Table of Contents

Advertisement

IDENTIFICATION TAG LOCATION AND INFORMATION ...............................................................

GENERAL DESCRIPTION AND OPERATION .....................................................................................

COMPONENT AND SOLENOID APPLICATION CHART ...................................................................

"PTO" GENERAL REQUIREMENTS ....................................................................................................

ELECTRICAL COMPONENT DIAGNOSIS ...........................................................................................

FLUID REQUIREMENTS .......................................................................................................................

SOLENOID PACK TESTING ..................................................................................................................

ABBREVIATION DESCRIPTION ..........................................................................................................

DIAGNOSTIC TROUBLE CODE CHART AND DESCRIPTION ........................................................

LINE PRESSURE TEST ..........................................................................................................................

NON-PTO AND PTO HYDRAULIC DIFFERENCES ...........................................................................

PWM AND NON-PWM OIL PUMP DIFFERENCES ...........................................................................

CASE CHECKBALL LOCATIONS .........................................................................................................

VALVE BODY CHECKBALL LOCATIONS ...........................................................................................

AIR PRESSURE CHECKS ......................................................................................................................

TRANSMISSION DISASSEMBLY .........................................................................................................

TRANSMISSION CASE ASSEMBLY ................................................................................................

FRONT AND REAR PLANETARY CARRIERS ...............................................................................

FORWARD CLUTCH HOUSING ......................................................................................................

DIRECT CLUTCH HOUSING ...........................................................................................................

FORWARD, DIRECT, SUN SHELL SUB-ASSEMBLY ....................................................................

CENTER SUPPORT ASSEMBLY ......................................................................................................

INTERMEDIATE/OVERDRIVE CYLINDER ASSEMBLY .............................................................

OVERDRIVE GEARSET ASSEMBLY ...............................................................................................

COAST CLUTCH HOUSING DIFFERENCES ................................................................................

COAST CLUTCH HOUSING ASSEMBLY ........................................................................................

OIL PUMP ASSEMBLY ......................................................................................................................

VALVE BODY ASSEMBLY ............................................................................................................... 100

TRANSMISSION FINAL ASSEMBLY .................................................................................................

MANUAL VALVE CHECK ....................................................................................................................

MANUAL SHIFT LEVER DIFFERENCES ........................................................................................

TORQUE SPECIFICATIONS ...............................................................................................................

VALVE BODY BOLT CHART AND IDENTIFICATION ....................................................................

BOLT CHART AND IDENTIFICATION .............................................................................................

SPECIAL SERVICE TOOLS .................................................................................................................

F OR D 4 R1 00

INDEX

18639 S.W. 107TH AVENUE

MIAMI, FLORIDA 33157

(305) 670-4161

Copyright © ATSG 2003

3

4

5

6

8

12

12

14

15

21

22

34

38

39

40

41

55

64

66

69

76

80

82

84

88

90

94

102

111

112

115

116

117

118

Advertisement

Table of Contents

Summary of Contents for ATSG FORD 4R100

-

Page 1: Table Of Contents

MANUAL SHIFT LEVER DIFFERENCES ..................TORQUE SPECIFICATIONS ....................... VALVE BODY BOLT CHART AND IDENTIFICATION ..............BOLT CHART AND IDENTIFICATION ..................... SPECIAL SERVICE TOOLS ......................... AUTOMATIC TRANSMISSION SERVICE GROUP 18639 S.W. 107TH AVENUE MIAMI, FLORIDA 33157 (305) 670-4161 Copyright © ATSG 2003... -

Page 2: F Or D 4 R1

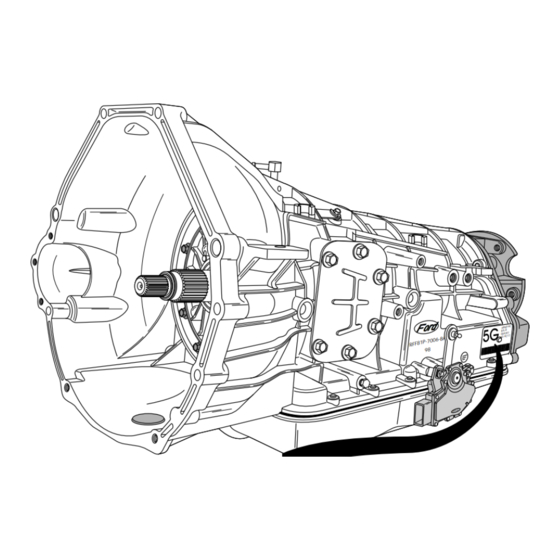

FORD 4R100 The Ford 4R100 transmission is an updated version of the E4OD and was first introduced in the 1999 model year, and is currently found in the F250, F350, F450 and F550 Super Duty trucks, E150, E250, E350, E450 vans and the Expedition/Navigator/Excursion vehicles equipped with the 5.4L, 6.8L, and 7.3L engines. -

Page 3: Identification Tag Location And Information

PTO is available as an option on 8500 GVW or above, Super Duty F-Series trucks with 6.8L gasoline and 7.3L Diesel engines. Ford 4R100 transmissions on other models are not PTO capable. F o r d F o r d... -

Page 4: General Description And Operation

Transmission Control Switch (TCS), also referred to General Description as "Overdrive Cancel Switch", and a Transmission The Ford 4R100 automatic transmission is a four Control Indicator Lamp (TCIL), located on the end of forward speed unit with electronic shift control. It is the manual gear shift lever, as shown in Figure 3. -

Page 5: Component And Solenoid Application Chart

*Off = Will be "On", if the TCS switch is pushed. Mod = Modulating at all times by the PCM and line pressure will be regulated based on throttle position, engine load and vehicle speed. Copyright © 2003 ATSG Figure 4 AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 6: Pto" General Requirements

(3) PTO is available as an option only on 8500 GVW or above, Super Duty F-Series trucks with 6.8L F or d F or d Gasoline and 7.3L Diesel engines. Ford 4R100 -7 00 6- RF F8 1P transmissions on other models are not PTO capable. - Page 7 The Double Arrow keys can also be This is the recommended used to manually raise or lower the method of elevating idle engine speed at a faster or slower speed for PTO operations. rate. Copyright © 2003 ATSG Figure 6 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 8: Electrical Component Diagnosis

AP sensor for control of EPC pressure and Instrument Cluster Terminal B11 shift scheduling. Copyright © 2003 ATSG The Idle Validation Switch is fed voltage through Figure 7 fuse number 19, as well as the Transmission Control Switch, as shown in Figure 7. - Page 9 The Park Gear is also a press fit to the output shaft, and the number 13 thrust washer, between the case and the park gear has been replaced with a needle bearing. Copyright © 2003 ATSG Figure 9 Output Shaft Speed Sensor All Models = 781-1979 Ohms Resistance...

