Table of Contents

Advertisement

Quick Links

OPERATOR AND MAINTENANCE MANUAL

G2 SERIES DECONTAMINATION WATER HEATER

33 Kings Highway

Orangeburg, NY 10962

,

TECH MANUAL PART NUMBER: 1006375

REVISED DATE: 17 NOVEMBER 11

TECHNICAL MANUAL

FOR

ISO 9001: 2008 Registered

Phone:

Quality Management System

Hotline: (800)-328-5563

Fax:

(845)-365-2114

Web:

www.reevesems.com

Email:

info@reevesems.com

845-359-6066

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Reeves G2 series

- Page 1 TECHNICAL MANUAL OPERATOR AND MAINTENANCE MANUAL G2 SERIES DECONTAMINATION WATER HEATER ISO 9001: 2008 Registered 33 Kings Highway Orangeburg, NY 10962 Phone: 845-359-6066 Quality Management System Hotline: (800)-328-5563 Fax: (845)-365-2114 TECH MANUAL PART NUMBER: 1006375 Web: www.reevesems.com REVISED DATE: 17 NOVEMBER 11 Email: info@reevesems.com...

- Page 3 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater SAFETY STEPS TO FOLLOW IF SOMEONE IS THE VICTIM OF ELECTRICAL SHOCK. SEND FOR HELP AS SOON AS POSSIBLE. DO NOT TRY TO PULL OR GRAB THE INDIVIDUAL. IF POSSIBLE, TURN OFF THE ELECTRICAL POWER.

- Page 4 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater ELECTRICAL HAZARD Under adverse conditions, voltage used in this equipment can cause death or serious injury. Observe the following safety precautions: GROUND THE EQUIPMENT Before connecting primary power cables; connect grounding cable from ground lug on power control box to earth ground.

- Page 5 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater WARNING HEAVY EQUIPMENT Improperly lifting or carrying heavy equipment can result in serious injury or death. Refer to the following weight limits as guidelines: Handling Function One-Person Two-Person Two-Person Max. Max. Lift Max.

- Page 6 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater DANGER Risk of Explosion or Fire. Do Not place unit in an area where flammable gas vapors may be present. A spark could cause an explosion or fire. DANGER Risk of Electrocution. This unit must be connected to a properly grounded outlet. Do Not use an adapter or remove the third grounding prong.

-

Page 7: Table Of Contents

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater TECHNICAL MANUAL OPERATOR AND MAINTENANCE MANUAL REEVES G2 SERIES DECONTAMINATION WATER HEATER TABLE OF CONTENTS WP Sequence No. WARNING SUMMARY HOW TO USE THIS MANUAL CHAPTER 1 – GENERAL INFORMATION, EQUIPMENT DESCRIPTION, AND THEORY OF OPERATION General Information ........................... - Page 8 HOW TO USE THIS MANUAL PURPOSE AND SCOPE This technical manual provides Operator and Maintenance information for the G2 Series Decontamination Water Heater. The information includes equipment description and theory of operation, operator instructions, troubleshooting procedures, maintenance and testing procedures, and supporting data.

-

Page 9: Wp Sequence No

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater Identifying WPs Each WP is identified by a six-digit number. The first four digits are assigned sequentially. The last two digits, if other than 00 (01, 02, 03, etc.), indicate WP revision level. WPs are revised due to equipment configuration differences, support equipment differences, or other similar situations. - Page 10 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater WP CONTENT AND PRESENTATION The content and the presentation techniques used in the WPs vary according to the material covered. Common Features In all cases, the WP title is placed at the top of the page immediately below the manual and WP number and is set off by horizontal lines as shown below.

- Page 11 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater CHAPTER 1 GENERAL INFORMATION REEVES G2 SERIES DECONTAMINATION WATER HEATER Part Number: 1006375 DHS Systems LLC...

-

Page 13: Chapter 1 - General Information, Equipment Description, And Theory Of Operation

Be sure that all damaged parts are replaced and that the mechanical and electrical problems are corrected prior to operation of the unit. If you require service, contact REEVES EMS, Customer Service. Please have the model number and serial number available for all service calls. - Page 14 (c). Wait for water heater to cool down. QUALIFIED PERSONNEL A qualified person is someone who is familiar with this manual, the operation of the G2 Series Decontamination Water Heater, the hazards involved in its operation and maintenance and who has been certified by the Reeves EMS training program.

-

Page 15: Equipment Description And Data

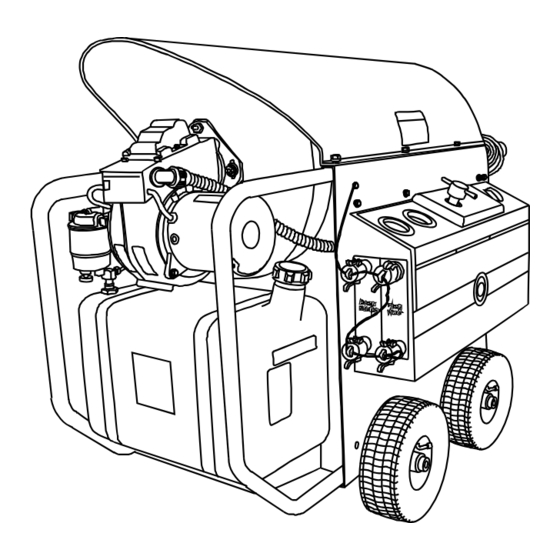

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0002 GENERAL INFORMATION, EQUIPMENT DESCRIPTION, AND THEORY OF OPERATION G2 SERIES DECONTAMINATION WATER HEATER EQUIPMENT DESCRIPTION AND DATA EQUIPMENT CHARACTERISTICS AND CAPABILITIES The G2 /G2-I Decontamination Water Heaters is a man portable, easy to maneuver, four outlet system, with a heating output of 425,000 BTU, capable of supplying multiple showers and sinks with heated water. - Page 16 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0002 Figure 2. G2S / G2S-I Configuration. Table 2. G2S / G2S-I Configuration. ITEM ASSEMBLY FUNCTION G2S Water Heater 165,000 BTU, G2S Water Heater G2S-I 165,000 BTU, G2S-I Water Heater with Decon Solution Injection...

