Ricoh Pro C9100 Operating Instructions Manual

Troubleshooting tcru/oru

Hide thumbs

Also See for Pro C9100:

- Operating instructions manual (236 pages) ,

- Technical bulletin (82 pages) ,

- Read this first manual (40 pages)

Summary of Contents for Ricoh Pro C9100

- Page 1 Operating Instructions Troubleshooting: TCRU/ORU For safe and correct use, be sure to read the Safety Information in "Read This First" before using the machine.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Introduction................................. 6 How to Read This Manual..........................7 Symbols................................7 Disclaimer................................7 Notes................................7 1. Before You Begin About This Manual............................. 9 Names of Components............................10 About the Display for Options.........................11 Before You Change a Setting..........................12 About Printing Surfaces............................13 Note about Vertical and Horizontal Directions..................... 15 2. - Page 4 Horizontal Streaks: When Using Thick Paper (3)..................46 Glossy Lines at the Edge of the Paper......................48 Oblique Wavy Streaks..........................48 Streaks like defect imagery Appear on the Paper Surface..............50 Bands.................................51 Vertical Black Bands............................ 51 Vertical White Bands........................... 51 Horizontal Streaks at the Area within 20 mm (0.8 inches) from the Leading Edge....... 52 6.

- Page 5 Uneven Glossiness due to Cooling......................88 Dirtied Printouts..............................90 Toner Scattering: Trailing Edge........................90 Toner Scattering: Around a Solid Fill Image....................92 Stained When Duplex Printing is Performed....................92 Paper Edges are Stained..........................93 Others................................95 Creases, Worm Track (Wavy Streaks), or Bends Appear............... 95 8. Troubleshooting Paper Delivery Problems The Jam Code Appears...........................

- Page 6 Trailing Edge of Stapled Sheets Close to the Paper Exit................ 128 Sheets Cannot Be Stapled Properly......................129 Paper Edges Are Stained (1)........................130 Paper Edges Are Stained (2)........................131 Paper Edges Are Stained (3)........................131 When Z-folded Paper is Punched, Jam Code J125 Appears............... 132 Jam code J122 appears when envelopes are delivered...............133 Multi-Folding Unit............................

- Page 7 Aligning the Image Position on Side 2 to That on Side 1 (Using a Template to Align the Image Position on Side 1 and 2)............................168 Prepunched Paper............................176 Preprinted Paper............................183 Envelopes............................... 184 Adjust Paper Curl............................186 Decurling Workflow..........................186 Decurling Examples...........................189...

-

Page 8: Introduction

Introduction This manual contains detailed instructions and notes on the operation and use of this machine. For your safety and benefit, read this manual carefully before using the machine. Keep this manual in a handy place for quick reference. -

Page 9: How To Read This Manual

How to Read This Manual Symbols This manual uses the following symbols: Indicates points to pay attention to when using the machine, and explanations of likely causes of paper misfeeds, damage to originals, or loss of data. Be sure to read these explanations. Indicates supplementary explanations of the machine’s functions, and instructions on resolving user errors. - Page 10 Certain options might not be available in some countries. For details, please contact your local dealer. Depending on which country you are in, certain units may be optional. For details, please contact your local dealer. Two kinds of size notation are employed in this manual.

-

Page 11: Before You Begin

1. Before You Begin About This Manual If the machine will not print, does not print as expected, or exhibits any other problem, find the problem in this manual and troubleshoot accordingly. • Before you replace any unit: • To prevent electrical shock, turn off the color controller on the machine control panel, switch off the main power switch then the AC power switch, and then disconnect the machine from the power supply. -

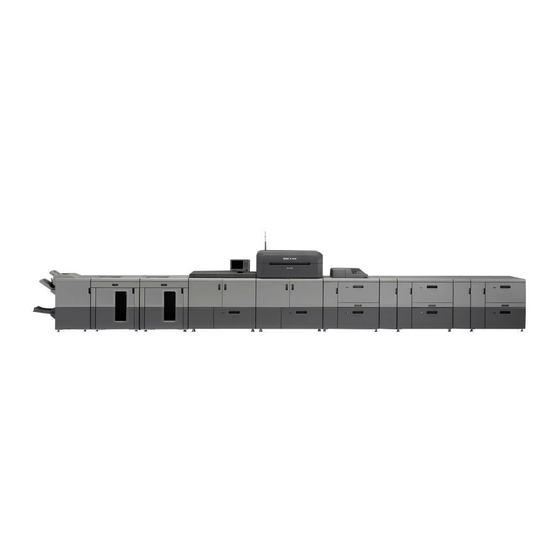

Page 12: Names Of Components

1. Before You Begin Names of Components • Do not remove any covers or screws other than those explicitly mentioned in this manual. Inside this machine are high voltage components that are an electric shock hazard. Contact your sales or service representative if any of the machine's internal components require maintenance, adjustment, or repair. -

Page 13: About The Display For Options

About the Display for Options About the Display for Options This machine displays all of the adjustment items in the [Adjustment Settings for Skilled Operators] menu and advanced settings for custom paper regardless of whether or not the items are for options. Note that any modifications to the option settings do not take effect unless the applicable options are installed on this machine. -

Page 14: Before You Change A Setting

1. Before You Begin Before You Change a Setting • If the problem persists despite the setting being changed, restore the value you made a note of. • Operating the machine with the changed setting may cause problems such as reduced print quality. -

Page 15: About Printing Surfaces

About Printing Surfaces About Printing Surfaces Side 1 is the surface of the paper printed during one-sided printing, or the surface of the first print during duplex printing. Side 2 is the surface of the paper printed after side 1 has been printed during duplex printing. Single-sided printing: Printed side face down DFP406 A. - Page 16 1. Before You Begin Duplex printing DFP407 A. Side 1 B. Paper feed direction of Side 1 C. Side 2 D. Paper feed direction of Side 2...

-

Page 17: Note About Vertical And Horizontal Directions

Note about Vertical and Horizontal Directions Note about Vertical and Horizontal Directions In this manual, with regard to the paper feed direction, the vertical and horizontal directions are as shown below: DFP311 1. Paper feed direction 2. Horizontal 3. Vertical... - Page 18 1. Before You Begin...

-

Page 19: Troubleshooting Service Call Problems (Sc Codes)

2. Troubleshooting Service Call Problems (SC Codes) What Are SC Codes? If an error occurs during operation, the machine displays an SC code ("SCnnn", where "nnn" is a three- digit number). The machine stops and cannot be used when an SC code is displayed. If an SC Code Appears: Write down the SC number. - Page 20 2. Troubleshooting Service Call Problems (SC Codes)

-

Page 21: Specifying And Checking Paper Settings

3. Specifying and Checking Paper Settings Adjusting Paper Settings Paper Setting Flowchart What is the problem you want to solve? Paper Delivery Image quality in fusing and image Image position/density transfer Specify the corresponding settings in [Adjustment Settings for Skilled Operators] and [Advanced Settings]. - Page 22 3. Specifying and Checking Paper Settings Solution: Carry out the following sequence of procedures. Terminate the sequence as soon as the problem is resolved. Procedure 1: Changing the fusing temperature In [Advanced Settings] for the custom paper, adjust the fusing heat roller temperature.

-

Page 23: Improving Transferability

Adjusting Paper Settings • Glossy lines • Change of gloss • If one or more of the above side effects occurs, adjust the fusing temperature and process speed by decreasing the fusing temperature and increasing the process speed. • After performing the solution, it is recommended to perform the color calibration of the external controller. - Page 24 3. Specifying and Checking Paper Settings...

-

Page 25: Troubleshooting Image Quality Problems

4. Troubleshooting Image Quality Problems Image Index Large Classification: Lines/Streaks A smudge or a white area inside an image, in a linear shape appears horizontally or vertically. DFP701 Middle classification: Lines/Streaks A smudge or a white area inside an image, in a linear shape with 1 mm or smaller width. DFP755... - Page 26 4. Troubleshooting Image Quality Problems Small classification Sample image Description Vertical black (color) streaks • See page 41 "Vertical Black Streaks (1)". Black (color) streaks appearing in the paper feed direction. • See page 42 "Vertical Black Streaks (2)". DFP754 Vertical white streaks •...

