Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for MUTOH ValueJet

- Page 1 Service manual ValueJet 1304...

-

Page 3: Important Notice

3. Trademark Mentioned in this Manual • MUTOH, ValueJet, VJ-1304 are registered trademarks or product names of MUTOH INDUSTRIES LTD. • Centronics and BiCentronics are registered trademarks or product names of Centronics Data Computer Corporation. -

Page 4: Warranty Limitations

ValueJet 1304 Service manual Warranty Limitations 1. MUTOH INDUSTRIES LTD. warrants part repair or replacement as a sole measure only if a failure is found in the system or in the materials and workmanship of the product the seller produced. However, if the cause of failure is uncertain, decide the action after due mutual consultation. -

Page 5: About This Manual

ValueJet 1304 Service manual About this Manual 1. Purpose and Target Readers This manual explains preparations needed before maintaining and checking operations for MUTOH Full Color Ink Jet Printer (VJ-1304). This manual is prepared for the maintenance personnel of this printer. - Page 6 ValueJet 1304 Service manual 3. Manual Notation The following symbols are used in this manual for easier understanding of the information. Symbol Meaning Must be followed carefully to avoid death or serious bodily injury WARNING Must be observed to avoid slight or moderate bodily injury or damage to...

-

Page 7: Safety Instructions

ValueJet 1304 Service manual General Table of Contents 1 Safety Instructions 1.1 Introduction ..........1-2 1.2 Warnings, Cautions and Notes . -

Page 8: Table Of Contents

ValueJet 1304 Service manual 3 Specifications 3.1 Introduction..........3-2 3.2 Product Specifications. - Page 9 ValueJet 1304 Service manual 4.5 Replacement of CR Driving Section Components....4-51 4.5.1 CR Motor Assembly ........4-51 4.5.2...

- Page 10 ValueJet 1304 Service manual 5 Self-Diagnosis Mode 5.1 Introduction..........5-4 5.2 Preparation .

- Page 11 ValueJet 1304 Service manual 5.9 Sample Printing Menu ........5-49 5.9.1...

- Page 12 7.2 Adjustment Item ..........7-3 7.3 Working with Mutoh Maintenance Engineer Assistant....7-8 7.3.1...

- Page 13 ValueJet 1304 Service manual 8 Maintenance 8.1 Introduction ..........8-2 8.2 Periodical Services .

- Page 14 ValueJet 1304 Service manual AP-74109 Rev 1.1 2-10...

- Page 15 ValueJet 1304 Service manual 1 Safety Instructions Introduction ..................... 1- 2 Warnings, Cautions and Notes.............. 1- 2 Important Safety Instructions ..............1- 3 Warning Labels ..................1- 9 1.4.1 Handling the Warning Labels............1-9 1.4.2 Locations and Types of Warning Labels........1-9 Operation Labels...................

-

Page 16: Introduction

ValueJet 1304 Service manual 1.1 Introduction This chapter explains the meaning of safety terms for personnel who installs, operates, or maintains this equipment, important safety instructions, and the warning labels attached to the equipment. WARNING Make sure to follow all instructions and warnings on this manual when installing, operating, or maintaining the equipment. -

Page 17: Important Safety Instructions

ValueJet 1304 Service manual 1.3 Important Safety Instructions General safety instructions that must be observed to use the equipment safely are explained below. WARNING Do not place the printer in the following areas. Doing so may result in the printer tipping or falling over and causing injury. - Page 18 ValueJet 1304 Service manual Do not insert or drop metal or flammable objects into the printer through openings such as a fresh air inlet. It could lead to an electric shock and fire. When foreign substances or liquids such as water entered the printer, do not use the printer as it is.

- Page 19 If you need to operate the printer with the cover removed for maintenance, be careful not to get hurt by the driving parts. Never lube the printer mechanism with lube other than that designated by MUTOH. Doing so may damage the parts or shorten the lifetime.

- Page 20 ValueJet 1304 Service manual Pay attention to the following points, while handling power cable. • Do not do anything forcefully on the power cable. • Do not keep heavy objects on the power cable. • Do not bend, twist or pull the power cable by force.

- Page 21 ValueJet 1304 Service manual While cleaning with the cleaning wiper • Do not touch the cleaning wiper and head cap unit. Head cleaning may not be operated correctly because of the grease attached. • Make sure to wipe the print head with a dry poly-knit wiper.

- Page 22 ValueJet 1304 Service manual When cleaning the printer, be sure to turn OFF the power and disconnect the power plug. Move the printer maintaining a horizontal position. Be sure to operate the following before attaching option units. • Turn the printer power off.

-

Page 23: Warning Labels

ValueJet 1304 Service manual 1.4 Warning Labels The handling, attachment locations, and types of warning labels are explained below. Warning labels are attached to areas where care should be taken. Read and understand the positions and contents thoroughly before maintenance operation. - Page 24 ValueJet 1304 Service manual Table 1-2 List of Warning Labels Warning label type (T fence handling caution) (Front cover open/close caution) (High temperature caution) (2) Winding unit The locations of warning labels on the winding unit are shown below. AP-74109 Rev 1.1...

-

Page 25: Operation Labels

ValueJet 1304 Service manual Warning label type (Catching caution) 1.5 Operation Labels This chapter describes the operation labels including their types and attaching positions. The operation labels are attached on the product to provide the brief instructions for the particularly important operations. -

Page 26: Locations And Types Of Operation Labels

ValueJet 1304 Service manual 1.5.2 Locations and Types of Operation Labels The locations of operation labels are shown below. Table 1-3 List of Operation Labels Operation label type (Roll media setting) "Operation manual" Setting Roll Media AP-74109 Rev 1.1 1-12... - Page 27 ValueJet 1304 Service manual Table 1-3 List of Operation Labels (Continued) Operation label type (Ink arrangement) "Operation manual" Replacing Ink Cartridges 1-13 AP-74109 Rev 1.1...

- Page 28 ValueJet 1304 Service manual AP-74109 Rev 1.1 1-14...

-

Page 29: Product Overview

ValueJet 1304 Service manual 2 Product Overview Introduction ..................... 2- 2 Features ....................2- 2 Part Names and Functions..............2- 3 2.3.1 Front Section ................. 2-4 2.3.2 Rear Section .................. 2-5 2.3.3 Winding unit (Optional) ..............2-6 2.3.4 Operation Panel ................2-8 Printer Status .................. -

Page 30: Introduction

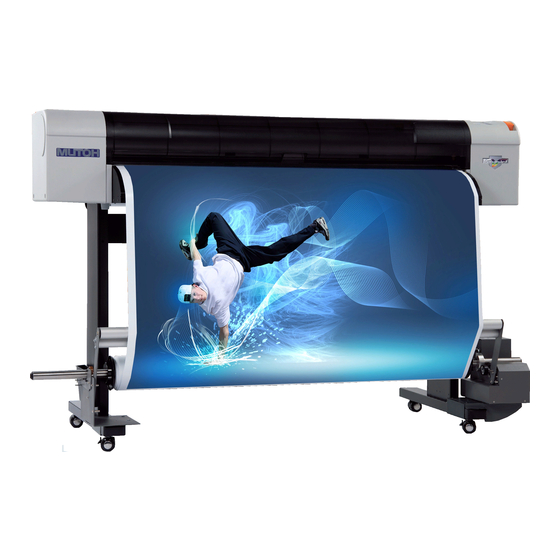

ValueJet 1304 Service manual 2.1 Introduction This chapter explains the features, part names, and functions of the printer. 2.2 Features The features of the printer are explained below. (1) Fast Print The new print head adopted on this printer performs fast to print images. -

Page 31: Part Names And Functions

ValueJet 1304 Service manual 2.3 Part Names and Functions Part names and functions are explained below. NOTE For the directions described in this document, refer to the following figure. Upper Rear Left Right Front Lower AP-74109 Rev 1.1... -

Page 32: Front Section

ValueJet 1304 Service manual 2.3.1 Front Section Table 2-1 Part Names and Functions of Front Section Name Function Media set lever This lever is used to fix or release the media. Operation panel This panel is used to set operational conditions, the status of the printer, and other functions. -

Page 33: Rear Section

ValueJet 1304 Service manual Table 2-1 Part Names and Functions of Front Section (Continued) Name Function Platen This is inside the front cover. There are heaters (platen heater) inside to dry ink. 2.3.2 Rear Section Table 2-2 Part Names and Functions of Rear Section... -

Page 34: Winding Unit (Optional)

ValueJet 1304 Service manual Table 2-2 Part Names and Functions of Rear Section (Continued) Name Function Waste fluid valve Open this valve to discharge the waste fluid from the waste fluid tank. In other case, close the valve. 2.3.3 Winding unit... - Page 35 ValueJet 1304 Service manual Table 2-3 Part Names and Functions of Winding Unit Name Function Operation panel Used for setting operation conditions, display of unit status. "Winding unit for VJ-1304" AP-74109 Rev 1.1...

-

Page 36: Operation Panel

ValueJet 1304 Service manual 2.3.4 Operation Panel The operation panel is used to set operational conditions, display the status of the printer, and set other functions. The names and functions of the operation keys and status lamps are explained below. Operation manual 8, 9 AP-74109 Rev 1.1... - Page 37 ValueJet 1304 Service manual (1) Operation Keys NOTE Some keys have multiple functions and names depending on the printer status (normal or setup menu display). See "2.4 Printer Status" p.2-11 for more details. Name Normal Setup menu display [Menu] key Changes the LCD monitor display to Changes the setup menu display setup menu status.

- Page 38 ValueJet 1304 Service manual Name Normal Setup menu display [Power] key Turns the printer on and off. Turns the printer on and off. (2) LCD Monitor and Status Lamps Name Color Status Function Power lamp Green On The printer is switched on.

