Emerson 3410 Series Maintenance And Troubleshooting Manual

Gas ultrasonic flowmeters

Hide thumbs

Also See for 3410 Series:

- Operation manual (192 pages) ,

- Installation manual (140 pages) ,

- Instructions for use, maintenance and installation manual (110 pages)

Summary of Contents for Emerson 3410 Series

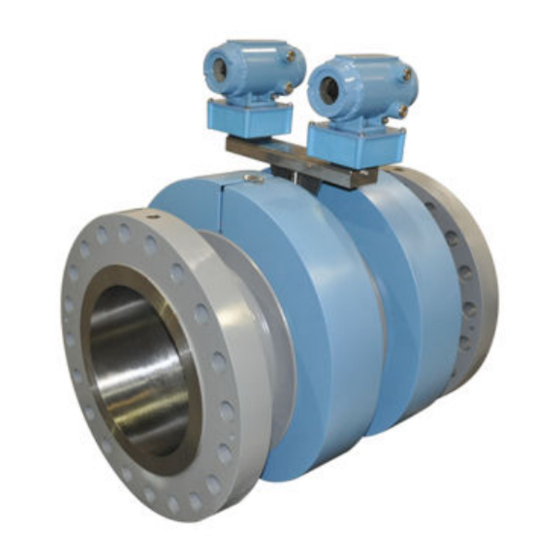

- Page 1 Maintenance and Troubleshooting manual P/N 3-9000-791, Rev DC August 2021 3410 Series Gas Ultrasonic Flow meters Models 3415, 3416 and 3417...

- Page 2 Emerson employees. Emerson will not accept your returned equipment if you fail to follow Emerson procedures. Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Emerson Customer Service department.

-

Page 3: Table Of Contents

3.9 Acquisition Module replacement....................83 Appendix A Conversion factors....................89 A.1 Conversion factors per units of measurement................89 A.2 K-Factor and inverse K-Factor conversions.................90 Appendix B Engineering drawings....................91 B.1 Daniel 3410 Series Ultrasonic Flow Meter Drawings..............91 Maintenance and Troubleshooting manual... - Page 4 Contents Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Models 3415, 3416 and 3417 GUSM...

-

Page 5: Chapter 1 Maintenance

Maintenance and Troubleshooting manual Maintenance P/N 3-9000-791 August 2021 Maintenance Precautions for meter maintenance This section includes discussion of the maintenance of Daniel 3410 Series Ultrasonic Meters. For reference, you may download the Daniel MeterLink Quick Start Manual from: http:// www.emerson.com/en-us/catalog/measurement-instrumentation/daniel-meterlink. CAUTION SURFACE TEMPERATURE HAZARD The meter body and piping may be extremely hot or cold. -

Page 6: Field Hydrostatic Pressure Testing Procedures

Failure to comply may result in injury to personnel or cause damage to the equipment. 1.2.1 T-Slot transducer assembly and mount Procedure 1. Slowly vent all line pressure on the 3410 Series Gas Ultrasonic Meter to atmosphere. 2. Disconnect transducer cable from the transducer holder. Models 3415, 3416 and 3417 GUSM... -

Page 7: Routine Maintenance

The T-200 transducer assembly has full-metal structure and can remain in place during field hydrostatic pressure test. Procedure 1. Leave T-200 transducers installed on the 3410 Series Gas Ultrasonic Meter while the line is pressurized. 2. Run the field hydrostatic test. - Page 8 Maintenance Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 the output file and click the Start button. You can open the file immediately after it is generated or view it at a later time. It is recommended that a Maintenance log be collected after an upset in the system.

- Page 9 Microsoft Excel workbook from multiple 3410 Series meter maintenance logs. Some parameters like gain, signal level,and noise level may show a shift over time which can be useful in detecting changes in the meter and the installation.

- Page 10 Failure to comply may cause excessive pressure in the meter system, resulting in death, serious injury or equipment damage. Figure 1-4: 3410 Series Gas Ultrasonic Flow Meter with flow conditioner for uni- directional flow Figure 1-5: 3410 Series Gas Ultrasonic Flow Meter with flow conditioner for bi-...