- Page 27 Image Index Small classification Sample image Description Vertical glossy streaks • See page 48 "Glossy Lines at the Edge of the Paper". Glossy streaks appearing in the paper feed direction. DFP706 Horizontal white streaks Glossy streaks appearing in the direction perpendicular to the paper feed direction.

- Page 28 4. Troubleshooting Image Quality Problems Small classification Sample image Description Jitter Blurred area visible as bands in the direction perpendicular to the paper feed direction. DFP709 Banding Banding at regular intervals in the direction perpendicular to the paper feed direction. (Gear eyes: Color unevenness in the same interval as the pitch of the gear.) DFP710...

-

Page 29: Large Classification: Spots

Image Index Small classification Sample image Description Vertical black (color) bands • See page 51 "Vertical Black Bands". Black (color) bands appearing in the paper feed direction. DFP713 Horizontal black (color) bands • See page 52 "Horizontal Streaks at the Area within 20 Black (color) bands appearing in the mm (0.8 inches) from the direction perpendicular to the paper... - Page 30 4. Troubleshooting Image Quality Problems DFP757 Middle classification: Spot White spots seen in solid image areas or black/color spots seen where there should be nothing printed. The description "white spots" excludes those with toner cores. White spots and Fireflies are considered different issues as the former does not consist a core in the center of the unprinted spot.

-

Page 31: Large Classification: Full Page

Image Index Small classification Sample image Description White spots • See page 60 "White Spots/ Toner Blasting". White spots are visible inside solid image or halftone image area because of missing toner. DFP718 Spots with toner • See page 57 "Black (color) Spots (1)". - Page 32 4. Troubleshooting Image Quality Problems DFP758 Middle classification: Full page Image/text does not appear on the printout. DFP721 Small classification Sample image Description All black Printed paper is all black. DFP721 Blank No image is reproduced. DFP722...

- Page 33 Image Index Middle classification: Unprinted Parts of the developed images and letters are not reproduced. DFP759 Small classification Sample image Description White zone • See page 65 "Fainter Trailing Edge". Part of a solid image or halftone is missing. • See page 79 "White Spots on a Textured Surface".

- Page 34 4. Troubleshooting Image Quality Problems Small classification Sample image Description Negative residual image Previously printed image is reproduced with its black and white reversed on the same page or the next page. DFP726 Positive residual image Previously printed image is reproduced on the same page or the next page.

- Page 35 Image Index DFP760 Small classification Sample image Description High density • See page 77 "Higher Density at the Leading Edge". Image density higher than configured. DFP730 Low density • See page 75 "Low Image Density". Image density lower than configured. DFP731 Uneven density •...

- Page 36 4. Troubleshooting Image Quality Problems Small classification Sample image Description Unevenness in indefinite shape • See page 84 "Uneven Gloss: Wavy". Image density unevenness in indefinite shapes. DFP733 Uneven glossiness • See page 82 "Uneven Gloss". The glossiness is uneven inside a •...

- Page 37 Image Index Small classification Sample image Description Rough image • See page 81 "Mottling". Color is uneven and small white spots are visible inside a solid image. With color copiers, white spots may not appear when two colors are overlapped. DFP737 Earthworm shape •...

- Page 38 4. Troubleshooting Image Quality Problems DFP743 Small classification Sample image Description Background stains Granular stains are visible in unprinted areas of the paper. DFP741 Backside stains Granular stains are visible on the backside of the paper. DFP742 Toner scattered • See page 90 "Toner Scattering: Trailing Edge".

- Page 39 Image Index Small classification Sample image Description Edge stains • See page 93 "Paper Edges are Stained". The side edges of paper are stained. DFP744 Middle classification: Disturbed image Image/text are disturbed and do not replicate the original. DFP746 Small classification Sample image Description Irregularity...

- Page 40 4. Troubleshooting Image Quality Problems Small classification Sample image Description Image contraction Image contracted abnormally in comparison with the original. DFP747 Skew The corners of an image copied from a rectangle original are not square. DFP748 Middle classification: Scratches Stains in the shape of vertical streaks which seem to result from being scratched by the guide plate ribs or other parts.

- Page 41 Image Index DFP751 Small classification Sample image Description Vertical image shift Images and lines shifted in the paper feed direction. DFP750 Horizontal image shift Images and lines shifted in the direction perpendicular to the paper feed direction. DFP751 Vertical color shift Color shifted in the paper feed direction where colors should be overlaid.

- Page 42 4. Troubleshooting Image Quality Problems Small classification Sample image Description Horizontal color shift Color shifted in the direction perpendicular to the paper feed direction where colors should be overlaid. DFP753 Others • For details see, page 48 "Oblique Wavy Streaks". •...

-

Page 43: Image Quality Problem: Lines

5. Image Quality Problem: Lines Streaks Vertical Black Streaks (1) Black streaks appear at intervals of approximately 60 mm (2.4 inches) from the center. This occurs Side 1 only. 110 mm (4.3 in.) 60 mm (2.4 in.) 60 mm (2.4 in.) DFT307 Cause: Because of inconsistent air volumes of the suction fan of the paper tray or the use of paper from different... -

Page 44: Vertical Black Streaks (2)

5. Image Quality Problem: Lines Go to the next step. Decrease the value in 108: [Paper Tray: Vacuum Fan Level] by 10 percentage point. Print the image. Has the problem been resolved? Finished! Repeat Steps 3 and 4. If the problem persists even though you have decreased the value to "50 %", contact your service representative. -

Page 45: Vertical White Streaks

Streaks If the streaks are black, replace the cleaning unit for the photoconductor unit for black. If the streaks are cyan, replace the cleaning unit for the photoconductor unit for cyan. Print the image. Has the problem been resolved? Finished! Carry out the procedure in page 41 "Vertical Black Streaks (1)". -

Page 46: Horizontal Streaks: When Using Thick Paper (1)

5. Image Quality Problem: Lines Solution: Open the right front cover of the left unit, and then lower the lever for A5/Half Letter to the right. DFT090 DFT090 Print the image. If the problem persists, contact your service representative. • If you are printing on paper whose weight is between 1 and 3 with the lever for A5/Half Letter lowered to the right, creases may appear in the center of the paper. - Page 47 Streaks • The horizontal streaks which appear on thick paper do not appear on the first printed sheet. • Streaks appear in various areas depending on the length and color of the paper. Solution: Carry out the following sequence of procedures. Terminate the sequence as soon as the problem is resolved.

-

Page 48: Horizontal Streaks: When Using Thick Paper (2)

5. Image Quality Problem: Lines Horizontal Streaks: When Using Thick Paper (2) Streaks appear at approximately 50 mm (2 inches) away from the leading or trailing edge of the paper. 50 mm 50 mm (2 in.) (2 in.) DFT034 Cause: This may occur if: •... - Page 49 Streaks 21 mm (0.8 in.) DFT306 Cause: This may occur if: • Thick paper is used • Coated paper is used • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings.

-

Page 50: Glossy Lines At The Edge Of The Paper

5. Image Quality Problem: Lines • White spots Glossy Lines at the Edge of the Paper A glossy line appears in parallel to the paper feed direction. This may occur on solid-fill images. DFP455 Cause: There is a trace (streak) of the paper edge on the fusing belt. Solution: In the 05: [Machine: Maintenance] group on the [Adjustment Settings for Skilled Operators] menu, select 0507: [Smooth Fusing Belt] and execute [For Belt Scratches]. - Page 51 Streaks 130 mm 130 mm (5.2 in.) (5.2 in.) DFT024 Cause: Due to the leading edge of the paper being curled or wavy directly after fusing, an angled force is applied to the paper until the trailing edge of the paper moves out of the fusing unit, producing oblique creases.

