Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

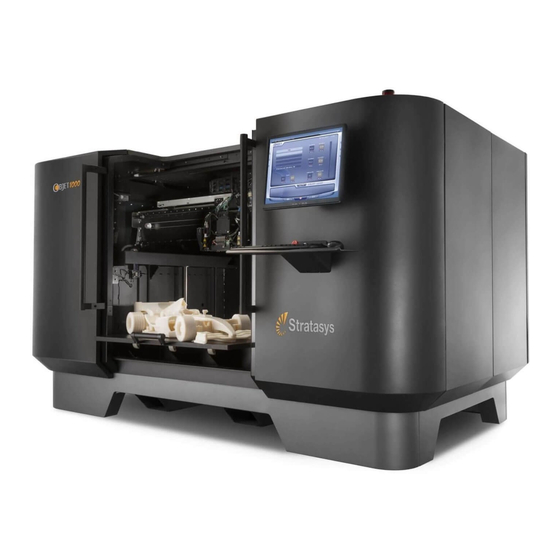

Summary of Contents for Stratasys J4100

- Page 1 User Guide Stratasys J4100 3D Printing System DOC-26000 Rev. C...

- Page 2 (even if Stratasys has been advised of the possibility of such damages), resulting from: (i) the use or the inability to use the product or software;...

- Page 3 This product is covered by one or more of the following U.S. patents and other granted or pending patents. 6,569,373 7,209,797 7,364,686 7,369,915 7,500,846 7,604,768 7,628,857 7,658,976 7,725,209 7,896,639 7,958,841 7,962,237 7,991,498 7,996,101 8,219,234 8,278,866 8,323,017 8,469,692 8,781,615 8,865,047 8,932,511 9,017,589 9,020,627 9,031,680 9,227,365 Stratasys Ltd. www.stratasys.com DOC-26000 Revision C January 2021 DOC-26000 Rev. C...

-

Page 4: Table Of Contents

1 About This Guide Using This Guide For More Information Revision History Terms Used in This Guide Additional Resources Stratasys Academy Stratasys Support Center GrabCAD Community 2 Safety Safety Features Symbols and Warning Labels Safety Guidelines Printer Installation Printer Operation... - Page 5 4 Operating and Maintaining the Printer Starting the Printer Loading Model and Support Containers Producing Models Preparing the Printer Starting Printing Printer Interface Color Key Printing Indicators 4-10 Resuming Production After Printing has Stopped 4-11 Changing the Printing Material 4-15 Changing Model Materials Without Flushing 4-20 Advanced Settings...

- Page 6 Removing the Support Material Removing Support by Hand Removing Support with Water Pressure Removing SUP705 with Caustic Soda Post-Printing Treatment Photobleaching for Transparent Models Storing Models DOC-26000 Rev. C...

- Page 7 About This Guide Using This Guide For More Information Revision History Terms Used in This Guide Additional Resources Stratasys Academy Stratasys Support Center GrabCAD Community DOC-26000 Rev. C...

-

Page 8: About This Guide

Important: Read the entire Safety chapter before using the system. The text and figures in this guide are based on the J4100 3D printer, software version 41.01 (DT 11). -

Page 9: Terms Used In This Guide

The computer inside the J4100 printer that operates it. computer Printer The GUI (graphical user interface) used for controlling J4100 printers. interface Printer Software running on the computer in the J4100 printer, controling all software, printer operations. printer-control application Resin The base substance from which photopolymer printing materials are made for use in Stratasys PolyJet printers. -

Page 10: Additional Resources

Stratasys J4100 User Guide 1 About This Guide Additional Resources Stratasys encourages you to learn more about your additive manufacturing printer, its capabilities and the technology. A wealth of information is available on our online digital platforms. Stratasys Academy Stratasys Academy is your online learning platform. -

Page 11: Stratasys Support Center

The site also has links to Web-based training, "how-to" videos and the Stratasys blog. In addition, you can check the latest revision of the user guide for your printer, and download documents in different languages. -

Page 12: Safety

Safety Safety Features Symbols and Warning Labels Safety Guidelines Printer Installation Printer Operation UV Radiation Printer Maintenance Model and Support Materials UV Lamps First Aid for Working with Printing Materials Contact with Skin Contact with Eyes Ingestion Inhalation Waste Disposal DOC-26000 Rev. -

Page 13: Safety Features

Stratasys J4100 User Guide 2 Safety Safety Features J4100 3D printers are equipped with the following safety features: Interlock Switch The power supplied to the UV lamp and the motion motors is turned off when the doors are opened. Warning Do not defeat (override) the interlock switch. - Page 14 Stratasys J4100 User Guide 2 Safety Emergency Stop Emergency stop switches are located on the front and back of the printer. Important: Pushing the emergency stop switch disconnects power to the motors only. This switch does not disconnect the power supply to the printer; printer circuits remain live.