- Page 11 Maintenance and Troubleshooting manual Maintenance P/N 3-9000-791 August 2021 Procedure 1. Fluids leaking from seals. This could be visually noticed for liquids leaking. It may be audible for gasses leaking. Ice may also form at a point of a gas leak. 2.

- Page 12 Maintenance Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Models 3415, 3416 and 3417 GUSM...

-

Page 13: Chapter 2 Troubleshooting

Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Troubleshooting Meter status alarms ™ Run Daniel MeterLink and open the Meter Monitor (Summary) view to perform a diagnostics health check. Figure 2-1: Meter Monitor status alarms If the meter is measuring flow and operating within the calibration parameters the Meter Status LED is green. - Page 14 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 2.1.1 Check status Click the Check Status button if any of the LEDs are yellow or red to see more specific information causing the status alarm. Some alarms do not require an acknowledge and will clear automatically when the alarm condition goes away.

- Page 15 Field I/O alarm Reports various field I/O devices that are in alarm. Click the Check Status button for more details on specific alarms. The field is grayed out if the Daniel 3410 Series Ultrasonic Gas Flow Meter does not support this alarm.

-

Page 16: Troubleshooting The Meter

Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Troubleshooting the meter Table 2-2 and the following sections show errors that may occur with the meter hardware, firmware or connections and recommend actions to resolve the problem(s). Table 2-2: Troubleshooting Error Recommended action(s) Acquisition Module Error... - Page 17 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Table 2-2: Troubleshooting (continued) Error Recommended action(s) Chord failure • Chord is hard failed, and meter is unable to obtain measurement data from a pair of transducers. — If a chord is failed and no other transducers are failed or are reporting status alerts, the issue is most likely isolated to this pair of transducers or its cabling.

- Page 18 If the LED is on, check the Ethernet cable connections. CPU Module LINK LED is • If you are connecting for the first time, refer to the 3410 Series on but I can't Installation Manual, in "Wiring and inputs/outputs" for instructions communicate with the on initial communication (via Ethernet) setup.

- Page 19 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Table 2-2: Troubleshooting (continued) Error Recommended action(s) Communication issues • Blocked network ports on the computer running Daniel MeterLink due to blocked network or on a company LAN can prevent connections to the meter or ports prevent certain features from working.

- Page 20 • Check RS-485 or RS-232 communication LEDs. Cannot communicate • Refer to the Emerson 475 Field Communication User’s Manual, Rev with Field Communicator D. This manual may be downloaded from the following location: http://www.fieldcommunicator.com. Note The 375 Field Communicator is no longer available for purchase since the release of the 475 Field Communicator.

- Page 21 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Table 2-2: Troubleshooting (continued) Error Recommended action(s) Configuration changed • One or more parameters have been modified in the meter's configuration, — Collect an Audit log using Daniel MeterLink in order to see what configuration parameters changed and when they changed.

- Page 22 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Table 2-2: Troubleshooting (continued) Error Recommended action(s) Flow pressure is outside • Startup issues: the alarm limits — Verify that there is voltage to the pressure sensor from either the meter's power supply board or from an external power supply.

- Page 23 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Table 2-2: Troubleshooting (continued) Error Recommended action(s) Flow temperature is • Startup issues: outside the alarm limits — Verify that there is voltage to the temperature sensor from either the meter's power supply board or from an external power supply.

- Page 24 — Enable the Allow FTP-only connection. — For Serial Port Connections: for Daniel 3410 Series Gas Ultrasonic meters connect to Port A. You may need to adjust your Meter Directory settings for the connection so that they match the port default settings. Port A will default to 19200 baud with a Modbus address of 32.

- Page 25 No power to the unit • Check for correct voltage (10.4 - 36 VDC) (refer to the System Wiring Diagram (P/N DMC-005324) in Daniel 3410 Series Ultrasonic Flow Meter Drawings). • Check the main power source for blown fuse or tripped circuit breaker.

