Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for MIMAKI TS3-1600

- Page 1 MIMAKI ENGINEERING CO., LTD. URL: http: // www.mimaki. co. jp/ D201937-15...

-

Page 2: Table Of Contents

TABLE OF CONTENTS CAUTION ..............vii DISCLAIMER OF WARRANTY ........vii Requests ..............vii FCC Statement (USA) ..........vii Interference to televisions and radios ......vii Foreword ..............viii On This Operation manual .........viii Features ...............ix Safety Precautions ............xi Symbols ..............xi CHAPTER 1 Before Use Moving this machine .......... - Page 3 CHAPTER 2 Basic Operations User type ..............2-2 Set items registrable to User type ......2-2 Using the registered user type ........2-2 Workflow ..............2-3 Turning the power ON/OFF ........2-4 Turning the power ON ..........2-4 Turning the power OFF ..........2-5 Setting medias ............2-6 Useable medias ............

- Page 4 CHAPTER 3 Convenient use User type ..............3-2 Registering the drawing conditions together (Type registration) .............3-2 Registering Type ............3-2 Setting media compensation ........3-5 Setting media compensation ........3-5 Changing the set value of Heater ......3-8 Changing temperature settings of Heater ....3-8 Adjusting suitable temperature adjustment (When solvent ink is used) ........3-10 In case the heater temperature is too low ....3-11...

- Page 5 To use sublimation transfer ink with more stable quality ...............3-48 To prevent color change ......... 3-48 Note on head height adjustment ......3-51 Confirming machine information ......3-52 Displaying Information ..........3-52 CHAPTER 4 Routine Maintenance Maintaining ..............4-2 Precautions in cleaning ..........4-2 Notes on cleaning solution ........

- Page 6 Other maintenance functions ........4-34 Changing the warning time of wiper replacement ...4-34 Setting the media remaining display .......4-35 White Ink Maintenance Function ......4-37 If Waste ink tank confirming message is displayed .4-39 Changing the ink .............4-43 Replacing the cutter blade ........4-44 CHAPTER 5 Troubleshooting Troubleshooting ............

-

Page 8: Caution

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. In the case where MIMAKI-recommended cable is not used for connection of this device, limits provided by FCC rules can be exceeded. -

Page 9: Foreword

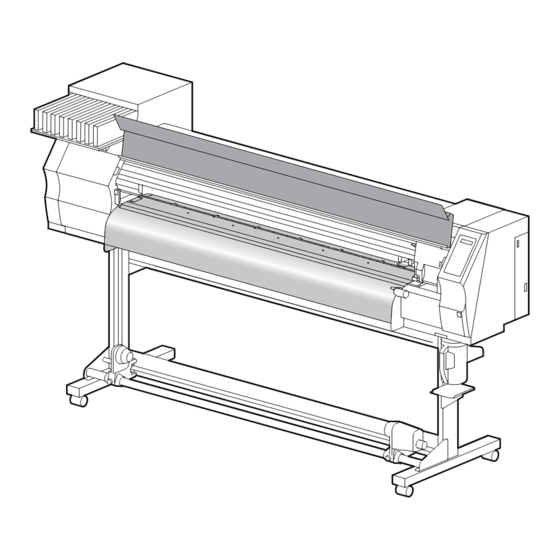

Foreword Congratulations on your purchase of MIMAKI color ink jet printer "TS3-1600" . The TS3-1600 is a color ink-jet printer for high quality printing with solvent ink (4-color/6-color and 6-color) or aqueos ink (4-color and 6-color). • 4-colors version : 2 each of Cyan, Magenta, Yellow and Black color ink cartridge are useable. -

Page 10: Features

Features The features of the machine are described below. Understanding them together with the operating instructions given in this manual will help you use the machine properly. High image quality and High-speed printing realized by the new generation printer head. Newly developed printer head, 1 head consisting of 1440 nozzles (180 nozzles x 8 lines), is adopted. - Page 11 Features Easy maintenance The automatic capping system for the heads eliminates the need of head cleaning before turning off the power. Ink discharge passage is automatically cleaned from the cap. Nozzles can be unclogged by performing the cleaning function. If the machine is not in use for a prolonged period of time, it automatically performs nozzle clogging preventive operation at fixed intervals.

-

Page 12: Safety Precautions

Safety Precautions Symbols Symbols are used in this Operation Manual for safe operation and for prevention of damage to the machine. The indicated sign is different depending on the content of caution. Symbols and their meanings are given below. Please follow these instructions as you read this manual. Examples of symbols Meaning Failure to observe the instructions given with this symbol can result in death or serious injuries to... - Page 13 Check first that the machine no longer produces smoke, and then contact your distributor or a sales office of MIMAKI for repair. • Never repair your machine by yourself since it is very dangerous for you to do so.

-

Page 14: Precautions In Use

MIMAKI. Note on maintenance • When cleaning the ink-station or the heads, make sure to wear the attached gloves. Further, when the solvent ink is used, it is necessary to wear the attached goggles. -

Page 15: Cautions And Notes

Handling of media • The machine does not operate with any ink • Use media recommended by MIMAKI to other than the TS3 genuine ink. ensure reliable, high-quality printing. • Do not use the TS3 genuine ink with other •... - Page 16 Safety Precautions Warning Notes on maintenance • It is strongly recommended to use the machine in a room that is not dusty. Set the Refresh level 2 or 3 when the machine is to be used in an unfavorable environment. (P.3-29 "Setting of Refreshing") •...

-

Page 17: Before Use

CHAPTER 1 Before Use This chapter describes the items required to understand before use, such as name of each part of the machine or the installation procedures. Moving this machine ..... 1-2 Connecting cables ....... 1-10 Where to install this machine .... 1-2 Connecting USB2.0 interface cable 1-10 Working environmental temperature . -

Page 18: Moving This Machine

1000 mm or more TS3-1600 : 3538 mm Working environmental temperature Use this machine in an environment of 20 to 35°C to ensure reliable printing. Depending on the ambient temperature, the heater temperature may not rise to the set value. -

Page 19: Moving This Machine

If you move it by yourself, failure or damage may occur. Be sure to request your distributor or a sales office of MIMAKI to move this machine. • When moving this machine, take care not to give a significant impact on it. -

Page 20: Names Of Parts And Functions

Names of Parts and Functions Front Maintenance cover Front cover Open the cover in maintenance. Open the cover in setting of medias, taking of measures Even when the power switch is off, keep against jamming of medias or in maintenance inside the all covers closed. -

Page 21: Rear / Sides

Names of Parts and Functions Rear / Sides Clamp lever (rear) Interlocks with the clamp lever in the font of this machine. Pre-heater Preheats the media before printing. (Located inside the platen) Cleaning solution cartridge Set a dedicated Washings cartridge (optional). -

Page 22: Operation Panel

Operation Panel Use the operation panel to make settings for printing or operate this machine. Display CONSTANT lamp Displays the status of the Lights in green when the heater temperature machine, set items and errors. reaches the set temperature. HEAT lamp Lights in orange during heating up of the ACTIVE lamp heater. -