-

Page 15: Symbols And Warning Labels

Stratasys J4100 User Guide 2 Safety Symbols and Warning Labels The following table lists the warning labels located on or in the printer. Warning Symbol Meaning Location Comments Hazard (general) On the name plate on the Read the instructions in back of the printer. -

Page 16: Safety Guidelines

Stratasys J4100 User Guide 2 Safety Safety Guidelines The following general guidelines, together with the instructions provided throughout this user guide, ensure user safety while operating and maintaining the system. If the system is not operated as specified, the user's safety may be compromised. -

Page 17: Uv Radiation

The UV lamps used in the printer emit dangerous radiation ➢ If the UV lamps remain on when the printer is open, do not stare directly at the UV light. Shut down the printer and call your Stratasys service provider. Printer Maintenance ➢... -

Page 18: Uv Lamps

Stratasys J4100 User Guide 2 Safety ➢ Uncured printing material is considered a hazardous substance, requiring certain precautions when directly handling it. To prevent skin irritation, wear neoprene or nitrile gloves. If there is any chance that Model and Support materials might splash into the eyes, wear safety goggles. -

Page 19: First Aid For Working With Printing Materials

Stratasys J4100 User Guide 2 Safety First Aid for Working with Printing Materials In general, try to avoid direct contact with uncured printing material. If skin or eyes come into contact with it, wash the area immediately and thoroughly with water, and follow these first-aid instructions. -

Page 20: Inhalation

Stratasys J4100 User Guide 2 Safety Inhalation Vapors from printing materials can be irritating to the respiratory system. If respiratory irritation occurs, expose the victim to fresh air immediately. ➢ If the victim has stopped breathing, perform artificial respiration or cardiopulmonary resuscitation. -

Page 21: Introducing The 3D Printer

Introducing the 3D Printer Work Configurations Source Files Printing Materials Storage Shelf Life Exposure to Light Safety Considerations Disposal Work Environment DOC-26000 Rev. C... -

Page 22: Work Configurations

3 Introducing the 3D Printer Work Configurations Stratasys J4100 3D printing systems can be set up as single-station systems or as multi-station systems. When connected to a local computer network, the system can serve multiple users. In such configurations, each user (client) prepares files for production. -

Page 23: Source Files

Print supports native CAD formats from these programs: Creo, SOLIDWORKS, NX, CATIA and Inventor. To see the complete list of file formats supported by GrabCAD Print, go to: help.grabcad.com/print/file-formats. J4100 systems feature the capability of producing different types of model files simultaneously. DOC-26000 Rev. C... -

Page 24: Printing Materials

Storage Materials used for printing models with J4100 printers are made of resins, which are composed of reactive monomers and oligomers. Although printing materials are supplied in sealed, UV-proof containers, care must be taken when storing and handling them. -

Page 25: Safety Considerations

Work Environment Extreme heat and humidity conditions can adversely affect the operation of your J4100 3D printer. Use ventilation or air-conditioning systems, if necessary, to keep the work area within the following ranges: • 18°–25° C (64°–77° F) •... - Page 26 Operating and Maintaining the Printer Starting the Printer Loading Model and Support Containers Producing Models Preparing the Printer Starting Printing Printer Interface Color Key Printing Indicators 4-10 Resuming Production After Printing has Stopped 4-11 Changing the Printing Material 4-15 Changing Model Materials Without Flushing 4-20 Advanced Settings 4-23...

- Page 27 Replacing Print Heads 4-64 Testing and Calibrating the UV Lamps 4-74 Replacing the Roller Waste Tubes 4-82 Calibrating the Load Cells 4-87 Replacing the UV Lamps 4-88 Dynamic Nozzle Test 4-98 Built-in Tests 4-99 Replacing Waste Containers 4-105 Cleaning the Exterior Panels 4-105 Cleaning the UV Screen 4-105...

