removable hard disk drive is readable, you have to perform the following steps. For details of the adjustment progra, refer to Chapter 6 on page 133. -

Page 151: Replacement Procedure

Replacement Procedure Removable Hard Disk Drive Replacement Figure 6-4 Removable Hard Disk Drive Removal e5052bse1106 Replacement Procedure Step 1. Replace the removable hard disk drive by inverse procedure of removal. NOTE Fasten the TORX T10 screws (item 5) using a torque screwdriver (set to 1.02 N-m / 9.0 lb-in). -

Page 152: Restore Backup Files Onto The New Removable Hard Disk Drive

Spot Adjustment Calibration of the Touch Screen When you have replaced the HDD on a E5052B equipped, you have to calibrate the touch screen. Follow the procedure described below to calibrate the touch screen. Step 1. Press Step 2. - Page 153 Replacement Procedure Removable Hard Disk Drive Replacement Figure 6-5 Touch Panel Calibration Screen e5071cse1078 Step 5. Touch the x mark on the upper left with your finger. The mark x appears also on the lower left, upper right, and lower right. Touch the x marks in that order with your finger. Touching the four locations described above with your finger automatically concludes the touch screen calibration.

-

Page 154: Power Supply Assembly Replacement

Replacement Procedure Power Supply Assembly Replacement Power Supply Assembly Replacement Tools Required • TORX screwdriver, T10, T15, and T20 Removal Procedure Refer to Figure 6-6 for this procedure. Step 1. Remove the outer cover as described in “Outer Cover Removal” on page 136. -

Page 155: Replacement Procedure

Replacement Procedure Power Supply Assembly Replacement Figure 6-6 Power Supply Assembly Removal e5052bse1066 Replacement Procedure Step 1. Replace the power supply assembly by inverse procedure of removal. NOTE Fasten the TORX T10 screws (item 1) using a torque screwdriver (set to 0.79 N-m / 7.0 lb-in). -

Page 156: A26 Digital Bridge Board Replacement

Replacement Procedure A26 Digital Bridge Board Replacement A26 Digital Bridge Board Replacement Tools Required • TORX screwdriver, T10, T15, and T20 Removal Procedure Refer to Figure 6-7 for this procedure. Step 1. Remove the outer cover as described in “Outer Cover Removal” on page 136. -

Page 157: Replacement Procedure

Replacement Procedure A26 Digital Bridge Board Replacement Figure 6-7 A26 Digital Bridge Board Removal e5052bse1067 Replacement Procedure Step 1. Replace the digital bridge board by inverse procedure of removal. Chapter 6... -

Page 158: A25 24 Bit I/O Board Replacement

Replacement Procedure A25 24 bit I/O Board Replacement A25 24 bit I/O Board Replacement Tools Required • TORX screwdriver, T10, T15, and T20 Removal Procedure Refer to Figure 6-8 for this procedure. Step 1. Remove the outer cover as described in “Outer Cover Removal”... -

Page 159: Replacement Procedure

Replacement Procedure A25 24 bit I/O Board Replacement Figure 6-8 A25 24 bit I/O Board Removal e5052bse1068 Replacement Procedure Step 1. Replace the 24 bit I/O board by inverse procedure of removal. Chapter 6... -

Page 160: A21 Pci Dsp / A24 Gpib Card Replacement

Replacement Procedure A21 PCI DSP / A24 GPIB Card Replacement A21 PCI DSP / A24 GPIB Card Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Open-end torque wrench, 5/8 inch (set to 1.97 N-m / 17.4 lb-in) Removal Procedure Refer to Figure 6-9... -

Page 161: Replacement Procedure

Replacement Procedure A21 PCI DSP / A24 GPIB Card Replacement Figure 6-9 A21 PCI / A24 GPIB Card Removal e5052bse1069 Replacement Procedure Step 1. Replace the PCI / GPIB card by inverse procedure of removal. NOTE Fasten the 5/8 inch nut (item 7) using a open-end torque wrench for replacement. Chapter 6... -