Page 23: Heater

Names of Parts and Functions Heater Pre-heater /Print heater / Post-heater are equipped on the platen. The Pre-heater is used for pre-heating of the media prior to printing to prevent rapid temperature changing. The Print-heater improves the image quality in printing. The Post-heater dries ink after printing. -

Page 24: Carriage

Carriage The carriage is provided with the ink heads for printing, the cutter unit for cutting off the sheet of media, etc. A lever is also provided to adjust the height of Head in 2 stages according to the thickness of media. ( P.2-6) Cutter blade and cutting line The carriage is provided with a cutter unit for cutting off the media that has been printed on. -

Page 25: Capping Station

Names of Parts and Functions Capping station • Be sure to wear the attached goggles in cleaning within the capping station to protect your eyes against ink. The capping station consists of the ink caps, the wiper for cleaning the heads, etc. The ink caps prevent the nozzles in the ink heads from drying up. -

Page 26: Connecting Cables

When a TS3-1600 printer is connected to the personal computer to an externally installed USB hard disk drive , the data output speed to the TS3-1600 machine may drop. That can cause the head unit to stop temporarily at the right or left end during printing. -

Page 27: Connecting The Power Cable

Connecting cables ● Removing USB memory If a USB memory module is inserted in the personal computer to which a TS3-1600 machine is connected, click "Stop" in the "Safely Remove Hardware" window by following the instructions given there first and then remove the module. -

Page 28: Inserting Ink Cartridges

Inserting ink cartridges Insert an ink cartridges. Shake the ink cartridge as shown on the right. Insert the ink cartridge. • Insert the ink cartridge lengthwise directing the surface having IC chips to the left side. • Colors are displayed on the display as follows. Black: K, Cyan: C, Magenta: M, Yellow: Y, Light cyan: c, Light magenta: m, White: W, Silver: S... -

Page 29: Caution In Handling Of Ink Cartridges

• Do not shake ink cartridges violently. This may result in ink leakage from the ink cartridges. • Never refill the ink cartridges with ink. This may result in troubles. MIMAKI will not bear any responsibility for any damage caused by the use of the ink cartridges refilled with ink. -

Page 30: Note On Silver And White Ink Of Es3 Ink

Inserting ink cartridges Note on Silver and White ink of ES3 ink Be sure to read below before using silver and white ink of ES3 ink. • Silver and white ink of ES3 ink are usable for the firmware V and later. ... -

Page 31: Media

Caution in handling of medias Pay attention to the followings for handling of medias. • Use media recommended by MIMAKI to ensure reliable, high-quality printing. Set the heater temperature to meet the characteristics of the media. • Set the temperature of the Pre-heater, Print heater and Post-heater according to the type and characteristics of the media used. -

Page 32: Menu Mode

Menu mode This machine has 4 modes. Each menu mode is described below. NOT-READY mode This is the mode in which the media has not been detected yet. The keys other than the key and the / key are effective. LOCAL mode Local mode is the mode for the drawing preparation state. -

Page 33: Basic Operations

CHAPTER 2 Basic Operations The procedures from the ink and media preparation to drawing and the setting procedures are described. User type ........2-2 Test printing ......... 2-20 Set items registrable to User type ..2-2 Perform test printing with the normal Using the registered user type .. -

Page 34: User Type

User type Drawing of higher quality prints is available by making (setting of User type) the print set matching to the characteristics of media when this machine is used for drawing. On this machine, 4 types of User type 1 to 4 are settable. Set items registrable to User type For the registering procedures to User type (1 to 4), refer to P.3-2 . -

Page 35: Workflow

Workflow Turning the power ON/OFF Referring to "Turning the power ON/ OFF" ( P.2-4). Setting medias Referring to "Setting medias" P.2-6). Preparing Heaters Referring to "Preparing Heaters" P.2-18). Test printing Referring to "Test printing" P.2-20). Drawing data Referring to "Drawing data" P.2-30). -

Page 36: Turning The Power On/Off

Turning the power ON/OFF Turning the power ON The machine is provided with the following two power switches. Main power switch : At the side of this machine. Keep it "ON" always. Power switch : Normally, use this switch to turn the power ON/OFF. The power switch lights in green when the power is ON and blinks in green when it is OFF. -

Page 37: Turning The Power Off

Turning the power ON/OFF Turning the power OFF Turn the power OFF by pressing the power switch located on the side of after using. Check the followings when the power is turned off. • If it is in receiving of data from the PC, or there is any data un-output. •... -

Page 38: Setting Medias

Setting medias Useable medias This machine can be used with roll media and leaf sheet media. For useable medias, refer to P.1-15 "Usable sizes of media". Adjusting the head height Adjust the head height according to the thickness of the media used. •... - Page 39 Setting medias Keeping the height adjusting lever held at the aforementioned position, tighten the two screws. • Be sure to fasten the screws, pressing the height- adjusting lever, otherwise the head can not be secured at the correct position. • Fasten the screws securely. Return the carriage to the station position.

-

Page 40: Setting A Roll Media

Setting a roll media Set a roll media to the roll media hanger located on the back of this machine. • Take care not to drop the media on a foot or so when the media is set. It may cause an injury due to the media. - Page 41 Setting medias Move the roll holder to the roll setting position. Roll holder Set the base position Basis of roll holder within this range. 3 Inch Roll Media Roll Holder Set Position 2 Inch Roll Media Setting position of 3inch tube 3 Inch Roll Media Roll Holder Set Position...

- Page 42 Insert the roll media in this machine. Pinch roller • The roll media can be smoothly inserted by slanting the media. ( 1 ) Pull the media out of the roll to the head of the platen. ( 2 ) Insert the media between the platen and the pinch roller. •...

- Page 43 Setting medias Hold the media with the media press gently. • Set the media so that no media sticks out from the right end pinch roller to the right side. • When using a thick media, remove the media press from the media before printing. Media press •...

- Page 44 Secure the media on the take-up device. P.2-13) ( 1 ) Feed the media up to the core of the roll media of the take-up device by pressing the key. ( 2 ) Fix the middle of the media with adhesive tape. ( 3 ) In the same manner, fix the left side and right side of the media.

-

Page 45: Take-Up Device

Setting medias Take-up device The take-up direction of media is selectable by using the switch of the take-up device. Lever in top position (REVERSE) : The take-up device winds the media with the printed side facing Lever in middle position (OFF) : The take-up device does not wind the media. -

Page 46: Setting Leaf Media

Setting leaf media Unlike roll media, leaf media does not need to be retained with the roll holders. Open the front cover. Front cover Raise the clamp lever. Clamp lever Insert the leaf media between the platen and the pinch rollers. •... - Page 47 Setting medias Press the key. Press the key to select “LEAF” . MED I A SE L EC T RO L L < > L E A F The media detection is started. DE T EC T I NG MED I A NOW P L E AS E WA I T ( 1 ) The media width is detected.

