Table of Contents

Advertisement

Quick Links

Operating

Instructions

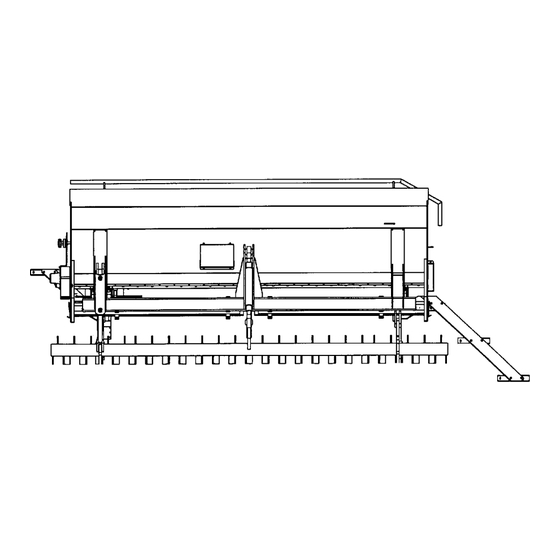

Seed drills

Saphir 7-B AutoLoad

- EN -

SAFETY IS OUR CONCERN!

Art.-Nr.: 175 3947

GB-1/03.05

LEMKEN GmbH & Co. KG

Weseler Straße 5, D-46519 Alpen / Postfach 11 60, D-46515 Alpen

Telefon (0 28 02) 81-0, Telefax (0 28 02) 81-220

eMail: lemken@lemken.com, Internet: http://www.lemken.com

Advertisement

Table of Contents

Summary of Contents for LEMKEN Saphir 7-B AutoLoad

- Page 1 - EN - SAFETY IS OUR CONCERN! Art.-Nr.: 175 3947 GB-1/03.05 LEMKEN GmbH & Co. KG Weseler Straße 5, D-46519 Alpen / Postfach 11 60, D-46515 Alpen Telefon (0 28 02) 81-0, Telefax (0 28 02) 81-220 eMail: lemken@lemken.com, Internet: http://www.lemken.com...

- Page 3 Only use genuine Lemken spare-parts. Spurious parts negatively influence the function of the implement, show a shorter lifetime and increase in nearly all cases additional maintenance. We trust that you will understand that LEMKEN is unable to guarantee poor operation and damage caused by using spurious parts!

-

Page 5: Table Of Contents

Therefore use this instruction book with the „General Health- and Safety precautions“! • The LEMKEN Saphir 7 AutoLoad have been designed purely for the agri- cultural use! • Any use beyond the one stipulated above is no longer considered as defi- ned use! •... - Page 6 Lift Rods................16 Check Chains or Sway Blocks ........... 16 Hydraulic equipment............16 Tractor hydraulics ............... 16 Axle load ................17 3.6.1 Calculation of the minimum front ballast GV min: ..17 3.6.2 Calculation of the increasing of the rear axle load ..17 Power supply ...............

- Page 7 SINGLE DISC COULTERS AND SUFFOLK COULTERS ....42 Mechanic coulter pressure adjustment / Drilling depth ...42 Hydraulic coulter pressure adjustment ......42 ROLLERS OF THE POWER HARROWS ZIRKON .......43 DRIVE WHEEL ................44 10 WHEEL PRESSURE INCREASING DEVICE ........46 11 HARROWS ..................47 11.1 Single harrows ..............47 11.2 S-harrow ................47 11.3 Hydraulic harrow lifting device...........49 12 TRAMLINE MECHANISM .............50...

- Page 8 16.5 Operation of the pre-emergence marker......61 17 RODS FOR AGITATOR SHAFT ........... 63 18 REMOTE CONTROL FOR THE ADJUSTMENT OF THE SEED RATE 18.1 Mechanical adjustment............64 18.2 Hydraulic adjustment............65 18.2.1General Instructions ........... 65 18.2.2Adjusting the maximum seed rate ......65 18.2.3Adjustment of the minimum seed rate ......

- Page 9 25 DISPOSAL ..................73 26 NOTES ...................73 INDEX ....................75 EC CERTIFICATE OF CONFORMITY ..........77...

