Summary of Contents for Primus XCONTROL PLUS

- Page 1 INDUSTRIAL WASHER EXTRACTORS HIGH SPIN WASHER EXTRACTORS: 7 kg 8 kg 11 kg 14 kg 18 kg 24 kg ORIGINAL PROGRAMMING MANUAL XCONTROL PLUS 540876 A Publication date: 1 Feb 2012...

- Page 2 Machine type selection: Dry load „Machine type“ capacity selection 7 kg / 15 lb => FX65 8 kg / 18 lb => FX80 11 kg / 25 lb => FX105 High spin industrial washer extractors 14 kg / 30 lb =>...

-

Page 3: Table Of Contents

INTRODUCTION 1. TABLE OF CONTENTS 1. TABLE OF CONTENTS ....................3 2.1. WARNINGS..............................5 2.2. SYMBOLS USED ............................6 3. BASIC DESCRIPTION OF CONTROLS ................. 8 3.1. GENERAL ..............................8 3.2. SPECIFIC ..............................9 3.3. HOW TO GET INTO THE SETUP MODE....................10 3.4. THE CREATION OF A WASH PROGRAM....................12 3.5. - Page 4 7.2. WASH PROGRAMS..........................59 Wash program 1: HOT WASH INTENSIVE - 90°C ..................59 Wash program 2: WARM WASH INTENSIVE - 60°C ................. 59 Wash program 3: COLORED WASH INTENSIVE - 40°C................60 Wash program 4: BRIGHT WASH INTENSIVE - 30°C ................60 ...

-

Page 5: Warnings

INTRODUCTION 2. WARNINGS AND SYMBOLS 2.1. WARNINGS BEFORE OPERATING A MACHINE CONTROLLED BY AN ELECTRONIC PROGRAMMER, READ THIS MANUAL. INCORRECT USE CAN RESULT IN SERIOUS INJURIES OR DAMAGE TO THE MACHINE CONTROLS. IGNORING INSTRUCTIONS CAN CAUSE AN INCORRECT MACHINE FUNCTION, WHICH MAY RESULT IN INJURIES OR MACHINE AND/OR LINEN DAMAGES. -

Page 6: Symbols Used

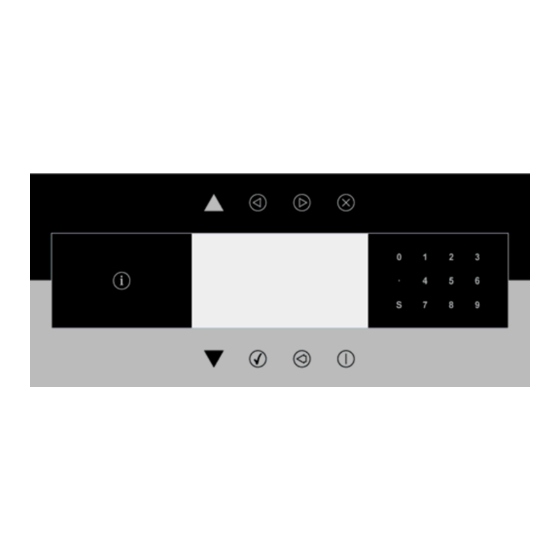

2.2. SYMBOLS USED BUTTONS START (ADVANCE function) STOP (program interruption) CONFIRM THE SELECTION (ENTER) CANCEL THE SELECTION MOVE UP MOVE DOWN SELECTION NO DECREASING THE TIME SEQUENCE SELECTION YES INCREASING THE TIME SEQUENCE INFO (overview of available wash programs and program information) SERVIS INFO (servicing information) DELAYED START FUNCTION... - Page 7 INTRODUCTION 540876_A_PUB_DATE_1_FEB_2012.DOC PROGRAMOVACÍ MANUÁL...

-

Page 8: Basic Description Of Controls

3. BASIC DESCRIPTION OF CONTROLS 3.1. GENERAL THE CONTROL OFFERS : 99 programmable programs (including 20 pre-programmed ones). Control of signal voltages for external pumps or liquid supply dispensers. Redistribution of the garments to avoid imbalance. ... -

Page 9: Specific

INTRODUCTION 3.2. SPECIFIC The PROGRAM Menu is designated for: the creation of a specific name for a wash program. the creation and implementation of a new wash program step by step. editing a wash program step by step. ... -

Page 10: How To Get Into The Setup Mode

3.3. HOW TO GET INTO THE SETUP MODE Press the SERVICE INFO button on the keypad. Press the Arrow Down Button several times until you see the screen with the Menu Selection: "To program mode press 0" SERVICE INFO To pogram mode Press 0 Press 0 (the Zero button). - Page 11 INTRODUCTION 99 Wash Programs - 99 Steps Program 1 Program 2 Program 3 . . . Program 99 Name Prog Name Prog Name Prog Name Prog Step 1 Step 1 Step 1 . . . Step 1 Wash Wash Wash Wash Sequence Sequence...