Page 162: A32 Usb (Usbtmc) Interface Card Replacement

Replacement Procedure A32 USB (USBTMC) Interface Card Replacement A32 USB (USBTMC) Interface Card Replacement Tools Required • TORX screwdriver, T10, T15, and T20 Removal Procedure Refer to Figure 6-10 for this procedure. Step 1. Remove the outer cover as described in “Outer Cover Removal”... -

Page 163: Replacement Procedure

Replacement Procedure A32 USB (USBTMC) Interface Card Replacement Figure 6-10 A32 USB (USBTMC) Interface Card Removal e5052bse1070 Replacement Procedure Step 1. Replace the USB interface card by inverse procedure of removal. Chapter 6... -

Page 164: Oven Ch1 Assembly Replacement

Replacement Procedure Oven CH1 Assembly Replacement Oven CH1 Assembly Replacement Tools Required • TORX screwdriver, T10, T15, and T20 Removal Procedure Refer to Figure 6-11 for this procedure. Step 1. Remove the outer cover as described in “Outer Cover Removal” on page 136. -

Page 165: Replacement Procedure

Replacement Procedure Oven CH1 Assembly Replacement Figure 6-11 Oven CH1 Removal e5052bse1071 Replacement Procedure Step 1. Replace the oven ch1 assembly by inverse procedure of removal. Chapter 6... -

Page 166: Oven Ch2 Assembly Replacement

Replacement Procedure Oven CH2 Assembly Replacement Oven CH2 Assembly Replacement Tools Required • TORX screwdriver, T10, T15, and T20 Removal Procedure Refer to Figure 6-12 for this procedure. Step 1. Remove the outer cover as described in “Outer Cover Removal” on page 136. -

Page 167: Replacement Procedure

Replacement Procedure Oven CH2 Assembly Replacement Figure 6-12 Oven CH2 Removal e5052bse1072 Replacement Procedure Step 1. Replace the oven ch2 assembly by inverse procedure of removal. Chapter 6... -

Page 168: A57 Dc Block Assembly Replacement

Replacement Procedure A57 DC Block Assembly Replacement A57 DC Block Assembly Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/8 inch (set to 1.97 N-m / 17.4 lb-in) Removal Procedure Refer to Figure 6-13 for this procedure. -

Page 169: Replacement Procedure

Replacement Procedure A57 DC Block Assembly Replacement Figure 6-13 A57 DC Block Removal e5052bse1073 Replacement Procedure Step 1. Replace the dc block by inverse procedure of removal. Chapter 6... -

Page 170: Fan Replacement

Replacement Procedure Fan Replacement Fan Replacement Tools Required • TORX screwdriver, T10,T15 and T20 • Flat edge screwdriver • 10 mm torque open wrench (set to 1.02 N-m / 9.0 lb-in) • Cutting plier • Open-end torque wrench, 5/8 inch (set to 1.97 N-m / 17.4 lb-in) Removal Procedure Refer to Figure 6-14... -

Page 171: Replacement Procedure

Replacement Procedure Fan Replacement Figure 6-14 Fan Removal e5052bse1074 Replacement Procedure Step 1. Replace the fan by inverse procedure of removal. NOTE Connecting the cables (items 3, 4) as described below. • Connect the cable from small fan to “J5” connector (item 3). •... -

Page 172: A22 Power Distribution Board Replacement

Replacement Procedure A22 Power Distribution Board Replacement A22 Power Distribution Board Replacement Tools Required • TORX screwdriver, T10,T15 and T20 Removal Procedure Refer to Figure 6-15 for this procedure. Step 1. Remove the outer cover as described in “Outer Cover Removal” on page 136. -

Page 173: Replacement Procedure

Replacement Procedure A22 Power Distribution Board Replacement Figure 6-15 A22 Power Distribution Board Removal e5052bse1075 Replacement Procedure Step 1. Replace the power distribution board by inverse procedure of removal. Chapter 6... -

