Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MIMAKI JV3-75 SP II

- Page 1 OPERATION MANUAL MIMAKI ENGINEERING CO., LTD. TKB Gotenyama Building, 5-9-41, Kitashinagawa, Shinagawa-ku, Tokyo 141-0001, Japan Phone: +81-3-5420-8671 Fax: +81-3-5420-8687 URL: http: // www.mimaki. co. jp / E-mail: traiding@mimaki.co.jp D201090...

- Page 3 ING CO., LTD. has been informed of the possible risk of such damages in prior. For example, MIMAKI shall not be liable to any damage to media (works) due to the use of the product or any indirect damage that is caused by a product that is manufactured with damaged media.

- Page 4 Operation of this equipment in a residential area is likely to cause harmful interference in which cause the user will be required to correct the interference at his own expense. • In the case where MIMAKI-recommended cable is not used for connection of this device, limits provided by FCC rules can be exceeded.

-

Page 5: On This Operation Manual

Foreword Congratulations on your purchase of a MIMAKI "JV3-75SPII/130SPII" model of color ink jet printer. The JV3-75SPII/130SPII is a color ink-jet plotter applicable to high quality plotting with solvent ink. The plotter can be set up in one of the two ink settings. The four-color setting uses four ink cartridges (cyan, magenta, yellow, black, 2 each). -

Page 6: Features

Features The features of the device are described below. Together with the method of operation of the device explained in this manual, they help you understand how to use the device properly. Newly developed high-reliability high-coloring solvent ink The newly developed solvent ink allows the use of raw tarpaulin or other commercially available media, realizing high quality plotting with a low running cost. - Page 7 Drier fan The fan provides cold air to reduce the drying time after printing and prevent color staining during the media take-up process. Indication of the INK Remains Since the amount of ink that remains can be checked even during operation of the device, you can use the ink and media without waste.

-

Page 8: For Safe Operation

For safe operation Pictorial signs Pictorial signs are used in this Operation manual for safe operation of and in prevention of damages to the device. Pictorial signs and their meanings are given below. Read and fully understand before reading the text. •... - Page 9 WARNING • Be sure to setup the appropriate air-moving system in case of using the device in a closed room or a room with bad ventilation. • The ink used for this device contains organic solvent. Since the ink is flammable, never use fire when using the device.

-

Page 10: Never Do The Following

Never refill the ink cartridge with from the receptacle. Check first ink. to be sure that the device no longer produces smoke, and MIMAKI assumes no contact a distributor in your responsibility for malfunction district for repair. Never repair caused by using the device after your device by yourself since it is replenishment of ink. -

Page 11: Precautions In Installation

Precautions in installation CAUTION A place that is not horizontal A place exposed to direct sunlight A place in which temperature and humidity A place that vibrates vary by a great margin Use the device under the following environment. Operating environment: 20 to 35°C 35 to 65% (Rh) A place exposed to direct air blow from air... -

Page 12: Precautions In Use

When moving it to a different • Store media in a bag. Wiping off place, contact representative of dust accumulated on a media will Mimaki Engineering. adversely affect the media due to static electricity. • Frequently wipe the capping station... - Page 13 CAUTION • Be sure to thoroughly consume the Media ink in the ink cartridge, once it is • If media that is likely to tightly opened, within three months. curl, flatten first the paper If an extended period of time has before using it for printing.

-

Page 14: Table Of Contents

TABLE OF CONTENTS Foreword ..........................i On This Operation manual ......................i Features ..........................ii For safe operation ....................... iv Pictorial signs ..........................iv Example of pictorial signs ......................iv Never Do the Following ........................ vi Precautions in installation ......................vii Precautions in use ........................ - Page 15 Switching the direction of winding of the media ..............2.15 Setting the torque limiter ......................2.15 Setting cut sheet media on the device ..................2.16 Changing the drier fan angle ....................2.18 Heater-Temperature control .................... 2.19 In case of faultiness with Heater ..................... 2.20 Checking and solving nozzle clogging (TEST plotting) ..........

- Page 16 Cleaning the station interior [STATION]-[CARRIAGEout] ..........5.4 When the message [REPLACE WIPER] is displayed ............. 5.5 [STATION]-[WIPER EXCHANGE] ..................5.5 Regular wiping function [INT.WIPING] ................5.7 When media thickness is changed [PRINT ADJUST] ............. 5.9 If nozzles are clogged even after the cleaning function is executed ......5.11 [FILL UP INK] ..........................

-

Page 17: How To Read This Operation Manual

How to read this operation manual Display on the LCD and Indication of the Keys In this Operation manual, the characters displayed on the LCD of the operation panel and the keys used to operate the device are explained, together with the operation procedure. page 1.6. -

Page 18: Structure Of This Operation Manual

Structure of this Operation manual This manual consists of the following seven chapters to describe the handling of the device. Chapter 1 Before Use This chapter describes the name and function of each section of the device as well as ink and media. Chapter 2 Operations This chapter describes a series of operations and settings, ranging from power-on to end of plotting. - Page 19 CHAPTER 1 Before Use This chapter describes the name and function of each section of the device as well as ink and media. Table of contents Where to install the device ................1.2 Moving the device ................... 1.3 Configuration and function ................1.4 The Front ......................