-

Page 28: Starting The Printer

Observe all safety warnings and follow the safety guidelines described in Chapter 2. 1. Turn on the main power switch, located at the back of the printer. Figure 4-2 Main power switch The main power switch turns on the J4100 printer, which includes the built-in computer. DOC-26000 Rev. C... - Page 29 ❒ On the printer-computer desktop, double-click the J4100 printer icon. or— ❒ From the Windows Start menu, select (All) Programs > Objet > J4100. A HASP plug containing a valid product activation key is required on the printer computer. This is supplied during printer installation or upgrade. If the application does not open and a HASP message appears, contact your Stratasys dealer or service provider.

-

Page 30: Loading Model And Support Containers

4 Operating and Maintaining the Printer Loading Model and Support Containers The number of material containers loaded in J4100 printers depends on the active printing mode. • In High Speed mode, you can print with up to three different Model materials. - Page 31 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 4. Attach the material feed tube to the container. When preparing a new feed tube, make sure that the air hole in the cap is open. Figure 4-5 Material container cap You should hear a clicking sound when the connector is securely attached to the container.

-

Page 32: Producing Models

90% alcohol (IPA or ethanol). The build tray for the J4100 printer is removable, which aids in the removal and handling of printed models. Make sure that the build tray is installed when preparing the printer for producing models. -

Page 33: Starting Printing

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer You can monitor printer status by switching the printer interface display. To do this, click the display toggle button on the printer interface screen. Figure 4-6 Printer status Starting Printing To begin printing: ➢... -

Page 34: Printer Interface Color Key

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer printer to ensure continuous printing. As each slice is printed, as a layer of the models on the build tray, another slice is sent to the printer. Depending on the size of the model(s) to be produced, printing can take between several hours to several days. -

Page 35: Printing Indicators

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Printing Indicators The printer interface screen changes when you send a print job to the printer, if the printer is online: • The mode changes from Pre-print to Printing. • The specific activity being performed is shown in the “current activity” field. -

Page 36: Resuming Production After Printing Has Stopped

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Resuming Production After Printing has Stopped If the printing process is interrupted, the print manager stops sending slices to the printer. This can happen, for example, if the printing material runs out in the middle of a print job, and you do not replace the empty container immediately. - Page 37 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Figure 4-8 Opening the Schedule screen 4. Locate the stopped job. Figure 4-9 Stopped job in the Schedule screen 5. Click on the job to display the Job Status details, and click the Resume icon OR—...

- Page 38 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Figure 4-11 Printer interface after interrupted printing 7. If, for any reason, the correct number does not appear in the dialog box, enter the number and click OK. You cannot continue printing the model if: •...

- Page 39 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer If you cannot continue printing: 1. Cancel the job. In GrabCAD Print, in the Schedule screen (see above): ❒ Right-click on the job to display the pop-up menu, and select Cancel job.

-

Page 40: Changing The Printing Material

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Changing the Printing Material Before producing models using a different type of printing material than is currently installed, run the Material Replacement wizard to flush the print block and feed tubes. - Page 41 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 4. Choose the configuration for producing models: ❒ 3 Materials (High Speed) ❒ Single Material (Super High Speed) Figure 4-13 Material Replacement Options 3 Materials Both sections of each print head are loaded with the same material.

- Page 42 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Single Material Both sections of two print heads are loaded with the same Model material. Both sections of two print heads are loaded with Support material. Figure 4-15 One Model material loaded in the print heads This mode produces parts in Super High Speed mode, at a layer resolution of 55 microns.

- Page 43 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 9. To flush out material currently in the system, choose the flushing cycle that fits your needs: The default flushing cycle is the one used for the last material replacement.

- Page 44 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 10. Click Next to begin the material replacement process in the printer. The positioning screen appears, showing you the new location of the containers in the materials compartments. Figure 4-16 Container placement Symbols: The correct container is in this position.

-

Page 45: Changing Model Materials Without Flushing

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 14. In the final wizard screen, click Done. The printer-control application is automatically updated, and it restarts. When it opens, the interface displays the new material(s). The interface in the job preparation application is also updated, and it displays the new material(s). - Page 46 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 3. When the Material Replacement Options screen opens, select the Replace materials without flushing check box and click Next. Figure 4-18 Replace materials without flushing 4. In the confirmation message that appears, click Yes to continue.