- Page 10 Testing the neutral start circuit is done across pins 10 and 12 of the DTR sensor, and must be checked in each selector position to determine switch integrity. Refer to Figure 13. Copyright © 2003 ATSG Figure 12 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 11 2 AND 6 CLOSED OPEN CLOSED OPEN OPEN CLOSED 9 AND 11 OPEN CLOSED OPEN OPEN OPEN OPEN 10 AND 12 CLOSED OPEN CLOSED OPEN OPEN OPEN DIGITAL TRANSMISSION RANGE SENSOR Copyright © 2003 ATSG Figure 13 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 12: Fluid Requirements

XT-2-QDX or an equivalent 1062k - 284k W -40 to -20 -40 to -4 Mercon® fluid should be used in all Ford 4R100 284k - 100k W -19 to -1 -3 to 31 transmissions. Before adding any fluid, ensure that it... - Page 13 Technical Service Information SOLENOID BODY PIN IDENTIFICATION AND FUNCTION VEHICLE HARNESS SOLENOID BODY CONNECTOR CONNECTOR Solenoid Resistance Chart Solenoid Body Solenoid Resistance Pin Numbers Shift Solenoid "B" (2) 1 and 2 20-30 Ohms Shift Solenoid "A" (1) 1 and 3 20-30 Ohms TCC Solenoid, (On-Off) 1 and 4...

-

Page 14: Abbreviation Description

Technical Service Information FORD 4R100 Abbreviation Description Abbreviation Description Abbreviation Description 4X4 Low Switch 4X4L Injector Control Pressure Sensor Antilock Brake System Injector Pressure Regulator Air Conditioning Idle Validation Switch ACCS Air Conditioning Clutch Status Keep Alive Memory Accelerator Pedal Position Sensor... -

Page 15: Diagnostic Trouble Code Chart And Description

Technical Service Information FORD 4R100 Diagnostic Trouble Code Chart Diagnostic Code Description Symptom MAF sensor system fails to operate in a High EPC pressure. Firm shifts P0102 normal manner, which may cause a and engagements. May flash TCIL. P0103 transmission concern. - Page 16 Technical Service Information FORD 4R100 Diagnostic Trouble Code Chart Diagnostic Code Description Symptom TFT sensor circuit open, exceeds scale set for TCC and stabilized shift schedule P0713 temperature of minus 40°F. may be enabled sooner after cold start. May flash TCIL.

- Page 17 Technical Service Information FORD 4R100 Diagnostic Trouble Code Chart Diagnostic Code Description Symptom 1-2 shift error because of SSA, SSB, or Improper gear selection depending P0781 internal transmission components. on failure mode and transmission range selector position. Refer to shift solenoid operation chart.

- Page 18 Technical Service Information FORD 4R100 Diagnostic Trouble Code Chart Diagnostic Code Description Symptom Digital Transmission Range (DTR) sensor Erratic harsh shift engagements. P1702 signal intermittent. (BPP) Brake Pedal Position switch not Failed on or not connected, TCC P1703 actuated during KOER test.

- Page 19 Technical Service Information FORD 4R100 Diagnostic Trouble Code Chart Diagnostic Code Description Symptom P1754 CCS circuit failure. Failed Off: No third gear engine braking in O.D. cancel. Failed On: Third gear engine braking in O.D. range. Coast clutch may be damaged causing eventual failure.

- Page 20 Technical Service Information Shift Solenoid Application Chart Selector Lever Commanded Shift Shift Coast Clutch Range Gear Solenoid "A" Solenoid "B" Solenoid Solenoid P/R/N First Through 3rd Gear Only, SSA, SSB, TCC, Same as Overdrive, CCS Always On. Cancel MANUAL 2 MANUAL 1 MANUAL 1 Controlled by PCM...

-

Page 21: Line Pressure Test

OD, M2 50-65 psi 136-156 psi line pressure test. 70-115 psi 175-210 psi Copyright © 2003 ATSG Figure 24 LINE PRESSURE TEST NOTE: Perform the line pressure test before 1. Install a 300 psi line pressure gauge to the line performing the "Stall"... -