-

Page 11: Safety Instructions

SAFETY INSTRUCTIONS General Safety Instructions • Before using the machine, always check both it and the tractor for roadworthiness and operational safety! •As well as the notes in these instructions the operator is advi- sed to comply with the generally applicable safety at work regu- lations and those relating to use of the public highway! •... - Page 12 • Adhere to the maximum permissible axle loads, total weights and transport width! • Fit and check transport gear, road lights and warning guards! • The release ropes for quick coupler latches should hang freely and in the lowered position must not release the quick coupling by themselves. •...

- Page 13 • Regularly check the hydraulic pipes and replace them in the event of da- mage or signs of ageing. The replacement pipes must comply with the technical specification as laid down by Lemken! • When searching for leaks appropriate equipment should be used because of the danger of injury! •...

- Page 14 Maintenance • Repair-, maintenance- and cleaning operations as well as adjustments and remedy of function faults should principally be conducted with engine stopped and brakes applied. Remove ignition key! • Check and tighten nuts and bolts regularly! • When conducting maintenance work on a lifted implement always place suitable supports underneath! •...

-

Page 15: Warning Stickers

WARNING STICKERS 2.1 General Instructions The LEMKEN Saphir 7 AutoLoad is equipped with all features to ensure safe operation. Where potential danger areas of the implement can not be fully safeguarded, warning stickers are fitted which draw attention to these. - Page 16 WARNING! Before maintenance and repair work, stop tractor engine and remove ignition key! WARNING! Do not ride with on the platform of the imple- ment! WARNING! Hydraulic accumulator contains gas and oil under pressure. For removal and repair in- structions in technical manual must be fol- lowed!

-

Page 17: Position Of Warning Stickers

2.3 Position of warning stickers... -

Page 18: Preparation Of Tractor

PREPARATION OF TRACTOR 3.1 Tyres Ensure that all are at the manufacturer's recommended pressures and that left and right hand side tyre pressures are identical. (See Manufacturer's In- structions)! 3.2 Lift Rods Adjust lift rods to equal length. Where there are alternative positions for the lift rods on the lower links, use the rearmost position, to unload the tractor hy- draulics. -

Page 19: Axle Load

3.6 Axle load The attachment of implements to the front- and rear-three point linkage must not lead to exceeding the allowed total weight, the allowed axle load and the allowed tyre load of the tractor. The tractor front axle must always be loaded with 20 % of the tractor dead weight at minimum. -

Page 20: Power Supply

The calculation of the required minimum front ballast and the increasing of the rear axle load requires that all above mentioned measurements and weights are known. If they are unknown and cannot be found out, there will be only one way to avoid overloads: Please weigh your tractor with mounted and lifted implement to find out the actual rear axle loading and front axle unloading and that in compa- rison with the axle loads of the tractor without implement! -

Page 21: Attaching And Detaching The Implement

With this version the seed drill can be fitted to a hydraulic three point linka- ge of a LEMKEN soil cultivation implement, which has been equipped with special attaching parts (1). The frame (AR) must be connected to the links of the hydraulic three-point linkage, that 1. - Page 22 b) Coupling parts for foreign models (FR) With this version the seed drill can also be attached to the three-point linkage of soil cultivation imple- ments of other manufacturers. Via the row of holes LR) the draw- bar (90) can be adjusted in a dis- tance to the seed drill as required.

- Page 23 The measurement „A“ has to be measured between the lower edge of the fra- me tube (53) of the coulter bar and the ground in working position. Saphir 7 AutoLoad with suffolk with single disc with double disc coulters coulters coulters 350 mm 350 mm...

-

Page 24: Attaching The Seed Drill

4.2 Attaching the seed drill After the hydraulic three-point lin- kage (HA) of the LEMKEN soil cul- tivation implement been equipped with attaching parts (1) respectively the coupling parts are fitted, the machine parked on its stands (A2) can be attached. -

Page 25: Detaching Seed Drill

4.3 Detaching seed drill The seed drill may only be parked with empty hopper, and that on a le- vel and firm ground. Dismounting should be done on firm and level ground, generally. Before dismounting of the seed drill the stands (A2) must be pushed ful- ly into the frame tube (53) on both sides until their stop. - Page 26 After the seed drill has been detached from the soil cultivating implement, drive away from the seed drill carefully. • Read and adhere to the General Safety Instructions as well as to the Instructions „Attached Implements“! • The horizontal bar of the stand (A2) can be a stumbling block in parked position.