-

Page 20: Where To Install The Device

Where to install the device Secure a suitable installation space before assembling the device. The place of installation must have space required not only for the device itself but also for plotting operation. Model Width Depth Height Gross weight (with exhaust unit) JV3-75SPII 1850 mm 750 mm... -

Page 21: Moving The Device

Moving the device • When moving the device to a different place, contact local representative of Mimaki Engineering. If you move it, failure of damage may occur. Be sure to request a specialist to move the device. When moving the device by necessity within the same floor without steps, perform the following procedure. -

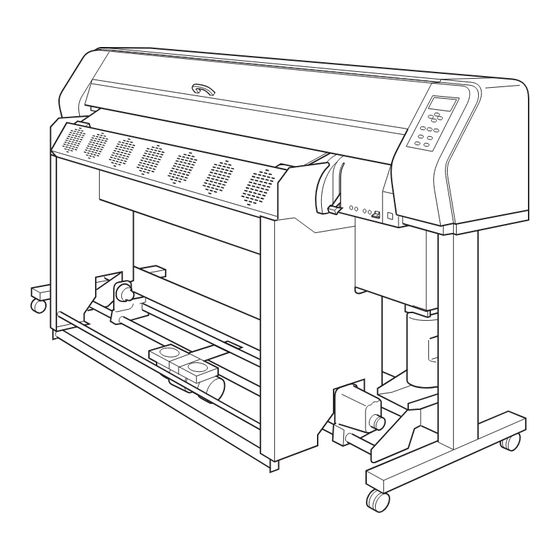

Page 22: Configuration And Function

Configuration and function The Front 12 * 11 * * This drawing illustrates fan unit set to the plotter. As for JV3-75SPII, this unit is option. Name Function Front cover It is opened when setting media or taking a corrective measure against a media jam. -

Page 23: The Rear

The REAR * This drawing illustrates 440cc ink cartridges set to the plotter. JV3-75SPII is supplied with 220cc cartridges as standard equipment. Name Function Rear exhauster Discharges plotting smell from the media to out of the room. Ink station Set the ink cartridges specified. Ink cartridge Each cartridge contains ink of a specific color. -

Page 24: Operation Panel

Operation Panel The operation panel that is used to operate the device. Display Displays a set item, a guidance error, etc. POWER lamp JOG keys [ ] [ ] [ ] [ ] It lights up (in green) when the They are used to shift the carriage power to the device is turned on. -

Page 25: Heater Panel

Heater panel The platen has heater built-in for printing and pre-printing. Turns on/off the power of the heaters and displays their statuses with LED indicators. When the power switch of the device is turned off, the power of the heaters is also turned off. CONSTANT indicator Heater power switch HEAT indicator... -

Page 26: Carriage

Carriage The carriage is provided with ink heads for printing, a cutter unit for cutting off media, etc. It is also provided with a lever for adjusting the head height according to the thickness of the media used. Adjusting lever Cutter Unit Heater The platen has heater built-in for printing and preprinting. -

Page 27: Capping Station

Capping station • When cleaning the capping station, be sure to wear the supplied goggle and gloves since you may get ink in your eyes. The capping station consists of ink caps, wipers for cleaning the heads, etc. : It covers the nozzle so as to prevent the head nozzle from drying up. Wiper : It is used to clean the head nozzle. -

Page 28: Media Sensor

Media sensor The media sensor detects the presence of the media and the media length. There is a media sensor on the platen. • Set up media to cover media sensor at the back side of platen absolutely. If the part of media is not on media, the media con not be detected. Media sensor Cutter blade and cutting line The carriage is provided with a cutter unit for cutting off the media that has been plotted on. -

Page 29: Precautions In Handling The Ink Cartridge

• Never refill the ink cartridge with ink. Refilling the ink cartridge can cause a trouble. Remember that Mimaki assumes no responsibility for any damage caused by the use of the ink cartridge replenished with ink. -

Page 30: Precautions In Handling The Media

Precautions in handling the media Carefully observe the following when handling the media. • Use media recommended by MIMAKI for stable, high-quality plotting. • Heater temperature setting according to media characteristics Set the temperature of the preheater and print heater according to the type and characteristic of the media used. -

Page 31: Types Of Media That Can Be Used

Types of media that can be used The types of media that can be used with the device are roll media and cut sheet media. The types and sizes of media that can be used with the device are explained below. Types of media that can be used •... -

Page 32: Setting The Heater Voltage

Setting the heater voltage Set the heater voltage according to the supply voltage to the plotter. For the voltage setting, use the voltage selectors under the left back of the cover. At shipping from the factory, the voltage is set to 220 V for safety. •... -

Page 33: Menu Mode

MENU mode There are the following four mode in this device. Each of the four modes is explained below. NOT-READY mode This is the mode before the media detector. The keys other than the [REMOTE] key are effective. LOCAL mode This is the mode after the media detection. - Page 34 - 1.16 -...

