Emerson Daniel 3410 Series Operation Manual

Gas ultrasonic flowmeters

Hide thumbs

Also See for Daniel 3410 Series:

- Operation manual (192 pages) ,

- Installation manual (140 pages) ,

- Instructions for use, maintenance and installation manual (110 pages)

Summary of Contents for Emerson Daniel 3410 Series

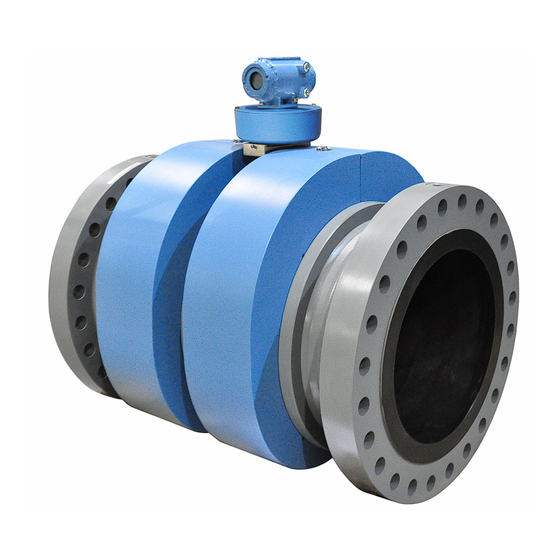

- Page 1 Operations manual DAN-20057316, Rev AA January 2019 ™ Daniel 3410 Series Gas Ultrasonic Flow meters Model 3418...

- Page 3 Email • Customer Service: DanielCST.Support@Emerson.com • Customer Support: Daniel.TechnicalSupport@Emerson.com • Field Lifecycle Services: Tech.Service@Emerson.com • Asia-Pacific: danielap.support@emerson.com • Europe: danielEMA.cst@emerson.com Return Material Authorization (RMA) A Return Material Authorization (RMA) number must be obtained prior to returning any equipment for any reason. Access and fill in the RMA form for Daniel products clicking on the link below.

- Page 4 Signal words and symbols Pay special attention to the following signal words, safety alert symbols and statements: Safety alert symbol This is a safety alert symbol. It is used to alert you to potential physical injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

- Page 5 • Verify that this is the correct instruction manual for your Daniel product. If this is not the correct documentation, contact Daniel at 1-713-827-6314. You may also download the correct manual from: https://www.emerson.com/en-us/automation/ daniel. • Save this instruction manual for future reference.

- Page 6 • Verify that this is the correct instruction manual for your Daniel product. If this is not the correct documentation, contact Daniel at 1-713-827-6314. You may also download the correct manual from: https://www.emerson.com/en-us/automation/ daniel. • Read and understand all instructions and operating procedures for this product.

- Page 7 Notice THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY, AND WHILE EVERY EFFORT HAS BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO BE CONSTRUED AS WARRANTIES OR GUARANTEES, EXPRESSED OR IMPLIED, REGARDING THE PRODUCTS OR SERVICES DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. ALL SALES ARE GOVERNED BY DANIEL'S TERMS AND CONDITIONS, WHICH ARE AVAILABLE UPON REQUEST.

- Page 8 Warranty and Limitations 1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein, Daniel Measurement & Control, Inc. (“Daniel”) warrants that the licensed firmware embodied in the Goods will execute the programming instructions provided by Daniel, and that the Goods manufactured by Daniel will be free from defects in materials or workmanship under normal use and care and Services will be performed by trained personnel using proper equipment and instrumentation for the particular Service provided.

-

Page 9: Table Of Contents

Operations manual Contents DAN-20057316 January 2019 Contents Chapter 1 Startup........................11 1.1 Checklist............................11 Chapter 2 Communications......................13 2.1 Setup meter communications......................13 Chapter 3 Optional feature keys....................21 3.1 General overview of the Optional feature keys................21 3.2 Configure optional keys........................22 Chapter 4 Measurement...................... - Page 10 Contents Operations manual January 2019 DAN-20057316 Appendix D Flow Rate charts......................145 D.1 Summary charts for Flow rate...................... 145 Appendix E Write-protected configuration...................149 E.1 Parameters for Write-protected configuration................149 Appendix F Engineering drawings....................163 F.1 3410 Series engineering drawings....................163 Operations manual...

-

Page 11: Chapter 1 Startup

Operations manual Startup DAN-20057316 January 2019 Startup Checklist During meter startup, have the following equipment and information on hand: Mater startup checklist Site pipe and ID drawings with elevations Site wiring diagrams Daniel Gas Ultrasonic Meter calibration data Daniel Gas Ultrasonic Meter manuals Information and manuals for all other flow instrumentation - flow computers, pressure and temperature transmitter data sheets, and wiring Shutoff and control valve information, specifications, operation and setup data. - Page 12 Startup Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 13: Chapter 2 Communications

The Daniel MeterLink Software for Gas and Liquid Ultrasonic Flow Meters Quick Start Manual (P/N 3-9000-763) is made available with the meter. The Daniel MeterLink installation program is available for download from the Daniel Measurement and Control, Inc. website: https://www.emerson.com/en-us/catalog/daniel- meterlink. 2.1.1 Daniel MeterLink utilities ™... - Page 14 Communications Operations manual January 2019 DAN-20057316 • Program Download • Communications Analyzer Log/Reports • Maintenance logs and reports • Trend maintenance logs • Meter archive logs ® • Compare Excel meter configurations Calibration • Analog inputs • Meter Factors • Flow calibration Setup the meter directory Setup the connection properties for your meter.

- Page 15 Operations manual Communications DAN-20057316 January 2019 Note ® For Windows 7, you cannot use the Communications cable between two computers at this time and must use the Daniel Direct Connection driver. • Baud Rate: Select the serial port baud rate from the drop-down list for which the meter hardware is configured.

- Page 16 Communications Operations manual January 2019 DAN-20057316 NOTICE It is strongly recommended that the meter be configured using an independent (off- network) single host computer. After configuration of the meter, the DHCP option should be disabled. • IP Address: Enter the IP Address for the meter's Ethernet port. The factory set IP Address is 172.16.17.200 for Daniel Gas Ultrasonic meters or you can use 192.168.135.100 if DHCP is enabled in the meter (see DHCP below for more details).

- Page 17 Operations manual Communications DAN-20057316 January 2019 2. The Import Meter Directory File dialog which allows you to select a meter directory .DAT file to import the file into the currently used meter directory file. If an identical meter record already exists and a duplicate is trying to be imported, Daniel MeterLink inserts the duplicate meter record.

- Page 18 Communications Operations manual January 2019 DAN-20057316 • System log • Save your meter's configuration file • Use the Tools > Edit/Compare Configuration menu to display the dialog. Enable the View All or Metrology radio button and click Read. The All View displays the meter's extended configuration parameters. Grayed out values are read-only, but help describe the configuration.

- Page 19 8N1 is supported. The communication ports provide automatic protocol detection - only the baud rate and Modbus ID need to be specified. Also, refer to the Daniel website and select the Product page for the model of your meter: https://www.emerson.com/en-us/automation/daniel Model 3418 GUSM...

- Page 20 Communications Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 21: Optional Feature Keys

Optional feature keys General overview of the Optional feature keys Daniel 3410 Series Gas Ultrasonic Flow Meters offer many industry-leading features including Chapter 21-compliant data log access, gas chromatograph (GC) interface, AGA10 sound velocity calculation (with comparison to measured sound velocity) and Continuous Flow Analysis diagnostics. -

Page 22: Configure Optional Keys

Optional feature keys Operations manual January 2019 DAN-20057316 3.1.3 AGA10 key (sound velocity calculation) The optional AGA10 sound velocity calculation feature allows the meter to calculate the predicted sound velocity based upon the gas composition and compare this value to the measured average sound velocity. -

Page 23: Chapter 4 Measurement

Operations manual Measurement DAN-20057316 January 2019 Measurement Flow measurement Daniel 3410 Gas Ultrasonic Flow Meters measure the transit times of ultrasonic pulses passing through the medium on two parallel planes. The measurement paths (also referred to as "chords") are angled to the pipe axis, and each chord has two transducers acting alternately as transmitter and receiver as shown in Direct path transit-time measurement... - Page 24 Measurement Operations manual January 2019 DAN-20057316 Figure 4-2: Signal Analyzer - update rate, stack size, filter and emission rate Terminology • Sequence - a complete cycle of firing all enabled transducers in a single round of transducer operation. • Stacking - the process of modifying a sequence so that each individual transducer is fired "x"...