Page 22: Non-Pto And Pto Hydraulic Differences

None of the parts listed above will interchange between "NON-PTO" and "PTO" versions. SERVICE INFORMATION: Valve Body To Case Spacer Plate (Non-PTO) ..........F81Z-7A008-DA Valve Body To Case Spacer Plate (PTO) ............F81Z-7A008-BA Copyright © 2003 ATSG AUTOMATIC TRANSMISSION SERVICE GROUP... - Page 23 Technical Service Information 4R100 CASE ASSEMBLY "NON-PTO" AND "PTO" MODELS ADDED OIL CENTRAL LUBE REAR LUBE Copyright © 2003 ATSG Figure 25 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 24 Technical Service Information 4R100 MAIN SPACER PLATE "NON-PTO" MODELS ONLY CENTRAL LUBE ORIFICE I.D.- 1 DOVE TAIL PART NUMBER F81Z-7A008-DA Copyright © 2003 ATSG Figure 26 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 25 Technical Service Information 4R100 MAIN SPACER PLATE "PTO" MODELS ONLY CENTRAL LUBE ORIFICE ADDED MAIN LINE PRESSURE HOLE FROM PRESSURE REGULATOR VALVE I.D.- 2 DOVE TAILS PART NUMBER F81Z-7A008-BA Copyright © 2003 ATSG Figure 27 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 26 Technical Service Information "UPPER SIDE" 4R100 MAIN VALVE BODY "NON-PTO" MODELS ONLY Copyright © 2003 ATSG Figure 28 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 27 Technical Service Information "UPPER SIDE" 4R100 MAIN VALVE BODY "PTO" MODELS ONLY PASSAGE ADDED TO FEED LINE PRESSURE TO THE 3-4 SHIFT VALVE Copyright © 2003 ATSG Figure 29 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 28 Technical Service Information "LOWER SIDE" 4R100 MAIN VALVE BODY "NON-PTO" MODELS ONLY I.D.-ROUGH FORGING NUMBER OF "RF-F6" WHICH INDICATES "96" LOW/REVERSE CLUTCH Copyright © 2003 ATSG Figure 30 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 29 I.D.-ROUGH FORGING NUMBER OF "RF-F8" WHICH INDICATES "98" PASSAGE ADDED LEADING TO THE EXHAUST IN THE LOWER VALVE BODY LOW/REVERSE PASSAGE RE-MOVED FROM SPRING SIDE OF 3-4 SHIFT VALVE LOW/REVERSE CLUTCH Copyright © 2003 ATSG Figure 31 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 30 Technical Service Information 4R100 LOWER VALVE BODY "NON-PTO" MODELS ONLY I.D.-ROUGH FORGING NUMBER OF "RF-F6" WHICH INDICATES "96" Copyright © 2003 ATSG Figure 32 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 31 Technical Service Information 4R100 LOWER VALVE BODY "PTO" MODELS ONLY EXHAUST PASSAGE ADDED FROM COAST CLUTCH VALVE TO 3-4 SHIFT VALVE I.D.-ROUGH FORGING NUMBER OF "RF-F8" WHICH INDICATES "98" Copyright © 2003 ATSG Figure 33 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 32 4R100 LOWER VALVE BODY SPACER PLATE "NON-PTO" MODELS ONLY "PTO" MODELS ONLY I.D.- 1 DOVE TAIL I.D.- 2 DOVE TAILS HOLE ADDED TO CONNECT WITH EXHAUST PASSAGE IN LOWER VALVE BODY Copyright © 2003 ATSG Figure 34 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 33 FROM SOLENOID 2 TO CB3/COAST CLUTCH LINE PRESSURE FROM PRESSURE REGULATOR VALVE FIGURE 29 FIGURE 7 COAST CLUTCH SHIFT VALVE 3-4 SHIFT VALVE TO CB7/OVERDRIVE CLUTCH FROM 2-3 FIGURE 33 SHIFT VALVE Copyright © 2003 ATSG Figure 35 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 34: Pwm And Non-Pwm Oil Pump Differences

"NON-PWM" Pump assy. (with "Cast Iron" coast clutch drum)....F81Z-7A103-AA "NON-PWM" Pump assy. (with "Stamped Steel" coast clutch drum)..F81Z-7A103-BA "PWM" Pump assy. (with "Stamped Steel" coast clutch drum)....F81Z-7A103-CA "NON-PWM" Solenoid Pack................F81Z-7G391-BA "PWM" Solenoid Pack..................F81Z-7G391-AB Copyright © 2003 ATSG AUTOMATIC TRANSMISSION SERVICE GROUP... - Page 35 THE DIAMETER AND THE LENGTH OF THE SPOOL ON THE VALVE LAND SHOWN ABOVE, WERE INCREASED ON PWM VERSIONS. THE BORE IN THE PUMP COVER WAS ALSO ENLARGED APPROXIMATELY .070" TO ACOMMODATE THE CHANGES IN THE DIAMETER OF THE VALVE Copyright © 2003 ATSG Figure 36 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 36 Technical Service Information 4R100 PUMP COVER ASSEMBLY "NON-PWM" MODELS ONLY CONVERTER REGULATOR VALVE CONVERTER CLUTCH CONTROL VALVE PRESSURE REGULATOR VALVE CONVERTER RELEASE ORIFICE .070" RETAINER LUBE ORIFICE .090" Copyright © 2003 ATSG Figure 37 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 37 CONNECT TO HOLE IN PRESSURE REGULATOR CONTROL VALVE BUSHING VALVE CONVERTER RELEASE ORIFICE OMITTED RETAINER LUBE ORIFICE .090" ADDED AIR ADDED ORIFICE IN BLEED TCC PWM SOLENOID SIGNAL PASSAGE .036" Copyright © 2003 ATSG Figure 38 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 38: Case Checkball Locations

Technical Service Information 4R100 CASE CHECKBALL LOCATIONS "NON-PTO" AND "PTO" MODELS EPC Ball And Spring CB14 Requires Eight 5/16" Diameter Rubber Checkballs Plus The EPC Ball And Spring, As Shown Above. Copyright © 2003 ATSG Figure 39 AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 39: Valve Body Checkball Locations

4R100 VALVE BODY CHECKBALL LOCATIONS "NON-PTO" AND "PTO" MODELS CB16 1/4" Rubber CB15 5/16" Rubber RFF61P- RFF61P- 09328 09328 7A092-AB 7A092-AB Du Page Du Page Ford Ford CB13 1/4" Rubber 5/16" Rubber Copyright © 2003 ATSG Figure 40 AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 40: Air Pressure Checks

Coast Low/Reverse Clutch Clutch Overdrive Clutch Intermediate Lube Intermediate Clutch Copyright © 2003 ATSG Figure 41 F o rd -B A P- 7 0 0 6 R FF 8 1 Copyright © 2003 ATSG Figure 42 AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 41: Transmission Disassembly

5. Rotate the transmission so that the bottom pan DIGITAL TRANSMISSION is facing up, as shown in Figure 47. RANGE SENSOR Copyright © 2003 ATSG Figure 43 Continued on Page 42. TURBINE SHAFT SPEED SENSOR Copyright ©... -

Page 42: Component Rebuild Section

Refer to Figure 50. 6. Set the main upper and lower valve bodies aside for the component rebuild section. Continued on Page 43. Copyright © 2003 ATSG RETAINING NUTS (2) Figure 47 RETAINING BOLTS (11) ACCUMULATOR... - Page 43 Figure 52. 10. Remove the solenoid body screen from spacer plate, as shown in Figure 52, by rotating and lifting straight up. Continued on Page 44. Copyright © 2003 ATSG Figure 51 RETAINING BOLTS (14) RETAINING NUTS (2) UPPER AND LOWER...

