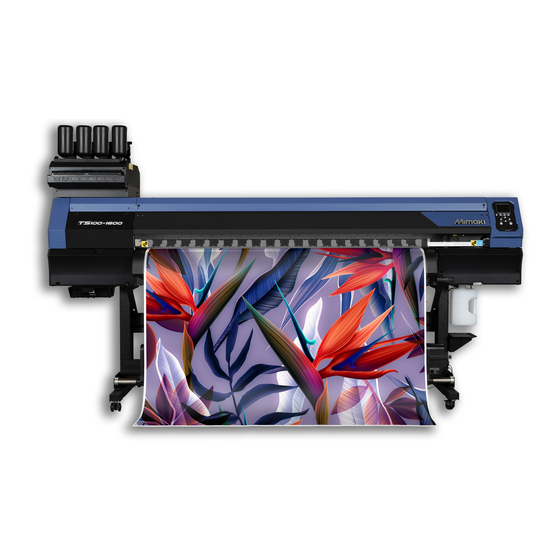

MIMAKI TS100-1600 Operation Manual

Hide thumbs

Also See for TS100-1600:

- Requests for care and maintenance (36 pages) ,

- Maintenance manual (196 pages)

Summary of Contents for MIMAKI TS100-1600

- Page 1 You can also download the latest manual from official website. MIMAKI ENGINEERING CO., LTD. https://mimaki.com/ D203534-14 Original instructions...

-

Page 2: Table Of Contents

1.3 Connecting a PC to the Product .......... 31 Using a USB Cable................ 31 Using a LAN Cable ................ 31 1.4 System Configuration ............. 33 Installing the Mimaki Driver.............. 34 Installing RIP Software ............... 34 Obtaining Color Profiles.............. 34 Setting Up RIP Software.............. 35 1.5 Ink Replacement Method............ - Page 3 2.3 Loading the media .............. 53 Media .................... 53 Take-up unit.................. 53 Loading the Roll Media ............... 56 2.4 Test Printing................ 60 Changing the Layout Direction for Test Printing ......... 60 Ejection Failures ................. 61 2.5 Head Cleaning ................ 62 2.6 Feed Correction ..............

- Page 4 4.3 Consumable Item Replacement ........... 104 Wiper Replacement ................ 104 Wiper Cleaner Replacement............. 105 Cap Replacement ................ 106 Cap Absorber Replacement ............. 107 Exhaust Fan Filter Replacement ............ 109 Blowing Fan Filter Replacement............ 109 Pinch Roller Replacement .............. 110 Media Holder Replacement .............. 111 Media Cutter Replacement ...............

-

Page 5: Introduction

Adobe, the Adobe logo, Acrobat, Illustrator, Photoshop, and PostScript are the trademarks or registered trademarks of Adobe Incorporated in the United States and other countries. RasterLink is the trademark or registered trademark of MIMAKI ENGINEERING CO., LTD. in Japan and in other countries. - Page 6 Use of this product in residential areas may cause harmful interference. If so, the user is responsible for rectifying such interference. • Use only the cables recommended by Mimaki Engineering when connecting to this product. Use of other cables may cause the product to exceed the restrictions stipulated by FCC regulations.

-

Page 7: To Ensure Safe Use

To Ensure Safe Use To Ensure Safe Use Symbols In this manual, the symbols indicate and explain precautions. Make sure you fully understand the meaning of each symbol and use the machine safely and correctly. Explanation Warning Indicates a potential hazard that may result in death or serious injury if handled improperly or if instructions are disregarded. -

Page 8: Usage Precautions

To Ensure Safe Use Usage Precautions l In the event of abnormal conditions • In the event of abnormal conditions such as smoke or unusual odor, turn off the main power immediately and unplug the power cable. Continuing to use the product under these conditions may result in failure, electric shock, or fire. - Page 9 To Ensure Safe Use l Power supply precautions • Use the power cable provided. Otherwise there is a risk of failure, electric shock, or fire. Do not use the power cable with other electronic devices. • Always grasp the plug when unplugging the power cable. Pulling on the power cable itself may damage the cable and result in failure, electric shock, or fire.

- Page 10 To Ensure Safe Use l Caution regarding moving parts • Keep parts of the body such as the face and hands away from moving parts. Also keep clothing (e.g., loose clothing and accessories) that may impede work away from the machine. Failure to do so may result in injury.

-

Page 11: Ink Or Any Other Liquid Used With The Machine

• Be sure to read the safety data sheet (SDS) before use. https://mimaki.com/supply/sds/ • Pay close attention to ventilation and be sure to wear safety glasses, gloves, and a mask when handling ink, maintenance liquid, waste ink, or other solutions used with the machine. Leaking ink may adhere to the skin or get into the eyes or mouth. -

Page 12: Ink Specifications

Storing in locations like this will increase the risk of failure or ejection failures (e.g., nozzle clogging and deflection). Ink Specifications Item Details Type Sublimation transfer ink (MIMAKI product) Color Blue (BL) Magenta (M) Yellow (Y) Black (K) Form... -

Page 13: Installation Precautions

Installation Precautions Installation Precautions • Do not install this machine in environments where flammable substances are present (e.g., gasoline, flammable spray, alcohol, thinner, lacquer, or powder). This machine is not explosion- proof. The product poses a risk of explosion. • Do not install this machine in locations where open flames are present. The ink may ignite. •... -

Page 14: Installation Space

Installation Precautions Installation Space Provide the following space around the machine to allow safe and proper replacement of ink and media: Item TS100-1600 At least 3,775 mm (2,775 mm) Width At least 2,700 mm (700 mm) Depth *1, *2 (1,475 mm) -

Page 15: Safety Interlocks

Safety Interlocks Safety Interlocks The machine is equipped with interlocks to ensure safety during use. Printing will abort if you open the covers while printing is underway. The RIP data will need to be resent. • Safety interlock locations... -

Page 16: Warning Labels

Warning Labels Warning Labels Make sure you fully understand the details indicated on the various warning labels. If any of the warning labels becomes dirty and illegible or peel off, contact your local dealer or our service office to request new warning labels. Carriage Maintenance space... - Page 17 Warning Labels Order code Label Details M910931 Beware of opening and closing parts. Injury may result if hands become trapped. M907833 Indicates dangerous moving parts. M903330 Wear safety glasses and gloves while working. M903405 Beware of the cutter. M905811 Indicates dangerous moving parts. M907935 Indicates dangerous live parts.

