KEB COMBIVERT F6 series Manuals

Manuals and User Guides for KEB COMBIVERT F6 series. We have 5 KEB COMBIVERT F6 series manuals available for free PDF download: Instructions For Use Manual, Instruction Manual

KEB COMBIVERT F6 series Instructions For Use Manual (92 pages)

Brand: KEB

|

Category: Controller

|

Size: 8 MB

Table of Contents

-

Preface

4 -

Glossary

11 -

-

-

-

-

Fan45

-

-

-

-

-

Supply Cable62

-

Accessories74

-

-

-

Condensation79

-

-

Advertisement

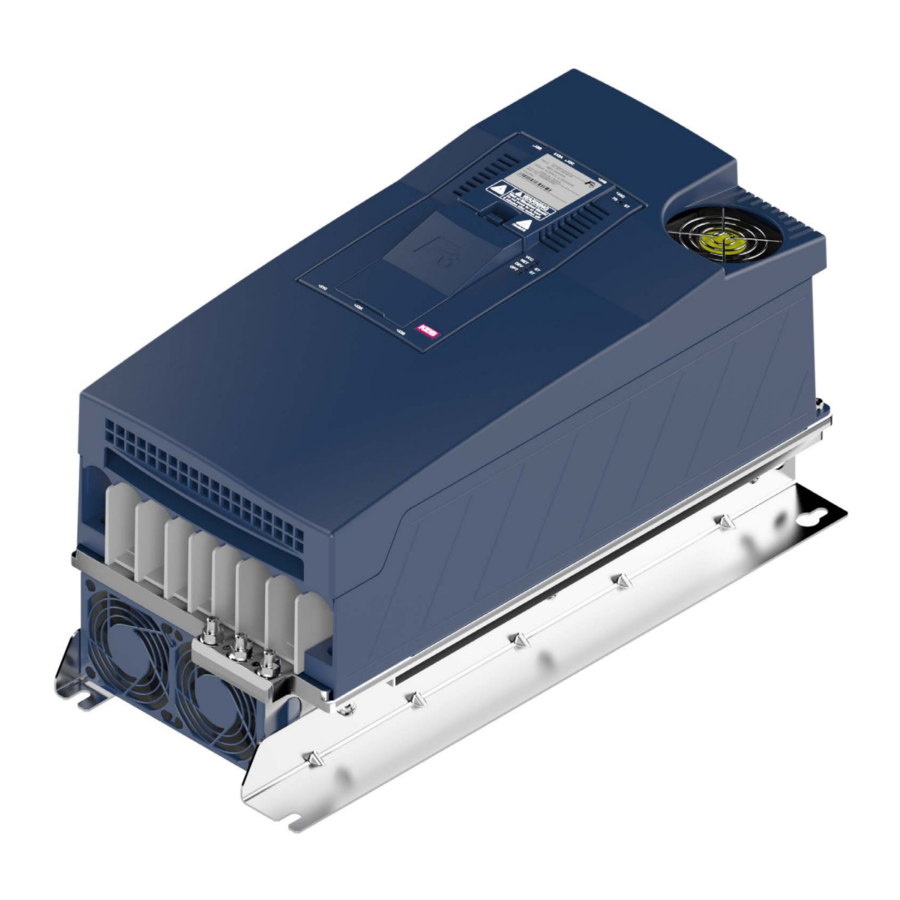

KEB COMBIVERT F6 series Instructions For Use Manual (84 pages)

INSTALLATION F6 HOUSING 2

Brand: KEB

|

Category: Controller

|

Size: 14 MB

Table of Contents

-

Preface

3 -

Glossary

11 -

-

Part Code24

-

-

-

-

-

-

Fan52

-

-

-

-

-

Supply Line65

-

Accessories76

KEB COMBIVERT F6 series Instructions For Use Manual (76 pages)

INSTALLATION F6 HOUSING 2 PEAK POWER STANDARD OL-FUNCTION

Table of Contents

-

Preface3

-

Support4

-

Glossary10

-

Target Group14

-

Installation15

-

Voltage Test17

-

Maintenance19

-

Repair20

-

Disposal20

-

Part Code23

-

Nameplate25

-

Fan41

-

Installation43

-

Accessories69

-

CE-Marking71

Advertisement

KEB COMBIVERT F6 series Instructions For Use Manual (34 pages)

Single axis frequency inverter

Table of Contents

-

Preface

3 -

4 Interfaces

14 -

5 Operation

16-

Up/Download30

-

Work List31

-

FTP Mode32

KEB COMBIVERT F6 series Instruction Manual (44 pages)

Table of Contents

-

Preface5

-

General5

-

DC Supply15

-

Accessories22

-

Annex a32

-

Maintenance33

-

Storage33

-

Annex B35

-

CE Marking35

-

UL Marking35

-

Annex C37

-

Annex D42

Advertisement