-

Page 48: Changing The Printing Origin

Changing the printing origin The position of the printing origin can be changed. Moving the LED pointer to the changing position and deciding the position. In the local mode, OR I G I N S E TUP press the keys. 0 . - Page 49 Setting medias Typical setting position of printing origin The printing origin in the depth direction (X') is positioned at about 40 mm rearward from the cutting line. The printing origin in the scanning direction (Y') is positioned at 15 mm from the right end of the media. The value in the scanning direction (Y') can be changed using [MARGIN] in FUNCTION mode.

-

Page 50: Preparing Heaters

Preparing Heaters Changing temperature settings of Heater The set temperature of Heater can be changed and stored by [HEATER] of the setup mode. ( P.3-8) The adjusting procedures of the temperature set in the setup mode are described below. Set the Heater temperature according to the media used. •... -

Page 51: Confirming The Heater Temperature

Preparing Heaters Reference for the temperature set (When solvent ink is used) Type of ink ES3 ink SS21 ink Glossy Type of media Tarpaulin All medias chloroethylene Set of the Pre-heater 40°C 40°C 40°C 35°C Set of the Print-heater 40°C 40°C 40°C 35°C... -

Page 52: Test Printing

Test printing Print a test pattern to check that there are no discharging defects such as nozzle clogging (slight touching of ink or nozzle missing). About test patterns This machine provides you two test patterns. Normal test pattern (when using ink other than white ink) When you use ink that you can check by printing a test pattern on a white media, print this test pattern. -

Page 53: Perform Test Printing With The Normal Test Pattern

Test printing Perform test printing with the normal test pattern Check before the • If a media has been set. P.2-6 • If the origin position has been set. test printing • If the head gap has been adjusted. P.2-6 In the local mode, T ES T DRAW press the... -

Page 54: Perform Test Printing With The Test Pattern For Checking White Ink

Perform test printing with the test pattern for checking white ink Check before the • If a media has been set. P.2-6 • If the origin position has been set. test printing • If the head gap has been adjusted. P.2-6 In the local mode, T ES T DRAW... -

Page 55: Check Warning Of White Nozzle Status (Only When Using Ss21 White Ink)

Test printing Check warning of white nozzle status (Only when using SS21 white ink) As SS21 white ink is easier to cause nozzle clogging compared to other ink, you must keep the nozzle status normal even when you do not discharge it. In order to keep the nozzle status normal, this machine displays the C h e c k t h e... -

Page 56: Head Cleaning

Head Cleaning About head cleaning There are two types of head cleaning. Depending on the test printing result, perform to solve nozzle clogging. Check the printed test pattern result and perform cleaning depending on the status. Select one from the three types below: NORMAL : When any line is missing SOFT : When only head wiping is needed (when lines are bent) -

Page 57: Perform Head Cleaning Depending On The Test Printing Result

Head Cleaning Perform head cleaning depending on the test printing result There are three types of head cleaning. Use one by checking the test pattern. In the local mode, C L E AN I NG press the key. T YP E : NORMA L Select the cleaning type by pressing the C L E AN I NG... -

Page 58: Perform Spot Color Maintenance

Perform spot color maintenance Perform this to solve color heterogeneity due to settling down of pigment when using silver ink or white ink of ES3 ink. Spot color maintenance is selectable only when silver ink or white ink of ES3 ink has been filled for the firmware Ver.4.60 and later. - Page 59 Head Cleaning Slowly shake the removed ink cartridge more than twenty times right and left. • To prevent ink from leaking when you shake the cartridge, wear gloves and firmly cover the A part of the upper surface of the cartridge and the B part of the bottom surface of the cartridge with paper towels.

- Page 60 About warning message display of performing spot color maintenance When silver ink of ES3 ink is used and when ink has been left for two days PER FORM S POT CO L OR and more without being used, to prevent color heterogeneity due to settling MA I N T ENANCE ? <...

- Page 61 Head Cleaning Slowly shake the removed ink cartridge more than twenty times right and left. • To prevent ink from leaking when you shake the cartridge, wear gloves and firmly cover the A part of the upper surface of the cartridge and the B part of the bottom surface of the cartridge with paper towels.

-

Page 62: Drawing Data

Drawing data Starting the print • When a roll media is used, rewind the roll media by hands prior to printing so that it is set in the tightened condition. The loosened may result in failures of the image quality. Set the media. -

Page 63: Stopping The Print Temporarily

Drawing data Stopping the print temporarily Perform the following operations when stopping the print halfway. Press the key in printing. < L OCA L . 1 > [ # 0 1 ] w i d t h : 1 2 7 2 mm •... -

Page 64: Cutting A Media

Drawing data Cutting a media For a roll media, two ways are available to cut the media after printing is completed, as follows. • Pay attention so that printed surface does not touch to a floor or other printed surfaces when the media is cut. - Page 65 CHAPTER 3 Convenient use This section describes the operation procedures for using the machine more conveniently and each setting procedure. User type ........3-2 Other settings....... 3-28 Registering the drawing conditions Initializing the settings ....3-30 together (Type registration) ....3-2 Machine settings ......

-

Page 66: User Type

User type Registering the drawing conditions together (Type registration) The drawing conditions are registered in each type (1-4). The most suitable drawing conditions are settable only by changing the type when replaced by a different type of media, if the drawing conditions that meet the media to be used have been registered in the type. Example of type registration When solvent ink is used. -

Page 67: List Of Functions

User type List of functions This section describes the outline of each SET UP function registerable to the user type and the setting value. The underlined has been set when purchased. Function name Set value Outline Prints a pattern to correct the MEDIA COMP. - Page 68 User type Function name Set value Outline Sets the priority of settings (host / panel) Sets each item of the followings individually when the individual setting is selected. • MEDIA COMP. • HEATER INDIVIDUALLY/ ALL HOST / • PRINT MODE PRIORITY ( P.3-20) ALL PANEL...

-

Page 69: Setting Media Compensation

Setting media compensation Correct the feeding rate of media after the type of media is replaced or the temperature of Heater is changed. If the correction value is not appropriate, stripes may appear on the print, thus resulting in a poor print. •... -

Page 70: The Key

Press the key twice. [ 1 ] MED I A COMP . PR I N T S T AR T Print the compensation pattern by pressing PR I N T I NG key. P L E AS E WA I T Check the compensation pattern then input [ 1 ] MED I A COMP . - Page 71 Setting media compensation When you need to correct the media feed during printing The media feeding amount can be corrected even in the remote mode or when printing image data. Press the key in the remote mode. F E ED COMP ENS A T I ON . Press the key.

-

Page 72: Changing The Set Value Of Heater

Changing the set value of Heater Rough guide for temperature setting (When solvent ink is used) Type of ink ES3 ink SS21 ink Type of media Tarpaulin All medias Pre-heater 40°C 40°C 40°C 35°C Print-heater 40°C 40°C 40°C 35°C Post-heater 50°C 50°C 50°C... - Page 73 Changing the set value of Heater Press the key. [ 1 ] MED I A COMP . < e n t > Select [HEATER] by pressing the [ 1 ] keys. HEA T ER < e n t > Press the key twice.