- Page 18 Warning Labels...

-

Page 19: Chapter 1 Before Use

Using a LAN Cable ........3 1 Carriage ............. 22 System Configuration ........3 3 Capping station .......... 22 Installing the Mimaki Driver ......3 4 Pinch Rollers and Grit Rollers ....22 Installing RIP Software......... 3 4 Platen ............23 Obtaining Color Profiles ....... -

Page 20: Part Names And Functions

Chapter 1 Before Use 1.1 Part Names and Functions Front Name Overview Platen Print area. "Platen"(P. 23) Pinch roller The pinch rollers and grit rollers are used to grip and feed the media. "Pinch Rollers and Grit Rollers"(P. 22) Grit roller Capping station Includes caps, wipers, and an NCU for monitoring print head nozzle conditions. -

Page 21: Rear And Right Side View

Chapter 1 Before Use Rear and Right Side View Name Overview Clamp lever (rear) Linked to the clamp lever at the front. Media Sensor Detects whether media is present. "Media Sensor"(P. 23) Blowing fan Blows air to dry ink after printing. Feeding unit Holds the roll media before printing. -

Page 22: Carriage

Chapter 1 Before Use Carriage The carriage includes a print head for ejecting ink, and a jam sensor for stopping the carriage when media clogs. Printing occurs as ink is ejected while traversing left and right. Capping station The capping station includes caps for keeping the print head nozzle surface from drying out, a wiper required for print head maintenance, and an NCU for monitoring print head nozzle conditions. -

Page 23: Platen

Chapter 1 Before Use • Attach the clamp changeover sliders to the pinch rollers at the left and right-hand ends of the media. The pinch rollers can be raised by attaching clamp changeover sliders. This prevents gripping the left and right-hand ends of the media for consistent feeding. Clamp changeover slider Platen... -

Page 24: Power Supply Switch

Chapter 1 Before Use Power Supply Switch l Main power switch This is located on the right-hand side of the product. Main power supply switch • Do not turn off the main power supply. Turning off the main power supply will disable the automatic maintenance function (including nozzle clogging prevention function and ink discharge channel cleaning function). -

Page 25: Operating Panel

Chapter 1 Before Use Operating Panel This is used to control the product and make/change settings. xxxx TEST PRINT MENU REMOTE CLEANING Name Outline Display "Display"(P. 26) [SEL] key Selects the function for the corresponding [FUNCTION] key. [FUNCTION] key Used for test printing, head cleaning, and editing settings "[FUNCTION] key"(P. - Page 26 Chapter 1 Before Use Display LOCAL<SETUP 1> MENU mode <setting type number> Connected cable type Head height 1620mm Detected media width Ink status TEST PRINT MENU REMOTE Function name assigned to [FUNCTION] CLEANING MENU mode Four menu modes are available. Name Outline LOCAL mode...

- Page 27 Chapter 1 Before Use [FUNCTION] key This section describes the functions and roles assigned to the [FUNCTION] key. Icon Outline Displays the various menu screens. "Settings"(P. 73) Displays maintenance functions such as test printing and cleaning. Used to switch from LOCAL mode to REMOTE mode. Displays adjustment functions such as feed adjustment and drop position adjustment.

- Page 28 Chapter 1 Before Use Displaying Machine Information (Local Guidance) Press the [ENTER] key on the LOCAL mode screen to display the following information. • Ink information: Displays ink type, remaining ink levels, and ink errors. • Ink IC chip registration information: Displays the information registered on the ink IC chip. •...

-

Page 29: Connecting The Power Cable

Chapter 1 Before Use 1.2 Connecting the Power Cable Check to confirm that the main power supply is turned off. Insert the cable band to the machine. Plug the power cable into the inlet of the machine. Secure the power cable to the cable band. •... -

Page 30: Turning Off The Power

Chapter 1 Before Use Press the [END/POWER] key to turn on power. • The firmware version appears on the display, and the initial operation is executed. LOCAL mode is then set and the machine is ready for use. [END/POWER] key Turn on the power for the connected PC. -

Page 31: Connecting A Pc To The Product

USB Connection Precautions l When connecting more than one TS100-1600 to a PC The TS100-1600 may not be correctly recognized. If the PC has more than one USB port, try connecting to a different USB port to check whether the product is correctly recognized. - Page 32 Chapter 1 Before Use • The PC used to transfer print data must be located on the same network as this product. This product cannot be connected via a router. • Use a 1000BASE-T compatible computer or switching hub. Printing requires 1000BASE-T support. Switching hub l Checking the LAN connection Check the display on this product.

