Solar-Log 200 Manual

Hide thumbs

Also See for 200:

- User manual (105 pages) ,

- Installation manual (224 pages) ,

- Connection manual (24 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Solar-Log 200

- Page 1 Manual V.3.6.0 Solar-Log™...

- Page 2 Publisher: Solare Datensysteme GmbH Fuhrmannstr. 9 72351 Geislingen-Binsdorf Germany International support Tel.:+49 7428 9418 -640 Fax:+49 7428 9418 -280 e-mail: support@solar-log.com Italy Technical support: +39 0471 631032 e-mail: italy-support@solar-log.com France Technical support: +33 97 7909708 e-mail: france-support@solar-log.com Switzerland Technical support: +41 565 355346 e-mail: switzerland-fl-support@solar-log.com...

-

Page 3: Table Of Contents

Solar-Log 1200 ................................21 Solar-Log 2000 ................................. 23 Optional Connections ....................25 Solar-Log™ GPRS ..............................25 Solar-Log™ Meter (Solar-Log 300 and 1200) ....................26 Solar-Log™ PM+ ................................. 29 Connector Assignments and Wiring ..............30 10.1 Notes on wiring the connections ........................30... - Page 4 Initial set up of the Solar-Log 1200 ........................68 14.4 Setting up of the Solar-Log™ with the configuration wizard ..............68 14.4.1 Carrying out the initial set up of the Solar-Log 250, 300, 1200 and 2000 (manually)....75 14.5 Starting the configuration ............................. 76 14.6...

- Page 5 Configuration Menu ....................86 16.1 Configuring network settings ..........................86 16.1.1 Ethernet ..................................87 16.1.2 GPRS (only Solar-Log™ GPRS) ..........................89 16.1.3 General Information about GPRS Devices ......................92 16.1.4 WiFi (only Solar-Log WiFi) ............................. 93 16.1.5 Proxy ....................................95 16.2 Internet Configuration .............................

- Page 6 16.12 Active power ................................156 16.12.1 Active power deactivated............................157 16.12.2 Remote controlled active power reduction (only Solar-Log™ PM+) ............157 16.12.3 Remote controlled active power reduction with the calculation of self-consumption (only So- lar-Log™ PM+) ................................160 16.12.4 70% fixed reduction ..............................160 16.12.5 70% Fixed reduction with the calculation of self-consumption ...............

- Page 7 17.5.2 Explanation of the Symbols in the Feed-in power (% DC) column: ............206 17.5.3 Explanation of the Values in the Reactive Power Reduction Section ...........206 17.5.4 PM History ..................................209 17.6 Accessing the SCB Monitor (only Solar-Log 1000 and 2000) ..............210 17.7 Accessing components ............................. 211 17.8 Smart Energy ................................

- Page 8 19.5 Error and Fault Messages on the Display ......................274 20 Notifications on the LCD Status Display (Solar-Log 250, 300, 1200 and 2000) ..........................276 20.1 Meaning of the symbols on the LCD display ...................... 276 20.1.1 Fault messages ................................278 20.2 Notifications on the LCD display ..........................279 20.3...

- Page 9 25.1 Internet ports ................................298 25.2 Country specific inverter detection with Easy Installation..............299 25.3 Wiring meters to record self-consumption ....................300 25.3.1 Meter connection options to record the total consumption via an RS485/S0 interface...300 25.3.2 Meter connection options for bi-directional recording of the total consumption via only an RS485 interface.

-

Page 10: Introduction

The wiring for the devices is described in detail in the Component Installation Manual. The Solar-Log™ must only be used by persons who have fully read and understood the manual before ins- talling, operating and/or servicing the device. -

Page 11: Notes For The Firmware Update

Notes for the Firmware Update 2 Notes for the Firmware Update The following models may be updated to the Solar-Log Firmware Version 3.6.0. • Solar-Log • Solar-Log 250 • Solar-Log 300 • Solar-Log • Solar-Log 1000 • Solar-Log 1200 •... -

Page 12: Updating From Firmware 2.X To 3.X

3 Updating from Firmware 2.x to 3.x The following note is for the Solar-Log 200, 500 and 1000 models when updating to firmware version 3.x. In order to update to 3.x, the Solar-Log™ must at least be running firmware version 2.x. The latest firmware can be downloaded from our website: http://www.solar-log.com/de/service-support/firmware.html. -

Page 13: Safety Information

This manual is intended for solar energy technicians and qualified electricians who are installing a Solar-Log 250 (read the additional information below), 300, 1200 and 2000, wiring them to inverters, con- figuring them to operate in particular systems, and putting them into operation. -

Page 14: Hazard Classes

Safety information Hazard Classes The safety instructions in this document are represented with standard signs and symbols. Two classes of risk are identified, depending on their probability of occurrence and the seriousness of their consequences. Danger! Indicates an imminently hazardous situation to life Non-compliance with this warning can lead to severe and irreversible injuries or death Caution! Indicates an imminently hazardous situation to people, or a risk of material damage... -

Page 15: Electric Current

Before picking up the component, ground yourself by holding the protective conduc- tor (PE) or the unpainted part of the inverter housing. Caution! Damage to the electrical components of the Solar-Log™ due to the wiring of the So- lar-Log™! Switch the Solar-Log™ off;... -

Page 16: Package Contents

Report any damage or missing parts to the forwarding agent and dealer immediately. The unit is supplied with the following components: • Solar-Log™ basic unit • 2x cover panels to be fitted to the top and bottom of the unit to protect the connections and reset button •... -

Page 17: Wall Mounting

Suitable wall plugs and screws are supplied for wall mounting. Please remember that an electrical outlet and a local network connection are required near the Solar-Log™ in order for it to operate. GPRS and WiFi models do not require the network connection. - Page 18 Wall mounting Note! concerning Solar-Log™ GPRS The SIM card should be inserted before attaching the unit, as the insertion slot will no longer be accessible after wall mounting. • Fasten the housing with the screws • Cable feed through – top and/or bottom covers.

-

Page 19: Unit Connections

S0 connection. USB connection. Suitable for USB sticks. Not suitable for a connection to a PC S0-IN B S0 pulse input for connection to an external power meter. *Only the Solar-Log 300 is equipped with this connection. -

Page 20: Fig.: Bottom Connections Solar-Log 300

Unit connections Bottom connections Fig.: Bottom connections Solar-Log 300 Solar-Log 300 / Solar-Log 250 RS485/422 - B RS485 interface, 6 pin: Connection for inverters and additional accessories Power 12 V 12 volt DC input Network Ethernet network interface, 10/100 Mbit... -

Page 21: Solar-Log 1200

Unit connections 8.2 Solar-Log 1200 Top connections Fig.: Top Connections Solar-Log 1200 Solar-Log 1200 S0-Out S0 pulse output for S0-IN A connecting to a large external display. S0 pulse input for connection to an external power meter. Please note the connection characteristics of the S0 connection. -

Page 22: Fig.: Top Connections Solar-Log 1200

Unit connections Bottom connections Fig.: Top Connections Solar-Log 1200 Solar-Log 1200 Relay Relay with change-over contact RS485 - A RS485 interface, 4 pin: Connection for inverters and/or accessories (inacti- ve if the optional Bluetooth interface is used) RS485/422 - B... -

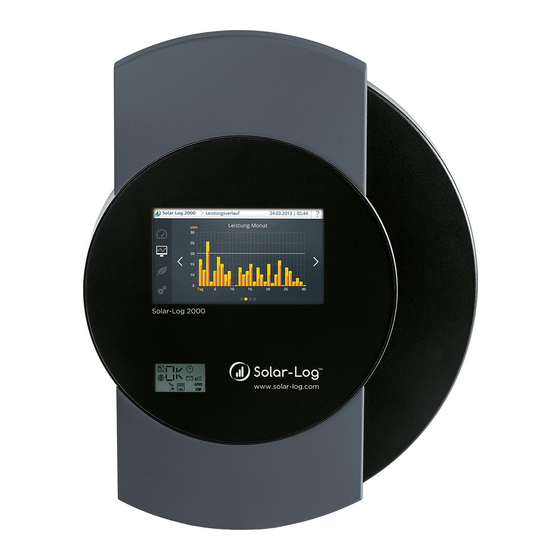

Page 23: Solar-Log 2000

Unit connections 8.3 Solar-Log 2000 Top connections Fig.: Top Connections Solar-Log 2000 Solar-Log 2000 S0-Out S0 pulse output for S0-IN A connecting to a large external screen. S0 pulse input for connection to an external power meter. Please note the connection characteristics of the S0 connection. -