-

Page 25: Signal Processing

Operations manual Measurement DAN-20057316 January 2019 • Sample - refers to one point on the waveform as in samples per cycle. The data that is collected from one Sequence of transducer operation. (This term is displayed in the ™ Daniel MeterLink Signal Analyzer screen, and is nearly synonymous with Sequence, as ™... - Page 26 4.2.4 Smoothing The Daniel 3410 Series Gas Ultrasonic Flow Meter applies a method for smoothing the output (particularly the frequency output) by averaging times collected from past batch periods with new times for the current batch period.

-

Page 27: Acquisition Mode

Operations manual Measurement DAN-20057316 January 2019 Smoothing can be applied in the following increments: 0 (i.e., smoothing is disabled), 20, 40, 60, or 80%. For example, setting Smoothing to 20% means that of the samples used for the current update, 20% will be from previously collected samples and 80% will be from the newly collected samples. -

Page 28: Chord Gas And Sound Velocity Measurements

Measurement Operations manual January 2019 DAN-20057316 Chord gas and sound velocity measurements At each batch update period, each firing path's transit time measurements are averaged. The average (mean) value for each path is available via data points MeanTmA1... MeanTmH2 (as appropriate for the meter type). NOTICE The data point names often use a "short-hand"... - Page 29 Optional AGA10 sound velocity calculation and comparison The Daniel 3410 Series Gas Ultrasonic Flow Meter offers an option to calculate the sound velocity (using AGA10 equations and gas property data) and compare the result to the meter- measured sound velocity on an hourly basis.

- Page 30 Measurement Operations manual January 2019 DAN-20057316 Table 4-2: AGA10 calculation status (continued) AGA10SndVelStatus value Description Calculation not performed as the selected AGA8 method is not the Detailed method (HCH_Method not set to Detailed Method (3)). AGA10SnVel is set to zero. Calculation not performed due to invalid AGA8 calculation results.

- Page 31 Operations manual Measurement DAN-20057316 January 2019 If all chords fail, then the meter re-enters the Acquisition mode as described in the acquisition section. The meter partitions the velocity range (for forward and reverse flow) into ten consecutive, non- overlapping "bins" (where the velocity range is as specified via the MeterMaxVel data point).

-

Page 32: Volumetric Flow Rate Values

Volumetric flow rate values The Daniel 3410 Series Gas Ultrasonic Flow Meter meter provides three volumetric flow rate values: raw, (expansion-corrected and/or profile-effect corrected) flow-condition, and base- condition. Note that a positive volumetric flow rate indicates flow in the forward direction whereas a negative volumetric flow rate indicates flow in the reverse direction. - Page 33 Operations manual Measurement DAN-20057316 January 2019 4.5.2 Flow-condition volumetric flow rate The flow-condition volumetric flow rate is the result of applying expansion correction and flow- profile correction to the raw volumetric flow rate as shown in Flow-condition volumetric flow rate subject to the low- flow cut-off.

- Page 34 Measurement Operations manual January 2019 DAN-20057316 = outside diameter of the meter or pipe (m) (PipeOutsideDiameter) = inside diameter of the meter or pipe (m) (PipeDiam) ʋ = Poisson’s Ratio (dimensionless) (PoissonsRatio) E = Young’s Modulus of elasticity (MPaa) (YoungsModulus) 4.5.4 Temperature-effect expansion correction The meter is capable of correcting the raw volumetric flow rate for the effect of pipe...

- Page 35 = flow-condition compressibility factor (ZFlow) 4.5.6 Volume The Daniel 3410 Series Gas Ultrasonic Flow Meter provides forward and reverse volume accumulators for each of the three volumetric flow rate values: raw, flow-condition (raw with expansion and/or profile correction), and base-condition.

- Page 36 NegEnergyFrac 4.5.8 Mass rate and totals The Daniel 3410 Series Gas Ultrasonic Flow Meter meter calculates the mass rate and mass totals (forward and reverse). These calculations requires that the flow-condition pressure and temperature are available (either fixed or optional analog inputs,...

-

Page 37: 3410 Series Gas Flow Meter Characterizations

3410 Series gas flow meter characterizations Symmetry For Daniel 3410 Series Gas Ultrasonic Flow Meter SeniorSonic meters only, the following flow characterizations are calculated/estimated: symmetry, cross-flow, chord turbulence, profile factor, and swirl angle. Alarm limits are provided for the chord turbulence and swirl angle values. - Page 38 Measurement Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 39: Chapter 5 Configurations

Local Display parameters. 5.1.1 Calibration methods The Daniel 3410 Series Gas Ultrasonic Flow meter uses two calibration steps: "dry" calibration and "wet" calibration. In this methodology, the "dry-calibration" values are set by Daniel at the factory and are not expected to be modified;... - Page 40 Configurations Operations manual January 2019 DAN-20057316 Note Note that the meter provides two sets of dry calibration coefficients - one set for each flow direction. Dry calibration procedure Prerequisites NOTICE Modification of dry calibration parameters is not recommended. The dry calibration parameters should not be modified unless directed by Daniel personnel.

- Page 41 Operations manual Configurations DAN-20057316 January 2019 Table 5-1: Data Points for dry calibration ™ Daniel MeterLink Data points, options and guidelines Display Name Forward A0 Data points affected: • FwdA 0 Options: • Enter a value (m/s or ft/s) within the range [-1,1 m/s]. Guidelines: •...

- Page 42 Gas flow velocity for wet calibration The Daniel 3410 Series Gas Ultrasonic Flow meter offers three selections for wet calibration: 12-point piece-wise linearization, a third-order polynomial, or none. The wet calibration method is selected via the CalMethod data point with "None" being the default value.

- Page 43 Operations manual Configurations DAN-20057316 January 2019 Wet calibration procedure using gas flow velocity Configure the date points listed below from the Daniel MeterLink Calibration > Meter Factors menu: Table 5-2: Data Points for wet calibration ™ Daniel MeterLink Data points, options and guidelines Display Name Flow calibration method Data points affected:...

- Page 44 Configurations Operations manual January 2019 DAN-20057316 Figure 5-2: Calibration - Meter Factor: None Piece-wise linearization for wet calibration If the 12-point piece-wise linearization (PWL) wet calibration method is selected, then the dry-calibration gas flow velocity is calculated as shown in Wet calibration - 12-point piece- wise linearization.

- Page 45 Operations manual Configurations DAN-20057316 January 2019 = wet-calibration gas flow velocity (m/s) (AvgFlow) WetCal = dry-calibration gas flow velocity (m/s) (DryCalVel) DryCal LinearMeterFctr = linear meter factor (dimensionless) (LinearMeterFctr) Wet calibration procedure using piece-wise linearization The linear meter factor is determined by the PWL inputs, the flow direction, and the dry- calibration gas flow velocity.

- Page 46 Configurations Operations manual January 2019 DAN-20057316 Table 5-3: Data points for Piece-wise linearization calibration (continued) ™ Daniel Meterlink Data points, options and guidelines Display Name Reverse Flow Rate Data points affected • RevFlwRate1...RevFltRate 12 Options: • Enter a value (m /h or ft /h) within the range [0.200000 m Guidelines:...

- Page 47 Operations manual Configurations DAN-20057316 January 2019 Figure 5-4: Calibration - Meter Factor: Polynomial Three coefficients are specified for each flow direction from the Daniel MeterLink Calibration > Meter Factors page as shown in the table below: Table 5-4: Data points for Polynomial wet calibration ™...

