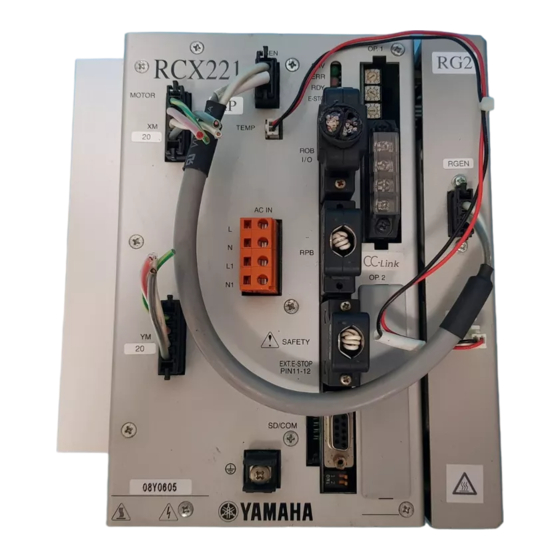

Yamaha CEmarking RCX221 Manuals

Manuals and User Guides for Yamaha CEmarking RCX221. We have 2 Yamaha CEmarking RCX221 manuals available for free PDF download: User Manual, Supporting Supplement Manual

Yamaha CEmarking RCX221 User Manual (468 pages)

YAMAHA 2-AXIS ROBOT CONTROLLER

Brand: Yamaha

|

Category: Controller

|

Size: 4 MB

Table of Contents

Advertisement

Yamaha CEmarking RCX221 Supporting Supplement Manual (92 pages)

ROBOT CONTROLLER

Brand: Yamaha

|

Category: Controller

|

Size: 2 MB