-

Page 52: Streaks Like Defect Imagery Appear On The Paper Surface

5. Image Quality Problem: Lines Print the image. Has the problem been resolved? Finished! Contact your service representative. Streaks like defect imagery Appear on the Paper Surface Streaks appear as if scratched a needle, so that the background can be seen. DFT300 Cause: The paper path is stained. -

Page 53: Bands

Bands Bands Vertical Black Bands Black bands that are 5 to 6 mm (0.2 inches) wide appear on a halftone image parallel to the paper feed direction. DFT054 Cause: The corona wire or grid in the charge roller unit is stained. Solution: In the 05: [Machine: Maintenance] group on the [Adjustment Settings for Skilled Operators] menu, select 0521: [Execute Charger Cleaning] and execute [All Colors]. -

Page 54: Horizontal Streaks At The Area Within 20 Mm (0.8 Inches) From The Leading Edge

5. Image Quality Problem: Lines DFT305 Cause: The amount of lubricant on the intermediate transfer belt is uneven. This may occur on half-tone images. Solution: In the 02: [Machine: Image Quality] group on the [Adjustment Settings for Skilled Operators] menu, select 0201: [Adjust Image Density/ DEMS] and execute [Image Density Adjustment: Manual Execute]. - Page 55 Bands 20 mm (0.8 in.) DFT056 Cause: This may occur if: • Thick paper is used • Coated paper is used • Printing is done at low temperature or humidity • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings.

- Page 56 5. Image Quality Problem: Lines Is it set to 150 A? Proceed to "Procedure 2: Adjust the transferability at the paper transfer unit". Go to the next step. Increase the value in 022: [Image Transfer Current: BW] or 023: [Image Transfer Current: FC: K] by 5 A.

- Page 57 Bands Decrease the value in 087: [Ppr Trns High Pressure Setting] by 1 step. If [High] is selected, change the value to [Standard]. If [Standard] is selected, change the value to [Low]. If [Low] is selected, change the value to [Off]. Print the image.

- Page 58 5. Image Quality Problem: Lines...

-

Page 59: Image Quality Problem: Spots

6. Image Quality Problem: Spots Spots Black (color) Spots (1) Black or colored spots appear. DFT067 Cause: This may occur if you use toner which has been left at high temperature and humidity. Solution: Has this problem occurred after replacing the toner bottle? Replace the toner bottle. -

Page 60: Black (Color) Spots (2)

6. Image Quality Problem: Spots Black (color) Spots (2) Paper is stained with toner spots of 0.5–1 mm (0.02–0.04 inches) in diameter. CEZ538 Cause: Toner fragments have slipped through the cleaning web. This may occur if: • Duplex printing • Printing on uncoated (especially rough-textured) paper •... - Page 61 Spots Print the image. Has the problem been resolved? Finished! Increase the temperature an additional 5 degrees in 088: [Fusing Temp: FC] or 089: [Fusing Temp: BW]. Print the image. Has the problem been resolved? Finished! Set 096: [Cleaning Web Rotation Interval] to "-75 %". Print the image.

-

Page 62: White Spots/Toner Blasting

6. Image Quality Problem: Spots • After performing the solution, it is recommended to perform the color calibration of the external controller. For details see, page 159 "Operating Procedure for Color Calibration". White Spots/Toner Blasting White Spots White spots of 0.2 to 0.3 mm (0.008 to 0.01 inches) in diameter appear. CEZ527 Toner Blasting Toner is scattered around a solid-fill print. - Page 63 Spots • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. Solution: <If paper dust is stuck to the paper> Clean the dust catcher, guide plate, rollers and paper feed rollers.

-

Page 64: Medaka (White Spots)

6. Image Quality Problem: Spots <b: If the problem occurs on side 2> White Spots Which problem occurs? Toner Blasting Decrease the paper transfer current applied to Increase the paper transfer current applied to side 2 by 5 μA. side 2 by 5 μA. E.g., -82 μA to -87 μA E.g., -82 μA to -77 μA [Advanced Settings]... - Page 65 Spots 307 mm (12.2 in.) DFT040 Cause: The photoconductor unit is stained. Solution: To identify the affected color, print three full-page, solid-fill A3 or DLT sheets for each of cyan, magenta, black, and green, and three full-page, halftone A3 or DLT sheets for each of cyan, magenta, and yellow.

- Page 66 6. Image Quality Problem: Spots • For details about replacing the PCU cleaning unit and photoconductor unit, see Replacement Guide.

-

Page 67: Image Quality Problem: Full Page

7. Image Quality Problem: Full Page Unprinted Fainter Trailing Edge The trailing edge is fainter. CEZ563 Cause: This may occur if: • Printing is done at low temperature or humidity • Halftone printing • Thick paper is used • Coated paper is used •... -

Page 68: Faint Printing

7. Image Quality Problem: Full Page Faint Printing Small text and lines are printed faintly. DFT057 Cause: When the machine setting is specified to print text and lines thinly, small text and lines may be printed faintly. Solution: In the 02: [Machine: Image Quality] group on the [Adjustment Settings for Skilled Operators] menu, select 0201: [Adjust Image Density/ DEMS] and execute [Image Density Adjustment: Manual Execute]. -

Page 69: Colorless Spots

Unprinted Colorless Spots White spots appear randomly. DFT058 Cause: This occurs due to the paper being stained with granular toner. Solution: Replace the toner bottle to a new one. -

Page 70: Uneven Density

7. Image Quality Problem: Full Page Uneven Density Uneven Image Density The density is uneven. Solution: The solution depends on the type of unevenness. Carry out the appropriate procedure from those in the following table: (A) The density is uneven across the entire image. Affected area Solution The density from top to bottom is uneven. - Page 71 Uneven Density (B) The density is uneven in a part of the image. Affected area Solution The leading edge is fainter. 1. In the 02: [Machine: Image Quality] group on the [Adjustment Settings for Skilled Operators] menu, select 0201: [Adjust Image Density/ DEMS] and execute [Image Density Adjustment: Manual Execute].

-

Page 72: Density Fluctuation At The Leading Edge (When Using Thick Paper)

7. Image Quality Problem: Full Page Affected area Solution Wavy unevenness 1. In the 02: [Machine: Image Quality] group on the [Adjustment Settings for Skilled Operators] menu, select 0201: [Adjust Image Density/ DEMS] and execute [Image Density Adjustment: Manual Execute]. 2. - Page 73 Uneven Density Cause: This may occur if: • Printing is done at low temperature or humidity • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. Solution: Carry out the following sequence of procedures.

- Page 74 7. Image Quality Problem: Full Page <Printing in full color> 029: [Image Transfer Current: LE: FC: K], 031: [Image Transfer Current: LE: FC: C], 033: [Image Transfer Current: LE: FC: M], 035: [Image Transfer Current: LE: FC: Y], 045: [Paper Transfer Current: LE: FC], 063: [AC Transfer Mode: Voltage: LE: FC], and 064: [AC Transfer Mode: Current: LE: FC] Increase these values by 10 percentage points.

-

Page 75: Density Fluctuation At The Trailing Edge (When Using Thick Paper)

Uneven Density Density Fluctuation at the Trailing Edge (When Using Thick Paper) The trailing edge is fainter or denser when using thick paper. 10 mm (0.4 in.) DFT059 Cause: This may occur if: • Printing is done at low temperature or humidity •... - Page 76 7. Image Quality Problem: Full Page In [Advanced Settings] for the custom paper, specify the area to apply the paper transfer current at the trailing edge of the paper values. <Printing in black and white> In 042: [Paper Transfer Current: TE Leng.: BW] or 068: [AC Transfer Mode: TE Leng.: BW], enter the value which is 10 mm higher than the value measured in Step 1.