-

Page 27: Use

5.1 General Instructions The Lemken seed drill Saphir 7 will be delivered completely as- sembled, but some parts are loo- se or not fitted in the working position for dispatch reasons. Fit these parts before use. For the seeding procedure 1. -

Page 28: Seeding Table

5.2 Seeding table Seed Adjustments Soil flap Seed wheel Slide Gear box Spelt-wheat 2 - 3 Barley Grass Oats Carrots Flax Lupine 2 - 3 Lucerne Oilreddish Phacelia Rape Red clover F (N) 100 (20) Mustard Sun flowers Wheat Onions 5.2.1 Saphir 7 with seed wheels Mono Plus Seed Adjustments... -

Page 29: Saphir 7 With Seed Wheels Mega Plus

5.2.2 Saphir 7 with seed wheels Mega Plus Seed Adjustments Soil flap Seed wheel Slide Gear box Big peas and 1 - 2 beans * Gear box adjustment for the first calibration test a) Switch off agitator shaft b) Fit grass seed agitator device The adjustment information for the setting of the seed drill and the adjustment of the first calibration test can be taken from the seeding table. -

Page 30: Filling The Hopper

5.3 Filling the hopper Before filling the hopper the bottom flaps must be adjusted in accordance to the seeding table. The hopper may only be filled, when the seed drill with soil cultivating imple- ment is attached to the tractor. For filling the seed drill has to be driven to the trailer with seed and according to the filling method eit-... -

Page 31: Adaptation Of The Seed Drill To The Used Seed

- current adjustments of the implement, - maintenance and - structure of the seed bed LEMKEN cannot take over responsibility for losses of output, which result from it. The function of the seed drill, the seeding depth quality a.s.o. must be chek-... -

Page 32: Agitator Shaft

5.4.1 Agitator shaft For fine seed, especially with en- crusted rape, the agitator shaft (52) must be switched off. For that the linch pin (27) is removed from the driving gear after dismounting the protection cover. The linch pin can be positioned in the tool box of the soil cultivation implement. -

Page 33: Bottom Flaps

5.4.3 Bottom flaps For careful seeding adjustable bottom flaps are provided below the seed wheels. By means of the adjusting lever (14) 6 different bottom flap positi- ons can be adjusted. Attention: With big-grained seed (peas, beans) either the bottom flap position 5 must be chosen. -

Page 34: Seed Wheels

5.4.4 Seed wheels a) Seed wheel Conti-Plus The two-parts Seed Wheel CONTI-PLUS can be adjusted in two different ad- justment positions. Normal seed wheel (N): This adjustment, where the normal seed wheel (N) is switched on, will be chosen for all all sorts of crops and big-grained seed. Fine seed wheel (F): This adjustment, where the fine seed wheel is switched on, will be used for fine seed. - Page 35 For switching on the seed wheel halves (N) or (F), first the seeding shaft is turned by means of the calibration lever so that the pressed in cam slide (55) is in view direction. After that the switched off seed wheel will be turned back- wards until both cam slides (55) are facing each other exactly.

-

Page 36: Adjusting The Seed Rate

5.4.5 Adjusting the seed rate The seed rate is adjusted by means of the gear box (20). The gear box can be adjusted stepless by means of the adjuster lever (63) after the handle nut (32) has been loosened. The higher the number on the scale (89) the higher is the seeding quan- tity. -

Page 37: Calibration Test

5.5 Calibration test For checking the adjusted seed rate a calibration test must be car- ried out. The operation terminal will be put into the holer (1) during calibration test so that it can be seen by the operator at any time. a) Adjust soil flaps, slides and seed wheels according to the seeding table. - Page 38 g) By means of turning the cali- bration lever (86) fill the cali- bration tray two or three times. h) Adjust the gear box (20) accor- ding to the seed table for the first calibration test. i) After that empty the calibration trays (6) and fit them again.