-

Page 39: Printer Status

ValueJet 1304 Service manual 2.4 Printer Status The status of the printer is explained below. 2.4.1 Normal Indicates that the printer can print when media is loaded. Each setup concerning printing can be operated by using operation panel. Operation manual 2.4.2 Setup Menu Each setup concerning printing can be operated by using operation panel. -

Page 40: Selecting Panel Language And Panel Temperature

ValueJet 1304 Service manual 2.4.5 Selecting Panel Language and Panel Temperature This section describes how to select the language displayed in the operation panel. Follow the steps below to select the language. NOTE You can choose panel language and panel temperature as follows. -

Page 41: Specifications

ValueJet 1304 Service manual 3 Specifications Introduction ..................... 3- 2 Product Specifications ................3- 2 Interface Specifications................3- 4 3.3.1 Network Interface Specifications............ 3-4 Choosing a Place for the Printer ............3- 5 AP-74109 Rev 1.1... -

Page 42: Product Specifications

ValueJet 1304 Service manual 3.1 Introduction This chapter explains the specifications of the product, optional parts, and supplies. Installation environment requirements are also explained. 3.2 Product Specifications (1) Main Unit Specifications Item Specifications Model name VJ-1304 Plotting method On-demand piezo drive... - Page 43 ValueJet 1304 Service manual Item Specifications 64Bit RISC CPU Memory 128MB Command MH-RTL (RTL-PASS) Interface Network Interface (IEEE802.3) ° After-heater OFF / 30 to 50 C (86 to 122F) ° Platen heater OFF / 30 to 50 C (86 to 122F) °...

-

Page 44: Interface Specifications

ValueJet 1304 Service manual 3.3 Interface Specifications This section explains the specification of the interfaces Supported for this printer. 3.3.1 Network Interface Specifications Item Specifications Network type Ethernet IEEE802.3 Network I/F 10BASE-T / 100BASE-TX Auto-switching (RJ-45 connector twist pair cable) MDI / MDI-X Auto-switching... -

Page 45: Choosing A Place For The Printer

ValueJet 1304 Service manual Choosing a Place for the Printer WARNING • Do not place the printer in a location under the following conditions. Doing so may cause the product to fall, become damaged, or cause injury. • Unstable surfaces • Slanted areas •... - Page 46 • Places where direct sunlight or excessive lighting are expected • Places where air conditioners blow directly • MUTOH recommends that the printer should be installed where air conditioning can be adjusted easily. (2) Required Space Install the printer on a flat surface that fulfills the following conditions.

- Page 47 ValueJet 1304 Service manual 4 Parts Replacement Introduction ..................... 4- 4 Removal of Covers ................. 4- 5 4.2.1 Removing R Side Cover ..............4-6 4.2.2 Removing Operation Panel Unit ............ 4-9 4.2.3 Removing L Side Cover ............... 4-10 4.2.4 Removing Ink Holder (I/H) Cover..........4-12 4.2.5 Removing Front Cover..............

- Page 48 ValueJet 1304 Service manual 4.4.2 Replacing PF_ENC Assembly............4-47 4.4.3 Replacing PF_ENC Scale ............4-48 4.4.4 Replacing Heater and Thermistor Assembly ........ 4-49 Replacement of CR Driving Section Components ......4- 51 4.5.1 CR Motor Assembly..............4-51 4.5.2 Replacing CR Origin Point Sensor ..........4-52 4.5.3 Replacing Lever Sensor ...............

- Page 49 ValueJet 1304 Service manual 4.9.2 Replacing P_REAR Sensor Assembly......... 4-90 4.10 Replacement of Cable Guide Section Components ......4- 91 4.10.1 Replacing CR Board Assembly............ 4-91 4.10.2 Replacing Ink Tube ..............4-93 4.10.3 Replacing CR Tape Wire ............. 4-97 4.11 Replacing Accessory Unit..............4- 101 4.11.1 Replacing Level Switch (Waste Fluid) ........

-

Page 50: Introduction

Do not disassemble the frame components and other components that are not instructed to disassemble in the manual. The machine has been assembled in the MUTOH factory with extremely high precision up to 1/100mm. If disassembled inappropriately, it may not restore its normal functionality. - Page 51 ValueJet 1304 Service manual NOTE After replacing any service parts, perform necessary lubrication and bonding following the instructions in section "8.4 Lubrication/Bonding" p.8-7. Upper Rear Left Right Front Lower AP-74109 Rev 1.1...

-

Page 52: Removal Of Covers

ValueJet 1304 Service manual 4.2 Removal of Covers Before replacing any service parts in the machine, you must remove some external covers. This section describes the procedure to remove covers. (Rear side) Table 4-1 Cover Component List Part name L side cover... -

Page 53: Removing R Side Cover

ValueJet 1304 Service manual 4.2.1 Removing R Side Cover 1. Move down the pressure lever backward. 表 4-2 Part name Pressure lever cap Pressure lever cap screw × 10, P tight binding) × 2. Remove the pressure lever cap-retaining screw (M4 10, P tight binding: 1). - Page 54 ValueJet 1304 Service manual × 4. Remove the waste fluid unit cover-retaining screw (tapping screw M3 6, S tight cup: 2) 表 4-4 Part name Waste fluid cover waste fluid unit cover-retaining × screw (Tapping screw M3 6, S tight cup: 2) 5.

- Page 55 ValueJet 1304 Service manual × 8. Remove the R side cover rear screw (tapping screw M4 12, S tight cup: 2). 表 4-6 Part name R side cover R side cover rear screw × (tapping screw M4 12, S tight cup) 9.

-

Page 56: Removing Operation Panel Unit

ValueJet 1304 Service manual 4.2.2 Removing Operation Panel Unit Before removing the operation panel unit, perform the following work. • Removing the R side cover: "4.2.1 Removing R Side Cover" p.4-6 • Unlocking and moving the carriage. 1. Remove the operation panel unit tape wire (FFC). -

Page 57: Removing L Side Cover

ValueJet 1304 Service manual 4.2.3 Removing L Side Cover × 1. Remove the L side cover front screw (tapping screw M4 12, P tight binding black: 2). 表 4-7 Part name L side cover L side cover inner screw × (tapping screw M4... - Page 58 ValueJet 1304 Service manual 5. Remove the L side cover. 6. To reassemble the unit, reverse the removal procedure. AP-74109 Rev 1.1 4-12...

-

Page 59: Removing Ink Holder (I/H) Cover

ValueJet 1304 Service manual 4.2.4 Removing Ink Holder (I/H) Cover NOTE Before removing the ink holder (I/H) cover, remove the following parts. • R side cover: "4.2.1 Removing R Side Cover" p.4-6 1. Remove the ink cartridge. × 2. Remove the I/H cover rear screw (tapping screw M4 8, S tight cup: 2). - Page 60 ValueJet 1304 Service manual 5. Remove the I/H cover. 6. To reassemble the unit, reverse the removal procedure. AP-74109 Rev 1.1 4-14...

-

Page 61: Removing Front Cover

ValueJet 1304 Service manual 4.2.5 Removing Front Cover 1. Open the front cover. 2. Remove the front cover by pulling it toward the direction of the arrow shown below. Part name Front cover Front cover receiver NOTE Do not remove the front cover by force.It may damage or deform the resin. -

Page 62: Removing Top Cover

ValueJet 1304 Service manual 4.2.6 Removing Top Cover NOTE Before removing the top cover, remove the following parts. • Front cover: "4.2.5 Removing Front Cover" p.4-14 × 1. Remove the top cover front side-retaining screw (round head spring screw M3 5: 2). -

Page 63: Removing Media Guide F

ValueJet 1304 Service manual 4.2.7 Removing Media Guide F × 1. Remove the media guide F lower-side screw (cup screw M3 6 Ni-3bk: 10). 表 4-13 Part name Media guide F Media guide F screw × (cup screw M3 6 Ni-3bk) ×... -

Page 64: Removing Media Guide R2

ValueJet 1304 Service manual 4.2.8 Removing Media Guide R2 × 1. Remove the media guide R2-retaining screw (tapping screw M3 6, S tight cup: 11). The number of screws varies depending on models. 表 4-15 Part name Rear cover Media guide R2-retaining screw ×... -

Page 65: Removing Scroller Receiver (L, R)

ValueJet 1304 Service manual 4.2.9 Removing Scroller Receiver (L, R) × 1. Remove the scroller receiver L-retaining screw (tapping screw M3 6, S tight cup: 2). 表 4-16 Part name Scroller receiver L screw × (tapping screw M3 6, S tight... - Page 66 ValueJet 1304 Service manual NOTE There are two hole to attach the scroller receiver on the frame side. See the right of illustration below for the hole for VJ-1304. Make sure that the part is attached to the appropriate position. Part name...

-

Page 67: Assembling Of Scroller Receiver L And R

ValueJet 1304 Service manual 4.2.10 Assembling of Scroller Receiver L and R NOTE Before assembling scroller receiver, remove the following part. • Scroller receiver: "4.2.9 Removing Scroller Receiver (L, R)" p.4-18 1. Attach the two position adjustment scroller roller shafts to the part A shown below of scroller receiver L (or R). - Page 68 ValueJet 1304 Service manual 3. From the other side of scroller receiver L (or R) explained in step 1 and 2, insert the scroller receiver R and fix the scroll receiver roller set in step 2. 表 4-20 Part name Scroller roller shaft R Scroller receiver L 4.

- Page 69 ValueJet 1304 Service manual 5. Set the scroller receiver roller to the position B and C in the figure below. Make sure that the rollers are set on the appropriate position of the scroller receiver R (or L). 表 4-22 Part name...

-

Page 70: Replacement Of Board Base Section Components

ValueJet 1304 Service manual 4.3 Replacement of Board Base Section Components This section describes replacement procedures of power board assembly, main board assembly, and cooling fan. CAUTION When you handle a circuit board, do not touch any elements on it with bare hands. -

Page 71: Removing Main Board Bracket

ValueJet 1304 Service manual (2) Replacing Cooling Fan (5V) 1. Remove the cooling fan (5V) cable from the clamp. 2. Remove the cooling fan (5V) connector. × 3. Remove the fan bracket screw (tapping screw M3 6, S cup: 2). 表 4-25... - Page 72 ValueJet 1304 Service manual CAUTION • Before replacing board or connecting/removing tape wire (FFC), unplug the power cable and leave the printer for a while. Or board may be damaged by overcurrent. • When connecting or removing the FFC type cables to the main board assembly connector, always pull or push the cables perpendicularly to the connector.