-

Page 33: System Configuration

Chapter 1 Before Use 1.4 System Configuration Use RIP software to request to print data created using applications like Illustrator or Photoshop. [Ethernet connection] RIP-PC Receiving Print Data Generating RIP Data [Local network] Preparing RIP Data Print request... -

Page 34: Installing The Mimaki Driver

The explanation here applies to MIMAKI RIP software (RasterLink). • If using TxLink, refer to the TxLink operating manual. Launch "Profile Update". (1) From the Start menu, select [Mimaki RasterLink7] > [Profile Update]. (2) Click [Next]. Select the TS100-1600 being used. -

Page 35: Setting Up Rip Software

Profile Manager. https://mimaki.com/download/inkjet.html [TS100-1600] > [Profile] Setting Up RIP Software The explanation here applies to MIMAKI RIP software (RasterLink). • If using TxLink, refer to the TxLink operating manual. Launch RasterLink. • The [Printer Management] screen appears. - Page 36 Chapter 1 Before Use Register TS100-1600. (1) Click [Add]. (2) Set the specifics for TS100-1600. • Model: Select the model. • Color: Select the ink set filled. • Output Port: Select the cable connected. • Available Printers: Select TS100-1600 connected.

-

Page 37: Ink Replacement Method

Chapter 1 Before Use 1.5 Ink Replacement Method When Ink Near End is Displayed Ink levels are low. We recommend replacing with new Ink bottle as soon as possible. Printing is still possible, but cleaning and continuous printing are not possible. Note that ink may run out during printing. To check which Ink bottle needs to be replaced, press the [ENTER] key on the LOCAL mode screen. -

Page 38: Replacing Ink

Chapter 1 Before Use Replacing Ink l Removing the Ink bottle Rotate the lever on the tank section from left to right. • Never attempt to rotate the ink bottles. Doing so may result in leaking ink. Lift the ink bottles vertically. Light-blocking cover •... - Page 39 Chapter 1 Before Use Wipe off any ink on the ink bottle caps with paper wipes. • Check to confirm that there is no foreign matter, such as paper towel scraps or dust, adhering to the ink bottle caps. Continuing to use it when it is dirty may result in foreign matter blocking the ink channels, causing ink leakage.

- Page 40 Chapter 1 Before Use • If the mouth of the ink bottle is fitted with a seal (1) Cut the seal open using a craft knife. There is a risk of ink leakage if parts of the seal remain. No good (2) Take care not to damage the mouth of the ink bottle.

- Page 41 Chapter 1 Before Use Use the tightening jig to tighten the ink bottle caps in place. Tightening tool [SPA-0232] Good example Bad example Position the upper arrow within this range! [SPA-0328] Good example Bad example Position the upper arrow within this range! •...

- Page 42 Chapter 1 Before Use Mount ink bottles. • Rotate the lever from the left to the right end, then mount the ink bottle. Lever • You may apply the maintenance liquid onto the O-ring of the ink bottle caps so that the ink bottle can be inserted easily.

- Page 43 Chapter 1 Before Use Insert a new ink IC chip into the ink IC chip slot on the right-hand side of the product. • A registration screen appears when the ink IC chip is inserted. Press the OK button. • The information on the ink IC chip is registered. Ink IC Chip Registrasion Color : Magenta Expiration : 2021/01/01...

- Page 44 Chapter 1 Before Use Message Cause Corrective action Replace Ink • The ink IC chip was • Mount new ink and register the ink IC registered when an ink chip. end or ink near-end error occurred. • Ink IC chips The marking on the ink IC chip indicates the color information.

- Page 45 Chapter 1 Before Use Press the [FUNC3] key. Ink IC Chip Registrasion This Ink IC chip has been registered Press [FUNC3] key to Ink IC write back ↓ • The rewritten ink information is reset, and "Ink IC is not registered" appears.

- Page 46 Chapter 1 Before Use...

-

Page 47: Chapter 2 Printing

Chapter 2 Printing This chapter This chapter describes printing procedures and settings. Print Process ...........48 Feed Correction..........6 3 Feed Correction Procedure......6 3 Adjust Print Head Height .........51 Correcting the Drop Position ......6 5 Loading the media ...........53 Drop Position Correction Procedure .... -

Page 48: Print Process

Chapter 2 Printing 2.1 Print Process Turn on the power. "Turning On the Power"(P. 29) [END/POWER] key Connect a RIP PC to the machine. "Using a USB Cable"(P. 31) "Using a LAN Cable"(P. 31) Setting Up RIP Software "Installing RIP Software"(P. 34) (required first time only) "Obtaining Color Profiles"(P. - Page 49 Chapter 2 Printing This machine can be used with roll media. "Loading the media"(P. 53) Take-up unit Core Check the state of the print head nozzles. "Test Printing"(P. 60) Good example Bad example Deflection Nozzle clogging Clean the head to clear malfunctioning nozzles. There are three different head cleaning methods.

- Page 50 Chapter 2 Printing Printing RIP Data "Printing"(P. 69) Cutting the Media "Cutting the media"(P. 71)

-

Page 51: Adjust Print Head Height

Chapter 2 Printing 2.2 Adjust Print Head Height Adjust the height of the print head according to the thickness of the media you are using. Range Gap between print head and platen 3.0 mm (default setting) High 3.5 mm • Be sure to correct the dot position after altering the print head height. "Correcting the Drop Position"(P. - Page 52 Chapter 2 Printing Retighten the carriage cover screws. • Do not touch the height adjustment lever. Once adjustment is complete, close the cover, then press the [ENTER] key.

-

Page 53: Loading The Media

Media l Media handling precautions • Use Mimaki-approved media to ensure consistent high-quality printing. • Assign at least two people to load roll media. Otherwise there is a risk of back injury due to the weight of the media. - Page 54 Chapter 2 Printing Name Overview ON/OFF button Press the button to start/stop the take-up unit. The setting can be altered so that the take-up unit operates only while the button is depressed. "Machine setup menu"(P. 81) Adjusting the Torque Limiter The take-up unit is fitted with a torque limiter.