-

Page 39: Seeding Control

wheel circumference or the driven distance per pulse (see in- struction book of the corresponding seed drill control). Weigh the seed which is caught in the calibration trays and convert it into 1 ha: Weighed out quantity of seed for 1/10 ha x 10 = quantity of seed per hectare. Weighed out quantity of seed for 1/40 ha x 40 = quantity of seed per hectare. -

Page 40: Emptying The Hopper

some influences are not taken into account, which influence the seeding rate. In properly cleaned seed and subsequent abrasion, (for example broken ears of barley or encrusted rape), this can influence the seeding rate. As a basis for the turning of the wheel rotations/ha an average wheel slip has been assumed. - Page 41 a) Move out laterally both calibrati- on trays (6) and move them in again with the opening to the top. Clean the trays first when they are dirty. b) Set emptying flaps to the calibra- tion position by means of pres- sing down the emptying lever (13) so that the hexagon shaft (57) turns.

-

Page 42: Double Disc Coulters

DOUBLE DISC COULTERS 6.1 Scrapers The double disc coulters (11) are equipped with a self-adjustable scrapers (9). As an option to these standard scrapers (9) made of plastic hard metal scrapers are available, which are equipped with hard metal plates at the margin. The single scraper (9) is put onto the holder (D8). -

Page 43: Drilling Depth

6.2 Drilling depth With the adjuster screw (67) the drilling depth is adjusted. Turn the screw clockwise => deeper drilling depth. Turn the screw anti-clockwise => less deep drilling depth. 6.3 Coulter pressure Each coulter row can be adjusted individually with regard to the coul- ter pressure by means of the coul- ter pressure adjustment. -

Page 44: Single Disc Coulters And Suffolk Coulters

SINGLE DISC COULTERS AND SUFFOLK COULTERS Mechanic coulter pressure adjustment / Drilling depth With the adjuster screw (67) the coulter pressure and the drilling depth of the seeding coulters (ES) or (S) is adjusted. Turn the screw (67) clockwise => deeper drilling depth. Turn the screw (67) anti-clockwise =>... -

Page 45: Rollers Of The Power Harrows Zirkon

ROLLERS OF THE POWER HARROWS ZIRKON In order to prevent that the coulters do not touch the roller during lifting pro- cedure and to ensure that the hopper can be swung safely, with reference to the rollers the following items must be adhered to: 1. -

Page 46: Drive Wheel

DRIVE WHEEL For the drive of the seed drill the drive wheel (66) is used. The drive wheel (66) must be con- nected to the axle by means of the expansion pin (S), that it runs bet- ween two seeding rows. The conversion from transport to calibration or working position is done by unlocking the spring... - Page 47 After the adjustment the securing screw (SC) must be tightened ca- refully, to avoid an unintentional adjusting of the stop eccenter. During work the spring loaded pin (51) must be unlocked. Then the handle (77) of the pin points to the drive wheel.

-

Page 48: Wheel Pressure Increasing Device

10 WHEEL PRESSURE INCREASING DEVICE If the drive wheel has too much slippage on soft ground, then the contact pressure increased by means of the wheel pressure increasing device (RV1). pressure positions possible. For this purpose the bolt (RV2) must engage in hole (RV3) or (RV4). -

Page 49: Harrows

HARROWS 11.1 Single harrows The harrow tines (59) will be fitted to the wheel stalk of the rear depth guiding rollers. After loosening the bolt (60), they can be adjusted in depth separa- tely. They should be adjusted so deep that the seed is covered well by soil. - Page 50 By means of turning the spring (FE) the harrow pressure will be adjusted: Higher harrow pressure => Turn spring clockwise Lower harrow pressure => Turn spring anti-clockwise The nut (MU) must be tightened so much that the spring (FE) is secu- red against unintentional adjus- ting, but a manual adjustment is possible.