- Page 48 Configurations Operations manual January 2019 DAN-20057316 Table 5-4: Data points for Polynomial wet calibration (continued) ™ Daniel Meterlink Data points, options and guidelines Display Name Reverse C0 Data points affected • RevC 0 Options: Enter a value (m/s or ft/s) within the range [-1, 1 m/s]. •...

- Page 49 Operations manual Configurations DAN-20057316 January 2019 The triggered delta volume functionality is retained across power cycles as the accumulated volumes values at the last event trigger are saved in non-volatile memory. The delta volume data points are stored internally in non-volatile memory as double- precision floating point numbers.

- Page 50 Configurations Operations manual January 2019 DAN-20057316 Table 5-5: Configure Operational parameters (continued) Calibration selection Description Flow calibration (Flow Calibrate the meter during flowing conditions. calibration) Frequency/Digital output Outputs that can be configured as either a frequency output or a sources (Configure digital status.

-

Page 51: Calibrate Analog Inputs And Outputs

Operations manual Configurations DAN-20057316 January 2019 Table 5-5: Configure Operational parameters (continued) Calibration selection Description Continuous flow analysis Configure the Continuous Flow Analysis features. Selections include: (Configure Continuous • Flow limits Flow Analysis parameters) • SOS comparison • Liquid detection •... - Page 52 Configurations Operations manual January 2019 DAN-20057316 • The Offset method requires a single calibration point and only affects the input's calibration offset parameter. • The two-point calibration requires calibrating at two different points (ideally far apart in value) and affects the input's calibration offset and gain parameters. Depending upon the selected calibration method, either one or two screens will follow when the Next button is clicked.

- Page 53 Operations manual Configurations DAN-20057316 January 2019 Table 5-6: Calibrate analog inputs and outputs Daniel Dat Points, options and guidelines MeterLink Display name Current output Data points affected: Output setting • AO1estModeOutputPercent Options: • Enter the integer percentage of full scale for the analog output within the range [0, 100 %] where 0% corresponds to the minimum output (4 mA) and 100% corresponds to the maximum output (20 mA).

-

Page 54: Calibrate Meter Factors

Configurations Operations manual January 2019 DAN-20057316 Table 5-6: Calibrate analog inputs and outputs (continued) Daniel Dat Points, options and guidelines MeterLink Display name Data points affected: • IsAO2EnableTest Options: • Click on the StartAO2 button to enter the test mode (TRUE). Note the Start button will become the Stop button after clicking on it. - Page 55 Operations manual Configurations DAN-20057316 January 2019 Figure 5-6: Gating configuration parameter Edge gated, active high • Edge gated, active low Figure 5-7: Gating configuration parameter Edge gated, active low • State gated, active high Figure 5-8: Gating configuration parameter State gated, active high •...

- Page 56 Configurations Operations manual January 2019 DAN-20057316 Figure 5-9: Gating configuration parameter State gated, active low ® A Microsoft Excel file is generated and the calibration log report can be saved or appended to an existing file. 5.3.2 Configure Frequency/Digital output sources The meter has three user-configurable outputs that can be configured for either a Frequency output or Digital output (FODO).

- Page 57 Operations manual Configurations DAN-20057316 January 2019 Frequency or Digital Outputs (FODO2, FODO3, FODO4, FODO5) source options ~ Group 2 • FO1A, DO1A, FO1B, DO1B, FO2A, DO2A, FO2B, DO2B • Frequency output 1A is the A Phase of Frequency output 1 content (Uncorrected volume flow rate, Corrected volume flow rate, Average flow velocity, Average speed of sound, Energy flow rate, Mass flow rate) •...

- Page 58 Configurations Operations manual January 2019 DAN-20057316 Frequency/Digital output Source configuration Frequency /Digital Output 1 • Frequency output 1A Frequency /Digital Output 2 • Frequency output 1B Frequency /Digital Output 3 • Digital output 1A Frequency /Digital Output4 • Digital output 1B Frequency /Digital Output 5 Frequency /Digital Output 6 •...

-

Page 59: Configure Frequency Outputs

Operations manual Configurations DAN-20057316 January 2019 Figure 5-11: CPU Module - Frequency/Digital outputs common ground - Type 4 A. FODO1 and DI1/FODO6 - shared common ground - Type 4 CPU Module (Group 1) B. FODO2, FODO3, FODO4 and FODO5 - shared common ground - Type 4 CPU Module (Group 2) Configure frequency outputs The Frequency Outputs allows you to configure the available frequency outputs for the... - Page 60 Configurations Operations manual January 2019 DAN-20057316 Maximum frequency output: • Valid frequency output options are 1000 Hz and 5000 Hz. The following fields are used to configure the frequency outputs selected to output a volumetric flow rate. The fields are only enabled if the associated output's Content is set to Uncorrected (Actual) or Corrected (Standard).

-

Page 61: Configure Digital Input/Outputs

Operations manual Configurations DAN-20057316 January 2019 Configure digital input/outputs Digital input The Daniel 3410 Gas Ultrasonic Flow Meters provides one digital input (referred to as DI1). The polarity of the input is configured via the DI1IsInvPolarity data point as follows: •... -

Page 62: Outputs Test Mode

Configurations Operations manual January 2019 DAN-20057316 Outputs test mode The Daniel 3410 Gas Ultrasonic Flow Meters provides a mode of operation for testing the frequency, current (analog) and digital output signals. Entering, configuring, and exiting this mode is accomplished by setting data points using the Daniel MeterLink Tools > Outputs Test. -

Page 63: Configure Temperature And Pressure

Daniel MeterLink will first end the test mode before returning to the Main Screen. Configure temperature and pressure 5.7.1 Flow-condition pressure and temperature The flow-condition pressure and temperature are used by the Daniel 3410 Series Gas Ultrasonic Flow Meter for various calculations such as: • Expansion correction ™... - Page 64 Data updates The Daniel 3410 Series Gas Ultrasonic Flow Meter samples the input analog signal(s) and updates the corresponding data point(s) (LiveFlowPressure, LiveFlowTemperature) once per second regardless of the input selection (disabled, live, or fixed).

- Page 65 Operations manual Configurations DAN-20057316 January 2019 Table 5-7: Flow-condition pressure and temperature data source Input Type Data Validity Data Source Upon "In-Use" Data Source (EnablePressureInput (PressureValidity or Alarm (FlowPressure or TemperatureValidity) (FloePOrtSrcUponA FlowTemperature) EnableTemperaturein larm) put) Disabled "In-Use" value unchanged Live Valid Average of live values...

-

Page 66: Configure Gas Chromatograph Parameters

Configurations Operations manual January 2019 DAN-20057316 • Fixed temperature - If Fixed was selected on the Daniel MeterLink Startup Page for Temperature It will also be enabled if a live temperature input was selected. Enter a fixed value to use for calculations if the live input goes into alarm. Enter an average temperature of the process fluid. - Page 67 Operations manual Configurations DAN-20057316 January 2019 • GC stream number - Enter the stream number for the gas composition the Daniel Gas Ultrasonic meter will read. GC heating value units - Select the units for which the heating value is configured in the •...

- Page 68 Configurations Operations manual January 2019 DAN-20057316 Table 5-8: Fixed gas composition data points Gas composition data points MoleFractionN2Method2 MoleFractionCO2 MoleFractionH2 MoleFractionCO MoleFractionMethane MoleFractionEthane MoleFractionPropane MoleFractionIsoButane MoleFractionNButane MoleFractionIsoPentane MoleFractionNPentane MoleFractionNHexane MoleFractionNHeptane MoleFractionNOctane MoleFractionNNonane MoleFractionNDecane MoleFractionH2S MoleFractionHelium MoleFractionWater MoleFractionOxygen MoleFractionArgon Live (GC) gas property data The purpose of this section is to give a brief overview of the gas property data read from a GC.

