Summary of Contents for Beckman Coulter CytoFLEX SRT

- Page 1 Instructions for Use CytoFLEX SRT Cell Sorter For Research Use Only. Not for use in diagnostic procedures. C37808AC March 2022 Beckman Coulter, Inc. 250 S. Kraemer Blvd. Brea, CA 92821 U.S.A.

- Page 2 • In the UK, call us at +44 845 600 1345. • In Ireland, call us at +353 (01) 4073082. • In Italy, call us at +39 0295392 456. • In other locales, contact your local Beckman Coulter Representative. May be covered by one or more pat.-see www.beckman.com/patents...

-

Page 3: Revision History

This document applies to the latest software listed and higher versions. When a subsequent software version affects the information in this document, a new issue will be released to the Beckman Coulter Web site. For labeling updates, go to www.beckman.com and download the latest version of the manual or system help for your instrument. - Page 4 This document applies to the latest software listed and higher versions. When a subsequent software version affects the information in this document, a new issue will be released to the Beckman Coulter Web site. For labeling updates, go to www.beckman.com and download the latest version of the manual or system help for your instrument.

- Page 5 This document applies to the latest software listed and higher versions. When a subsequent software version affects the information in this document, a new issue will be released to the Beckman Coulter Web site. For labeling updates, go to www.beckman.com and download the latest version of the manual or system help for your instrument.

- Page 6 This document applies to the latest software listed and higher versions. When a subsequent software version affects the information in this document, a new issue will be released to the Beckman Coulter Web site. For labeling updates, go to www.beckman.com and download the latest version of the manual or system help for your instrument.

-

Page 7: Safety Notices

Beckman Coulter, Inc. urges its customers to comply with all national health and safety standards such as the use of barrier protection. This may include, but it is not limited to, protective eyewear, gloves, and suitable laboratory attire when operating or maintaining this or any other automated laboratory analyzer. -

Page 8: Safety Precautions

• This equipment is used in a manner other than specified. Operate the instrument as instructed in the Product Manuals. • You introduce software that is not authorized by Beckman Coulter into your computer. Only operate your system's computer with software authorized by Beckman Coulter. -

Page 9: Instrument Safety Precautions

Safety Notices Instrument Safety Precautions CAUTION If you purchased this product from anyone other than Beckman Coulter or an authorized Beckman Coulter distributor, and it is not presently under a Beckman Coulter service maintenance agreement, Beckman Coulter cannot guarantee that... - Page 10 BSL Level II or higher. This information will be kept confidential and will be used to inform Beckman Coulter Field Service Representatives of any hazards prior to visiting any instrument site. Failure to report this information may delay service on an instrument. Safety of the user as well as safety of Beckman Coulter employees is of overriding importance.

-

Page 11: Electrical Safety

Safety Notices Instrument Safety Precautions For additional information on laboratory biosafety, please review the U.S. Department of Health and Human Services, Centers for Disease Control document, Biosafety in Microbiological and Biomedical Laboratories. Contact the safety officer at your site and discuss proper waste disposal precautions and practices. -

Page 12: Deflection Plates

Safety Notices Instrument Safety Precautions Deflection Plates CAUTION Risk of personal injury. Do not touch the charged plates when power is applied. The range of voltage applied to these plates is ±3800 ~ ±4200 Vdc. This high voltage is present only when the plate voltage is turned on and the interlock is closed. - Page 13 In addition, other equipment can radiate RF energy to which this device is sensitive. If one suspects interference between this device and other equipment, Beckman Coulter recommends the following actions to correct the interference: 1. Evaluate the electromagnetic environment before installation/operation of this device.

- Page 14 European Union. For products under the requirement of WEEE directive, please contact your dealer or local Beckman Coulter office for the proper decontamination information and take-back program which will facilitate the proper collection, treatment, recovery, recycling, and safe disposal of device.

- Page 15 Safety Notices Symbol Explanations Symbol Warning Condition Action Laser Class I This label indicates that this product is a Class I Laser product. Take precautions to prevent CLASS 1 LASER PRODUC CLASS 1 LASER PRODUCT PRODUIT LASER CLASSE 1 exposure. Consider all materials Wear standard laboratory attire and follow safe (specimens, controls,...

-

Page 16: Table Of Contents

Contents Revision History, iii Safety Notices, vii Alerts for Warning, and Caution, vii Safety Precautions, viii Instrument Safety Precautions, ix General Safety, ix Biohazard Safety, x Electrical Safety, xi Safety Interlocks, xi Stream Charge, xi Drop Drive Voltage, xi Deflection Plates, xii Deflection Plate Arcing, xii... - Page 17 Contents Optical Components, 1-16 Laser Beam Shaping, 1-17 Cell Illumination, 1-17 Forward Scatter, 1-17 Side Scatter and Fluorescent Light, 1-17 Forward Scatter Collection, 1-18 Side Scatter and Fluorescent Light Collection, 1-18 Side Scatter, 1-18 Fluorescent Light, 1-18 Wavelength Division Multiplexer (WDM), 1-19 Optical Fiber, 1-22...

- Page 18 Contents Analysis Screen, 2-11 Compensation Experiment Screen, 2-12 QC Experiment Screen, 2-14 QC Report Screen, 2-14 QC Experiment Screen, 2-15 QC Screen Navigation, 2-15 Software Menu, 2-16 Acquisition and Analysis Screen Menu, 2-17 User Management, 2-21 Creating, Deleting, and Modifying Users in User Manager, 2-23 Unlocking a User Account, 2-25...

- Page 19 Contents System Startup Program, 3-8 Selecting Experiments from the Start Page, 3-18 CHAPTER 4: Instrument Quality Control and Standardization, 4-1 Overview, 4-1 Quality Control, 4-2 Preparing the QC Sample, 4-3 Required Materials, 4-3 CytoFLEX Daily QC Fluorospheres Preparation Process, 4-3 CytoFLEX Ready to Use Daily QC Fluorospheres Preparation Process, 4-4 Importing Lot-Specific Target...

- Page 20 Contents Setting Plot Display Conditions, 5-49 Setting Customized Parameters, 5-50 Setting Custom Statistics, 5-51 Load Sample and Record Data, 5-55 Before Running Samples, 5-55 Setting Up Violet Side Scatter (VSSC) Channel, 5-56 Verifying, Selecting, Editing, and Creating Detector Configuration, 5-60 Sampling and Collecting Data, 5-63 Sorting, 5-67...

- Page 21 Contents Adjusting Compensation, 6-13 Manually Adjusting Compensation, 6-13 Importing and Exporting Compensation, 6-13 Importing Compensation Settings from Compensation Matrix Files, 6-13 Importing Compensation Settings from the Compensation Library, 6-15 Exporting Compensation Settings, 6-16 Managing the Compensation Library, 6-18 Adding Channels for Compensation, 6-19 CHAPTER 7: Data...

- Page 22 Contents Troubleshooting Table, 9-9 Backup and Restore, 9-55 Backup, 9-55 Restore, 9-59 Cleanup, 9-62 CHAPTER 10: Cleaning Procedures, 10-1 Overview, 10-1 Routine Cleaning, 10-1 Daily Clean Program, 10-2 Flow Cell Clean Program, 10-7 Aseptic Clean Program, 10-22 Cleaning the Side Stream Illumination Source and the Deflection Plates, 10-35 Cleaning the Nozzle, 10-38...

- Page 23 Contents APPENDIX A: Approved Cleaners and Disinfectants, A-1 Overview, A-1 Cleaners, A-1 Disinfectants for Use in the Sample Line, A-1 Disinfectants for Use in the Sheath Line, A-2 Disinfectants for Use in the Waste Container, A-2 Sheath Tank, A-3 Deflection Plate Cleaning Materials, A-3 APPENDIX B: Consumables, B-1...

- Page 24 Viewing Windows Security Logs, E-106 Enabling Installation Restriction, E-107 Enabling Firewall Defender, E-110 Enabling Network Time Protocol, E-112 APPENDIX F: Table of Hazardous Substances, F-1 Table of Hazardous Substances, F-1 Abbreviations Beckman Coulter, Inc. SOFTWARE END-USER LICENSE AGREEMENT Related Documents...

- Page 25 Illustrations Illustrations Sort Overview Diagram, 1-3 Main Components, 1-4 Fluidic Flow, 1-5 Fluidics Cart, 1-6 Fluidics Cart (Back), 1-7 Fluidics Cart Connection Panel, 1-8 Connector Color Convention, 1-9 Sheath Tank, 1-10 Shutdown Fluid Container, 1-11 1.10 Waste Container, 1-12 1.11 Interconnections on the Right Side of Sorter, 1-13 1.12...

- Page 26 Illustrations 1.33 Aerosol Evacuation Vents, 1-35 1.34 Power and Signal Cable Connections, 1-37 1.35 Power and Signal Cable Connections [Waster Container inside Biosafety Cabinet], 1-38 1.36 Fluid Harness Connections, 1-39 1.37 Overview of Sorter Connections, 1-39 Drawing Controls Toolbar (Top of Screen), 2-11 QC Report Screen, 2-14...