- Page 55 Chapter 2 Printing Media diameter Distance between edge guide and media edge ⌀161 mm to ⌀200 mm 5 mm...

-

Page 56: Loading The Roll Media

Chapter 2 Printing Loading the Roll Media Raise the clamp lever. Move the rear left roll holder to the roll setting position. • Unscrew the roll holder retaining screw before moving. Setting position for 3-inch paper core Set the roll holder reference line within the area indicated by the arrows as shown below. - Page 57 Chapter 2 Printing Insert the media. • Insert into the gap between the pinch rollers and the grit rollers. • Inserting the media at an angle allows smooth insertion without catching or sticking. Lower the clamp lever. • Hold the media with the pinch roller and grit rollers. Move to the front of the machine and open the front cover.

- Page 58 Chapter 2 Printing Lower the clamp lever. Secure the media in the media holder. Media holder • Do not use the media holder when printing on thicker media. Press , then select "Roll". • This starts media width detection. • If the setting for [Machine Setup] > [Media Detect] > [Detection Type] is "MANUAL", the area for printing must be determined manually.

- Page 59 Chapter 2 Printing Secure the media to the take-up unit. (1) Press to feed the media until it reaches the core on the take-up unit. (2) Secure the middle of the media with adhesive tape. (3) Secure the media on the right and left in the same way. •...

-

Page 60: Test Printing

Chapter 2 Printing 2.4 Test Printing Print a test pattern to confirm that the ink prints correctly. Perform head cleaning if you observe any ejection failures (e.g., nozzle clogging or deflection). "Head Cleaning"(P. 62) Head 1 Head 1 Head 2 Head 2 Check beforehand •... -

Page 61: Ejection Failures

Chapter 2 Printing Ejection Failures Typical examples of ejection failures (e.g., nozzle clogging, deflection) are as shown below. In order to prevent printing in such a state, check whether the ink has been properly ejected regularly before printing. Nozzle Deflection Nozzle clogging Ink drips Mist... -

Page 62: Head Cleaning

Chapter 2 Printing 2.5 Head Cleaning The following head cleaning methods are available. Choose the method based on test results. Item Details Soft If the print shows a bent line (deflection) Normal If the print shows a missing line (nozzle clogging) Hard If soft cleaning and normal cleaning fail to resolve print defects (e.g., nozzle clogging, deflection) -

Page 63: Feed Correction

Chapter 2 Printing 2.6 Feed Correction Changing the media may affect the feed amount due to various factors, including the weight and thickness of the media and whether the take-up unit is used. Correct the drop position to suit the type of media used. Image defects (e.g., dark or light streaks) will result if the feed is not properly corrected. - Page 64 Chapter 2 Printing • Once adjustment is complete, the medium will be fed to the print origin. Sagging may occur in the rear roll medium. Rewind roll media by hand to eliminate any sagging. Correcting the Media Feed During Printing You can also correct the media feed amount in REMOTE mode or while printing.

-

Page 65: Correcting The Drop Position

Chapter 2 Printing 2.7 Correcting the Drop Position Changing the media and print head height will also alter the drop positions. Correct the drop position to suit the type of media used. Image defects (e.g., overlaid lines or blurred images) will result if the drop position is not properly corrected. - Page 66 Chapter 2 Printing • If the lines do not coincide when the correction value is within the range -40 to 40, the print head height may have been improperly adjusted. Adjust the print head height. "Adjust Print Head Height"(P. 51) Enter the correction value in the same way for pattern 2 and subsequent patterns.

-

Page 67: Preparing Rip Data

(1) Select [File] > [Open]. (2) Select the desired image data, then click [Open]. • If multiple printers are registered, select TS100-1600 in "Printer Name". Select the image data imported. • The image is displayed in the tab for TS100-1600 selected in "Printer name". - Page 68 (execute) from the function icons on the right-hand side of the screen. Select "Immediate Print" or "RIP and Print", then click [Start]. • Media width must be reacquired after replacing media. (1) Select the tab for TS100-1600 in the main window. (2) Click (Update the printer status) in the Printer tab.

-

Page 69: Printing

• The carriage moves left and right and feeds the medium. Press the [ENTER] key. • The origin is updated. Starting Printing Send the RIP data from the PC. • "Preparing RIP data"(P. 67) • When the message "Attention20A Driver version" appears, install the latest Mimaki driver available from: https://mimaki.com/download/inkjet.html... -

Page 70: Stopping Printing (Data Clear)

Chapter 2 Printing Start printing. • Printing starts once RIP data is received. Resolution Number of passes Scan direction (Uni: unidirectional, Bi: bidirectional) Scan speed (Std: standard, Hi: high speed) REMORT Dot type 600x600 16p / Bi / Hi / Vd VD: Variable dot ND: Normal dot 0.0m... -

Page 71: Cutting The Media

Chapter 2 Printing 2.10 Cutting the media On the LOCAL mode screen, press • The Origin Setup screen appears. Press to feed the media to the position required for cutting. Select [CUT], then press the [ENTER] key. • The media is cut. - Page 72 Chapter 2 Printing...

-

Page 73: Chapter 3 Settings

Chapter 3 Settings This chapter This chapter describes the methods for replacing maintenance parts. Setup menu .............74 Machine setup menu ........8 1 Changing the name of a setting type ..76 Event Email Function Settings ..... 8 4 Maintenance Menu ..........77 Nozzle check menu .......... -

Page 74: Setup Menu

Chapter 3 Settings 3.1 Setup menu Print conditions (settings 1 to 4) can be saved in advance for specific media. l Menu List The user can select to prioritize the settings on the machine or the settings on the PC. Setting individual menus to "Host"... - Page 75 HOST/0.0 to Sets the time to stop the carriage each time the carriage 9.9 sec scans. • In the MIMAKI RIP software (RasterLink), it is indicated as the “drying time after each scan”. PRINT END HOST/0 to Sets the stop time after printing. After the set time passes, the 120 min next data is printed.

