Table of Contents

Advertisement

Quick Links

INSTRUCTION MANUAL

MULTI-STAGE DRY VACUUM PUMP

MODEL EV-S20

MODEL EV-S50

MODEL EV-S100

MODEL EV-S200

CE / SEMI / NRTL MODEL

200-220V(50/60Hz)

Caution:

Please read and understand this INSTRUCTION MANUAL

thoroughly before using this equipment.

Be sure to keep this INSTRUCION MANUAL on hand for future

reference.

To Facility and Tool Manufactures:

Be sure to distribute this INSTRUCTION MANUAL to all end-user

personnel actually operation this equipment.

「Model ООО」 in this INSTRUCTION MANUAL is our model code.

PM40U

ISSUED BY PRECISION MACHINERY COMPANY

Doc.No.EVS_CSN_2_E_Rev.3

EBARA

CORPORATION

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for EBARA EV-S20

- Page 1 Doc.No.EVS_CSN_2_E_Rev.3 INSTRUCTION MANUAL MULTI-STAGE DRY VACUUM PUMP MODEL EV-S20 MODEL EV-S50 MODEL EV-S100 MODEL EV-S200 CE / SEMI / NRTL MODEL 200-220V(50/60Hz) Caution: Please read and understand this INSTRUCTION MANUAL thoroughly before using this equipment. Be sure to keep this INSTRUCION MANUAL on hand for future reference.

- Page 2 Do not reproduce or reprint any portion of this manual without permission. Manufacturer reserves the right to discontinue or change any specifications or designs without notice and without incurring obligations. Model ООО in this catalog is our model code. All rights reserved, copyright EBARA Corporation. EBARA CORPORATION M10U...

- Page 3 Corporation, and each person will demonstrate this awareness when carrying out his or her duties. We will widely publicize these basic policies to regional societies and the general public and work to make Ebara's position on the environment clear to society in general. EBARA CORPORATION...

-

Page 4: Safety Information

EBARA in detail. If you have any questions on pump operation, safety, and maintenance, please do not hesitate to contact EBARA directly. Refer to Global network for contact address. Three terms designating the level of hazard are used in this manual. -

Page 5: Important Prior Warnings

Always work in a location with an escape route in an emergency. WARNING Do not use the pump for another process without a previous overhaul. Gases or reaction products remaining in the pump will react and lead to accidents with the formation of large amounts of products. EBARA CORPORATION PM10U... - Page 6 WARNING In designing the dry pumps, Ebara does not assume risks caused by hazardous chemical reactions resulted from simultaneous injection or mixture of multiple process gases in the pumps, and the pump is not equipped with a protection against the dangers from such pump usage.

- Page 7 Failure to comply could result in damage to the sensitive devices. WARNING In MODEL EV-S20 type pump, the bolt which is fixing the lifting bracket to a pump is M6✕12. This lifting bracket can use as fixing bracket. When you use this bracket as fixing bracket, you use M6✕...

- Page 8 Hazardous Voltage may shock, burn, or cause death. Turn power off and lockout before servicing. WARNING 警 告 Hazardous Voltage Contact will cause injury or death by electrical shock. Disconnect line power before servicing. 危険電圧部あり。接触すると重傷または死亡の 危険があります。電源供給を止めてブレーカを切った状態で メンテナンスをして下さい。 C-7110-313-0001 EBARA CORPORATION PM10U...

- Page 9 Raise all adjuster-feet fully when moving. 危 険 DANGER Heavy Object Can cause impact injury through falling or tipping. Use appropriate, properly rigged lifting equipment and keep from under suspended pump. Raise all adjuster feet fully when moving. 重量物。落下及び転倒により重傷または死亡の危険があります。 吊り上げたポンプの下に入らないで下さい。 移動時は全アジャスタフットを上限まであげて下さい。 C-7110-316-0001 EBARA CORPORATION PM10U...

- Page 10 ( ) LOCATION, WARNING LABEL1 EBARA CORPORATION PM10U...

- Page 11 ( ) LOCATION, WARNING LABEL2 EBARA CORPORATION PM10U...

-

Page 12: Safety Interlocks

Motor thermostat protect the pump motor from overheating due to extended current draws in excess of the motor rating. Under a persistent overload condition, motor thermostat opens a contact, which interrupts the motor run circuit. A brief cool down interval permits restarting the pump. EBARA CORPORATION PM10U... - Page 13 ( ) Interlock Schematic (MODEL EV-S20) EBARA CORPORATION PM10U...