Page 24: Fig.: Top Connections Solar-Log 2000

Unit connections Bottom connections Fig.: Top Connections Solar-Log 2000 Solar-Log 2000 Relay Relay with change-over contact RS485 - A RS485 interface, 4 pin: Connection for inverters and/or accessories (inacti- ve if the optional Bluetooth interface is used) RS485/422 - B... -

Page 25: Optional Connections

Solar-Log™ GPRS Antenna connection and SIM card slot In addition to the connections on the standard Solar-Log™, the Solar-Log™ GPRS model with an integrated GPRS modem has a SIM card slot and a screw connection for an antenna. •... -

Page 26: Solar-Log™ Meter (Solar-Log 300 And 1200)

9.2 Solar-Log™ Meter (Solar-Log 300 and 1200) The Solar-Log Meter version of the Solar-Log™ has an integrated interface to connect up to six current transformers (CTs). This optional Meter interface makes it possible to measure generating units (producti- on meter) and consumption from individual appliances. -

Page 27: Fig.: Two 6-Pin Terminal Block Connectors For The Meter Interface

2x2 Phases + 2x1 Phase • 1x2 Phases + 4x1 Phase The current transformers have to be connected to the Meter interface with the secondary side. Fig.: Two 6-pin terminal block connectors for the Meter interface Solar-Log™ Meter 1 Interface Description Label Current transformer... - Page 28 Characteristics of the Meter interface The current transformer may not exceed a maximum output or secondary current of 200 mA. The input / rated current is calculated by the maximum amount of power that is to be measured and has to be selec- ted for each measuring point.

-

Page 29: Solar-Log™ Pm

Optional Connections 9.3 Solar-Log™ PM+ Fig.: 6-pin PM+ interface Assignment Description Control voltage for active power control D_IN_1 Control input 1 D_In_2 Control input 2 D_In_3 Control input 3 D_In_4 Control input 4 Control voltage for reactive power reduction... -

Page 30: Connector Assignments And Wiring

If you want to connect several inverters to Solar-Log™, you need suitable cables and connectors to connect the inverters to each other. • For each connection to the Solar-Log™ (RS485 - A and RS485/422 - B or - C) a separate cable must be used. •... -

Page 31: Rs485-A (Only Solar-Log 1000, 1200 And 2000)

Connector Assignments and Wiring Fig.: Terminal block connector with ferrules 10.2 RS485-A (only Solar-Log 1000, 1200 and 2000) Use the provided terminal block connectors when connecting inverters or accessories to the RS485 A interface. Fig.: 4-pin Terminal block connector RS485 - A... -

Page 32: Rs485/422 - B

Connector Assignments and Wiring 10.3 RS485/422 - B Use the provided terminal block connectors when connecting inverters or accessories to the RS485/422 - B interface. Fig.: 6-pin Terminal block connector RS485/422 - B Assignments RS485 Assignments RS422 Data + T/RX+ 12 V Ground Ground... -

Page 33: Rs485/422 - C (Only Solar-Log 2000)

Connector Assignments and Wiring 10.4 RS485/422 - C (only Solar-Log 2000) Use the provided terminal block connectors when connecting inverters or accessories to the RS485/422 C interface. Fig.: 6-pin Terminal block connector RS485/422 C Assignments RS485 Assignments RS422 Data +... -

Page 34: S0 Out / In A (S0-Out And S0-In A)

Fig.: Schematic diagram of the S0 output Note! We recommend not using the S0 output for sending current feed amount response sig- nals to your grid operator. Due to the internal calculating processes of the Solar-Log™, there would be a delay in sending the pulses. -

Page 35: S0-In B

Connector Assignments and Wiring 10.5.2 S0-IN B The S0 In interface is a hardware interface used for recording measurement values from power meters. Use the supplied terminal block connector for the connection to the Solar-Log™. Fig.: 4-pin Terminal block connector S0-IN B... -

Page 36: Fig.: 4-Pin Terminal Block Connector

Connector Assignments and Wiring 10.6 PM+ The Solar-Log™ PM+ models come with a 6-pin PM+ interface on the top side of the Solar-Log The interface has been designed to link the ripple control receivers or telecontrol plants with potential-free signal contacts. Up to two ripple control receivers can be connected. This allows the commands from grid operators for active and reactive power to be interpreted. -

Page 37: Connecting The Inverters

Always read the manufacturer-specific instructions for connecting the data cable. You will find these inst- ructions in the manufacturer's documentation. However, when assigning the inverter wiring on the Solar-Log™, follow the instructions in this manual, otherwise the inverters will not be detected by Solar-Log™. -

Page 38: Switch Off The Inverters And The Solar-Log

Switch off the inverters and the Solar-Log™. Switching inverters off Before a making a cable connection between the Solar-Log™ and the connections inside the inverter and before installing an interface card in the inverter, always turn off all of the inverters first. -

Page 39: Connecting Accessories

Solar-Log™. • The sensors are connected to the Solar-Log™ via the RS485 interface parallel to the inverter bus or via a free RS485 interface. Please pay attention to the notes in the component database. Sensors cannot be connected to the same bus with some inverters. - Page 40 4 (Data -) Orange: Data - Installation When the Solar-Log™ is switched on, the sensor is also automatically powered. Then the Sensor Basic and Professional have to be configured to the desired RS485 interface: • Select the "Mencke&Tegtmeyer" sensor via the device definition according to the device class and manufacturer.

-

Page 41: Sensor Box Professional Plus

Solar-Log™ to calculate the deviations in the current output compared to the potential output. Up to 9 Sensor Box Professional Pluses can be connected to the Solar-Log™. The solar radiation sensor must be fitted in such a way that the sensor's solar cell and the plant's modules are aligned as similarly as possible to the sun, i.e. - Page 42 The connection cable between the Sensor Box Professional Plus and the Solar-Log consists of 4 wires and includes the 12 volt power supply and the data connection to the Solar-Log The cable shielding must be connected with an equipotential bonding system.

- Page 43 4 (Data -) Orange: Data - B Installation When the Solar-Log™ is switched on, the Sensor Box Professional Plus is also automatically powered. Then the Sensor Box Professional Plus must be configured to the desired RS485 interface: • Select "M&T Sensor" and the corresponding bus for the initial configuration.

-

Page 44: Ripple Control Receiver

Wiring The relay contacts for the ripple control receiver are connected to the Solar-Log™ PM+ via the 6 pin PM+ interface on the top side of the Solar-Log™. Fig.: 6-pin PM+ interface The ripple control receivers used by grid operators utilize various numbers of relays. -

Page 45: Large External Displays

Connecting accessories 12.4 Large External Displays Large external displays can be connected to the Solar-Log™ via two interfaces: • Connection via RS485 • S0 pulse output The connection via RS485 is preferred Cable lengths can be up to 1000 meters and the data which is dis- played on the Solar-Log™... - Page 46 Further information about the connection can be obtained from the manufacturer of the display. Pulse factor In the standard setting, Solar-Log™ sends 1000 pulses/kWh over the S0 output. The pulse factor must be configured according to the size of the plant (kWp) in the...

-

Page 47: External Power Meter

The impulse factor in the Solar-Log™ and the connected device has to be identical. 12.5 External power meter External power meters can be connected to every Solar-Log™ model via the S0 input and/or the RS-485 bus. Solar-Log™ devices have a varying number of SO inputs: S0 inputs Solar-Log™... -

Page 48: External Power Meters/Accumulating Meters

Connecting accessories 12.5.1 External power meters/accumulating meters With multiple phase meters, a basic distinction is made between phase-exact and accumulating meters. Accumulating meters provide the total values from all three phases. The meter calculates the total output (also to and from the grid) of the individual phases and provides this total as a single value. In the example: Phase 1 supplies 3 kW via an inverter (single phase). -

Page 49: Wiring For S0 Meter

Power meter Solar-Log™ Assignment Place a cable bridge between pin 3 and 4 on the Solar-Log™. The maximum cable length between the power meter and Solar-Log™ is 10 meters. Wiring for Inepro 75D meter via S0 Article Number: 255420 Inepro 75D Power meter Solar-Log™... - Page 50 Inepro 1250D Power meter Solar-Log™ Assignment Pin 9 - S0+ Pin 8 - S0- Place a cable bridge between pin 3 and 4 on the Solar-Log™. Wiring for Iskra WS0021 meter via S0 Article Number: 255346 Iskra WS0021 Power meter Solar-Log™...

-

Page 51: Wiring For Rs485 Meter

After the detection is finished, the detected meter can be configured under Configuration | Device | Configuration. 12.7 Wiring for RS485 meter The meter's RS485 output can be connected to any RS485 interface (A, B and C) on the Solar-Log™. Overview • 2-pin wiring. - Page 52 Note! Inepro 1250D All three phases have to be connected for the Solar-Log™ to accurately detect the meter. If an Inepro 1250D is used, the PRG button on the meter must be pressed and held down during entire detection process.