-

Page 35: Chapter 2 Operation

CHAPTER 2 Operation This chapter describes a series of operations and settings, ranging from power-on to end of plotting. Table of contents Operation ....................... 2.2 Switching on the power supply ..............2.3 Turning the power on ..................2.3 Front cover /Maintenance cover ..............2.4 Opening/closing the front cover and maintenance cover ........ -

Page 36: Operation

Operation The following shows a series of operations and settings, ranging from power-on to end of plotting. For details on each item, refer to the reference page. Turn on the power on P. 2.3 Check the head height P. 2.6 Set the media P. -

Page 37: Switching On The Power Supply

Switching on the power supply The device is provided with the following two different power switches. Main power switch : Located on the rear face of the device. Normally, leave this switch turned on. If this switch is left turned off, the head nozzles may be clogged. Nozzle clogging may not be recovered depending on the symptom. -

Page 38: Front Cover /Maintenance Cover

Front cover /Maintenance cover Opening/closing the front cover and maintenance cover • Keep the front cover and maintenance cover closed during plotting opera- tion. Opening the cover during plotting interrupts image plotting and disables continuous processing. If you open the cover during plotting, the carriage will stop for safety, resulting in abortion of plotting. -

Page 39: Relationships Between Ink Station And Head Row

Relationships between ink station and head row The carriage mounts four heads each with two rows of nozzles. One color ink is applied to each row of nozzles. Remember these relationships when checking the heads for clogged nozzles, replacing ink cartridge and replenishing inks. -

Page 40: Adjusting The Head Height

Adjusting the head height The head can be adjusted in height in two different stages, upper and lower, according to thickness of a media used for plotting. This adjusting function enables the device to respond to light-weight media such as paper and film and heavy-weight media such as tarpaulin as thick as 1.0 mm. - Page 41 3. Adjust the height adjusting lever according to the media to be used. • Set the height adjusting lever to the highest stage or the lowest stage. Setting it to the intermediate height, a plotting fault can result. 4. Keeping the height adjusting lever held at the aforementioned position, tighten the two screws.

-

Page 42: Setting The Media On The Device

Setting the media on the device The media that can be used with the device are roll media and leaf media. Use the media commended by MIMAKI. • If a transparent media is set, the following message appears on the LCD and the media may not be detected. - Page 43 2. Remove the 3 roll guide rails. 3. Attach the roll guides rail to another position. 4. Fit the roll assembly. Fit the roll assembly so that the horseshoe-shaped section at the end of the roll base fits the roll guide rail. - 2.9 -...

-

Page 44: Setting Roll Media On The Device

Setting roll media on the device The procedure for setting roll media on the device is described below. • The roll media is heavy in weight. Take care not to drop it on your foot. 1. Pull up the clamp lever at the back of the de- vice. - Page 45 6. Insert the right-hand roll holder into the core of the roll media. After inserting the roll holder completely into the core of the roll media, fix it with the screw. 7. Pull out the roll media from the back of the device until it reaches the end of the platen.

- Page 46 10. Open the front cover and pull up the clamp lever at the front of the device. 11. Pull out the roll media gently and then stop pulling when locked lightly. • When using a leaf media, set it so that it does not run off to the right of the pinch roller at the right end.

- Page 47 13. Set an empty paper tube to the take-up device. 14. Close the front cover and press the [ENTER] key. The width of the media is detected. Press the [ ] jog key to feed the media up to the paper tube position of the take-up device.

-

Page 48: Operating The Lock Pin

Operating the lock pin Use the lock pin attached to the roll holder when it is attached to the top or bottom position. • Be sure to pull out the media on the platen before using the lock pin. Once unlocked, resetting of the media is necessary. 1. -

Page 49: Switching The Direction Of Winding Of The Media

Switching the direction of winding of the media The take-up device is mounted with a switch that specifies the direction in which a media is wound. FORWARD : The take-up device winds the media Switch with its plotting face faced out. : The take-up device will not wind the Torque limiter media. -

Page 50: Setting Cut Sheet Media On The Device

Setting cut sheet media on the device Unlike roll media, the cut sheet media need not be fixed onto the roll holders. • When using cut sheet media, take care that it is set straight forward. 1. Open the front cover. 2. - Page 51 • When using a leaf media, set it so that it does not run off to the right of the pinch roller at the right end. 4. Push down the clamp lever. 5. Close the front cover. 6. Press the [ENTER] key. ( COVER OPEN ) PRESS <...

-

Page 52: Changing The Drier Fan Angle

Changing the drier fan angle Enable to change the angle of the drying fan to the two directions as “Media set” or “Print”. Change the angle in need. Loosen the upper knob screws at both sides of the drier fan. 2. -

Page 53: Heater-Temperature Control

Heater-Temperature control To store the Heat temp., set the [HEATER] of the FUNCTION mode. page 4.6 FUNCTION mode - SET UP - TYPE - HEATER This section describes how to adjust the Heat Temp., which has been stored at FUNCTION mode beforehand. -

Page 54: In Case Of Faultiness With Heater

3. Press the [ENTER] key. 40° 40° C Print 35° 35° C The cursor is shown up on the LCD display, then can change the Temp. of Pre-Heater. 4. Select the temperature by pressing the JOG 40° 45° C keys [ ] and [ ]. Print 35°... -

Page 55: Checking And Solving Nozzle Clogging (Test Plotting)

Checking and solving nozzle clogging (TEST plotting) Make test plotting to check whether there is nozzle clogging or other plotting failures. If the finished test pattern shows any sign of abnormal conditions, carry out the cleaning function. • To perform the test plot on a cut sheet media, use a media whose size is A4 or larger with placed in landscape configuration. - Page 56 STEP 1. The device enters the LOCAL mode. < LOCAL > width : 1272 mm Press the [REMOTE] key and put the device back into the LOCAL mode. 2. Press the [TEST&CLEANING] key. TEST & TEST DRAW CLEANING < ENT > 3.

-

Page 57: Correcting The Media Feed Rate [Media Comp.]