-

Page 77: Low Image Density

Uneven Density Procedure 3: Decreasing the current In [Advanced Settings] for the custom paper, make a note of the following values: <Printing in black and white> 041: [Paper Transfer Current: TE: BW], 066: [AC Transfer Mode: Voltage: TE: BW], and 067: [AC Transfer Mode: Current: TE: BW] <Printing in full color>... - Page 78 7. Image Quality Problem: Full Page Black is fainter CEZ584 Cause: This may occur if: • Printing is done at high temperature or humidity • Coated paper is used • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings.

-

Page 79: Higher Density At The Leading Edge

Uneven Density Print the image. Has the problem been resolved? Finished! Repeat Steps 1 to 3. If the problem persists even though you have increased the value in 0203: [Maximum Image Density] to "5", contact your service representative. • After performing the solution, it is recommended to perform the color calibration of the external controller. -

Page 80: Uneven Density Within 107 Mm (4.2 Inches) Of The Trailing Edge

7. Image Quality Problem: Full Page Print the image. Has the problem been resolved? Finished! Contact your service representative. Uneven Density within 107 mm (4.2 inches) of the Trailing Edge Printing in the area extending approximately 107 mm (4.2 inches) from the trailing edge is fainter or denser. -

Page 81: White Spots On A Textured Surface

Uneven Density <If the area within 107 mm (4.2 inches) of the trailing edge is fainter> In [Advanced Settings] for the custom paper, check the present value in 016: [Transfer Timing Roller Feed Speed]. Is it higher than +0.5%? Contact your service representative. Increase the value by 0.1 percentage point. - Page 82 7. Image Quality Problem: Full Page CXM001 Cause: This may occur if: • Heavily textured paper is used. • Thick paper is used. • Documents with a small image area are printed continuously. • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings.

-

Page 83: Mottling

Uneven Density Increase the value in 043: [Paper Transfer Current: FC: Side 1] or 044: [Paper Transfer Current: FC: Side 2] by -20 A. Eg., -120 A to -100 A Print the image. Has the problem been resolved? Finished! Decrease the value in 087: [Ppr Trns High Pressure Setting] by one step. If [High] is selected, change the value to [Standard]. -

Page 84: Uneven Gloss

7. Image Quality Problem: Full Page Cause: This may occur if: • Using paper with a rough surface • Continuously printing solid fills covering small areas • Printing in a low humidity environment • Printing in a high humidity environment Solution: Perform the color calibration of the external controller. - Page 85 Uneven Density • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. Solution: In [Advanced Settings] for the custom paper, adjust the fusing heat roller temperature. <Printing in full color>...

-

Page 86: Uneven Gloss: Wavy

7. Image Quality Problem: Full Page • After performing the solution, it is recommended to perform the color calibration of the external controller. For details see, page 159 "Operating Procedure for Color Calibration". Uneven Gloss: Wavy When duplex printing is performed on paper whose paper thickness level is between 1 and 4, wavy density fluctuations may occur on side 2. -

Page 87: Uneven Gloss: Foggy

Uneven Density Print the image. Has the problem been resolved? Finished! Proceed to "Procedure 2: Increase the fusing heat roller temperature". Procedure 2: Increase the fusing heat roller temperature In [Advanced Settings] for the custom paper, adjust the fusing heat roller temperature. <Printing in full color>... -

Page 88: Uneven Gloss: Thick Paper

7. Image Quality Problem: Full Page DFT047 Cause: This may be due to paper coiling around the fusing belt at the fusing nip exit. • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. -

Page 89: Uneven Gloss: Orange Peel

Uneven Density Cause: This may occur if: • Paper with a thickness equivalent to Paper Weight 7 or 8 is used • Duplex printing • Printing solid fills • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. -

Page 90: Uneven Glossiness Due To Cooling

7. Image Quality Problem: Full Page Solution: In [Advanced Settings] for the custom paper, increase all the value in 018: [Maximum Image Density: K], 019: [Maximum Image Density: C], 020: [Maximum Image Density: M] and 021: [Maximum Image Density: Y] by one step. Print the image. - Page 91 Uneven Density Cause: When the paper comes into contact with the cooling belt and the toner's surface temperature is 95°C (203°F) or higher, uneven glossiness may occur. This may occur if: • Coated paper is used • Paper with paper weight 4 or 5 is used •...

-

Page 92: Dirtied Printouts

7. Image Quality Problem: Full Page Dirtied Printouts Toner Scattering: Trailing Edge Parts of a line or character exhibit splatter. This may occur in a line or character that is 8 to 13 mm (0.3 to 0.5 inches) from the trailing edge and 20 mm (0.8 inches) or less from the left edge facing the paper feed direction. - Page 93 Dirtied Printouts Solution: <Printing in black and white> In [Advanced Settings] for the custom paper, check the present value in 022: [Image Transfer Current: BW]. Is it lower than 150 A? Carry out all of the following: • Increase the value by 5 A in 022: [Image Transfer Current: BW]. •...

-

Page 94: Toner Scattering: Around A Solid Fill Image

7. Image Quality Problem: Full Page • After performing the solution, it is recommended to perform the color calibration of the external controller. For details see, page 159 "Operating Procedure for Color Calibration". Toner Scattering: Around a Solid Fill Image Toner is scattered around a solid-fill print. -

Page 95: Paper Edges Are Stained

Dirtied Printouts Solution: Apply duplex printing to 5 full-page solid-fill sheets. Using coated paper with a thickness of 2 to 3 is effective. Print the image. Has the problem been resolved? Finished! Contact your service representative. Paper Edges are Stained DFT322 Cause: The paper path is stained. - Page 96 7. Image Quality Problem: Full Page Print the image. Has the problem been resolved? Finished! Increase the value in 094: [Additional Fusing Temp 1] and 095: [Additional Fusing Temp 2] by 5 degrees. Print the image. Has the problem been resolved? Finished! If the problem persists, proceed the steps in page 130 "Paper Edges Are Stained (1)", page 131 "Paper Edges Are Stained (2)"...

-

Page 97: Others

Others Others Creases, Worm Track (Wavy Streaks), or Bends Appear A. Crease Creases appear. B. Worm track Wavy streaks appear. DFT303 Bent Umbrella-like creases appear at the center of the paper. DFT304 Cause: This may occur if: • Thin paper is used •... - Page 98 7. Image Quality Problem: Full Page • A3 or DLT size paper is used • An envelope is used • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. Solution: If no envelope is used, follow Procedure 1 and Procedure 2 as specified.

- Page 99 Others Print the image. Has the problem been resolved? Finished! Repeat Steps 3 to 4. If the problem persists after the value in 102: [Fusing Nip Width Adjustment: Envelope] is reduced to 400 milliseconds, contact your service representative. Procedure 2: Decrease the pressure roller temperature In [Advanced Settings] for the custom paper, adjust the pressure roller temperature.

- Page 100 7. Image Quality Problem: Full Page...

-

Page 101: Troubleshooting Paper Delivery Problems

8. Troubleshooting Paper Delivery Problems The Jam Code Appears Paper misfeeds are reported by messages and jam codes. Resolve the problem according to the jam code. CWH406 If (J038) Appears Cause: When thin paper is used, paper jam occurs at the fusing unit. This may occur if: •... -

Page 102: If (J040/J042/J090) Appears

8. Troubleshooting Paper Delivery Problems Contact your service representative. If (J040/J042/J090) Appears Cause: A paper jam has occurred in the area around the separation claw. Solution: Remove the scrap of paper in the paper feed path in the area around the separation claw. -

Page 103: If (J086) Appears

The Jam Code Appears • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. • When prepunched paper is used, see page 176 "Prepunched Paper". Solution: In [Advanced Settings] for the custom paper, set 114: [Registration Gate Position Setting] to"-2". -

Page 104: If (J097) Appears

8. Troubleshooting Paper Delivery Problems Print the image. Has the jam code J086 appeared? Finished! Go to the next step. Adjust the fusing heat roller temperature. <Printing in full color> Decrease the value in 088: [Fusing Temp: FC] by 5 degrees. <Printing in black and white>... -

Page 105: If (J098) Appears

The Jam Code Appears If (J098) Appears Cause: Sheets cannot be positioned properly by image position adjustment. Solution: Depending on the cause of the problem, do one of the following: The side fences in the paper trays are not positioned correctly. Adjust the side fences to match the paper width. - Page 106 8. Troubleshooting Paper Delivery Problems To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. The solution varies depending on the 115: [Ppr Edge Detection: Sensing Duration] setting. In [Advanced Settings] for the custom paper, check the 115: [Ppr Edge Detection: Sensing Duration] setting.