- Page 73 ValueJet 1304 Service manual Table 4-26 Connectors to Main Board Assembly Connector # of pins Color Connect to Remarks White Power board assembly Connected to CN301 by using DC cable assembly. Black Operation panel unit assembly Black CR board assembly J203 Connected to J203 by using CR tape wire.

- Page 74 ValueJet 1304 Service manual Table 4-26 Connectors to Main Board Assembly (Continued) Connector # of pins Color Connect to Remarks Natural HEATER CONT board color SODIMM 128MB 2. Remove the cable from the three clamps on the main board bracket. 3. Remove the following parts (if needed);...

- Page 75 ValueJet 1304 Service manual × 4. Remove the board bracket-retaining screws (tapping screw M3 6, S tight cup: 5). 表 4-27 Part name Main board bracket Main board bracket-retaining screw × (tapping screw M3 6, S tight cup) 5. Slide the main board bracket to the right then lift from the front side and remove it.

-

Page 76: Removing Connector Panel And Cooling Fan

4. Install the parameters and firmware by following the instructions in "7.3 Working with MUTOH Maintenance Engineer Assistant" p.7-8 "7.4 Working with MUTOH Service Assistance" p.7- 5. Perform adjustment on media edge sensor and the P_REAR sensor by following the instructions in "7.2 Adjustment Item"... -

Page 77: Replacing Heater Cont Board Assembly

ValueJet 1304 Service manual 4.3.4 Replacing HEATER CONT board assembly 1. Remove the cable from the five brackets at the top of the HEATER CONT board assembly. 表 4-29 Part name Board bracket Clamp 2. Remove the following connectors from the HEATER CONT board assembly. - Page 78 ValueJet 1304 Service manual Table 4-30 Connectors to HEATER CONT board assembly (Continued) Connector # of Color Connect to Remarks pins Unused Unused Unused Unused Unused Unused Unused White Main board assembly Connected to J46 by using power cable assembly between MAIN - CNT.

- Page 79 ValueJet 1304 Service manual × 4. Remove the HEATER CONT board bracket-retaining screw (tapping screw M3 6, S tight cup: 4), and remove it. 表 4-31 Part name HEATER CONT board bracket HEATER CONT board bracket-retaining screw × (tapping screw M3 6, S tight cup) ×...

-

Page 80: Replacing Heater Relay Board Assembly

ValueJet 1304 Service manual 4.3.5 Replacing HEATER RELAY board assembly 1. Remove the cable from the five clamps on the top of HEATER CONT board bracket. 表 4-33 Part name HEATER CONT board bracket Clamp 2. Remove the following connectors from the HEATER RELAY board assembly. - Page 81 ValueJet 1304 Service manual Table 4-34 Connectors to HEATER RELAY board assembly Connector # of Color Connect to Remarks pins Pre-thermistor White After-thermistor 3. Replace the AC cable assembly between CNT-RLY, and RLY_AC cable assembly. × 4. Remove the HEATER CONT board bracket-retaining screws (tapping screw M3 6 tight cup: 4), and remove the board bracket.

-

Page 82: Replacing Power Board Assembly

ValueJet 1304 Service manual × 5. Remove the relay board assembly retaining screws (cup screw M3 6 white: 9). 表 4-36 Part name Relay board assembly Relay board assembly screw × (cup screw M3 6 white) 6. Replace the relay board assembly. - Page 83 ValueJet 1304 Service manual 1. Remove the following connector from the power board assembly. Table 4-37 Connectors to Power Board Assembly No. Connector No. # of pins Color Connect to Remarks CN301 White Main board assembly Connected to J1 by using DC cable assembly.

- Page 84 ValueJet 1304 Service manual 4. Remove the three cables from clamp of the front side of HEATER-RELAY board bracket. 表 4-40 Part name HEATER-RELAY board bracket Clamp × 5. Remove the power board bracket-retaining screw (tapping screw M3 6 S tight cup).

-

Page 85: Replacing Fuse

ValueJet 1304 Service manual × 6. Remove the power board assembly-retaining screw (cup screw M3 6 white: 9). 表 4-42 Part name Power board assembly Power board screw × (cup screw M3 6 white) 7. Replace the power board assembly. 8. To reassemble the unit, reverse the removal procedure. - Page 86 ValueJet 1304 Service manual 1. Pick up the fuse using a finger on the center of the part and remove it. 表 4-43 Part name Fuse 2. Replace the fuse. × 3. Remove the two screws (pan head small screw M4 6) retaining the noise filter to fuse AC cable assembly and fuse to terminal block AC cable assembly.

- Page 87 ValueJet 1304 Service manual 7. Remove the protect cover on the top of terminal block, then remove the screws retaining the fuse to terminal block AC cable assembly to terminal block. 表 4-45 Part name Protect cover of terminal block Screws retaining the fuse to...

-

Page 88: Replacing Inlet Assembly

ValueJet 1304 Service manual 4.3.8 Replacing Inlet Assembly NOTE Before replacing the inlet assembly, remove the following parts. • Media guide R2: "4.2.8 Removing Media Guide R2" p.4-17 (1) Removing Cooling Fan (24V) × 1. Remove the screw retaining the cooling fan (24V) (pan head small screw M 4 30: 2). - Page 89 ValueJet 1304 Service manual • When reassembling the cooling fan, spread the fan seal (shown in the diagram below) under the fan, then screw the fan on it 表 4-48 Part name Fan seal • Installation direction of the cooling fan assembly (sealing surface and cable pulling direction) is specified.

- Page 90 ValueJet 1304 Service manual (2) Replacing Inlet Assembly × 1. Remove the inlet assembly-retaining screws (round head spring screw (finishing) M3 10: 2). 表 4-49 Part name Inlet assembly connector Inlet assembly Inlet assembly screw (round head spring screw × (finishing) M3 2.

-

Page 91: Replacement Of Pf Driving Section Components

ValueJet 1304 Service manual 4.4 Replacement of PF Driving Section Components 4.4.1 Replacing PF Motor Assembly NOTE Before replacing parts in the PF motor assembly, remove the following covers. • L side cover: "4.2.3 Removing L Side Cover" p.4-10 • Media guide R2: "4.2.8 Removing Media Guide R2"... - Page 92 ValueJet 1304 Service manual × 3. Remove the screw (round head spring screw M3 6: 1) retaining PF encoder fixing board t2 to PF bracket, then remove the PF encoder fixing board t2. 表 4-53 Part name PF bracket Screws retaining PF encoder fixing board t2 (round head ×...

- Page 93 ValueJet 1304 Service manual NOTE Move the PF speed reduction pulley with your hand to check if the PF speed reduction belt is equally balanced on the pulley center section of the PF motor assembly. 7. Perform adjustments by following the instructions in "7.2 Adjustment Item"...

-

Page 94: Replacing Pf_Enc Assembly

ValueJet 1304 Service manual 4.4.2 Replacing PF_ENC Assembly NOTE Before replacing parts in the PF_ENC assembly, remove the following covers. • L side cover: "4.2.3 Removing L Side Cover" p.4-10 • Rear cover: "4.2.8 Removing Media Guide R2" p.4-17 1. Remove the PF_ENC assembly connectors from the main board assembly. -

Page 95: Replacing Pf_Enc Scale

ValueJet 1304 Service manual 4.4.3 Replacing PF_ENC Scale NOTE Before replacing parts in the PF_ENC scale assembly, remove the following parts. • L side cover: "4.2.3 Removing L Side Cover" p.4-10 × 1. Remove the ENC holder-retaining screw (tapping screw M3 6, P tight cup). -

Page 96: Replacing Heater And Thermistor Assembly

ValueJet 1304 Service manual 4.4.4 Replacing Heater and Thermistor Assembly (1) Replacing After-heater 1. Remove the media guide F. "4.2.7 Removing Media Guide F" p.4-16 2. Remove the connectors from both AFT_H relay assembly and AFT_T relay assembly. 3. Remove the after-heater and thermistor. - Page 97 ValueJet 1304 Service manual × 3. Remove the media guide stay b-retaining screw (cup screw M3 6 Ni-3 bk: 5), and remove the media guide stay b. 表 4-58 Part name Media guide stay b Media guide stay b-retaining × screw (cup screw M3 6 Ni-3 4.

-

Page 98: Replacement Of Cr Driving Section Components

ValueJet 1304 Service manual 4.5 Replacement of CR Driving Section Components 4.5.1 CR Motor Assembly NOTE Before replacing parts in the CR motor assembly, remove the following covers. • R side cover: "4.2.1 Removing R Side Cover" p.4-6 • L side cover: "4.2.3 Removing L Side Cover"... -

Page 99: Replacing Cr Origin Point Sensor

ValueJet 1304 Service manual 6. Remove the screws retaining the CR motor assembly to the CR motor mounting material (cup screw M4 × 8: 4). 表 4-61 Part name CR motor mounting material CR motor screw × (cup screw M4 CR motor 7. - Page 100 ValueJet 1304 Service manual 2. Pull out the CR_HP cable assembly connector from the CR_HP sensor. 表 4-62 Part name Hook CR_HP sensor Connector 3. Release the hook retaining the CR_HP sensor, then remove the CR_HP sensor. 4. Replace the CR_HP sensor.

-

Page 101: Replacing Lever Sensor

ValueJet 1304 Service manual 4.5.3 Replacing Lever Sensor NOTE Before replacing the lever sensor, remove the following covers. • R side cover: "4.2.1 Removing R Side Cover" p.4-6 1. Move down the pressure lever forward (downward). 2. Detach the lever sensor cable assembly connector from the lever sensor. -

Page 102: Replacing T Fence

ValueJet 1304 Service manual 4.5.4 Replacing T Fence NOTE Before replacing the T fence, remove the following covers. • R side cover: "4.2.1 Removing R Side Cover" p.4-6 • L side cover: "4.2.3 Removing L Side Cover" p.4-10 1. Remove the T fence spring from T fence spring hook on the L frame side. - Page 103 ValueJet 1304 Service manual CAUTION When removing the T fence, note the following. • Do not pull the T fence by force; the fence guide can be easily broken. • Pay attention not to damage or break the T fence. 3. Remove the T fence from the CR rail frame R hook on the R frame side, then pull it out toward the direction of the arrow in the diagram.