- Page 44 184 SPACER PLATE TO CASE GASKET 185 SPACER PLATE 188 SPACER PLATE REINFORCING PLATE 189 REINFORCING PL ATE RETAINING BOLT, M6 X 1.0 X 42 (3) Copyright © 2003 ATSG Figure 53 .312" DIA. RUBBER CHECKBALLS 55 MANUAL INTERMEDIATE SERVO ASSEMBLY 182 EPC BLOW-OFF BALL, .250"...

- Page 45 FEED BOLTS 10 NUMBER 1 THRUST WASHER (USED NON-PTO MODELS ONLY) 11 OIL PUMP ASSEMBLY TO CASE GASKET 13 NUMBER 2 THRUST BEARING, PUMP TO O.D. SUN GEAR Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 56 Figure 57...

- Page 46 COAST CLUTCH HOUSING ASSEMBLY FOR "PTO" MODELS 31 OVERDRIVE CLUTCH BACKING PLATE SNAP RING (SELECTIVE) 34 OVERDRIVE CLUTCH BACKING PLATE 35 OVERDRIVE CLUTCH FRICTION PLATES Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 58 Figure 59 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 47 CLUTCH SPRING FIXTURE OVERDRIVE CARRIER CLUTCH SPRING AND CENTER SHAFT COMPRESSOR BAR ASSEMBLY CLUTCH SPRING COMPRESSOR PLATE NUMBER 5 THRUST BEARING Figure 61 CLUTCH SPRING COMPRESSOR BAR SNAP RING Copyright © 2003 ATSG Figure 60 Figure 62 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 48 46 INTERMEDIATE CLUTCH PISTON RETURN SPRING 40 INTERMEDIATE/OVERDRIVE CYLINDER SNAP RING 48 CENTER SUPPORT ASSEMBLY 42 INTERMEDIATE/OVERDRIVE CYLINDER ASSEMBLY 49 NUMBER 6 THRUST WASHER, CENTER SUPPORT Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 63 Figure 64 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 49 T89T-70010-E DIRECT CLUTCH, FORWARD CLUTCH AND SUN SHELL ASSEMBLY 52 INTERMEDIATE CLUTCH FRICTION PLATES 53 INTERMEDIATE CLUTCH STEEL PLATES 54 INTERMEDIATE CLUTCH BACKING PLATE Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 65 Figure 66 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 50 103 NUMBER 10B THRUST WASHER 107 REAR PL ANETARY RING GEAR 104 REAR PL ANETARY CARRIER ASSEMBLY 112 NUMBER 12 THRUST BEARING (RING GEAR TO INNER RACE) Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 67 Figure 69 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 51 28. Remove the snap ring from case, as shown in Figure 72. Continued on Page 52. Figure 71 LOW REVERSE CLUTCH SNAP RING 110 REVERSE CLUTCH HUB AND LOW ROLLER CLUTCH ASM. Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 70 Figure 72 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 52 EXTENSION HOUSING EXTENSION HOUSING GASKET OUTPUT SHAFT 98 LOW/REVERSE CLUTCH BACKING PLATE 99 LOW/REVERSE CLUTCH FRICTION PLATES (6) 100 LOW/REVERSE CLUTCH STEEL PLATES (6) Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 73 Figure 74 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 53 Figure 76. Continued on Page 54. RETAINING BOLTS PARK PAWL, PIVOT PIN, AND RETURN SPRING PARK ROD GUIDE PLATE OUTPUT SHAFT SPEED SENSOR RELUCTOR WHEEL Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 75 Figure 76 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 54 LUBE ORIFICE PLUG rear of case, as shown in Figure 78. Continued on Page 55. OUTPUT SHAFT AND PARK GEAR Copyright © 2003 ATSG Figure 78 NUMBER 13 THRUST BEARING LOW ROLLER CLUTCH INNER RACE RETAINING BOLTS (5) Copyright © 2003 ATSG Copyright ©...

-

Page 55: Transmission Case Assembly

114 REVERSE CLUTCH PISTON RETURN SPRING ASSEMBLY 115 REVERSE CLUTCH PISTON INNER LIP SEAL 116 REVERSE CLUTCH PISTON OUTER LIP SEAL 117 REVERSE CLUTCH PISTON Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 80 Figure 81 AUTOMATIC TRANSMISSION SERVICE GROUP... - Page 56 Continued on Page 57. TWO THREADED RODS 5/16"-24 X 3 INCH LONG Figure 82 LUBE ORIFICE PLUG LUBE HOLE LOW ROLLER CLUTCH INNER RACE Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 83 Figure 84 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 57 Continued on Page 58. INSTALL THREE LOW ROLLER CLUTCH INNER RACE RETAINING BOLTS TWO THREADED RODS Copyright © 2003 ATSG Figure 86 113 LOW ROLLER CLUTCH INNER RACE 114 REVERSE CLUTCH PISTON RETURN SPRING ASSEMBLY 115 REVERSE CLUTCH PISTON INNER LIP SEAL...