-

Page 12: The Creation Of A Wash Program

3.4. THE CREATION OF A WASH PROGRAM A Wash Program is built up step by step. Each step always consists of a Wash sequence and a Drain/Extraction sequence. Programming the Wash sequence : First choose the type of Wash sequence. ... - Page 13 INTRODUCTION Programming the Drain sequence : After programming the Wash sequence, next program the Drain/Extraction sequence. DRAIN EXTRACTION No DRAIN STATIC DRAIN REVERSING DRAIN Then program all the related functions of the Drain/Extraction sequence. The available functions are : ...

-

Page 14: Programming The Functions

3.5. PROGRAMMING THE FUNCTIONS Limits To ensure the correct functionality of the washing machine you have to program values within certain limits. If you program a value that falls below the minimal or above the maximal programmable limit then the new value will not be accepted and the previous value stays valid. - Page 15 INTRODUCTION ATTENTION! FOR MACHINES WITH LIQUID SUPPLY PUMPS, DIRECT WATER INLET VALVE 7 MUST BE PROGRAMMED BECAUSE THE LIQUID IS ADDED AT THE DIRECT WATER INLET CHANNEL. FOR WASHING MACHINES WITH WATER RECYCLING, THE WATER RECYCLING SUPPLY MUST BE CONNECTED TO INLET VALVE 5 OR 7. ...

- Page 16 Programmable water level units related to the amount of water in the tub FX65 FX80 FX105 FX135 FX180 FX240 Machine type 9,5 10,5 10,5 11,5 18,8 21 11 12 12,5 14 21,3 ...

- Page 17 INTRODUCTION Programming the Wash Speed Standard reversing wash speed is between 40 and 50 RPM. ( Verify exact value at table 3.5.B.) For some special applications the drum should only turn very slowly. - Speed Limits ...

- Page 18 Programming the Motor On and Off times for Reversing The standard Reversing Motor On and Off times at Wash speed is 12 Seconds On and 3 Seconds Off. For Delicates and Woolens it’s recommended to program a gentle wash action with a Reversing On time of 3 Seconds and an Off time of 12 Seconds.

-

Page 19: Initializing The Machine

SETUP 4. INITIALIZING THE MACHINE Initializing the machine goes in four steps: 1. Install the machine mechanically. (See Installation Manual) 2. Select the machine specific settings in the Configuration Menu. 3. Select the operator specific settings in the Initialization Menu. 4. - Page 20 Main Menu Initialization … Program … Servis … Configuration … Advanced … Press the ENTER button to make your selection. Now you will see the first menu item. By pressing the ARROW DOWN or UP button you can select the menu items one by one. Menu Item Default Info...

- Page 21 SETUP Menu Item Default Info Limits Temperature Balance The right water temperature at the water fill process is No / Yes obtained by switching the cold and hot water inlet valves. For high temperatures extra heating will be required after the fill process. For some special customer applications, it is allowed to switch off the automatic Temperature Balance control.

- Page 22 Menu Item Default Info Limits Max. Water Fill Time 10 Min A diagnostic message is generated by the wash 5 - 99 Min computer when the water hasn't reached the programmed level in 10 Minutes. (Err 11) Attention! If 99 minutes has been selected, NO error message will be generated at all, even if the heating time exceeds 99 minutes.

- Page 23 SETUP (*) Automatic Cooldown To avoid mechanical temperature shock and to extend the life time of your washing machine, after a hot wash, cold water is injected bit by bit. As a result at the end of the hot wash, the temperature will be lowered to about 65°C.

-

Page 24: Configuration Menu

4.2 CONFIGURATION MENU This electronic wash computer has been specially constructed for a wide range of washing machines. For that reason it must be individually set up with important parameters for various machine types. Basic machine adjusting is made in the factory. WARNING! ONLY A QUALIFIED TECHNICIAN SHOULD CHANGE THE CONFIGURATION SET UP. - Page 25 SETUP Menu Item Default Info Limits Machine Type FX65 Select the right machine type. List Look at Machine Name Plate at the rear of the Are You Sure ? No / Yes washing machine. Confirm that you want to change the machine type.