-

Page 74: Adjusting Suitable Temperature Adjustment (When Solvent Ink Is Used)

Adjusting suitable temperature adjustment (When solvent ink is used) This section describes the procedure for setting the heater temperatures properly. The proper heater temperatures depend on the media type and ambient temperature. Set temperatures that are appropriate to the media. For non-coated media or media on which ink is slow to dry, set the heater temperatures so that the ink fixing and drying characteristics will be improved. -

Page 75: In Case The Heater Temperature Is Too Low

Changing the set value of Heater In case the heater temperature is too low When solvent ink is used, this may result in printing failures such as beading or banding if the heater temperature or the ink acceptable amount (the ink limit) is too low. Beading is a phenomenon that adjacent dots attract each other and join. -

Page 76: Setting Print Mode

Setting print mode Upon the setting of the print mode, set each item for printing as follows. • Print quality (DRAFT) : Setting the print quality in the DRAFT mode (Resolution in the scanning direction: 540dpi) • Print quality (FINE) : Setting the print quality in the FINE mode (Resolution in the scanning direc- tion: 720dpi) •... - Page 77 Setting print mode When changing the details of printing quality at each resolution. [ 1 ] DRA F T QUA L I T Y Select the resolution by pressing the 5 4 0 x 7 2 0 < e n t > key.

-

Page 78: Setting Scanning Direction

Setting scanning direction Perform operations up to P.3-12 the step 5. [ 1 ] PR I N T MODE DRA F T QUA L I T Y < e n t > Select [SCAN DIRECTION] by pressing the [ 1 ] PR I N T MODE keys. -

Page 79: Setting Logical-Seek

Setting print mode Setting Logical-seek The motion of Head varies depending on the set of Logical-seek. UNI-DIRECTIONAL BI-DIRECTIONAL Movement of heads when LOGICAL seek is OFF Movement of heads when UNI-DIRECTIONAL BI-DIRECTIONAL LOGICAL seek is ON Perform operations up to P.3-12 the step 5. [ 1 ] PR I N T MODE DRA F T QUA L I T Y <... -

Page 80: Setting Whitelay Print

Setting WhiteLay Print When using SS21 white ink, you can print with other colors after printing with white ink, without returning the media. In this page, set the printing method of white ink and other color ink. Set Value Outline Printing the white ink and the color ink at the same time. - Page 81 Setting print mode Press the key. [ 1 ] PR I N T MODE Wh i t e L a y P r t < e n t > Press the key several times to end. 3-17...

-

Page 82: Setting Drying Time

Setting drying time Upon the setting of drying time, set each item for ink drying as follows. • SCAN : Set the time to wait for ink drying after each pass. During bidirectional printing, the machine stops temporarily after every scanning back and forth. •... -

Page 83: Setting Margins

Setting margins Set a non-printing area along the right and left edges of the media. The offset value against the standard margin 15mm is set hereupon. Press the key in the local mode. F UNC T I ON S E T UP <... -

Page 84: Setting Priority

Setting Priority For the following items, the priority is selected either the setting by the machine (by the panel) or the setting by the PC (by the host). Items to be selected : MEDIA COMP. / HEATER / PRINT MODE / INK LAYERS / DRYING TIME / AUTO CUT / PRE-FEED / MARGIN / COLOR PATTERN / REFRESH / VACUUM / FeedSPEED LEVEL Press the... - Page 85 Setting Priority Select either “HOST” or “PANEL” by press- [ 1 ] PR I OR I T Y ing the keys. MED I A COMP . ANE L Press the key. • You can also press keys to move between items. Be sure to press the key to register the setting.

-

Page 86: Setting Auto Cleaning

Setting Auto cleaning The machine is settable so that the head cleaning is automatically carried out when printing is completed for the set length. At the completion of printing, the machine counts the length printed after the previous head cleaning and performs the cleaning automatically if required. - Page 87 Setting Auto cleaning Select “ON” by pressing the [ 1 ] AU TO CREAN I NG keys. S E T UP : ON • Proceed to the step 9 when “OFF” is selected. Press the key. I N T ERV A L : T YP E 0 0 0 mm : NORMA L...

-

Page 88: Setting Cleaning While Printing

Setting cleaning while printing Set it whether the head cleaning is carried out automatically during printing or not. Upon cleaning during printing, set the cleaning interval to the length printed. The printing is interrupted each in the set length and the head cleaning is carried out automatically. Press the key in the local mode. - Page 89 Setting cleaning while printing Press the key. Press the key several times to end. • This function does not operate when ink near-end occurs. Solve the ink near-end, referring to P.1-12. • Depending on the conditions of the heads, etc., the defective printing could not be recovered even performing this function.

-

Page 90: Setting Media Detection

Setting media detection Set the method for detecting a media when the media is set and the detecting type when the media is cut. Press the key in the local mode. F UNC T I ON S E T UP <... - Page 91 Setting media detection Press the key. [ 1 ] MED I A DE T EC T DE T EC T : BOT H EDGE Select the set value by pressing the keys. • Set value : BOTH EDGE / LEFT EDGE / RIGHT EDGE / NONE Press the key.

-

Page 92: Other Settings

Other settings Change the setting according to the use. Press the key in the local mode. F UNC T I ON S E T UP < EN T > Press the key. S E T UP S E L EC T : T Y PE . -

Page 93: List Of Settings

Other settings List of Settings The underlined has been set when purchased. Item Outline Set value Setting of Media Corrects the feeding rate of media Refer to P.3-5 compensation Setting Heater temperature Setting of Heater Refer to P.3-8 Setting Heater standby time and OFF time Setting Print quality Setting Scanning direction... -

Page 94: Initializing The Settings

Initializing the settings Initialize the settings to the conditions that have been set when purchased. (Set resetting) The set resetting can be executed per type. Press the key in the local mode. F UNC T I ON S E T UP <... -

Page 95: Machine Settings

Machine settings It is each type of setting for using this machine more comfortably. [MACHINE SETUP] and [MACHINE SETUP2] are available in this machine. The following items are settable in MACHINE SETUP 1, 2. Item Outline Set value 0 ~ 120 ~ 240min/ Setting the time until the rotation of the exhaust STOP TIME DEODORIZE... -

Page 96: Setting The Deodorize Fan

Setting the deodorize fan The fan operates during printing, and operates according to the set of [STOP TIME] from the completion of printing. Upon the setting of the deodrize fan, two items are settable as follows. • STOP TIME : Setting the time from the completion of printing until the fan operation is interrupted. •... -

Page 97: Setting Dryness Feeding

Machine settings Setting Dryness feeding Setting whether feeding for drying a media is performed after the completion of printing or not. Press the key in the local mode. F UNC T I ON S E T UP < EN T > Select [MACHINE SETUP] by pressing the F UNC T I ON keys. -

Page 98: Setting Stamp

Setting Stamp Set whether information such as the drawing conditions or the date printed is output after the completion of printing or not. Press the key in the local mode. F UNC T I ON S E T UP < EN T > Select [MACHINE SETUP] by pressing the F UNC T I ON keys. - Page 99 Machine settings Examples of Output 3-35...