-

Page 76: Changing The Name Of A Setting Type

Sets whether nozzle checking is performed after auto head cleaning is completed. MAPS4 MAPS: Mimaki Advanced Pass System • This function disperses the boundaries between passes to make feed streaks between passes less visible. • Altering MAPS may alter the color. This function may be less effective with certain types of images. -

Page 77: Maintenance Menu

Chapter 3 Settings 3.2 Maintenance Menu This menu is used for maintenance actions. It also lets the user perform nozzle recovery if nozzle clogging persists even after cleaning and nozzle washing. l Menu List Item Details Setting Station This moves the carriage to allow station and print head maintenance. Carriage Out Move To Cleans around the station, including the cap, wiper, and NCU. -

Page 78: Registering Nozzle Recovery

Chapter 3 Settings Item Details Setting • Cleans the print head. This will help prevent nozzle clogging. Cleaning Type Normal/Soft/ Sets the cleaning type for head cleaning. Hard Waste ink tank Resets or corrects the waste ink tank usage count. "Waste Ink Tank Replacement"(P. - Page 79 Chapter 3 Settings Select the "head number and nozzle row" for nozzle recovery, then press the [ENTER] key. SELECT ENTRY NOZZLE > Head1-A Head1-B > Head number Nozzle row number Head1-C > Head1-D > Head2-A > << >> Enter the "nozzle number" for nozzle recovery, then press the [ENTER] key. •...

- Page 80 Chapter 3 Settings Press the [FUNC2] key. • The judgment result is displayed. No good Judgement result Judgement result Judgement result Judgement result HEAD1-A HEAD1-B HEAD1-C HEAD1-D Head number - nozzle row Number of nozzles that cannot be recovered Press the [ENTER] key once entry is complete.

-

Page 81: Machine Setup Menu

Chapter 3 Settings 3.3 Machine setup menu This is used to set various operations to ensure optimal machine performance. l Menu List Item Details Setting Auto Power-off None/5 min to Sets the time until the power is automatically turned off. 15 min to 600 Auto Power-on Sets the time to automatically turn on the power. - Page 82 Chapter 3 Settings Item Details Setting • Standard: Select “Standard” if the medium is not detected successfully. LANGUAGE English/ Sets the display language. Japanese/ Chinese Time Set -20 h to 0 to Sets the current time and date. (With respect to JST) +4 h •...

- Page 83 Chapter 3 Settings Item Details Setting Select Event Print Start ON/OFF Sets whether an email is sent when printing starts. Event Print End ON/OFF Sets whether an email is sent when printing ends. Event Plot Start ON/OFF Sets whether an email is sent when cutting starts. Event Plot End ON/OFF...

-

Page 84: Event Email Function Settings

• Internet communication charges for email notifications, etc. are the responsibility of the customer. • Event emails may not be delivered if problems arise with the Internet setup or equipment. Mimaki rejects all liability for damages resulting from delivery failure or delay. - Page 85 Chapter 3 Settings Error code Likely cause Corrective action No valid email address • Enter a valid email address. 11003 No POP server could be • Check the POP server address. found. or the DNS server 11004 • Check if the network setup allows this machine to use could not be accessed.

-

Page 86: Nozzle Check Menu

Chapter 3 Settings 3.4 Nozzle check menu This is used to check if the nozzles are clogged before printing. Sets whether to perform maintenance functions automatically if nozzle clogging is detected. [Printing Check] The nozzles are not checked. Nozzle check (nozzle clogging detection) [Judgment Condition] setting for nozzle clogging detection If less than the set value... -

Page 87: Information Menu

Chapter 3 Settings 3.5 Information menu This is used to check machine information. l Menu List Item Details Usage Wiping Displays the wiping count. • To reset this count, press the [FUNC2] key while the count is displayed. Waste ink Displays the approximate level of waste ink in the waste ink tank as a percentage. - Page 88 Chapter 3 Settings...

-

Page 89: Chapter 4 Maintenance

Chapter 4 Maintenance This chapter To ensure years of precise performance, maintain the machine periodically based on frequency of use. Read the maintenance precautions thoroughly before maintaining this product. Maintenance Precautions ........90 Consumable Item Replacement ..... 1 04 Wiper Replacement ........1 04 Maintenance Methods ........91 Wiper Cleaner Replacement ...... -

Page 90: Maintenance Precautions

Chapter 4 Maintenance 4.1 Maintenance Precautions • This machine includes parts that must be replaced periodically. We therefore recommend taking out a maintenance contract. Carry out maintenance periodically and replace consumable items to prevent quality defects and accidents. • Clean periodically. Debris and dust will accumulate on electrical components when the machine is used for extended periods. -

Page 91: Maintenance Methods

Unused for a Long Time"(P. 101) Items Required for Maintenance To order replacement consumable items, contact your local dealer or our service office. For more information on consumable items, refer to our website (https://mimaki.com/supply/inkjet.html). • Avoid storing this product in locations accessible to children. -

Page 92: Ink Maintenance

Chapter 4 Maintenance Ink Maintenance If ink constituents are sedimented, the ink density may become uneven. We recommend shaking the Ink bottle periodically to keep printing consistent. Dye sublimation ink: once a week. l Shaking the Ink bottle Shake the Ink bottle to the left and right slowly at least 20 times. •... - Page 93 Chapter 4 Maintenance Remove the wiper. • Hold the lug at the rear of the wiper bracket, then pull out the wiper. Clean the wiper and bracket. • Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid. Wipe off the maintenance liquid.