- Page 26 Menu Item Default Info Limits Brightness Display The brightness of the display is changed by adjusting 1 - 20 the contrast of the optimal viewing angle. Attention! The washing machine can only operate correctly if the Inverter Menu… right inverter (same as washing machine) has been set in the Configuration menu.

- Page 27 SETUP Menu Item Default Info Limits Total N° of Inlets A washing machine can be delivered with 2 or 3 main 2 / 3 water Inlet supplies. A machine with 2 main water inlet supplies is prepared for : - soft warm water - soft cold water A machine with 3 main water inlet supplies is prepared for : - soft warm water...

- Page 28 Menu Item Default Info Limits Wet Cleaning Selection Wet Cleaning allows to program water No / Yes levels below the standard minimum programmable levels. The heating will not be functional for a water level below the standard minimum programmable water level. Erase All Wash Prog ? Allows erasing all the wash programs at once.

-

Page 29: Advanced Menu

SETUP 4.3 ADVANCED MENU Some special wash computer applications are only accessible by the Advanced Menu. In the advanced menu you can find the not frequently used, optional and special applications. HOW TO GET INTO THE ADVANCED MENU The Advanced menu can only be accessed when the machine is in standby (the power is switched on, but no program is started). - Page 30 HYGIENIC CYCLE MENU A. Strict Temperature Control In normal operation, the washing machine heating system works with a temperature control hysteresis below the programmed target temperature value. This corresponds with line 1 at the fig.4.3. Some washing machine operators want a strict temperature control in case of hygienic wash cycles. Example: this means when 70°C is programmed, the linen must be washed at a temperature that doesn't drop below 70°C.

- Page 31 SETUP PROGRAM MODE LOCK MENU The access to the Program Mode can be locked by a password. It means that without password you can't have access to the Main Menu Screen. Menu Item Default Info Limits Password ..None Enter a 4 digit value for the Password and press 0000 - 99999...

- Page 32 TRACEABILITY MENU Traceability is a function to store wash cycle data outside the washing machine, to be able to prove that the laundering process has been correctly executed. In case of any failure, the Wash Cycle must be stopped and there must be a warning that the wash cycle must be repeated correctly.

- Page 33 SETUP 540876_A_PUB_DATE_1_FEB_2012.DOC PROGRAMOVACÍ MANUÁL...

-

Page 34: Programming

5. PROGRAMMING 5.1 GENERAL Specific functions have been implemented in the wash computer to allow a detailed programming. Functions for the complete program. - Program Number : Selecting the wash Program. - Name : Insert or Modify the Name for the Program. - View : Inspecting the Program settings without making changes. -

Page 35: Step : Program Functions

PROGRAMMING Main menu Initialization … Program … Servis … Configuration … Advanced … Press the ENTER button to confirm your selection. Go to 5.3. STEP : PROGRAM FUNCTIONS Program menu Select Program N: 1 Name: HOT INTENS View …... - Page 36 Menu Item Info View In Program View you can look to the Program Settings, without making any changes. Edit Editing a program is changing the program by selecting a new element from a list or by changing values in an existing program. You can also add, insert or delete steps in an existing program.

-

Page 37: Step : Program Step Function

PROGRAMMING 5.4. STEP : PROGRAM STEP FUNCTION Edit Step Menu Prog. 1: HOT INTENS Select Step N: 1 Add … Edit ... Insert … View … Delete … Exit Menu Item Info Select Step N°: 1 Insert the desired step number. Step 1 to 99 can be selected. -

Page 38: Step : Programming The Wash Part

5.5. STEP : PROGRAMMING THE WASH PART STEP Step number Program number Wash Spin part + name Program 1: HOT INTENS Step 2 Wash Spin Time: [4.0-20.0] Menu Value menu Original Limits Position item item value menu item menu item This paragraph gives a detailed explanation about programming the Wash Sequences. - Page 39 PROGRAMMING SELECTING THE WASH PART Prewash Spin If you have selected Add Step, Edit Step or Insert Step, you Type: Prewash have to select the wash sequence now. Depending on the machine type, with top or front soap dispenser, you have more or less sequences available.