- Page 69 Operations manual Configurations DAN-20057316 January 2019 Table 5-9: GC-reported gas composition data points GC reported composition data points N2GC CO2GC H2GC COGC MethaneGC EthaneGC PropaneGC IsoButaneGC NButaneGC IsoPentaneGC NPentaneGC NHexaneGC NHeptaneGC NOctaneGC NNonaneGC NDecaneGC H2SGC HeliumGC WaterGC OxygenGC ArgonGC C6PlusGC (C6PlusGCComponentID) NeoPentaneGC The validity of the GC-read gas property data is readable via the AreGasPropertiesInvalidGC data point where TRUE(1) indicates invalid data and FALSE(0)

- Page 70 Configurations Operations manual January 2019 DAN-20057316 The meter maps the appropriate input gas property data points (fixed or GC-reported as discussed above) to the corresponding "In-Use" data points (the HeatingValueInUse data point and the gas composition data points listed in the Table 5-10 below).

- Page 71 Optional gas chromatograph interface The Daniel 3410 Series Gas Ultrasonic Flow Meter can optionally interface with any Daniel gas chromatograph (GC) that supports the SIM 2251 mode to read gas property data (such as for AGA8, AGA10, energy rate, mass rate, and/or profile correction calculations).

- Page 72 Configurations Operations manual January 2019 DAN-20057316 Table 5-12: Gas chromatograph Sim 2251 Registers (continued) Sim 2251 Register Description 3001 - 3016 Component codes 7001 - 7016 Mole fractions for corresponding component codes 7033 BTU (dry) 7034 BTU (sat) 7035 Specific gravity) 7038 Total unnormalized mole percent 7054...

- Page 73 Operations manual Configurations DAN-20057316 January 2019 Table 5-13: Supported Components IDs (continued) Component IDs C6PLUS_COMP_ID_2 (109) Note Components read from the register 3001-3016 had 100 subtracted from them by the GC. The Daniel Gas Ultrasonic Meter must add 100 to each ID read from the GC before looking it up in this table.

- Page 74 Configurations Operations manual January 2019 DAN-20057316 Table 5-14: GC Communications status list (continued) GCComm status value Error description GC detected an illegal data value from the meter. Failure in associated device (Modbus defined error). GC has accepted the meter's request but is still processing. A firmware logic error was detected.

- Page 75 Operations manual Configurations DAN-20057316 January 2019 Table 5-15: GC-read gas property invalid conditions (continued) Indication Data Point Condition IsGCDataErr The total unnormalized gas composition mole percentage is not within [85%, 115%]. An individual gas composition mole percentage is not within [0%, 100%]. The specific gravity is not within [0.2, 0.8].

- Page 76 Configurations Operations manual January 2019 DAN-20057316 • Specific gravity reference pressure • Volumetric gross heating value • Volumetric gross heating value reference temperature • Molar density reference temperature • Molar density reference pressure • Flow mass density • Flow compressibility •...

- Page 77 Operations manual Configurations DAN-20057316 January 2019 • Select baseline flow direction - forward or reverse • Select baseline data source 1-minute averages from the meter - the preferred option when setting the baseline — for a new meter. The meter must be under typical flowing conditions when the baseline is set.

- Page 78 Configurations Operations manual January 2019 DAN-20057316 Mode Select Scroll items 1-10 or Uncorrected volume only. The default value is Scroll items 1-10. Scroll items 1-10 mode, allows selection of up to ten data points to be displayed on the local display. In Uncorrected volume only mode, the display will only alternate between the forward and reverse uncorrected volume in units of cubic meters in compliance with OIML R-137-1 and the European MID directive.

- Page 79 Operations manual Configurations DAN-20057316 January 2019 Table 5-16: Local display labels, descriptions and valid units (continued) Local display labels, descriptions and valid units TDYVL - Current day's reverse uncorrected volume — -ACF - Actual Cubic Feet — -ACM - Actual Cubic Meters —...

- Page 80 Configurations Operations manual January 2019 DAN-20057316 Table 5-16: Local display labels, descriptions and valid units (continued) Local display labels, descriptions and valid units TDYVL- Current days reverse corrected volume — -SCF - Standard Cubic Feet — -SCM - Standard Cubic Meters —...

- Page 81 Operations manual Configurations DAN-20057316 January 2019 Table 5-16: Local display labels, descriptions and valid units (continued) Local display labels, descriptions and valid units PRESS - Flow-condition pressure — PSI - Pound per square inch — MPA_ Megapascals FRQ1A - Frequency channel 1A —...

- Page 82 Configurations Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 83: Chapter 6 Directory

Daily log The Daniel 3410 Series Gas Ultrasonic Flow Meter stores a daily log record once per day at the specified contract hour. (Refer to the Daniel MeterLink Help files for information on specifying the ContractHour data point.) - Page 84 Directory Operations manual January 2019 DAN-20057316 The data points included in the daily log and the corresponding log action are as shown in the table below. Data points required by the API Chapter 21 standard are marked with an asterisk (*). For information on a particular data point, consult Daniel MeterLink online help (see the help topic for any data point in Daniel MeterLink.

- Page 85 Operations manual Directory DAN-20057316 January 2019 Table 6-1: Daily log content (continued) Data point Content Log action bit 31 IsHardFailedH Paths A-H, 8- paths meters bit 30 IsHardFailedG bit 29 IsHardFailedF bit 28 IsHardFailedE bit 27 IsHardFailedD bit 26 IsHardFailedC bit 25 IsHardFailedB bit 24...

- Page 86 Directory Operations manual January 2019 DAN-20057316 Table 6-1: Daily log content (continued) Data point Content Log action FlowVelA, Flow-Gated FlowVelB, FlowVelC, FlowVelD, FlowVelE, FlowVelF, FlowVelG, FlowVelH AvgFlow Flow-Gated (Percent of good batch signals) PctGoodA1, PctGoodA2, PctGoodB1, PctGoodB2, Average PctGoodC1, PctGoodC2, PctGoodD1, PctGoodD2, PctGoodE1, PctGoodE2, PctGoodF1, PctGoodF2, PctGoodG1, PctGoodG2, PctGoodH1, PctGoodH2 QFlow Flow-Gated...

- Page 87 Gated SpecificGravityInUse Flow-Gated Hourly log The Daniel 3410 Series Gas Ultrasonic Flow Meter meter stores an hourly log record once per hour on the hour. The meter can store up to 2400 hourly records (100 days' worth). Model 3418 GUSM...

- Page 88 Directory Operations manual January 2019 DAN-20057316 The user can select whether old, unread records can be overwritten by new records when the log becomes full via the data point DoOverwriteUnreadHourlyLog. ™ Tools > Edit/Compare This point can be modified using the Daniel MeterLink Configuration screen.

- Page 89 Operations manual Directory DAN-20057316 January 2019 Table 6-2: Hourly log action type (continued) Data point Content Log action bits 30-31 (unused) Paths A-H, bit 29 8-path meters bits 26-28 (unused) bit 25 IsAcqMode bit 24 IsAcqModuleError bit 23 DidPowerFail bit 22 DidCnfgChksumChg bit 21 IsElecTempOutOfRange...

- Page 90 Directory Operations manual January 2019 DAN-20057316 Table 6-2: Hourly log action type (continued) Data point Content Log action bit 31 IsHardFailedH Paths A-H, 8- paths meters bit 30 IsHardFailedG bit 29 IsHardFailedF bit 28 IsHardFailedE bit 27 IsHardFailedD bit 26 IsHardFailedC bit 25 IsHardFailedB...

- Page 91 Operations manual Directory DAN-20057316 January 2019 Table 6-2: Hourly log action type (continued) Data point Content Log action FlowVelA, Flow-Gated FlowVelB, FlowVelC, FlowVelD, FlowVelE, FlowVelF, FlowVelG, FlowVelH AvgFlow Flow-Gated (Percent of good batch signals) PctGoodA1, PctGoodA2, PctGoodB1, PctGoodB2, Average PctGoodC1, PctGoodC2, PctGoodD1,PctGoodD2, PctGoodE1, PctGoodE2, PctGoodF1, PctGoodF2, PctGoodG1, PctGoodG2, PctGoodH1, PctGoodH2 QFlow Flow-Gated...