- Page 58 Continued on Page 59. "4WD VERSION" OUTPUT SPEED SENSOR SHAFT RELUCTOR WHEEL OUTPUT SHAFT AND PARK GEAR NUMBER 13 OUTPUT THRUST BEARING SHAFT SPEED SENSOR RELUCTOR WHEEL Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 88 Figure 89 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 59 Continued on Page 60. RETAINING BOLTS RETURN SPRING RETURN SPRING IS HOOKED ON IS HOOKED ON CASE CASE PARK PAWL, Copyright © 2003 ATSG PIVOT PIN, ENSURE THAT ENSURE THAT AND RETURN PARK ROD PARK ROD SPRING TRAVELS FREELY TRAVELS FREELY...

- Page 60 29. Torque the extension housing bolts, as shown in Figure 93 to 41-54 N·m (30-40 ft.lb.). EXTENSION Continued on Page 62. HOUSING EXTENSION HOUSING GASKET OUTPUT SHAFT Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 92 Figure 93 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 61 4 WHEEL DRIVE LUBE PLUG SHOULDER NO SHOULDER FORD 4R100 ALL OTHER 4R100 E4OD WITHOUT 6.8L AND 7.3L 2 WHEEL DRIVE LUBE PLUG 2 WHEEL DRIVE APPLICATIONS NO SHOULDER ADDED BOSS SHOULDER Copyright © 2003 ATSG Figure 94 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 62 REVERSE HUB ASSEMBLY INSTALL IN THIS DIRECTION AND TURN SLIGHTLY CLOCK-WISE TO LOCK IN PLACE 110 REVERSE CLUTCH HUB AND LOW ROLLER CLUTCH ASM. Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 96 Figure 97 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 63 100 LOW/REVERSE CLUTCH STEEL PLATES (6) 107 REAR PL ANETARY RING GEAR 101 LOW/REVERSE CLUTCH "WAVE" PLATE 112 NUMBER 12 THRUST BEARING (RING GEAR TO INNER RACE) Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 98 Figure 99 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 64: Front And Rear Planetary Carriers

REQUIRES 4 TANG REQUIRES 3 TANG THRUST WASHERS THRUST WASHER BOTH SIDES F0TZ-7A166-D Copyright © 2003 ATSG Figure 100 Planetary Carrier Differences COMPONENT REBUILD Both planetary carriers are model sensitive parts, and Front And Rear Planetary Carriers may contain a 4 pinion carrier or a 6 pinion carrier, as 1. - Page 65 79 FORWARD CLUTCH APPLY PLATE 80 FORWARD CLUTCH "WAVE" PLATE 81 FORWARD CLUTCH FRICTION PLATES 82 FORWARD CLUTCH STEEL PLATES 83 FORWARD CLUTCH BACKING PLATE 84 FORWARD CLUTCH BACKING PLATE SNAP RING (SELECTIVE) Copyright © 2003 ATSG Figure 102 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 66: Forward Clutch Housing

73 FORWARD CLUTCH HOUSING INNER "O" RING SEAL 74 FORWARD PISTON OUTER LIP SEAL 70 FORWARD CLUTCH SEALING RINGS (2 REQUIRED) 75 FORWARD CLUTCH PISTON ASSEMBLY 72 FORWARD CLUTCH HOUSING ASSEMBLY Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 103 Figure 104 AUTOMATIC TRANSMISSION SERVICE GROUP... - Page 67 79 FORWARD CLUTCH APPLY PLATE 77 FORWARD CLUTCH PISTON "BELLVILLE" RETURN SPRING 78 FORWARD CLUTCH RETURN SPRING SNAP RING 80 FORWARD CLUTCH "WAVE" PLATE Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 105 Figure 106 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 68 82 FORWARD CLUTCH STEEL PLATES 2.79-2.90mm (.110" - .114") 83 FORWARD CLUTCH BACKING PLATE 3.25-3.35mm (.128" - .132") 84 FORWARD CLUTCH BACKING PLATE SNAP RING (SELECTIVE) Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 107 Figure 108 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 69: Direct Clutch Housing

59 DIRECT CLUTCH HOUSING ASSEMBLY "DO NOT USE" REPLACE WITH PARTS SHOWN ABOVE DIRECT DRUM FOR "DIODE" ONE-WAY "DIODE" ONE-WAY CLUTCH ASSEMBLY CLUTCH ASSEMBLY "DO NOT USE" REPLACE WITH PARTS SHOWN ABOVE Copyright © 2003 ATSG Figure 109 AUTOMATIC TRANSMISSION SERVICE GROUP... - Page 70 64 DIRECT CLUTCH PISTON RETURN SPRING SNAP RING 66 DIRECT CLUTCH FRICTION PLATES 67 DIRECT CLUTCH STEEL PLATES 68 DIRECT CLUTCH BACKING PLATE 69 DIRECT CLUTCH BACKING PLATE SNAP RING (SELECTIVE) Copyright © 2003 ATSG Figure 110 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 71 "Late" design sun shell will retro-fit back on all models. SLOTS TO ACCEPT NUMBER 8A NUMBER 8A "NO" SLOTS THRUST WASHER THRUST WASHER Copyright © 2003 ATSG Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 111 Figure 112 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 72 7. Install the number 7 thrust washer, as shown in "DIODE" STYLE Figure 114, and retain with Trans-Jel®. ONE-WAY CLUTCH Copyright © 2003 ATSG Figure 113 57 INTERMEDIATE SPRAG ASSEMBLY 58 INTERMEDIATE SPRAG OUTER RACE THRUST WASHER (NO. 7) 58 INTERMEDIATE SPRAG OUTER RACE THRUST WASHER (NO. 7)

- Page 73 SPRAG RACE 59 DIRECT CLUTCH HOUSING ASSEMBLY HOLD DIRECT 60 DIRECT CLUTCH PISTON INNER LIP SEAL CLUTCH DRUM 61 DIRECT CLUTCH PISTON OUTER LIP SEAL Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 116 Figure 117 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 74 59 DIRECT CLUTCH HOUSING ASSEMBLY 63 DIRECT CLUTCH PISTON RETURN SPRING ASSEMBLY 65 NUMBER 8A THRUST WASHER (NOT USED ALL MODELS) 64 DIRECT CLUTCH PISTON RETURN SPRING SNAP RING Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 118 Figure 119...