- Page 26 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Table 2-2: Troubleshooting (continued) Error Recommended action(s) Waveform contains an • Use the Daniel MeterLink Meter → Signal Analyzer to increase the excessive amount of StackSize until noise level decreases (settings can be 1 (none) 2, 4, noise 8, or 16).

- Page 27 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Figure 2-5: Meter Monitor (Detailed) view The following details the information displayed in this dialog box. • Flow Properties Table - the table at the top of the Meter Monitor dialog box shows basic information about the condition of the flow in the meter.

- Page 28 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 • Chart - the chart utility displays the data collected for the value selected from the Chart drop-down list. Refer to Table 2-1 for error resolutions and Table 2-2 for meter maintenance hardware diagnostics.

- Page 29 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Table 2-3: Meter Monitor maintenance (continued) Daniel MeterLink utility Diagnostics Action(s) Meter Monitor (Detailed) view Flow Profile • A chord that causes the spread for the Speed of Sound to vary morethan0.35%of the Average Speed of Sound, the bar for that chord turns...

- Page 30 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Table 2-3: Meter Monitor maintenance (continued) Daniel MeterLink utility Diagnostics Action(s) click the Baseline button. The Baseline Viewer displays the meter's flow characteristics including: Flow Velocity, Profile Factor, Swirl Angle, Symmetry, Cross-flow, and Path Turbulences.

- Page 31 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Table 2-3: Meter Monitor maintenance (continued) Daniel MeterLink utility Diagnostics Action(s) Meter Monitor (Detailed) view Electronics Temperature of out • Temperature of the Meter Data List range electronics is out of nominal operating range below -40 °C or above 100 °C (-40 °F or above 212 °F).

- Page 32 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Table 2-3: Meter Monitor maintenance (continued) Daniel MeterLink utility Diagnostics Action(s) • Analog outputs • Run Analog Outputs test • Verify outputs are within 4mA - 20mA range — 0% = 4mA —...

- Page 33 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 Table 2-3: Meter Monitor maintenance (continued) Daniel MeterLink utility Diagnostics Action(s) MeterLink Logs/ Reports Menu • Meter performed a Warm • Meter performed a Warm start or a Warm start start: required —...

- Page 34 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Table 2-3: Meter Monitor maintenance (continued) Daniel MeterLink utility Diagnostics Action(s) • Collect a complete Archive log and contact your local area Daniel service representative. Daniel MeterLink Meter • Chord failure Daniel •...

- Page 35 The only work around is to only install one modem driver per COM port on the PC at a time. Refer to the Daniel MeterLink Quick Start Manual (P/N 3-9000-763) for phone and modem details. The manual may also be downloaded from the Daniel website. http:// www.emerson.com/en-us/catalog/measurement-instrumentation/daniel-meterlink Maintenance and Troubleshooting manual...

-

Page 36: Troubleshoot Maintenance Log Files And Trend Files

Verify the Comms Address and Baud rate are correct in the Meter Directory record. For additional information on wiring and configuring the meter for the various communication options refer to the Daniel 3410 Series Gas Ultrasonic Flow Meters Installation manual (P/N 3-9000-789, Wiring and inputs/outputs). - Page 37 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 ® are not currently connected to the network, then Excel will most likely not be able to ™ ® access the printer driver information and Daniel MeterLink cannot use Excel to generate reports or logs.

- Page 38 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 The Security dialog appears. 2. Select the Trusted Sources tab. 3. Click the Trust access to Visual Basic Project radio button and click OK to apply your selections. ® Figure 2-7: Excel 2007 Trusted Access Setting ®...

- Page 39 Maintenance and Troubleshooting manual Troubleshooting P/N 3-9000-791 August 2021 ® Figure 2-9: Excel 2007 Developer tab - Macro Security 5. Select Macro Settings from the left panel, then click the Enable all macros (not recommended; potentially dangerous code can run) radio button. 6.

- Page 40 Troubleshooting Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Models 3415, 3416 and 3417 GUSM...