- Page 14 ( ) Interlock Schematic (MODEL EV-S50/ EV-S100/ EV-S200) EBARA CORPORATION PM10U...

-

Page 15: Standard Limited Warranty

For overhauled pumps, the warranty period shall be six (6) months from shipment by EBARA. Coverage For the duration of the Warranty period, EBARA warrants this EV-S pump from failure due to defects in materials or workmanship. For such failures, EBARA will, at its option, either replace... - Page 16 ( ) EBARA CORPORATION PM10U...

-

Page 17: Table Of Contents

3.5.1 Model Description ................. 9 3.5.2 Model Spectications ..............10 3.5.3 Outline Drawing ................14 MODEL EV-S20 OUTLINE DRAWING ............ 14 MODEL EV-S20P / EV-S 20N OUTLINE DRAWING ....... 15 MODEL EV-S50 OUTLINE DRAWING ............ 16 MODEL EV-S50P / EV-S50N OUTLINE DRAWING ........ 17 MODEL EV-S100 OUTLINE DRAWING .......... - Page 18 MODEL EV-S100P / EV-S 100N OUTLINE DRAWING ......19 MODEL EV-S200 OUTLINE DRAWING ..........20 MODEL EV-S200P / EV-S 200N OUTLINE DRAWING ......21 MODEL EV-S20 OUTLINE DRAWING(OPTION) ........22 MODEL EV-S20P / EV-S 20N OUTLINE DRAWING(OPTION) ....23 MODEL EV-S50 OUTLINE DRAWING(OPTION) ........24 MODEL EV-S50P / EV-S50N OUTLINE DRAWING(OPTION)....

- Page 19 8. Disconnection and Transportation ............87 9. For SEMI S2 standard ................89 10. Troubleshooting ..................90 10.1 Troubleshooting (1) Basic trouble ..........91 10.2 Troubleshooting (2) WARNING ............92 10.3 Troubleshooting (3) ALARM ............93 10.4 Troubleshooting (4) Option ............. 94 EBARA CORPORATION PM10U...

-

Page 20: Foreword

1. Foreword We appreciate that you have selected an EBARA Model EV-S series dry vacuum pumps. These pumps have been manufactured with much care and attention so that it can be operated safely and satisfactorily. Incorrect operation will result in lack of performance and cause accidents and injuries to personnel. -

Page 21: Environmental Concerns

WARNING If the pump becomes damaged during shipment or if parts are missing, immediately contact EBARA. If a leaking or damaged product is used, an accident resulting in injury or death could occur or the product could become further damaged. -

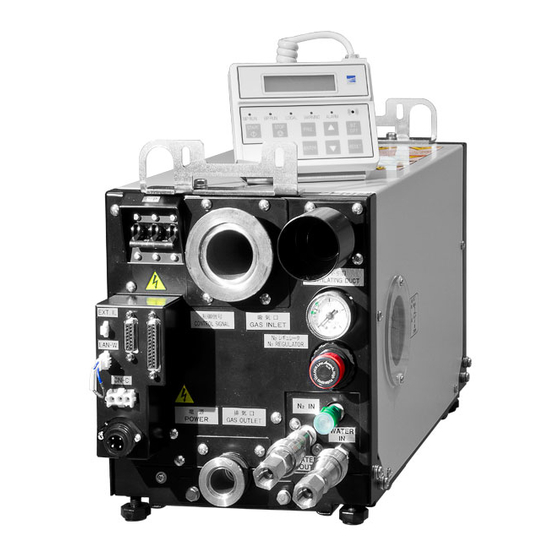

Page 22: Product Description

The nitrogen gas selector is locating on the right side of the unit, facing the utility connectors. It is under the outer cover. EBARA CORPORATION PM10U... -

Page 23: Cooling Water

The pump will continue to operate in this condition. An ALARM signal output is generated and the pump will stop automatically when the upper mechanical safety limit is reached during pump operation. EBARA CORPORATION PM10U... -

Page 24: Operation Status Control

WARNING signal will be generated to ensure that the plant operation is not discontinued. This enables the operator to check the pump after the equivalent of one cycle has been completed. Be sure to contact EBARA Corporation for details on checking the WARNING and ALARM setting conditions. 3.2.2 Operation Status Control The sensor data are displayed on the LCD provided on the controller to facilitate operation status control and daily inspection. -