- Page 40 Menu Item Default Info Limits Off Time 3 sec The wash action, motor Off Time. 1 - 99 sec Gentle wash action : 12 sec. (The suggested default values can be adjusted at the Initialization menu) Time 4.0 Min The Prewash Sequence Time. 0 - 99.5 Min (for 0 Minutes the Prewash sequence will be skipped) (programmable in steps of 0,5 Minutes)

- Page 41 PROGRAMMING THE WASH SEQUENCE Wash Prewash | Cooldown | Rinse | Last Rinse | Soak | Spray | No wash Menu Item Default Info Limits Temperature 60 °C The water temperature. 1 - 92 °C Inlet I2-I3-I6-I8 The suggested inlet valves are related to the I1...I8 temperature and the soap box to be used.

- Page 42 THE COOLDOWN SEQUENCE Cooldown Prewash | Wash | | Rinse | Final Rinse | Soak | Spray | No wash After a Hot wash you can program a Cool-down Sequence to avoid temperature shock and shrinking of the garments. ...

- Page 43 PROGRAMMING THE RINSE SEQUENCE Rinse Prewash | Wash | Cooldown | | Final Rinse | Soak | Spray | No wash No temperature can be programmed as a Rinse is only dedicated for cold water. Menu Item Default Info Limits Inlet...

- Page 44 THE FINAL RINSE SEQUENCE Final Rinse Prewash | Wash | Cooldown | Rinse | | Soak | Spray | No wash No temperature can be programmed as a Last Rinse is only dedicated for cold (hard) water. Menu Item Default Info Limits...

- Page 45 PROGRAMMING THE SOAK SEQUENCE Soak Prewash | Wash | Cooldown | Rinse | Final Rinse Flush | Spray | No wash Menu Item Default Info Limits Temperature 40 °C The water temperature. 1 - 45 °C Inlet I1 - I7 The suggested inlet valves are related to the I1...I8 temperature and the soap box to be used.

- Page 46 THE SPRAY SEQUENCE Spray Prewash | Wash | Cooldown | Rinse | Final Rinse | Soak | | No wash Water or Liquid is injected at Distribution or Low Spin Speed No standard water inlets can be programmed in this function. ...

-

Page 47: Step : Programming The Drain Step

PROGRAMMING 5.6. STEP : PROGRAMMING THE DRAIN STEP This paragraph gives a detailed explanation about programming the Drain/Extraction Sequences. After programming the wash step, the drain/extraction step still has to be programmed. ATTENTION! YOU DON’T HAVE TO PROGRAM A DRAIN SEQUENCE BEFORE AN EXTRACTION SEQUENCE AS THE WATER WILL AUTOMATICALLY BE DRAINED AT THE EXTRACTION SEQUENCE ... - Page 48 THE EXTRACT SEQUENCE Extract Drain | | No Drain | Static Drain | Reversing Drain Menu Item Default Info Limits Drain Valve Only available on washing machines with both : a 1 - 2 normal Open and normal Closed Drain valve. The suggested RPM depends on the machine Type.

- Page 49 PROGRAMMING Attention! It’s not recommended to program a spin sequence just after a Static Drain Sequence. At a Static Drain sequence, the garments are not distributed around the drum while the water is drained. When the spin sequence starts, the garments are a big imbalance and the imbalance (tilt) function will be activated.

-

Page 50: Operation Menu

6. OPERATION MENU 6.1. STARTING UP ATTENTION! BEFORE STARTING UP THE FIRST TIME, BE SURE THAT THE MACHINE IS WELL INSTALLED. SEE INSTALLATION MANUAL. MAKE SURE THAT THE CONFIGURATION AND INITIALIZATION MENU HAVE THE RIGHT SETTINGS. SEE CHAPTER 4. 6.2. SWITCHING ON THE POWER ... -

Page 51: Programming A Delay Time

OPERATION 6.6. PROGRAMMING A DELAY TIME Enter the selected Program Number. Press the Dot button. The Delay time message will be displayed. The door must be closed first. Now you can insert the value for a delay time DELAYED START _ _ : _ _ ... -

Page 52: Advancing A Wash Program

Progression 35 Min. Prog 2: WARM WASH Program Wash program Remaining time Time unit number name wash program 6.8. ADVANCING A WASH PROGRAM Press the ARROW RIGHT button to increase the wash sequence time. Press the ARROW LEFT button to decrease the wash sequence time. ... -

Page 53: Program End

OPERATION 6.10. PROGRAM END The time on the display counts down until 0. At the end of the cycle, the door lock is released, the display shows the UNLOAD message and it is possible to open the door (unload the laundry). ... -