-

Page 41: Chapter 3 Meter Repairs

Meter repairs P/N 3-9000-791 August 2021 Meter repairs Precautions prior to repairs This section includes discussion of the maintenance of Daniel 3410 Series Ultrasonic Meters. For reference, you may download the Daniel MeterLink Quick Start Manual from: http:// www.emerson.com/en-us/catalog/measurement-instrumentation/daniel-meterlink. CAUTION SURFACE TEMPERATURE HAZARD The meter body and piping may be extremely hot or cold. - Page 42 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 WARNING CRUSHING HAZARD Do not remove flange stabilizers. Attempting to do so could allow the meter to roll, resulting in serious injury or equipment damage. A. Flange stabilizers WARNING FLUID CONTENTS MAY BE UNDER PRESSURE When the meter is under pressure, DO NOT attempt to remove or adjust the transducer holder of the T-Slot transducer assembly, or loosen the screws holding the T-200 transducer assembly.

- Page 43 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 WARNING CONTENTS MAY BE HAZARDOUS The meter must be fully depressurized and drained before attempting to remove the transducer holder of T-Slot transducer assembly, or the T-200 transducer assembly. If gas or fluid begins to leak from the transducer holder of T-Slot transducer assembly, or T-200 transducer stalk assembly, stop immediately and reinstall the transducer holder or T-200 stalk assembly.

-

Page 44: T-Slot Transducer Removal And Installation

Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 CAUTION ESCAPING GASES OR FLUIDS HAZARD Process Seal Materials Single Seal Certification (T-XX and T-200 Transducers) • Wetted material for T-XX style transducers are 316SS or Inconel holders with Hastelloy-C pins, Stycast 2850 Epoxy, and glass. •... - Page 45 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 Table 3-1: Temperature ranges for transducers, mounts and holders (continued) Transducer type Temperature range Mount and holder type T-22 -50 °C to +100°C (-58°F to 212 Standard mounts/Holders/NBR °F) O-ring Inconel mounts/316L Holders, NBR O-ring Inconel Mounts/Inconel...

- Page 46 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Figure 3-1: T-21 and T-22 transducer assembly A. Transducer cable (max. length 15 ft.) B. Retainer clips C. Transformer retainer (Standard P/N 1-360-01-958 or High Temperature P/N 1-360-01-978) D. Transformer module T-21/T-41 (W-01 P/N 1-360-03-090) or T-22 (W-02 P/N 1-360-03-110) E.

- Page 47 T-Slot transducer installation Procedure 1. Ensure that the Daniel 3410 Series Ultrasonic Gas Flow Meter transducer port, mount, and T-Slot transducer holder assembly are clean and free of debris. 2. Apply a small amount of Molykote 111 to the female contacts on the transducer.

- Page 48 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Note Replacing the O-rings at this point minimizes the chances of damaging the transducer by dropping it. 6. Apply a small amount of nickel anti-seize (N.A.S.) compound (P/N 2-9-9960-134) to the outer threads of the transducer holder (see Figure 3-2).

- Page 49 12. Check that the Daniel 3410 Series Ultrasonic Gas Flow Meter is pressure tight. Pressurize the meter to line pressure. Check for leaks around all mounts and transducer holders, which were removed, using soapy water or other recognized leak detector.

- Page 50 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 7. Place the transformer retainer over the transformer module. Ensure the retainer threads are aligned correctly and hand-tighten. Use an 1 1/8” wrench and turn clockwise until fully seated in the transducer holder. Note Do not over tighten the retainer.

- Page 51 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 Figure 3-4: Daniel MeterLink Transducer Swap-out Wizard Chord “L” dimension calculation The chord “L” dimension is calculated from the meter housing length as well as the transducer pair lengths, mount lengths, holder lengths, and stalk lengths as shown in Equation 3-1.

-

Page 52: T-Slot Transducer Holder Removal And Installation

Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Equation 3-1: Chord “L” Dimension cℎord MeterHousing Mount1 Mount2 −L − L − L Xdcr1 Stalk1 Hldr1 −L − L − L Xdcr2 Stalk2 Hldr2 = chord “L” dimension (in) (LA ... LD) chord = meter housing length (in) MeterHousing... - Page 53 Failure to comply could cause serious injury. 3.3.1 Remove the T-Slot transducer holder Daniel 3410 Series Ultrasonic Gas Flow Meters utilize transducer holders that contain the transducer assemblies and act as the pressure barrier between the transducers and the fluid.