Correcting the media feed rate [MEDIA COMP.] When the media type or heater temperature is changed, the amount of media feed changes. Be sure to correct dot positions. If the correction value is not appropriate, stripes may occur in the plotting, disturbing neat plotting. •... - Page 58 STEP 1. Put the device into the LOCAL mode. < LOCAL > width : 1272 mm 2. Press the [FUNCTION] key. FUNCTION SET UP < ENT > 3. Press the [ENTER] key. SET UP SELECT : TYPE. 1 4. Press the [ ] and [ ] key to select a type. SET UP page 4.4 SELECT...

-

Page 59: Correcting The Media Feed Rate During Operation

Correcting the media feed rate during operation In the “MEDIA COMP.”, operations are in a LOCAL mode. The following describes the procedures altering the media feed rate during operation or in the REMOTE mode. ( [MEDIA COMP.] page 2.22). STEP ∗... -

Page 60: Plotting An Image From Source Data

Plotting an Image from source data Starting the plotting operation The following describes the mode selection for data reception from the computer and LCD display during plotting. For various function settings necessary for plotting, refer to “CHP4 Setting Function”. • When in use of a roll media, make sure the back side of roll media is not loosened before executing plotting. -

Page 61: Interrupting The Plotting Operation

Interrupting the plotting operation To interrupt the plotting operation, stop the carriage and erase (the receive data) from the device. STEP 1. Press the [REMOTE] key to stop the plotting < LOCAL > operation. width : 1272 mm 2. If data is being transmitted from the computer to the device, stop the data transmission. -

Page 62: When [Near End] Or [Ink End] Appears

When [NEAR END] or [INK END] appears If ink in the cartridge comes to an empty, the corresponding message appears. Plotting can be continued but ink may run out during plotting. Immediately put a new ink cartridge. • In case [NEAR END] is indicated on the LCD, replace a ink cartridge in good time. -

Page 63: Ink Cartridge Trouble

Ink cartridge trouble When an ink cartridge trouble is detected, a warning message appears and plotting, cleaning and all other activities that use ink are deactivated. When this is the case, replace the ink cartridge in ques- tion immediately. • Do not leave the ink cartridge unreplaced for a long time as this will cause malfunction of the clogged nozzle prevention function and the plotter must be repaired by a service person. -

Page 64: Turning The Power Off

Turning the power off When plotting is completed, push the power switch on the front face to turn the power off. To turn the power off, check first whether or not there is data received and there remains data that has not yet been output in the device. -

Page 65: Chapter 3 Daily Cleaning

CHAPTER 3 Daily cleaning This chapter describes daily cleaning. Table of contents Routine Maintenance ................3.2 Notes on cleaning ................. 3.2 Cleaning the platen ................3.3 Cleaning the media sensor ..............3.3 Maintenance for frame components ............3.3 Cleaning the wiper and ink caps ............3.4 Cleaning the head sides .............. -

Page 66: Routine Maintenance

Routine Maintenance Be sure to conduct maintenance works for the device when necessary or periodically so as to use the device for a long time while keeping its plotting accuracy. Notes on cleaning • When using the maintenance cleaning fluid RS, be sure to wear the protec- tive glasses. -

Page 67: Cleaning The Platen

Maintenance for frame components If the frame components of the device have stained, dampen a piece of soft cloth with water or neutral detergent diluted with water, squeeze it and wipe the frame components clean. Cleaning the platen • Clean the platen after the platen cools down. The platen may be stained by lint or dust since the media is cut on it. -

Page 68: Cleaning The Wiper And Ink Caps

Cleaning the wiper and ink caps The ink cap prevents clogging of the head nozzle caused by dried nozzle. The wiper wipes out ink adhered to the head nozzle. As the device is used to plot images, the wipers and ink caps gradually become stained with ink and dust. - Page 69 8. Remove the ink at the wiper and the bracket using a cotton bud dampened with cleaning fluid RS. • If dirt of curl is serious, replace the wiper with a new one. At the time of replacement, be sure to terminate the plotter operation and follow the wiper replacement procedure.

-

Page 70: Cleaning The Head Sides

Cleaning the head sides As the device is used to plot images, the head sides gradually become stained with ink and dust. Open the maintenance cover, and wipe the head sides with a cotton bud. • Be sure to wear the supplied goggle and gloves. Ink is organic solvent. -

Page 71: Use The Cleaning Kit

Use the cleaning kit In case the internal section is dirty or if nozzle missing cannot be resolved even after cleaning ( page 2.21, 4.10), use the cleaning kit. The cleaning kit contains the following items. Do not use alcohol or water. When using the supplied maintenance cleaning fluid, be sure to wear the supplied protective glasses. -

Page 72: Cleaning The Nozzle [Nozzle Wash]

Cleaning the nozzle [NOZZLE WASH] • If nozzle clogging cannot be resolved even after cleaning several times, execute the [FILL UP INK] and [WASH] functions. page 5.11 If this error cannot be resolved with these functions, contact your dealer. • If there exist cartridges with [NEAR END] and/or [INKEND], the cleaning function (suctioning through nozzles) is not activated. - Page 73 9. Holding the projections at both ends, insert the wiper which has cleaned into place. 10. Press the [ENTER] key. Fill the Liquid. COMPLETED :ent 11. Fill the cap with the cleaning fluid using a dropper. 12. Close the front cover, 13.