Page 54: Cooldown Function

6.13. COOLDOWN FUNCTION AUTOMATIC COOLDOWN : this function avoids thermal shock in the washing machine. For Hot washes above 65°C, Cold water is added at the end of the step. PROGRAMMED COOLDOWN : this function is recommended to avoid the shrinking of the garments. -

Page 55: How To Handle Failure Messages

OPERATION 6.19. HOW TO HANDLE FAILURE MESSAGES When a failure has been detected by the Wash Computer, a failure message is generated to inform the operator about the problem. Out Of Order (Pr: XX St: YY) Ask For Service (Err ZZZ : Fault Message) : The Program number : The Step number... -

Page 56: How To Handle Power Interruptions

6.20. HOW TO HANDLE POWER INTERRUPTIONS See Installation, maintenance and user's manual. 6.21. SPECIAL FUNCTION BUTTONS The Special Function buttons Info and Service are dedicated to supply the operator with more information about the wash programs and the wash machine functions. 6.21.1. -

Page 57: External Liquid Soap Boxes

OPERATION 6.21.4. DRAIN If, during a process in operation, you want to open the draining valve, move in the Service Info menu to the last page and activate the draining by pressing the button 0. Only functional at a running wash sequence. ... -

Page 58: Pre-Programmed Programs

7. PRE-PROGRAMMED PROGRAMS The Wash Computer contains 20 pre-programmed Standard Wash Programs. (Standard Programs : 1 to 20. Programs 21 to 57 are dedicated.) ATTENTION! THE PRE-PROGRAMMED PROCESSES ARE GIVEN AS AN EXAMPLE ONLY. FOR THE CREATION OF YOUR OWN WASH PROGRAMS, CONTACT YOUR SOAP SUPPLIER. 7.1. -

Page 59: Wash Programs

WASH PROGRAMS 7.2. WASH PROGRAMS WASH PROGRAM 1: HOT WASH INTENSIVE - 90°C Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Prewash / wash 30°C 5 min W (normal) 1=30“ Step 1 Spin 1 min Main wash 2-3-6-8 90°C 10 min W (normal... -

Page 60: Wash Program 3: Colored Wash Intensive - 40°C

WASH PROGRAM 3: COLORED WASH INTENSIVE - 40°C Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Prewash / wash 30°C 5 min W (normal) 1=30“ Step 1 Spin 1 min Main wash 2-3-6-8 40°C 10 min W (normal) 2=30“... -

Page 61: Wash Program 5: Woolens - 15°C

WASH PROGRAMS WASH PROGRAM 5: WOOLENS - 15°C NO PREWASH Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Main wash 15°C 6 min W (gentle) 2=30“ Step 1 Drain 30 s Rinse 1 1-2-7 2 min W (gentle) Step 2 Drain 30 sec... -

Page 62: Wash Program 7: Warm Wash - 60°C

WASH PROGRAM 7: WARM WASH - 60°C NO PREWASH Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Main wash 2-3-6-8 60°C 20 min W (normal) 2=30“ Step 1 Drain 30 s Rinse 1 1-2-7 4 min W (normal) Step 2 Spin 1 min... -

Page 63: Wash Program 9: Bright Wash - 30°C

WASH PROGRAMS WASH PROGRAM 9: BRIGHT WASH - 30°C NO PREWASH Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Main wash 2-3-6-8 30°C 20 min W (normal) 2=30“ Step 1 Drain 30 s Rinse 1 1-2-7 4 min W (normal) Step 2 Drain... -

Page 64: Wash Program 11: Eco Warm Wash - 60°C

WASH PROGRAM 11: ECO WARM WASH - 60°C NO PREWASH Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Main wash 2-3-6-8 55°C 10 min W (normal) 2=30“ Step 1 Drain 1 min Rinse 1 1-2-7 2 min W (normal) Step 2 Spin 1 min... -

Page 65: Wash Program 13: Eco Bright Wash - 30°C

WASH PROGRAMS WASH PROGRAM 13: ECO BRIGHT WASH - 30°C NO PREWASH Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Main wash 2-3-6-8 30°C 8 min W (normal) 2=30“ Step 1 Drain 1 min Rinse 1 1-2-7 2 min W (normal) Step 2 Spin... -

Page 66: Wash Program 16: Sport - 60°C

WASH PROGRAM 16: SPORT - 60°C NO PREWASH Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Main wash 2-3-6-8 54°C 6 min W (normal) 2=30“ Step 1 Drain 1 min Rinse 1 1-2-7 2 min W (normal) Step 2 Drain 1 min Rinse 2... -

