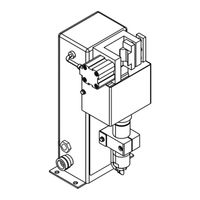

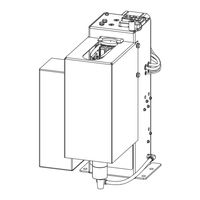

Fronius Robacta Reamer Twin Manuals

Manuals and User Guides for Fronius Robacta Reamer Twin. We have 3 Fronius Robacta Reamer Twin manuals available for free PDF download: Operating Instructions Manual, Manual

Fronius Robacta Reamer Twin Manual (96 pages)

Welding torch cleaning

Brand: Fronius

|

Category: Welding System

|

Size: 4 MB

Table of Contents

Advertisement

Fronius Robacta Reamer Twin Operating Instructions Manual (92 pages)

Brand: Fronius

|

Category: Welding System

|

Size: 4 MB

Table of Contents

Fronius Robacta Reamer Twin Operating Instructions Manual (96 pages)

Brand: Fronius

|

Category: Welding Accessories

|

Size: 3 MB

Table of Contents

Advertisement

Advertisement