-

Page 100: Setting Test Draw Arrange

Setting Test draw arrange You can set the deployment direction of the test pattern to be printed when performing test printing repeatedly. : when the setting value is “FEED DIR.” : when the setting value is “SCAN DIR.” Media feed direction Press the key in the local mode. - Page 101 Machine settings Press the key. Press the key several times to end. 3-37...

-

Page 102: Change The Operation Condition Of The Room Temperature

Change the operation condition of the room temperature If you print in the status that the temperature of the place in which the machine has installed (room temperature) is out of the usable temperature range, ink discharging defect or changing color may occur, and it adversely affects the printing quality. -

Page 103: Setting Confirmation Feeding

Machine settings Setting confirmation feeding Set whether media feeding is performed for checking the result after test printing or not Press the key in the local mode. F UNC T I ON S E T UP < EN T > Select [MACHINE SETUP 2] by pressing the F UNC T I ON keys. -

Page 104: Setting Time

Setting time Press the key in the local mode. F UNC T I ON S E T UP < EN T > Select [MACHINE SETUP 2] by pressing the F UNC T I ON keys. MACH I NE S E T UP 2 < EN T > Press the key. -

Page 105: Setting Unit

Machine settings Setting Unit Set a unit of measurement to be used in the machine. Press the key in the local mode. F UNC T I ON S E T UP < EN T > Select [MACHINE SETUP 2] by pressing the F UNC T I ON keys. -

Page 106: Setting Machine Name

Setting Machine name Set a machine name (machine No.) for recognizing each machine when plural machines are connected through USB2.0 interface. Press the key in the local mode. F UNC T I ON S E T UP < EN T > Select [MACHINE SETUP 2] by pressing the F UNC T I ON keys. -

Page 107: Setting Key Buzzer

Machine settings Setting Key buzzer Set a buzzer sound of the time when a key is pressed. Press the key in the local mode. F UNC T I ON S E T UP < EN T > Select [MACHINE SETUP 2] by pressing the F UNC T I ON keys. -

Page 108: Extension Of Ink Expiry Month

Extension of Ink Expiry Month Ink expiry month can be extended for six months from the expired month. When used without extension, ink becomes unusable after two months of the expiry month. Extension of Ink Expiry Month The following setting or confirmation screen appears when the power of this machine is turned on, or when expired ink cartridge is set. -

Page 109: When A Cartridge Extended The Expiry Month Is Set

Extension of Ink Expiry Month When a cartridge extended the expiry month is set When a cartridge extended the expiry month is set and the power is turned on, or when a cartridge extended the expiry month is set to this machine, the following screen appears. EX P I RED I NK I N US E PRE S S [ EN T ]... -

Page 110: Switch Setting Of Ink Supply Path

Switch Setting of Ink Supply Path For the ink supply, condition of the ink cartridge to be used first by the double-cartridge automatic switching function can be selected. This setting is only available for 4-color set. • When expired ink cartridge is set, the expired cartridge is used first regardless of the setting below. - Page 111 Switch Setting of Ink Supply Path When both ink cartridge and MBIS are used When both an ink cartridge and the optional bulk ink system (MBIS) are set in the supply paths of the same color for 4-color ink set, you can select the ink to be used first. •...

-

Page 112: To Use Sublimation Transfer Ink With More Stable Quality

To use sublimation transfer ink with more stable quality To prevent color change When you print with sublimation transfer ink after you have left this machine, color may change due to color material settling. By shaking the ink cartridge or performing ink filling periodically, the status will be improved. (Before performing ink filling, it is necessary to shake the ink cartridge.) In the firmware version 5.00 and later, when the time to shake the ink cartridge or to perform ink filling has come, a message (warning preventing color material settling) is displayed to inform you of it. - Page 113 To use sublimation transfer ink with more stable quality How to shake the ink cartridge To prevent ink from leaking when you shake the cartridge, wear gloves and firmly cover the A part of the upper surface of the cartridge and the B part of the bottom surface of the cartridge with paper towels. Then, shake it more than twenty times right and left so that ink flows inside the cartridge.

-

Page 114: Set The Interval To Display The Warning Message

Set the interval to display the warning message Depending on the ambient temperature, set the interval to display the warning preventing color material settling. • When you use sublimation transfer ink Sb52 or Sb53, the display interval of the message is set to 72 hours in the initial condition. -

Page 115: Note On Head Height Adjustment

To use sublimation transfer ink with more stable quality Note on head height adjustment When you use sublimation transfer ink, if you make the head height 5mm (H range/ thick), it may affect the drawing quality. It is recommended to use with making head height 4mm (H range/ thin) or L range. •... -

Page 116: Confirming Machine Information

Confirming machine information The machine information of the machine is confirmable. Confirmable items of the machine information are as follows. Item Description Displays the history of errors and warnings. ERROR HISTORY Using the key, the errors and warnings can be displayed one by one in the order of occurrence. - Page 117 Confirming machine information For the information displayed This section describes the way to read the information displayed. ERROR HISTORY MAINTE. HISTORY Displaying the Displaying the ERROR H I STORY [ 0 1 ] 1 2 . 1 0 . 1 0 1 2 : 1 5 occurrence date contents of...

- Page 118 3-54...

-

Page 119: Routine Maintenance

CHAPTER 4 Routine Maintenance This section describes the items required to use this machine more comfortably, which are the procedures of ink replacing, cleaning or the like. Maintaining........4-2 Preventing nozzle clogging while power-off ......4-25 Precautions in cleaning ...... 4-2 Notes on cleaning solution .... -

Page 120: Maintaining

Maintaining Be sure to perform maintenance of the machine periodically or whenever necessary so that the machine can be used with its inherent accuracy for a long time. Precautions in cleaning Pay attentions to the following items when the machine is maintained. •... -

Page 121: Cleaning Exterior Surfaces

Maintaining Cleaning exterior surfaces If exterior surfaces of the machine is stained, dampen a soft cloth with water or a neutral detergent diluted with water, squeeze it and wipe the surfaces with the cloth. Cleaning the platen On the platen, it is easy to become dirt due to lint, paper dust or the like caused by cutting medias. For a conspicuous stain, wipe it off with a soft-hair brush, a dry cloth, a paper towel or the like. -

Page 122: Cleaning The Media Sensor

Maintaining Cleaning the media sensor A media sensor is located at the platen on the backside. It may cause misdetection of media when dust or the like is accumulated on the sensor. Using a cotton swab, clean the surface of the sensor of dust and dirt. When cleaning the sensor on the lower surface of the head is cleaned, move the carriage to the left end by the operations of step 1 of P.4-16 "Cleaning the heads and their surrounding parts", and then clean it. -

Page 123: Maintaining Capping Station

Maintaining Capping station Maintain Ink cap, Wiper or the like, which are located in the capping station. [ST.MAINTENANCE] The ink cap and wiper function respectively as follows. • Wiper : Wiping ink sticking to the head nozzle off. • Ink cap : Preventing the head nozzle from clogging due to drying. As the machine is used, the wiper and ink caps gradually become stained with ink and dust. - Page 124 Wiper Clean the wiper and bracket. • Wipe ink sticking to the wiper and the bracket off with a clean stick dipped in the cleaning solution. Bracket Clean the wiper slider. • Wipe ink sticking to the wiper slider off with a clean stick dipped in the cleaning solution.