- Page 53 This address is therefore not allowed to be used for other devices. After the configuration, the display on the Inepro meter alternates between the meter status and the address display (ID=EA). This can be used to check if Solar-Log™ has cor- rectly detected the meter.

-

Page 54: Installation Utility Meter / Janitza Umg 104 / Umg 604 (Only Solar-Log 1000 And 2000)

12.8 Installation Utility Meter / Janitza UMG 104 / UMG 604 (only Solar-Log 1000 and 2000) The Solar-Log™ Utility Meter is a universal metering device. It can be integrated in both low- and medi- um-voltage networks (via a transformer) and is needed for various functions: •... -

Page 55: Fig.: Example - Utility Meter Umg 104 Connection Diagram For Voltage Measurements In Low-Voltage Power Grids

Connecting accessories Connecting the Utility Meter to the power grid Fig.: Example - Utility Meter UMG 104 connection diagram for voltage measurements in low-voltage power grids Fig.: Utility Meter connection diagram for voltage measurements with current transformers (medium volta-... -

Page 56: Fig.: Example - Utility Meter Umg 104 Connection Diagram For Current Measurements With Current Transformers

Connecting accessories Fig.: Example - Utility Meter UMG 104 connection diagram for current measurements with current transformers Procedure • Enter the supply voltage into the Utility Meter Note! We recommend using a fuse to safeguard the connection lines for the supply voltage. Please follow the instructions in the Janitza UMG 104 manual. - Page 57 The measurement voltage must in effect be at least 10V or an exact measurement is not possible. • Connect the Utility Meter to the RS485 bus of the Solar-Log™ according to the following diagram: Wiring the Utility Meter Terminal block connec- Utility meter tor RS485 Solar-Log™...

-

Page 58: Solar-Log™ Smart Relay Box

0.25 A @ 240 V 1 A @ 30V 0.3 A @ 110V Procedure • Connect the Relay Box to the RS485 bus of the Solar-Log™ according to the following diagram: Relay Box Wiring Terminal block connec- Relay Box tor RS485 Solar-Log™... -

Page 59: Fig.: Smart Relay Box Relay Output (Change-Over Contact) Diagram

RS485 interface. The Relay Box requires its own separate RS485 bus. It is possible to combine the Utility Meter with sensors. Note! The Solar-Log™ Smart Relay Box cannot be connected together with PM+ packages on a Solar-Log™. Relay output assignments Fig.: Smart Relay Box relay output (change-over contact) diagram... -

Page 60: Wemo Insight Switch

A direct connection between the Solar-Log™ WiFi and WeMo is not possible. The Solar-Log™ has to be connected to a router via a LAN cable or to be in a network. The last step is configuring the Smart Energy Logics. Refer to the Solar-Log ™ Smart Energy Manual for... -

Page 61: Allnet Network Power Socket

To ensure functionality with the Solar-Log™, the ALL3075v3 still has to be set to remote control in the Allnet socket configuration. The last step is configuring the Smart Energy Logics. Refer to the Solar-Log ™ Smart Energy Manual for more information. It is available from our website at https://www.solar-log.com/en/support/downloads... -

Page 62: Connecting The Allnet Network Power Socket To The Solar-Log

Connecting accessories 12.11.1 Connecting the Allnet network power socket to the Solar-Log™ The Allnet socket has to be defined with the device detection function to connect to the Solar-Log™. From Configuration | Devices | Definition the WEB interface of the Solar-Log™ go to and select the device class "Switch"... -

Page 63: Other Connections

Other connections 13 Other connections 13.1 Alarm contact (only Solar-Log 1000 and 2000) The Solar-Log 1000 and 2000 have an alarm contact which is triggered if the connection is broken. This function can be used for various applications: • Anti-theft protection for the modules or inverters •... -

Page 64: Relay (Only Solar-Log 1000, 1200 And 2000)

Other connections 13.2 Relay (only Solar-Log 1000, 1200 and 2000) The Solar-Log™ has a potential-free control relay, which is activated under the following conditions: • Alarm contact triggered • Active power reduction activated • Optimization of self-consumption The relay may be loaded with a maximum of 24 V DC and 2 A. -

Page 65: Usb

WEB interface. The acknowledgment is automatic once the notifications have been loaded. 13.3 USB Solar-Log™ 300, 1000, 1200 and 2000 have a USB connection. This USB connection can only be used for USB sticks and not for a direct PC connection. Note! When a USB stick is connected, the Solar-Log™... -

Page 66: Installation

• Connection through a wireless network (Solar-Log™ WiFi) If the Solar-Log™ is operated via a router, ensure that the necessary ports have been activated (see Chap- ter „Internet-Ports“). Since the Solar-Log™ obtains its IP address while booting, it needs to be connected to the network before... -

Page 67: Instructions For Connection Through The Powerline Package

• The DHCP service is enabled on the Internet router. • The DHCP service is enabled when connecting directly to the Solar-Log™ with a PC. (We recom- mend using a patch cable.) Easy Installation After selecting the language and country, the initial set up can be carried out with the "Easy Installation"... -

Page 68: Initial Set Up Of The Solar-Log 1200

For more information, please refer to the Quick Start Guide that was included with the device. 14.4 Setting up of the Solar-Log™ with the confi guration wizard After the initial set up of the Solar-Log™ (see chapter 14.2 and 14.3), the Solar-Log™ starts to ask about the following settings: •... -

Page 69: Fig.: Startup Screen Of The Solar-Log™ Configuration Wizard

Click on the „Start“ button to run the configuration wizard. Once started, the Ethernet Settings menu ap- pears (see image „Solar-Log™ Ethernet Settings via the Solar-Log™ configuration wizard“). In the network settings can be entered in the IP address, subnet mask and gateway boxes. Instead of manually entering the network settings, „Obtain IP address automatically (DHCP)“... -

Page 70: Fig.: Displayed Firmware Update Window

If the test is successful, click on the „Next“ button to go to the next section. A dialog window appears. From this window, you can check if a new Solar-Log™ firmware version is available (see image „Displayed Firmware Update Window“). -

Page 71: Fig.: Device Detection With Help Text Displayed

Installation Fig.: Device Detection with help text displayed Note The device detection is to be performed after the components have been connected. Otherwise the corresponding boxes for the components are grayed out.. „Easy Installation“ selection When „Easy Installation“ is selected, the detection is started automatically after clicking on the „Start“ but- ton. -

Page 72: Fig.: Example - Configuration Wizard - Device Configuration

“) Fig.: Example - Confi guration Wizard - Device Confi guration The „Portal“ menu appears after clicking on the „Next“ button. The data transfer to the Solar-Log WEB Enerest™ portal and local monitoring can be activated from this menu. The box „Portal Server“ appears once the data transfer to the Solar-Log WEB Enerest™ portal is activated. -

Page 73: Fig.: Example - Summary Of The Configuration Wizard With Deactivated Data Transfers

Installation If local monitoring remains deactivated, the configuration wizard is finished once you click on the „Next“ button. The system information page appears with a summary. (See illustration: „Summary of the configu- ration wizard with deactivated data transfers“) Fig.: Example - Summary of the confi guration wizard with deactivated data transfers Note When local monitoring is deactivated, the e-mail, text message notifications, FTP export and FTP backup functions are also deactivated. -

Page 74: Fig.: Example Of The Configuration Wizard Summary

Installation After the E-mail Configuration, the Device Notification menu appears. The error and status codes that, for example, are sent as e-mails can be defined in this menu. The maximum number of e-mails per day can also be defined. (See Chapter „Setting up Notifications for more information“) When the Definition is completed, click on „Next“... -

Page 75: Carrying Out The Initial Set Up Of The Solar-Log 250, 300, 1200 And 2000 (Manually)

14.4.1 Carrying out the initial set up of the Solar-Log 250, 300, 1200 and 2000 (manually). The initial configuration of the Solar-Log 250, 300 and 2000 is performed via a web browser. All of the device connections need to be established and it is best to connect the Solar-Log™ to an Internet router. -

Page 76: Starting The Configuration

Installation 14.5 Starting the configuration The various options to open the main menu of the Solar-Log™ are listed below: Device URL • Start the web browser • Enter http://solar-log in the address bar and press the ENTER key • The main menu of the Solar-Log™ is displayed... -

Page 77: Fig.: Solar-Log™ Model Tag

Start the web browser • Enter http://solar-log-wxyz in the address bar and press the ENTER key Here wxyz stands for the last 4 digits from serial number of the Solar-Log™. The serial number is printed on the model tag. •... -

Page 78: Fig.: Pop-Up Window With Security Information

Installation Setting passwords If no password has been defined after the update to firmware 3.5.3, the following window appears with security information. Fig.: Pop-up window with security information Click on “Yes” here to directly define a user password. The following configuration page appears: Fig.: Configuration page “Access control”... - Page 79 Installation In the Access protection for the browser section, the user password can be activated and defined. Click on “save” after the defining the password. It is necessary to log in as a user with the newly defined password (log in button on the button right) to continue with the configuration. Set password later (not recommended) It is possible to define the user password later by clicking on “No”...