- Page 47 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 5. In the Cartridge Positioning and Process Progression screen, click Start. Figure 4-20 Cartridge Positioning and Process Progression screen 6. Read the Warning message that appears, and click OK to continue.

-

Page 48: Advanced Settings

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Advanced Settings The Advanced Settings dialog box enables you to configure the Material Replacement wizard for special purposes. If necessary, click Advanced Settings in the Material Replacement Options screen before clicking Next. - Page 49 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 4. After selecting the materials for the appropriate cartridge slots, the Cartridge Positioning screen appears. Place the cartridges in the materials cabinet as shown in this screen. Figure 4-24 Cartridge Positioning screen (High Speed mode) DOC-26000 Rev.

- Page 50 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Additional Flushing Cycles The flushing cycle you select in the Material Replacement Options screen determines how thoroughly to flush out material currently in the system. After selecting the Economy cycle and completing the wizard, you might decide that you require a more thorough flushing, to ensure accurate model color.

-

Page 51: Keeping The Printer In Idle Mode

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Keeping the Printer in Idle Mode Between printing jobs, the printer can be left unused for up to one week. If the printer will not be used for more than a week, use the Shutdown wizard to automatically perform the procedures that must be done before turning off the printer (see "Shutting Down the Printer"... -

Page 52: Shutting Down The Printer

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Shutting Down the Printer You only need to shut down the printer if it will not be used for 30 days or more. Otherwise, the printer can remain on, in Idle mode. However, if there is a need to... - Page 53 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 3. Select the option corresponding to the length of time that the printer will not be used—less or more than 30 days. Note: Before selecting More than 30 days, make sure that cleaning-fluid cartridges are available.

- Page 54 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 5. When the final wizard screen appears, close all open programs on both computers, and shut down the computers. Figure 4-29 Final Shutdown wizard screen 6. After both printer computers shut down turn off the main power switch at the back of the printer (see Figure 4-2 on page 4-3).

-

Page 55: Maintaining The Printer

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Maintaining the Printer Performing routine maintenance tasks is essential for getting satisfactory results from your printer. Perform the tasks at specified intervals. Routine Maintenance Schedule Frequency Task For More Information Before printing Clean the UV lamp lenses. -

Page 56: Maintenance Counters

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Frequency Task For More Information Every 500 hours of printing Replace the wiper. See "Cleaning the Print Heads, UV Lamp Glass, Roller and Wiper" on page 4-37. Every 700 hours of printing Replace the roller pump tubes. - Page 57 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer If there is a maintenance task due, this is indicated on the main interface screen. Figure 4-31 Maintenance Required indicator If this indicator appears, you can display the Maintenance Counters screen by clicking on it.

-

Page 58: Uv Lamp Check

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer UV Lamp Check A heat-sensitive label is fixed to the UV lamp covers as a warning against overheating. Its center changes from white to black if the temperature of the cover reaches 65°C (150°F). - Page 59 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Figure 4-34 Selecting Pattern Test 5. Click Yes in the Confirm dialog box to begin. Figure 4-35 Pattern Test confirmation 6. If the build tray is not clear, click No in the following dialog box.

- Page 60 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer The printer prints a series of lines on the test paper (see next figure). Figure 4-37 Sample Pattern Test 7. Carefully inspect the test paper to see if there are missing lines.

-

Page 61: Backing Up The Printer Configuration

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Backing up the Printer Configuration It is recommended that you periodically back up the printer's configuration files. In case of printer malfunction or the need to re-install the software on the printer computer, parameters can be restored from the backup. -

Page 62: Improving Print Quality

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Improving Print Quality If you suspect that print quality is poor, perform the Pattern Test (see "Pattern Test" on page 4-33). If the results are poor, use the following procedure to improve print quality. - Page 63 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer To clean the printer components: 1. Prepare— ❒ 90% isopropanol (IPA—isopropyl alcohol) or ethanol (ethyl alcohol) ❒ disposable cleaning gloves ❒ a supplied 3M sanding sponge ❒ a supplied cleaning cloth or equivalent ❒...

- Page 64 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 4. When the following screen appears, open the printer. Figure 4-41 Wizard screen during cleaning tasks Warning: Hot Surface The print head orifice plates (bottom surface) may be hot. Do not touch them with your bare hands, and proceed with caution.