- Page 104 ValueJet 1304 Service manual 6. Insert the T fence into the CR encoder assembly. 表 4-65 Part name T fence CR encoder assembly 7. Install the T fence to the fence guide. 表 4-66 Part name side view T fence Fence guide Slide the T fence in the order of arrows shown above to install.

-

Page 105: Replacing Cr Driven Pulley And Cr Belt

ValueJet 1304 Service manual 4.5.5 Replacing CR Driven Pulley and CR belt NOTE Before replacing CR driven pulley assembly and CR belt, remove the following covers. • R side cover: "4.2.1 Removing R Side Cover" p.4-6 • L side cover: "4.2.3 Removing L Side Cover" p.4-10 •... - Page 106 ValueJet 1304 Service manual NOTE • Installation direction of the driven pulley shaft is specified.Thin shaft side faces down. Also refer to " " p.10-4. • After installing the CR driven pulley, move the carriage with your hand from side to side, and check if the CR belt is equally balanced on the pulley center section of the CR motor assembly.

-

Page 107: Replacing Pressure Arm Assembly

ValueJet 1304 Service manual 4.5.6 Replacing Pressure Arm Assembly This section describes how to replace the pressure spring, pressure roller assembly, and pressure arm assembly. (1) Replacing Pressure Spring 1. Remove the spring attached to pressure bracket and pressure arm using spring hook, tweezers, or longnose pliers. -

Page 108: Replacement Of Head Section Components

ValueJet 1304 Service manual 4.6 Replacement of Head Section Components 4.6.1 Replacing Print Head NOTE • Before replacing the print head, remove the R side cover or the top cover. "4.2.1 Removing R Side Cover" p.4-6 "4.2.6 Removing Top Cover" p.4-15 1. - Page 109 ValueJet 1304 Service manual 5. Remove the CR board cover. × 8 W 6. Remove the cable cover L-retaining screw ( round head spring screw M3 sems ) (tapping screw × 8, S tight cup: 1). 表 4-70 Part name Cable cover L screw ×...

- Page 110 ValueJet 1304 Service manual 9. While rotating the damper fixing material, remove the eight ink tubes from the damper fixing material hook. 表 4-72 Part name Ink tube Damper fixing material 10. Remove the damper fixing material. 11. Remove the eight damper assemblies connected to the print head that needs to be replaced, with a flat- head driver.

- Page 111 ValueJet 1304 Service manual 表 4-73 Part name Flat-head driver insertion point Damper assembly × 12. Remove the damper locating material-retaining screw (round head spring screw M3 6 W sems: 2). 表 4-74 Part name Damper locating material Damper locating material screw ×...

- Page 112 ValueJet 1304 Service manual 14. Remove the print head from the carriage. 表 4-75 Part name Print head Head tape wire 15. Remove the two head tape wire from the print head. CAUTION • The QR code label on the print head should be written down for later use or kept in a safe place.

-

Page 113: Replacing Print Head

ValueJet 1304 Service manual 4.6.2 Replacing Cutter Holder Assembly Replacing Cutter Holder Assembly NOTE Before replacing parts in the cutter holder assembly, remove the following parts referring to the instructions shown below. Removing the cable cover L, R: refer to "4.6.1 Replacing Print Head" p.4-61 Removing the P_EDGE sensor, cutter sensor connector: refer to "4.10.1 Replacing CR Board... - Page 114 ValueJet 1304 Service manual Replacing Cutter Solenoid Assembly 1. Remove the cutter holder assembly. 2. Push the tab of the CR lock kicker with a sharp-pointed tool or a flat-head driver to remove the CR lock kicker. 表 4-77 Part name...

- Page 115 ValueJet 1304 Service manual NOTE When installing the cutter solenoid, note the following. • Joint the cutter cap and the CR lock kicker, push down the cutter cap and the CR lock kicker together to install them onto the cutter holder.

- Page 116 ValueJet 1304 Service manual Replacing Assembly CR_ENC 1. Remove the cutter holder assembly. × 2. Remove the CR_ENC assembly-retaining screw (round head spring screw M 3 8 W sems: 1). 表 4-79 Part name Mounting plate screw CR_ENC assembly CR_ENC assembly screw (round head spring screw M 3 ×...

- Page 117 ValueJet 1304 Service manual × 2. Remove the P_EDGE sensor assembly-retaining screw (M3 6, P tight cup: 1). 表 4-80 Part name P_EDGE sensor assembly screw × 6, P tight cup) P_EDGE sensor assembly 3. Detach the cable from the three clamps.

-

Page 118: Replacement Of Maintenance Section Components

ValueJet 1304 Service manual 4.7 Replacement of Maintenance Section Components 4.7.1 Removing Maintenance Base Assembly NOTE • When replacing the parts inside the maintenance assembly, make sure to clear the following counter parameters. • “Waste Ink” or “Cleaning”: "6.3.1 Counter Display Menu" p.6-4 •... - Page 119 ValueJet 1304 Service manual 2. Pull up the pressure lever. 表 4-82 Part name Pressure lever × 3. Remove the lock bracket-retaining screw (tapping screw M3 6, S cup tight: 1). 表 4-83 Part name Head lock-retaining screw × (tapping screw M3...

- Page 120 ValueJet 1304 Service manual 表 4-84 Part name Motor relay connector Clamp 5. Remove the motor relay connector. 6. Remove the wiper phase sensor connector. 表 4-85 Part name Wiper phase sensor connector Pump unit × 7. Remove the maintenance base 1 front part-retaining screw (tapping screw M3 6, S tight cup: 2).

- Page 121 ValueJet 1304 Service manual 表 4-86 Part name Maintenance base 1-retaining × screw (tapping screw M3 6, S tight cup) Maintenance base 2 × 8. Remove the maintenance base 1 rear part-retaining screw (tapping screw M3 6, S tight cup: 2).

- Page 122 ValueJet 1304 Service manual 9. Hold the maintenance base 1 up and rotate it to remove as shown below. 10. To reassemble the unit, reverse the removal procedure. AP-74109 Rev 1.1 4-76...

-

Page 123: Replacing Maintenance Assembly

ValueJet 1304 Service manual 4.7.2 Replacing Maintenance Assembly This section describes how to replace the maintenance assembly. Maintenance assembly consists of pump cap assembly, frame cap, cap slider, cap head, and cap spring. NOTE Before removing the pump cap assembly, remove the following parts. -

Page 124: Replacing Cleaner Head (Cleaning Wiper)

ValueJet 1304 Service manual 表 4-89 Part name Tube Drain guide 2 5. Attach the maintenance base 1 to where it is. 6. To reassemble the unit, reverse the removal procedure. 4.7.3 Replacing Cleaner Head (Cleaning Wiper) NOTE Before replacing the cleaner head, remove the following covers. - Page 125 ValueJet 1304 Service manual NOTE To remove the wiper, use the tweezers to unhook the lower hook of the wiper. Hook 2. Replace the cleaner head. 3. To reassemble the unit, reverse the removal procedure. NOTE When removing the cleaner head, note the following.

-

Page 126: Replacement Of Ink Supply Section Components

ValueJet 1304 Service manual 4.8 Replacement of Ink Supply Section Components Four Ink Holder (I/H) assemblies are installed in this product. The replacement procedures for one of these I/H assemblies are explained in this section. NOTE Before replacing parts in the I/H assembly, remove the following covers. - Page 127 ValueJet 1304 Service manual 3. Take the removed sensor assembly cable off the clamp (2 points). 表 4-92 Part name Clamp I/H assembly 4. Remove the joint screw (M6) connecting the I/H assembly and the SUS pipe, and remove the o-ring inside.

- Page 128 ValueJet 1304 Service manual NOTE When attaching the part, make sure the followings: • When tighten the joint screw, use the optional jig and pay attention to the fastening torque. "10.3 Jigs and Tools" p.10-3 • Used O-ring become deformed. Do not use the O-ring removed and attach the new one.

-

Page 129: Replacing Ink Holder (I/H) Assembly

ValueJet 1304 Service manual 4.8.2 Replacing Ink Sensor Assembly NOTE Before replacing the ink ID sensor assembly, remove the following parts. • I/H assembly: "4.8.1 Replacing Ink Holder (I/H) Assembly" p.4-79 1. Detach the ink ID sensor assembly cable from the hooks (2 pieces) on the back of the I/H assembly. - Page 130 ValueJet 1304 Service manual 4. Release the tab of the frame assembly needle, push down and slide it sideways (see the directions of the arrows), then remove the cartridge frame assembly. 表 4-96 Part name Frame assembly needle Frame assembly needle tab ×...

- Page 131 ValueJet 1304 Service manual 6. Replace the ink cable assembly. 7. To reassemble the unit, reverse the removal procedure. NOTE When reassembling the unit, note the following sensor fastening torque. • Ink NOT sensor: Slight overtorque may damage the parts. Gradually torque the sensor to avoid tightening it too much.

-

Page 132: Replacing Cover Sensor Assembly

ValueJet 1304 Service manual 4.8.3 Replacing Cover Sensor Assembly NOTE Before replacing the cover sensor assembly, remove the parts as follows. "4.2.1 Removing R Side Cover" p.4-6 "4.2.3 Removing L Side Cover" p.4-10 × 1. Remove the screw retaining the sensor cover (L/R) to the frame (tapping screw M3 6, S tight cup: 1 per cover). - Page 133 ValueJet 1304 Service manual 3. Detach the cable from the cover (L/R) sensor cable-retaining clamp.(The diagram below shows the cover R sensor). 表 4-99 Part name Clamp Cover R sensor cable 4. Replace the cover sensor assembly. 5. To reassemble the unit, reverse the removal procedure.