-

Page 107: If (J430/J431/J445/J446/J460/J461) Appears

The Jam Code Appears Repeat Step 2. If the problem persists even though you have increased the value by "10", set 115: [Ppr Edge Detection: Sensing Duration] to [Long Time] and proceed the steps in "Procedure 2: If set to [Long Time]". Go to the next step. - Page 108 8. Troubleshooting Paper Delivery Problems Set 111: [Paper Tray: Paper Feed Position] to [High]. Print the image. Has the problem been resolved? Finished! If the problem persists, contact your service representative.

-

Page 109: Troubleshooting Paper Delivery Problems

Troubleshooting Paper Delivery Problems Troubleshooting Paper Delivery Problems Paper Skew Depending on the cause of the problem, do one of the following: The side fences in the paper tray are too far apart. If the side fences are too far apart, the paper may be skewed. Adjust the side fences to match the paper width. -

Page 110: Wrong Detection Of Skew

8. Troubleshooting Paper Delivery Problems 2. Print the image on both sides of 50 sheets. 3. Has the jam code J097, J098 or J048 appeared? If (J097) or (J098) appears Carry out the procedure in page 107 "Paper Skew" or page 108 "Wrong Detection of Skew", and then go to the next step. -

Page 111: Double Feeding

Troubleshooting Paper Delivery Problems <If custom paper is not used> In the [Machine: Image Position] group on the [Adjustment Settings for Skilled Operators] menu, set 0104: [Skew Detection] to [Off]. An envelope is used. If an envelope flap at the trailing edge is oblique, a skew may be wrongly detected when the envelope is transferred with its flap open. -

Page 112: Paper Misfeeding

8. Troubleshooting Paper Delivery Problems 1. If the jam code J099 appears more than three times, in [Advanced Settings] for the custom paper, set 112: [Paper Tray: Paper Feed Mode] to [Modrate Dble Fd Red. (Lower)]. 2. Print the image. Has the problem been resolved? Finished! Set 112: [Paper Tray: Paper Feed Mode] to [Max Dble Fd Reduc. - Page 113 Troubleshooting Paper Delivery Problems Remove the paper, ruffle it, and reload it. For details about ruffling paper, see "Fanning the Paper", About This Machine. Have you ruffled the paper sufficiently? Double feeding may result if the paper is not ruffled properly. Remove the paper, ruffle it, and reload it.

-

Page 114: Other Paper Delivery Problems

8. Troubleshooting Paper Delivery Problems Two-tray wide LCT (Vacuum Feed LCIT RT5100) is used. The factory-set airflow of the wide LCT may not be strong enough to separate the sheets. Increase the airflow. For details see, page 105 "If (J430/J431/J445/J446/J460/J461) Appears". Other Paper Delivery Problems If the Paper Jams in the Fusing Unit during Duplex Printing A paper jam has occurred at the separation claw. -

Page 115: Cleaning The Paper Feed Path

Cleaning the Paper Feed Path Cleaning the Paper Feed Path Paper dust sticking to the paper transfer guide plate, roller, paper feed roller, or sensor may cause white spots, paper jam, or double feeding. Clean the paper feed path from the paper tray to the paper exit in the drawer. -

Page 116: Cleaning Paper Trays

8. Troubleshooting Paper Delivery Problems CZC350 Sensor Remove dust with a blower brush. CZC347 Cleaning Paper Trays Remove the paper tray. Clean the sensors. DFT002... -

Page 117: Cleaning The Paper Feed Path For Paper Tray 1

Cleaning the Paper Feed Path Cleaning the Paper Feed Path for Paper Tray 1 Open the front cover of the left unit. DFT003 Open the plates. DFT004 Clean the rollers, sensors, and guide plates. Open the F1 plate and clean the separation claw. Lift the separation claw and clean the area around the tip on the side which comes into contact with the paper. -

Page 118: Cleaning The Paper Feed Path In The Drawer

8. Troubleshooting Paper Delivery Problems Close the front covers. DFT006 Cleaning the Paper Feed Path in the Drawer Left drawer unit Open the front cover of the left unit. DFT005 Raise the E1 plate, lower the lever D1, and then pull out the unit in the left drawer until it stops. - Page 119 Cleaning the Paper Feed Path Pull up the lever D2 and clean the sensors. DFT008 Use a dry cloth to clean the plate. DFT009 Push down the lever D2. Push the left drawer into the main unit until it stops, and then pull up the lever D1. Close the E1 plate.

- Page 120 8. Troubleshooting Paper Delivery Problems Pull down the lever C2 and pull out the right drawer until it stops. DFT011 Remove the two screws and then remove the cover plate. DFT012 Remove the two screws and then remove the dust catcher. DFT013...

- Page 121 Cleaning the Paper Feed Path Use a clean dry cloth to remove any dust remaining in the dust catcher. CEZ199 Reattach the dust catcher with the two screws. DFT014 Reattach the cover plate with the two screws. DFT015...

- Page 122 8. Troubleshooting Paper Delivery Problems Push the right drawer into the main unit until it stops, and then pull up the lever C2. DFT016 Open the plates. DFT017 Clean the rollers, sensors, and guide plates. Close the plates opened in Step 9. Close the front covers.

-

Page 123: Cleaning The Paper Feed Path In The Multi Bypass Tray

Cleaning the Paper Feed Path Clean the sensors. DFT018 Close the left front cover. Cleaning the Paper Feed Path in the Multi Bypass Tray Clean the side fences and front guide. CEZ587 Remove the cover. CZC128... - Page 124 8. Troubleshooting Paper Delivery Problems Remove one screw. CZC124 Remove the plate. CZC129 Remove one screw and slide the bracket. CZC125 Remove the paper feed rollers as follows: (1) Snap ring and pick-up roller (2) Snap ring and feed roller (3) Snap ring and separation roller...

-

Page 125: Cleaning The Paper Feed Rollers And Paper Feed Belt In The Interposer

Cleaning the Paper Feed Path CZC132 Clean the paper feed rollers. Attach the paper feed rollers, bracket, plate, and cover in the reverse order from the procedure to remove them. Release the lock and slide the unit to the right. DFT312 Clean the guide plate. - Page 126 8. Troubleshooting Paper Delivery Problems Open the upper cover, and then detach the paper feed unit. Pull it out slightly, release the metal shaft, and then detach it. CEZ507 Clean the paper feed belt and paper feed rollers in the detached paper feed unit. CEZ508 After cleaning, restore the machine so that it resumes operation.

-

Page 127: Post-Processing Option Troubleshooting

9. Post-Processing Option Troubleshooting Finisher Delivered Sheets Are Not Stacked Properly Solution: Depending on the cause of the problem, do one of the following: Coated paper is being used. In the 06: [Finishing: Finisher] group on the [Adjustment Settings for Skilled Operators] menu, set 0617: [Adjust Output Fan Level] to [Increase Air Volume]. -

Page 128: Large Delivered Sheets Are Not Stacked Properly

9. Post-Processing Option Troubleshooting There are too many stacked sheets. Reduce the number of the stacked sheets. To do this, suspend printing and remove the stacked sheets, and then resume printing. To suspend printing, press the [Suspend/Resume] key on the finisher. To resume printing, press the [Suspend/Resume] key on the finisher. - Page 129 Finisher Paper exit Output tray Paper feed direction CEZ595 Paper deflection Because of high paper friction, the delivered sheet may arch up and become crimped. Paper exit Output tray Paper feed direction CEZ596 Solution: Depending on the cause of the problem, do one of the following: <Sheet bending>...