-

Page 51: Hydraulic Harrow Lifting Device

• Before each transport, the S-harrows must be folded-in and secured, in order to prevent injury. Worn harrow tines, which show points pointing rearwards, only, must be covered by a transport safety device. 11.3 Hydraulic harrow lifting device If desired a hydraulic harrow lifting device is available. -

Page 52: Tramline Mechanism

12 TRAMLINE MECHANISM 12.1 General Instructions The tramline mechanism allows for tramlines to be laid out at set distances by not seeding the rows which are within the track, of the following tractor used for spraying and fertilising. The sequence of the recurring tramline outlets is determined by the working width of the seed drill and the subsequent machinery, such as sprayer and fertiliser spreader. -

Page 53: Tramline Rhythm

A tramline rhythm must be chosen. There are two possibiliies: 12.2.1 Uneven rhythm The working width of the sprayer or fertiliser spreader may be 3, 5, 7, 9, 11, 13, 15,17, or 19 times wider with the LEMKEN Easytronic than the seed drill width. Example:... -

Page 54: 2Even Rhythm

12.2.2 Even rhythm The working width of the sprayer or fertiliser spreader may be 2, 4, 6, 8, 10, 12, 14, 16,18 or 20 times wider than the seed drill width. Example: Sprayer Seed drill Tramline rhythm 12 metres 3 metres The tramline rhythm in the shown example is 4. -

Page 55: Making Tramlines

12.3 Making tramlines 12.3.1 Switchable seed wheels For making tramlines switchable seed wheels (1) with gears (2) will be fitted, which can be switched off for making tramlines. Each gear (2) of the switchable seed wheels must mesh with the gear (4) of the intermediate shaft (5) and set into free running posi- tion. - Page 56 When the switchable seed wheels (1) should be switched off for ma- king tramlines the following must be done: 1. Separate the stud screws (7) of the seed wheels from the see- ding shaft (6) by screwing-out the stud screw (7) by 1 - 2 mm and set seed wheels to free running position.

-

Page 57: Adjustment Of The Tramline Width

12.4 Adjustment of the tramline width The tramline width must correspond to the track width of the tractor which will be used with a sprayer or fertiliser spreader. Starting from the middle of the seed drill one must measure a half track width for example in connec- tion with a track of 1,5 m = 0,75 m to the left and to the right. -

Page 58: Switching Off Of Further Rows

12.5 Switching off of further rows The width of the track will be determined by the row distance and the number of switched off seed wheels. If wider tracks are desired than can be reached with 2 rows, a third row can be fitted. - Dismount seeding shaft (1) as descriped in section „Changing seed wheels“... -

Page 59: Changing Seed Wheels

13 CHANGING SEED WHEELS For an optimum seeding of different grains universal seed wheels or special seed wheels can be fitted. If required the change of the seed wheels will be done as follows: Dismount linch pin (1). Connect grip (2) to the seed wheel shaft by means of the linch pin (3). - Page 60 Remove seed wheels e.g. Mono Plus and fit new seed wheels e.g. Conti Plus. Where switchable seed wheels fitted, switchable seed wheels again. All seed wheels (6) must be fitted identically, that means that the gaps (10) or other stricking points of the seed wheels are on one line.

-

Page 61: Intermediate Plate For Rape

14 INTERMEDIATE PLATE FOR RAPE The intermediate plates (54) for rape can be fitted to the walls of the hopper. For seeding rape they can be mo- ved down by loosening the clam- ping bolt. After that tighten the clamping bolts (99) carefully again. -

Page 62: Pre-Emergence Markers

16 PRE-EMERGENCE MARKERS 16.1 General Instructions The hydraulic single acting pre- emergence marker consists out of units (EH), which are fitted to the carrier (RA). This carrier is also used for car- rying the S-harrows. 16.2 Adjusting to the track measurement of the following tractor The hollow discs can be adjusted exactly to the track measurement of the following tractor. -

Page 63: Depth Of The Marking Line

16.4 Depth of the marking line By means of turning the the spring (F) the depth of the marking line can be pre-adjusted: Turning the spring clockwise => deeper marking line Turning the spring anti-clockwise => lower marking line By means of the screw (SS) the brake disc (BS) will be pressed against the spring that it cannot adjust unintentionally, but the spring can be adjusted ma- nually. - Page 64 Via an additional hydraulic accu- mulator (HP) the hollow discs (HS) will be lifted and always then lowered when a marking line should be made. This will be con- trolled via the used seed drill con- trol, which switches if required the magnet valve (HV) for the oil sup- ply of the hydraulic rams (HZ).