- Page 65 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 8. Clean the orifice plates, with a back-and-forth motion. Use the mirror to make sure that you have removed all of the residue material. Figure 4-42 Cleaning the heads Once a month, remove and clean the print-head splash shield. (See step 4 on page 4-55.)

- Page 66 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Note: When returning the waste collector to the purge unit, make sure to insert it as shown. 13. Inspect the wiper. If the wiper is scratched, torn or worn, or if you cannot clean it completely, replace it.

-

Page 67: Cleaning The Roller Waste Collector And Inspecting The Roller Scraper

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer The roller stops rotating when you click Next. 18. Remove the cleaning materials from the printer and close the printer doors. 19. Select the confirmation check boxes in the wizard screen and click Next. - Page 68 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 4. Remove the right UV-lamp assembly: a. Disconnect the UV power cable and the fan power cable. Figure 4-46 Disconnecting the right UV assembly b. Remove the screw that secures the right UV lamp, and then pull and lift up the UV lamp.

- Page 69 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 5. Detach the UV bracket from the print block. a. Loosen screws A, B and C. b. Remove screws D and E. Figure 4-47 UV bracket attached to the print block c.

- Page 70 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 8. Remove the two screws securing the covering of the roller waste collector and remove it. Be very careful to save the covering screws. These are special screws; if they are lost, you need to order replacements.

-

Page 71: Replacing The Roller Scraper

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 6. Before returning the roller waste collector to the print block, make sure that the pins are clean. Figure 4-52 Roller waste collector pins To re-assemble the components: 1. Return the roller waste collector to the print block and screw on the covering (see Figure 4-50 on the previous page). - Page 72 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer To replace the roller scraper: 1. Prepare— ❒ a new roller scraper blade ❒ a Phillips 1x75 mm screwdriver ❒ a 2.5-mm and a 2-mm hex (Allen) key 2. Remove the right UV lamp and the roller waste collector covering (see steps 4 to 8 on page 4-43).

- Page 73 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 5. Remove the scraper blade and discard it. Figure 4-56 Removing the old roller scraper blade 6. Place the new scraper blade onto the pins in the holder, as shown.

-

Page 74: Aligning The Print Heads

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 7. Insert and tighten the roller scraper blade screws. Important: Tighten the screws in the order shown in Figure 4-58. Use the new screws supplied in the replacement kit Figure 4-58 Tightening the roller scraper screws 8. - Page 75 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 3. When the following screen appears, place the transparency on the build tray—next to the left and rear edges of the tray (see below). Figure 4-59 Transparency confirmation Figure 4-60 Positioning the transparency on the build tray 4.

- Page 76 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer The transparency sheet is printed with sets of vertical lines in seven columns, each showing the results from a different print head. Figure 4-62 Sample head-alignment test Note: There is no column for head H7 because its alignment is used as a reference for aligning all other heads.

- Page 77 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 10. In the head-alignment screen, select the number that indicates which lines align in the upper and lower rows of a pair on the transparency (counting from the left) for this print head.

- Page 78 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 13. In the following screen, you can choose to either repeat the head alignment procedure, or close the wizard. Figure 4-66 Repeat head alignment option ❒ If the most closely aligned vertical lines for a print head were at either extreme, choose Repeat the test, then click Next.

-

Page 79: Cleaning The Print-Head Splash Shield

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Cleaning the Print-Head Splash Shield To prevent excess printing material from accumulating around the print heads, a splash shield is installed on the bottom of the print block. Remove the shield and clean it once a month, when cleaning the print heads (see "Cleaning the Print... - Page 80 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 4. Using a 2-mm hex (Allen) key, remove the screws to remove the splash shield. Figure 4-68 Print-head splash shield installed on the print block Figure 4-69 Removing the print-head splash shield Warning: Hot Surface The print head orifice plates (bottom surface) may be hot.

-

Page 81: Optimizing (Calibrating) Print Heads

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Optimizing (Calibrating) Print Heads The condition of the print heads directly affects the quality of printed models. To maintain optimum printing, you should routinely test the print heads, and calibrate them to the best working configuration possible by running the Head Optimization wizard every 300 hours of printing. - Page 82 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 2. Start the Head Optimization wizard from the Options menu. Figure 4-70 Starting the Head Optimization wizard 3. In the opening wizard screen, click Next to begin. The Wizard Conditions screen appears.