- Page 27 Illustrations Laser Setting Window, 5-41 [Two 5 ml tubes and two 15 ml tubes], 5-67 [Four 5 ml tubes], 5-68 [Standard 96-well plate], 5-74 [96-well deep well plate], 5-74 [Slide], 5-74 [Standard 96-well plate], 5-76 [Slide], 5-76 [Standard 96-Well Plate], 5-82 [Slide], 5-83 [Standard 96-Well Plate], 5-83...

- Page 28 Illustrations 9.10 Pinch Hazard Label on the Sample Station, 9-8 9.11 Pinch Hazard Label on the Sort Chamber, 9-8 11.1 Sheath Fluid Filter and De-bubble Filter, 11-21 11.2 Aseptic Cleaning Solution Filter, 11-34 11.3 Sample Line, 11-70 [Straight Down Mode], 11-96 [Default Mode], 11-96 [Sheath Tank Type...

- Page 29 Tables Tables WDM Optical Filter Mount Color Codes, 1-21 Waste Catcher, 1-28 Temperature Control Setting, 1-34 Sheath Status, 3-7 Waste Status, 3-7 Shutdown Fluid Status, 3-7 Target Power Ranges in the Laser Setting Screen, 5-41 Sort Statistics, 5-102 Additional Information for Plate Sorting, 5-104 Troubleshooting-[Error Codes], 9-10...

-

Page 30: Introduction

The information in your Instructions for Use manual is organized as follows: CHAPTER 1, System Overview Provides information regarding the individual components of the CytoFLEX SRT Sorter and the corresponding functions of these components. CHAPTER 2, Using the CytExpert SRT Software Provides an overview of each aspect of the software’s functions. -

Page 31: Conventions Used

Introduction Conventions Used CHAPTER 5, Sorting Provides instructions for operating the CytoFLEX SRT instrument, including data acquisition, sorting, analyzing, and exporting results, and manually adjusting the compensation during the acquisition and analysis. CHAPTER 6, Compensation Describes how to create a compensation experiment and automatically calculate compensation values after acquiring the single color data. -

Page 32: Graphics

All graphics, including screens and printouts, are for illustration purposes only and must not be used for any other purpose. For example, software screens that show the CytoFLEX SRT system in the background may not depict the latest production version of the system. -

Page 33: System Overview

For Research Use Only. Not for use in diagnostics procedures. The use of data generated by this instrument depends upon the regulatory status of the reagents used. The CytoFLEX SRT Cell Sorter is a research instrument that analyzes and sorts cellular suspensions and other similarly sized particle suspensions. - Page 34 The CytoFLEX SRT Sorter can acquire and analyze up to 15 fluorescence, and two light-scatter parameters for each particle. Additional computed parameters can be created based on collected data.

-

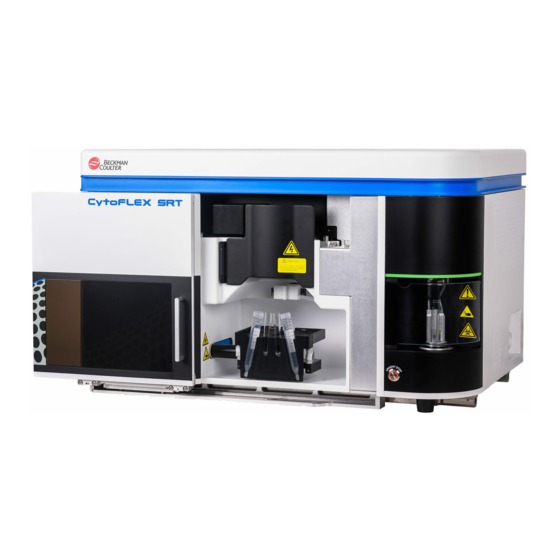

Page 35: Main Components

System Overview Main Components Figure 1.1 Sort Overview Diagram Main Components CAUTION Risk of instrument damage and/or instrument stability. Do not place any unnecessary objects on top of the instrument, as this could cause warping of the top cover or affect the stability of the optical path. However, airfoil is an exception if the instrument is used inside a Biosafety Cabinet. -

Page 36: Main Components

System Overview Main Components Figure 1.2 Main Components 1. Fluidics cart. Accommodates sheath fluid and shutdown fluid as required for operation of the instrument, and collects the waste fluid from the Sorter. 2. Sorter. Provides signal generation and sorting. 3. Workstation. Acquires and analyzes data using the CytExpert SRT software, and displays data generated by the Sorter. -

Page 37: Fluidics System

System Overview Fluidics System Fluidics System The fluidics system helps to transmit the sheath fluid at a stable rate into the flow cell, forming a laminar flow to ensure that the tested particles go through the detection area sequentially. The fluidics system consists of the Sample Station, the fluidics module, and the fluidics cart. -

Page 38: Fluidics Cart

The system accommodates both the rubber pads and the wheels for the fluidics cart. However, the stability of the fluidics cart is critical to the soring performance. Beckman Coulter recommends using the rubber pads for the fluidics cart on a solid and stable surface. - Page 39 System Overview Fluidics System Figure 1.5 Fluidics Cart (Back) 1. Signal cable of sheath tank scale 2. Shutdown fluid tubing 3. Waste fluid tubing 4. Sheath fluid tubing 5. Fluidics cart signal cable 6. Sheath pressure check point (for service) 7.

-

Page 40: Fluidics Cart

9. Sheath fluid filter. Filters particles larger than 0.2 μm. NOTE Beckman Coulter recommends replacing the sheath fluid filter every six months or sooner to ensure system performance. Using unfiltered sheath fluid can shorten the service life of the flow cell and/or nozzle, and increase noise and debris detection. -

Page 41: Sheath Tank

System Overview Fluidics System Figure 1.7 Connector Color Convention 1. Green: shutdown fluid 2. Orange or red: waste fluid 3. White: air tubing 4. Blue: sheath fluid Sheath Tank The sheath tank is an autoclavable, electroplated and stainless-steel tank, with 4-L capacity. Refer Figure 1.8. -

Page 42: Shutdown Fluid Container

System Overview Fluidics System Figure 1.8 Sheath Tank 1. Sheath outlet. Connects the sheath tubing to the sheath filter. 2. Air inlet. Provides pressure to convey the sheath to the flow cell or wash station. 3. Safety valve. Releases the pressure from the tank in case of emergency. 4. -

Page 43: Waste Container

For the shutdown fluid status information, refer to Table 3.3. NOTE Beckman Coulter recommends using CytoFLEX SRT Shutdown fluid to ensure system performance. For instructions on filling the Shutdown Fluid container, refer to Filling the Shutdown Fluid Container CHAPTER 11, Replacement/Adjustment Procedures. -

Page 44: Fluidics Module

System Overview Fluidics System Figure 1.10 Waste Container 1. Waste air filter. Filters the contaminated aerosol. 2. Waste level sensor. Monitors the volume of waste in the waste container. 3. Waste inlets. Carries the waste fluid from the Sorter to the waste container. Fluidics Module The Fluidics module is on the right side of the Sorter. -

Page 45: Sample Station

System Overview Fluidics System Figure 1.11 Interconnections on the Right Side of Sorter 1. Waste out. Connects the waste tubing from the Sorter to the fluidics cart. 2. Air outlet. Connects the sheath air tubing from the Sorter to the fluidics cart. 3. -

Page 46: Sample Station

System Overview Fluidics System WARNING Risk of personal injury. Keep your hands off the sample station when the sample chamber is moving to avoid pinching your hand. The Sample Station is where to load a tube and introduce a sample to the instrument. During acquisition, the sample chamber is enclosed and pressurized to force the sample toward the flow cell. - Page 47 After using the Urgent Stop button, follow the Daily Startup procedures to resume use. Refer to CHAPTER 3, Daily Startup. Beckman Coulter recommends running Shutdown Program prior to perform the acquisition or sorting. Provides fluid to clean the sample probe, and conveys the waste Backflush tubing.