- Page 54 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 3. Disconnect the transducer cable by removing the retaining clips and pulling the cable plug straight out. Do not twist or rotate the plug. (See Figure 3-2). 4. Remove the transformer retainer using a 1 1/8” wrench and then disconnect and remove the transformer module (Figure 3-3).

- Page 55 Install the T-Slot transducer holder Procedure 1. Ensure that the Daniel 3410 Series Ultrasonic Gas Flow Meter transducer port, mount, and T-Slot transducer holder assembly are clean and free of debris. 2. Insert the transducer (parts are keyed and can only be assembled one way) into the stalk or into the new transducer holder if no stalk is required.

- Page 56 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 8. Insert the T-Slot transducer assembly into the meter transducer port. Tighten with crescent wrench to securely seat the assembly in the mount. Do not over tighten. 9. Plug the transformer module into the transducer holder assembly. The transformer module is keyed and can only be installed one way.

-

Page 57: T-200 Transducer Assembly Removal And Installation

Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 T-200 transducer assembly removal and installation WARNING CONTENTS MAY BE HAZARDOUS The meter must be fully depressurized and drained before attempting to remove the T-200 transducer assembly. If gas or fluid begins to leak, stop immediately and reinstall the transducer assembly. - Page 58 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Figure 3-8: Transducer assembly installed in a meter body Procedure 1. Blow the line down according to the site standard operating procedures. 2. Ensure that the line pressure is down to atmospheric pressure prior to disassembly. 3.

- Page 59 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 8. Place the T-200 transducer assembly in a safe place to avoid any damages to the assembly. 3.4.2 T-200 transducer assembly installation This procedure is for installing a T-200 transducer assembly on a meter body. Procedure 1.

-

Page 60: T-200 Transducer Capsule Assembly Removal And Installation

Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Procedure 1. Update average delay time and delta delay time. The transducer pair average delay time and delta delay time are located on the transducer pair calibration sheet. These values must be downloaded to the appropriate meter data points (AvgDlyA... AvgDlyD, DltDlyA... - Page 61 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 T-200 transducer capsule assembly (see Figure 3-9) can be removed or installed while the line is pressurized or at atmospheric pressure. 3.5.1 T-200 transducer capsule assembly removal This procedure is for removing a transducer capsule assembly from a T-200 transducer assembly installed in a meter body.

- Page 62 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Table 3-2: T-200 transducer stalk assembly configuration and capsule setting (continued) Stalk assembly configuration Smart capsule setting Figure 3-10: Setting of T-200 transducer capsule assembly A. Tab B. Position 1 Models 3415, 3416 and 3417 GUSM...

- Page 63 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 Figure 3-11: T-200 transducer stalk assembly configuration A. Stalk assembly configuration B. Transducer stalk C. Stalk assembly serial number 3. Ensure that the setting of the transducer capsule assembly matches the stalk assembly configuration (see Table 3-2).

- Page 64 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Note Do not press the Kapton tape while spreading the coupling fluid. 6. Wait for 30 - 60 seconds to let the coupling fluid spread more evenly on the surface. 7.

-

Page 65: T-200 Transducer Housing Removal And Installation

Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 T-200 transducer housing removal and installation WARNING CONTENTS MAY BE HAZARDOUS The meter must be fully depressurized and drained before attempting to remove the T-200 transducer assembly. If gas or fluid begins to leak, stop immediately and reinstall the transducer assembly. - Page 66 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 10. Place the stalk upward on a flat table and do not lose the PAI spacer inside the stalk. 3.6.2 T-200 transducer housing installation This procedure is for installing a T-200 transducer housing into a transducer stalk and restoring the transducer assembly in a meter body.