Page 67: Wash Program 18: Horse Cloths - 40°C

WASH PROGRAMS WASH PROGRAM 18: HORSE CLOTHS - 40°C Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Prewash / wash 28°C 4 min W (normal) 1=30“ Step 1 Spin 1 min Main wash 2-3-6-8 35°C 6 min W (normal) 2=30“... -

Page 68: Wash Program 20: Starching

WASH PROGRAM 20: STARCHING Sequence Inlet Temp. Level Time R.P.M (x) Soap Supply Prewash / wash 28°C 4 min W (normal) 1=30“ Step 1 Spin 9 min Slowdown Tumble 30 s W (5s / 5s) PROGRAMOVACÍ MANUÁL 540876_A_PUB_DATE_1_FEB_2012.DOC... -

Page 69: Troubleshooting

TROUBLESHOOTING 8. TROUBLESHOOTING 8.1. DISPLAY MESSAGES Various messages may appear on the display at the start, during or at the end of a washing cycle. In some specific cases, an acoustic signal will alert the operator. When an error occurs the machine will automatically go over to a safe state. With the diagnostic program you can determine the problem. -

Page 70: How To Handle Fault Messages

8.3. HOW TO HANDLE FAULT MESSAGES ATTENTION! CHECK IN THE MANUAL TO SEE WHAT PROBLEM THE ERROR MESSAGE CORRESPONDS WITH. ASK THE ASSISTANCE OF AN EXPERIENCED TECHNICIAN TO SOLVE THE PROBLEM. ALL THE SAFETY PRECAUTIONS MUST BE FOLLOWED BEFORE EACH INTERVENTION. ... - Page 71 TROUBLESHOOTING ATTENTION! THE ERROR MESSAGE TOO HOT CAN ALSO APPEAR AT THE END OF A CYCLE EVEN IF NO FAILURE HAS OCCURED AS AN EXAMPLE, SUPPOSE A WASH PROGRAM WITH A HOT WASH. AFTER THIS HOT WASH SEQUENCE, NO SEQUENCE WITH A LOW WATER TEMPERATURE HAS BEEN PROGRAMMED.

-

Page 72: Overview

8.4. OVERVIEW N° Failure message Failure Action Fault occurrence Drain failure Full Stop + tumble Draining sequence No Drain Out of balance Full stop + tumble Whole cycle Tilt Fault Out of balance : Skip + continue After 5 x tilt Imbalance Normal spin Out of balance : high... - Page 73 TROUBLESHOOTING N° Failure message Failure Action Fault occurrence No successful wash Info that the wash cycle Abnormal Cycle Termination Cycle Fail cycle termination has to be repeated. (Traceability only) Real Time Clock, No For Info only. End cycle Battery or battery low RTC Low Batt (Traceability only) power...

-

Page 74: Service Menu

8.5. SERVICE MENU In the Service menu you have some extra utilities: The Software Version Number. An overview of the 20 last failure messages. Statistics for 10 general error messages. Pulley ratio. An overview of the input states. ... - Page 75 TROUBLESHOOTING Menu Item Info Software XXX Version: 771.100.0 The software version number. FAULTS MENU (SERVICE FAULTS) Menu Item Info View Fault Messages … - check the last 20 fault messages from the Err log 1 Fault 1: E XXX: YYYYYYYYYYYY Fault N°...

- Page 76 TOOLBOX MENU The purpose of the Toolbox Menu is to give support at technical interventions. Menu Item Info View Input States ? The Input states for Input 1, …, Input 20. The exact function of the inputs can be found on the 1 Input 1 electrical drawing of the washing machine programmer.

- Page 77 TROUBLESHOOTING Reset Service Counts No Once the washing machine has reached the total number of wash cycles like set at the „Service Interval“ a warning is given at the end of each cycle until the Cycle Counter has been reset. Exit Return to Service Menu 540876_A_PUB_DATE_1_FEB_2012.DOC...

-

Page 78: Diagnostic Program

8.6. DIAGNOSTIC PROGRAM The purpose of the diagnostic program is to test the wash machine functions one by one. HOW TO GET INTO THE DIAGNOSTIC MENU The Diagnostic menu can only be accessed when the machine is in standby (the power is switched on, but no program is started). - Page 79 TROUBLESHOOTING TEST SEQUENCE Display test and door lock test Sensor test Motor test Water fill, heating and drain test BASIC Diagnostic Wash program Test Info Explanation Door lock test (locks and unlocks 5 x the door) Black display followed by a Text display.