- Page 92 Directory Operations manual January 2019 DAN-20057316 Table 6-2: Hourly log action type (continued) Data point Content Log action WaterInUse Flow-Gated OxygenInUse Flow-Gated ArgonInUse Flow-Gated H2InUse Flow-Gated COinUse Flow-Gated CnfgChksumValue Snapshot CnfgChksumDate Snapshot HeatingValueInUse Flow-Gated PosEnergy Totalize NegEnergy Totalize PosEnergy Snapshot NegEnergy Snapshot TurbulenceA...

- Page 93 Operations manual Directory DAN-20057316 January 2019 which data point changed, the date and time of the change, and both the 'as-found' and 'as-left' values. The meter can store up to 3000 audit records. The user can select whether old, unread records can be overwritten by new records when the log becomes full via the data point DoOverwriteUnreadAuditLog.

- Page 94 Directory Operations manual January 2019 DAN-20057316 Table 6-3: Audit log AGA 8 group monitored data points AGA 8 data group Data Point HCH_Method PBase RefPressureGr RefPressureMolarDensity RefTemperatureGr RefTemperatureHV RefTemperatureMolarDensity Tbase Table 6-4: Audit log AGA 10 group monitored data points AGA 8 data group Data Point AGA10Key...

- Page 95 Operations manual Directory DAN-20057316 January 2019 Table 6-5: Audit log Baseline group monitored data points Baseline data group Data Point FwdBaselineAvgFlow FwdBaselineComment FwdBaselineCrossFlow FwdBaselineFlowPressure FwdBaselineFlowTemperature FwdBaselineProfileFactor FwdBaselineSwirlAngle FwdBaselineSymmetry FwdBaselineTime FwdBaselineTurbulenceA FwdBaselineTurbulenceB FwdBaselineTurbulenceC FwdBaselineTurbulenceD FwdBaselineTurbulenceE FwdBaselineTurbulenceF FwdBaselineTurbulenceG FwdBaselineTurbulenceH RevBaselineAvgFlow RevBaselineComment RevBaselineCrossFlow RevBaselineFlowPressure RevBaselineFlowTemperature RevBaselineProfileFactor...

- Page 96 Directory Operations manual January 2019 DAN-20057316 Table 6-6: Audit log calibration group monitored data points Calibration data Data Point group AvgDlyA AvgDlyB AvgDlyC AvgDlyD AvgDlyE AvgDlyF AvgDlyG AvgDlyH CalFlag CalMethod DltDlyA DltDlyB DltDlyC DltDlyD DltDlyE DltDlyF DltDlyG DltDlyH FwdA0 FwdA1 FwdA2 FwdA3 FwdC0...

- Page 97 Operations manual Directory DAN-20057316 January 2019 Calibration data Data Point group FwdMtrFctr2 FwdMtrFctr3 FwdMtrFctr4 FwdMtrFctr5 FwdMtrFctr6 FwdMtrFctr7 FwdMtrFctr8 FwdMtrFctr9 PipeDiam RevA0 RevA1 RevA2 RevA3 RevC0 RevC1 RevC2 RevC3 RevFlwRt1 RevFlwRt10 RevFlwRt11 RevFlwRt12 RevFlwRt2 RevFlwRt3 RevFlwRt4 RevFlwRt5 RevFlwRt6 RevFlwRt7 RevFlwRt8 RevFlwRt9 RevMtrFctr1 RevMtrFctr10 RevMtrFctr11...

- Page 98 Directory Operations manual January 2019 DAN-20057316 Calibration data Data Point group RevMtrFctr4 RevMtrFctr5 RevMtrFctr6 RevMtrFctr7 RevMtrFctr8 RevMtrFctr9 SystemDelay WtA ... WtH XA ... XH Table 6-7: Audit log Chord proportions group monitored data points Chord proportions Data Point data group LowFlowLmt NumVals PropUpdtBatches...

- Page 99 Operations manual Directory DAN-20057316 January 2019 Table 6-11: Audit log Expansion correction group monitored data point Expansion correction Data Point data group EnableExpCorrPress EnableExpCorrTemp LinearExpansionCoef PipeOutsideDiameter PoissonsRatio RefPressExpCoef RefTempLinearExpCoef YoungsModulus Table 6-12: Audit log Flow analysis group monitored data point Flow analysis data Data Point group...

- Page 100 Directory Operations manual January 2019 DAN-20057316 Table 6-13: Audit log frequency, digital and analog group monitored data point Frequency, digital & Data Point analog signals data group AO1ActionUponInvalidContent AO1Content AO1CurrentTrimGain AO1CurrentTrimZero AO1Dir AO1FullScaleEnergyRate AO1FullScaleMassRate AO1FullScaleVolFlowRate AO1MaxVel AO1MinVel AO1TestModeOutputPercent AO1TrimCurrent AO1TrimGainExtMeasCurrent AO1TrimZeroExtMeasCurrent AO1ZeroScaleEnergyRate AO1ZeroScaleMassRate...

- Page 101 Operations manual Directory DAN-20057316 January 2019 Frequency, digital & Data Point analog signals data group FODO2Mode FODO2Source FODO3Mode FODO3Source FODO4Mode FODO4Source FODO5Mode FODO5Source FODO6Mode FODO6Source Freq1BPhase Freq1Content Freq1Dir Freq1FeedbackCorrectionPcnt Freq1FullScaleEnergyRate Freq1FullScaleMassRate Freq1FullScaleVolFlowRate Freq1MaxFrequency Freq1MaxVel Freq1MinVel Freq1TestModeOutputPercent Freq1ZeroScaleEnergyRate Freq1ZeroScaleMassRate Freq1ZeroScaleVolFlowRate Freq2BPhase Freq2Content Freq2Dir Freq2FeedbackCorrectionPcnt Freq2FullScaleEnergyRate...

- Page 102 Directory Operations manual January 2019 DAN-20057316 Frequency, digital & Data Point analog signals data group IsFreq2BZeroedOnErr IsFreq2EnableTest Table 6-14: Audit log gas chromatograph group monitored data point Gas chromatograph Data Point data group GasPropertiesSrcSel GasPropertiesSrcSelGCAlarm GCBaud GCCommTimeout GCDesiredStreamTimeout GCHeatingValueType GCHeatingValueUnit GCKey GCModbusID GCProtocol...

- Page 103 Operations manual Directory DAN-20057316 January 2019 Table 6-15: Audit log general group monitored data point General data group Data Point AlarmDef AsyncEnable AvgSoundVelHiLmt AvgSoundVelLoLmt ChordalConfig ChordInactvA ChordInactvB ChordInactvC ChordInactvD ChordInactvE ChordInactvF ChordInactvG ChordInactvH DampEnable DeviceNumber DitherEnable FlowDir MaxNoDataBatches MeterMaxVel MinChord MinPctGood NonNormalModeTimeout RTCSecondsSinceEpochSet...

- Page 104 Directory Operations manual January 2019 DAN-20057316 Table 6-16: Audit log HART data group monitored data point HART data group Data Point HARTDate HARTDescriptor HARTDeviceFinalAssyNum HARTEnergyUnit HARTLongTag HARTMassUnit HARTMessage HARTMinNumPreambles HARTNumPreambleBytesFromSlave HARTPollingAddress HARTPressureUnit HARTQVContent HARTRateTimeUnit HARTSlot0Content HARTSlot1Content HARTSlot2Content HARTSlot3Content HARTTag HARTTemperatureUnit HARTTVContent HARTVelUnit HARTVolUnit Table 6-17: Audit log indicators group monitored data point...