-

Page 125: Replacing The Wiper

• The wiper to be newly installed is available as an option. Order it from your dealer or a sales office of MIMAKI. • Do not select [WIPER EXCHANGE] at any time other than when the wiper is to be replaced.Once it is selected, the number of wiper operations that is counted in the machine... -

Page 126: Prior To Pump Tube Washing

Prior to Pump tube washing Prior to washing of the pump tube, it is required that the cleaning solution has been filled within the tube. • When the following messages are indicated, check the waste ink tank, and then operate it, referring to P.4-39 "If Waste ink tank confirming message is displayed"... - Page 127 Maintaining Capping station Discharging Cleaning solution Perform the following operations to discharge the cleaning solution within the tube. Select [HD.MAINTENANCE] of the maintenance menu. (1) Press the key in the local mode. (2) Select [MAINTENANCE] by pressing the keys then press the key.

-

Page 128: Washing Of Head Nozzle

Washing of Head nozzle Perform cleaning of the nozzles in the heads to prevent them being clogged with coagulated ink. Is [NEAR END] or [INK END] displayed ? Make sure the • The cleaning solution or ink is absorbed in washing. followings in At this time, washing is unable to operate if the ink end or near-end is advance. - Page 129 Maintaining Capping station Press the key then fill the cap with the cleaning solution. • The cleaning solution is applied by drops when the is pressed. • When the is pressed again, drops stop. • Repeat the drops several times to fill the cap with the cleaning solution just before the solution overflows from the cap.

-

Page 130: Cleaning The Ink Discharge Passage (Pump Tube Wash)

Cleaning the ink discharge passage (PUMP TUBE WASH) Perform washing of the ink discharge passage (the pump tube) periodically to prevent ink from clogging due to the coagulation of ink within the ink discharge passage. • When the following messages are indicated, check the waste ink tank, and then operate it, referring to P.4-39 "If Waste ink tank confirming message is displayed"... - Page 131 Maintaining Capping station Close the front cover and press the * B e i n g I n i t i a l i z e d * key. P L E AS E WA I T • It returns to the local mode after the idle absorbing is <...

-

Page 132: When Not Using For A Long Term (Custody Wash)

When not using for a long term (CUSTODY WASH) When the operation of the machine is to be suspended for a week or more, use the [CUSTODY WASH] function to clean the nozzles in the heads and the ink discharge passage. After the cleaning, store the machine properly. -

Page 133: Open The Front Cover

Maintaining Capping station Press the key. F i l l t h e l i q u i d COMP L E T ED ( NE X T ) : e n t Press the key to fill the cap with the cleaning solution. -

Page 134: Cleaning Heads And Surroundings Parts

Cleaning heads and surroundings parts Take great care, especially during cleaning, not to damage the heads, which employ very precise mechanisms. Using a clean stick, rub off the gelatinous ink that may be adhering to the lower part of the slider and surrounding parts of the heads. - Page 135 Cleaning heads and surroundings parts Press the key after the cleaning. C l o s e a c o v e r Close the maintenance cover then press the ( COVER OP EN ) key. PRE S S < EN T > K EY •...

-

Page 136: When Nozzle Clogged After Cleaning

When Nozzle clogged after cleaning When the nozzle clogging is not improved even after the head cleaning( P.2-24) or the head nozzle washing ( P.4-10), execute two functions as follows. FILL UP INK • Supplies ink to correct nozzle clogging. •... -

Page 137: Discharge & Wash

When Nozzle clogged after cleaning DISCHARGE & WASH Discharge ink from the heads, dampers and ink tubes, and then wash them. • To use this function, the dedicated cleaning solution ( P.4-2 “Notes on cleaning solution”) is required. In addition, before performing the work, check whether ink to be filled again remains or not. -

Page 138: Ink Station

Remove the cleaning solution cartridge. * D I SCHARGE * 0 0 : 0 0 • The ink left in the head or tube is discharged to the waste ink tank. • The right display on the right is displayed after discharging. -

Page 139: Initial Ink Fill Up

4 - C o l o r ( MMCCYY K K ) • You cannot change the current ink set to other ink set yourselves. • If you want to change the ink set, contact sales office of MIMAKI. Press the key. - Page 140 When Nozzle clogged after cleaning Set an ink cartridge to the ink station. S e t : ES 3 - 4 c o l o r I n k - - C - Y - K K • When the ink cartridge is set, filling is automatically F I L L I NG UP NOW.

-

Page 141: If Dots Misalign

If dots misalign When the thickness of the media, the height of the head, or the type of the ink used is changed, follow the steps below and adjust the ink drop position for Bi-directional (Bi) printing to print properly. Example of Pattern printing Output direction... - Page 142 If dots misalign As the same as the step 4, correct the dot position of the from pattern 2 then press the key. Press the key several times to end. 4-24...

-

Page 143: Preventing Nozzle Clogging While Power-Off

Preventing nozzle clogging while power-off Even while the power switch is off, the machine starts periodically and executes various functions to prevent nozzle clogging. [SLEEP SETUP] includes the following functions. Function name Descriptions Set the interval at which refreshing operation is to be performed REFRESH periodically. -

Page 144: Setting Tube Washing Interval In Sleep Mode

Setting tube washing interval in Sleep mode Set the interval at which cleaning of the caps and pump tubes is to be performed using the cleaning solution during sleep mode. Select [SLEEP SETUP] of the maintenance menu. (1) Press the key in the local mode. -

Page 145: Setting Cleaning Interval In Sleep Mode

Preventing nozzle clogging while power-off Setting cleaning interval in Sleep mode This function is to be executed instead of TUBE WASH after the cleaning solution has been used up. Set the cleaning type and the interval at which cleaning operation is to be performed during sleep mode. Select [SLEEP SETUP] of the maintenance menu. -

Page 146: Setting Routine Operations

Setting Routine operations Troubles such as ink clogging or the like are preventable by performing each periodical operation in the condition of the power ON. (Initial setting) The [ROUTINE SETUP] function is available for the following items : Function name Descriptions While printing, the nozzle surface is wiped with a certain interval to remove ROUTINE WIPING... - Page 147 Setting Routine operations Press the key. ROU T I NE WI P I NG SCAN COUN T Set the number of scans by pressing the ROU T I NE WI P I NG keys. SCAN COUN T • Set value : 0 to 9990 times •...