Page 25: Moving Method

/ ditches and pump shall be moved on it by two persons with care. Steel Plate If pump should lose its balance when moving and start tripping over, never try to sustain the pump, get away from the pump immediately. EBARA CORPORATION PM10U... -

Page 26: Release And Shut Off Residual Internal Energy

Check with a voltmeter that the power is shut off the pump. 3. Insert padlock through holes provided on locking device. Close padlock and attach tag. Keep the key with you while working. 4. Check that the LCD display is off. EBARA CORPORATION PM10U... -

Page 27: Cooling Water

3.4.4 Returning to Service 1. Unlock and open water and nitrogen valves. 2. Remove handle stop bracket and switch circuit breaker on. 3. Restrart pump and open foreline valve only after appropriate leak checks and safety verifications. EBARA CORPORATION PM10U... -

Page 28: Detailed Specifications

EV – S 20 P Mark Description Pumping Speed 1670 L/min 5000 L/min 10000 L/min 20000 L/min Materials / N2 Purge Unit Standard / Without N2 purge unit Standard / With N2 purge unit Corrosion Resistant / With N2 purge unit EBARA CORPORATION PM10U... -

Page 29: Model Spectications

P.10 3.5.2 Model Spectications Table 3.1 Specifications (Model EV-S20 / EV-S20P / EV-S20N) Model Model Model Model EV-S20 EV-S20P EV-S20N Pumping Speed 1670 L/min Ultimate Pressure 3.0 Pa 5.0 Pa Gas Inlet NW50 Connection Gas Outlet NW25 Approx. Power at Ultimate 0.4 kW... - Page 30 Airborne noise test data 57 dB Max inlet pressure / Flow Rate (N 1.0kPa / 50L/min 0.7kPa / 35L/min (for reference) [Note] The ambient temperature of the pump installation place shall be 30 degrees of centigrade of lower. EBARA CORPORATION PM10U...

- Page 31 Airborne noise test data 57 dB Max inlet pressure / Flow Rate (N 0.65kPa / 50L/min 0.4kPa / 35L/min (for reference) [Note] The ambient temperature of the pump installation place shall be 30 degrees of centigrade of lower. EBARA CORPORATION PM10U...

- Page 32 Airborne noise test data 63 dB Max inlet pressure / Flow Rate (N 0.08kPa / 15L/min 0.08kPa / 15L/min (for reference) [Note] The ambient temperature of the pump installation place shall be 30 degrees of centigrade of lower. EBARA CORPORATION PM10U...

-

Page 33: Outline Drawing

P.14 3.5.3 Outline Drawing MODEL EV-S20 OUTLINE DRAWING EBARA CORPORATION PM10U... -

Page 34: Model Ev-S20P / Ev-S 20N Outline Drawing

P.15 MODEL EV-S20P / EV-S 20N OUTLINE DRAWING EBARA CORPORATION PM10U... -

Page 35: Model Ev-S50 Outline Drawing

P.16 MODEL EV-S50 OUTLINE DRAWING EBARA CORPORATION PM10U... -

Page 36: Model Ev-S50P / Ev-S50N Outline Drawing

P.17 MODEL EV-S50P / EV-S50N OUTLINE DRAWING EBARA CORPORATION PM10U... -

Page 37: Model Ev-S100 Outline Drawing

P.18 MODEL EV-S100 OUTLINE DRAWING EBARA CORPORATION PM10U... -

Page 38: Model Ev-S100P / Ev-S 100N Outline Drawing

P.19 MODEL EV-S100P / EV-S 100N OUTLINE DRAWING EBARA CORPORATION PM10U... -

Page 39: Model Ev-S200 Outline Drawing

P.20 MODEL EV-S200 OUTLINE DRAWING EBARA CORPORATION PM10U... -

Page 40: Model Ev-S200P / Ev-S 200N Outline Drawing

P.21 MODEL EV-S200P / EV-S 200N OUTLINE DRAWING EBARA CORPORATION PM10U... -

Page 41: Model Ev-S20 Outline Drawing(Option

P.22 MODEL EV-S20 OUTLINE DRAWING(OPTION) EBARA CORPORATION PM10U... -

Page 42: Model Ev-S20P / Ev-S 20N Outline Drawing(Option)