- Page 75 1.15 - 2.06mm (.045" - .081") Selective Snap Rings Available 1.65-1.75mm (.065" - .069") 1.88-1.98mm (.074" - .078") 2.10-2.20mm (.083" - .087") Copyright © 2003 ATSG Figure 121 66 DIRECT CLUTCH FRICTION PLATES 67 DIRECT CLUTCH STEEL PLATES 68 DIRECT CLUTCH BACKING PLATE Copyright ©...

-

Page 76: Forward, Direct, Sun Shell Sub-Assembly

Thrust Washer And Requires Late Sun Shell 59 "EARLY" DIRECT CLUTCH HOUSING ASSEMBLY 59 "L ATE" DIRECT CLUTCH HOUSING ASSEMBLY 72 FORWARD CLUTCH HOUSING ASSEMBLY Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 122 Figure 123 AUTOMATIC TRANSMISSION SERVICE GROUP... - Page 77 Technical Service Information NUMBER 8C THRUST WASHER FORWARD RING GEAR AND HUB ASSEMBLY Copyright © 2003 ATSG Figure 125 59 DIRECT CLUTCH HOUSING ASSEMBLY 59 DIRECT CLUTCH HOUSING ASSEMBLY 72 FORWARD CLUTCH HOUSING ASSEMBLY 72 FORWARD CLUTCH HOUSING ASSEMBLY 89 NUMBER 9A THRUST BEARING ASSEMBLY 88 FORWARD RING GEAR AND HUB ASSEMBLY Copyright ©...

- Page 78 Note: Black side faces up. PLANETARY 9. Install the complete forward planetary carrier assembly into the ring gear, by rotating into position, as shown in Figure 129. Continued on Page 79. Copyright © 2003 ATSG Figure 127 NUMBER 9B THRUST BEARING FORWARD PLANETARY...

- Page 79 Figure 131. COMPLETED FORWARD/DIRECT ASSEMBLY 59 DIRECT CLUTCH HOUSING ASSEMBLY 72 FORWARD CLUTCH HOUSING ASSEMBLY 94 "L ATE" SUN GEAR AND SHELL ASSEMBLY Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 130 Figure 131 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 80: Center Support Assembly

BALL BEARING RETAINING BOLTS (3) 48 CENTER SUPPORT ASM. (SERVICED AS ASSEMBLY) 49 CENTER SUPPORT DIRECT CLUTCH SEALING RINGS (2) 50 NUMBER 6 THRUST WASHER Copyright © 2003 ATSG Figure 132 COMPONENT REBUILD CENTER BALL BEARING Center Support Assembly SUPPORT... - Page 81 Continued on Page 82. 48 CENTER SUPPORT ASM. (SERVICED AS ASSEMBLY) 49 CENTER SUPPORT DIRECT CLUTCH SEALING RINGS (2) 50 NUMBER 6 THRUST WASHER Copyright © 2003 ATSG Figure 134 COMPLETED CENTER SUPPORT ASSEMBLY Copyright © 2003 ATSG Figure 135...

-

Page 82: Intermediate/Overdrive Cylinder Assembly

38 OVERDRIVE CLUTCH PISTON RETURN SPRING 44 INTERMEDIATE CLUTCH PISTON OUTER LIP SEAL 39 OVERDRIVE CLUTCH PISTON 45 INTERMEDIATE CLUTCH PISTON 41 INTERMEDIATE CLUTCH PISTON INNER LIP SEAL Copyright © 2003 ATSG Figure 136 COMPONENT REBUILD Intermediate/Overdrive Support Assembly 1. Disassemble intermediate/overdrive cylinder 6. - Page 83 38 OVERDRIVE CLUTCH PISTON RETURN SPRING 39 OVERDRIVE CLUTCH MOLDED PISTON ASSEMBLY 41 INTERMEDIATE CLUTCH PISTON INNER LIP SEAL 42 INTERMEDIATE AND OVERDRIVE CLUTCH CYLINDER Copyright © 2003 ATSG 44 INTERMEDIATE CLUTCH PISTON OUTER LIP SEAL Figure 138 45 INTERMEDIATE CLUTCH PISTON Copyright ©...

-

Page 84: Overdrive Gearset Assembly

29 OVERDRIVE INTERNAL RING GEAR 30 CENTER SHAFT ASSEMBLY 32 CENTER SHAFT TO RING GEAR "WAVE" SNAP RING 33 NUMBER 5 THRUST BEARING, CENTER SHAFT TO SUPPORT Copyright © 2003 ATSG Figure 140 COMPONENT REBUILD Overdrive Gearset Assembly 1. Disassemble overdrive gearset using Figure 140 4. - Page 85 Technical Service Information Ensure that snap ring is fully seated. GROOVE FACING UP Copyright © 2003 ATSG Figure 142 24 OVERDRIVE ROLLER OUTER RACE "FLAT" SNAP RING 25 OVERDRIVE ROLLER OUTER RACE 29 OVERDRIVE INTERNAL RING GEAR Copyright © 2003 ATSG...

- Page 86 26 NUMBER 3 THRUST WASHER, OUTER RACE TO CARRIER 28 NUMBER 6 THRUST BEARING, CARRIER TO CENTER SHAFT 27 OVERDRIVE PLANETARY CARRIER ASSEMBLY 28 NUMBER 6 THRUST BEARING, CARRIER TO CENTER SHAFT Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 144 Figure 145...

- Page 87 Technical Service Information COMPLETED OVERDRIVE GEARSET Copyright © 2003 ATSG Figure 147 30 CENTER SHAFT ASSEMBLY 32 CENTER SHAFT TO RING GEAR "WAVE" SNAP RING 33 NUMBER 5 THRUST BEARING, CENTER SHAFT TO SUPPORT Copyright © 2003 ATSG Figure 146...