-

Page 148: Setting Refreshing Interval In Standby Mode

Setting Refreshing interval in Standby mode Set the interval at which refreshing operation is to be performed periodically. Select [ROUTINE SETUP] of the maintenance menu. (1) Press the key in the local mode. (2) Select [MAINTENANCE] by pressing the keys then press the key. -

Page 149: Setting Pump Tube Washing Interval In Standby Mode

Setting Routine operations Setting Pump tube washing interval in Standby mode Perform the pump tube washing periodically to prevent ink from clogging due to the coagulation of ink, which occurs within the tube. • This function is operable only under the condition that the machine is left in the following displays. -

Page 150: Setting Cleaning Interval In Standby Mode

Setting Cleaning interval in Standby mode This function is to be executed instead of TUBE WASH after the cleaning solution has been used up. Set the cleaning type and the intervals at which cleaning operation is to be performed. • This function does not operate when the error message relating to ink, such as [NEAR END] or [INK END], is displayed. - Page 151 Setting Routine operations Press the key several times to end. 4-33...

-

Page 152: Other Maintenance Functions

Other maintenance functions Changing the warning time of wiper replacement The wiper is consumable. The heads are easily soiled in a dusty environment. The heads cannot be cleaned adequately with a curled or worn wiper. Setting the wiper level so that a warning for the wiper replacement period is indicated earlier than the standard depending on the operating environment. -

Page 153: Setting The Media Remaining Display

Other maintenance functions Setting the media remaining display Set the media remaining amount display. When the media remaining The media remaining amount is displayed in the remote mode. amount display is turned to (The print length is displayed when a leaf media is used.) "ON"... - Page 154 Print the media remaining amount You can print the current media remaining amount. • Set [MEDIA RESIDUAL] to “ON”. ( P.4-35) • When changing the media, it is recommended to print the remaining amount to the currently used media. If you print the media remaining amount in advance, for using the changed media, you can enter the correct value in the screen for entering media remaining amount after detecting the media ( P.2-12).

-

Page 155: White Ink Maintenance Function

Other maintenance functions White Ink Maintenance Function If SS21 white ink is left unused for a while, the color may become uneven by clogging of the nozzle or set- tling of dyestuff. If the color does not improved by the head cleaning ( P.2-24), use this maintenance function. - Page 156 Slowly shake the removed white ink cartridge more than twenty times right and left. • To prevent ink from leaking when you shake the cartridge, wear gloves and firmly cover the A part of the upper surface of the cartridge and the B part of the bottom surface of the cartridge with paper towels.

-

Page 157: If Waste Ink Tank Confirming Message Is Displayed

Other maintenance functions If Waste ink tank confirming message is displayed Waste ink which was used for cleaning the heads and other parts, gathers in the waste ink tank. Upon the machine, the ink discharging amount is counted by accumulated counting then a message for suggesting the check is displayed when it reaches a certain amount. - Page 158 Check message in Local mode The right message is displayed. < L OCA L . 1 > [ # 0 1 ] C h e c k w a s t e i n k <MN T > Check the waste ink tank, and then replace the waste ink tank P.4-41) if required.

- Page 159 Other maintenance functions Replacing waste ink tank When the right message is displayed, check the waste ink tank < L OCA L . 1 > [ # 0 1 ] immediately, and then replace it according to the condition. C h e c k w a s t e i n k <MN T >...

- Page 160 Close the waste ink tank guard. • Hook the waste ink tank guard in a hole of the machine then lock it. Hole Hook Select [Ink Tank Exchange] of the maintenance menu. (1) Press the key in the local mode. (2) Select [MAINTENANCE] by pressing the keys then press the key.

-

Page 161: Changing The Ink

Other maintenance functions Changing the ink Ink type or the color used can be changed. • To change the ink set such as changing from “4-color model“ to “6-color model” or “8-color model”, the machine must be worked by our service engineer. Contact our service office or the distributor in your region. -

Page 162: Replacing The Cutter Blade

Replacing the cutter blade The cutter blade is consumable. When the cutter blade gets dull, replace it with a new one (SPA-0107). • The blade is sharp. Be careful not to hurt yourself or anyone else. • Keep the cutter blades away from the reach of children. Be sure to dispose of the worn-out cutter blades according to the applicable national and local laws and regulations. - Page 163 Replacing the cutter blade Close the front cover. Press the key. • The machine returns to LOCAL mode. 4-45...

- Page 164 4-46...

- Page 165 CHAPTER 5 Troubleshooting This section describes the corrective measures to be taken for a phenomenon suspected to be trouble and the procedures to clear the error number displayed on the LCD. Troubleshooting ............5-2 Power does not turn on ............5-2 The machine does not start printing ........5-2 Media get jammed / media is soiled ........5-3 [HEAT] or [CONSTANT] LED does not light up ....5-3...

-

Page 166: Troubleshooting

Troubleshooting Take appropriate actions as described below before taking the trouble as a failure. If still the problem is not solved after troubleshooting, contact your dealer or an office of MIMAKI. Power does not turn on In most cases, this is due to improper connection of the power cable for the machine or computer. Check that the power cable is connected properly. -

Page 167: Media Get Jammed / Media Is Soiled

Troubleshooting Media get jammed / media is soiled Media jamming or stained media is considered to be due to the use of an unsuitable media or improper setting of media. Is a recommended media used ? Use recommended media. Avoid using any media with curls or bent Is the media not curled or bent ends ? ends. -

Page 168: Image Quality Is Poor

This section describes the corrective actions to be taken in case the image quality is not satisfactory. Take remedy for particular problems with image quality. If the remedy does not work, contact your dealer or an office of MIMAKI. Phenomenon Measures (1) Execute the head cleaning. -

Page 169: Ink Cartridge Warning Appears

• Once cartridge trouble is displayed, do not leave the ink cartridge without replacing it for a long time; otherwise, the machine will lose the nozzle clogging prevention function. If nozzles are clogged, the machine must be repaired by MIMAKI's service engineer. Displaying the description of ink cartridge trouble The contents of cartridge error are confirmable by the following operations. -

Page 170: Warning / Error Messages

Warning / Error Messages If some trouble occurs, the buzzer sounds and the display shows a corresponding error message. Take an appropriate remedy for the displayed error. Warning messages Message Cause Solution Check the front cover and maintenance covers. The front cover or the maintenance C l o s e a c o v e r . -

Page 171: Warning Messages

- - - - Y Y K K The ink cartridge is not MIMAKI Replace the cartridge generating the NON - OR I G I N A L I N K genuine. - Page 172 Message Cause Solution The expiration date of an ink cartridge has passed (two months Replace the cartridge generating the E x p i r a t i o n : 2 MON T H have passed after the specified warning with a new one. - - - - - - - - expiration date).

-

Page 173: Error Messages

Warning / Error Messages Error messages When an error message is displayed, eliminate the error according to the chart below. If the same error message appears again, contact your dealer or an office of MIMAKI to call for service. Message Cause... - Page 174 Message Cause Solution Turn off the main power to the machine Any parameter outside the range of and turn it on after a while. * * * * * E R ROR 1 1 * * * * * acceptable numeric values was If the same error message appears again, P A R AME T E R E R ROR received.

- Page 175 D V E I C E CON S T R U C T I ON service. The head is not MIMAKI genuine. Turn off the main power to the machine and turn it on after a while. If the same error message appears again,...

- Page 176 Warning / Error Messages Message Cause Solution An abnormal temperature of the * * * * E R ROR 2 1 1 * * * * media heater was detected. H e a t e r T EMP ( - - / - - / - - ) * * * * E R ROR 2 1 1 * * * * The head heater is disconnected.