-

Page 74: When The Waste Ink Tank Becomes Full

When the waste ink tank becomes full Waste ink used for cleaning the heads will gather in the waste ink tank. When the waste ink has gathered to exceed the marker line on the tank, immediately replace the tank with a new waste ink tank. STEP 1. -

Page 75: Chapter 4 Setting Function

CHAPTER 4 Setting Function This chapter describes operations and setting necessary for plotting. Table of contents Basic operations of menus ................4.2 Function mode ....................4.4 Registering a type ................... 4.4 Changing the type ................... 4.4 Setup functions ....................4.5 Setting suitable heater temperature ............4.11 Setting exhaust fan and drier fan .............. -

Page 76: Basic Operations Of Menus

Basic operations of menus This section describes how to change over the operation modes and how to operate the menus. The following gives the key operation flow to invoke menus. For detailed menu configuration, refer to Appendix. REMOTE < LOCAL > ∗... - Page 77 1. Select the LOCAL mode. Ascertain first that the device does not perform printing under the REMOTE mode, then press the [REMOTE] key to enter the LOCAL mode. 2. Select the FUNCTION mode. Press the [FUNCTION] key, and the device will enter the FUNCTION mode. The FUNCTION mode is divided into two: the setup function and maintenance function.

-

Page 78: Function Mode

Function mode The FUNCTION mode consists of 16 items. The 16 items can be registered for each of the following four types. If the type has been registered for each media type, it becomes easy to change plotting conditions when the media type is changed. Example) Type1 For Tarpaulin 1... -

Page 79: Setup Functions

Setup functions The following describes the overview of and settings for each function. Name Function MEDIACOMP. Correct the amount of feed for media P.4-6 HEATER Set the printer heater condition P.4-6 PRINT MODE Set the plot quality, plot direction, and logical seek P.4-7 INK LAYERS Set the number of over writing... - Page 80 MEDIACOMP. P.2-20 When the media type or heater temperature is changed, be sure to correct the amount of feed according to the media thickness. (-255-255) HEATER (Temperature setting during plotting P.2-18 ) Sets the printer heater and preheater built in the platen. PRE HEAT : Sets the temperature of the preheater.

-

Page 81: Print Mode

PRINT MODE Sets the plot quality, plot direction, and logical seek. QUALITY : Select the quality image from three items. (STANDARD, FINE, FAST) DIRECTION : Specifies the head movement direction along which plotting is made. [UNI-D] specifies that plotting is made while the head is moving to the left. [BI-D] specifies that plotting is made while the head is moving to the left and right. -

Page 82: Drying Time

INK LAYERS Sets the number of overwriting if ink coloring is poor. (1-9 times) DRYING TIME This function sets an ink drying time. It sets the function for drying ink. The drying time is the wait time by scanning and the time interval between the instant at which the plotting operation is completed and the instant at which the media plotted is cut off. - Page 83 PRE-FEED Media that require high heater temperature for plotting, or other types of media that have a soft surface, sometimes stick to the platen or rise from the platen. This will cause a feed problem and a service call may be necessary. When such a problem is anticipated, set PRE-FEED to ON.

- Page 84 MEDIA SET This function sets the method of media detection. SELECT : During the initial operation, the device displays a menu for selection of “roll media” or “cut sheet media”. When “roll media” is selected, only the width of the media is detected. When “cut sheet media”...

-

Page 85: Setting Suitable Heater Temperature

Setting suitable heater temperature The following describes the procedure for setting the suitable heater temperature at the time of heater temperature depends on the media type and ambient temperature. page 2.18,4.5 Set a temperature which is suitable for each media. Non-coated media and media with a long ink drying time improve the ink fixing and drying characteristics. -

Page 86: Setting Exhaust Fan And Drier Fan

Setting exhaust fan and drier fan The following sets up the rotational operation of the exhaust fan which lets out the order of ink and the drier fan which used to provide cool air for drying the media after plotting. STOP TIME Stops rotation of the exhaust fan and the drier fan at the specified period of time interval after plotting. -

Page 87: Effective Plotting Area

Effective Plotting Area The device has an area which cannot perform printing, due to mechanical reasons. This area is called “ dead space”. 0 mm 110 mm Effective Effective 15 mm 15 mm 15 mm 15 mm printing printing area area Media feeding... -

Page 88: Establishing An Origin

Establishing An Origin Establish an origin in terms of data on media loaded on the device. In the case of printing with the unspecified origin, set the origin again. STEP 1. After the media detection is completed, move <LOCAL> Width : 1272 mm the carriage to the position at which to estab- lish an origin by pressing the JOG keys [ ], [ ], [ ] and [ ]. -

Page 89: Chapter 5 Maintenance

CHAPTER 5 Maintenance In order to keep the plotter in good operating condition, it is necessary to carry out maintenance of the device periodically. This chapter describes the functions that help solve the problem of deterioration in image quality and replace a worn cutter blade. The device needs maintenance when it is left out of operation for a long period of time. -

Page 90: Maintenance Of The Device

Maintenance of the device The term “maintenance” as used herein refers to the operation that has to be performed to keep the device in good operating condition. To carry out maintenance of the device, select [MAINTENANCE] from the FUNCTION menu and make the necessary settings. -

Page 91: Setup Functions

Setup functions The following describes the overview of and settings for each function. Name Function page 5.4 STATION Clean the inside of the station and replace the wiper. through 5.6 (CARRIAGEout, WIPER EXCHANG, NOZZLE WASH) page 5.7 INT.WIPING Wipe off the condensed ink. page 5.9 PRINT ADJUST Adjust the dot position when changing the media type and/or ink. -

Page 92: Cleaning The Station Interior [Station]-[Carriageout]

Cleaning the station interior [STATION]-[CARRIAGEout] Move the carriage when cleaning the station interior and replacing the consumable parts. • Do not move the carriage out of the capping station by hand. Select the [STATION]-[CARRIAGEout] to move the carriage. For the [STATION] function, there are two following items. CARRIAGEout : Move the carriage for maintenance of the station interior. -

Page 93: When The Message [Replace Wiper] Is Displayed

When the message [REPLACE WIPER] is displayed [STATION]-[WIPER EXCHANGE] The wipers are consumable parts. When the following message is displayed, replace the wipers with new ones. < LOCAL > REPLACE WIPER At the same time, clean the ink at the bottom of the slider. •... - Page 94 5. Clean the wiper guide shaft using a cotton bud or cloth. If dirt is hard to remove, use a cotton bud of cloth dampened with water. 6. Close the front cover. 7. Press the [ENTER] key. INITIALIZING The device enters the LOCAL mode. PLEASE WAIT <...