-

Page 80: Using The Browser Menu

Installation 14.6 Using the browser menu The browser menu of the Solar-Log™ functions like a website and is divided into fourth main sections: • Header bar (A) • Left navigation (B) • Tabs (C) • Configuration page (D) The sections Yield data and Diagnostic are described in the user manuals of the respective models. -

Page 81: Control Elements

Installation 14.6.1 Control elements The following control elements are used: Control elements in the browser menu Control element Meaning Text field Text field with incorrect or missing entry Drop-down selection list Virtual switch deactivated and activated The question mark boxes display additional informa- tion Check boxes... -

Page 82: Explanations Of The Names In The Main Menu

Installation 14.6.2 Explanations of the names in the main menu Header bar The header contains three main sections: • Yield data: Here you will find your plant’s yield overview within certain periods of time such as day, month, year and the total yield to date. •... -

Page 83: Fig.: Automatic Firmware Update Check With Notification Text Displayed

Installation Note! Automatic Firmware Update Check Configuration | has to be activated in the System | Firmware menu to use this function. (See illustration: Automatic Firmware Update Check with notification text displayed) Fig.: Automatic Firmware Update Check with notifi cation text displayed The following notification text is displayed by clicking on the question mark: “This settings allows firmware versions with critical errors to be automatically updated. -

Page 84: Fig.: Window Displayed Indicating That A New Firmware Version Is Available

Clicking on the green exclamation mark in the header displays the following window: Fig.: Window displayed indicating that a new firmware version is available Selecting “OK” redirects you to the page of the Solar-Log™ for firmware updates. Selecting “Cancel” closes the window. -

Page 85: Main Menu

LCD display. (Refer to the illustration “VLCD Display” and the chapter “ the symbols on the LCD display” The notifications are in real-time and are identical to those on the Solar-Log™ LCD Display. (Solar-Log 300, 1200 and 2000) (Also refer to the chapter “Notifications on the LCD Status Display”) -

Page 86: Configuration Menu

Requests and control commands are sent to the inverters, battery systems and intelli- gent appliances via the network interface. For this reason, the network should always be available (24/7). If the Solar-Log™ is connected via WiFi, we recommend deactivating the overnight shutdown function. -

Page 87: Ethernet

The Subnet mask is 255.255.255.0 by default and must be the same for every device in the subnet. Gateway The gateway is typically the IP address of the router to which Solar-Log™ is connected. That IP address is to be entered here. -

Page 88: Fig.: Example Of An Unsuccessful Connection Test

Configuration Menu Alternate DNS server In some networks, the DNS server is a separate address for resolving Internet addresses (unlike a gate- way). If an Alternate DNS server is needed, switch the function to activated and enter the IP address of the DNS server. -

Page 89: Gprs (Only Solar-Log™ Gprs)

Configuration Menu 16.1.2 GPRS (only Solar-Log™ GPRS) Fig.: GPRS settings In many cases where no DSL or telephone connection is available, a GPRS mobile network is the only opti- on to connect to the Internet to send e-mails, text messages (SMS) and data to the homepage. - Page 90 If this option is activated, the GPRS modem is continuously connected to the service provider. This setting is only recommended for flat-rate data plans. Roaming allowed By activating the roaming function, the Solar-Log™ can also connect to other mobile networks when the home network is unavailable. Note! Activating the roaming function could potentially result in enormous additional costs.

- Page 91 Configuration Menu Caution! After sending the PUK code / super PIN, the PIN of the SIM card is reset to the one de- GPRS Settings | SIM PIN fined in the menu. Status and Test section The GPRS connection can be tested and disconnected with this function. The error codes displayed under Last Error are „21.2.1 Fault messages GPRS“...

-

Page 92: General Information About Gprs Devices

Caution! Only remove the SIM card after the Solar-Log™ has been turned off. Removing the SIM card during normal operation may cause a card defect. Corrosion on the SIM card contact points is an indication that the installation location does conform to the... -

Page 93: Wifi (Only Solar-Log Wifi)

Configuration Menu 16.1.4 WiFi (only Solar-Log WiFi) Fig.: WiFi settings The Solar-Log™ WiFi models are equipped to be connected in a wireless local area network. Status section The WiFi function can be switched on and off with the Activate WiFi function. - Page 94 Once the search is completed, the wireless networks found are listed and can be selected from the SSID. The Solar-Log™ automatically switches to the encryption used by this network. If the network name is hid- den ("Hidden SSID"), the Access Point is not displayed by the network scan. In this case, enter the network name and security key.

-

Page 95: Proxy

The proxy function is not enabled by default. Configure the proxy in the menu. The proxy settings need to be configured in the Solar-Log™ to enable Internet communication via the pro- xy server. Proxy servers are typically used in the networks of organizations and companies. -

Page 96: Internet Configuration

Text message (SMS) • Export • Backup 16.2.1 Access type The type of Internet access that the Solar-Log™ uses to connect to a portal or server is adjusted in this tab. Procedure • Internet Access Select the type of Selection options:... - Page 97 Configuration Menu Solar-Log WEB Enerest™ settings section (Solar-Log 250, 300, 1200 and 1000) In this section, the following selection options are available: • Activate / Deactivate transfers • Portal Server • Transfer interval WEB-Portal settings section (Solar-Log 200, 500 and 1000) In this section, the type of portal used can be selected.

- Page 98 Configuration Menu Test Solar-Log WEB Section A connection test can be performed in the Test section. A separate pop-up window is displayed with the progress of test. The connection test also indicates if the test was successful or not. If it was not successful, it displays the error.

-

Page 99: E-Mail

E-mail settings section Enter the settings for sending e-mail via the Solar-Log™'s e-mail client in this section. The data for the boxes SMTP Server, SMTP user name, SMTP password and sender is in the confirmation message from the portal registration. -

Page 100: Text Message (Sms)

Status & Test e-mail section In this section, the e-mail settings can be tested and the information from the last sent e-mail displayed. 16.2.4 Text message (SMS) The Solar-Log™ text message (SMS) program sends customized messages with any of the following cont- ent: •... -

Page 101: Export

FTP server access data. • An FTP directory only has to be entered here if the Solar-Log™ homepage is not to be located di- rectly in the main directory of your homepage. Otherwise, this box can be left empty. -

Page 102: Configuring Connected Devices

Configuration Menu 16.3 Configuring connected devices Configuration | Devices From the menu , the PV plant components connected to the Solar-Log™ can be • defined • detected • and configured. We recommend the following procedures for new installations: • First define the interface to be used for the connected devices •... -

Page 103: Fig.: Adding Components

Caution: Using different manufacturers on the same serial bus may cause communication problems. Only the network interface (Ethernet) can have multiple assignments according to our component database at www.solar-log.com. If the device class is correct, confirm the selection with OK. Define additional connected device classes as described. -

Page 104: Fig.: Overview Of The Selected Components

Configuration Menu Fig.: Overview of the selected components From the overview, there is the option to check whether the settings are correct and, if need be, adjust or delete them with the symbols. (The symbols are only displayed by moving the mouse over the components.) Additionally, the following is displayed in the overview of the device interfaces: •... -

Page 105: Fig.: Device Definition For The Solar-Log™ Meter

Input definition • Reference voltage The Operating Mode section describes the setting for the various operating modes of the Solar-Log™ Meter and is to be selected in the Device Definition before Device Detection. (See figure „Operating mode Solar-Log™ Meter)“ Fig.: Device definition for the Solar-Log™ Meter Input definition section •... - Page 106 Solar-Log™ • or set in the box reference voltage [V]. If the Solar-Log™ does not receive voltage values from the inverters (for example during night), an average value is calculated and used. Always use stored voltage button...