-

Page 48: Optical Components

Risk of instrument damage. Do not place sample tubes in the optical filter holder. Liquid spills can damage instrument components. Use a tube rack to hold any sample tubes. 5. Optical filter holder. Securely holds additional CytoFLEX SRT optical filters. 1-16... -

Page 49: Laser Beam Shaping

System Overview Optical Components Laser Beam Shaping Before the laser beam reaches the sample stream, lenses focus the beam (refer to Figure 1.14). Focusing keeps the beam perpendicular to the sample stream flow while making the beam small enough to illuminate only one cell at a time. Figure 1.14 Laser Beam Shaping 1. -

Page 50: Forward Scatter Collection

System Overview Optical Components Forward Scatter Collection The Forward Angle Light Scatter (FALS) detector collects scattered light from a particle that intersects with a laser and delivers information roughly proportional to the size of the particle. The forward angle light is filtered with a 488 nm band pass before it reaches the FS sensor which generates voltage pulse signals. -

Page 51: Wavelength Division Multiplexer (Wdm)

System Overview Optical Components Figure 1.15 Light Path through the WDM with a Single Port 1. Fiber array photo detectors (FAPD) 2. Filter 3. 45-degree reflector 4. Doublet lens 5. Light path 6. Mirror Wavelength Division Multiplexer (WDM) Each WDM corresponds to a different laser, or in some cases two lasers. The color of the ring on each cap corresponds to the color of the respective laser. -

Page 52: Optical Filter Mount With Optical Filter

System Overview Optical Components Each optical filter mount has an optical filter glass piece. Refer to Figure 1.17. Figure 1.17 Optical Filter Mount with Optical Filter 1. Optical filter glass piece Each optical filter mount is labeled with the corresponding laser and band-pass information. Refer Figure 1.18. -

Page 53: Wdm Optical Filter Mount Color Codes

System Overview Optical Components Table 1.1 WDM Optical Filter Mount Color Codes CytoFLEX SRT Commonly used Laser Fluorescent Channel Channel Names Fluorescent Dyes V450 Pacific Blue™ dye, V450, 405 nm 450/45 BP eFluor™ 450, BV421 V525 Krome Orange, AmCyan, V500, BV510... -

Page 54: Optical Fiber

System Overview Optical Components Optical Fiber CAUTION Risk of data integrity damage. • During use, verify that the optical fibers are securely connected to the WDM. A loose connection can alter the optical path and affect fluorescence detection. • Do not disconnect the fiber as this could contaminate the tip and weaken the signal. -

Page 55: Cell Sorting

System Overview Cell Sorting Cell Sorting Sort Chamber The Sort Chamber is located in the center enclosure. The Sort Chamber is well lit, and designed for easy access and cleaning. The sort chamber sliding door, is part of a passive aerosol containment assembly that isolates the contents of a sort from the rest of the instrument, the operator, and the laboratory. -

Page 56: Overview Of Sort Chamber

System Overview Cell Sorting Figure 1.22 Overview of Sort Chamber 1. Sort protection door (open) 2. High voltage safety interlock 3. Waste catcher 4. CyClone movement system 5. Sort chamber illumination 6. Side stream illumination source 7. Nozzle module 1-24 C37808AC... -

Page 57: Stream Camera And Droplet Monitor

System Overview Cell Sorting Figure 1.23 Sort Chamber [with Side Stream Illumination Source Removed] 1. Deflection plates 2. Side stream detection window 3. Side stream illumination Stream Camera and Droplet Monitor The camera located opposite to the laser axis is not accessible by the operator. The camera is used to view the real-time break-off point, and the droplet status in the stream. -

Page 58: Deflection Plates

System Overview Cell Sorting Figure 1.24 Droplet Status NOTE For more details, refer to Starting and Monitoring a Sort CHAPTER 5, Sorting. Deflection Plates CAUTION Risk of personal injury. Do not touch the deflection plates when the high-voltage power is applied. High-voltage deflection plates deflect droplets from the mainstream and direct droplets to specific appropriate receptacles. -

Page 59: Nozzle Module

System Overview Cell Sorting instructions on removing and cleaning the Deflection Plate, refer to Cleaning the Side Stream Illumination Source and the Deflection Plates CHAPTER 10, Cleaning Procedures. Nozzle Module The nozzle module (hereinafter referred to as Nozzle) contains a detachable 100-μm nozzle (1), O-ring (2) and a nozzle holder (3). -

Page 60: Waste Catcher

System Overview Cell Sorting For instructions on cleaning the nozzle, refer to Cleaning the Nozzle CHAPTER 10, Cleaning Procedures. For instruction on removing/installing the nozzle module, refer to Removing/Installing the Nozzle Module CHAPTER 11, Replacement/Adjustment Procedures. Waste Catcher The waste catcher is located under the Side Stream Illumination Source. The waste catcher extends during the QC, and sort calibration. -

Page 61: Cyclone Movement System

System Overview Cell Sorting CyClone Movement System WARNING Risk of hand pinching. Keep your hands away from the sort chamber when the CyClone Movement System is moving. CAUTION Risk of damaging the CyClone Movement System. Do not place objects like tube holders, unused tubes, slides, gloves inside the Sort Chamber, which might interfere with the movement of CyClone System or damage the CyClone System. -

Page 62: Four 5 Ml Tubes

System Overview Cell Sorting Figure 1.27 Four 5 mL Tubes NOTE The tube adapters are required in the lateral tube slots for 5 mL tubes. Figure 1.28 Standard 96-Well Plate 1-30 C37808AC... -

Page 63: Sample Temperature Control

Water Bath through the body of the sort output holder and the sample tube holder. The Water Bath console is connected to the Sorter by two dedicated interconnection adapters (refer to Figure 1.30) which you can find in the CytoFLEX SRT system package. 1-31 C37808AC... -

Page 64: Interconnection Adapters

System Overview Cell Sorting Figure 1.30 Interconnection Adapters 1-32 C37808AC... -

Page 65: Connecting Water Bath To The Sorter

System Overview Cell Sorting Figure 1.31 Connecting Water Bath to the Sorter 1. Communication cable 2. Power cord 3. Power supply for Water Bath 4. Return flow tubing from Sorter to Water Bath 5. Circulating flow tubing from Water Bath to Sorter NOTE Ensure that the color of the quick connectors on the interconnection adapters match that of the quick connectors on the Sorter. -

Page 66: Aerosol Evacuation System

System Overview Cell Sorting CAUTION Risk of instrument damage and/or erroneous results. To ensure a long service life of the Sorter, the allowable range of the temperature setting for a Water Bath is 5°C - 49 °C if using DI water, and 0°C - 49 °C if using 25% propylene glycol-Water. For the recommended temperature control setting, refer to Table 1.3. -

Page 67: Aerosol Evacuation System

Cell Sorting Figure 1.32 Aerosol Evacuation System NOTE The sorting performance is sensitive to air disturbances. Beckman Coulter recommends using the 30% Suction Setting. The aerosol connector is located at the lower right corner of the Sorter. Refer to Figure 1.11. -

Page 68: Instrument Electronics

System Overview Instrument Electronics Instrument Electronics The instrument achieves an acquisition rate of 40,000 particles per second, and a sorting rate of 30,000 particles per second. Electronics and 64-bit software can store up to 34 million events in a single data file. System Connections CAUTION Risk of data loss and/or instrument damage. -

Page 69: Power And Signal Cable Connections

System Overview System Connections Figure 1.34 Power and Signal Cable Connections e fg h ij 1) 1! 1& 1. Sorter 10. Earthing protective cable 11. Fluidics cart signal cable 2. Back of fluidics cart 12. Camera cable (USB 3.0) 3. Workstation 13. -

Page 70: Power And Signal Cable Connections

System Overview System Connections Figure 1.35 Power and Signal Cable Connections [Waster Container inside Biosafety Cabinet] 1& 1#1$ efg h ij 1)1! 7809421AB 1. Sorter 12. Camera cable (USB 3.0) 13. USB 2.0 cable 2. Back of fluidics cart 14. Ethernet cable 3. -

Page 71: Fluid Harness Connections

System Overview System Connections Figure 1.36 Fluid Harness Connections 1. Shutdown fluid harness cable 2. Waste harness cable 3. Sheath harness cable NOTE For the fluidic connections on the fluidic cart, refer to Figure 1.6. Figure 1.37 Overview of Sorter Connections 1. -

Page 72: Instrument Specifications

System Overview Instrument Specifications Instrument Specifications Dimensions Dimensions Instrument dimensions Sorter 72.5 cm x 47.5 cm x 45 cm (Length x Width x Fluidics cart 34.5 cm x 60 cm x 48.5 cm Height) Sorter 62 kg Weight Fluidics cart (without fluid) 13.5 kg NOTE For the Biosafety Cabinet dimensions, refer to the manufacturer’s Product Specification. -

Page 73: Installation Category

If operating the instrument at an altitude greater than 2000 m, you could encounter startup failure, sort calibration failure, electric spark, fluid leakage, high carryover rate, or other unknown problems. Beckman Coulter assumes no responsibility for any problem resulting from operating instrument at an altitude greater than 2000 m (6561 ft). -

Page 74: Sorter

Optics Excitation Optics The CytoFLEX SRT system is configured with four spatially separated lasers. The optical system is alignment-free. The laser delays are automatically adjusted by the daily QC system, if required. No user intervention is required to ensure optimum system performance. -

Page 75: Performance Characteristics

Windows 10 (2019 LTSC) is the only operating system that has been validated to work with the CytoFLEX SRT workstation. b. If you need connect an external device or USB to the computer, Beckman Coulter recommends using the wireless keyboard and/or wireless mouse for the computer. -

Page 76: Material Safety Data Sheets (Sds/Msds)

Poisson’s statistics. Material Safety Data Sheets (SDS/MSDS) To obtain an SDS or MSDS for the CytoFLEX SRT reagents used on the CytoFLEX SRT systems: • On the Internet, go to www.beckman.com: 1. -