Page 174: A20 Digital Motherboard Replacement

Replacement Procedure A20 Digital Motherboard Replacement A20 Digital Motherboard Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Open-end torque wrench, 5/8 inch (set to 1.97 N-m / 17.4 lb-in) Removal Procedure Refer to Figure 6-16 for this procedure. Step 1. -

Page 175: Replacement Procedure

Replacement Procedure A20 Digital Motherboard Replacement Figure 6-16 A20 Digital Motherboard Removal e5052bse1076 Replacement Procedure Step 1. Replace the digital motherboard by inverse procedure of removal. Chapter 6... -

Page 176: A1 Freq / Power Detector Module Replacement

Replacement Procedure A1 Freq / Power Detector Module Replacement A1 Freq / Power Detector Module Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Refer to... -

Page 177: Replacement Procedure

Replacement Procedure A1 Freq / Power Detector Module Replacement Figure 6-17 A1 Freq/Power Detector Module Removal e5052bse1085 Replacement Procedure Step 1. Replace the freq/power detector module by inverse procedure of removal. NOTE Fasten the semi-rigid cable using a open-end torque wrench for replacement. Chapter 6... -

Page 178: A2 Dc Source Board Replacement

Replacement Procedure A2 DC Source Board Replacement A2 DC Source Board Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Refer to... -

Page 179: Replacement Procedure

Replacement Procedure A2 DC Source Board Replacement Figure 6-18 A2 DC Source Board Removal e5052bse1086 Replacement Procedure Step 1. Replace the DC source board by inverse procedure of removal. NOTE Fasten the semi-rigid cable using a open-end torque wrench for replacement. Chapter 6... -

Page 180: A3 Adc/Dsp Board Replacement

Replacement Procedure A3 ADC/DSP Board Replacement A3 ADC/DSP Board Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Refer to Figure 6-19... -

Page 181: Replacement Procedure

Replacement Procedure A3 ADC/DSP Board Replacement Figure 6-19 A3 ADC/DSP Board Removal e5052bse1087 Replacement Procedure Step 1. Replace the ADC/DSP board by inverse procedure of removal. NOTE Fasten the semi-rigid cable using a open-end torque wrench for replacement. Chapter 6... -

Page 182: A4/A5 Local Synthesize Module Replacement

Replacement Procedure A4/A5 Local Synthesize Module Replacement A4/A5 Local Synthesize Module Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Refer to... -

Page 183: Replacement Procedure

Replacement Procedure A4/A5 Local Synthesize Module Replacement Figure 6-20 A4/A5 Local Synthesize Module Removal e5052bse1088 Replacement Procedure Step 1. Replace the local synthesize module by inverse procedure of removal. NOTE Fasten the semi-rigid cable using a open-end torque wrench for replacement. Chapter 6... -

Page 184: A6 Phase Detector Board Replacement

Replacement Procedure A6 Phase Detector Board Replacement A6 Phase Detector Board Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Step 1. -

Page 185: Replacement Procedure

Replacement Procedure A6 Phase Detector Board Replacement Figure 6-21 A6 Phase Detector Board Removal e5052bse1089 Replacement Procedure Step 1. Replace the phase detector board by inverse procedure of removal. NOTE Fasten the semi-rigid cable using a open-end torque wrench for replacement. Chapter 6... -

Page 186: A50 Analog Motherboard Replacement

Replacement Procedure A50 Analog Motherboard Replacement A50 Analog Motherboard Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end wrench, 9/16 inch (set to 3.39 N-m / 30.0 lb-in) • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Refer to... -

Page 187: Replacement Procedure

Replacement Procedure A50 Analog Motherboard Replacement Figure 6-22 A50 Analog Motherboard Removal e5052bse1090 Replacement Procedure Step 1. Replace the analog motherboard by inverse procedure of removal. NOTE Fasten the 9/16 inch nut (item 1) using a open-end torque wrench for replacement. Chapter 6... -

Page 188: Front Panel Cover Removal

Replacement Procedure Front Panel Cover Removal Front Panel Cover Removal Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Refer to Figure 6-23... -