-

Page 107: Fig.: Solar-Log™ Meter Operating Mode

Configuration Menu Operating mode with the Solar-Log™ Meter in connection with the interface assignment: • Select the desired Operating mode before the device detection in the Device Definition menu. The listed operating modes refer to the different possible measuring combinations. -

Page 108: Device Detection

During the Device Detection process, all of the predefined components in the Device Definition menu which are connected to the Solar-Log™ interfaces are searched for and recognized. During the Device De- tection process, the Solar-Log™'s internal data structure is prepared for these devices. -

Page 109: Configuring Devices

Configuration Menu 16.3.3 Configuring devices After the Device Detection has been successfully completed, the detected devices have to be defined Configuration | Devices | Configuration in the menu. Depending on the device, different settings might be needed for the configuration. Procedure: •... -

Page 110: General Information On The Pac Correction Factor

8% can arise. In practice, meters and inverters both can display too much or too little kWh. To correct these inaccuracies in the medium term, the Solar-Log™ firmware uses a PAC correction factor. Configuration | Devices | Configuration The PAC correction factor is located in the menu. -

Page 111: Configuring Power Meters

Configuration Menu 16.3.5 Confi guring power meters An operating mode needs to be assigned to power meters to configure them. Possible operating modes for power meters: • Generator (records the individual producers, e.g. PV inverter or CHP • Meter for the entire plant (records the complete PV plant output) •... -

Page 112: Configuring Sensors

Configuration Menu 16.3.6 Confi guring sensors Under sensors, the configuration only comprises of activating other sensors. Procedure: • Ambient Temperature Wind activate Use the and/or button to the sensors. • If needed, make assignments to the module field. • SAVE the settings. - Page 113 Example: If the rotary switch is set to 40°C and the Solar-Log™ to 60°C, the settings from the Solar-Log™ will be ignored and the value from the rotary switch will be applied. The range for the rotary switch has to be set higher so that the Solar-Log™...

- Page 114 Configuration Menu Configuring IDM Heat Pumps IDM heat pumps can be selected from the drop-down menu from the Device Configuration menu and con- figured accordingly. Procedure: • Select the IDM heat pumps from the drop-down menu under devices. • Select the operating mode from the meter configuration menu. •...

- Page 115 Solar-Log™ to consume the defined maximum power levels without any restrictions, regardless of the production or surplus levels. If a wall switch has not been installed, the Solar-Log™ configuration defined for the current limiting functi- on can be set to „always charge.“ This also allows for charging according to the defined maximum power...

-

Page 116: Fig.: Example Of The Module Field Division

Configuration Menu Module Fields Each connected MPP tracker is assigned to a module field. Module fields are subdivided according to the type of the solar module, angles of inclination and alignment. If all modules within a system are of the same type and have the same alignment, only one module field, e.g. -

Page 117: Fig.: Battery Configuration With Help Text

Configuration Menu Battery Section Battery The following configuration options are available for connected batteries from the menu (it only appears when a battery is connected). • Battery size Enter the battery size in Wh in this box. • Consumption meter includes battery charge This box enables recording the battery charges from the consumption meter. -

Page 118: Configuring Plant Data

The general plant information is to be entered in the plant information menu. This tab is only displayed when Export and Backup is activated. These values need to be entered in the portal when Solar-Log WEB Enerest™ or Solar-Log WEB Enerest™ Home are used.Plant name •... -

Page 119: Plant Groups

16.4.2 Plant groups Since the Solar-Log™ can manage up to 100 inverters at the same time, it is helpful to divide these inver- ters into groups. To provide a clearer overview, these groups are then shown in all selection dialog boxes. -

Page 120: Defining The Pv Plant's Forecast Data

In the forecast, Solar-Log™ also takes account of the yields in all previous years, and in this way can allow for local weather events (in most cases, snow in December). The yearly forecast is therefore usually fairly accurate by September. -

Page 121: Defining The Feed-In Tariff

The electricity prices are entered in an extra tab. The Solar-Log™ calculates the amount of power fed into the grid based on the inverter information. -

Page 122: Fig.: Tariff - Tariff Settings

To implement this function, the Solar-Log™ requires an additional consumption meter. In this mode, the electricity price needs to be defined in an extra tab. The feed-in tariff has to be defined as zero (0). The Solar-Log™... -

Page 123: Define Electricity Costs

Since the prices may change, there is the option in this section to enter prices with a particular valid date in the fields “Start Date” and “Rate [ /kWh].” The Solar-Log™ can include this in its calculations (see section “Finances”). -

Page 124: Configuring Notifications

• Deviation from target power E-mail The e-mail addresses can be entered in the box. The Solar-Log™ sends all e-mail notifications to these e-mail addresses. SMS (only with GPRS) A mobile number can be entered in the box. The text message (SMS) is then sent to this mobile number. - Page 125 Configuration Menu In group A, inverter specific messages are numbered in ascending order, starting with 0. The code which is automatically determined is used for the filter function. In group B, the actual messages from the inverters are displayed. The meaning of these fault messages can be found in the particular manufacturer's manual.

-

Page 126: Fig.: Configuration Example For Filtering Status And Fault Codes

Configuration Menu Note! If the maximum number of notifications per day is defined too low, this can lead to im- portant messages not being sent. • SAVE the settings. In the Save menu, there are three different options: • SAVE •... -

Page 127: Yield

Configuration Menu 16.6 Yield The Solar-Log™ come with an e-mail program that can send a daily overview of the day’s performance to two different e-mail addresses. Configuration | Notifications The settings are configured under the menu. Recipient tab Click on the to enter the recipient’s e-mail address. -

Page 128: Fig.: Defining Notification Times And Setting Types

Configuration Menu Yield tab In the , you can define yield notifications to be sent via e-mail or text message (SMS). Fig.: Defi ning Notifi cation times and setting types The time frame for notifications can be defined here. There are many types of settings: •... -

Page 129: Explanation Of The Individual E-Mail Functions

Configuration Menu 16.6.1 Explanation of the individual E-mail Functions: Deactivated • When no e-mail notifications are to be sent. Yield overview short • The yield data from the entire plant is totaled and displayed for the day, month and year . -

Page 130: Fig.: Yield Overview (All Inv) In Html Format

Configuration Menu Yield overview (all INV) • Yield data is totaled for the entire plant with the totals for every individual inverter (also SO me- ters) broken down by day, month and year . This is then displayed in HTML format as a table. See the figure: Yield overview (all INV) in HTML format. - Page 131 Configuration Menu Explanation of the individual sections of the Yield Overviews Subject : The Solar-Log serial number and time and date Day: Field Explanation Text Total The actual amount of grid feed for the day in kWh. Specific Yield specific. The energy yield divided by the amount of generator power installed.

-

Page 132: Text Message (Sms) Notifications

16.7 Alarm (only Solar-Log 1000 and 2000) The Solar-Log™ continuously monitors its internal alarm contact. If this contact is opened, it sets off an Alarm alarm which can be indicated in various ways. In the tab, the alarm contact can be activated and different types of notification can be configured. - Page 133 Configuration Menu • Select the device that is to be monitored • Select the Performance Monitoring mode. Select per MPP tracker or for the total of all of the MPP trackers. There is also the option to deacti- vate the performance monitoring. •...

-

Page 134: General Information On Performance Monitoring

Other than production meters, meters can be largely excluded from this section. 16.8.1 General Information on Performance Monitoring To monitor different sized inverters, the Solar-Log™ normalized the value from every inverter to 1 kWp. The Configuration | Devices | Configuration Solar-Log™... -

Page 135: Fig.: Configuring Module Fields

Configuration Menu Fig.: Configuring module fields Configuration | Notifications. Performance Monitoring Configuration under Fig.: Configuring performance monitoring The output measured from the inverters is compared to the generator capacity that is listed in the system. - Page 136 Configuration Menu A notification is sent (by email) when the deviation exceeds the amount configured (for example 10%) over a set time period (for example 30 minutes). Note For performance monitoring configurations, see the chapter " Configuring Notifi- cation Installation Manual "...

-

Page 137: Fig.: Performance Monitoring With Notification And Inverter

Configuration Menu Fig.: Performance Monitoring with notification and inverter Inverter 1, Inverter 1 house Inverter 2, Inverter 2 house Generator Power = 5500 Wp = 3300 Wp Current power output = 3950 W = 2950 W Current efficiency = 71.81 % = 89.39 % Inverter with a deviation Reference Inverter... - Page 138 Configuration Menu Calculation and Explanation of the Notification In regard to the reference inverter, inverter 1 is compared to all of the inverters in the same module field (in the example only output is used). A deviation of 19.65% is determined based on the comparison of the generator capacity and IRV forecast. Calculating the Deviation for Inverter 1 Deviation Calculation Inverter 1 IRV calculation...