P.23 MODEL EV-S20P / EV-S 20N OUTLINE DRAWING(OPTION) EBARA CORPORATION PM10U... -

Page 43: Model Ev-S50 Outline Drawing(Option)

P.24 MODEL EV-S50 OUTLINE DRAWING(OPTION) EBARA CORPORATION PM10U... -

Page 44: Model Ev-S50P / Ev-S50N Outline Drawing(Option)

P.25 MODEL EV-S50P / EV-S50N OUTLINE DRAWING(OPTION) EBARA CORPORATION PM10U... -

Page 45: Model Ev-S100 Outline Drawing(Option)

P.26 MODEL EV-S100 OUTLINE DRAWING(OPTION) EBARA CORPORATION PM10U... -

Page 46: Model Ev-S100P / Ev-S 100N Outline Drawing(Option)

P.27 MODEL EV-S100P / EV-S 100N OUTLINE DRAWING(OPTION) EBARA CORPORATION PM10U... -

Page 47: Model Ev-S200 Outline Drawing(Option)

P.28 MODEL EV-S200 OUTLINE DRAWING(OPTION) EBARA CORPORATION PM10U... -

Page 48: Model Ev-S200P / Ev-S 200N Outline Drawing(Option)

P.29 MODEL EV-S200P / EV-S 200N OUTLINE DRAWING(OPTION) EBARA CORPORATION PM10U... -

Page 49: Performance Curve

P.30 3.5.4 Performance Curve 10000 EV-S20/EV-S20P 1000 EV-S20N EV-S20 EV-S20P/EV-S20N 1000 10000 100000 Inlet Pressure (Pa) Fig 3.1 MODEL EV-S20(P/N) Performance Curve 10000 EV-S50 EV-S50P 1000 EV-S50N 1000 10000 100000 Inlet Pressure (Pa) Fig 3.2 MODEL EV-S50(P/N) Performance Curve EBARA... - Page 50 P.31 100000 EV-S100 10000 EV-S100P 1000 EV-S100N 1000 10000 100000 Inlet Pressure (Pa) Fig 3.3 MODEL EV-S100(P/N) Performance Curve 100000 EV-S200 10000 EV-S200P 1000 EV-S200N 1000 10000 100000 Inlet Pressure (Pa) Fig 3.4 MODEL EV-S200(P/N) Performance Curve EBARA CORPORATION PM10U...

- Page 51 Regulator Booster Pump Motor 2 Gas Outlet (BP) Water Main Pump Motor 1 (MP) Cooling Water Flow Seneor Silencer Check Valve * The MODEL EV-S20 pump is supplied without a booster pump (BP). Figure 3.5 System Flow EBARA CORPORATION PM10U...

-

Page 52: Installation

Casters and adjusters of four each are attached under the pump base. When moving the pump, lift up all of the four adjusters. To lift them up, use the wrench and turn them to the left. Fig. 4.1 Caster EBARA CORPORATION PM10U... -

Page 53: How To Stack Pumps

(2) Please make sure to tighten the fixing bolt enough to fix the bracket. (3) Please fix a lower pump and the floor. CAUTION Please do not move the pumps with stacked. CAUTION Please do not stack three pumps or more. CAUTION Please fix to a floor firmly. EBARA CORPORATION PM10U... - Page 54 Adjuster Fig. 4.2 How to stack pumps WARNING In MODEL EV-S20 type pump, the bolt which is fixing the fixing bracket to a pump is M6✕16. This fixing bracket can use as lifting bracket. When you use this bracket as lifting bracket, you use M6✕12 bolts for fixing this bracket to the upper side of the pump.

-

Page 55: Pump Fixation (Option)

Anchor bolts should be fit for conditions of the floor where the pump is anchored. WARNING In MODEL EV-S20 type pump, the bolt which is fixing the fixing bracket to a pump is M6✕16. This fixing bracket can use as lifting-bracket. - Page 56 P.37 EV-S20 LOCATION,FIXTURE EBARA CORPORATION PM10U...

- Page 57 P.38 EV-S50 LOCATION,FIXTURE EBARA CORPORATION PM10U...

- Page 58 P.39 EV-S100 LOCATION,FIXTURE EBARA CORPORATION PM10U...