-

Page 95: Regular Wiping Function [Int.wiping]

Regular wiping function [INT.WIPING] In case of setting for heaters at high temperature, or setting too much amount of ink per unit (high concentration, render set, etc.) on the plotter, “spray”, “mass of ink”, or “nozzle-out” phenomena may happen due to evaporation of the solvent media that may condense on a print-head surface resulting inferior image quality. - Page 96 8. Press the [ENTER] key. INT.WIPING SCAN COUNT < ent > [SCAN COUNT] is displayed. 9. Press the [ ] or [ ] key until the display gives INT.WIPING the indication [TEMP.DIFF.]. TEMP.DIFF. < ent > 10. Press the [ENTER] key. INT.WIPING TEMP.DIFF.

-

Page 97: When Media Thickness Is Changed [Print Adjust]

When media thickness is changed [PRINT ADJUST] When the media thickness, head height, ink type is changed, the dot position is subtly different. This function corrects the dot positions to ensure that the accurate plotting result is obtained. The dot positions are corrected by comparing the ink dropping positions on each of the seven test patterns between the two plotting directions. - Page 98 5. Repeat Steps 5 and 6 to correct the dot posi- MAINTENANCE PATTERN 2 = 0. 0 tions on Patterns 2 to 7. Select the correct dot positions on each of the patterns. MAINTENANCE Enter the dot position correction value on Patterns 1 to 7 and PATTERN 3 = 0.

-

Page 99: If Nozzles Are Clogged Even After The Cleaning Function Is Executed

If nozzles are clogged even after the cleaning function is executed If nozzle clogging is resolved after HEAD CLEANING ( page 2.21) and NOZZLE WASH page 3.7) perform the following functions. FILL UP INK : The device is charges ink. HEAD WASH : Cleans the head, tube, and damper with the dedicated cleaning fluid (option). - Page 100 4. When the display shown at right appears, set WASH the cleaning cartridge. SET CLEAN TOOL Cleaning fluid is suctioned up. 5. When the display shown at right appears, WASH remove the cleaning cartridge. REMOVE TOOL Suck in air. 6. When the display shown at right appears, set WASH the cleaning cartridge.

-

Page 101: Ink Discharge Way Cleaning [Disway Wash]

Ink discharge way cleaning [Disway WASH] The ink discharge way may become clogged by coagulated ink. It must be cleaned at regular intervals to avoid clogging. Ink discharge way: Tubing between the cap and the waste ink tank • When cleaning the ink station and head, be sure to wear the supplied goggle and gloves since you may get ink in your eyes. - Page 102 7. Open the front cover. 8. Remove cleaning fluid RS with a dropper. During the suction pause period, drop cleaning fluid RS until just before it overflows from the cap. Repeat at all other caps. 9. Close the front cover. 10.

-

Page 103: Sleep Cleaning [Sleep Clean]

Sleep cleaning [SLEEP clean] To prevent clogging while the power switch has been turned off, ink is ejected from the head at regular intervals. The head itself must be cleaned also at regular intervals which are set as shown below. STEP 1. -

Page 104: When Not In Use The Plotter Over The Long Term [Custodywash]

When not in use the plotter over the long term [CUSTODYwash] When not in use the plotter over a week, perform “CUSTODYwash” function to clean the head nozzle and ink discharge way. After performing the function, store the plotter. Cleaning tools •... - Page 105 9. Holding the projections at both ends, insert the wiper which has cleaned into place. 10. Press the [ENTER] key. Fill the Oiquid. COMPLETED :ent 11. Fill the cap with the cleaning fluid using a dropper. 12. Close the front cover. 13.

-

Page 106: Switching The Ink From Ss To Ss2 [Ss2< >Sschg]

Switching the ink from SS to SS2 [SS2< >SSCHG] Switching the ink from SS to SS2, or the other way around, make sure to perform these procedure as follows. • Changing the ink sets (4 colors/6 colors) is not available on this func- tion. -

Page 107: Drawing Setup Conditions [List]

Drawing setup conditions [LIST] This function outputs the current settings of the device. They are useful in carrying out maintenance of the device. : Indicates a value that is specified with the FUNCTION. SET UP PRINTadjust : Indicates a correction value for dot position. REPLACE COUNTER : Indicates the number of times the ink cartridges are replaced. -

Page 108: Plotting Hex Code [Data Dump]

Plotting HEX CODE [DATA DUMP] Use the function when command error ( Page 6.8) or parameter error ( Page 6.9) occurs. This function plots data commands received from the computer, in HEX code. The HEX code is an alphanumeric representation of plotting commands. By using this code, it is possible to check if there are any abnormal data commands. -

Page 109: Wiper Life Warning [Wipe Level]