Page 77: Chapter 2: Using The Cytexpert Srt Software

CHAPTER 2 Using the CytExpert SRT Software Overview The CytExpert SRT software is a full-feature software package that controls the instrument's operation, which allows you to acquire, sort, and analyze flow cytometry data and then save the data in FCS format. This chapter will explain the software’s functions and features. This chapter contains information on: Launching the Software •... -

Page 78: Start Page

Using the CytExpert SRT Software Main Software Screen Start Page The start page automatically opens after logging into the software. The following operations can be selected from the start page: • . Creates a new experiment. The process creates a file with the .xits extension New Experiment and a folder with the same file name where the raw data (.fcs files) are kept. -

Page 79: Acquisition Screen

Using the CytExpert SRT Software Main Software Screen Opens a previously created compensation experiment. • Open Compensation. • . Exits the CytExpert SRT software. Exit The Experiment, Template, and Compensation tabs below give you the option of opening one of the 10 most recently opened experiments. -

Page 80: Acquisition Screen Navigation

Using the CytExpert SRT Software Main Software Screen Acquisition Screen Navigation The Acquisition screens have two navigation icons, the Acquisition screen, and the Analysis screen. 1. Acquisition screen icon. Accesses the Acquisition screen. 2. Analysis screen icon. Accesses the Analysis screen. C37808AC... -

Page 81: Collection

Using the CytExpert SRT Software Main Software Screen Collection Idle state Standby state Initialized state System: idle System: standby System: ready for use • Sample chamber: open • Sample chamber: open • Sample chamber: open • CyClone: home position • Cyclone: loading position •... - Page 82 Using the CytExpert SRT Software Main Software Screen 1. Acquisition control. Controls sample loading/unloading, sorting, and access acquisition setting. 2. Acquisition status. Displays information such as the acquisition rate (Events/Sec), Processed Events (%), Events, and Time. • Events/Sec: events acquired/acquisition time. NOTE The sorting pause during the data acquisition is excluded from the acquisition time.

-

Page 83: Acquisition/Sorting Control

Using the CytExpert SRT Software Main Software Screen Acquisition/Sorting Control Acquisition Sorting Ready for acquisition: Ready for sorting: Acquisition in process: Sorting in process: Sorting paused: C37808AC... -

Page 84: Tube Management

10. Standby. Turns off the sheath and puts the system in the Standby state. NOTE Beckman Coulter recommends re-running the sort calibration to ensure the auto drop delay is accurate if the system enters standby state during a sorting. For Sort... - Page 85 Using the CytExpert SRT Software Main Software Screen 1. Tube management controls. Used to add or delete a tube, open the tube property, open the experiment folder, open the compensation matrix, define the tube/plate sorting settings, and open the sort report. 2.

-

Page 86: Plot Area

Using the CytExpert SRT Software Main Software Screen Plot Area 1. Plot controls. Creates single or multiple plots, such as dot plots, histograms, density plots, pseudo color plots, and contour plots. 2. Index sorting. Enables index sorting. Refer to Index Sorting CHAPTER 5, Sorting. -

Page 87: Status Bar

Using the CytExpert SRT Software Main Software Screen Status Bar 1. Communication connection status. Displays whether the Sorter and the Workstation are connected. 2. Instrument state information. Displays the working state of the instrument. 3. System log information. Accesses the system log window. 4. -

Page 88: Compensation Experiment Screen

Using the CytExpert SRT Software Main Software Screen Plots Scale Index Gain sorting Statistics Compensation Hierarchy Threshold Gates Undo/Redo Zoom Compensation Experiment Screen The Compensation Experiment screen appears when you open or create a new compensation experiment. 1. Tube management. Displays sample tubes required for the compensation experiment. 2. - Page 89 Using the CytExpert SRT Software Main Software Screen Compensation Single Side Calculation Compensation Adjust Gain Matrix Compensation Undo/Redo Setup Add/Delete Alignment Negative Gate Zoom Rearrange Print 2-13 C37808AC...

-

Page 90: Qc Experiment Screen

Using the CytExpert SRT Software Main Software Screen QC Experiment Screen The Quality Control (QC) Experiment screen appears when select from the Start QC/Standardization QC/Standardization tab. QC Report Screen Before starting the QC routine, a Settings screen appears. Figure 2.2 QC Report Screen 1. -

Page 91: Qc Experiment Screen

Using the CytExpert SRT Software Main Software Screen QC Experiment Screen When acquiring QC samples, the software opens the QC screen. 1. QC experiment progress indicator. Displays the QC stage. 2. Plot area. Displays the QC plots. QC Screen Navigation The Analysis screens have two navigation icons, one for the QC screen and the other for the Levey-Jennings (LJ) charts. -

Page 92: Software Menu

Using the CytExpert SRT Software Main Software Screen Software Menu IMPORTANT All menu items apply to the CytExpert SRT Default software option unless otherwise specified. Depending on the Sorter state, certain functions may not be available. The CytExpert SRT software contains the following selectable menu items: Figure 2.3 Software Menu Tree *Only available in the CytExpert User Management software option. -

Page 93: Acquisition And Analysis Screen Menu

Using the CytExpert SRT Software Main Software Screen Acquisition and Analysis Screen Menu CytExpert Default Software Option CytExpert User Management Software Option File Menu For creating new experiments, opening existing experiments, saving new experiments and data, and importing/exporting FCS data files. 2-17 C37808AC... - Page 94 Using the CytExpert SRT Software Main Software Screen Cytometer Menu For configuring Cytometer settings and controlling Sorter functions. Depending on the Sorter state, certain functions may not be available. [CytExpert SRT Software Option-Standby State] QC/Standardization Menu Select from the QC/Standardization menu to start the QC routine. Start QC/Standardization 2-18 C37808AC...

- Page 95 Using the CytExpert SRT Software Main Software Screen Sorting Menu For controlling sorting options. Settings Menu Used to select and/or change software options and settings. [Acquisition Mode] [QC/Standardization Mode] Advanced Menu Used to access advanced settings for experienced users, including laser time delay settings, calibrations.

- Page 96 Using the CytExpert SRT Software Main Software Screen Account Menu Used for user account management settings. NOTE The Account menu is only available in the CytExpert User Management software option. Log Menu Used to access logs including the User Management Operation Log, System Operation Log, and the User Management Operation Log.

-

Page 97: User Management

Using the CytExpert SRT Software User Management User Management IMPORTANT Only an Administrator or authorized users can manage users. You must have the CytExpert User Management software option installed to use this feature. Refer to CytExpert Software Installation Options APPENDIX D, Instrument Installation. -

Page 98: User Manager (Grid View)

Using the CytExpert SRT Software User Management Figure 2.6 User Manager (Grid View) 1. Search text box: Filters users by user name and 6. Unlock: Used to unlock an existing account that full name. has been locked. 2. View drop-down: Toggles between Card View NOTE An account locks after 3 failed password (see... -

Page 99: Creating, Deleting, And Modifying Users In User Manager

Using the CytExpert SRT Software User Management Creating, Deleting, and Modifying Users in User Manager The initial System Administrator is a system default user and it cannot be deleted, modified, or disabled. Creating a New User in User Manager Select in the User Manager window. - Page 100 Using the CytExpert SRT Software User Management e. Optional: Select the portrait to import an image. Select . The new user displays in User Manager. Select Deleting Users in User Manager IMPORTANT If an account has been used and log information has been generated related to it, the account cannot be deleted, but it can be disabled.

-

Page 101: Unlocking A User Account

Using the CytExpert SRT Software User Management Modify the user information as necessary. NOTE Uncheck the enabled box to disable a user. Select Select Unlocking a User Account Select a Locked user in the User Manager window and select Unlock NOTE You cannot unlock an active user. -

Page 102: Resetting A User Password

Using the CytExpert SRT Software User Management Resetting a User Password IMPORTANT Only an administrator or authorized users can reset a password for the users who forget their passwords. However, a common administrator cannot reset a password for the initial System Administrator because the initial System Administrator is a super administrator. -

Page 103: Changing A User Password

The user is required to change the new random password immediately upon the initial login. Changing a User Password Beckman Coulter recommends changing your password on a regular basis. Select . The Change Password window appears. -

Page 104: Forgot Username Or Password

The System Administrator password cannot be reset without the system administrator credential file. Beckman Coulter is not responsible for and will not be able to recover your system administrator account if the system administrator password is forgotten and the credential file is lost. - Page 105 Using the CytExpert SRT Software User Management IMPORTANT Find the system administrator credential file from the backup folder when installing the CytExpert software. You can also export the credential file by selecting Export Credential File from the Account menu if you are logged in. Navigate to the system administrator credential file and select Open Select...

-

Page 106: Role Management

Using the CytExpert SRT Software Role Management Enter the new password, and confirm the new password. NOTE The new password must contain at least ten digits and all four of the following character types by default: • letter in upper case •... -

Page 107: Role Manager

Using the CytExpert SRT Software Role Management Select . The Role Manager window appears. Refer to Figure 2.7. Account Role Manager > Figure 2.7 Role Manager 1. New: Used to create a new role profile. 2. Modify: Used to modify an existing role profile. 3. -

Page 108: Creating, Deleting, And Modifying User Roles In Role Manager

Using the CytExpert SRT Software Role Management Creating, Deleting, and Modifying User Roles in Role Manager Creating New User Roles in Role Manager Select . The New window appears. Fill in the new role information. a. Enter the role name. NOTE Role Name has the following naming requirements: •... - Page 109 Using the CytExpert SRT Software Role Management b. Enter the role description. NOTE Role Description has the following naming requirements: • The maximum number of allowable characters is 100. • Special symbols are allowed. • The text box cannot be left blank. c.