-

Page 67: Transducer Cable Removal And Installation

Section 3.5.2 to install the transducer assembly in a meter body. Transducer cable removal and installation Daniel 3410 Series Ultrasonic Gas Flow Meters have red transducer cables that plug directly in the back of the transformer retainer. Note Make a note of the exiting cabling path layout to allow proper tie-wrap configuration later in this procedure. - Page 68 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 3.7.1 Replace transducer cables The meter body ports are identified by stamped or cast lettering adjacent to the transducer port. Transducers for transmitter head 1 will be labeled 1-A1, 1-A2, etc. while the transducer for transmitter head 2 will be labeled 2-A1, 2-A2, etc.

- Page 69 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 Figure 3-15: Model 3410 Ultrasonic Meter Acquisition Module Wiring 3.7.2 Install transducer cables Procedure 1. Use the existing cable and cut the new cable (Daniel P/N 1-360-01-310) for each cable to same length. 2.

- Page 70 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 block J1 and J2 as shown in Figure 3-16 Ultrasonic Meter Acquisition Module wiring. Figure 3-16: Models 3415, 3416, 3417 Ultrasonic Meter Acquisition Module wiring 6. Only connect wires for Chords A1, A2, B1 and B2 for 3416 and 3417 meter applications or A1 and A2 for 3415 meter applications.

- Page 71 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 10. Inspect the Transmitter Electronics Enclosure gasket for wear and replace it if necessary. 11. Lubricate it with Molykote 111 (P/N 2-9-9960-135) if replacing the gasket. 12. Prop the Transmitter Electronics Enclosure at an angle on top of the Base Enclosure. 13.

- Page 72 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 20. Adjust the security wire, removing all slack and thread into the lead seal. 21. Cut wire ends to remove excess wire. 22. If required, attach the security wire seals on the Base Enclosure. Figure 3-18: Meter with and without security shrouds A.

-

Page 73: Replace The Meter Electronics

Optional I/O module (RS-232 or RS-485) • Expansion I/O module • I.S. Barrier Board (P/N 360-03-004) • Power Supply (P/N 360-03-003) • Backplane Board (P/N 360-03-007) The Daniel 3410 Series Gas Ultrasonic Flow Meter Base Enclosure consists of the following: Maintenance and Troubleshooting manual... - Page 74 • Transducer Cable (5FT P/N 1-360-03-232, 15FT P/N 1-360-03-233) Should the Daniel 3410 Series Ultrasonic Gas Flow Meter require disassembly in the field (i.e., check boards, change switch settings, or replace boards), to prevent electrostatic damage to the electronic boards, always use a ground strap while handling the circuit boards.

- Page 75 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 Figure 3-21: CPU or I/O Module replacement A. Terminal end of Transmitter Electronics Enclosure B. CPU Module C. Optional I/O Module D. Power Supply board E. Fuse F. Internal chassis ground Figure 3-22: CPU module Type 2 and Type 4 A.

- Page 76 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 4. Grasp the outer ends of the module you want to replace and pull it out of the enclosure. 5. Insert the new CPU Module or I/O Module into the enclosure and firmly push until the board is fully seated into the Backplane Board connectors and the lock is engaged.

- Page 77 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 10. If replacing other electronics or the fuse, continue with Fuse replacement, Backplane replacement, I.S. Barrier Board replacement Power Supply Board replacement Acquisition Module replacement before replacing the end caps and sealing the enclosure.

- Page 78 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 2. Disconnect the Transmitter Electronics Enclosure security seals, loosen the end cap security latches (3mm Allen wrench required) and remove both end caps (see Figure 3-23). 3. Remove the CPU Module and the Optional I/O Module (if installed). See Figure 3-21 for board locations and associated terminal blocks.

- Page 79 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 8. Attach the Acquisition Cable terminal block to the new Backplane Board and plug the Power Supply Board and I.S. Barrier board into the Backplane board. 9. Insert the Backplane (with the Power Supply and I.S. Barrier Boards attached to the Backplane) into the enclosure.

- Page 80 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Figure 3-25: I.S. Barrier board replacement A. Non-terminal end of Transmitter Electronics Enclosure B. Power Supply board C. I.S. Barrier board (inside the Guide Plate) D. Acquisition cable E. Backplane board 6.