-

Page 139: Smart Energy

The following selection manufacturers are available: • AllNet • Belkin • Gude • Solar-Log • After that, the Type has to be defined. Depending on the selected manufacturer, all of the suppor- ted models can be selected here. • Allnet: •... -

Page 140: Smart Energy Switching Groups

The switch contacts for the switching groups can be added in this section and new switching groups can be created and configured. Switching contacts in the switching groups are activated by the Solar-Log™. Unassigned contacts are only recorded – as long as the values can be recorded (depends on the hardware). -

Page 141: Fig.: Creating Switching Groups

Configuration Menu Creating switching groups There are two ways to create a switching group: The first method: • Left-click on the “Create switch contact here via Drag & Drop” box. The second method: • Drag a defined switch from the hardware section to the “Create switch contact here via Drag & Drop”... - Page 142 Click on this symbol to display all of the hardware data that can be accessed and recorded by the Solar-Log™ and to display the target state. Switch states / Color Definition The switching state of each contact is displayed with the following symbols:...

-

Page 143: Fig.: Adjustable Switch With Help Text

Configuration Menu Switch definitions There is the option to assign one of the following states with a mouse click. (See illustration: “Adjustable switch with help text”): • All of the contacts are permanently switched off (switch position “left”). • The contacts are switched on according to the configured automatic switching rule. •... -

Page 144: Configuring Switching Groups

Configuration Menu 16.10.3 Configuring switching groups Use this symbol to configure the switching group. The following window appears after clicking on the symbol: Fig.: Control logic configuration window The configuration is divided into two section. The top section contains the following boxes: •... - Page 145 Configuration Menu Surplus The following types can be configured under the Surplus category: • Surplus management • Surplus management and Temperature Control • Surplus management and Time Control • Surplus management and Runtime Control • Surplus matrix • Surplus visualization Surplus management: The following consumption definition can be selected in the Surplus management section: •...

- Page 146 Configuration Menu The following settings can be made and/or activated under temperature configuration: • Switch on when temperature is (C°): • greater • less • Runtime (min.): If the appliance was activated because of the temperature threshold, it will be deactivated after this time has passed, even if the minimum/maximum temperature has not been reached.

- Page 147 Note! This function is only for the visualization and no loads may be switched on since the Solar-Log™ would then have incorrect calculations which would lead to faulty switching operations. Production With output visualization, its own output threshold can be configured for every contact (1-8) assigned to the group.

- Page 148 Configuration Menu Note! This function is only for the visualization and no loads may be switched on since the Solar-Log™ would then have incorrect calculations which would lead to faulty swit- ching operations. Device-specific The following types can be configured under the Device-specific category: •...

- Page 149 Appliances, such a laundry dryer, have a short high peak of power consumption and times in which little power is required. Based on this, it would be problematic to calculate the current power consumption for power management control. The is why the Solar-Log™ calculates the entire runtime with Configu-...

-

Page 150: Control Logics Definition - Operating Mode Generator

Configuration Menu 16.10.5 Control Logics Definition - Operating Mode Generator Various control logics can be defined with the input boxes. (See the Smart Energy Manual for more details – available for download from our website – The individual boxes can be combined differently, depending on the control is used. The following rules can be selected from the Category box: •... - Page 151 Configuration Menu The configuration of grid power (see the section „Grid Power“ above). Up to two daily runtimes can be set in the time configuration. If only one runtime is needed, the second one can be deleted by clicking on the trash can symbol. Grid Power and Runtime Control: This production determination is identical to that of the grid power After selecting the production determination, the following sections are to be configured:...

-

Page 152: Smart Energy Surplus Management

Configuration Menu 16.10.6 Smart Energy Surplus Management The Surplus Management menu is divided into the following sub-sections: • Settings • Surplus priority (See illustration: “Surplus management”) Fig.: Surplus management Settings The following values can be defined in the section: • Measurement values for control logic •... - Page 153 Battery discharging suspension: When activated, the Solar-Log™ turns on the generators to provide enough power production to cover the amount required for consumption. This means that the battery is only discharged when the power produc- tion cannot cover the consumption.

-

Page 154: Feed-In Management

Note! The Solar-Log™ is not equipped with protection functions such as grid and plant pro- tection, section switches and Q/U protection. When it comes to such functions, special protection hardware needs to be installed. All protection commands, for example the emergency stop, cannot be switched on with or via the Solar-Log™. - Page 155 Configuration Menu Plant passwords Configuration | Feed-in Management | Plant Pa- The log-on data can be entered for the inverters in the rameters | Plant Passwords menu – as long as the devices configured support this function.. • Inverter Password Plant password, if service password is required to access the inverters.

-

Page 156: Active Power

Solar-Log™ devices and more details on sup- ported functions of a particular inverter: http://www.solar-log.com/en/service-support/supported-inverters.html. Interface assignments section The inverters with their assigned interfaces that are connected to the Solar-Log™ are displayed in this section. Select the inverter(s) to control and activate it/them. LCD Display In the LCD Display section, the values that are displayed can be defined. -

Page 157: Active Power Deactivated

The type of ripple control receiver or telecontrol technology used depends on the level of development of the respective grid operator. The control signals emitted by the grid operator are converted to potenti- al-free signal contacts by the ripple control receiver and can be evaluated by the Solar-Log™ PM+ models via the digital PM+ interface. -

Page 158: Fig.: Schematic Diagram Of A Ripple Control Receiver With Four Relays

Configuration Menu Channel settings for power reduction section The relay outputs for the ripple control receiver are connected to the PM+ input of the Solar-Log™ PM+. This allows the grid operator’s signals to be evaluated by the Solar-Log™. Fig.: Schematic diagram of a ripple control receiver with four relays. -

Page 159: Fig.: Channel Settings For Power Reduction

Closing relay during power reduction (only Solar-Log 1200 PM+ and 2000 PM). Select this option in order to signal any power reduction via the relay output on the Solar-Log 2000 PM+. • The relay may be loaded with a maximum of 24 V DC and 5A. -

Page 160: Remote Controlled Active Power Reduction With The Calculation Of Self-Consumption

This function does not correspond to provisions of the German EEG laws and has to be arranged with the grid operator before being used. Note! The Solar-Log PM+ needs to be linked to a consumption meter to implement this function. Please note the instructions in chapter “12.5 External power meter“. -

Page 161: 70% Fixed Reduction With The Calculation Of Self-Consumption

AC power 10kW 70% of the DC power corresponds to 8.4kW. For this reason the inverter controlled by the Solar-Log™ is reduced to 84% (8.4kW) and not only to 70% (7kW). 16.12.5 70% Fixed reduction with the calculation of self-consumption This function is an enhancement to the 70% fixed reduction described in the previous chapter. -

Page 162: Adjustable Reduction

(X%). The amount of self-consumption is taken into account for this calculation. The Solar-Log™ only regula- tes the inverters when the amount of feed-in power for the grid has reached the limit. If there is enough self-consumption, the inverters continue to operate without any reductions. -

Page 163: Fixed Reduction In Watts

Example: The total consumption of an installation is at 2000 W and the reduction of the inverters is configured to 90%, leaving 1800 W. 200 W has to be purchased from the grid to cover the total consumption. Procedure: •... -

Page 164: Reactive Power

(with negative totals). For more information, refer to http://en.wikipedia.org/wiki/Electric_current#Referen- ce_direction Interface assignments section The inverters with their assigned interfaces that are connected to the Solar-Log™ are displayed in this section. Select the inverter(s) to control and activate it/them. 16.13.1 Reactive power deactivated When this menu item is selected, reactive power control is deactivated. -

Page 165: Fixed Value Cos (Phi) Shift Factor

Configuration Menu 16.13.2 Fixed value cos (Phi) shift factor With this function it is possible to adjust the connected inverters to a fixed shift factor. Using this matrix it is possible to specify a fixed cos (Phi) for certain periods of time. If over the course of one day various shift factors must be adhered to, they can be configured here. -

Page 166: Variable Cos (Phi) Shift Factor Over Characteristic Curve P/Pn

The function is also referred to as Phi (P). The currently generated power (P) is calculated by the Solar-Log™ based on the inverter data. If an Utility Meter with power measurement is available, the output value will be used instead. -

Page 167: Variable Reactive Power Via The Characteristic Curve Q(U)

The characteristic curve displayed changes according to the values entered. 16.13.5 Variable reactive power via the characteristic curve Q(U) (only Solar-Log 2000 with Utility Meter) In order to be able to achieve this function, the Solar-Log™ Utility Meter is required in addition to a Solar-Log 2000. Reactive Power Management The Solar-Log™... -

Page 168: Fig.: Q(U) Control Function Diagram

Configuration Menu Fig.: Q(U) control function diagram Type of characteristic curve section Using this menu item a characteristic curve specified by the grid operator can be stored. In principle a dis- tinction is made here between a 2 point and a 4 point characteristic curve. 2-point characteristic curve By selecting “2-point characteristic curve”... - Page 169 Configuration Menu Reductions The following configuration options are available in the Reductions section. • Gradient limit (adjustment rate): If the power company requires a reduction, it has to be configured in this box. (Enter the values in seconds) • Max. cos(phi) inductive/under excited and max. cos(phi) capacitive/over-excited: A maximum shift factor can be defined wit this the reduction.