Page 189: Control Touch Panel Replacement

Replacement Procedure Control Touch Panel Replacement Control Touch Panel Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Refer to Figure 6-24... -

Page 190: A52 Inverter Assembly Replacement

Replacement Procedure A52 Inverter Assembly Replacement A52 Inverter Assembly Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) • Flat edge screwdriver Removal Procedure Refer to Figure 6-25... -

Page 191: Replacement Procedure

Replacement Procedure A52 Inverter Assembly Replacement Figure 6-25 A52 Inverter Board Removal e5052bse1093 Replacement Procedure Step 1. Replace the inverter assembly by inverse procedure of removal. NOTE Fasten the TORX T15 screws (item 2) using a torque screwdriver (set to 1.02 N-m / 9.0 lb-in). -

Page 192: A51 Lcd Replacement

Replacement Procedure A51 LCD Replacement A51 LCD Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) • Flat edge screwdriver Removal Procedure Refer to Figure 6-26 for this procedure. -

Page 193: Replacement Procedure

Replacement Procedure A51 LCD Replacement Figure 6-26 A51 LCD Removal e5052bse1094 Replacement Procedure Step 1. Replace the LCD by inverse procedure of removal. NOTE Fasten the TORX T15 screws (item 5) using a torque screwdriver (set to 1.02 N-m / 9.0 lb-in). -

Page 194: A22 Front Keyboard Replacement

Replacement Procedure A22 Front Keyboard Replacement A22 Front Keyboard Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) •... -

Page 195: Replacement Procedure

Replacement Procedure A22 Front Keyboard Replacement Figure 6-27 A22 Front Keyboard Removal e5052bse1095 Replacement Procedure Step 1. Insert the whole jut of the rubber key into the hole on the new front panel keyboard. Step 2. Replace the front panel keyboard by inverse procedure of removal. NOTE Replace the keyboard rubber to new one, if it’s pulled the keyboard rubber from the front panel keyboard. -

Page 196: Front Usb Pca Board Replacement

Replacement Procedure Front USB PCA Board Replacement Front USB PCA Board Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) • Flat edge screwdriver Removal Procedure Refer to Figure 6-28... -

Page 197: Replacement Procedure

Replacement Procedure Front USB PCA Board Replacement Figure 6-28 Front USB PCA Board Removal e5052bse1096 Replacement Procedure Step 1. Replace the front USB PCA by inverse procedure of removal. Chapter 6... -

Page 198: Probe Power And Power Switch Board Replacement

Replacement Procedure Probe Power and Power Switch Board Replacement Probe Power and Power Switch Board Replacement Tools Required • TORX screwdriver, T8, T10, T15, and T20 • Flat edge screwdriver • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) •... -

Page 199: Replacement Procedure

Replacement Procedure Probe Power and Power Switch Board Replacement Figure 6-29 Probe Power and Power Switch Board Removal e5052bse1097 Replacement Procedure Step 1. Replace the prove power board or switch board by inverse procedure of removal. Chapter 6... -

Page 200: Front Bnc Connector Replacement

Replacement Procedure Front BNC Connector Replacement Front BNC Connector Replacement Tools Required • TORX screwdriver, T10, T15, and T20 • Flat edge screwdriver • Cutting plier • Open-end wrench, 9/16 inch (set to 3.39 N-m / 30.0 lb-in) • Open-end torque wrench, 5/16 inch (set to 1.02 N-m / 9.0 lb-in) (for reconnecting SMA connector) Removal Procedure Refer to... -

Page 201: Replacement Procedure

Replacement Procedure Front BNC Connector Replacement Figure 6-30 Front BNC Connector Removal Rear Front e5052bse1098 Replacement Procedure Step 1. When the diode is replaced, cut the new diode leads as show in the figure (item 7). Solder the new diode as show in the figure (item 8). NOTE Ensure that the polarity of the diode is correct. - Page 202 Replacement Procedure Front BNC Connector Replacement NOTE Fasten the 9/16 inch nut (item 5) using a open-end torque wrench for replacement. Chapter 6...