- Page 83 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 6. In the following screen, make sure Optimize all print heads is selected, and click Next. Figure 4-72 Procedure selection screen 7. Select the printing mode for which you want to optimize the print heads and click Next.

- Page 84 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer After warming the print block and turning on the UV lamps, the printer prints a frame on the build tray for positioning the scale. Figure 4-75 Scale positioning frame on the build tray 9.

- Page 85 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 11. When the following screen appears, open the printer and remove the Pattern Test paper. Figure 4-77 Enter Missing Nozzles screen 12. Carefully inspect the Pattern Test paper with the Missing Nozzles Ruler to see if there are missing lines.

- Page 86 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 14. The wizard continues according to the number of missing nozzles you entered. ❒ If there are too many missing nozzles for acceptable printing, the wizard instructs you to replace the defective print head(s). You can do this now, or abort the wizard.

- Page 87 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 16. After confirming all of the items listed in the wizard screen, click Next. Printing material (resin) is jetted from each head and its weight is automatically recorded. Then, the following screen appears.

- Page 88 • Select Replace defective head(s) if you are prepared to replace the print heads now (see below). or— • Select Abort wizard if you want to replace the print heads at another time. Replace print heads only after consulting with an authorized Stratasys service provider. DOC-26000 Rev. C 4-63...

-

Page 89: Replacing Print Heads

❒ Head Heater temperature timeout ❒ Head Heater thermistor open ❒ Head Heater thermistor short Replace print heads only after consulting with an authorized Stratasys service provider. The Head Optimization wizard guides you through the procedure of replacing a print head, and configures printer components to enable you to perform it. Only replace a print head with the aid of the wizard. - Page 90 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer The entire print-head replacement procedure takes 75—90 minutes, and consists of the following phases: A. Identifying the head(s) needing replacement. This is normally done by the Head Optimization wizard. Otherwise, evidence of physical damage to the head surface or a malfunction message indicates which head needs replacing.

- Page 91 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 5. In the following screen, select Continue with Head optimization if you have recently cleaned the print heads. Otherwise, cancel the wizard and run the Cleaning wizard. Figure 4-85 Clean print heads screen 6.

- Page 92 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer The printer heats and empties the print block, and prepares the printer. (This should take up to 15 minutes.) The following screen appears when the printer is ready for you to replace print heads.

- Page 93 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 11. Loosen the screws that secure the driver-card bracket, and lower the bracket. Figure 4-90 Loosening the driver-card bracket screws 12. Release the driver-card support. Figure 4-91 Releasing the driver-card support DOC-26000 Rev.

- Page 94 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 13. Remove the driver card by releasing the latch at the points shown. Figure 4-92 Releasing the driver-card latch 14. Release the upper and lower screws that secure the print head in the block.

- Page 95 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 15. Press down on the upper and lower locking screws to release the print head, and remove it from the bottom of the print block. Figure 4-94 Releasing the print head 16.

- Page 96 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Important If the seals are not removed with the head, they are probably stuck to the print block housing. If so, remove them. Figure 4-96 Making sure the O-rings are not stuck to the print block Installing the New Head 17.

- Page 97 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 22. In the Replace print heads screen, select the check box to confirm that you have replaced the head(s), and click Next. Figure 4-98 Head replacement confirmation 23. With your fingers, make sure that the new head is level and even with the other heads.

- Page 98 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 25. In the next wizard screen, confirm that you have removed all tools and objects from the printer. Figure 4-101 Cleared-tray confirmation screen 26. Close the printer doors. The wizard continues by heating the heads, then filling and purging them.

-

Page 99: Testing And Calibrating The Uv Lamps

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer ➢ If the replacement head was not calibrated by Stratasys, remove the head and replace it with another one. Figure 4-103 Invalid-head warning Contact your Stratasys service provider about the uncalibrated head. - Page 100 Figure 4-105 UV device selection UV Measuring Device When you use the Stratasys UV sensor box (TOL-03005-S), you connect it to the printer. The wizard automatically measures and calibrates the UV radiation. If you use a stand-alone UV radiation meter, you need to manually enter the readings from the meter in the wizard screens.

- Page 101 4. Make sure that the build tray is empty. Confirm this in the wizard screen and click Next. Figure 4-106 Printer preparation ➢ When using a Stratasys UV sensor box that you connect to the printer (TOL-03005-S), continue with "UV Sensor Connected to Printer" on the next page.