- Page 59 P.40 EV-S200 LOCATION,FIXTURE EBARA CORPORATION PM10U...

-

Page 60: Piping

When checking for gas leaks by pressurization, please pressurize by less than 0.05 MPa into the purge port and do check. EBARA CORPORATION PM10U... -

Page 61: Cooling Water Piping

Table 4.1 below. Table 4.1 Industrial Water Supply Quality Specification (Japan Industrial Water Association, Industrial Water Quality Standards Committee) Turbidity (ppm) 6.5-8.0 Alkalinity(CaCO3) (ppm) Hardness(CaCO3) (ppm) Evaporation residue (ppm) Chlorine ion (ppm) Iron (ppm) Manganese (ppm) EBARA CORPORATION PM10U... -

Page 62: N 2 Gas Piping

After this, use a tool to tighten the nut further by 1 + 1/4 turns. To connect the tube again after this, install the tube already fitted to the ferrule and re-tighten the retaining nut slightly after the initial tightening (generally, tighten by a further quarter turn after tightening by hand). EBARA CORPORATION PM10U... -

Page 63: Ventilation Duct(Model Ev-S***N / Model Ev-S***P

The exhaust noise of the pump will give rise to acoustic resonance inside the pump unit and result in an abnormal noise being generated. CAUTION Never operate the pump without pump cover for safety. EBARA CORPORATION PM10U... -

Page 64: Electrical Wiring

Circuit breaker(CB) type of UL489 to SEMI correspondence.) CAUTION Do not supply a power supply to other instruments out of a pump package. It becomes an operation mistake of a control part, and a cause of pump failure. EBARA CORPORATION PM10U... -

Page 65: Power Supply Wiring

P.46 4.3.1 Power Supply Wiring Fig4.3.1,2,3 show the power supply connector and a control singnal connector position on the control panel. ・ MODEL EV-S20 CN-Z COM1 COM2 EXT.IL LCD1 LCD2 CN-Y CN-C (Power supply for accessories) Power supply receptacle Fig 4.3.1 Power Supply and Control Signal connects position ・... - Page 66 Wire the connector for the main power supply (3-phase, 200V-220V and 50Hz/60Hz). Fig. 4.4, 4.5 and Tables 4.2, 4.3, 4.4 and 4.5 show the connector pin assignment. Please wire the connector pin by the specialized tool. EBARA CORPORATION PM10U...

- Page 67 Table 4.2 Pin Assignment of Power Supply Receptacle Fig 4.4 Power Supply Receptacle (As seen from connecting side) Table 4.3 Receptacle Specification Pump model MODEL EV-S20 Receptacle type C016 20C003 100 12 Recep. Manufacturer Amphenol Adapted plug type C016 20D003 100 12...

-

Page 68: Control Signal Wiring

Tables 4.6, 4.7, 4.8 and 4.9 and Figs. 4.6 and 4.7 show the pin assignment. Table 4.6 Receptacle Specification Connector No. Connector type 15 pin D sub-miniature Female receptacle CN-Z (In accordance with SEMI-E73) CN-Y 25 pin D sub-miniature Female receptacle EBARA CORPORATION PM10U... - Page 69 WARNING STATUS (+) WARNING:OPEN, Alternate ALARM STATUS (+) ALARM:OPEN, Alternate REMOTE STATUS (+) REMOTE: CLOSE − MP START (−) BP START (−) MP START STATUS (−) BP START STATUS (−) WARNING STATUS (−) ALARM STATUS (−) REMOTE STATUS (−) EBARA CORPORATION PM10U...

- Page 70 PUMP N2 WARNING STATUS (−)*2 RESERVED (−) SAVING ENERGY STATUS (−) RESERVED (−) RESERVED (−) RESERVED (−) *1 : Optional *2 : Only “P” and “N” model. *3 : It can change to “Abnormality:OPEN, Alternate” by DIP SW. setting. EBARA CORPORATION PM10U...

- Page 71 Table 4.9 CN-Z & CN-Y Signal Contacts Customer's connection Pump side Circuit 12VDC Input 1kΩ Signal 10mA Min. Open Collector Dry Contact Pump side Circuit Customer's connection 4VDC-27VDC 100mA Max. Open Collector Output Signal [ OPTION] 4VDC-27VDC 100mA Max. Dry Contact EBARA CORPORATION PM10U...