-

Page 134: Replacing Heater Junction Board

ValueJet 1304 Service manual 4.8.4 Replacing Heater Junction Board NOTE Before replacing the heater junction board, remove the parts as follows. "4.2.1 Removing R Side Cover" p.4-6 1. Remove the following connectors shown in the table below from the heater junction board. - Page 135 ValueJet 1304 Service manual Table 4-100 Connectors to Heater junction board Connector # of Color Connect to Remarks pins Unused Unused 2. Replace the power cable between CNT - JC and serial cable between MAIN - CNT. × 3. Remove the screw retaining the heater junction board (cup screw M3 6, white: 4).

-

Page 136: Replacement Of Frame Section Components

ValueJet 1304 Service manual 4.9 Replacement of Frame Section Components 4.9.1 Replacing Suction Fan Assembly × 1. Remove the screw retaining the fan plate to the B frame (tapping screw M3 6, S tight cup: 3), then remove the suction fan assembly. -

Page 137: Replacing P_Rear Sensor Assembly

ValueJet 1304 Service manual × 40 4. Remove the suction fan assembly retaining-screw (round head spring screw M4 finishing (pan : 1) × 8: 1) head small screw M4 5. Replace the suction fan assembly 6. To reassemble the unit, reverse the removal procedure. -

Page 138: Replacement Of Cable Guide Section Components

ValueJet 1304 Service manual 表 4-105 Part name P_REAR sensor assembly × screw (cup screw M2 P_REAR sensor assembly PE sensor plate 5. Replace the P_REAR sensor assembly. 6. To reassemble the unit, reverse the removal procedure. 4.10 Replacement of Cable Guide Section Components 4.10.1 Replacing CR Board Assembly... - Page 139 ValueJet 1304 Service manual Table 4-106 Connectors to CR Board Assembly Connector # of Color Connect to Remarks pins J204 Print head Connected to J1. 31 pins Black J205 Print head Connected to J2. 31 pins Black J201 Main board assembly Connected to J11.

-

Page 140: Replacing Ink Tube

ValueJet 1304 Service manual 4.10.2 Replacing Ink Tube NOTE Before replacing the ink tube, remove the following covers. • R side cover: "4.2.1 Removing R Side Cover" p.4-6 • I/H cover: "4.2.4 Removing Ink Holder (I/H) Cover" p.4-12 • Top cover: "4.2.6 Removing Top Cover"... - Page 141 ValueJet 1304 Service manual 表 4-109 Part name Tube guide Tube film guide retainer 4. Remove the CR board cover. Up to step 4 in "4.6.1 Replacing Print Head" p.4-61 5. Remove the CR tape wire from the CR board. 6. Remove the screw retaining the bearer mounting material and the bearer fixing material (tapping screw ×...

- Page 142 ValueJet 1304 Service manual 表 4-111 Part name Joint screw (M6) F branch AP-74109 Rev 1.1 4-96...

- Page 143 ValueJet 1304 Service manual 2. Loosen the joint screw (M6) connecting the ink tube and the cartridge pipe. 表 4-112 Part name Joint screw (M6) Cartridge pipe 3. Remove the ink tube. 4. Remove the following parts from the ink tube.

-

Page 144: Replacing Cr Tape Wire

ValueJet 1304 Service manual 4.10.3 Replacing CR Tape Wire CAUTION • Before replacing board or connecting/removing tape wire (FFC), unplug the power cable and leave the printer for a while. Or board may be damaged by overcurrent. • When connecting or removing the FFC type cables to the CR board assembly connector, always pull or push the cables perpendicularly to the connector. - Page 145 ValueJet 1304 Service manual 3. Take the CR tape wire off the clamp (one point) nearby the R frame cable inlet (I/H assembly side). 表 4-114 Part name CR tape wire Clamp × 4. Remove the bearer holder-retaining screw (round head spring screw M3 6: 2), then remove the bearer holder.

- Page 146 ValueJet 1304 Service manual 5. Remove the tube holder 1 and the tube holder 2. 表 4-116 Part name Tube holder 1 Tube holder 2 AP-74109 Rev 1.1 4-100...

- Page 147 ValueJet 1304 Service manual 6. Remove the following parts from the I/H backing plate. • Tube guide film • Steel bearer assembly • CR cable (3 cables) 表 4-117 Part name Tube guide film Steel bearer CR cable 7. Replace the CR cable.

-

Page 148: Replacing Accessory Unit

ValueJet 1304 Service manual 4.11 Replacing Accessory Unit 4.11.1 Replacing Level Switch (Waste Fluid) 1. Remove the level switch (waste fluid) from connector. 表 4-118 Part name Level switch (waste fluid) VJ16 Connector 2. Remove the level switch (waste fluid) from the cap of the waste fluid bottle assembly. -

Page 149: Replacing Take Up Unit

ValueJet 1304 Service manual 4.12 Replacing Take Up Unit This section describes the procedure to replace the Take Up unit. NOTE Have two or more people to replace the part of take up unit. 4.12.1 Removing Tension Arm × 1. Remove the two screws (hexagon socket pan flat head M4 8) retaining tension arm R. - Page 150 ValueJet 1304 Service manual NOTE If the scroller is not in an horizontal position after the installation, loosen the fixing screw for scroller height. Loosen the screw for scroller height adjustment to adjust the horizontal balance. Part name Take up Unit...

-

Page 151: Removing Take Up Unit Fixing Plate

ValueJet 1304 Service manual 4.12.2 Removing Take Up Unit Fixing Plate × 1. Remove the screws (hexagon socket head bolt M4 10: 4 pieces) that retain the take up unit fixing plate on the origin side. 表 4-121 Part name Take up fixing bracket... -

Page 152: Removing Take Up Unit Cover

ValueJet 1304 Service manual × 5. Remove the screws (hexagon socket head bolt M4 10: 4 pieces) that retain take up fixing plate on the opposite of the origin side. 表 4-123 Part name Take up base L Screw that retains the take up unit fixing plate (hexagon socket ×... - Page 153 ValueJet 1304 Service manual 表 4-125 Part name Rubber foot Screws that retain the rubber × foot (pan head small screw M3 4-107 AP-74109 Rev 1.1...

- Page 154 ValueJet 1304 Service manual 3. Detach the lever from the release cam. 表 4-126 Part name Release cam Lever × 4. Remove the screws (binding head small screw M3 5: 7 pieces) that retain the take up unit cover. 表 4-127...

-

Page 155: Replacing Scroller

ValueJet 1304 Service manual 4.12.4 Replacing Scroller (1) Replacing Holding Roller 1. Remove the E ring (E-6) that retains the holding roller using a driver. 表 4-128 Part name holding roller E ring that retains the holding roller (E-6) 2. Remove the holding roller and the bearing. -

Page 156: Replacing Vj Take Up Unit Cnt Board Assembly

ValueJet 1304 Service manual (3) Replacing Drive Collar × 1. Remove the screws (round head spring screw M3 8: 2 pieces) that retain the drive collar on the take up unit scroller (left). 表 4-130 Part name Drive collar Screws that retain the drive collar (round head spring screw ×... - Page 157 ValueJet 1304 Service manual 2. Detach the motor cable, W_ON sensor relay assembly and the W_OFF sensor relay assembly from the connector to the VJ take up unit CNT board assembly that appears. 表 4-132 Part name VJ take up unit CNT board...

- Page 158 ValueJet 1304 Service manual (2) Replacing VJ Take Up Unit CNT Board Assembly NOTE Remove the screw that retains the board chassis. "(1) Removing Board Chassis" p.4-109 1. Remove the cable of the DC cable assembly and the VJ take up unit SW board assembly from the connector to the VJ take up unit CNT board assembly.

- Page 159 ValueJet 1304 Service manual (3) Replacing Power Board Assembly (of take up unit section for foreign use) NOTE Remove the screws that retains the board chassis before replacing the power board assembly. "(1) Removing Board Chassis" p.4-109 1. Detach the AC cable assembly and the DC cable assembly from the connector to the power board assembly (of take up unit section for foreign use).

- Page 160 ValueJet 1304 Service manual (4) Replacing VJ Take Up Unit SW Board Assembly NOTE Remove the screws that retains the board chassis before replacing the VJ take up unit SW board assembly. "(1) Removing Board Chassis" p.4-109 1. Detach the cable of the VJ Take Up Unit SW Board Assembly from the connector to the VJ take up unit CNT board assembly.

- Page 161 ValueJet 1304 Service manual × 3. Remove the screws (pan head small screw M3 8: 4 pieces) that retain the VJ take up unit SW board assembly on the SW mounting plate. 表 4-139 Part name VJ take up unit SW board...

- Page 162 ValueJet 1304 Service manual (5) Replacing AC Cable Assembly NOTE Remove the screws that retains the board chassis before replacing the AC cable assembly. "(1) Removing Board Chassis" p.4-109 1. Remove the cable of the VJ take up unit SW board assembly from the connector to the VJ take up unit CNT board assembly.

- Page 163 ValueJet 1304 Service manual (6) Replacing DC Cable Assembly NOTE Remove the screws that retains the board chassis before replacing the DC cable assembly. "(1) Removing Board Chassis" p.4-109 1. Remove the screws that retain the DC cable assembly on the board chassis (round head spring screw ×...

-

Page 164: Replacing Cr_Hp Sensor, Lever Sensor

ValueJet 1304 Service manual 4.12.6 Replacing CR_HP Sensor, Lever Sensor (1) Replacing W_ON Sensor Relay Assembly, W_OFF Sensor Relay Assembly NOTE Remove the screws that retains the board chassis before replacing W_ON sensor relay assembly or W_OFF sensor relay assembly. "(1) Removing Board Chassis" p.4-109 1. - Page 165 ValueJet 1304 Service manual (2) Replacing CR_HP Sensor, Lever Sensor NOTE Remove the screws that retains the board chassis before replacing the CR_HP sensor or the lever sensor. "(1) Removing Board Chassis" p.4-109 1. Remove the cable of the W_ON sensor relay assembly and W_OFF sensor relay assembly from the connector to the VJ take up unit CNT board assembly.