-

Page 94: Cap Rubber Cleaning

Chapter 4 Maintenance • Do not remove the absorbent material in the absorbent material case. Doing so may result in leaking ink. Once cleaning is complete, close the cover, then press the [ENTER] key. Cap Rubber Cleaning The cap prevents the print head nozzle surface from drying out. Continuing to use a dirty cap may affect ink take-up and lead to print defects (e.g., nozzle clogging, deflection). -

Page 95: Ncu Cleaning

Chapter 4 Maintenance NCU Cleaning The NCU uses a sensor to monitor the ink droplets ejected from the print head nozzles. Continuing to use the dirty NCU may prevent the nozzle check function from operating correctly. • Be careful to avoid leaving fragments from the cleaning stick behind when cleaning. These fragments will increase the risk of ejection failures (e.g., nozzle clogging or deflection). -

Page 96: Automatic Correction Sensor (Das) Cleaning

Chapter 4 Maintenance Open the maintenance covers. Clean around the print head. • Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid. Wipe off the maintenance liquid. Make sure none remains. Clean the print head sides (dark red area) using a cleaning stick. -

Page 97: Ink Discharge Channel Cleaning

Chapter 4 Maintenance Open the maintenance covers. Clean the DAS sensor. • Wipe clean using cotton swabs or a soft cloth. • For heavy soiling, wipe using a soft cloth soaked in diluted neutral detergent and thoroughly wrung out. Once cleaning is complete, close the cover, then press the [ENTER] key. Ink Discharge Channel Cleaning Clean the ink discharge channel regularly to prevent clogging of the ink discharge channel below the cap. -

Page 98: Media Sensor Cleaning

Chapter 4 Maintenance • If not, use a syringe to draw up some maintenance liquid and fill until it almost overflows from the cap. Close the front cover, then press the [ENTER] key. • Pump tube (ink discharge channel below the cap) washing starts. Media Sensor Cleaning Media sensors are located on the rear cover and carriage underside. -

Page 99: Media Holder Cleaning

Chapter 4 Maintenance Once cleaning is complete, close the cover, then press the [ENTER] key. Media Holder Cleaning • Turn off the main power supply and unplug the power cable before carrying out maintenance. • Do not allow liquids to get inside the machine. Otherwise there is a risk of failure, electric shock, or fire. -

Page 100: Cover (Exterior) Cleaning

Chapter 4 Maintenance • For heavy soiling, wipe using a soft cloth soaked in diluted neutral detergent and thoroughly wrung out. Cover (Exterior) Cleaning • Do not allow liquids to get inside the machine. Otherwise there is a risk of failure, electric shock, or fire. -

Page 101: When This Printer Is Left Unused For A Long Time

Chapter 4 Maintenance Remove the filter. Blowing fan filter Wash the filter. • Dry the filter after washing. Attach the dry filter together with the fan filter cover. • Push in the fan filter cover until the tab clicks. When this Printer is Left Unused for a Long Time Clean as follows if the product is not used for one week or longer: Check beforehand Is [Near End] or [Ink End] displayed? - Page 102 Chapter 4 Maintenance Press the [ENTER] key once cleaning is complete. • "Cap Cleaning Completed (Next) [ENT]" appears on the display. Clean the cap rubber. • "Cap Rubber Cleaning"(P. 94) Once cleaning is complete, close the cover, then press the [ENTER] key. •...

- Page 103 Chapter 4 Maintenance • If not, use a syringe to draw up some maintenance liquid and fill until it almost overflows from the cap. Close the front cover, then press the [ENTER] key. • Pump tube (ink discharge channel below the cap) washing starts. •...

-

Page 104: Consumable Item Replacement

4.3 Consumable Item Replacement To order replacement consumable items, contact your local dealer or our service office. For more information on consumable items, refer to our website (https://mimaki.com/supply/inkjet.html). • Avoid storing this product in locations accessible to children. • When disposing of the product, contact an industrial waste disposal operator or dispose of the product in accordance with the local laws and regulations. -

Page 105: Wiper Cleaner Replacement

Chapter 4 Maintenance Mount a new wiper. Once replacement is complete, close the cover, then press the [ENTER] key. • The wiper usage count is reset. Wiper Cleaner Replacement Replace with a new wiper cleaner once a year. On the LOCAL mode screen, select [MENU] > [Maintenance], then press the [ENTER] key. •... -

Page 106: Cap Replacement

Chapter 4 Maintenance Mount a new wiper cleaner. • Slide backward to attach. Install the fitting. • Improper attachment may result in leaking maintenance solution. Once replacement is complete, close the cover, then press the [ENTER] key. Cap Replacement If ejection failures (e.g., nozzle clogging or deflection) remain unresolved even after cleaning, replace with a new cap. -

Page 107: Cap Absorber Replacement

Chapter 4 Maintenance Remove the cap. • Squeeze the lugs on either side of the cap and pull off. Apply maintenance liquid. • Use a syringe to apply two or three drops of maintenance liquid to the hole at the front. Mount a new cap. - Page 108 Chapter 4 Maintenance Open the front cover. Remove the cap absorber. • Push up the two tabs at the front to remove the cap absorber. Cap absorber • Avoid ink dripping when removing the cap absorber. Clean the carriage base. Cap base Mount a new cap absorber.