-

Page 72: Emergency Stop Switch Box (Ems Switch Box) - Optional

“Emergency Off” which shut down pump power supply with additional components to be prepared by users (see section 4 for detail). (2) EMS System Flow Motor Driver Dsub-25, 6-19Pin (CN-Y) Tool DRY PUMP Pump power supply Fig. 4.8 System Flow EBARA CORPORATION PM10U... - Page 73 See Specification Table for current value Magnetic Contactor Motor Driver See Specification Table CN-Y for current value DRY PUMP Internal Pump Dry Contact is turned OFF when EMS is activated (pushed). Fig. 4.9 Example, EMO System Flow EBARA CORPORATION PM10U...

-

Page 74: Safety Interlock Connector (Connector Ext.il)

For example: ADAPTER for Central Monitoring System Interface Controller DANGER Power Supply for the options is kept applying voltage during the pump is supplied the power. WARNING Do not use the power supply for other purposes. EBARA CORPORATION PM10U... -

Page 75: Lcd Controller

For "buzzer mute in WARNING / ALARM " PRG. For changing screen of pump status and Dip Switch selection ENTER For using at DIP switch selection [LED] BP RUN BP running (It doesn't operate in EV-S20(P/N)) MP RUN MP running LOCAL LOCAL mode WARNING WARNING condition ALARM ALARM condition Fig 5.1 LCD controller... -

Page 76: Lcd Indication

Two control modes are available: LOCAL “(local operation)” and “REMOTE (remote operation)”. Two running modes are available “NORMAL (rate operation)” and “S.ENERGY (energy-saving operation)” " % " shows present number of WARNING/ALARM. Upper row "$$$$$$" distinguishes between WARNING/ALARM and indicates the position where WARNING/ALARM has occurred. EBARA CORPORATION PM10U... - Page 77 Use the Display Select Switch (▲ ▼) to change the display. The WARNINGs/ALARMs that have currently been generated can be displayed with the Display Select Switch. See Fig. 5.2 for the key operation of the pump operation status display. EBARA CORPORATION PM10U...

- Page 78 (Indication of history) ALARM/WARNING ALARM:CASING 001 06 00 #### ENTER ENTER HISTORY? TEMP.HIGH 020901 12:23:21 ▽ △ ▽ △ EV-S20 ***V Pump type Voltage WARNING:BP MOTOR 002 51 00 #### &&&&&&&& Pump unit No. ENTER TEMP.HIGH 020901 12:25:26 ▽ △ OPE.TIME...

- Page 79 MP overload 2 BP step out MP step out Cooling water flow low Motor thermostat Inner communication error (MP driver) Inner communication error (IO) Inner communication error (BP driver) MP Driver Gate OFF BP Driver Gate OFF EBARA CORPORATION PM10U...

-

Page 80: Setting The Operational Mode

Sets the DIP switch to ON. Switches the display of the operational mode setting screen. ▼ Sets the DIP switch to OFF. Switches the display of the operational mode setting screen. ENTER Determines the selected setting. See Fig. 5.3 for how to set the operational modes. EBARA CORPORATION PM10U... - Page 81 ▼ SET POINT • Setting the pump N2 flow low warning threshold N2 FLOW WARNING? ▲ ▼ SET POINT • Setting the Back Pressure high warning threshold BACK PRES.? Fig. 5.3 How to set the operational mode EBARA CORPORATION PM10U...

-

Page 82: Setting The Pump Operation Control Mode

OFF ロ △ ▽ Setting Completed B1 ON Countdown beginning ENTER PRG. PRG. DIP SW B? OFF ロロロロロロロロ △ ▽ C1 ON ENTER PRG. DIP SW C? OFF ロロロロロロロロ See 5.4 for details of the DIP switch. PRG. EBARA CORPORATION PM10U... -

Page 83: Setting The Pump Running Mode

Use the up and down arrow keys to change the setting value. ▲: Increase the setting speed by 0.1 kmin ▼: Decrease the setting speed by 0.1 kmin Upper limit MP/BP: The value lower than the set value for the rated speed Lower limit MP/BP: 4.0 kmin EBARA CORPORATION PM10U... -