-

Page 203: Post-Repair Procedures

Post-Repair Procedures This chapter lists the procedures required to verify the E5052B operation after an assembly is replaced with a new one. -

Page 204: Post-Repair Procedures

Post-Repair Procedures Post-Repair Procedures Post-Repair Procedures Table 7-1 Post Repair Procedures lists the required procedures that must be performed after the replacement of an assembly. These are the recommended minimum procedures to ensure that the replacement is successfully completed. Table 7-1 Post-Repair Procedures Replaced Required Adjustments... - Page 205 Post-Repair Procedures Post-Repair Procedures Table 7-1 Post-Repair Procedures Replaced Required Adjustments Verification Assembly or Part Correction Constants (CC) A3 ADC/DSP Perform the following required “Power On Test” on page 64 Board adjustments using “A3 ADC/DSP” in Spot Adjustment of the program. RF IN Port VSWR Test Reference Frequency Adjustment Frequency Measurement Test...

- Page 206 Post-Repair Procedures Post-Repair Procedures Table 7-1 Post-Repair Procedures Replaced Required Adjustments Verification Assembly or Part Correction Constants (CC) A22Power No adjustment needed Inspect the Booting Process Distribution Board “Power On Test” on page 64 A50 Analog No adjustment needed Inspect the Booting Process Motherboard When the symptom of failure is out of specification, perform the performance test.

- Page 207 Post-Repair Procedures Post-Repair Procedures Table 7-1 Post-Repair Procedures Replaced Required Adjustments Verification Assembly or Part Correction Constants (CC) Power Supply No adjustment needed Inspect the Booting Process Assembly A51 LCD Calibration of the Touch Screen Inspect the Booting Process “To Check the LCD” on page 73 A52 Inverter Board No adjustment needed Inspect the Booting Process...

- Page 208 Post-Repair Procedures Post-Repair Procedures Chapter 7...

-

Page 209: Manual Changes

This appendix contains the information required to adapt this manual to versions or configurations of the E5052B manufactured earlier than the current printing date of this manual. The information in this manual applies directly to the E5052B units with the serial number that is printed on the title page of this manual. -

Page 210: Manual Changes

Manual Changes Manual Changes Manual Changes To adapt this manual to your E5052B, refer to Table A-1 Table A-2. Table A-1 Manual Changes by Serial Number Serial Prefix or Number Make Manual Changes Table A-2 Manual Changes by Firmware Version... -

Page 211: System Recovery

System Recovery This appendix describes how to recover the operating system (Windows XP) when the operating system has been damaged. -

Page 212: System Recovery

(at the time of purchase NOTE System recovery is a function of Windows and not a function of the E5052B Firmware. The system recovery procedure is different in accordance with the HDD revision. The HDD revision can be confirmed using the following procedure: Step 1. -

Page 213: Notes On Executing The Factory Recovery Function

Notes on executing the factory recovery function Executing the factory recovery function causes the following conditions: o In addition to the Windows operating system and the firmware, the following settings of the E5052B are returned to the factory state. • Network setting •... -

Page 214: Procedure To Execute The Factory Recovery (Hdd Revision: Nm321 Or Above)

The User back up function is not available. Step 1. Turn ON the E5052B. Step 2. The boot option is displayed. Use the downward arrow key to select the “Keysight Recovery Solution” and press Enter Step 3. Windows PE starts up and “Keysight Recovery Program” window is displayed. Press 1, and then press Enter. - Page 215 Figure B-4 Keysight Recovery Program(1/4) Step 8. When factory recovery is finished, E5052B restarts. Step 9. After restart, the screen for initial registration appears. Execute initial registration. For information on the execution procedure, refer to “Initial Registration Procedure (HDD Revision: NM321 or above)”...