- Page 110 Using the CytExpert SRT Software Role Management Modifying User Roles in the Role Window IMPORTANT The Administrator and Operator Roles are system defaults and may not be modified. Select the role to be modified and then select . The Modify window appears. Modify the role information as necessary.

-

Page 111: Account Policies

Using the CytExpert SRT Software Account Policies Account Policies IMPORTANT Only an Administrator can manage users. Account policies are used to define the default properties for the password policy, account lockout policy, and application inactivity policy. Select > . The Account Policies window appears. Account Account Policies Figure 2.8 Account Policies - Password Policy... -

Page 112: Account Policies - Account Lockout Policy

Using the CytExpert SRT Software Account Policies Figure 2.9 Account Policies - Account Lockout Policy NOTE The allowable range for each entry is as follows: • Invalid Login Attempts: 3-5 times • Lockout Time: 30-1,440 minutes 2-36 C37808AC... -

Page 113: Operation Log

Using the CytExpert SRT Software Operation Log Figure 2.10 Account Policies - Application Inactivity Policy NOTE The allowable range for each entry is as follows: • Inactivity Duration: 1-15 minutes Operation Log Use the Log feature to view, export, or manage the operation logs including the experiment operation log, the system operation log, and the user management operation log. -

Page 114: Viewing And Exporting Experiment Operation Logs

Using the CytExpert SRT Software Operation Log Viewing and Exporting Experiment Operation Logs Select . The Experiment Operation Log window appears. Log > Experiment Operation Log Select . The Select Experiment Profile window appears. 2-38 C37808AC... - Page 115 Using the CytExpert SRT Software Operation Log Select the experiment to be viewed. Enter the filter conditions: User and Time Range, and then select . The logs appear. To export the log, select NOTE Experiment Operation logs are exported as a .pdf or .csv file. 2-39 C37808AC...

-

Page 116: Viewing And Exporting System Operation Logs

Using the CytExpert SRT Software Operation Log Viewing and Exporting System Operation Logs Select . The System Operation Log window appears. Log > System Operation Log 2-40 C37808AC... - Page 117 Using the CytExpert SRT Software Operation Log Enter the filter conditions: User and Time Range, and then select . The logs appear. To export the log, select NOTE User logs are exported as a .pdf or .csv file. 2-41 C37808AC...

-

Page 118: Viewing And Exporting User Management Operation Logs

Using the CytExpert SRT Software Operation Log Viewing and Exporting User Management Operation Logs Select . The User Management Operation Log window Log > User Management Operation Log appears. Enter the filter conditions: User and Time Range, and then select . -

Page 119: Graphic And Gating Styles

Using the CytExpert SRT Software Graphic and Gating Styles To export the log, select NOTE User logs are exported as a .pdf file. Graphic and Gating Styles Plots The CytExpert SRT software offers a variety of plot formats including: • Single-parameter plots and histogram overlays •... -

Page 120: Gates

Using the CytExpert SRT Software Graphic and Gating Styles Pseudo color plot Contour plot Dot plot overlay Gates Various gating choices are available. The software includes the following gate types: • For dual-parameter plots: lasso, polygon, rectangle, four-quadrant, hinged gates, and auto polygon •... -

Page 121: Collection Device Library

Using the CytExpert SRT Software Collection Device Library Vertical gate a. This gate can be created using the autogate functionality. Refer to Creating and Adjusting Auto Gates CHAPTER 5, Sorting. Collection Device Library The Collection Device Library is used to manage and calibrate the position of plates or slides. To calibrate a plate or a slide, refer to Calibrating the Sort Collection Device CHAPTER 5,... -

Page 122: Default Collection Device Library

Using the CytExpert SRT Software Collection Device Library Figure 2.11 Default Collection Device Library 1. Add. Creates a new plate or slide. 2. Edit. Edits a plate or slide. 3. Duplicate. Duplicates a plate or slide. 4. Delete. Deletes an existing plate or slide. 5. -

Page 123: Sort Mode Library

Using the CytExpert SRT Software Sort Mode Library Sort Mode Library The Sort Mode Library is used to manage the sort modes, and set the default sort mode for sorting. To customize a sort mode, you have to add a sort mode first. Refer to Figure 2.12. -

Page 124: Sort Precision Level

• Purity1-2 Mode more inclusive than Purity Mode. for sorting NOTE Beckman Coulter recommends the Purity 1-2 Mode macro-particles • : Used when recovery is the most important aspect of the sort. With Enrich, all Enrich Mode positive events (an event that falls within the sort logic) are sorted. -

Page 125: Drop Envelope

Using the CytExpert SRT Software Sort Mode Library (red highlight) depending on the sort precision level chosen. The sort precision levels are showed from left to right: Single Purify Enrich Figure 2.13 Sort Precision Modes Applied to the Same Sort Stream Drop Envelope The sort drop envelope defines how many drops are sorted based on the position of the positive event in the drop. -

Page 126: Sort Guard Band

Using the CytExpert SRT Software Sort Mode Library volume/dilution must be minimized. When using this envelope and the drop delay is not perfect, recovery will be reduced by 1% for each 1% error in drop delay. • One drop is sorted if all positive events are in the center of the droplet. If a positive 1-2 Drop: event is outside the center, then the drop adjacent to the edge containing that event is also sorted. -

Page 127: Sort Stream Precedence

Using the CytExpert SRT Software Sort Mode Library The sort decision with the 25% Sort Guard Band applied are illustrated in Figure 2.16. The stream is represented by the gray dots flowing down the figure with either the target population (red) or the contaminant population (blue) located within the droplet. -

Page 128: Adding A Sort Mode

Using the CytExpert SRT Software Sort Mode Library population. The sort mode precedence is as follows: > > . The Stream Precedence Single Purify Enrich is from outside to inside streams (L2>R2>L1>R1). Adding a Sort Mode Select from the Advanced menu. The Sort Mode Library window appears. Sort Mode Library NOTE The Sort Mode Library is editable only when the experiment has been closed. - Page 129 Using the CytExpert SRT Software Sort Mode Library A new sort mode is added in the Sort Mode Library. NOTE Enter a name for this new sort mode. Select the desired Sort Precision Level from the dropdown menu. 2-53 C37808AC...

- Page 130 Using the CytExpert SRT Software Sort Mode Library Select the desired Drop Envelope from the dropdown menu. Select The SortMode1 is added in the Sort Mode Library. To apply this new sort mode, refer to Setting Up Tube Sorting Setting Up Plate/Slide Sorting CHAPTER 5, Sorting.

-

Page 131: Deleting A Sort Mode

Using the CytExpert SRT Software Sort Mode Library Deleting a Sort Mode IMPORTANT The system default sort modes that are in bold cannot be deleted. Select from the Advanced menu. The Sort Mode Library window appears. Sort Mode Library 2-55 C37808AC... - Page 132 Using the CytExpert SRT Software Sort Mode Library Select a sort mode to be deleted, and select Delete 2-56 C37808AC...

-

Page 133: Software Settings

Using the CytExpert SRT Software Software Settings Software Settings Select in the Settings menu to configure the software settings. Options In the experiment settings, you can set the experiment’s default save path. 2-57 C37808AC... - Page 134 Using the CytExpert SRT Software Software Settings In the tube settings, you can select the columns that display in the tube section of the screen. 2-58 C37808AC...

- Page 135 Using the CytExpert SRT Software Software Settings In the plot settings, you can define the background of the graphics display area, configure the histograms, and set the default signal parameters to either the channel’s area or the channel’s height. The default is area. You can also set the default axis display range. 2-59 C37808AC...

- Page 136 Using the CytExpert SRT Software Software Settings In the Gate settings, you can choose to display population percentage on all plots except overlay. NOTE Show as rare events is to increase the visibility of the gated population anywhere they appear on the plots.

- Page 137 Using the CytExpert SRT Software Software Settings In the Page Setup settings, you can change the page size, orientation, margin size, and display options. Select to display page boundaries within the Acquisition or Analysis Show page breaks views for simplifying plot arrangement for printing. 2-61 C37808AC...

- Page 138 Using the CytExpert SRT Software Software Settings In the Bubble Detect settings, you can enable/disable the Bubble Detector function. IMPORTANT Only use the Bypass Bubble Detector for the colored or turbid samples. The bubble detector is sensitive to light scattering and attenuation. When running colored or turbid samples, or sample with high concentration, the error 090025 is likely to occur.