- Page 80 BASIC Diagnostic Wash program Sequence Supply Inlet Temp. Level Wash action Time R.P.M. Wash 2=30” 2-3-6-8 40°C A=12“ R=3“ 6 min Step 1 Drain 30 s Rinse 1 1-2-7 A=12“ R=3“ 1,5 min Step 2 Spin 1 min Final Rinse 3=30”...

-

Page 81: Problem Check List

TROUBLESHOOTING 8.7. PROBLEM CHECK LIST Problem Cause Solving the problem no external power Switch on the external power supply When the power is switched on : the display is not illuminated verify the external power to the machine ... -

Page 82: External Communication Problems

8.8. EXTERNAL COMMUNICATION PROBLEMS The machine communicates with the PC (TraceTech SW) via the RS485 line. If the external communication is not working, check the connection between the PC and machine. Check also if you have selected the right machine communication address. 8.9. - Page 83 TROUBLESHOOTING FAILURE 5 : OUT OF BALANCE HIGH SPIN Failure 5 occurs when the out of balance sensor is activated during high spin. This failure indicates that there will probably is a mechanical defect. DIAGNOSE: 1. Check the position of the out of balance switch. If the out of balance switch is not correctly mounted, install the out of balance switch properly 2.Check the springs and the other mechanical...

- Page 84 FAILURE 8: DOOR LOCK CHECK AT START FAILURE The washing machine will not start a new process when the door is not locked after pressing the START button. Failure message 8 will be generated each time the door lock sequence could not be finished once started. DIAGNOSE: 1.

- Page 85 TROUBLESHOOTING FAILURE 11: FILL FAILURE Failure 11 occurs when the water level has not reached its target level in x minutes. x = Max fill time, a value that can be programmed at the Initialization Menu. ATTENTION! The rubber hose must be fixed with a flexible clamp on the electronic water level sensor. DIAGNOSE: 1.

- Page 86 FAILURE 13: HEATING FAILURE If the heater elements are not functioning : message 13 will be displayed. The message is generated when the temperature is not raising with 3°C in 10 minutes time. DIAGNOSE: 1. Check if the heating contactor is activated. If the heating contactor is not activated: repair the wiring or replace the contactor.

- Page 87 TROUBLESHOOTING 2. Check if the correct water inlet valves are See diagnostics Failure 11 : Fill Failure Functional. If the cold water inlet valves are not functional or if the main cold water supply is not available and only hot water inlet valves are open, and if the hot water supply has a temperature value above the programmed wash sequence value then the temperature...

- Page 88 FAILURE 25: DEFECTIVE TEMPERATURE SENSOR When the temperature sensor is broken then fault 25 will be displayed. The fault is only generated when the machine is in standby mode and no wash cycle is running. The fault can only be erased by switching off and on the power. If the fault is still available after switching on the power : fault 25 will be displayed again.

- Page 89 TROUBLESHOOTING FAILURE 28: THT (Mitsubishi) TIME OUT Fault 28 occurs when the wash computer can not handle the THT (Mitsubishi) / E.OL (KEB) fault of the frequency inverter. This fault is a specific fault of the frequency inverter caused by an over current. DIAGNOSE: 1.

- Page 90 FAILURE 32: VERIFICATION FAULT INVERTER Fault 32 occurs if a wrong parameter is detected at the verification of the inverter parameters. After writing the inverter parameters in the inverter, the parameters are verified one by one to ensure that they have been correctly loaded.

- Page 91 TROUBLESHOOTING FAILURE 41: SERVICE DUE WARNING Failure 41 occurs when the cycle counter of the Electronic timer has reached the Programmed Value for Service due. The fault message will be erased by opening the door. If the cycle counter has not been reset the message will appear again at the end of the next wash cycle.

- Page 92 FAILURE 81: NO REHEAT Traceability only. Failure 81 occurs when the heating is not restarted (at the wash sequence) when the water temperature of the bath is below its normal programmed value. When the temperature drops below the predefined temperature limit of a hygienic wash cycle, the wash cycle can not be validated for hygienic reasons as the wash process has not followed the standards of the wash program in execution.