- Page 166 ValueJet 1304 Service manual 3. Detach the W_ON sensor relay assembly and the W_OFF sensor relay assembly from the CR_HP sensor and lever sensor. 表 4-148 Part name CR_HP sensor, the lever sensor W_ON sensor relay assembly, W_OFF sensor relay assembly 4.

-

Page 167: Replacing Peripheral Devices Of Vj Take Up Unit Motor Assembly

ValueJet 1304 Service manual 4.12.7 Replacing Peripheral Devices of VJ Take Up Unit Motor Assembly (1) Replacing Drive Roller × 1. Remove the flat head screws (set screw (top cup point) M4 6: 2 pieces) that retain the drive roller on the drive axis C. - Page 168 ValueJet 1304 Service manual × 1. Remove the screws (round head spring screw finishing M4 10: 3 pieces) that retain the motor mounting plate on the right of the inside chassis. 表 4-151 Part name Motor mounting plate Screws that retain the motor mounting plate (round head ×...

- Page 169 ValueJet 1304 Service manual 6. To reassemble the unit, reverse the removal procedure. 4-123 AP-74109 Rev 1.1...

- Page 170 ValueJet 1304 Service manual AP-74109 Rev 1.1 4-124...

- Page 171 ValueJet 1304 Service manual 5 Self-Diagnosis Mode Introduction ..................... 5- 4 Preparation ....................5- 4 5.2.1 Preparations on Machine ............... 5-4 5.2.2 Starting Up ..................5-5 Operations in Self-Diagnosis Mode ............5- 6 5.3.1 Operating Self-Diagnosis Mode ............. 5-6 5.3.2 Diagnosis Items in Self-Diagnosis Menu ........5-8 Platen Adjustment Menu ..............

- Page 172 ValueJet 1304 Service manual 5.7.5 Voltage Adjustment ..............5-33 5.7.6 Uni-D / Bi-D Low and High Adjustment ........5-36 5.7.7 Side Margin Adjustment Menu ............. 5-42 5.7.8 Test Printing Menu ............... 5-43 5.7.9 HeadWash Menu................5-44 5.7.10 Software Counter Initialization Menu..........5-45 5.7.11 Feed Pitch Check Menu ...............

- Page 173 ValueJet 1304 Service manual 5.13.5 General Endurance Menu............5-72 5.13.6 Endurance Running Check Menu ..........5-73 5.14 Media Feed Menu .................. 5- 73 5.15 ExControl Menu ..................5- 74 5.15.1 Version..................5-74 5.15.2 Sensor ..................5-75 5.15.3 Heater ..................5-76 5.15.4 History..................5-76 5.16 PaperInitial Menu ..................

-

Page 174: Introduction

ValueJet 1304 Service manual 5.1 Introduction This chapter provides information on the self-diagnosis function. The self-diagnosis function adjusts the printing accuracy. It is used in the manufacturing process, adjustment, and maintenance. The self-diagnosis function is implemented in the system firmware. All functions are available from the operation panel. -

Page 175: Starting Up

ValueJet 1304 Service manual 5.2.2 Starting Up To use the self-diagnosis function, you must first call up the self-diagnosis menu on the operation panel. The self-diagnosis menu is completely independent of the normal operation mode and self-diagnosis display mode. To call up the self-diagnosis menu, follow the steps below. -

Page 176: Operations In Self-Diagnosis Mode

ValueJet 1304 Service manual 5.3 Operations in Self-Diagnosis Mode This section explains how to operate in the self-diagnosis mode as well as providing the list of available diagnosis items. 5.3.1 Operating Self-Diagnosis Mode Follow the operation flow shown below to operate the self-diagnosis mode. - Page 177 ValueJet 1304 Service manual 4. To quit the diagnosis, press [Cancel] key in the operation panel. The system returns to an upper hierarchy of the diagnosis menu. 5. To exit the self-diagnosis menu, press [Power] key. AP-74109 Rev 1.1...

-

Page 178: Diagnosis Items In Self-Diagnosis Menu

ValueJet 1304 Service manual 5.3.2 Diagnosis Items in Self-Diagnosis Menu The self-diagnosis menu includes the following diagnosis items. Diagnosis item Contents Reference Platen Adjustment Performs temperature setting for the pre-heater and platen "5.4 Platen ° Menu heater to 30 Adjustment Menu"... - Page 179 ValueJet 1304 Service manual [<] key [Enter] key Platen Adjustment Me [Cancel] key [>] key [<] key [Enter] key Inspenction Menu [Cancel] key [<] key [>] key [Enter] key Ink Charging Menu [Cancel] key [>] key [<] key [Enter] key Adjustment Menu [Cancel] key [<] key...

-

Page 180: Platen Adjustment Menu

ValueJet 1304 Service manual 5.4 Platen Adjustment Menu ° In the platen adjustment menu, you can set the temperature of the pre-heater and platen heater to 30 Parts assembly and adjustment should be done in the condition. * This item displays platen temperature only. -

Page 181: Inspection Menu

ValueJet 1304 Service manual 5.5 Inspection Menu In the inspection menu, you can perform various inspections on the circuit boards, sensors, and fans. The inspection menu includes the following diagnosis items. Table 5-1 Diagnosis Items for Inspection Menu Diagnosis Contents Reference... -

Page 182: Memory Size Menu

ValueJet 1304 Service manual [<] key [Enter] key Ram Capacity Menu [Cancel] key [>] key [<] key [Enter] key Version Menu [Cancel] key [<] key [>] key [Enter] key Panel Menu [Cancel] key [>] key [<] key [Enter] key Sensor Menu [Cancel] key [>] key... -

Page 183: Version Menu

ValueJet 1304 Service manual 5.5.2 Version Menu This menu displays the following contents about the firmware and MAIN board assembly. • Firmware version • Backup parameter version • Setting of dip switches of MAIN board assembly • Revision of MAIN board assembly •... -

Page 184: Operation Panel Menu

ValueJet 1304 Service manual 5.5.3 Operation Panel Menu This menu is used to check the functions of the operation panel keys, LCD, and LEDs. (1) Operation Panel Key Check When you press a key in the operation panel, the name of the key is displayed on the LCD. To exit the operation panel key check, press [Cancel] key twice. -

Page 185: Sensor Menu

ValueJet 1304 Service manual 5.5.4 Sensor Menu This menu displays the sensor status on the operation panel. If the displayed sensor status does not match the actual machine status, replace or adjust the relevant sensor referring to the table below. Table 5-2 Inspection Items in Sensor Menu... - Page 186 ValueJet 1304 Service manual [<] key CR_HP Sensor [>] key [<] key Waste Fluid Tank Sensor [>] key [<] key Wiper Sensor [>] key [<] key Cover Sensor [>] key [<] key Lever Sensor [>] key [<] key P_EDGE Sensor [<] key [>] key...

-

Page 187: Encoder Menu

ValueJet 1304 Service manual 5.5.5 Encoder Menu This menu displays the detected values from the following encoders. • CR_ENC (Carriage) • PF_ENC (Media feed) NOTE For the encoder-detected values, the encoder pulse numbers are displayed in hexadecimal number. [<] key CR_ENC [<] key... -

Page 188: History Menu

ValueJet 1304 Service manual 5.5.7 History Menu This menu is used to check maintenance history and serious error history. This menu is used to check maintenance history and serious error history and to initialize serious error history. [<] key Maintenance history [>] key... - Page 189 ValueJet 1304 Service manual [<] key Frequenc of the wiper blade used [>] key [<] key CR Motor driving (Unit : Operation count) (Ink tube reciprocating count and the function) [>] key [<] key PF Motor driving (Unit : 10m) [<] key [>] key...

- Page 190 ValueJet 1304 Service manual (2) Serious Error History Indicates serious error history. NOTE • The serious error history does not include CPU error. • The serious error history menu indicates the history up to 64. [<] key [>] key [<] key [>] key...

-

Page 191: Head Waveform Menu

ValueJet 1304 Service manual 5.5.8 Head Waveform Menu This menu is used to check the head-driving waveform. * This function is used in factory only. NOTE • SHOT COUNT can be selected from 1 to 655. • Magnification can be selected from the range of x1 - 100000. Nozzle can be selected among A - H and ALL. -

Page 192: Ink Charging Menu

ValueJet 1304 Service manual 5.6 Ink Charging Menu In the ink charging menu, you can charge ink. The ink charging menu includes the following items. Table 5-3 Ink Charging menu Charging item Contents InkCharge Performs initial ink charging. LittleCharge Performs a small amount of ink charging. -

Page 193: Adjustment Menu

ValueJet 1304 Service manual 5.7 Adjustment Menu In this menu, you can align the printing position and correct the media feed operation. The adjustment menu includes the following diagnosis menus. Table 5-4 Diagnosis Items in Adjustment Menu Diagnosis item Contents Reference... -

Page 194: Uni-D / Bi-D Adjustment High

ValueJet 1304 Service manual Table 5-4 Diagnosis Items in Adjustment Menu (Continued) Diagnosis item Contents Reference HeadWash Cleans the tubes and heads using cleaning liquid. "5.7.9 HeadWash Menu" p.5-44 Software counter Clears various software counters. "5.7.10 Software initialization Counter Initialization Menu" p.5-45 Feed amount check Used to check the media feed amount per band. -

Page 195: Cr Return Position Adjustment Menu

ValueJet 1304 Service manual 5.7.1 CR Return Position Adjustment Menu In this menu, you can adjust the CR return position (near end position of the carriage) on the origin side. “CR Return: Check” moves the carriage three times.. “CR Return: Input” adjusts the return position of the carriage. -

Page 196: Head Nozzle Check Menu

ValueJet 1304 Service manual 5.7.2 Head Nozzle Check Menu In this menu, you can check if the head nozzles that has been charged can discharge ink correctly by printing a sample printing. To check the head nozzle, follow the steps below. - Page 197 ValueJet 1304 Service manual 4. If any abnormal conditions are found in the ink discharge status of the head nozzles, perform cleaning. "5.8 Cleaning Menu" p.5-48 5. After cleaning, make the machine print out head nozzle check patterns again. Media set...