-

Page 139: Language Settings

Using the CytExpert SRT Software Software Settings In the Record settings, you can set the default record count. Language Settings Select to open the Language Settings window. In the Language Settings > Language Settings Settings window, you can select which language to use for the software menus and graphical statistics. -

Page 140: Daily Startup

• Selecting Experiments from the Start Page Pre-Startup Inspection Before using the CytoFLEX SRT instrument, perform the following system checks. System Connections Inspection Verify that the power cable of the computer is securely connected to the power source. Check that the monitor, mouse, keyboard, and the Sorter USB cable are properly connected to the computer. -

Page 141: Checking Fluid Levels

Daily Startup Pre-Startup Inspection Verify that all sheath fluid tubing, waste fluid tubing, shutdown fluid tubing, and the sensor cable from the fluidics cart are properly connected to the Sorter. Refer to Figure 1.11. Verify that the power cable located below the power switch on the lower left side of the Sorter, and verify it is securely connected to both the Sorter and the power source. -

Page 142: Turning On The Instrument

If necessary, fill the sheath fluid tank while not exceeding the upper position ring. Refer to Filling the Sheath Tank CHAPTER 11, Replacement/Adjustment Procedures. If necessary, fill the shutdown fluid container with CytoFLEX SRT Shutdown fluid while not exceeding the bottom of the neck. Refer to Filling the Shutdown Fluid Container CHAPTER 11, Replacement/Adjustment Procedures. -

Page 143: Logging Into The Software

Daily Startup Logging Into the Software Wait for the Sorter to finish powering on, then turn on the Workstation. Logging Into the Software Log into the Windows operating system and double-click the CytExpert SRT desktop icon to open the software. If you are running the CytExpert Default software installation, login is not required. - Page 144 Daily Startup Logging Into the Software Confirm that the software and the Sorter are properly connected. a. Open the software. The Startup screen appears. C37808AC...

- Page 145 • Select the status information in the lower left to open the system log. Send a copy of the system log to your Beckman Coulter Representative for support if a service call is requested. c. Verify that the Sheath, Waste and Shutdown flow indicators in the lower right corner of the software screen are green indicating that the fluidics system is normal.

-

Page 146: Sheath Status

Daily Startup Logging Into the Software Table 3.1 Sheath Status Normal Insufficient Empty (with audible warning) Overfilling (with audible warning) The value in the symbol indicates the remaining time that the sheath can sustain. NOTE When the sheath flow indicator displays “empty”, refill the sheath tank as soon. Otherwise, the system stops the fluid and goes into standby automatically. -

Page 147: System Startup Program

Ensure that the sheath tank you used matches with the sheath tank type you selected. Otherwise, you could encounter startup failure, aseptic cleaning failure, long-term shutdown failure, or sheath flow indication error. Restarting after the Daily Shutdown (CytoFLEX SRT Shutdown Fluid in the Instrument) Select in the Cytometer menu. - Page 148 Daily Startup System Startup Program Open the sort chamber sliding door and the sort protection door. Clean the bottom of the flow cell, the sliding rails for the nozzle lift, and the V-plate surface. For instructions, refer to Daily Decontamination During Shutdown CHAPTER 10, Cleaning Procedures.

- Page 149 Daily Startup System Startup Program Insert the nozzle module carefully into Sorter with the UP symbol facing up. The nozzle module is locked into its position when you hear a click. Close the sort protection door, the sort chamber sliding door, and the sample station door. 3-10 C37808AC...

- Page 150 Daily Startup System Startup Program Select Next 3-11 C37808AC...

- Page 151 Daily Startup System Startup Program The system starts running Startup Program. NOTE Select Hide to hide the System Startup window. 3-12 C37808AC...

- Page 152 Daily Startup System Startup Program The Confirm window displays when the System Startup Program is finished, NOTE Select Yes to start QC now. For instructions on running QC, refer to CHAPTER 4, Instrument Quality Control and Standardization. Or select No to defer the QC. Select to quit the System Startup program.

- Page 153 Daily Startup System Startup Program Restarting after the Long-Term Shutdown (70% Ethanol in the Instrument) Select in the Cytometer menu. System Startup The following message appears. IMPORTANT Ensure the sheath is sterile. Empty the sheath tank and refill the sheath tank with at least 1.5 L sheath. Refer to Filling the Sheath Tank CHAPTER 11, Replacement/Adjustment...

- Page 154 Daily Startup System Startup Program Select . The system starts to rinse the sheath line with sheath. Next The following message appears when the system finishes the perfusion. Switch the aseptic cleaning filter with the sheath fluid filter. Refer to Replacing the Aseptic Cleaning Solution Filter CHAPTER 11, Replacement/Adjustment...

- Page 155 Daily Startup System Startup Program Select Next Open the sort chamber sliding door and the sort protection door. 3-16 C37808AC...

- Page 156 Daily Startup System Startup Program Insert the nozzle module carefully into Sorter with the UP symbol facing up. The nozzle module is locked into its position when you hear a click. Close the sort protection door, the sort chamber sliding door, and the sample station door. Select .

-

Page 157: Selecting Experiments From The Start Page

Daily Startup Selecting Experiments from the Start Page The Confirm window displays when the System Startup Program is finished, NOTE Select Yes to start QC now. For instructions on running QC, refer to CHAPTER 4, Instrument Quality Control and Standardization. Or select No to defer the QC. -

Page 158: Chapter 4: Instrument Quality Control And Standardization

Standardization Overview This chapter provides information on performing daily Quality Control (QC) on the CytoFLEX SRT Sorter and how to confirm that the instrument is working properly within the specified parameters. Quality Control allows you to determine whether your instrument can provide adequate signal strength and precision. -

Page 159: Quality Control

Instrument Quality Control and Standardization Quality Control Standardization Workflow: Obtain target Perform Apply standardization acquisition standardization Ô Ô Ô standardization settings settings sample This chapter contains information on: Quality Control • — Preparing the QC Sample Importing Lot-Specific Target Values —... -

Page 160: Preparing The Qc Sample

Instrument Quality Control and Standardization Quality Control Notifies you if laser delay is > 5 μs from the previous setting. Manual laser delay adjustments are required. Refer to Setting Laser Delay CHAPTER 11, Replacement/Adjustment Procedures. 6. Verifies and calibrates the gain settings. If any of these parameters are outside of the operating limits, the system automatically adjusts these parameters. -

Page 161: Cytoflex Ready To Use Daily Qc Fluorospheres Preparation Process

Instrument Quality Control and Standardization Quality Control Place the sample tube in a dark location at 2-8 C until ready to load the tube into the instrument for QC. NOTE Tubes containing diluted CytoFLEX Daily QC Fluorospheres should be sealed and stored in a dark location at 2-8 C for up to 5 days. - Page 162 Settings menu. The Target Library window appears. Target Library IMPORTANT The Beckman Coulter website may prompt you to select your Region and Country prior to the Beckman Coulter Technical Documents and Software page. Select . The Beckman Coulter Software Downloads page appears.

- Page 163 Instrument Quality Control and Standardization Quality Control In the Search By Product section of the screen, select the following: a. Select from the Market Segment drop-down menu. Research & Discovery b. Select from the Product Line drop-down menu. Flow Cytometry c.

- Page 164 Instrument Quality Control and Standardization Quality Control [CytoFLEX QC Fluorospheres Target] [CytoFLEX Ready to Use Daily QC Fluorospheres Target] C37808AC...

- Page 165 Instrument Quality Control and Standardization Quality Control Select under the Software Name column. The CytoFLEX QC Fluorospheres Target Values CytoFLEX QC Fluorospheres Target Values page appears. Select under the correct lot number from the CytoFLEX QC Fluorospheres Target Download Values page. If the File Download pop up window appears, select and browse to the desired file path.

- Page 166 Instrument Quality Control and Standardization Quality Control Select from the Target Library window in the CytExpert SRT software. Import Navigate to the file saved in step and select Open Select to exit the Target Library window. Close C37808AC...

-

Page 167: Collecting Qc Data

Ensure that the instrument configuration is properly configured for the QC experiment. The QC experiment may not be completed or may end in erroneous results if incorrect settings are chosen. Beckman Coulter recommends using the factory configuration and ensuring that the proper optical filters are in place. - Page 168 Instrument Quality Control and Standardization Quality Control Select in the QC/Standardization menu to access the QC experiment. Start QC/Standardization Ensure that the QC bead lot number is selectable in the Lot No. drop-down menu. If the lot number is not selectable, refer to Importing Lot-Specific Target Values, then select the proper lot number.

- Page 169 Instrument Quality Control and Standardization Quality Control During QC, the software automatically seeks the CytoFLEX QC Fluorospheres and computes the results. The software returns to the QC Report screen after the QC run is complete. If the sampling rate is too low, the Sorter stops the QC run and displays a prompt alerting you that the QC run failed to reach the required event flow rate.

-

Page 170: Confirming Results

Instrument Quality Control and Standardization Quality Control Select to start Sort Calibration now. Refer to Sort Calibration (Auto Drop Delay) CHAPTER 5, Sorting. Select to defer the Sort Calibration. NOTE Sort calibration is required prior to the sorting. For analysis experiments, skip the Sort Calibration. Confirming Results Select in the QC/Standardization menu to return to the QC Setting screen... - Page 171 Instrument Quality Control and Standardization Quality Control Select a QC run from the QC Process list on the left and a QC report appears on the right. NOTE The results column indicates a passing QC result with a and a failed QC result with QC results must meet the following criteria to pass: •...