-

Page 109: Exhaust Fan Filter Replacement

Chapter 4 Maintenance Close the front cover, then turn on the power. • Check to confirm that the carriage returns to the station. Exhaust Fan Filter Replacement Check the exhaust fan filter condition. Replace if very dirty. Remove the exhaust fan box. •... -

Page 110: Pinch Roller Replacement

Chapter 4 Maintenance Remove the fan filter cover. • Push the fan filter cover claw outward, and pull the cover to the front. Fan filter cover Claw Remove the filter. Blowing fan filter Mount a new filter and the fan filter cover. •... -

Page 111: Media Holder Replacement

Chapter 4 Maintenance Raise the clamp lever. Remove the O-ring retaining the pinch rollers. O-ring • The pinch rollers are small. Be careful to avoid dropping them into the product interior. Remove the pinch rollers. Pinch roller Mount new pinch rollers, and secure them using the O-ring. Close the front cover. - Page 112 Chapter 4 Maintenance Remove the side screw, and detach the media holder stopper. Remove the media holder. Remove the sliders from the media holder. • Be careful to avoid misplacing the sliders. Mount the sliders on to the new media holder. •...

-

Page 113: Media Cutter Replacement

Chapter 4 Maintenance Mount the new media holder on to the platen. Secure the media holder stopper with the screw. Close the maintenance covers. Media Cutter Replacement Replace cutters when blades are chipped or blunt. • Avoid touching the cutter blade. Failure to do so may result in injury. •... -

Page 114: Media Edge Guide Film Replacement

Chapter 4 Maintenance Unscrew the screw, then open the carriage cover hatch. Replace the media cutter. (1) Unscrew the cutter screw. Screw (2) Remove the cutter. (3) Mount a new cutter. (4) Tighten the screw to clamp the cutter. Close the carriage cover hatch, then retighten the screw. Once replacement is complete, close the cover, then press the [ENTER] key. -

Page 115: Waste Ink Tank Replacement

Chapter 4 Maintenance • Make sure no parts of the double-sided tape remain. Remove the double-sided tape on the media edge guide film and attach it to the media edge guide. • Align and attach the film hole (x2) to the screw hole (x2) of the media edge guide. Media edge guide film L Media edge guide film R Media edge guide L... - Page 116 Chapter 4 Maintenance Select [Adjust Waste Ink Volume], then press the [ENTER] key. Press to adjust the level. Press the [ENTER] key once adjustment is complete. Replacing the Waste Ink Tank On the LOCAL mode screen, select [MENU] > [Maintenance], then press the [ENTER] key. •...

- Page 117 Chapter 4 Maintenance • When disposing of the product, contact an industrial waste disposal operator or dispose of the product in accordance with the local laws and regulations. Mount a new waste ink tank. Close the waste ink tank stopper. Press the [ENTER] key.

- Page 118 Chapter 4 Maintenance...

- Page 119 Chapter 5 Troubleshooting This chapter This chapter explains procedures for troubleshooting and addressing messages on the display. Troubleshooting..........120 Problems Causing Messages to Appear ..1 25 The power does not turn on..... 120 Warning Messages ........1 25 Printing is not possible......120 Ink Error .............

-

Page 120: Chapter 5 Troubleshooting

Chapter 5 Troubleshooting 5.1 Troubleshooting For information on troubleshooting, refer to this chapter. Refer to our website (https://mimaki.com/support/) for frequently asked questions (FAQs) about this product and customer support videos. If the recommended corrective action does not resolve the problem, contact your local dealer or our service office. -

Page 121: Image Defects Occur

Attach the tape, taking care not to block the vacuum hole. For more information, refer to the description on transporting media on the platen. https://mimaki.com/download/inkjet.html Image defects occur. Symptom Corrective action White streaks, blurriness, and dark Remove any paper scraps or other debris adhering to areas over which the head passes (e.g., media holders). - Page 122 Attach the tape, taking care not to block the vacuum hole. For more information, refer to the description on transporting media on the platen. https://mimaki.com/download/inkjet.html Print Head Nozzle Washing If printing defects (e.g., nozzle clogging or deflection) remain unresolved even after head cleaning ( "Head Cleaning"(P.

-

Page 123: The Ink Has Leaked Out

Chapter 5 Troubleshooting • If not, use a syringe to draw up some maintenance liquid and fill until it almost overflows from the cap. Close the front cover. Set the exposure time, then press the [ENTER] key. • Print nozzle washing starts. The elapsed time is displayed on the display. •... - Page 124 Chapter 5 Troubleshooting Insert the lug on the other side while pushing in toward the first hole in Step 1.

-

Page 125: Problems Causing Messages To Appear

Chapter 5 Troubleshooting 5.2 Problems Causing Messages to Appear If a problem arises, the buzzer sounds and a message appears on the display. You can also check the local guidance. "Displaying Machine Information (Local Guidance)"(P. 28) Take the appropriate action in accordance with the content of the message. If a message reappears even after taking the prescribed action, contact your local dealer or our service office. -

Page 126: Ink Error

Chapter 5 Troubleshooting Message Cause Corrective action No media detected • The media width has not • Detect the media width. "Loading been detected. the media"(P. 53) Replace Wiper • The wiping count • Replace the wiper, then reset the count. exceeded the preset "Wiper Replacement"(P. -

Page 127: Messages Displayed On The Ink Ic Chip Registration Screen

Chapter 5 Troubleshooting Message Cause Corrective action Ink Near End • Ink levels are low. • The ink will run out soon. Have new ink ready. "When Ink Near End is Displayed"(P. 37) Check to confirm the ink IC chip was Wrong Ink IC •... -

Page 128: Error Message

Chapter 5 Troubleshooting Message Cause Corrective action Check to confirm the ink IC chip was Wrong Ink IC • An error occurred with the inserted correctly. "Registering the Ink information on the ink IC IC Chip"(P. 42) chip. Turn off the main power and wait a while before turning back on. - Page 129 RIP software. parameters that do not allow printing. Driver Version • Printing is not possible • Install the latest Mimaki driver because the Mimaki driver available from: version is old. https://mimaki.com/download/ inkjet.html USB INIT ERR •...