-

Page 198: Skew Check Menu

ValueJet 1304 Service manual 5.7.3 Skew Check Menu Feed the paper to check the skew size using sensor. When you select this item from the Adjustment Menu, the printer feeds the loaded media by one pass and checks difference of the media edge positions before and after the media feed detected by the sensor. -

Page 199: Head Slant Check Menu

ValueJet 1304 Service manual 5.7.4 Head Slant Check Menu Table 5-6 Head Slant Items Items Contents Head slant: slant Head slant check: horizontal direction Head slant: vertical Head slant check: vertical direction (1) Horizontal Direction Checking This menu prints out a sample printing to check for head slant in the horizontal direction. - Page 200 ValueJet 1304 Service manual 4. If any head slant is found, perform mechanical adjustment. "7.7 Head Alignment (Horizontal Height)" p.7-36 5. After mechanical adjustment, make the machine print out head nozzle check patterns again. Display during adjustment printing Finish printing [<] key Finishes printing [<] key...

- Page 201 ValueJet 1304 Service manual 4. If any head slant is found, perform mechanical adjustment. "7.8 Head Alignment (Vertical Slant)" p.7-38 5-31 AP-74109 Rev 1.1...

- Page 202 ValueJet 1304 Service manual 5. After mechanical adjustment, make the machine print out head nozzle check patterns again. Display during adjustment printing Finish printing [<] key Finishes printing [<] key [>] key Outputs pattern [>] key AP-74109 Rev 1.1 5-32...

-

Page 203: Voltage Adjustment

ValueJet 1304 Service manual 5.7.5 Voltage Adjustment This menu is used to adjust the voltage of VSD 3 small dot so that the print position will be corrected. Check the small dot is on the center of the middle dots in the CR direction. - Page 204 ValueJet 1304 Service manual The following figure shows a case for 240 CW. [Enter] key If media is not set Media set If head gap is PG-Low Change head gap (to PG-Low) If the temperature of the pre-heater and platen heater is below 42 C...

- Page 205 ValueJet 1304 Service manual A: Print direction B: Adjust the voltage so that the small dot printed positions (shown as dot-line) are the same with the middle dot printed positions (in the CR direction). C: Executed adjustment item is printed like this.

-

Page 206: Uni-D / Bi-D Low And High Adjustment

ValueJet 1304 Service manual 5.7.6 Uni-D / Bi-D Low and High Adjustment Adjusts the gap of the print heads (in the CR moving direction) when the head is in the PG Low or High and the print position of the head in repeatability printing. - Page 207 ValueJet 1304 Service manual 3. Check the printed pattern of CW adjustment. • The following shows a case for Uni-D Low 240B Print. Prints the pattern in the order of 1A to 4B. Uni-Lo 240CPS 4B 4A 3B 3A 2B 2A 1B A: Media feed direction B: Adjust the setting value so that these point matches.

- Page 208 ValueJet 1304 Service manual C: Executed adjustment item is printed like this. Bi-D 240: Bi- Lo/Hi 240 CPS Bi-D 320: Bi- Lo/Hi 320 CPS Bi-D 240B: Bi- Lo/Hi 240 CPS Banner Bi-D 320B: Bi- Lo/Hi 320 CPS Banner * Either “Lo” or “Hi” is displayed at where explained as “Lo/Hi” above.

- Page 209 ValueJet 1304 Service manual Check the print patterns of origin, center, and opposite side to adjust the gap equally. If any abnormal conditions are found, identify the gap of the print positions and enter it as the CW adjustment parameter. After that, print test pattern again as necessary.

- Page 210 ValueJet 1304 Service manual (1) A case for “Print1” or “Print2” is selected. * The sample image is in common with Bi-D and Uni-D. Select “Print2” when adjusting Print 2 If media is not set Media set If head gap is PG-High...

- Page 211 ValueJet 1304 Service manual If Bi-D is selected, the parameter input process is as shown below. (The following shows a case for “Bi-D 240 - Setup” is selected.) [<] key Press [Setting/Value+] or [Setting/Value-] key to change unit to pulse 1 pulse = 1/2880 inch [>] key...

-

Page 212: Side Margin Adjustment Menu

ValueJet 1304 Service manual 5.7.7 Side Margin Adjustment Menu This menu is used to adjust the printing margins. To adjust the margins, follow the steps below. 1. Set media as necessary. 2. The printer detects the media size and the size is displayed on the operation panel. -

Page 213: Test Printing Menu

ValueJet 1304 Service manual 5.7.8 Test Printing Menu In this menu, you can print out adjustment patterns for checking various adjustment items. The actual procedure is as follows. 1. Set media as necessary. 2. After media is set, the machine prints out the following test printings. -

Page 214: Headwash Menu

ValueJet 1304 Service manual 5.7.9 HeadWash Menu This menu is used to purge ink and clean the heads at the end of the manufacturing process and before print head replacement. The actual procedure is as follows. 1. Press [Enter] key in the operation panel to determine the Head Cleaning Menu. -

Page 215: Software Counter Initialization Menu

ValueJet 1304 Service manual 5.7.10 Software Counter Initialization Menu This menu is used to initialize the software counters such as the waste ink counter. NOTE The counters are initialized before delivery. Do not initialize them during maintenance. The software counters that can be initialized through this menu are as follows. -

Page 216: Feed Pitch Check Menu

ValueJet 1304 Service manual 5.7.11 Feed Pitch Check Menu In this menu, you can check the media feed amount for one band by reviewing a sample printing.There is no adjustment items. To check the feed pitch, follow the steps below. 1. Set media as necessary. -

Page 217: Solid Print Menu

ValueJet 1304 Service manual 5.7.12 Solid Print Menu This menu is used to print solid print patterns with head on both ends. • Print pattern Specified color nozzles of both series A and B Nozzles for series B only Nozzles for series A only... -

Page 218: Cleaning Menu

ValueJet 1304 Service manual 5.8 Cleaning Menu In this menu, you can clean ink from the print heads. The cleaning menu includes the following diagnosis items. Table 5-10 Diagnosis Items in Cleaning Menu Diagnosis item Contents Economy Performs economy cleaning. Normal Performs normal cleaning. -

Page 219: Sample Printing Menu

ValueJet 1304 Service manual 5.9 Sample Printing Menu This menu prints out a sample printing. The sample printing menu includes the following items. Table 5-11 Diagnosis Items in Sample Printing Menu Diagnosis item Contents Adjustment pattern ALL Prints adjustment pattern. Parameter ALL Prints out the set values of various adjustment items. -

Page 220: Adjustment Pattern All

ValueJet 1304 Service manual 5.9.1 Adjustment pattern ALL Confirms printing and prints adjustment pattern. If media is not set Media set If head gap is PG-Low Change head gap (to PG-Low) If the temperature of the preheater and platen heater is below 42 C Finish warm-up [>]key... -

Page 221: Dot Pattern

ValueJet 1304 Service manual 5.9.4 Dot pattern Prints dot diameter check pattern [<] key [>] key [<] key [>] key [<] key [>] key [<] key [>] key [<] key [>] key [<] key [>] key [<] key [<] key [>] key [>] key... -

Page 222: Time Check

ValueJet 1304 Service manual 5.10 Time Check Confirms the date and time controlled by RTC (Real Time Clock) on the MAIN board assembly. NOTE You cannot set the date and time using this menu. In that case, use the time setting function of “MUTOH Maintenance Engineer Assistant”. -

Page 223: Parameter Initialization Menu

ValueJet 1304 Service manual 5.11.1 Parameter Initialization Menu This menu initializes the adjustment parameters. The parameters that can be initialized through this menu are as follows. • Uni-D / Bi-D parameter, wiper, CR motor, PF motor, pump, waste ink • Initialization of all items [Enter] [<] key... - Page 224 ValueJet 1304 Service manual (1) Voltage Offset This menu updates the voltage offset parameter (VSD3 small dot). Table 5-13 Voltage offset item Items Contents 240 CW Adjusts the VSD 3-S at 240 cps / CW printing. 240 CCW Adjusts the VSD 3-S at 240 cps / CCW printing.

- Page 225 ValueJet 1304 Service manual (2) Uni-D / Bi-D Low This menu updates the Uni-D / Bi-D adjustment parameter. or “Update 3: Uni/Bi High” [<] key [>] key [<] key [<] key [>] key [<] key [>] key [>] key [<] key [>] key...

-

Page 226: Parameter Update Menu

ValueJet 1304 Service manual 5.11.2 Parameter Update Menu This menu updates the adjustment parameters. The parameters that can be updated through this menu are as follows. NOTE The updated parameters will not be stored in the flash memory unless the system power is turned OFF. - Page 227 ValueJet 1304 Service manual (1) Head Rank This menu updates the head rank parameters. The head rank is used to determine the print head driving voltage and correct the head temperature. After head rank is entered, the system shifts to the Ink Charge Menu.

- Page 228 ValueJet 1304 Service manual (2) Voltage Offset This menu updates the voltage offset parameter (VSD3 small dot). Table 5-14 Voltage offset item Items Contents 240 CW Adjusts the VSD 3-S at 240 cps. CW printing. 240 CCW Adjusts the VSD 3-S at 240 cps. CCW printing.

- Page 229 ValueJet 1304 Service manual (3) Uni-D / Bi-D Low and High This menu updates the Uni-D / Bi-D adjustment parameter. or “Update 4: Uni/Bi High” [<] key [>] key [<] key [<] key [>] key [<] key [>] key [>] key [<] key...

- Page 230 ValueJet 1304 Service manual (The following shows a case for “Uni-D 240” is selected.) If any parameter has been changed [<] key [Enter] key [>] key [<] key [>] key [<] key [>] key [<] key [>] key [<] key [>] key [<] key...