- Page 172 Instrument Quality Control and Standardization Quality Control The report area on the right displays detailed experiment results, including laser power, delay, testing conditions, and signal results. The same symbols are used to indicate each result. For items that fail, values falling outside the prescribed range are displayed in red font. In the Comment area, an explanation appears for each failed item.

- Page 173 Instrument Quality Control and Standardization Quality Control e. Run Performing the Sheath Filter De-bubble CHAPTER 11, Replacement/Adjustment Procedures, and retest. f. Run Backflush. Select > , and retest. Cytometer Backflush g. Verify whether the Nozzle is clean and installed properly. Refer to Cleaning the Nozzle CHAPTER 10, Cleaning Procedures, and retest.

- Page 174 Instrument Quality Control and Standardization Quality Control IMPORTANT When there are multiple lots, select which lot to create the LJ charts from. Select LJ Chart Settings on the top of the LJ Chart screen. The LJ Chart Settings screen appears. 4-17 C37808AC...

- Page 175 Instrument Quality Control and Standardization Quality Control Select the tab, and select the power and/or delay checkboxes for each laser as needed. Laser 4-18 C37808AC...

- Page 176 Instrument Quality Control and Standardization Quality Control Select the tab, and select each channel checkbox as needed. Channel Select Apply Select 4-19 C37808AC...

-

Page 177: Qc Result Manager

Instrument Quality Control and Standardization Quality Control Select the Levey-Jennings plot and select the start and end date from the drop-down boxes at the top of the LJ Chart screen to specify the desired date range. NOTE Select the desired configuration and date range from the drop-down menus located at the top of the LJ Chart screen to sort by the configuration used during the specified date range. -

Page 178: Standardization

Preparing the Standardization Sample Use Beckman Coulter CytoFLEX Daily QC fluorospheres or CytoFLEX Ready to Use Daily QC Fluorospheres or any other reference material that is relevant for your application. 4-21... -

Page 179: Required Materials

Instrument Quality Control and Standardization Standardization Required Materials The following materials are required to complete the QC process: • CytoFLEX Daily QC Fluorospheres or CytoFLEX Ready to Use Daily QC Fluorospheres, or other material applicable for your application • IsoFlow or ISOTON II sheath •... - Page 180 Instrument Quality Control and Standardization Standardization Change the tube name. Refer to Changing the Tube Name CHAPTER 5, Sorting. Select from the File menu to save the experiment. Save As Select to delete all the remaining tubes. 4-23 C37808AC...

- Page 181 Instrument Quality Control and Standardization Standardization Select . The Compensation Matrix window appears. Select to clear the compensation matrix. The message Are you sure you want to clear the Clear compensation matrix? appears. Select Load the sample tube. NOTE The sample tube holder only accommodates 12 x 75 mm sample tubes. Select 4-24 C37808AC...

- Page 182 Instrument Quality Control and Standardization Standardization View the plots and establish the gates. Refer to Creating Plots and Gates CHAPTER 5, Sorting. NOTE Use the FSC channel as the trigger channel and select Automatic threshold. NOTE The threshold may need to be adjusted to visualize the QC beads populations. If so, record this value for future reference.

- Page 183 Instrument Quality Control and Standardization Standardization Right-click the table and select . The Statistics Setting window appears. Statistics Settings 4-26 C37808AC...

- Page 184 Instrument Quality Control and Standardization Standardization Select the Population tab and select the relevant population for the tube. 4-27 C37808AC...

- Page 185 Instrument Quality Control and Standardization Standardization Select the tab then select the Median Fluorescence value for all parameters used. Statistics NOTE The median values are the target settings that will be used for standardization. Select Stop Right-click the statistics table and select Export to CSV file 4-28 C37808AC...

-

Page 186: Adding A New Standardization Item

Instrument Quality Control and Standardization Standardization If Excel is not available, manually record all the median values or take a screen shot. Save the experiment. NOTE Rerun the experiment if: • You change the standardization fluorosphere used. • The Lot number for the standardization fluorosphere is changed. Adding a New Standardization Item Select in the QC/Standardization menu to access the Standardization... - Page 187 Instrument Quality Control and Standardization Standardization Select from the Settings menu. Standardization Target Library 4-30 C37808AC...

- Page 188 Instrument Quality Control and Standardization Standardization Select . The Add Standardization Target Value window appears. Enter the Item, Lot No., and Expire date from the dropdowns located at the top of the Add Standardization Target Value window. NOTE A single Lot No. can include several Items, but you cannot add duplicate Items under the same Lot No..

- Page 189 Instrument Quality Control and Standardization Standardization Set the channels to be standardized. NOTE The contents of the channel, laser, and filter column come from the current detector configuration setting. Refer to Verifying, Selecting, Editing, and Creating Detector Configuration CHAPTER 5, Sorting.

-

Page 190: Performing The Standardization

Instrument Quality Control and Standardization Standardization Select to save the target value. The saved results display in the Standardization Target Library window. This item is ready to be run through the Standardization experiment. Refer to Performing the Standardization CHAPTER 4, Instrument Quality Control and Standardization. - Page 191 Instrument Quality Control and Standardization Standardization Select the radio button. Standardization Select the correct Lot No. from the Lot No. dropdown. NOTE Ensure the Lot No. corresponds to the standardization sample that generated the target median values. Select the Items to be standardized. 4-34 C37808AC...

- Page 192 Instrument Quality Control and Standardization Standardization Select the proper detector configuration. Refer to Verifying, Selecting, Editing, and Creating Detector Configuration CHAPTER 5, Sorting. Select The Process section of the screen displays the process details. Once the process is complete, the Standardization Report displays. NOTE The updated Standardization item is added to the Acquisition Catalog automatically and overwrites the previously existing standardized settings for this item.

-

Page 193: Applying The Standardized Acquisition Settings

Instrument Quality Control and Standardization Standardization Select from the Cytometer menu to verify the gain settings. The Acq. Acq. Setting Catalog Setting Catalog window appears. NOTE designates test items from Standardization. Run Daily Clean. Refer to Daily Clean Program CHAPTER 10, Cleaning Procedures. - Page 194 Instrument Quality Control and Standardization Standardization Select from the Cytometer menu. The Acq. Setting window appears. Acq.Setting Select . The Acq. Setting Catalog window appears. Import from Catalog 4-37 C37808AC...

- Page 195 Instrument Quality Control and Standardization Standardization Browse for the item to import and select Import. The standardized settings are applied to the sample tube. The Information window appears to notify of the corresponding channels with the changed gain as a result of the Standardization. 4-38 C37808AC...

-

Page 196: Standardization Target Library

Instrument Quality Control and Standardization Standardization Select Standardization Target Library Select from the Settings menu. The standardization Target Library Standardization Target Library... window appears. NOTE The Item name displays in the Acquisition Setting Catalog window as the saved acquisition setting name. - Page 197 Instrument Quality Control and Standardization Standardization Select to exit the Standardization Target Library window. Exporting a Standardization Item Browse for the Item to export. The available items display on the left panel of the Standardization Target Library window. Select on the Standardization Target Library window. Navigate to the desired file path and select Save NOTE...

- Page 198 Instrument Quality Control and Standardization Standardization Edit Item, Lot No., Expire date and the parameters for that item and select NOTE Perform a new standardization if the Lot No. of standardization sample is changed. Ensure the item parameters are correct then select and save the file.

-

Page 199: Chapter 5: Sorting

CHAPTER 5 Sorting Overview This chapter contains information on how to use your CytoFLEX SRT instrument to perform an acquisition or sorting experiment. Workflow: Sort Create Load Acquisition Save Ô Ô Ô Ô calibration experiment sample and sorting experiment This chapter contains information on: Sort Calibration (Auto Drop Delay) •... -

Page 200: Sort Calibration (Auto Drop Delay)

Sort Calibration (Auto Drop Delay) Sort Calibration (Auto Drop Delay) IMPORTANT Beckman Coulter recommends performing the sort calibration immediately after passing QC for better sorting performance. For analysis experiments, skip the Sort Calibration. IMPORTANT Sort calibration is mandatory after reinstalling a nozzle or replacing a new nozzle. Beckman Coulter recommends re-running the sort calibration to ensure the auto drop delay is accurate if the system enters standby state during a sorting. - Page 201 Sorting Sort Calibration (Auto Drop Delay) IMPORTANT The system is sensitive to airflow interference. Ensure that the sort protection door and the sort chamber sliding door are always closed during the sort calibration. Select to begin the Sort Calibration procedure. Start C37808AC...

- Page 202 Sorting Sort Calibration (Auto Drop Delay) a. The system automatically scans the frequency and amplitude to form an optimal droplet. The dynamic stream appears on the right. Completed processes appear on the left. C37808AC...