- Page 105 Operations manual Directory DAN-20057316 January 2019 Table 6-18: Audit log local display group monitored data point Local display data Data Point group LocalDisplayFlowRateTimeUnit LocalDisplayItem1 LocalDisplayItem10 LocalDisplayItem2 LocalDisplayItem3 LocalDisplayItem4 LocalDisplayItem5 LocalDisplayItem6 LocalDisplayItem7 LocalDisplayItem8 LocalDisplayItem9 LocalDisplayScrollDelay LocalDisplayVolUnitMetric LocalDisplayVolUnitUS Table 6-19: Audit log meter information group monitored data point Meter information Data Point data group...

- Page 106 Directory Operations manual January 2019 DAN-20057316 Table 6-20: Audit log pressure and temperature group monitored data point Pressure and Data Point temperature data group AtmosphericPress EnablePressureInput EnableTemperatureInput FlowPOrTSrcUponAlarm FlowPressureWhileCal FlowTemperatureWhileCal HighPressureAlarm HighTemperatureAlarm InputPressureUnit LiveFlowPressureCalCtrl LiveFlowPressureGain LiveFlowPressureOffset LiveFlowTemperatureCalCtrl LiveFlowTemperatureGain LiveFlowTemperatureOffset LowPressureAlarm LowTemperatureAlarm MaxInputPressure MaxInputTemperature...

- Page 107 Operations manual Directory DAN-20057316 January 2019 Table 6-22: Audit log signal processing group monitored data point Signal processing Data Point data group BatchPercentSmoothing BatchSize CRange DltChk EmRateActual EmRateDesired Filter FireSeq GainHighLmt GainLowLmt MaxHoldTm MaxNoise MinHoldTime MinSigQlty NegSpan Pk1Pct Pk1Thrsh Pk1Wdth PosSpan SampInterval SampPerCycle...

- Page 108 Boolean data points only have a single alarm limit (i.e., either TRUE or FALSE). The Daniel 3410 Series Ultrasonic Flow Meter stores an alarm log record whenever any monitored data point's alarm status (cleared or set) changes. The alarm log record indicates the data point, date and time, alarm status, corresponding alarm limit, and data point value.

- Page 109 Operations manual Directory DAN-20057316 January 2019 The user-settable data points AlarmTurnOffHysterisisCount and AlarmTurnOffHysterisisTimeSpan are used to prevent very repetitive alarms from filling up the alarm log. When an alarm is set AlarmTurnOffHysterisisCount times within AlarmTurnOffHysteresisTimeSpan seconds, then the alarm is suppressed until the alarm frequency drops below the specified rate (counts per time span) at which point the next alarm clearing "unsuppresses"...

- Page 110 IsClkInvalid TRUE System log The Daniel 3410 Series Gas Ultrasonic Flow Meter meter logs all system messages in the system log. The meter can store up to 3000 system records. The user can select whether old, unread records can be overwritten by new records when the log becomes full via the data point DoOverwriteUnreadSystemLog.

- Page 111 Operations manual Directory DAN-20057316 January 2019 Select the desired log group(s) via the Collect daily log/Collect hourly log/Collect event log check boxes. If the event group is selected, the audit, alarm, and system logs are individually selectable. Whenever any log is collected, the current meter configuration is also collected.

- Page 112 Directory Operations manual January 2019 DAN-20057316 If a log type to be read is configured so that unread records are not over-written, then Daniel MeterLink queries the user as to whether or not that log's records should be marked as 'read'. Once the data collection is completed, the data is displayed in the Meter Archive Logs dialog box one log type at a time.

- Page 113 Operations manual Directory DAN-20057316 January 2019 The duration value can be changed by clicking the number in the display/edit box and entering a new value. 4. If desired, a comment may be included in the log file by entering it in the display/ edit box provided.

- Page 114 Directory Operations manual January 2019 DAN-20057316 ® ® Figure 6-4: Microsoft Excel charts view 12. The Inspection Report is the report view. Operations manual...

-

Page 115: Dan-20057316 January

Operations manual Directory DAN-20057316 January 2019 ® ® Figure 6-5: Microsoft Excel inspection report view ® ® 13. The next Microsoft Excel report view is Meter Config. Model 3418 GUSM... - Page 116 Directory Operations manual January 2019 DAN-20057316 ® ® Figure 6-6: Microsoft Excel Meter Config. view ® ® 14. The last Microsoft Excel report view is Raw Data. ® ® Figure 6-7: Microsoft Excel Raw Data view Operations manual...

- Page 117 Operations manual Directory DAN-20057316 January 2019 6.1.8 Collect meter archive logs This utility allows you to collect historical log information from an ultrasonic meter. This dialog box is only available while connected to a meter. Select the checkboxes for the types of logs you will collect. All of the logs will be collected ®...

- Page 118 Directory Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 119: Chapter 7 Commands

Operations manual Commands DAN-20057316 January 2019 Commands Tools commands The Daniel MeterLink Tools menu commands provides the following utilities for the meter's health status, monitoring operational conditions, establishing a baseline of the meter's flow characteristics, updating the meter's program components and monitoring communications between Daniel MeterLink and the meter. - Page 120 Commands Operations manual January 2019 DAN-20057316 This dialog's options include: • View and edit configurations collected from the meter or opened from a file. • Write all or a portion of changed parameters of a configuration to a connected meter. •...

- Page 121 Operations manual Commands DAN-20057316 January 2019 Figure 7-3: Compare Configurations Options dialog • Exclude registers that are typically different: includes items that could change regularly such as SpecFlowPressure, SpecFlowTemperature, Gas composition, etc. A complete list is defined in reg_list_compare_config_exclude.txt found under the installation directory for Daniel MeterLink.

- Page 122 (via the Filter data point). For diagnostic purposes, the transducer waveform signals can be stored to a file using the Diagnostic Collection - Stream to file checkbox. This utilizes the Daniel 3410 Series Gas Ultrasonic Flow Meter's patented "snapshot-and-playback" feature to accurately record the flow signals that can then be later reproduced for detailed analysis.

- Page 123 Operations manual Commands DAN-20057316 January 2019 Figure 7-4: Waveform viewer - time domain The waveforms may also be displayed in the frequency domain. In this mode a Fast Fourier Transform is taken of the waveform so that the frequency content of the waveform can be displayed.

- Page 124 Commands Operations manual January 2019 DAN-20057316 Figure 7-5: Waveform viewer - frequency domain Zero crossing and first motion markers Two markers display along the horizontal axis for either the Stacked or Filtered waveform. If filtering is on, the markers will be on the Filtered waveform. If filtering is off, the markers will be on the Stacked waveform.

- Page 125 Operations manual Commands DAN-20057316 January 2019 • Chord F • Chord G • Chord H 2. Daniel MeterLink starts to continuously stream waveforms from the meter. 3. Click Save while streaming waveforms or click Stop opens a Save As dialog box to allow you to choose a name for the Waveform file.

- Page 126 Commands Operations manual January 2019 DAN-20057316 • Markers - displays markers for the series in order to see the data points collected. • Zoom In - zooms in on both the horizontal and vertical scales centered on the cursor. • Zoom Out - zooms out on both the horizontal and vertical scales centered on the cursor.

- Page 127 Operations manual Commands DAN-20057316 January 2019 7.1.3 Gas SOS calculator The SOS Calculator dialog box allows you to calculate a Speed of Sound (SOS) for a given gas composition and operating conditions. Figure 7-6: Gas SOS Calculator The SOS calculations are selectable as either AGA-10 (AGA Report No. 10 - May 2003) or GERG-2008 (AGA-8 Part 2, 2017).

- Page 128 Commands Operations manual January 2019 DAN-20057316 2. Click Normalize to adjust the percentages so that the TOTAL gas composition equals 100%. The normalize operation maintains the ratios between the different components. 3. If you are connected to a meter with pressure or temperature set to Fixed or Live, the values are read from the meter and entered in the Pressure/temperature inputs.