-

Page 170: Remote-Controlled Fixed Value Cos (Phi) Shift Factor Only Solar-Log™ Pm+)

Command impulses cannot be processed. Channel settings for power reduction section The relay outputs for the ripple control receiver are connected to the PM+ input of the Solar-Log™. This allows the grid operator’s signals to be evaluated by the Solar-Log™. -

Page 171: Fig.: Channel Settings For Remote Controlled Cos (Phi)

Ripple control receivers generally possess 2 to 5 relays. The assignment of the individual relay states for a particular shift factor is specified by the respective grid operator and stored in the Solar-Log™ using this matrix. In this way the connected inverters can be adjusted to meet the specified reduction levels. -

Page 172: Linking (Only Solar-Log 1000 And 2000)

Configuration Menu 16.13.7 Linking (only Solar-Log 1000 and 2000) The linking function is to be used when there are not enough interfaces on one Solar-Log™ or the cable lengths between the Solar-Log™ and the various inverters exceeds the RS485 specifications. -

Page 173: Profile

Configuration Menu 16.13.8 Profile For feed-in management, PM+ profiles come with the Solar-Log™ PM Package equipment. These profiles contain the pre-configured settings for feed-in management and enable the PM+ Package I/O Boxes The profiles are delivered in the config_pmprofil_NameGridOperator.dat file format. - Page 174 Configuration Menu Note! current profile first If a new PM+Profile needs to be imported, the has to be reset Note! A special operator specific installation manual is included for the installation of the PM+ Package.

-

Page 175: Direct Marketing

Configuration Menu 16.14 Direct Marketing Note! With the amendment of the German Renewable Energy Act (EEG 2014), direct marke- ting is required for all new plants with an output greater than 500 kW. Starting 01 January 2016, the requirement applies to all plants with an output greater than 100 kW. -

Page 176: Editing Data

16.15.1 Initial yield This function manually imports initial yields from previous recorded daily data into the Solar-Log. This is useful any time that a large amount of data has to be changed and would take too long with the "Data correction"... -

Page 177: Data Correction

Delete all of the old data and initialize structure Import daily data Calculate monthly/yearly data restart • The Solar-Log™ resets itself • Check the imported data in the yield data section. 16.15.2 Data correction Here you can adjust the values for previous days or change daily totals. - Page 178 The solarlog_config_YYMMDD.dat file is saved in the /Backup directory of the USB stick. YYMMDD = year, month and day - each two digits, e.g. solarlog_config_170321.dat is then the ba- ckup from 21 March 2017. • The configuration file can be saved elsewhere as a backup or imported into the Solar-Log™ again.

-

Page 179: Backup

RESTORE. • Backup files are searched for on the USB stick that is directly connected to the Solar-Log™ First it looks in the main directory of the USB stick for solarlog_config.dat, then it looks in the /ba- ckup directory. And lastly it looks in the backup directory for solarlog_config_YYMMDD.dat. When it looks for the solarlog_config_YYMMDD.dat. - Page 180 The solarlog_backup_YYMMDD.dat file is saved in the /Backup directory of the USB stick. YYMMDD = year, month and day - each two digits, e.g. solarlog_backup_170321.dat is then the backup from 21 March 2017. The Solar-Log™ backup can be copied to another storage medium or imported into the Solar-Log™ again.

-

Page 181: Reset

Resetting the yield data section In certain circumstances after an inverter detection, it may occur that incorrect or unusable data is display- ed. In this case, the stored data can be deleted without having to reconfigure the Solar-Log completely. Procedure •... - Page 182 • The data and inverter configuration are deleted. • The Solar-Log™ reboots itself. Restore factory settings section This function restores the Solar-Log™ to its factory settings. All of the yield data and configuration is dele- ted. Procedure • Click on RESET.

-

Page 183: System Configuration

Displaying advanced configuration Access protection for the display (only Solar-Log 1000, 1200 and 2000) A pin code can be activated to restrict access to the Solar-Log™'s display. The pin code may contain a maximum of 8 numerical digits. Access at the display can be restricted for the entire display or just the settings section. -

Page 184: Language/Country/Time

Time section Solar-Log™ has an integrated real-time clock which can maintain the clock time even in the case of a pow- er failure or grid disconnection, and for a long period (50 days). The clock time is factory-set, but it may be lost due to long periods of storage. - Page 185 To automatically synchronize the system time, the Solar-Log™ regularly contacts a network time protocol (NTP) server. If the Solar-Log™ is connected to the Internet via a router, the synchronization occurs during the night. With a GPRS connection, the time synchronization occurs during a data transfer.

-

Page 186: Display

Dimming when all of the inverters are offline When this function is active, the Solar-Log™ automatically dims when all of the inverters are offline (no more power feed). The Solar-Log automatically resumes from the sleep the next morning and starts recor- ding again. -

Page 187: Licenses

Configuration Menu 16.16.4 Licenses Certain Solar-Log™ functions have to be activated by entering a license code. You receive a license certifi- cate after purchasing a license for a particular function. The licenses are always linked to the serial number of the particular Solar-log™ and can only be used with the device with this serial number. - Page 188 Check for Update from USB With this function, the Solar-Log™ checks the USB stick connected directly to the device if a new version is available. When this function is used, the progress and status of the update are displayed •...

- Page 189 Configuration Menu Automatic Firmware Updates With this function, the Solar-Log™ regularly checks the firmware servers to see if a new version is available. When a new version is available, it is automatically downloaded and installed during the night. Note! By activating this function, you give Solare Datensysteme GmbH permission to auto- matically load minor updates.

-

Page 190: Accessing Diagnostic Values

• Event log • Notifications • Feed-In Management • SCB Monitor (only Solar-Log 2000 with SCB activated) • Alarm contact (only Solar-Log 2000) • CSV Export 17.1 Inverter Diagnostic Diagnostic | Inverter Diagnostic. To access the Inverter diagnostic menu, go to The following tabs can be selected from this menu: •... -

Page 191: Inverter Details

Accessing Diagnostic values 17.1.1 Inverter details Diagnostic | Inverter Diagnostic | Inverter details. To access the Inverter details menu, go to A particular date and device (e.g. inverter or sensor) can be selected under inverter details and evaluated. Fig.: Inverter details graph In the example (see Fig.: Inverter details graph), the following values can be displayed for the inverter: •... -

Page 192: Tracker Comparison

Accessing Diagnostic values 17.1.2 Tracker comparison Diagnostic | Inverter Diagnostic | Tracker comparison. To access the Tracker comparison menu, go to Two trackers (either from the same device or two different devices) can be compared on a particular date by selecting the date, device and tracker. Fig.: Tracker comparison graph In the example (see Fig.: Tracker comparison graph), two different inverters have been selected and evaluated. -

Page 193: Module Field Comparison

Accessing Diagnostic values 17.1.3 Module field comparison Diagnostic | Inverter Diagnostic | Module field com- To access the Module field comparison menu, go to parison. Fig.: Module field comparison graph Date and Module Field With the boxes, the module field comparison permits all devices (e.g. inverters and sensors) and their strings that are assigned to the same module field to be compared on the current and previous days (see Fig.: Module field comparison graph) in order to more efficiently detect faults from the performance monitoring. -

Page 194: Battery Diagnostic

Accessing Diagnostic values 17.2 Battery Diagnostic Diagnostic | Battery Diagnostic. To access the Battery diagnostic menu, go to The following tabs can be selected from this menu: • Current Measurement Values • Charging History 1-Day • Charging History 7-Days • Balances 17.2.1 Current Measurement Values Current Measurement Values... -

Page 195: Charging History 1-Day

Accessing Diagnostic values 17.2.2 Charging History 1-Day Charging History 1-Day A daily graph with the following values is in the tab. • Charge The battery’s charge levels throughout the day in watts. • Discharge The battery’s discharge levels throughout the day in watts. •... -

Page 196: Charging History 7-Days

Accessing Diagnostic values 17.2.3 Charging History 7-Days Charging History 7-Days A graph containing the last seven days with the following values is in the tab. • Charge The battery’s charge levels from the last 7 days in watts. • Discharge The battery’s discharge levels from the last 7 days in watts. -