- Page 130 Chapter 5 Troubleshooting Error Message Cause Corrective action number Take-up Roll Sns Err • A problem was detected Check to confirm the [Machine Setup] > [ Feeding/Take-up] > [Take-up Unit] with the take-up unit setting is "ON". sensor spindle. Check to confirm the media is loaded correctly.

- Page 131 Chapter 5 Troubleshooting Error Message Cause Corrective action number NCU CONNECT • A problem was detected with the NCU connection. Replace NCU • A problem was detected • The NCU must be replaced. with the nozzle clogging Contact your local distributor, our assessment.

-

Page 132: System Halt

Chapter 5 Troubleshooting SYSTEM HALT Error Message Corrective action number WIPER ORG Clean the wiper and around the wiper. "Wiper Cleaning"(P. 92) Turn off the power on the machine and turn it on after a while. "Turning Off the Power"(P. 30) Turn off the power on the machine and turn it on after a while. -

Page 133: Chapter 6 Appendix

Chapter 6 Appendix This chapter This chapter explains the specifications of this machine. Specifications ..........134 LICENSE Library ..........1 37... -

Page 134: Specifications

Chapter 6 Appendix 6.1 Specifications Item Details Print head Type On-demand piezo head Specifications Two staggered heads with 420 nozzles × 4 rows each Resolution Y: 360 dpi, 720 dpi X: 600 dpi, 900 dpi, 1,200 dpi Ink set 4-color BL, M, Y, K Media Type... - Page 135 Chapter 6 Appendix Item Details Interface Data transfer USB 2.0 Hi-speed, Ethernet 1000BASE-T function Email function Ethernet 10BASE-T/100BASE-TX/1000BASE-T Commands MRL-V Languages English, Japanese, Chinese Noise During standby Not more than 58dB (FAST-A, 1 m on all sides) levels Continuous Not more than 65dB operation Non-continuous Not more than 75dB...

- Page 136 Chapter 6 Appendix Item Details 168 kg (215 kg) Weight *1. Setup menu margins set to the minimum (5 mm) on either side *2. External diameter and weight after winding media *3. Free of sagging due to weight *4. 3 inch only for high-speed printing *5.

-

Page 137: License Library

Chapter 6 Appendix 6.2 LICENSE Library Mimaki printer Firmware Copyright @2020 MIMAKI ENGINEERING CO.,LTD. All rights reserved. This product contain open source software listed in the tables below. Component License StarterWare for ARM® based TI Sitara Processors BSD-TI The following license terms and conditions shall apply to the open source software listed in the table above: BSD-TI Copyright (C) 2010 Texas Instruments Incorporated - http://www.ti.com/... - Page 138 Chapter 6 Appendix...

- Page 139 Index Index AC inlet ................................ 21 Adjust Waste Ink Volume .......................... 116 Auto Cleaning .............................. 75 Auto Correct .............................. 126 Auto Correct .............................. 74 Auto Maint.............................. 77 Auto Nozzle Recovery ............................ 86 Auto Power-off.............................. 81 Auto Power-on.............................. 81 Auto Remote .............................. 83 Auto-correction ............................... 96 Blowing fan ............................. 21, 100, 109 Bottle cap ............................. 38, 39, 40, 41 Cancel ................................ 25 Cap .............................. 91, 94, 106...

- Page 140 Index DRYING TIME .............................. 75 Ejection failures ............................ 120 [END/POWER] key.......................... 24, 25, 30 [ENTER] key.............................. 25 Error................................ 25, 125 Error History .............................. 87 Event Mail.............................. 82, 84 Exhaust fan BOX ............................ 109 Exhaust fan filter............................ 109 FCC .................................. 5 Feed Comp........................... 27, 49, 63, 74 Feed Speed .............................. 75 Feeding unit.............................. 21 Feeding Before Cut ............................

- Page 141 Media edge guides ............................ 20 Media feed.............................. 25 Media hanger .............................. 56 Media holder............................. 91, 99 Media Remain .............................. 81 Media sensor .............................. 91 Media Sensor ............................. 21, 23, 98 MENU mode .............................. 26 Mimaki driver .............................. 34 Move To Maint. Space ........................... 77 Move To Platen Right End .......................... 77...

- Page 142 Index NCU.............................. 22, 91, 95 Network ................................ 82 NOT-READY mode ............................ 26 Nozzle check menu ............................ 86 Nozzle Recovery ............................ 77 Nozzle Wash .............................. 122 Nozzle Wash .............................. 77 Operating Panel ............................ 20, 25 Pinch roller ............................ 20, 22, 110 Platen ............................ 20, 23, 91, 99 Power cable.............................. 29 Power outlet .............................. 29 Power plug .............................. 29 Prefeed ................................ 76...

- Page 143 Index Smoothing Level............................. 76 Space Btwn PP.............................. 82 Space Feed Mode ............................ 82 Station ................................ 77 Status lamp .............................. 25 Switching hub .............................. 32 Symbols................................ 7 SYSTEM HALT .............................. 25 Take-up SW .............................. 81 Take-up Unit ............................ 20, 53, 81 Test printing.............................. 25, 60 Time Set ................................. 82 Top blower.............................. 81 Torque limiter .............................. 54 UNIT / LENGTH.............................. 82 UNIT / TEMP .............................. 82 Usage ................................ 87...

- Page 144 MEMO...

- Page 145 Operation manual February, 2023 MIMAKI ENGINEERING CO.,LTD. 2182-3 Shigeno-otsu, Tomi-shi, Nagano 389-0512 JAPAN D203534-14-10022023...

- Page 146 © MIMAKI ENGINEERING CO., LTD.2021 FW : 4.4...

Need help?

Do you have a question about the TS100-1600 and is the answer not in the manual?

Questions and answers