- Page 231 ValueJet 1304 Service manual (5) Ink Not-filled Flag This updates the ink parameter. The setting items are as follows. • User/: Charge; Cleaned, Ink not charged • User/Init:Not Charge; Not Cleaned, Ink not charged • User/Init:Charge; Cleaned, Ink charged Change the value by pressing [+] or [-] key ”User/...

- Page 232 ValueJet 1304 Service manual (6) Serial Number Entry This is for entering the serial number. Enter Serial Number (digit by digit) [<] key [>] key [>] key [<] key [>] key [<] key [>] key [<] key [<] key [>] key [>] key...

- Page 233 ValueJet 1304 Service manual (7) Debug Bit update Updates the debug bit. This is a trial function for firmware. • Debug bit is displayed as a binary number. The factory-setting value and default value are as follows. • Factory-setting value: 000000 •...

-

Page 234: Servo Setting

ValueJet 1304 Service manual 5.12 Servo Setting Changes the servo setting. * Do not change the parameters. This menu is basically for checking printer trouble (noise or vibration) and print quality. Table 5-15 Servo setting item Items Contents 240 cps CW... - Page 235 ValueJet 1304 Service manual [>] key [<] key [>] key [<] key [>] key [<] key [>] key [<] key [Enter] key When selecting 240cps CW [<] key [>] key [<] key [<] key [>] key [>] key [<] key [<] key [>] key...

- Page 236 ValueJet 1304 Service manual The initial set value for each item is shown below. If the speed is same, the initial value for CW and for CCW will be the same. Table 5-17 Initial value for Servo setting Items Initial value...

-

Page 237: Endurance Running Menu

ValueJet 1304 Service manual 5.13 Endurance Running Menu Performs endurance running of mechanicals and the head. The endurance running menu includes the following items. Table 5-18 Diagnosis Items in Endurance Running Menu Diagnosis item Contents Reference CR motor Performs carriage stroke. -

Page 238: Cr Motor Endurance Menu

ValueJet 1304 Service manual 5.13.1 CR Motor Endurance Menu This menu performs endurance running for the CR motor. You can operate the carriage stroke according to your desired settings. The available settings are shown below. Table 5-19 Set Items in CR Motor Endurance Menu... -

Page 239: Pf Motor Endurance Menu

ValueJet 1304 Service manual 5.13.2 PF Motor Endurance Menu This menu performs endurance running for the PF motor. You can drive the PF motor according to your desired settings. The available settings are shown below. Table 5-20 Set Items in PF Motor Endurance Menu... -

Page 240: Pump Endurance Menu

ValueJet 1304 Service manual 5.13.3 Pump Endurance Menu This menu performs endurance running for the pump motor assembly. You can drive the pump motor assembly according to your desired settings. The available settings are shown below. Table 5-21 Set Items in Pump Motor Assembly Endurance Menu... -

Page 241: Print Head Endurance (Nozzle Print) Menu

ValueJet 1304 Service manual The pump endurance running sequence is as follows. 1. Pump endurance running starts. 2. Pump phase detection is performed. 3. Rotates with the specified suction speed. This rotation is counted as one cycle. Step 2 above is repeated the number of times specified as follows. -

Page 242: General Endurance Menu

ValueJet 1304 Service manual 5.13.5 General Endurance Menu This menu performs the general endurance running. You can operate various driving systems according to your desired settings. The available settings are shown below. Table 5-23 Set Items in General Endurance Menu Set item... -

Page 243: Endurance Running Check Menu

ValueJet 1304 Service manual 5.13.6 Endurance Running Check Menu In this menu, you can confirm the number of endurance running cycles that have been already finished. The number of endurance running cycles is stored in NVRAM in the system. Therefore, even if a serious error occurs during endurance running, you can confirm the number of finished cycles just before the occurrence of the serious error. -

Page 244: Excontrol Menu

ValueJet 1304 Service manual 5.15 ExControl Menu In this menu, you can diagnose the equipment on the controller board. Table 5-24 Controller Board Check Item Items Contents Remark Version Firmware, board revision Sensors Pre-heater thermistor, platen heater thermistor 1 and 2,... -

Page 245: Sensor

ValueJet 1304 Service manual 5.15.2 Sensor The status of the following sensors on the controller board is displayed. • Pre-heater thermistor sensor • Platen heater thermistor sensor 1 and 2 • After-thermistor sensor • Ink ID for each ink sensor •... -

Page 246: Heater

ValueJet 1304 Service manual 5.15.3 Heater In this menu, you can check whether pre-heater, platen heater, and after-heater works properly or not. The ° printer sets the temperature at 50 C and controls the selected heater process. Press [Cancel] key to stop the operation. -

Page 247: Paperinitial Menu

ValueJet 1304 Service manual 5.16 PaperInitial Menu In this menu, you can set the media detection method in the self-diagnosis mode. The default value is the same as the one in the normal operation mode. Select either Top & Width / Width / Off. When Off is selected, you can set the media width in the media width setting menu. - Page 248 ValueJet 1304 Service manual AP-74109 Rev 1.1 5-78...

- Page 249 ValueJet 1304 Service manual 6 Maintenance Mode 2 Introduction ..................... 6- 2 Operations in Maintenance Mode 2............6- 2 6.2.1 Starting Up the Maintenance Mode 2 ..........6-2 6.2.2 Operating Maintenance Mode 2............. 6-3 Maintenance Menu.................. 6- 3 6.3.1 Counter Display Menu ..............6-4 6.3.2 Counter Initialization Menu ............

-

Page 250: Operations In Maintenance Mode

ValueJet 1304 Service manual 6.1 Introduction This chapter provides information on the maintenance mode2. The maintenance mode2 provides the user with functions of displaying and initializing the life counters. It is used in the manufacturing process, adjustment, and maintenance. The maintenance mode2 is implemented in the system firmware. All functions are available from the operation panel. -

Page 251: Operating Maintenance Mode

ValueJet 1304 Service manual 6.2.2 Operating Maintenance Mode 2 "5.3 Operations in Self-Diagnosis Mode" p.5-6 6.3 Maintenance Menu The maintenance menu includes the following diagnosis items. Table 6-1 Diagnosis Items in Maintenance Menu Diagnosis item Contents Reference Counter: Indication Displays the life counter "6.3.1 Counter Display... -

Page 252: Counter Display Menu

ValueJet 1304 Service manual 6.3.1 Counter Display Menu This menu displays the life counters. It consists of the following diagnosis items. NOTE All life counters are displayed in decimal number. Table 6-2 Diagnosis Items in Counter Display Menu Diagnosis item Contents Used Ink K Displays the ink consumption (K) counter. - Page 253 ValueJet 1304 Service manual [<] key Ink consumption (K) counter [<] key [>] key Ink consumption (C) counter [<] key [>] key Ink consumption (M) counter [>] key [<] key Ink consumption (Y) counter [<] key [>] key Total number of printed copies [<] key...

-

Page 254: Counter Initialization Menu

ValueJet 1304 Service manual 6.3.2 Counter Initialization Menu This menu initializes the life counters. The parameters that can be initialized in this menu are as follows. Table 6-3 Diagnosis Items in Counter Initialization Menu Diagnosis item Contents Print Num. Initializes the total print counter. - Page 255 ValueJet 1304 Service manual [Enter] [<] key [>] key [<] key [<] key [>] key [<] key [>] key [>] key [<] key [>] key [<] key [>] key [<] key [<] key [>] key [>] key [<] key [<] key [>] key...

-

Page 256: Counter Print Menu

ValueJet 1304 Service manual 6.3.3 Counter Print Menu This menu prints the life counter values. [Enter] key After media is set 6.3.4 Media Feed Menu This menu feeds media into the printer frontward or backward. The mechanical initialization should be performed, if it is not performed yet. - Page 257 VJ-1304 QUICK REFERENCE Adjustment Introduction ..................... 7- 3 Adjustment Item..................7- 3 Working with MUTOH Maintenance Engineer Assistant..... 7- 8 7.3.1 Parameter Backup ............... 7-12 7.3.2 Jigs and Tools................7-12 7.3.3 Required Environment ..............7-12 7.3.4 Receiving Parameters..............7-19 7.3.5 Firmware Installation..............7-21 7.3.6 Sending Parameters ..............

- Page 258 ValueJet 1304 Service manual 7.10.1 Jigs and Tools ................7-43 7.10.2 Adjustment Procedure ..............7-43 7.11 Media Sensor Sensitivity Adjustment ..........7- 45 7.11.1 P_EDGE Sensor Sensitivity Adjustment ........7-45 7.11.2 P_REAR Sensor Adjustment............7-48 AP-74109 Rev 1.1...

-

Page 259: Adjustment Item

ValueJet 1304 Service manual 7.1 Introduction This chapter provides information on necessary adjustment items and procedures. "10.3 Jigs and Tools" p.10-3 7.2 Adjustment Item This section describes the adjustment items required in part replacement procedures. When you adjust or replace any of the maintenance parts listed in “Table 7-1 Adjustment Item List”, you must always adjust the printout quality using the self-diagnosis function referring to Table 7-1“Adjustment Item... - Page 260 ValueJet 1304 Service manual Table 7-1 Adjustment Item List (Continued) Part replaced or Adjustment Adjustment item Reference adjusted order Main board Parameter backup "7.3.1 Parameter assembly Backup" p.7-12 Firmware installation "7.3.5 Firmware Installation" p.7-21 Voltage input (no need for initial ink "(1) Head Rank"...

- Page 261 ValueJet 1304 Service manual Table 7-1 Adjustment Item List (Continued) Part replaced or Adjustment Adjustment item Reference adjusted order PF motor assembly PF speed reduction belt tension "7.4 PF Speed adjustment Reduction Belt Tension Adjustment" p.7-32 PF encoder assemblyy position "7.5 PF Encoder...

- Page 262 ValueJet 1304 Service manual Table 7-1 Adjustment Item List (Continued) Part replaced or Adjustment Adjustment item Reference adjusted order T fence CR encoder inspection "5.5.5 Encoder Menu" p.5-17 Uni-D / Bi-D Low Adjustment "5.7.6 Uni-D / Bi-D Uni-D / Bi-D High Adjustment Low and High Adjustment"...