- Page 93 TROUBLESHOOTING FAILURE 95: WATCH DOG If the watch dog has been activated, message 95 is logged in the Error log register. If this occurs often, ask the help of a technician. FAILURE 300-353: MITSUBISHI INVERTER ALARM MESSAGE Always make sure you have the correct inverter parameter settings in the inverter, especially when you have replaced an inverter.

- Page 94 Err N° Failure Failure Name Explanation Err CTE PU short circuit Short circuit on the RS485 communication connector. Check for short circuit in the communication cable. Err P24 24VDC short circuit Short circuit on the 24VDC power output (PC terminal). Check for short circuit on the inverter control terminals.

- Page 95 TROUBLESHOOTING Err N° Failure Failure Name Explanation Err EP* Encoder phase Rotation command different than the motor rotation error direction Err E.11* Opposite rotation Rotation direction of the speed command different than the deceleration estimated speed causing overload Err E.13 Internal circuit error Problem with an internal circuit, replace the inverter * : This option or function is not used.

- Page 96 DIAGNOSE FAILURE 313/315: OPT/PUE-ERROR (OPTION FAULT/PARAMETER UNIT LEAVE OUT) If the inverter doesn't receive requests from the wash computer (= no serial communication), after some time (about 10-30 seconds), the inverter will go into OPT/PUE-alarm state. 1. Check at the end of the wash cycle, if the Replace the contactor if the problem is persistent.

-

Page 97: Service Information

TROUBLESHOOTING 9. SERVICE INFORMATION ATTENTION! PROFESSIONAL REPAIRS IN ELECTRO INSTALLATION CAN BE CARRIED OUT ONLY BY SERVICE ORGANIZATION WITH PERMISSION GIVEN BY PRODUCER / SUPPLIER. IN CASE OF ANY MAINTENANCE OR REPAIR, DISCONNECT THE MACHINE FROM SOURCE OF ENERGY AND WAIT UNTIL THE MACHINE COOLS DOWN OR DRAINS WATER. PLEASE FOLLOW ALL INSTRUCTIONS IN THE MANUALS AND THE LABELS AND AS WELL AS VALID BASIC SECURITY LAWS IN ORDER TO PREVENT BURNS AND SCALDS AND INJURIES CAUSED BY ELECTRICITY. -

Page 98: Programmer Circuit Board

9.3. PROGRAMMER CIRCUIT BOARD CPU board I/O board Fig.9.3. WARNING! CONNECTION TO THE WRONG VOLTAGE SUPPLY MAY CAUSE SERIOUS BODILY INJURY AS WELL AS DAMAGE TO THE ELECTRONIC PARTS AND TO THE WASHING MACHINE ITSELF. - Voltage : 200-240 Vac, 50/60 Hz - Power : max 20 VA - Outputs... -

Page 99: Instructions For Installing New Software

TROUBLESHOOTING ATTENTION! MAKE SURE THAT THE SMALL HOSE OF THE LEVEL SENSOR IS CORRECTLY SECURED BY A FLEXIBLE CLAMP. IF THE HOSE IS NOT AIR TIGHT THEN THE LEVEL SENSOR WILL NOT MAKE A CORRECT MEASUREMENT. MAKE SURE THAT YOU DON’T DAMAGE THE FLEX CABLE OF THE KEYPAD WHEN YOU PUT THE WASH COMPUTER BACK INTO THE MACHINE. -

Page 100: Specification Of Your Machine

10. SPECIFICATION OF YOUR MACHINE MACHINE DATA type phases :……………………. ……………………. serial number frequency :……………………. ……………………. voltage output :……………………. ……………………. water supply cold soft cold hard hot soft heating ... - Page 102 IMPORTANT! MACHINE TYPE: PROGRAMMER: Xcontrol Plus INSTALLATION DATE: INSTALLATION CARRIED OUT BY: SERIAL NUMBER: ELECTRICAL DETAILS: .....VOLT....PHASE....HZ NOTE: ANY CONTACTS WITH YOUR DEALER REGARDING MACHINE SAFETY, OR SPARE PARTS, MUST INCLUDE THE ABOVE IDENTIFICATION. MAKE CERTAIN TO KEEP THIS MANUAL IN A SECURE PLACE FOR FUTURE REFERENCE.

Need help?

Do you have a question about the XCONTROL PLUS and is the answer not in the manual?

Questions and answers

please advise where to connect the external soap dispenser supply

Connect the external soap dispenser supply to Inlet Valve 7, labeled as "Cold Hard Water Direct Inlet (External liquid soap)."

This answer is automatically generated