-

Page 130: Trailing Edge Of Stapled Sheets Close To The Paper Exit

9. Post-Processing Option Troubleshooting If "Off" is selected, change the value to "Weak". If "Weak" is selected, change the value to "Medium". If "Medium" is selected, change the value to "Strong". Coated paper is being used. In the 06: [Finishing: Finisher] group on the [Adjustment Settings for Skilled Operators] menu, set 0617: [Adjust Output Fan Level] to [Increase Air Volume]. -

Page 131: Sheets Cannot Be Stapled Properly

Finisher If this happens, stapled sheets, when delivered, may push the previously delivered sheet, resulting in paper bending or misfeeding. This may occur if: • There is a tight curl on a delivered set of stapled sheets. • Limp paper such as thin or recycled paper is used. Trailing edge too near exit Paper exit... -

Page 132: Paper Edges Are Stained (1)

9. Post-Processing Option Troubleshooting When coated or other paper producing higher paper-to-paper friction is used, the paper edges are not aligned properly, resulting in misaligned stapling. This may occur if: • Coated or other paper producing higher paper-to-paper friction is used. •... -

Page 133: Paper Edges Are Stained (2)

Finisher Solution: In the 03: [Machine: Paper Feed/ Output] group of the [Adjustment Settings for Skilled Operators] menu, set 0301: [Adjust Paper Curl] to [Adjust Curl]. If "Curl: Off" is selected, change the value to Curl: Weak". If "Curl: Weak" is selected, change the value to "Curl: Strong". -

Page 134: When Z-Folded Paper Is Punched, Jam Code J125 Appears

9. Post-Processing Option Troubleshooting Solution: In the 06: [Finishing: Finisher] group on the [Adjustment Settings for Skilled Operators] menu, set 0623: [Z-fold Skew Correction] to [On]. Print the image. Has the problem been resolved? Finished! Set 0624: [Correct Z-fold Skew] to "-6.0". Print the image. -

Page 135: Jam Code J122 Appears When Envelopes Are Delivered

Finisher Jam code J122 appears when envelopes are delivered Cause: When 120 to 130 large-size envelopes with flaps at the trailing edges are delivered to the finisher shift tray, a jam may occur because a flap may be caught with the paper delivery rollers. Solution: Attach the Z-fold support tray to the finisher shift tray. -

Page 136: Multi-Folding Unit

9. Post-Processing Option Troubleshooting Multi-Folding Unit Inaccurate Folding (Folding Deviation) Cause: Depending on paper hardness, inaccurate folds may result. This is referred to as folding deviation. Solution: Change the folding position by adjusting the position of the paper edge stopper for folding. •... -

Page 137: Folding Deviation

Multi-Folding Unit Folding Deviation Cause: Depending on paper hardness, folding deviations (skewed folding) may appear. A deviation may appear if the edge dimensions of the parts between folds are different. For example, in the following illustration, the dimensional difference between the top (L2[2]) and bottom (L2[1]) edges is a deviation. - Page 138 9. Post-Processing Option Troubleshooting Adjusting screw Adjusting screw hole Mounting screw CEZ599 Mounting screw Adjusting screw hole Adjusting screw CEZ600 Adjusting screw Mounting screw Adjusting screw hole CEZ601 The screws adjust the folding deviations of the following parts:...

- Page 139 Multi-Folding Unit Z-fold Paper feed direction CEZ532 Half Fold Paper feed direction CEZ533 Letter Fold-in Paper feed direction CEZ535...

- Page 140 9. Post-Processing Option Troubleshooting Letter Fold-out Paper feed direction CEZ534 Double Parallel Paper feed direction CEZ536 Gate Fold Paper feed direction CEZ537 mark indicates the leading edge (relative to the paper feed direction), and the mark indicates the trailing edge. <How to adjust the folding deviation>...

-

Page 141: Folds Stained By Multi-Sheet Folding

Multi-Folding Unit Remove the mounting screw. If the mounting screw is attached to the adjusting screw hole, unfasten it. Turn the adjusting screw to adjust the deviation. • To increase the length at the bottom part of paper, turn the screw clockwise. •... - Page 142 9. Post-Processing Option Troubleshooting CEZ571 This will produce paper stain of 1-3 cm (0.4-1.2 inches) in width (equal to the width of the blade) in the fold in the center of paper. Solution: Clean the blade. Open the front cover of the multi-folding unit. Pull the multi-folding unit out.

-

Page 143: Edges Of Letter Fold Bent

Multi-Folding Unit Wipe the tip and top of the blade with a soft dry cloth. Be careful not to damage the blade. CEZ513 After cleaning, restore the machine so that it resumes operation. Apply multi-sheet folding and print 3-5 copies. The paper stain will disappear. Edges of Letter Fold Bent When letter folding is applied, the edge of the inner flap may become bent. -

Page 144: Z-Folding Is Not Performed Properly

9. Post-Processing Option Troubleshooting Print the image. Has the problem been resolved? Finished! Contact your service representative. Z-Folding is Not Performed Properly Cause: If a sheet is curled and its edge touches the guide plate, proper folding may not be possible. This may occur if: Upward curl (radius 4 cm [1.6 in.] or less) on the leading edge of delivered paper. -

Page 145: Folded Sheets Are Not Stacked Properly

Multi-Folding Unit Contact your service representative. • This folding error will not occur if uncurled paper is used or sheets that curl downward. Folded Sheets Are Not Stacked Properly Cause: If a large number of half-folded multi-sheet is delivered, the edge of the sheets may bulge and some part of the edge will be swollen. - Page 146 9. Post-Processing Option Troubleshooting DFP351 For details about attaching the Z-fold support tray for multi-folding unit, see "About This Machine" supplied with the machine. • If the Z-fold support tray for the multi-folding unit is attached, folded paper such as letter-folded paper or gate-folded paper will not turn over in the output tray when delivered.

-

Page 147: Ring Binding

Ring Binding Ring Binding • Be sure not to exit from Energy Saver mode or to switch the machine on when the ring binder door is open and the binding unit is disconnected. Doing so will affect initialization, causing the ring binder function to become unavailable (although other functions will be unaffected). -

Page 148: High Capacity Stacker

9. Post-Processing Option Troubleshooting High Capacity Stacker Delivered Sheets Are Severely Curled Cause: Sheets with downward curls cause strong friction on the leading edges. This may result in paper misfeeds. Sheets will not be ejected completely and the trailing edges will be left inside the paper exit. If this happens, other sheets may slip under the delivered sheets, so that the delivered sheets may be curled when loaded. - Page 149 High Capacity Stacker Paper exit Paddle Stacker shift tray Paper feed direction CEZ575 4. The next sheet to be delivered slips under the sheet still in the paper exit and bends back. Paper exit Paddle Stacker shift tray Paper feed direction CEZ576 Solution: Straighten out the sheet by decurling it upward.

-

Page 150: Delivered Sheets Are Not Aligned

9. Post-Processing Option Troubleshooting Set 0301: [Adjust Paper Curl] to [Adjust Curl: Strong]. Print the image. Has the problem been resolved? Finished! Contact your service representative. Delivered Sheets Are Not Aligned Cause: When sheets are delivered to the stacker tray, because of paper-to-paper friction, the paddle fails to pull the trailing edge back into the front guide, resulting in misalignment. - Page 151 High Capacity Stacker Paper exit Paper edge stopper Paddle Stacker shift tray Paper feed direction CEZ578 3. The paper edge stopper fails to push back the protruding leading edge and align the sheet as required. Paper exit Paper edge stopper Paddle Stacker shift tray Paper feed direction...

