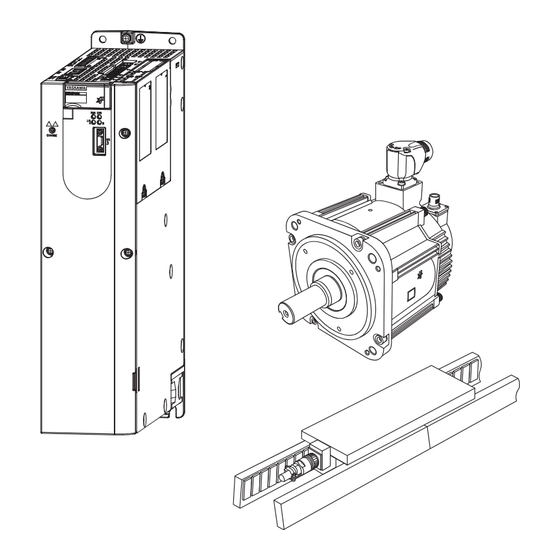

YASKAWA SGD7S-xxxDA0 series Manuals

Manuals and User Guides for YASKAWA SGD7S-xxxDA0 series. We have 1 YASKAWA SGD7S-xxxDA0 series manual available for free PDF download: Product Manual

YASKAWA SGD7S-xxxDA0 series Product Manual (636 pages)

S-7-Series AC Servo Drive; S-7S SERVOPACK with 400V-Input Power and EtherCAT (CoE) Communications References

Brand: YASKAWA

|

Category: Controller

|

Size: 10 MB

Table of Contents

-

-

Maintenance35

-

Part Names42

-

Functions48

-

-

-

-

-

-

Dynamic Brake117

-

-

Holding Brake172

-

-

Preparations189

-

Applicable Tools189

-

-

-

Software Limits

220 -

-

Software Reset

239-

Preparations239

-

Applicable Tools239

-

-

-

Preparations241

-

Applicable Tools241

-

-

-

-

-

Preparations266

-

Applicable Tools267

-

-

-

Precautions270

-

Preparations270

-

-

-

Program Jogging272

-

Origin Search278

-

-

Tuning

284-

-

Tuning Functions288

-

Diagnostic Tool289

-

-

-

Outline299

-

Restrictions299

-

Applicable Tools300

-

-

Custom Tuning

324 -

-

Outline338

-

Preparations339

-

Applicable Tools339

-

-

Manual Tuning

360 -

Diagnostic Tools

374-

Easy FFT376

-

-

Monitoring 10

380-

10

381-

Alarm Tracing

395

-

-

-

11

397-

-

Loop Control400

-

Pitches400

-

Sequence400

-

Signals402

-

-

Safety Functions

407-

12

408-

-

Risk Assessment410

-

Recovery Method413

-

Stopping Methods416

-

-

-

Procedure419

-

-

-

13

423-

PDO Mappings

427

-

-

-

14

435-

Device Control

435 -

-

Related Objects437

-

Homing

446-

Related Objects446

-

-

-

-

15

460 -

16

508 -

17

573 -

18

623-

Torque Limits

453-

Related Objects455

-

Touch Probe455

-

General Objects462

-

Device Control478

-

Homing Mode488

-

Inspections508

-

Alarm Displays511

-

List of Alarms511

-

Resetting Alarms548

-

List of Warnings554

-

Warning Displays554

-

Appendices622

-

-

Advertisement

Advertisement