Wiper Life warning [WIPE LEVEL] The wipers are consumable parts. The head becomes dirty easily on dusty locations. The head cannot be cleaned adequately with a curled or worn wiper. This setting moves up the wiper replacement warning depending on the operating environment. 10/10 : Displays the wiper replacement warning when the standard number of wiping is reached (initial value). -

Page 110: When Use The 440Cc Ink Cartridges [Use 440Cc]

When use the 440cc ink cartridges [USE 440cc] In case of JV3-75SPII, 440cc cartridges and protection cover are optional items. When 440cc cartridges is used on JV3-75SPII, the following steps are required. • The protection cover is separately available from your local distributor. •... -

Page 111: Setting Time [Time Set]

Setting time [TIME SET] The device incorporates a calender. [TIME STAMP] function of the FUNCTION mode displays the date and time depending on this setting. page 4.10 STEP 1. Select the [TIME SET]. MAINTENANCE TIME SET < ent > 2. Press the [ENTER] key. MAINTENANCE DATE = 2 0 0 2 . -

Page 112: Displaying Device Information [Information]

Displaying device information [INFORMATION] Displays the firmware version, serial number, and dealer number of the device. If trouble occurs, please inform the dealer of the contents of the trouble as well as this information. This can make solution quicker. STEP 1. -

Page 113: Replace The Cutter Blade

Replace the cutter blade Cutter blades are consumables. When the cutter blade has became blunt, replace the cutter blade with a new one (SPA-0107). • The blade tip is sharp. Take care to prevent possible personal injury. • Store the cutter blades in a place that is out of the reach of children. Be sure to dispose of the worn-out cutter blades according to the relevant national and local ordinances in which the device is used. -

Page 114: Ink Exchanging Procedure

Ink exchanging procedure The current ink set can be altered. Change from 4-color ink set to 6-color ink set. Change from 6-color ink set to 4-color ink set. 4-color ink set Two ink cartridges of the same color can be placed per head for fast and high-quality printing. Four colors (Black, Magenta, Cyan, Yellow) are used. - Page 115 STEP 1. Select the [WASH]. MAINTENANCE WASH < ent > 2. Press the [ENTER] key. 3. Take out the ink cartridge. WASH REMOVE CARTRIDGE Discharge of the filled ink is started. • The washing liquid (SPC-0352) is separately available from your local distributor. 4.

- Page 116 10. Use the jog keys [ ][ ] to select an ink set (4- INK SET colors, 6-colors). M Sol - 4 color 11. Place the ink cartridges in the ink stations. Set a cartridge A beep sound is heard when the ink cartridge is placed correctly. Ink is filled automatically when the ink cartridge is set.

-

Page 117: Using The Small Amount Of Remaining Ink In The 440Cc Ink Cartridge

Using the small amount of remaining ink in the 440cc ink cartridge For the 440cc ink cartrige, when [NEAR END] or [INK END] is displyed some ink may remain in the ink cartridge. At this time it is possible to use remaining ink by selecting the amount. •... -

Page 118: Using Further Remaining Ink In The Ink Cartridge

5. Select the amout of ink you want to use by Example of adding 20cc pressing the [ ] or [ ] keys. (in 10cc incre- ADD REMAIN ments). + 0 cc + 20 cc * Maximum ink amount can be used for this function is 30cc. Current Value Total Value 6. - Page 119 3. To use the remaining ink, reinsert the ink car- ADD REMAIN ? - K - - - - - - tridge. ADD REMAIN 4. Press the [ENTER] key. Yes : ent No : end If press the [END] key, it cancel the operation and return to the LOCAL mode.

- Page 120 - 5.32 -...

-

Page 121: Chapter 6 When Abnormal Conditions Are Encountered

CHAPTER 6 When abnormal conditions are encountered Chapter 6 describes corrective measures to be taken in the case where an abnormal phenomenon arises on the device and where an error message is given on the display. Table of contents Before taking a phenomenon as a sign of failure .......... 6.2 The device cannot be energized .............. -

Page 122: Before Taking A Phenomenon As A Sign Of Failure

Be sure to take the following measures before taking the trouble as a sign of failure. If the measures fail restore the device to the normal state, contact your local MIMAKI distributor or MIMAKI office to call for service. -

Page 123: Paper Jamming Arises/Media Is Soiled

Paper jamming arises/media is soiled A jam of the media or a stained media is considered to occur when an unsuitable media is used or the media is set improperly. Use media specific to the device. Are you using media specific to the device? Avoid media that has curls or Are you using media that has... -

Page 124: If Image Quality Declines

Take measures in accordance with actual state of the picture. If the measures fail restore the device to the normal state, contact your local MIMAKI distributor or MIMAKI office call for service. While lines/thin spots are obvious or dark stripes occur... -

Page 125: Troubles For Which Error Messages Are Given On The Lcd

Troubles for which error messages are given on the LCD If something is wrong with the device, the buzzer sounds and a corresponding error message is given on the LCD. Take an appropriate corrective measure in accordance with the message. Errors accompanied by warnings These errors arise on the ink-related components. -

Page 126: Warning Message

DO TEST DRAW left for a prolonged period of TION] - [WASH] for maintenance. time. The loaded ink cartridge is not Use the ink specified by MIMAKI. NON-ORIGINAL INK KKMMCCYY MIMAKI genuine. The IC chip of the ink cartridge Attach the ink cartridge(s) WRONG INK IC cannot be read normally. - Page 127 Warning message Cause Corrective measure The print heater is disconnected. Contact your local distributor to 40° 45° C call for service. Print BREAKAGE The preheater is disconnected. BREAKAGE Print 43° C ( 4 7) The thermistor of the preheater THERMISTOR is defective.