-

Page 216: Procedure To Execute The Factory Recovery (Hdd Revision: Nm320 Or Below)

NOTE After Step 5, if the E5052B freezes with the cursor does not blink, turn the power off and remove unnecessary USB devices. Then, replace the keyboard with a PS/2 keyboard to execute the process again. Appendix B... - Page 217 Figure 0-2 Recover Factory Backup e5052bse1018 Step 8. When the recovery is finished, push the enter select OK. The E5052B restarts automatically. Step 9. After restart, the screen for initial registration appears. Execute initial registration. For information on the execution procedure, refer to “Initial Registration Procedure (HDD Revision: NM320 or below)”...

-

Page 218: Procedure To Create The User Backup Image (Only Available When Hdd Revision Is Nm320 Or Below)

This section describes how to create the user backup image. The C and F drives’ contents saved in this procedure are recalled when the user recovery function is executed. Step 1. Close the E5052B application by pressing System > Service Menu > Administrator Menu >... - Page 219 System Recovery System Recovery Step 5. Click Backup e5071cse1125 Step 6. Click button. Next e5071cse1126 Appendix B...

- Page 220 System Recovery System Recovery Step 7. Select “The entire disk contents or individual partition,” then click button. Next e5071cse1127 Step 8. Select the C drive and F drive. e5052bse1019 Step 9. Select the destination folder and input a file name, then click Next button.

- Page 221 System Recovery System Recovery never save the contents of the drive to the C, E or F drive. e5052bse1020 Step 10. Select “Set the options manually” and click Next button. e5071cse1130 Step 11. Select “Backup priority” in the left field and “High” in the right field, then click Next Appendix B...

- Page 222 System Recovery System Recovery button. e5071cse1131 Step 12. If necessary, input comments and click button. The comments can be omitted. Next e5071cse1132 Appendix B...

- Page 223 System Recovery System Recovery Step 13. Click button. Proceed e5052bse1021 Step 14. The following screen appears during backup. e5052bse1022 Step 15. The following screen appears when the user backup image was created. Click e5052bse1023 Appendix B...

- Page 224 System Recovery System Recovery CAUTION Never turn off the power during creating the user backup image because doing so may cause serious damage to the E5052B. Appendix B...

-

Page 225: Procedure To Execute The User Recovery Function (Only Available When Hdd Revision Is Nm320 Or Below)

“Procedure to create the user backup image (only available when HDD Revision is NM320 or below)” on page 210. Step 1. Close the E5052B application by pressing System > Service Menu > Exit. Step 2. Close all other applications you currently open. - Page 226 System Recovery System Recovery Step 6. Click button. Next e5071cse1137 Step 7. Select the saved backup image file, then click Next button. e5052bse1024 Appendix B...

- Page 227 System Recovery System Recovery Step 8. Select “Restore disks or partitions,” then click button. Next e5071cse1139 Step 9. Select the C drive, then click button. Next e5052bse1025 Appendix B...

- Page 228 System Recovery System Recovery Step 10. Select the C drive to restore, then click button. Next e5052bse1026 Step 11. Select “Active” and click button. Next e5071cse1145 Appendix B...

- Page 229 System Recovery System Recovery Step 12. Click button. Next e5052bse1027 Step 13. Select “Yes, I want to assign a logical drive letter to the restored partition.” and click Next button. e5071cse1147 Appendix B...

- Page 230 System Recovery System Recovery Step 14. Select “Yes, I want to restore another partition or hard disk drive.” then click button. Next e5052bse1077 Step 15. Select the F drive to restore, then click Next button. e5052bse1028 Appendix B...

- Page 231 System Recovery System Recovery Step 16. Select the F drive to restore, then click t button. e5052bse1029 Step 17. Select “Logical” and click Next button. e5052bse1078 Appendix B...

- Page 232 System Recovery System Recovery Step 18. Click button. Next e5052bse1030 Step 19. Select “Yes, I want to assign a logical drive letter to the restored partition,” then click Next button. e5052bse1031 Appendix B...

- Page 233 System Recovery System Recovery Step 20. Select “No, I do not.” and click button. Next e5052bse1079 Step 21. Select “Set the options manually” and click button. Next e5052bse1080 Appendix B...