-

Page 65: Rods For Agitator Shaft

17 RODS FOR AGITATOR SHAFT For extreme awney and light grass seed a grass seed agitator device (additional equipment) can be necessary, in order to avoid bridging. Therefore additional rods (19) are fitted to the agitator shaft (52) insi- de the hopper by means of clamps. Fit rods so that they do not touch the discharge wedges provided below. -

Page 66: Remote Control For The Adjustment Of The Seed Rate

18 REMOTE CONTROL FOR THE ADJUSTMENT OF THE SEED RATE 18.1 Mechanical adjustment This remote control is available in a length of 8 metres. When ordered with the seed drill this equipment is already fitted. Only the bracket for the adjuster lever must be fitted in the area of the tractor driver. -

Page 67: Hydraulic Adjustment

18.2 Hydraulic adjustment 18.2.1 General Instructions With the hydraulic remote control, the adjusted seed rate kg/ha can be changed up to 25 graduation marks from the tractor seat. One graduation mark of the 25 scale (77) corres- ponds to one graduation mark of the 150 scale (89). -

Page 68: 3Adjustment Of The Minimum Seed Rate

18.2.3 Adjustment of the minimum seed rate After loosening the lower handle nut (78) the desired minimum seed rate will be adjusted by means of the lever (WH). The desired percentage seed rate reduction can be calculated as follows: Scale value of the 25 scale = (adjusted scale value x desired percentage of the seed rate reduction) : (100) Example: With the adjustment of the 150 scale of 80 and a desired seed rate reduction... -

Page 69: Hopper Level Control

19 HOPPER LEVEL CONTROL 19.1 Hopper level indicator The level indicator is fitted as standard. The seed level inside the hopper will be shown by means of a indi- cator (15). 19.2 Hopper level control, electronical The adjustable electronical hopper level indicator with sensor is available as option. -

Page 70: Working Lights

20 WORKING LIGHTS The working lights (AW) and the hopper lights (TI) will be switched on and off by means of the key F5 of the operation terminal. -

Page 71: Driving On Public Roads

21 DRIVING ON PUBLIC ROADS 21.1 Warning boards with lighting equipment If it is required to drive on public roads with the seed drill, fit warning boards and lighting equipment. As option warning boards with lighting equipment are available. They ensure an orderly „marking“... -

Page 72: Maintenance

22 MAINTENANCE IMPORTANT: Do not clean this implement with a Pressure Washer during the first 6 weeks. After this time a minimum nozzle distance of 60 cm must be observed with a maximum 100 bar and 50 ° C temperature! The life time of the seed drill depends on good maintenance. -

Page 73: Drive Chains

22.2 Drive chains After the first 10 hours the drive chain of the agitator shaft must be readjusted and after that once a year. After each seeding period they must be cleaned and greased. 22.3 Bolts All bolts must be checked regularly and tightened if necessary. The pivot bolts of the coulters must be tightened after the first 8 hours of use, after that once a year. -

Page 74: Pivot Points

22.9 Pivot points All pivot points of all coulters, harrows, drive wheel and pre-emergence mark- ers must be greased every 25 hours. The pivot points must also be greased with a quality grease before and after the winter interruption. IMPORTANT: Do not clean this implement with a Pressure Washer during the first 6 weeks. -

Page 75: Technical Data

7/400 AutoLoad S* 1.050 * weight S-harrow 24 NOISE, AIRBORNE SOUND The noise level of the LEMKEN Saphir 7 AutoLoad does not exceed 70 dB (A) during work. 25 DISPOSAL After useful life of the implement, it must be disposed of environment-friendly by a specialist. - Page 77 INDEX Adjusting the seed rate ........34 Adjustment of the tramline width .

- Page 78 Maintenance ..........70 Minimum axle load .

Need help?

Do you have a question about the Saphir 7-B AutoLoad and is the answer not in the manual?

Questions and answers