- Page 81 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 a) If required, install the security seal wire into and through one of the two holes in the end cap. b) Choose holes that minimize counterclockwise rotation of the end cap when the security wire is taut (maximum wire diameter.078 inch;...

- Page 82 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 use a flat blade screw driver and install the four flat-head screws into the enclosure standoffs. Figure 3-27: Power Supply board replacement A. Non-terminal end of Transmitter Electronics Enclosure B. Power Supply board C.

-

Page 83: Acquisition Module Replacement

Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 11. If replacing other electronics, continue with Acquisition Module replacement before replacing the end caps and sealing the enclosure. 12. If you are not replacing other electronics, replace the Transmitter Electronics Enclosure end caps, install the end cap security latches (3 mm Allen wrench required). - Page 84 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Figure 3-28: Conduit removal A. Transmitter electronics enclosure B. Conduit nuts 3. If the meter is equipped with security seals, remove the seals from the bolts on the Base Enclosure. Figure 3-29: Transmitter Electronics Enclosure and Base Enclosure security seal removal A.

- Page 85 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 4. Use a 6 mm Allen wrench and remove the four hex head bolts securing the Transmitter Electronics Enclosure to the Base Enclosure. Figure 3-30: Transmitter Electronics Enclosure removal A. Transmitter electronics enclosure B.

- Page 86 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Figure 3-31: Acquisition Module cable and transducer wiring A. Acquisition cable B. Acquisition wiring terminal blocks C. Acquisition Module NOTICE Ensure the transducer cables are labeled for the chord configuration. 6.

- Page 87 Maintenance and Troubleshooting manual Meter repairs P/N 3-9000-791 August 2021 11. Retighten or reattach the conduit to the Transmitter Electronics Enclosure using a crescent wrench or channel lock pliers. 12. If required, install security wire seal into and through the hole in the socket head screw on the Base Enclosure cover (maximum wire diameter 0.078 inch;...

- Page 88 Meter repairs Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 Figure 3-33: Base Enclosure security seals A. Transmitter Electronics Enclosure B. Transmitter Electronics endcap security latch C. Security wire seals (optional) D. Base Enclosure 15. Cut wire ends to remove excess wire. 16.

-

Page 89: Appendix A Conversion Factors

Conversion factors Conversion factors per units of measurement The following table includes conversion factors for many of the Metric and U.S. Customary units of measure used with Daniel 3410 Series Ultrasonic Gas Flow Meters and Daniel ™ MeterLink Table A-1: Conversion factors per units of measurement... -

Page 90: K-Factor And Inverse K-Factor Conversions

Conversion factors Maintenance and Troubleshooting manual August 2021 P/N 3-9000-791 K-Factor and inverse K-Factor conversions FreqQ FullScale Equation A-1: Frequency volumetric flow rate K-Factor KFactor = (MaxFreq)3600s § ℎr ( * ) (MaxFreq)(3600s § ℎr) ( * ) Equation A-2: Frequency volumetric flow rate inverse K-Factor InvKFactor = FreqQ FullScale where... -

Page 91: Appendix B Engineering Drawings

Engineering drawings P/N 3-9000-791 August 2021 Engineering drawings Daniel 3410 Series Ultrasonic Flow Meter Drawings This appendix contains the following engineering drawing(s) for the ultrasonic meter: DMC-005324 Daniel 3410 Series Gas Ultrasonic Flow Meter System Wiring Diagram Maintenance and Troubleshooting manual... - Page 92 Daniel Measurement and Control...

- Page 93 ≥ ≥ ≥ ≥ ≥ ≥ Daniel Measurement and Control...

- Page 94 · · · 90Y1 · LISTED TELEMETERING EQUIPMENT FOR HAZ. LOC. 3/4 NPT Daniel Measurement and Control...

- Page 95 ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ Daniel Measurement and Control...

- Page 96 2021 Emerson. All rights reserved. Unauthorized duplication in whole or part is prohibited. Printed in the USA. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other trademarks are the property of their respective companies.

Need help?

Do you have a question about the 3410 Series and is the answer not in the manual?

Questions and answers