- Page 129 This is necessary anytime transducers, mounts, holders, or stalks have to be replaced for a chord. Refer to the Daniel 3410 Series Gas Ultrasonic Flow Meters Maintenance and Troubleshooting Manual (P/N DAN-XXXXXXXX) for detailed instructions for replacing the transducers, mounts and stalks and setting the parameters for the pairs of transducers you replaced.

- Page 130 Commands Operations manual January 2019 DAN-20057316 7.1.6 Baseline viewer Use the Baseline viewer to monitor the meter's flow direction and flow characteristics including: • Flow Velocity • Profile Factor • Swirl Angle • Symmetry • Cross-flow • Path Turbulences Access the Baseline viewer from the Meter > Monitor (Detailed) dialog while connected to your meter.

- Page 131 Operations manual Commands DAN-20057316 January 2019 Table 7-2: Baseline viewer gauge values (continued) Value Description Profile Factor Displays the velocity flow profile factor for the meter. The profile factor is calculated from the chordal velocities as ((VelocityB+VelocityC+VelocityF +VelocityG)/(VelocityA+VelocityD+VelocityE+VelocityH)). The green zone is centered on the profile factor set in the baseline ±...

- Page 132 Commands Operations manual January 2019 DAN-20057316 Figure 7-9: Program download dialog Procedure 1. Click Open to display an Open Download File dialog and select the desired file and click Open. The filename displays in the File edit box under Upgrade. The Version and Date of the components to download display in the table under Upgrade.

- Page 133 Operations manual Commands DAN-20057316 January 2019 upgrade is complete you will be able to reconnect to the meter with Daniel ™ MeterLink ™ 5. Daniel MeterLink prompts you with a message that it must disconnect from the meter. Once the firmware upgrade is complete you will be able to reconnect to the ™...

- Page 134 Commands Operations manual January 2019 DAN-20057316 192.168.135.100 with a subnet of 255.255.255.0. Ensure your PC has a compatible address and attempt a connection using this IP address. 2. Once your cabling and Meter Directory record are setup, attempt the connection to the meter.

- Page 135 Operations manual Commands DAN-20057316 January 2019 Figure 7-10: Communications analyzer Procedure 1. Check Browse to disable automatic scrolling. This is useful if you want to look at a certain message while new message are being added to the list. 2. Click Copy to copy the messages to your clipboard so that they can be pasted into another Windows application, e.g.

- Page 136 Commands Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 137: Appendix A Conversion Factors

Operations manual Conversion factors DAN-20057316 January 2019 Conversion factors Conversion factors per unit of measurement The following table includes conversion factors for many of the Metric and U.S. Customary units of measure used with Daniel Ultrasonic Gas Flow Meters and Daniel MeterLink. Table A-1: Conversion Factors per unit of measurement Conversion Factors Unit of Measurement... - Page 138 Conversion factors Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 139: Appendix B Miscellaneous Equations

Operations manual Miscellaneous equations DAN-20057316 January 2019 Miscellaneous equations K-Factor and Inverse K-Factor KFactor = (MaxFrq)(3600s/ℎr) Equation B-1: Frequency Volumetric Flow Rate K-Factor FreqQFullScale InvKFactor = FreqQFaullScale Equation B-2: Frequency Volumetric Flow Rate Inverse K-Factor (MaxFreq)(3600s/ℎr) where KFactor = frequency "K-Factor" (pulses/m or pulses/ft ) (Freq1KFactor and Freq2KFactor) -

Page 140: Calculation Of Chord "L" Dimension

Miscellaneous equations Operations manual January 2019 DAN-20057316 πD Equation B-4: Volumetric Flow Rate - Metric Units ×3600s/hr × m 3 /hr 3600×π ×D × s/hr ×D × 20827.433 s/hr where = volumetric flow rate (m /h) (QMeter) = gas flow velocity(m/s) (AvgFlow) p = geometric constant, pi (dimensionless) (3.14159265...) = pipe inside diameter (m) (PipeDiam) Calculation of Chord "L"... -

Page 141: Appendix C Troubleshooting Comm., Mech., And Elec

Operations manual Troubleshooting comm., mech., and elec. DAN-20057316 January 2019 Troubleshooting comm., mech., and elec. Communications troubleshooting Q1. Why won't the CPU Module LINK LED come on when connecting to the meter via the Ethernet? A1. The LINK light indicates good electric connectivity between two LAN ports. It also indicates proper polarity in the Ethernet connection. -

Page 142: Mechanical/Electrical Troubleshooting

Troubleshooting comm., mech., and elec. Operations manual January 2019 DAN-20057316 IP Address: 0.0.0.0 then the PC has not yet receivedan IP address from the DHCP server and you should wait (up to 30 seconds) to receive an IP address before attempting to connect to the meter. If after 30 seconds the PC has not received an IP address from the meter DHCP server or the IP addressshown above (from ipconfig) is different from the range of 192.168.135.35 through 192.168.135.44, verify that the PC is configured to receive its IP address... - Page 143 Operations manual Troubleshooting comm., mech., and elec. DAN-20057316 January 2019 electronic/electrical troubleshooting techniques, using lap top computers as well as digital volt/ohm meters. Great care should be taken not to "short out" a given electronic/electrical circuit when Troubleshooting. Table C-1: Mechanical/Electrical troubleshooting Problem Solution(s) No power the unit...

- Page 144 Troubleshooting comm., mech., and elec. Operations manual January 2019 DAN-20057316 Table C-1: Mechanical/Electrical troubleshooting (continued) Problem Solution(s) Connected • Check for loose connections at the flow meter and the flow computer communication line to (see 3410 Series engineering drawings). the flow computer but •...

-

Page 145: Appendix D Flow Rate Charts

Operations manual Flow Rate charts DAN-20057316 January 2019 Flow Rate charts Summary charts for Flow rate Table D-1: Flow rate summary charts Flow Rates (MSCFH) Based upon 100 ft/s PSIG 4 1 532 2 174 3 432 5 398 7 807 12 607 18 154 1 065... - Page 146 Flow Rate charts Operations manual January 2019 DAN-20057316 Flow Rates (MSCFH) Based upon 30 M/s 3500 33.37 75.92 131.5 207.2 294.1 464.4 730.4 1056 1706 2457 4000 38.41 87.39 151.3 238.5 338.6 534.6 840.8 1216 1964 2828 4500 43.56 99.10 171.6 270.5 384.0...

- Page 147 Operations manual Flow Rate charts DAN-20057316 January 2019 Flow Rates (MMSCFD) Based upon 100 ft/s 1800 116.4 264.0 457.2 720.9 1 023 1 615 2 540 3 674 5 933 8 544 1900 126.5 280.3 485.4 765.3 1 086 1 715 2 697 3 901 6 299...

- Page 148 Flow Rate charts Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 149: Appendix E Write-Protected Configuration

Operations manual Write-protected configuration DAN-20057316 January 2019 Write-protected configuration Parameters for Write-protected configuration This appendix contains a table of configuration parameters that are write-protected against changes when the CPU Board WRITE PROT. switch is in the ON position. The data points in Table E-1 are applicable for firmware v1.06 and later. - Page 150 Write-protected configuration Operations manual January 2019 DAN-20057316 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters AO2TrimGainExtMeasCurrent AO2TrimZeroExtMeasCurrent AO2ZeroScaleEnergyRate AO2ZeroScaleMassRate AO2ZeroScaleVolFlowRate AsyncEnable AO2MinVel AO2TrimCurrent AO2TrimGainExtMeasCurrent AO2TrimZeroExtMeasCurrent AO2ZeroScaleEnergyRate AO2ZeroScaleMassRate AO2ZeroScaleVolFlowRate AsyncEnable AtmosphericPress AvgDlyA AvgDlyB AvgDlyC AvgDlyD AvgDlyE AvgDlyF AvgDlyG AvgDlyH AvgSoundVelHiLmt AvgSoundVelLoLmt BatchSize BlockageTurbulenceLmtA...