- Page 102 4 Operating and Maintaining the Printer UV Sensor Connected to Printer The following steps apply when using the Stratasys UV sensor box that you connect to the printer. They do not apply when using a UV external radiation measuring device.

- Page 103 External UV Meter The following steps apply when using a stand-alone UV meter. This section does not apply when using the Stratasys UV sensor box connected to the printer. 1. When the following screen appears, open the printer and place the UV sensor (probe) at the rear edge of the tray, in the center.

- Page 104 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 2. Lead the cable out of the printer so that you can close the printer, and tape it down to make sure that it does not interfere with the moving print block.

- Page 105 20–40 minutes, you need to monitor the progress as displayed in the wizard screen. Figure 4-112 UV measurement progress When using a stand-alone radiation meter (not the Stratasys UV sensor box connected to the printer): Reset the meter and enter the reading (measurement) when you are prompted to do so.

- Page 106 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer If the UV level measured is not acceptable, the wizard calibrates the UV lamp by adjusting the current supplied to it, and then tests it again. When all UV tests have finished, the results are displayed, showing the condition of the lamps after calibration (see Figure 4-114 below).

-

Page 107: Replacing The Roller Waste Tubes

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Figure 4-116 Final UV Calibration Wizard screen Replacing the Roller Waste Tubes As routine maintenance, you should replace the tube in the roller waste pumps every 700 hours of printing. - Page 108 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 4. Open the printer doors and locate the roller waste pumps. Figure 4-117 Roller waste pumps 5. Release the tube latch on the pump, as shown below. Figure 4-118 Releasing the tube latch DOC-26000 Rev.

- Page 109 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 6. Separate the tube holder from the pump assembly. Figure 4-119 Tube holder removed from pump assembly 7. Remove the tube from the tube holder and save the two parts of the clamp for re-assembly.

- Page 110 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 12. Insert the tube holder into the pump assembly, making sure that the side with the clamp is on the side of the pump marked SUCTION. Figure 4-121 Tube clamp on SUCTION side of pump 13.

- Page 111 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 14. From the Options menu, select Maintenance Counters. 15. Scroll to the General Pumps section and locate the counters for the roller waste pump tubes ("Roller Tube Left" / "Roller Tube Right").

-

Page 112: Calibrating The Load Cells

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Calibrating the Load Cells Load cells are sensors that measure the weight of the material containers and the waste container in the printer. It is important that you periodically check that the weight measurements are accurate to prevent unnecessary waste of printing materials or printer malfunctions. -

Page 113: Replacing The Uv Lamps

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 6. Click Done in the final wizard screen. Figure 4-125 Final wizard screen Replacing the UV Lamps The UV lamps used for curing models have a long, but limited, working life. You can test and adjust their effective power with the UV Calibration wizard (see "Testing and Calibrating the UV Lamps"... - Page 114 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 2. Start the UV Lamp Replacement wizard from the Options menu. Figure 4-127 Selecting the UV Lamp Replacement wizard 3. Make sure that the build tray is empty, and confirm this in the wizard screen.

- Page 115 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 4. Select the UV lamp(s) to be replaced and click Next. Figure 4-129 UV lamp selection screen 5. Disconnect the UV-lamp power connector and the UV heat fuse connector. Figure 4-130 Disconnecting the UV lamp Note: Do not disconnect the power connection to the cooling fans.

- Page 116 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 6. Loosen the screw securing the UV lamp cover (A), and pull the cover up (B), then out (C). Figure 4-131 Removing the UV lamp cover 7. Pull the UV reflector out of the UV housing.

- Page 117 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 9. Remove the UV lamp bulb from the UV reflector. Figure 4-134 Removing the UV lamp bulb 10. Before continuing, inspect the spring-loaded pins. If there are burn marks around the pins or if the pins are loose—their springs are not functioning properly—and do not support the bulb, continue with step...

- Page 118 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 11. Using the polyurethane tube provided in the kit, push the new UV lamp bulb into the UV reflector. Make sure that the tip on the bulb is facing the slot.

- Page 119 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Figure 4-138 Pushing the UV lamp into place 14. Using a 2.5-mm hex key, secure the clamp to the UV reflector, and continue with step Figure 4-139 Attaching the UV lamp clamp 15.