- Page 152 9. Post-Processing Option Troubleshooting Print the image. Has the problem been resolved? Finished! In the 03: [Machine: Paper Feed/ Output] group on the [Adjustment Settings for Skilled Operators] menu, set 0301: [Adjust Paper Curl] to [Adjust Curl: Weak]. Print the image. Has the problem been resolved? Finished! Set 0301: [Adjust Paper Curl] to [Adjust Curl: Medium].

-

Page 153: The Machine Wrongly Detects That The Tray Is Full

High Capacity Stacker The Machine Wrongly Detects That the Tray Is Full Cause: Depending on the paper size, the machine may detect that the shift tray has reached the maximum number of sheets that can be stacked on it. This may occur if: •... -

Page 154: The Paper Press Leaves An Impression On The Paper

9. Post-Processing Option Troubleshooting Print the image. Has the problem been resolved? Finished! Set 0301: [Adjust Paper Curl] to [Adjust Curl: Medium]. Print the image. Has the problem been resolved? Finished! Set 0301: [Adjust Paper Curl] to [Adjust Curl: Strong]. Print the image. -

Page 155: Sheets Becoming Misaligned When The Paper Cart Is Pulled Out

High Capacity Stacker Sheets Becoming Misaligned When the Paper Cart Is Pulled Out Cause: When the machine prompts the user to pull out the paper cart as the paper tray becomes full, the sheet of paper at the top comes into contact with the paddle and the paper will be misaligned. Solution: After the machine notifies you that the paper tray is full, lower the paper tray. - Page 156 9. Post-Processing Option Troubleshooting...

-

Page 157: 10. Improving Throughput

10. Improving Throughput Reducing the Waiting Time Prior to Printing After receiving a print job, the machine usually stops to let the fusing temperature reach an appropriate level for printing. The waiting time for the fusing unit to cool down may be quite long, especially before printing on thin paper. -

Page 158: Improving Throughput When Continuously Printing On Paper Of Different Types Or Thicknesses

10. Improving Throughput Improving Throughput when Continuously Printing on Paper of Different Types or Thicknesses When printing is performed continuously on paper of different types or thicknesses, the waiting time prior to printing may be long due to the temperature to allow paper feeding, resulting in lower throughput. -

Page 159: Improving Throughput When Continuously Performing Black And White And Color Printing

Improving Throughput when Continuously Performing Black and White and Color Printing Improving Throughput when Continuously Performing Black and White and Color Printing When printing intermixed black-and-white and full-color print jobs, switching from full-color mode to black-and-white mode takes time, causing loss of throughput each time the mode is switched. When the machine prints a full-color print job followed by a black-and-white job, you can improve throughput by adjusting the number of black-and-white sheets the machine prints in full-color mode before switching to black-and-white mode. - Page 160 10. Improving Throughput...

-

Page 161: 11. Advanced Instructions

11. Advanced Instructions Operating Procedure for Color Calibration To improve color reproduction and achieve color output with consistent quality, follow this procedure. It is recommended to perform color calibration for each print job. You can improve CMYK image reproduction by adjusting image density and performing calibration. Also, you can improve mixed color reproduction by adjusting image density and color registration and performing calibration. - Page 162 11. Advanced Instructions • Click [Print]. When patch printing is completed, click [Measure] in the [4. Get Measurements] menu. Check that the page type and size are correct, and then click [Measure]. Check the printed patches using ES-2000. After checking all the patches, select [Measurement vs. Target] in the [6. View Measurements (optional)] menu, and then click [View].

-

Page 163: Shortening The Leading/Trailing Edge Margins

Shortening the Leading/Trailing Edge Margins Shortening the Leading/Trailing Edge Margins Depending on the paper being used, the margins on the copy vary. You can shorten the leading/trailing edge margins. Leading-edge margin Trailing-edge margin Paper feed direction CEZ586 • To adjust the following settings, pre-register the type of paper in use as a custom paper. For details about registering custom papers, see "Registering a Custom Paper", Paper Settings. -

Page 164: Adjusting The Image Position Of The Either Side Of The Paper

11. Advanced Instructions Adjusting the Image Position of the Either Side of the Paper Adjusting the Image Position on Side 1 <If custom paper is used> Perform the solution described in "(a) Adjust the image skew", "(b) Adjust the image position (If custom paper is used)", "(c) Adjust the magnification (Across feed direction)"... - Page 165 Adjusting the Image Position of the Either Side of the Paper Check the direction of the skew. In the 01: [Machine: Image Position] group on the [Adjustment Settings for Skilled Operators] menu, select 0107: [Perpendicularity Adjustment] and adjust the value. Move the cursor to [+] to skew the image counterclockwise or to [−] to skew it clockwise.

- Page 166 11. Advanced Instructions DFP320 In [Advanced Settings] for the custom paper, adjust the value in 005: [Magnification: Across Feed: Side 1]. Press [+] to increase the scaling and [−] to reduce it. (d) Adjust the magnification (With feed direction) Adjust the vertical magnification to adjust the length (position of (C)) of the image. DFP321 In [Advanced Settings] for the custom paper, adjust the value in 007: [Magnification: With Feed: Side 1].

-

Page 167: Adjusting The Image Position On Side 2

Adjusting the Image Position of the Either Side of the Paper DFP492 In the 01: [Machine: Image Position] group on the [Adjustment Settings for Skilled Operators] menu, adjust the image position. • 0101: [Image Position: Across Feed] • 0102: [Image Position: With Feed] Adjusting the Image Position on Side 2 If you want to align an image position on Side 2 to an image position on Side 1 that has been adjusted, see page 168 "Aligning the Image Position on Side 2 to That on Side 1 (Using a Template to Align the... - Page 168 11. Advanced Instructions (a) Adjust the image skew Adjust the vertical position of the print image. Default Paper feed direction DFT310 Print the image in black and white. Check the direction of the skew. In the 01: [Machine: Image Position] group on the [Adjustment Settings for Skilled Operators] menu, select 0107: [Perpendicularity Adjustment] and adjust the value.

- Page 169 Adjusting the Image Position of the Either Side of the Paper DFP492 In [Advanced Settings] for the custom paper, adjust the image position. • 002: [Image Position: Across Feed: Side 2] • 004: [Image Position: With Feed: Side 2] (c) Adjust the magnification (Across feed direction) Adjust the horizontal magnification to adjust the width between the front (B) and back corners (B) on the leading edge of the image.

-

Page 170: Aligning The Image Position On Side 2 To That On Side 1 (Using A Template To Align The Image Position On Side 1 And 2)

11. Advanced Instructions DFP321 In [Advanced Settings] for the custom paper, select 008: [Magnification: With Feed: Side 2]. Press [+] to increase the scaling and [−] to reduce it. (e) Adjust the image position (If custom paper is not used) Adjust the vertical and horizontal image position so that the center (A) of the leading edge of the image is aligned to the registration mark. - Page 171 Adjusting the Image Position of the Either Side of the Paper It is necessary to specify the settings for each paper size being used. The adjusted settings are stored as custom paper presets and can be applied again in the future. To adjust the image position, the machine administrator privilege is required.

- Page 172 11. Advanced Instructions Printing the Format Using the computer and the machine, print the format matching the size of the paper requiring image position adjustment. Continuously print the format on both sides of 10 sheets. The format has arrows on 4 corners. Measure the length of specified parts on the 6th sheet among the printed copies of the format.

- Page 173 Adjusting the Image Position of the Either Side of the Paper Entering the Value When you specify the lengths of the template after measuring them, the values to adjust the image position are automatically calculated and applied. In [Advanced Settings] for the custom paper, select [Registration to Align Front and Back Images Using Template].

- Page 174 11. Advanced Instructions 014: [Erase Margin: Trailing Edge] Eliminating misregistrations on the front and back of the paper Adjust the image position and magnification on Side 2 to match those on Side 1. Carry out the following sequence of procedures. Terminate the sequence as soon as the problem is resolved. •...