- Page 203 Sorting Sort Calibration (Auto Drop Delay) Or perform Manual Droplet Calibration. IMPORTANT Manual Droplet Calibration should be activated before the Droplet Calibration starts. Refer to Step 2. Enter the frequency and amplitude values manually and select to begin the Continue manual droplet calibration.

- Page 204 Sorting Sort Calibration (Auto Drop Delay) b. After completing the droplet calibration, the system sequentially calibrates charge phase, charge voltage, and defanning automatically. These calibrated parameters appear in the middle. : The rate at which the crystal in the nozzle vibrates. •...

- Page 205 Sorting Sort Calibration (Auto Drop Delay) c. After completing the droplet calibration, the system determines the drop delay automatically. When the Sort Calibration procedures finish and pass, select Close C37808AC...

-

Page 206: Default Amplitude Setting (Optional)

Sorting Sort Calibration (Auto Drop Delay) Default Amplitude Setting (Optional) This function allows you to set the default amplitude as the datum point to scan the amplitude during the automatic Sort Calibration. Use this function only when the Droplet Calibration fails and prompts the error code 070015 or error code 070030. -

Page 207: Setting Drop Delay Manually (Optional)

Sorting Setting Drop Delay Manually (Optional) Setting Drop Delay Manually (Optional) IMPORTANT The Auto Drop Delay generated from the Sort Calibration may differ from Manual Drop Delay due to different measurement criteria. Manual Drop Delay is the most accurate, while the Auto Drop Delay is accurate to ±10%. - Page 208 Sorting Setting Drop Delay Manually (Optional) Place a clean slide on the sort output holder. Select from the Sorting menu. Manual Drop Delay 5-10 C37808AC...

- Page 209 Sorting Setting Drop Delay Manually (Optional) The Manual Drop Delay window displays. Select the desired gate for the Sort Logic. 5-11 C37808AC...

- Page 210 Sorting Setting Drop Delay Manually (Optional) Enter a desired Drop Delay for the puddle in the middle. The Drop Delay setting appears in the puddle. NOTE If you did not run the Manual Drop Delay test, the system starts with an Auto Drop Delay as the initial Drop Delay setting.

- Page 211 Sorting Setting Drop Delay Manually (Optional) Set a Delay Increment to specify a set of drop delays for the adjacent puddles. NOTE The range of Delay increment is 0.01-100. Set Beads Per Puddle to specify the target count of beads for each puddle. NOTE The range of Beads Per Puddle is 1-1,000,000.

- Page 212 Sorting Setting Drop Delay Manually (Optional) Set the Number of Puddles. NOTE The range for Number of Puddles is 3-20. The default setting is 10 puddles. Select to stop loading. Stop 5-14 C37808AC...

- Page 213 Sorting Setting Drop Delay Manually (Optional) IMPORTANT The slide calibration archived in the Collection Device Library cannot be used for the Manual Drop Test. Slide calibration is mandatory for the initial use of a slide during the Manual Drop Delay Test. Skip the slide calibration if you have calibrated a slide for a Manual Drop Delay Test.

- Page 214 Sorting Setting Drop Delay Manually (Optional) Select Test You will see the circles turn blue as the puddles are created. 5-16 C37808AC...

- Page 215 Sorting Setting Drop Delay Manually (Optional) Select when all puddles have been created. The following window displays. Calculate Remove the slide and inspect the puddles under a fluorescent microscope. Determine the puddle that contains the most beads. Puddle number one is located on the edge of the slide closest to the CyClone arm when the test was run.

- Page 216 Sorting Setting Drop Delay Manually (Optional) Enter the values in the Drop Delay Test window. The system automatically calculates the Drop Delay. NOTE The Test Result indicates a passing result with a and a failed result with NOTE The passing criteria: the difference between the number of beads in the puddles adjacent to the target puddle is less than 3%.

- Page 217 Sorting Setting Drop Delay Manually (Optional) If the test result passes, select to save the calibrated manual drop delay. If the test result fails, select and repeat Steps 18-21 until the test result passes. Retest Select Close 5-19 C37808AC...

-

Page 218: Creating An Experiment

Sorting Creating an Experiment Optional: Save this experiment as a template if needed. Creating an Experiment Creating an Experiment CAUTION Risk of file corruption. When modifying experiment (*.xit) file names in Windows Explorer, ensure you modify the corresponding experiment folder name to match the new file name. -

Page 219: Changing The Tube Name

Experiments are saved as an .xits file. Template are saved as an .xitm file. NOTE The CytoFLEX SRT software can read the experiments with the suffix xits. Selecting Convert CytExpert Experiment from the File menu to convert the .xit file to the .xits file if you want to use the CytoFLEX SRT software to analyze the experiments with the suffix xit. -

Page 220: Setting The Channel And Label

Sorting Creating an Experiment Setting the Channel and Label Select in the Settings menu. The Set Channel window appears. Set Channel 5-22 C37808AC... - Page 221 Sorting Creating an Experiment In the Set Channel window, modify which channels are used and how they are displayed. a. Select the channel signal check box, then you can add the reagent name in the Label column. The information you add appears in the corresponding axis of the relevant plot in the plot area.

- Page 222 Sorting Creating an Experiment b. Select . The Apply Channel Setting window appears. Apply to c. Select the tubes to apply the channel settings to and select d. If you only need to modify the label name, select in the Settings menu to make the Set Label required changes.

-

Page 223: Creating Plots And Gates

Sorting Creating an Experiment e. Select . The Apply Label Setting window appears. Apply to f. Select the tubes to apply the label settings to and select Creating Plots and Gates IMPORTANT The maximum number of elements allowed in an experiment is 200. Elements include plots, statistics tables, and gate hierarchy tables. - Page 224 Sorting Creating an Experiment b. Select an axis name to change which channel is displayed. An “A” after the channel name indicates signal pulse area, while an “H” indicates height. The default setting is "A". NOTE To modify the default settings, select Options in the Settings menu. The Options window appears.

- Page 225 Sorting Creating an Experiment c. Signal width can be used as a tool for doublet discrimination and to differentiate somatic cell adhesion. If necessary, select to open the Acq. Setting window. 5-27 C37808AC...

- Page 226 Sorting Creating an Experiment d. Select the tab, and select a channel with the required signal width. Width e. Plot properties can be configured to display axes in Log, Log-Linear, or Linear format. 5-28 C37808AC...

- Page 227 Sorting Creating an Experiment 1) Double-click the plot or right-click the plot and select from the drop-down Property menu. The Plot Property screen appears. 2) Select whether to display the axes in logarithmic or linear format for both the X-axis and Y-axis.

- Page 228 Sorting Creating an Experiment Dot plot with logarithmic X-axis Dot plot with log-linear X-axis f. You can adjust axis ranges using the pan axis display controls located at the top of the screen. • Select , to zoom-in and define which area of a plot to enlarge. The selected area can be magnified to fill the entire graph.

- Page 229 Sorting Creating an Experiment • In the Plot Property window, manually enter the minimum and maximum display values for the X- and Y-axes. You can also select to let the software Fit With Sample automatically adjust the lower limit according to the signal and perform the corresponding log-linear transformation.

- Page 230 Sorting Creating an Experiment To create gates, use the control buttons or right-click the plot and select the gate type required. Gates can be set according to different requirements to differentiate cell populations. NOTE To add a vertex to a polygon gate: Select the gate.

-

Page 231: All Gates - Example Experiment

Sorting Creating an Experiment Select the gates to display. a. Select the heading area of the plot, select the parent population/gate to display in the plot from the drop-down menu. The selected parent gate appears in the tab area of the plot. NOTE The auto gates cannot be used as the sort logic. - Page 232 Sorting Creating an Experiment b. If necessary, you can select the option from the drop-down menu to Combo Population create a combination gate, using the Boolean relationships “and”, “or”, and “not” to produce a new gate. You can also select the population color or change the gate name. •...

-

Page 233: Creating And Adjusting Auto Gates

Sorting Creating an Experiment Select to display the population hierarchy. The Population Hierarchy function allows you to view how gates rank in relation to one another. To change the display color, double-click the default color and select the desired color from the drop-down color palette. - Page 234 Sorting Creating an Experiment Select the population you want to gate in the histogram to automatically gate that population. To create an auto polygon gate, select from the tool bar or right-click on the 2D plot and select from the drop-down menu. Auto Polygon 5-36 C37808AC...

-

Page 235: Turning Auto Recalculate On/Off

Sorting Creating an Experiment Select the population you want to gate in the 2-D plot. The gate will automatically be drawn to fit the population. NOTE To add a vertex to an auto polygon gate: 1. Select the gate. 2. Hover your cursor over the perimeter of the gate until the cursor changes to the hand icon. 3. -

Page 236: Adjusting Autogate Movement And Extent

Sorting Creating an Experiment Adjusting Autogate Movement and Extent Movement — The distance an autogate can move to find the target population. To adjust movement, right-click an autogate and drag the Movement handle in the auto gate menu left and right. NOTE The default value setting for movement is 20 units. -

Page 237: Movement - Max Setting