-

Page 88: Coast Clutch Housing Differences

This Style This Style "STAMPED STEEL" COAST CLUTCH DRUM USED WITH 6.8L AND 7.3L "WITH" PTO OPTION Copyright © 2003 ATSG Figure 148 Coast Clutch Housing Changes The coast clutch housing is model sensitive and there The sealing ring locations on the oil pump stator are three different versions, as shown above. - Page 89 18 COAST CLUTCH FRICTION PLATES 19 COAST CLUTCH STEEL PLATES 20 COAST CLUTCH BACKING PLATE 21 COAST CLUTCH BACKING PLATE SNAP RING (SELECTIVE) KOYO 6912 C3 (AVAILABLE LOCAL BEARING SUPPLY HOUSE) Copyright © 2003 ATSG Figure 149 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 90: Coast Clutch Housing Assembly

KOYO 6912 C3. "PTO" EQUIPPED MODELS 6. Place the coast clutch housing on a flat work surface, as shown in Figure 151. KOYO 6912 C3 (AVAILABLE LOCAL BEARING SUPPLY HOUSE) Copyright © 2003 ATSG Continued on Page 91. Figure 150 SEAL PROTECTOR 307-387 13 COAST CLUTCH HOUSING ASM. - Page 91 20 COAST CLUTCH BACKING PLATE 13 COAST CLUTCH HOUSING ASM. ("PTO" VERSION SHOWN) 21 COAST CLUTCH BACKING PLATE SNAP RING (SELECTIVE) 14 OVERDRIVE ROLLER CLUTCH ASSEMBLY Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 153 Figure 154 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 92 0.76 - 1.27mm (.030" - .050") Selective Snap Rings Available 1.35 - 1.45mm (.053" - .057") 1.75 - 1.85mm (.068" - .072") 2.15 - 2.25mm (.084" - .088") Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 155 Figure 156 Coast Clutch Housing (Cont'd) Coast Clutch Housing (Cont'd) 19.

- Page 93 Technical Service Information "REQUIRED" ASSEMBLY TOOL 307 S383 Copyright © 2003 ATSG Figure 158 COMPLETED OVERDRIVE GEARSET ASSEMBLY 13 COAST CLUTCH HOUSING ASM. ("PTO" VERSION SHOWN) 18 COAST CLUTCH FRICTION PLATES 19 COAST CLUTCH STEEL PLATES 20 COAST CLUTCH BACKING PLATE 21 COAST CLUTCH BACKING PLATE SNAP RING (SELECTIVE) Copyright ©...

-

Page 94: Oil Pump Assembly

10 STATOR SHAFT TO OIL PUMP COVER RETAINING BOLTS (3 REQUIRED) 11 STATOR SHAFT ASSEMBLY 12 OIL PUMP COVER ASSEMBLY 13 OIL PUMP COVER TO OIL PUMP BODY RETAINING BOLTS (12 REQUIRED) Copyright © 2003 ATSG Figure 159 AUTOMATIC TRANSMISSION SERVICE GROUP... - Page 95 Oil Pump Differences 13 CONVERTER CLUTCH CONTROL SPRING ("ON-OFF" ONLY) between "PWM" and "NON-PWM" 14 CONVERTER CLUTCH CONTROL VALVE BORE PLUG 15 CONVERTER CLUTCH CONTROL VALVE LINE-UP ("PWM" ONLY) Copyright © 2003 ATSG Figure 160 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 96 7. Turn the oil pump body over and install inner OIL PUMP BODY and outer pump gears, as shown in Figure 162, Copyright © 2003 ATSG and lubricate with transmission fluid. 8. Set the completed pump body aside for the Figure 161 future sub-assembly (See Figure 163).

- Page 97 (LIKE E4OD) USED WITH THE "CAST IRON" USED WITH THE "STAMPED STEEL" COAST CLUTCH DRUM COAST CLUTCH DRUM Copyright © 2003 ATSG Figure 164 Oil Pump Body And Cover Assembly (Cont'd) 11. If removal was necessary because of damage, COAST CLUTCH...

- Page 98 Technical Service Information STATOR SHAFT PUMP BODY TO SEALING RING PUMP COVER BOLTS (12 REQUIRED) Copyright © 2003 ATSG RF-F81P-7B324-AA Figure 167 Ford Ford Oil Pump Body And Cover Assembly (Cont'd) 14. Turn the oil pump cover over and install the...

- Page 99 CASE SEAL RING RF-F81P-7B324-AA Ford Ford ALIGNMENT STRAP Copyright © 2003 ATSG Figure 169 Oil Pump Body And Cover Assembly (Cont'd) 22. Install pump body to case seal ring, as shown RF-F81P 7A105-AA in Figure 171, and ensure that it is not twisted in the groove.

- Page 100 Technical Service Information FORD 4R100 MAIN, LOWER, AND ACCUMULATOR VALVE BODIES DISASSEMBLED 29 30 Copyright © 2003 ATSG Figure 173 AUTOMATIC TRANSMISSION SERVICE GROUP...

-

Page 101: Valve Body Assembly

Technical Service Information FORD 4R100 MAIN, LOWER, AND ACCUMULATOR VALVE BODY LEGEND Item Description Item Description 1 LOWER VALVE BODY CASTING 37 4-3-2 SHIFT TIMING VALVE RETAINING PLATE 2 HEX HEAD BOLT, (2 REQUIRED) 38 4-3-2 SHIFT TIMING VALVE 3 RETAINING PLATE... -