Page 84: Setting The Rotational Speed In The S. Energy Mode

: Increase the setting speed by 0.1 Pam /s (Delay time:1 sec) ▽ : Decrease the setting speed by 0.1 Pam /s (Delay time:1 sec) Upper limit : 81.0 Pam /s (Delay time:60 sec) Lower limit : 0.5Pam /s (Delay time:5 sec) EBARA CORPORATION PM10U... -

Page 85: Setting The Back Pressure High Warning Threshold

Use the up and down arrow keys to change the setting value. △ ▽ △ : Increase the setting speed by 0.5 kPa ▽ : Decrease the setting speed by 0.5 KPa Upper limit 30.0 KPa Lower limit 5.0 KPa EBARA CORPORATION PM10U... -

Page 86: Dip Switch

------- ------- ------- ------- ------- ------- ------- ------- DIP SW-A. No.1 This switch allows you to select the data length out of 7 or 8 bits for the pump running status monitoring with the RS232C communication port. EBARA CORPORATION PM10U... - Page 87 Be sure always to use the N gas selector valve and dip switch-A No. 7 in combination. [ NOTE ] The N gas selector valve is positioned on the right panel when viewing facing the utility side of the pump. EBARA CORPORATION PM10U...

- Page 88 Locks or unlocks the currently selected operation status display, which usually returns to the power display in 60 seconds. DIP SW-C. No.1 This switch allows you to select "NORMAL OPEN" or "NORMAL CLOSE" for PUMP N2 WARNING output. EBARA CORPORATION PM10U...

-

Page 89: Dip Switch Setting Display

* indicates the dip switch number (1 to 8) currently you are setting. Fig 5.5 DIP Switch [NOTE] Duration of pump operation, dip switches, except A-3 (BUZZER) and B-8 (Initializes the LCD screen), can not be used for parameter setting. EBARA CORPORATION PM10U... -

Page 90: Starting/Stopping The Pump With The Lcd Controller

Two controller connected connected The one with its LED START/STOP Allowed “LOCAL” allowed. When you use two LCD controllers, disconnect the one which you will not use for the operation from the pump once. Then, attach it again. EBARA CORPORATION PM10U... -

Page 91: Operation

CAUTION Unless a sufficient supply of N gas is maintained, serious problems will occur such as pump corrosion and accretion of reaction by-products. EBARA CORPORATION PM10U... - Page 92 10 seconds after the CP is placed in the ON position. (5) Check on the WATER FLOW display of the LCD Controller that the cooling water flow rate is 1.5L/min. or more. (EV-S20:1.5L/min, EV-S50/S100/S200:2.0L/min) (6) Re-check on the PUMP N2 FLOW display of the LCD Controller that the dilution N gas flow rate is within the 17 - 21Pam3/s range.

- Page 93 (8) When the pump exhaust pipe is equipped with a valve, open this valve before starting the pump. CAUTION Problems will occur when the pump is operated with the valve closed as the exhaust pipe will be pressurized. EBARA CORPORATION PM10U...

-

Page 94: Start/Stop

2 hours and it is recommended not to start exhausting the process gases earlier than this. [ NOTE ] Do no suddenly make a pump inlet port the pressure that is higher than atmospheric pressure. EBARA CORPORATION PM10U... - Page 95 P.76 When DIP switch-A No. 4 is placed into the ON position and this switch is changed from the LOCAL to the REMOTE setting the pump will stop regardless of the external signal input. EBARA CORPORATION PM10U...

-

Page 96: Local (Pump Side) Start/Stop

[ NOTE ] The pump will not start when a WARNING/ALARM has been generated. When a START signal is entered, "STARTFAIL" will appear on the display. b) STOP Interrupt the external MP start signal and the pump will stop. EBARA CORPORATION PM10U... -

Page 97: Communication Start/Stop

In the momentarily power failure condition, pump rotor is driven by inertia due to interception of power supply. Thus, pumping performance may be decreased than guaranteed specification. EBARA CORPORATION PM10U... -

Page 98: Maintenance And Inspection

Close nitrogen port with blank off plug. If the pump has already operated with process gases, purge the residual gases with nitrogen gas after stopping the pump operation. Then, conduct maintenance. EBARA CORPORATION PM10U... -

Page 99: Routine Inspection

RESET signal is entered. After you have taken the remedial action, press the RESET button on the controller or enter the RESET signal from the control signal connector to reset the WARNING. EBARA CORPORATION PM10U... -

Page 100: Vacuum And Exhaust Piping

WARNING The pump and exhaust piping will remain at a high temperature during operation and for a short time after the pump has stopped. Be sure to avoid contact and keep inflammable substances out of reach. Do not remove the outer cover during operation. EBARA CORPORATION PM10U... - Page 101 N2 gas purge has been discontinued and then remove the piping. (3) Be sure to switch off the power supply. (4) After you have washed the piping do not reconnect until it has dried completely. EBARA CORPORATION PM10U...