- Page 234 System Recovery System Recovery Step 22. Select “Restoration Priority” in the left field and “High” in the right field, then click Next button. e5052bse1081 Step 23. Click button. Proceed e5052bse1032 Step 24. Click button. Reboot e5052bse1082 Appendix B...

- Page 235 Never turn off the power during the recovery of the user backup image because doing so may cause serious damage to the E5052B. Step 25. After boot up, perform “Initial Registration of E5052B” on page 27 and “Calibration of the Touch Screen” on page 32.

-

Page 236: Initial Registration Of E5052B

Initial Registration of E5052B Initial Registration of E5052B When you start up the E5052B at the first time, you need to perform the initial registration of the Windows XP operating system of the E5052B. There are two procedures in accordance with the HDD revision. - Page 237 E5052B Name Next> (Figure B-7). Figure B-7 Windows XP Professional Setup dialog box (2/2) E5052 e5052bse1033 Step 5. The E5052B restart automatically. Step 6. The Keysight Recovery Image Setup screen (Figure B-8) appears. Click OK to proceed. Appendix B...

- Page 238 Keysight Recovery Image Setup Screen(1/2) Step 8. A message dialog box appears after the completion of the Recovery Image Setup procedure. The dialog box disappears automatically after a few seconds. Step 9. E5052B firmware is executed, then the measurement display appears. Appendix B...

-

Page 239: Initial Registration Procedure (Hdd Revision: Nm320 Or Below)

System Recovery Initial Registration of E5052B Initial Registration Procedure (HDD Revision: NM320 or below) Step 1. Turns on the E5052B. Step 2. The Windows XP Professional Setup wizard appears. Click the button (Figure Next > B-10). Figure B-10 Windows XP Professional Setup wizard e5071cse1073 Step 3. - Page 240 System Recovery Initial Registration of E5052B Figure B-12 Windows XP Professional Setup dialog box (2/2) E5052 e5052bse1033 Step 5. After a while, the E5052B restarts automatically. Then, the measurement display appears. Appendix B...

-

Page 241: Calibration Of The Touch Screen

System Recovery Calibration of the Touch Screen Calibration of the Touch Screen After E5052B measurement screen appears, you have to calibrate the touch screen. Follow the procedure described below to calibrate the touch screen. Step 1. Press Step 2. Press Service Menu Step 3. - Page 242 System Recovery Calibration of the Touch Screen Appendix B...

-

Page 243: Firmware Update

Firmware Update This appendix describes how to update the E5052B firmware. When you want to update the E5052B firmware, refer to this appendix. -

Page 244: Firmware Update

Step 2. Run the “E5052B_xx.xx.exe” to extract the E5052.msi and.setup.vbs. Then, save these files to USB mass storage devie. Step 3. Connect the mouse and keyboard to the E5052B rear panel. Then turn the E5052B on. Step 4. Connect the USB mass storage divice into the front USB port of the E5052B. - Page 245 Step 6. Double-click the “My Computer” icon on the Windows desktop. Step 7. Double-Click the “Removable Disk (G:)” icon. Step 8. Remove the old version of the firmware using the following procedure. 1. Double-Click “Setup.vbs” icon. The E5052B Setup Wizard (uninstall) will start automatically as shown in Figure C-1.

- Page 246 Firmware Update Firmware Update Figure C-3 E5052B Setup Wizard (install) e5052bse1101 2. Click “Next” to continue the firmware installation on the E5052B Setup Wizard as shown in Figure C-3. 3. Please wait until “Install Wizard” (Figure C-4) disappears. Figure C-4...

- Page 247 Firmware Update Firmware Update Figure C-5 E5052B Setup Wizard (Completed) e5052bse1103 Step 10. Double-click "E5052B" icon on the Windows desktop, and the measurement screen will appear. Step 11. Press . Confirm the firmware revision you have just Product Information installed.

- Page 248 Firmware Update Firmware Update Appendix C...