- Page 120 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Warning: Broken UV lamp hazard UV lamps contain mercury. Deal with broken lamps with caution. Ventilate the room thoroughly. Use protective gloves when collecting mercury and lamp components. Remove spilled mercury with a method that prevents the generation of mercury vapor, such as a syringe, packing tape or paper.

- Page 121 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer 19. Reconnect the power and heat fuse connectors. Figure 4-142 Connecting the UV lamp 20. In the wizard screen, confirm that you have replaced the UV lamp(s) and that the black strip is attached, then click Next.

- Page 122 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer The wizard operates the UV lamps and checks if their power is within the acceptable range for each printing mode. Note: The mode currently being checked appears in the lower-left corner of the printer interface.

-

Page 123: Dynamic Nozzle Test

Many gaps in the sample indicates that many nozzles in the print head are not functioning. This might indicate the need to replace the defective head. In this case, consult with your Stratasys service provider. Samples printed from certain Model materials in this test might not be completely cured. -

Page 124: Built-In Tests

A large number of hardware defects (or near-defects) warns you of possible printing problems, either for current or future jobs. Stratasys recommends running the built-in tests in the following cases: as a routine test, once every two weeks as a system check, before major (long) jobs as needed, for troubleshooting DOC-26000 Rev. - Page 125 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer To open the Built-in Tests screen, do one of the following: • From the Options menu, select Built-In Tests. • Press Ctrl+Alt+B. Figure 4-148 Selecting Built-In Tests from the Options menu The Built In Tests screen lists pre-configured tests, grouped by component categories.

- Page 126 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Test List Test Name This column lists all of the tests, together with selection check boxes. Click the check boxes to select the tests you want to run. To remove a selection, click the check box again.

- Page 127 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Test Results To save and view a report of all tests: ➢ Use the Save and View command buttons. Command Buttons Click the command buttons, on the right side of the screen to perform the following operations: Click to run the selected tests.

- Page 128 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Close Click to close the Built-in Tests screen. Summary On the right side of the screen, a symbol represents the combined results of all the tests run, using the symbols from the Status column.

- Page 129 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Test Name Description Possible Reason for Failure Head/Block Heaters Tests the heaters in the print heads Faulty heaters or thermistors. and in the print-block body. System Voltages Checks if the following voltages are •...

-

Page 130: Replacing Waste Containers

Stratasys J4100 User Guide 4 Operating and Maintaining the Printer Replacing Waste Containers Printer waste contains partially cured polymeric material, collected during normal operation and maintenance of the printer. For safety and environmental reasons, this material is kept in two leak-proof containers. - Page 131 Stratasys J4100 User Guide 4 Operating and Maintaining the Printer UV radiation. Use extreme care when cleaning them to prevent the appearance of scratch marks. Caution Do not use abrasive cleaners or cleaning fluids containing ammonia, alcohol, acetone, benzine, carbon or tetrachloride. These materials can cause permanent damage to the surface.

-

Page 132: Handling Printed Models

Handling Printed Models Removing Models After Printing Removing the Build Tray From the Printer Removing the Support Material Removing Support by Hand Removing Support with Water Pressure Removing SUP705 with Caustic Soda Post-Printing Treatment Photobleaching for Transparent Models Storing Models DOC-26000 Rev. -

Page 133: Removing Models After Printing

Removing the Build Tray From the Printer The build tray for the Stratasys J4100 printer is removable, which aids in the handling of printed models. You use a special cart to remove the build tray and transfer it to the cleaning station. -

Page 134: Removing The Support Material

For special printing applications, refer to documents on the Stratasys Support Center or consult a Stratasys 3D printing expert. SUP705 (FullCure705) Support material can be removed from printed models using the following methods, in this order: 1. by hand 2. -

Page 135: Removing Support With Water Pressure

Removing Support with Water Pressure For most models, the most efficient way to remove Support material is by using a high-pressure water jet. Consult Stratasys Customer Support for advice on purchasing and using suitable cleaning units for your printer and requirements. -

Page 136: Post-Printing Treatment

Photobleaching methods and instructions are described in the Best Practices for the relevant clear material. These are available on the Transparent materials page on the Stratasys Support Center. Refer to the Best Practices for: VeroClear RGD810 Storing Models Models are cured as they are printed, making them safe and stable for a long time.

Need help?

Do you have a question about the J4100 and is the answer not in the manual?

Questions and answers