-

Page 102: Lubricating Oil

7.3). (4) After you have checked that there are no depositions and fragments adhering to the O ring attached to the plug, close the oil-filler inlet. (5) Please check the air leak after supplying lubricating oil. EBARA CORPORATION PM10U... - Page 103 Fig. 7.3 Oil Level Gauge CAUTION Be sure only to use the lubricant oils listed in specification table 3.1. CAUTION Waste oil shall be disposed of by industrial waste disposal dealer in accordance with Material Safety Data sheets. (appendix1,2) EBARA CORPORATION PM10U...

-

Page 104: Spare (Maintenance) Parts List

Table 7.3 Labels Label’s Name Parts No. [DANGER] HAZARDOUS WAIGHT DANGER LABEL C-7110-316-0001 C-7110-313-0001 [WARNING] HAZARDOUS VOLTAGE WARNING LABEL C-7110-312-0001 [WARNING] HIGH TEMPERATURE WARNING LABEL [WARNING] HAZARDOUS MATERIAL WARNING LABEL C-7110-314-0001 [CAUTION] CHARGE MARK LABEL C-7110-155-0001 EBARA CORPORATION PM10U... -

Page 105: List Of Wastes During Maintenance

(No necessary to replace at Safety Data Sheet. usual maintenance.) O-ring Connection of vacuum line Usual industrial waste. 7.7 Overhaul Overhaul is performed in EBARA. Contact EBARA Sales office or Overhaul service center. Please overhaul once a year. EBARA CORPORATION PM10U... -

Page 106: Disconnection And Transportation

WARNING When the pump has been used for exhausting highly toxic gases such as arsenic and mercury compounds, be sure to contact EBARA Corporation before you return the pump. CAUTION In the interest of safety during the transportation, disassembly and cleaning of the pump, be sure to take note of the gases that have been handled. - Page 107 (10) For transportation, secure the pump by lowering the adjustment feet. Place a protective cloth around the pump to avoid shock and position protective members between the outer cover and the wires in order to distribute the load of the fastening wires. EBARA CORPORATION PM10U...

-

Page 108: For Semi S2 Standard

Hard interlock signal is open. Customer's connection Pump side Circuit Safty Interlock 4VDC-27VDC EXT.IL 100mA Max. (N.C) Dry Contact Pump Fixation Please fix the pump to the floor or other firm ground with the brackets at the installation. EBARA CORPORATION PM10U... -

Page 109: Troubleshooting

Gas leaks will result in the discharge of harmful and dangerous substances and in abnormal reactions due to the ingress of air into the pump. When checking for gas leaks by pressurization, please pressurize by less than 0.05 MPa into the purge port and do check. EBARA CORPORATION PM10U... -

Page 110: Troubleshooting (1) Basic Trouble

Leak from vacuum piping. Check piping. Accumulation of by-products in pumps. Replace or overhaul pump. **MEMORY ERROR** is None Need “Countermeasure against displayed on LCD after electric Noise” to pump. activating CP or changing the dip switch setting. EBARA CORPORATION PM10U... -

Page 111: Troubleshooting (2) Warning

(at the side of pump) After you have taken the remedial actions above, reset the pump. If the problem that has caused the WARNING signal still remains, the WARNING display will appear again even after you have reset. EBARA CORPORATION PM10U... -

Page 112: Troubleshooting (3) Alarm

Instrument failure Replace instrument. After you have taken the remedial actions above, reset the pump. If the problem that has caused the WARNING signal still remains, the WARNING display will appear again even after you have reset. EBARA CORPORATION PM10U... -

Page 113: Troubleshooting (4) Option

After you have taken the remedial actions above, reset the pump. If the problem that has caused the ALARM signal still remains, the ALARM display will appear again even after you have reset. EBARA CORPORATION PM10U...

Need help?

Do you have a question about the EV-S20 and is the answer not in the manual?

Questions and answers