-

Page 128: Error Messages

If any error message is given on the LCD, turn off the power to the device and turn it on after a while. If the same error message appears again on the LCD, contact your local MIMAKI distributor or MIMAKI office to call for service. -

Page 129: Error Message

Error message Cause Corrective measure HOST I/F Timeout error has Check to be sure that the cable is ERROR 23 HOST I / F arisen during communication securely connected to the host between the host computer and computer and interface board. interface board. - Page 130 - 6.10 -...

-

Page 131: Appendix

APPENDIX This appendix describes the specifications and components the device, func- tion menu structure. Table of contents Basic specifications ..............A.2 Specification for ink ..............A.4 Position of the warning label ............A.5 Function Flowchart ..............A.7 - A.1 -... -

Page 132: Basic Specifications

Basic specifications Item JV3-75SPII JV3-130SPII Printing head Method Piezo-electric drop-on demand Specification 4-heads Inlines Nozzle 360 nozzles for each color Resolution 360, 540, 720, 1440 dpi Drawing mode 4-color ink set 360 x 360 dpi : 1 / 2 / 4 passes, Unidirection / bidirection 360 x 720 dpi : 2 / 4 / 8 passes, Unidirection / bidirection 720 x 720 dpi : 2 / 4 / 8 passes, Unidirection / bidirection 720 x 1440 dpi : 4 / 8 / 16 passes, Unidirection / idirection... - Page 133 Replacement timing is judged visually. Interface IEEE1394 compliant, IEEE1284 compliant Command MRL-II (ESC/PV.2 base, MIMAKI original command) Noise during standby : Less than 58 dB (FAST-A, Front & Rear & Left & Right 1 m) during continuous printing : Less than 65 dB...

-

Page 134: Specification For Ink

Specification for ink Item Specifications Color Black ink cartridge Cyan ink cartridge Magenta ink cartridge Yellow ink cartridge Light cyan ink cartridge Light magenta ink cartridge Contents of ink 220 cc / 440 cc per cartridge Shelf life One year from the data of manufacture (at room temperature) Within three months after opening the package Storage temperature During storage : -30 to 40°C... -

Page 135: Position Of The Warning Label

Position of the warning label This device is adhered with the warning label. Be sure to fully understand the warning given on the labels. In the case where any of the warning label has become so soiled that the warning message is illeg- ible or has come off, purchase a new one from your local distributor or our office. - Page 136 - A.6 -...

-

Page 138: Function Flowchart

Function Flowchart In Media Fitting < > <LOCAL> Detevting MEDIA MEDIA SELECT ** MEDIA ** PLEASE WAIT Y=xxxx X=xxxx ROLL< >LEAF <LOCAL> width:xxxxmm How to set origin < > <LOCAL> ORIGIN SETUP ORIGIN SETUP width:xxxxmm ** ORIGIN ** ------- FUNCTION MEDIA CUT ENTER MEDIA CUTTING... - Page 139 FUNCTION Key : FUNCTION > FUNCTION ENTER ENTER ENTER ENTER <LOCAL> FUNCTION SET UP TYPE. TYPE. PRINTING TYPE. width:xxxxmm SET UP <ENT> SELECT :TYPE.1 MEDIACOMP. <ent> PRINT START PLEASE WAIT ADJUST TYPE.1~4 -255~255 ENTER ENTER TYPE. TYPE. TYPE. HEATER <ent> PRE HEAT <ent>...

- Page 140 Following Following ENTER TYPE. TYPE. FUNCTION COLOR PTN. <ent> COLOR PTN. : OFF SET UP <ENT> ON, OFF ENTER TYPE. TYPE. REFRESH <ent> REFRESH : LEVEL3 LEVEL1~3 ENTER TYPE. TYPE. MEDIA SET <ent> :SELECT SELECT, WIDTH ENTER TYPE. TYPE. VACUUM <ent>...

- Page 141 Following Following ENTER ENTER MAINTENANCE PRINTING MAINTENANCE FUNCTION MAINTENANCE MAINTENANCE<ENT> PRINT START :ent PLEASE WAIT PATTERN1 = 0.0 PRINTadjust <ent> PATTERN1~7 -40.0~40.0 > FUNCTION ENTER ENTER INT.WIPING MAINTENANCE INT.WIPING SCAN COUNT = SCAN COUNT <ent> INT.WIPING <ent> 0 ~ 9990 FUNCTION ENTER INT.WIPING...

- Page 142 Following Following ENTER ENTER < > MAINTENANCE FUNCTION MAINTENANCE MAINTENANCE MAINTENANCE MAINTENANCE<ENT> TIME SET <ent> DATE=xxxx.xx.xx DATE=xxxx.xx.xx TIME=xx:xx:00 ENTER MAINTENANCE FUNCTION TIME=xx:xx:xx ENTER ENTER MAINTENANCE MAINTENANCE MAIN Ver xx.xx INFORMATION<ent> Ver xx.xx VERSION <ent> FUNCTION ENTER MAINTENANCE MAINTENANCE SERIAL No. <ent>...

- Page 144 Printed in Japan © MIMAKI ENGINEERING Co., Ltd. 2004...

Need help?

Do you have a question about the JV3-75 SP II and is the answer not in the manual?

Questions and answers