Page 197: Balances

Accessing Diagnostic values Charge Level of the Battery via the LCD Display The charge level of the battery is displayed via the charge history in the Web interface and via the LCD display. The following charge levels of the battery are indicated with the battery symbol elements. (see the following illustration) •... -

Page 198: Fig.: Battery Diagnosis - Balance

Accessing Diagnostic values Battery efficiency The following columns are in this section: • Charge The battery’s charge during its entire run-time in kWh. • Discharge The battery’s discharge during its entire run-time in kWh. • Efficiency values The battery’s efficiency values during its entire run-time as a percentage. Fig.: Battery diagnosis - Balance... -

Page 199: Accessing Event Logs

Accessing Diagnostic values 17.3 Accessing Event logs Diagnostic | Event logs. To access the Event logs menu, go to The following mode is loaded when accessing the event logs. Fig.: The event log is being loaded. After the event log has been loaded, the window switches back to the normal view. Fig.: Event log The following settings are available from the four drop-down menus in this view: •... -

Page 200: Accessing Notifications

This column displays the type message (for example, . If an inverter is offline). • Recipient: The method with which the message is sent is displayed here. • Text: There is the option to display the messages sent by the Solar-Log™ under Text. -

Page 201: Fig.: Message With Text Field

Accessing Diagnostic values Note For sending notifications, see the chapter "Configuring Notifications" in the Instal- lation Manual. Fig.: Message with text fi eld... -

Page 202: Accessing Feed-In Management

Accessing Diagnostic values 17.5 Accessing Feed-In Management Diagnostic | Feed-In Management. To access the Feed-In Management menu, go to Note Feed-In Management Diagnostic | Feed-In Management The menu under only Configuration | Feed-In Ma- appears if active power has been configured in the nagement section. -

Page 203: Explanation Of The Values In The Power Reduction Section

Accessing Diagnostic values Diagnostic | Feed-In Management The inverter control can be analyzed and adjusted in the settings sec- tion. 10% Diagnosis Function There is also a to simulate a dynamic reduction to 10%. The values are displayed in the table. Note The 10% Diagnosis Function can only be used when the 70% Fixed Reduction has been activated. - Page 204 Accessing Diagnostic values Type of Reduction: This contains the current type of power reduction that is specified by the control source. Displayed Text Explanation Text PMF_NONE No power reduction function. PMF_PR_ERROR An error occurred while determining the power reduction func- tion.

- Page 205 The consumption value is normally subtracted from the allowed power from the entire plant. Control value power (kW): This value is calculated by the Solar-Log™ and is the maximum current power output from the inverters. It is used for the current target power output.

-

Page 206: Explanation Of The Symbols In The Feed-In Power (% Dc) Column

The value refers to the current output generated by the inverter per interface (column) and for the entire plant. Control value power (% AC): The Solar-Log™ calculates the control value power (kW) as a percentage of the maximum AC power and relays this to the inverters. Current power output (AC%): The value indicates the total output generated as a percentage of the maximum AC power for the inverter or all of the inverters on a bus. - Page 207 Accessing Diagnostic values Type of Reactive Power Reduction: This contains the type of reactive power reduction that is specified by the active control source. Displayed Text Explanation Text PMF_RP_NONE No reactive power control. PMF_RP_ERROR An error occurred while determining the reactive power control function.

-

Page 208: Fig.: Feed-In Management - Feed-Balance

Accessing Diagnostic values Secondary Type of Reactive Power Control: If “PMF_RP_ADJUSTABLE” is entered as the “Type of Reactive Power Reduction,” the variable assignment from the selected type of reactive power control is indicated in this field. For example, a PM profile defines that the type of reactive power control is determined by the Adam Box. That means: The profile is responsible for the control. -

Page 209: Pm History

Accessing Diagnostic values Move the mouse cursor over the black line to display the following values for the power reductions: • Time • Percentage (%DC) • Watt 17.5.4 PM History The power reductions are displayed in a table with three columns in the PM History tab. -

Page 210: Accessing The Scb Monitor (Only Solar-Log 1000 And 2000)

Accessing Diagnostic values 17.6 Accessing the SCB Monitor (only Solar-Log 1000 and 2000) Diagnostic | Components | SCB Monitor. To access the SCB Monitor menu, go to Fig.: SCB string overview SCB String Overview is displayed in a split-screen window. The connected devices (SCBs) can be individually accessed in the top screen via the pull-down menu. -

Page 211: Accessing Components

The following values are displayed in the Pulse meter box: • Total number of pulses for the SO meter since the last restart of the Solar-Log™ (first number) • Number of pulses since the menu has been accessed (second number) •... -

Page 212: Fig.: Alarm Contact

(e.g. alarm), the internal status (e.g. OK) and if the notification has been manually or automatically ack- nowledged. Note The alarm contact is only available with the Solar-Log 2000. Diagnosis | Components | Wireless Package You can access the Wireless Package test function from the... - Page 213 Accessing Diagnostic values To perform a connection test a Wireless Package has to be connected to the Solar-Log™, the interface with Configuration | Devices | Definition the Wireless Package has to be activated in the menu and the inver- ter has to be selected (refer to the RS485 Wireless Package Installation notes).

-

Page 214: Smart Energy

Accessing Diagnostic values 17.8 Smart Energy The following tabs are visible under the Smart Energy menu: • Status (current) • History • Simulation Status (current) Status (current) The following values are displayed as a table in the tab: • Averaging (is visible when managing with average values) •... -

Page 215: Fig.: Smart Energy Status (Current)

Accessing Diagnostic values • Theoretical surplus [W] The theoretical surplus is the amount that would be fed into the grid if no Smart Energy logic was operating (including smart appliances). It is calculated accordingly: [(Production-Smart Energy Production)-(Consumption Smart Energy Consumption)]. Current or average value. The selection for “Measurement values for control logic”... -

Page 216: History Section

Accessing Diagnostic values Depending on the device or profile type selected, different information is displayed. For example: surplus available, runtime or temperature. By clicking on the question mark the current configuration for the switching groups is displayed without switching to the configuration section. 17.8.2 History Section Daily graphics, all of the configured control logics and the intelligent appliances are displayed according to History... - Page 217 Accessing Diagnostic values Depending on the connected device and configured control logic the labels may be different and also the values may vary (e.g. runtime and switching status can be saved, as well as charging states when a hybrid or battery system is connected). Note The selected section can be enlarged by clicking on the graphic and dragging it.

-

Page 218: Simulation Section

Accessing Diagnostic values 17.8.3 Simulation Section The configured control logics can be simulated under the Simulation tab to check if the logics are correct. The simulation is always based on the the underlying calculated averages. (See the example Figure: “Smart Energy - Simulation with EGO - Surplus Priority 1”) Fig.: Smart Energy - Simulation with EGO - Surplus Priority 1... - Page 219 Accessing Diagnostic values Similar to the History view, there are various values displayed in the graphic view. These values depend on the particular connected device and/or configured control logic. All of the values displayed in the key can be selected and deselected at anytime with a left-click to display individual values (curve) or to display or hide all values (curves).

-

Page 220: Accessing Csv Export

Pac and DC values from the individual inverters and also from every MPP tracker. The CSV file with day values is in a table format and contains the day values from every individual inverter since the start of the plant’s operation (with Solar-Log™ monitoring). Note Files in the CSV format can be created with simple text editors or spreadsheet programs like MS Excel or Open Office Calc. -

Page 221: Accessing Support

CLIB (Version number of the Solar-Log™ library used) • Creating diagnostic reports: You have the option to create and download a diagnostic report. This can be sent to Solar-Log support for analysis. See Figure: Support - General. • Creating screenshots: You have the option to create and download screenshots of the display in this section. -

Page 222: Accessing Yield Data

Accessing Yield Data 18 Accessing Yield Data Click on Yield Data in the tool bar to access the Yield Data menu. The following options can be selected from the left-side navigation menu. • Current values • Production • Consumption (only appears when a consumption meter is connected) •... - Page 223 Additional tabs can be selected in this view: • Energy flow • Table Note If the Solar-Log™ is just used as a consumption monitoring tool, the menu is limited Current values Consumption System information All of the other menus are hidden. Note When only consumption meters are connected to the Solar-Log™, a large...

-

Page 224: Energy Flow

Accessing Yield Data 18.1.1 Energy flow The plant is displayed as a flow graphic in the Energy flow tab. Fig.: Example of a plant with an energy flow Depending on the particular devices connected, the following values are displayed in the flow graphic in real time: •... -

Page 225: Table