-

Page 249: Power Requirement

Power Requirement... -

Page 250: Power Supply And Blown Fuses

Step 2. Use the supplied cable to connect between the power cable receptacle (Figure D-2 on page 246) on the rear panel of the E5052B and a three-wire power outlet, with the grounding prong firmly connected in the ground slot. - Page 251 Power Requirement Power Supply and Blown Fuses Figure D-1 Power cable options Appendix D...

-

Page 252: Blown Fuses

Blown fuses If the fuse appears to have blown during operation, this instrument may be subject to failure and must be repaired. Ship the E5052B to the nearest Keysight Technologies Service Center. The product uses the following fuse type: UL/CSA Type, Slow-Blo, 15 A-250 V WARNING Do NOT replace the fuse yourself;... -

Page 253: Starting The E5052B

Power Requirement Starting the E5052B Starting the E5052B This section explains how to turn on/off the E5052B power, how to cut off the power supply in an emergency, and how to set the internal clock. Turning the Power ON and OFF Perform the following steps to turn the power ON or OFF. -

Page 254: Disconnection From Supply Source

Line switch (Always ON) and power cable receptacle Disconnection from supply source The power supply of the E5052B is cut off by disconnecting the plug of the power cable (on either AC outlet side or E5052B side). When it is necessary to disconnect the power supply in order to avoid shock hazards, etc., pull out the power cable plug from either the... -

Page 255: Messages

This appendix explains what these messages mean. They are listed in alphabetical order. Messages showing the status of the E5052B are displayed in the lower-left area of the E5052B LCD screen. These messages include error messages that occur during the... - Page 256 Messages execution of GPIB commands and others that indicate the internal status of the equipment. Error messages are indicated following the character string “[Err]” and can be read out by a GPIB command. Other kinds of messages are indicated without the “[Err]” character string and cannot be read out by a GPIB command.

- Page 257 A21 flash ROM write error This error occurs when writing the system calibration data to ROM on the A21 board fails. Contact Keysight Technologies’ Customer Contact given at the end of this guide or the company from which you bought the device.

- Page 258 Error Messages This error occurs when the internal local signal of the instrument cannot be unlocked. There is the possibillity of a device failure. Contact a Keysight Technologies sales office or the company from which you bought the device. -222...

- Page 259 Downconverter Unlock local This error occurs when the local of the downconverter cannot be locked. A device failure is suspected. Contact Keysight Technologies’ Customer Contact given at the end of this guide or the company from which you bought the device.

- Page 260 DUT that has an unstable output level is measured, or if the carrier frequency of DUT is out of the specified frequency band. Aside from the above reasons, there is the possibility of a device failure. Contact a Keysight Technologies sales office or the company from which you bought the device.

- Page 261 This error is not generated by front key operations. Oven Cold This error occurs when PLL cannot be locked because the oven is not warm enough after start-up the E5052B. -220 Parameter error When a parameter-related error other than Errors -221 through -229 occurs, that error is displayed.

- Page 262 See the command reference to confirm the required number of parameters. Power on test failed This error occurs when the power-on test fails, indicating a failure of the instrument. Contact a Keysight Technologies sales office or the company from which you bought the instrument. Printer error This error occurs when the previous printing is still in progress or the printer fails (offline, short of paper, etc.) at the time of outputting the display image on the LCD screen to the...

- Page 263 One of the errors designated as “system errors” in this instrument has occurred. Target freq out of range This error indicates the 2nd, 3rd, or nth order harmonics is not within the E5052B measurement range. At this time, the previous measurement conditions still remain (any of sweep parameters are not changed).

- Page 264 Messages Error Messages The internal thermometer reading is out of the proper range. Adjustment or repair is necessary. -113 Undefined header A command not defined in this instrument, although not illegal in the syntactic structure, has been received. See the command reference and use correct commands. Appendix E...

- Page 265 This information is subject to change without notice. © Keysight Technologies 2007, 2008, 2009, 2012, 2014 Edition 7, August 2014 *E5052-90240* E5052-90240 www.keysight.com...

Need help?

Do you have a question about the E5052B and is the answer not in the manual?

Questions and answers