- Page 151 Operations manual Write-protected configuration DAN-20057316 January 2019 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters BlockageTurbulenceLmtH CalMethod ChordInactvA ChordInactvB ChordInactvC ChordInactvD ChordInactvE ChordInactvF ChordInactvG ChordInactvH City ColocMeterMode ContractHour CRange DailyLogInterval DampEnable DeviceNumber DI1IsInvPolarity DitherEnable DltChk DltDlyA DltDlyB DltDlyC DltDlyD DltDlyE DltDlyF DltDlyG...

- Page 152 Write-protected configuration Operations manual January 2019 DAN-20057316 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters DO2AContent DO2AIsInvPolarity DO2BContent DO2BIsInvPolarity DO2PairTestEnable EmRateDesired EnableExpCorrPress EnableExpCorrTemp EnablePressureInput EnableTemperatureInput FireSeq FlowAnalysisHighFlowLmt FlowAnalysisLowFlowLmt FlowDir FlowPOrTSrcUponAlarm FODO1Mode FODO1Source FODO2Mode FODO2Source FODO3Mode FODO3Source FODO4Mode FODO4Source FODO5Mode FODO5Source FODO6Mode FODO6Source...

- Page 153 Operations manual Write-protected configuration DAN-20057316 January 2019 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters Freq1FullScaleVolFlowRate Freq1MaxFrequency Freq1MaxVel Freq1MinVel Freq1ZeroScaleEnergyRate Freq1ZeroScaleMassRate Freq1ZeroScaleVolFlowRate Freq2BPhase Freq2Content Freq2Dir Freq2FeedbackCorrectionPcnt Freq2FullScaleEnergyRate Freq2FullScaleMassRate Freq2FullScaleVolFlowRate Freq2MaxFrequency Freq2MaxVel Freq2MinVel Freq2ZeroScaleEnergyRate Freq2ZeroScaleMassRate Freq2ZeroScaleVolFlowRate FwdA0 FwdA1 FwdA2 FwdA3 FwdBaselineAvgFlow FwdBaselineComment FwdBaselineCrossFlow...

- Page 154 Write-protected configuration Operations manual January 2019 DAN-20057316 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters FwdBaselineTurbulenceA FwdBaselineTurbulenceB FwdBaselineTurbulenceC FwdBaselineTurbulenceD FwdBaselineTurbulenceE FwdBaselineTurbulenceF FwdBaselineTurbulenceG FwdBaselineTurbulenceH FwdC0 FwdC1 FwdC2 FwdC3 FwdFlwRt1 FwdFlwRt10 FwdFlwRt11 FwdFlwRt12 FwdFlwRt2 FwdFlwRt3 FwdFlwRt4 FwdFlwRt5 FwdFlwRt6 FwdFlwRt7 FwdFlwRt8 FwdFlwRt9 FwdMtrFctr1 FwdMtrFctr10 FwdMtrFctr11...

- Page 155 Operations manual Write-protected configuration DAN-20057316 January 2019 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters FwdMtrFctr7 FwdMtrFctr8 FwdMtrFctr9 GasPropertiesSrcSel GasPropertiesSrcSelGCAlarm GCBaud GCCommTimeout GCDesiredStreamTimeout GCHeatingValueType GCHeatingValueUnit GCModbusID GCProtocol GCSerialPort GCStreamNumber HARTDate HARTDescriptor HARTDeviceFinalAssyNum HARTEnergyUnit HARTLongTag HARTMassUnit HARTMessage HARTMinNumPreambles HARTNumPreambleBytesFromSlave HARTPollingAddress HARTPressureUnit HARTQVContent HARTRateTimeUnit...

- Page 156 Write-protected configuration Operations manual January 2019 DAN-20057316 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters HARTTVContent HARTVelUnit HARTVolUnit HCH_Method HighPressureAlarm HighTemperatureAlarm HourlyLogInterval InputPressureUnit IsAO1EnableTest IsAO2EnableTest IsFreq1BZeroedOnErr IsFreq1EnableTest IsFreq2BZeroedOnErr IsFreq2EnableTest LinearExpansionCoef LiquidDetectionSDevCrossFlowLmt LiquidDetectionSDevProfileFactorLmt LiquidDetectionSDevSymmetryLmt LiveFlowPressureCalCtrl LiveFlowPressureGain LiveFlowPressureOffset LiveFlowTemperatureCalCtrl LiveFlowTemperatureGain LiveFlowTemperatureOffset LowFlowLmt Operations manual...

- Page 157 Operations manual Write-protected configuration DAN-20057316 January 2019 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters LowPressureAlarm LowTemperatureAlarm MaxHoldTm MaxInputPressure MaxInputTemperature MaxNoDataBatches MaxNoise MeterMaxVel MeterName MeterSerialNumber MinChord MinHoldTime MinInputPressure MinInputTemperature MinPctGood MinSigQlty NegSpan NonNormalModeTimeout NumVals PBase PipeDiam PipeOutsideDiameter Pk1Pct Pk1Thrsh Pk1Wdth PoissonsRatio PosSpan...

- Page 158 Write-protected configuration Operations manual January 2019 DAN-20057316 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters RefTemperatureMolarDensity RefTempLinearExpCoef RevA0 RevA1 RevA2 RevA3 RevBaselineAvgFlow RevBaselineComment RevBaselineCrossFlow RevBaselineFlowPressure RevBaselineFlowTemperature RevBaselineProfileFactor RevBaselineSwirlAngle RevBaselineSymmetry RevBaselineTime RevBaselineTurbulenceA RevBaselineTurbulenceB RevBaselineTurbulenceC RevBaselineTurbulenceD RevBaselineTurbulenceE RevBaselineTurbulenceF RevBaselineTurbulenceG RevBaselineTurbulenceH RevC0 RevC1 RevC2 RevC3...

- Page 159 Operations manual Write-protected configuration DAN-20057316 January 2019 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters RevFlwRt2 RevFlwRt3 RevFlwRt4 RevFlwRt5 RevFlwRt6 RevFlwRt7 RevFlwRt8 RevFlwRt9 RevMtrFctr1 RevMtrFctr10 RevMtrFctr11 RevMtrFctr12 RevMtrFctr2 RevMtrFctr3 RevMtrFctr4 RevMtrFctr5 RevMtrFctr6 RevMtrFctr7 RevMtrFctr8 RevMtrFctr9 SampInterval SampPerCycle SetXdcrType SndSpdChkMaxVel SndSpdChkMinVel SndVelCompErrLimit SNRatio...

- Page 160 Write-protected configuration Operations manual January 2019 DAN-20057316 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters Tamp TampHi TampLo TampSen TampWt TBase TmDevFctr1 TmDevLow1 Tspe TspeHi TspeLmt TspeLo TspeSen TspeWt Tspf TspfHi TspfLo TspfMatch TspfSen TspfWt UnitsSystem VelHold VolFlowRateTimeUnit VolUnitMetric VolUnitUS WallRoughness Operations manual...

- Page 161 Operations manual Write-protected configuration DAN-20057316 January 2019 Table E-1: Write-protected configuration parameters (continued) Write-protected configuration parameters XdcrFiringSync XdcrFreq XdcrNumDriveCycles YoungsModulus ZeroCut Model 3418 GUSM...

- Page 162 Write-protected configuration Operations manual January 2019 DAN-20057316 Operations manual...

-

Page 163: Appendix F Engineering Drawings

Operations manual Engineering drawings DAN-20057316 January 2019 Engineering drawings 3410 Series engineering drawings This appendix contains the following engineering drawing(s) for the ultrasonic meter. DMC-005324 3410 Series Gas Ultrasonic Flow Meters System Wiring Diagram Model 3418 GUSM... - Page 168 Daniel Measurement and Control, Inc. ("Daniel") is an Emerson Automation Solutions business unit. The Daniel name and logo are trademarks of Daniel Industries, Inc. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other trademarks are the property of their respective...

Need help?

Do you have a question about the Daniel 3410 Series and is the answer not in the manual?

Questions and answers