- Page 177 CHAPTER 6 Appendix This section attaches a list of the specifications and a list of the functions of this printer. Machine specifications ..........6-2 Ink specifications ............6-4 Sheet for inquiry ............6-5 Warning labels ............. 6-6 Function Flowchart ............. 6-8...

-

Page 178: Machine Specifications

Machine specifications Item TS3-1600 Method Drop-on-demand piezoelectric print heads Print head Specification 1 head 720 x 540dpi / 540 or 720 x 720dpi / 540 x 900dpi / 540 or 720 x 1080dpi Drawing mode (scan x feed) 720 x 1440dpi / 1440 x 1440dpi... - Page 179 Machine specifications Item TS3-1600 Maximum 1620mm Leaf media size Minimum 210mm Left end and right end : 15 mm (Default) Leaf media Front : 40.0 mm Rear : 98.5 mm Margin Left end and right end : 15 mm (Default) Roll media Front : 40.0 mm...

-

Page 180: Ink Specifications

Ink specifications Item When solvent ink is used When sublimation dye ink is used Supply Dedicated solvent ink cartridges Dedicated sublimation dye ink cartridge Black ink cartridge Cyan ink cartridge (Blue ink cartridge Black ink cartridge Magenta ink cartridge Cyan ink cartridge Yellow ink cartridge Magenta ink cartridge Light cyan ink cartridge... -

Page 181: Sheet For Inquiry

Sheet for inquiry Use this sheet for troubles and abnormal functions of the machine. Fill in the following necessary items, and then fax the sheet to our sales office. Company name Person in charge Telephone number machine model Operating OS Machine information Error message Contents of inquiry... -

Page 182: Warning Labels

Warning labels Warning labels are stuck on the machine. Be sure to fully understand the warning given on the labels. If a warning label is illegible due to stains or has come off, purchase a new one from a distributor or our sales office. - Page 183 Warning labels Reorder Label M901549 M903239 M903330 M903405 M904810...

-

Page 184: Function Flowchart

Function Flowchart < L OCA L . 1 > [ # 0 1 ] w i d t h : * * * * mm OR I G I N S E T UP OR I G I N S E T UP 0 . - Page 185 Function Flowchart MED I A RE S I DUA L DR AW < EN T > Only when [MEDIA RESIDUAL] is “ON” Shake the cartridge fifth or Remove the cartridge. Set the cartridge. sixth times.

- Page 186 From P6-8 US ER T Y P E CH ANGE T Y P E ( 1 ) - > < > : e n t E S 3 MMCCY Y K K H E AD HE I GH T : T H I N REMA I N 3 4 5 6 7 8 9 9 MED I A W I D T H :...

- Page 187 Function Flowchart NON - OR I G I NA L I NK WRONG I NK I C K i n d o f I NK M - C - - - - K M - C - - - - K M - C - - - - K C o l o r o f...

- Page 188 < L OCA L . 1 > [ # 0 1 ] F UNC T I ON SETUP w i d t h : * * * * mm S E T UP < EN T > F UNC T I ON MAINTENANCE MA I N T ENANCE <...

- Page 189 Function Flowchart To P.6-14 To P.6-20 To P.6-26 To P.6-27 To P.6-28 6-13...

- Page 190 SETUP S E T UP [ 1 ] [ 1 ] MED I A COMP . S E L EC T : T Y P E . 1 MED I A COMP . < e n t > PR I N T S T AR T TYPE.2 TYPE.3 TYPE.4...

- Page 191 Function Flowchart End the P L E A S E WA I T [ 1 ] ME D I A COMP . printing PR I N T I NG V A L UE -255 ~ 255 PR T POS T 5 °...

- Page 192 From P6-14 From P6-14 [ 1 ] PR I N T MODE Wh i t e L a y P r t < e n t > When SS21 (6+ white) ink is filled [ 1 ] [ 1 ] I NK L A Y ERS I NK L A Y ERS <...

- Page 193 Function Flowchart [ 1 ] Wh i t e L a y P r t S E L . : OF F OFF / LEVEL 1~3 6-17...

- Page 194 From P6-16 When INDIVIDUALLY is selected [ 1 ] [ 1 ] PR I OR I T Y PR I OR I T Y < e n t > S E T U P ND I V I DUA L L Y INDIVIDUALLY / ALL HOST / ALL PANEL...

- Page 195 Function Flowchart [ 1 ] PR I OR I T Y [ 1 ] PR I OR I T Y [ 1 ] PR I OR I T Y MED I A COMP . : HOS T HE A T ER : HOS T P R I N T MODE : HOS T...

- Page 196 MAINTENANCE MA I N T ENANCE S T . MA I N T ENA NCE S T . MA I N T ENANCE S T . MA I N T ENANCE < e n t > CARR I AGE OU T <...

- Page 197 Function Flowchart Close a cover C l o s e a c o v e r RESTART Close a cover C l o s e a c o v e r RESTART F i l l t h e l i q u i d S T .

- Page 198 From P6-20 MA I N T ENANCE HD . MA I N T ENA NCE F I L L I NG U P NOW . HD . MA I N T ENANCE < e n t > F I L L UP I NK <...

- Page 199 Function Flowchart * D I S CHARGE * S e t : Wa s h i n g C a r t r i d g e * A B SORP T I ON * 0 0 : 0 0 1 2 3 4 5 6 7 8 0 0 : 0 0 R e mo v e : C a r t r i d g e s...

- Page 200 From P6-22 MA I N T ENANCE ROU T I NE S E T UP ROU T I NE W I P I NG ROU T I NE S E T UP < e n t > ROU T I NE W I P I NG < e n t > SCAN COUN T <...

- Page 201 Function Flowchart ROU T I NE W I P I NG SC AN COUN T ROU T I NE W I P I NG T EMP . D i f f e r e n c e = 0 ° C Settable except for OFF ROU T I NE S E T UP C L E AN .

- Page 202 MACHINE SETUP MACH I NE S E T UP DEODOR I Z E F AN DEODOR I Z E F AN DEODOR I Z E F AN < e n t > S TOP T I ME < e n t > S TOP T I ME 2 0 M i n 0 ~ 240 min...

- Page 203 Function Flowchart MACHINE SETUP2 Only when CONFIRM.FEED is set ON MACH I NE S E T UP 2 CON F I RM . F E E D CON F I RM . F E ED CON F I RM . F E ED <...

-

Page 204: Start Printing

Function Flowchart INFOMATION I N FOMA T I ON ERROR H I S TORY Error is displayed ERROR H I S TORY < e n t > [ 0 1 ] 0 5 . 0 9 . 2 9 0 8 : 1 8 I N FOMA T I ON [ 0 1 ] 0 5 . - Page 205 D201937-15-17022012...

- Page 206 Printed in Japan © MIMAKI ENGINEERING CO., LTD.2012 FW : 5.3...

Need help?

Do you have a question about the TS3-1600 and is the answer not in the manual?

Questions and answers