- Page 175 Adjusting the Image Position of the Either Side of the Paper DFT315 Select 004: [Image Position: With Feed: Side 2] and adjust the horizontal position of the image to be printed on Side 2 of the paper to match the image position on Side 1. Eg., Adjusting the image (a) on the leading edge of the paper on Side 2 to match the corresponding image (b) on Side 1 DFT316...

- Page 176 11. Advanced Instructions DFT318 Press [+] to increase the scaling. (Press [−] to reduce the scaling.) The adjustment value is applied evenly both upward and downward. To feed A3 paper with its short side parallel to the paper feed direction, increase the value by 0.025 percentage point to move the image by approximately 0.1 mm (0.004 inches).

- Page 177 Adjusting the Image Position of the Either Side of the Paper To feed A3 paper with its long side parallel to the paper feed direction, increase the value by 0.025 percentage point to move the image by approximately 0.07 mm (0.0028 inches). DFT321 When to check for misregistrations on the front and back of the paper Check for misregistrations on the front and back of the paper when:...

-

Page 178: Prepunched Paper

11. Advanced Instructions Prepunched Paper When using pre-punched paper, the pre-punched holes may be wrongly detected as paper edge and jam code J097 or J098 appears. If this happens, carry out the following settings; • For details about specifying settings in the [Advanced Settings] menu, see "Details of Menu Items in Advanced Settings", Adjustment Item Menu Guide. - Page 179 Prepunched Paper Table 1: When the punching position is on the control panel (For Position 2) (Mainly North America) 118: 119: [Image Number of 015: [Skew [Registration Paper Size Magnification holes Detection] Adjustment: Auto Adjustment] Across Feed] HLT/LEF [Off] [Activate] [Deactivate] HLT/SEF [Off]...

- Page 180 11. Advanced Instructions (Mainly Europe and Asia) 118: 119: [Image Number of 015: [Skew [Registration Paper Size Magnification holes Detection] Adjustment: Auto Adjustment] Across Feed] A5/LEF [On] [Activate] [Activate] B5/LEF [On] [Activate] [Activate] A5/SEF [On] [Activate] [Activate] A4/LEF B5/SEF [On] [Activate] [Activate] [On]...

- Page 181 Prepunched Paper 118: 119: [Image Number of 015: [Skew [Registration Paper Size Magnification holes Detection] Adjustment: Auto Adjustment] Across Feed] A5/SEF [On] [Activate] [Activate] A4/LEF [On] [Activate] [Activate] B5/SEF [On] [Activate] [Activate] [Off] [Activate] [Activate] A4/SEF [On] [Activate] [Activate] [On] [Activate] [Activate] [On]...

- Page 182 11. Advanced Instructions 118: 119: [Image Number of 015: [Skew [Registration Paper Size Magnification holes Detection] Adjustment: Auto Adjustment] Across Feed] [On] [Activate] [Activate] LT/LEF [On] [Activate] [Activate] [On] [Activate] [Activate] 12 × 18 [On] [Activate] [Activate] [On] [Activate] [Activate] [On] [Activate] [Activate]...

- Page 183 Prepunched Paper (Mainly North Europe) 118: 119: [Image Number of 015: [Skew [Registration Paper Size Magnification holes Detection] Adjustment: Auto Adjustment] Across Feed] A5/SEF [On] [Activate] [Activate] [Off] [Deactivate] [Deactivate] B5/SEF [On] [Activate] [Activate] [On] [Activate] [Activate] A5/LEF [On] [Activate] [Activate] A4/SEF [On]...

- Page 184 11. Advanced Instructions 1. 15 mm (0.6 inches) 2. 70 mm (0.8 inches) 3. 30 mm (1.2 inches) When paper length longer than 297 mm (11.8 inches) is used. DFT074 1. 15 mm (0.6 inches) 2. 70 mm (0.8 inches) 3.

-

Page 185: Preprinted Paper

Preprinted Paper Preprinted Paper When printing is performed on pre-printed paper, the machine may wrongly detect the pre-printed area as the edge of the paper and display the jam code J097 or J098. Carry out the following settings; Procedure 1: Wrong masking <If custom paper is used>... -

Page 186: Envelopes

11. Advanced Instructions Envelopes Before printing on envelops, carry out the following settings; Specify the envelope size with the flap open Have you specified the paper size with the as the custom paper size. flap of the envelope open (custom size)? Open the envelope's flap and load the Have you loaded the envelope with its flap envelope with the flap at the trailing edge... - Page 187 Envelopes Lf: Flap length Lb: Length without the flap...

-

Page 188: Adjust Paper Curl

11. Advanced Instructions Adjust Paper Curl This section explains how to use the decurling function of 0301: [Adjust Paper Curl] in the 03: [Machine: Paper Feed/ Output] group on the [Adjustment Settings for Skilled Operators] menu. Decurling Workflow This shows how to select the type of decurling. Are you printing on one side only? Are you printing the copy delivered with its printed side face down? - Page 189 Adjust Paper Curl Table 1 Item to select in 0301: Type of decurling Machine's operation [Adjust Paper Curl] Decurling Type 1 [Adjust Curl: Weak] - Single-sided printing: printed side face down [Adjust Curl: Medium] - Duplex printing: printing on side 1 [Adjust Curl: Strong] The paper is decurled downward.

- Page 190 11. Advanced Instructions Item to select in 0301: Type of decurling Machine's operation [Adjust Paper Curl] Decurling Type 2 [Adjust Curl: Weak] - Single-sided printing: printed side face down [Adjust Curl: Medium] - Duplex printing: printing on side 1 [Adjust Curl: Strong] The paper is decurled upward.

-

Page 191: Decurling Examples

Adjust Paper Curl Selecting the degree of decurling Select the degree of decurling from "Weak", "Medium", and "Strong" according to the degree of curling. If you cannot assess the degree of curling, try decurling in the order of "Weak", "Medium", and "Strong". - Page 192 11. Advanced Instructions In the 03: [Machine: Paper Feed/ Output] group on the [Adjustment Settings for Skilled Operators] menu, select 0301: [Adjust Paper Curl]. Select [The paper tray' name (1 Sided)]. For example, to decurl the paper fed from Tray 1, select [Tray 1 (1 Sided)]. Select [Adjust Curl: Weak], [Adjust Curl: Medium], or [Adjust...

- Page 193 Adjust Paper Curl In the 03: [Machine: Paper Feed/ Output] group on the [Adjustment Settings for Skilled Operators] menu, select 0301: [Adjust Paper Curl]. Select [The paper tray' name (1 Sided)]. For example, to decurl the paper fed from Tray 1, select [Tray 1 (1 Sided)]. Select [Adjust Curl: Weak], [Adjust Curl: Medium], or [Adjust...

- Page 194 11. Advanced Instructions Example 4: Jam code J031 appears when duplex printing is performed (downward curling) When printing on side 2 for duplex printing, due to downward curling, paper is caught at the paper transfer belt, causing a paper jam. Decurling method Because this problem occurs while printing, the paper needs to be decurled before printing on side Perform "Decurling Type 1"...

- Page 195 Adjust Paper Curl Select [Adjust Curl: Weak], [Adjust Curl: Medium], or [Adjust Curl: Strong]. Select the degree of decurling from "Weak", "Medium", and "Strong" according to the degree of curling. If you cannot assess the degree of curling, try decurling in the order of "Weak", "Medium", and "Strong".

- Page 196 11. Advanced Instructions Select [Adjust Curl: Weak], [Adjust Curl: Medium], or [Adjust Curl: Strong]. Select the degree of decurling from "Weak", "Medium", and "Strong" according to the degree of curling. If you cannot assess the degree of curling, try decurling in the order of "Weak", "Medium", and "Strong".

- Page 197 MEMO...

- Page 198 MEMO M238-1039C...

- Page 200 M238-1039C © 2014-2016...

Need help?

Do you have a question about the Pro C9100 and is the answer not in the manual?

Questions and answers