Page 102: Transmission Final Assembly

AND SUN SHELL ASSEMBLY 102 REAR CARRIER TO REVERSE HUB RETAINING SNAP RING 103 NUMBER 10B THRUST WASHER 104 6 PINION REAR PL ANETARY CARRIER ASSEMBLY Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 174 Figure 175 AUTOMATIC TRANSMISSION SERVICE GROUP... - Page 103 46 INTERMEDIATE CLUTCH PISTON RETURN SPRING 53 INTERMEDIATE CLUTCH STEEL PLATES 48 CENTER SUPPORT ASSEMBLY 54 INTERMEDIATE CLUTCH BACKING PLATE 49 NUMBER 6 THRUST WASHER, CENTER SUPPORT Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 176 Figure 177 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 104 6 o'clock (bottom) position in case. Continued on Page 105. OVERDRIVE CYLINDER FEED BOLT CENTER SUPPORT FEED BOLTS 40 INTERMEDIATE/OVERDRIVE CYLINDER SNAP RING 42 INTERMEDIATE/OVERDRIVE CYLINDER ASSEMBLY Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 178 Figure 179 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 105 CLUTCH SPRING FIXTURE CLUTCH SPRING COMPRESSOR BAR 31 OVERDRIVE CLUTCH BACKING PLATE SNAP RING (SELECTIVE) 34 OVERDRIVE CLUTCH BACKING PLATE CLUTCH SPRING 35 OVERDRIVE CLUTCH FRICTION PLATES COMPRESSOR PLATE Copyright © 2003 ATSG Figure 180 Figure 181 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 106 1.95 - 2.05mm (.077" - .081") = E9TZ-7B421-BA 2.50 - 2.60mm (.098" - .102") = E9TZ-7B421-CA 3.00 - 3.10mm (.118" - .122") = E9TZ-7B421-DA 3.50 - 3.60mm (.138" - .142") = E9TZ-7B421-EA Copyright © 2003 ATSG Figure 182 Figure 183 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 107 9 OIL PUMP AND COVER ASSEMBLY 10 NUMBER 1 THRUST WASHER (USED NON-PTO MODELS ONLY) 11 OIL PUMP ASSEMBLY TO CASE GASKET 13 NUMBER 2 THRUST BEARING, PUMP TO O.D. SUN GEAR Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 184 Figure 185...

- Page 108 Continued on Page 109. OVERDRIVE CYLINDER FEED BOLT. TORQUE TO 8-14 N·m (6-10 ft.lb.) CENTER SUPPORT FEED BOLTS TORQUE TO 11-16 N·m (8-12 ft.lb.) Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 186 Figure 187 AUTOMATIC TRANSMISSION SERVICE GROUP...

- Page 109 Note: The stamped word "UP" on reinforcing 55 MANUAL INTERMEDIATE SERVO ASSEMBLY 182 EPC BLOW-OFF BALL, .250" DIAMETER STEEL BALL plate should be facing up. 183 EPC BLOW-OFF SPRING Copyright © 2003 ATSG Continued on Page 110. Figure 189 .312" DIAMETER RUBBER CHECKBALLS 184 SPACER PLATE TO CASE GASKET .312"...

- Page 110 Note: Refer to Valve Body Bolt Chart found on Page 116 for proper locations. Continued on Page 111. 186 SPACER PLATE TO MAIN VALVE BODY GASKET 187 SOLENOID SCREEN ASSEMBLY Copyright © 2003 ATSG Figure 191 RETAINING BOLTS (14) RETAINING RETAINING NUTS (2)

-

Page 111: Manual Valve Check

It should be approximately .050", as shown in Figure 195. If dimension is not correct, replace the detent spring and Copyright © 2003 ATSG roller assembly with a "New" one. Figure 194 15. Lubricate the seal on the new filter with small amount of Trans-Jel®, and install new filter... -

Page 112: Manual Shift Lever Differences

(or equivalent). 3. Install the two sensor retaining bolts, as shown in Figure 199, and torque retaining bolts to, 8-10 N·m (71-88 in.lb.). Copyright © 2003 ATSG Continued on Page 113. Figure 197 FORD 4R100 MANUAL SHIFT LEVERS "With"... - Page 113 6. Install the cooler bypass valve with the sealing washers positioned as shown in Figure 202, and install threaded cooler line case fittings. 7. Torque front fitting to, 30 N·m (22 ft.lb.). Copyright © 2003 ATSG Torque rear fitting to, 36 N·m (27 ft.lb.) Figure 200 OUTPUT SHAFT SPEED SENSOR Continued on Page 114.

- Page 114 F o rd -B A P- 7 0 0 6 R FF 8 1 LONGER SPLINES Copyright © 2003 ATSG Figure 203 FINAL ASSEMBLY External Components (Cont'd) 8. Remove the transmission from bench fixture 11. Install torque converter and check the seating and set on flat work surface (See Figure 203).

-

Page 115: Torque Specifications

22-27 16-20 Extension Housing Bolts (9) 41-54 30-40 Front Cooler Line Connector to Case (1) Rear Cooler Line Connector to Case (1) Transmission Oil Pan to Case (20) 14-16 10-12 Copyright © 2003 ATSG Figure 206 AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 116: Valve Body Bolt Chart And Identification

Lower V.B. Solenoid to Main V.B. Body Accum Main (35mm) Valve Body Valve Body (40mm) to Case to Case (11) (42mm) (42mm) Lower V.B. to Case Reinforcing Plate (65mm) (16mm) Copyright © 2003 ATSG Figure 207 AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 117: Bolt Chart And Identification

Park Rod (14mm) (17mm) (16mm) Guide Plate (23mm) Pump Cover Case to to Pump Body BOLTS DRAWN Inner Race (45mm) ACTUAL SIZE (1.875") Pump to Case (65mm) Copyright © 2003 ATSG Copyright © 2003 ATSG Figure 208 AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 118: Special Service Tools

Technical Service Information Copyright © 2003 ATSG AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 119: Automatic Transmission Service Group

Technical Service Information Copyright © 2003 ATSG AUTOMATIC TRANSMISSION SERVICE GROUP... -

Page 120: Automatic Transmission Service Group

Technical Service Information Copyright © 2003 ATSG AUTOMATIC TRANSMISSION SERVICE GROUP...

Need help?

Do you have a question about the FORD 4R100 and is the answer not in the manual?

Questions and answers