-

Page 17: Theory Of Operation

THEORY OF OPERATION GENERAL The following WP identifies the theory of operation for each model of the G2 Series Decontamination Water Heaters. The G2 Series Water Heaters consists of a self-heating water system with or without mobile Decon injection system designed to connect to a Reeves S and XB Decon Shelter which support various operations. - Page 18 Includes two (2) 35-foot, ½” supply hoses with cam lock fittings that provide heated water and solution to Reeves shower plumbing • Discharge outlets and supply hoses can be factory modified in order to supply heated water to non-Reeves shower systems FEATURES OF INJECTION SYSTEM: •...

- Page 19 WATER HEATERS CONTINUED G2S: The Reeves G2S multi-fuel 165,000 BTU, self-heating water system is portable, easy to maneuver and built for field use. The unit is the ideal way to supply multiple decontamination showers or multiple field showers and sinks with heated water, thus increasing the safety and comfort of both patients and personnel.

- Page 20 Includes two (2) 35-foot, ½” supply hoses with cam lock fittings that provide heated water and solution to Reeves shower plumbing • Discharge outlets and supply hoses can be factory modified in order to supply heated water to non-Reeves shower system FEATURES OF INJECTION SYSTEM: •...

-

Page 21: Chapter 2 - Operator Instructions

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater CHAPTER 2 OPERATOR INSTRUCTIONS REEVES G2 SERIES DECONTAMINATION WATER HEATER Part Number: 1006375 DHS Systems LLC... - Page 23 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0004 OPERATOR INSTRUCTIONS G2 SERIES DECONTAMINATION WATER HEATER DESCRIPTION AND USE OF OPERATOR CONROLS, INDICATORS AND CONNECTIONS GENERAL This work package contains illustrations and tables that describe location and functions used for operation of the G2 Series Decontamination Water Heaters.

- Page 24 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0004 G2 / G2-I WATER HEATER (CONT) Figure 2. G2 / G2-I Water Heater Functions. Part Number: 1006375 0004-2 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be reproduced...

- Page 25 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0004 Table 1. G2 / G2-I Water Heater Functions. CONTROLS, INDICATORS AND ITEM FUNCTION CONNECTIONS On / Off Lever to toggle between Off and Run position (G2-I Bypass Lever (G2-I Only)

- Page 26 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0004 G2S / G2S-I WATER HEATER Figure 3. G2S / G2S-I Water Heater Functions. Part Number: 1006375 0004-4 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be reproduced...

- Page 27 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0004 G2S / G2S-I WATER HEATER (CONT) Figure 4. G2S / G2S-I Water Heater Functions. Part Number: 1006375 0004-5 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be reproduced...

- Page 28 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0004 Table 2. G2S / G2S-I Water Heater Functions. CONTROLS, INDICATORS AND ITEM FUNCTION CONNECTIONS Instructional decal for ease of operation Operation Decal Power Switch w/Indicator Light On / Off Switch with Indicator Light...

-

Page 29: Water Heater Preparation, Set-Up And Pre-Start Procedures

WATER HEATER PREPARATION, SET-UP, AND PRE-START PROCEDURES GENERAL This Work Package details the Water Heater preparation, set-up, and pre-start procedures of the G2 Series Decontamination Water Heater. It also covers information pertaining to ventilation options, power cord connections, extension cords, burner fuel tank, water supply, pressure relief valve, thermostatic stop and check valves and mixing valve. - Page 30 Improper connection of the equipment-grounding conductor can result in a risk of electrocution. Check with a qualified electrician or Reeves EMS, if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug, if it will not fit the outlet; have a proper outlet installed by a qualified electrician.

- Page 31 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0005 POWER CORD CONNECTION (CONT) 6. EXTENSION CORDS: e) USING EXTENSION CORDS IS NOT RECOMMENDED. If an extension cord must be used, it must be plugged into a GFCI found in circuit boxes or protected receptacles. When using an extension cord, consult a qualified electrician to determine the proper wire gauge needed for the length of the extension cord.

- Page 32 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0005 WATER SUPPLY NOTE Always flush water source and water supply hose before attaching supply hose to the water source inlet of the water heater. 1. This system accepts water supply from commercial buildings, standard hydrant, or truck with adequate pressure and flow.

- Page 33 3. Inspect the system for water leaks and fuel leaks. If fuel leak is detected, DO NOT START THE UNIT. Be sure that all damaged parts are replaced and that the mechanical problems are corrected prior to operation of the unit. If you require service, contact Reeves EMS (see WP 0001 for contact information). END OF TASK...

-

Page 35: Flushing The System Procedures

G2 SERIES DECONTAMINATION WATER HEATER FLUSHING THE SYSTEM PROCEDURES GENERAL This Work Package details the procedures for Flushing the System before start-up procedures of the G2 Series Decontamination Water Heater. FLUSHING THE SYSTEM To ensure minimal problems and optimal performance of the G2 Series Decontamination Water Heater, please read this manual carefully and follow all procedures. -

Page 37: G2 Series Start-Up Procedures

G2 SERIES START-UP PROCEDURES GENERAL The following WP details the start-up, hot water operation and solution injector operation (G2-I and G2S-I Water Heater Only) procedures of the G2 Series Decontamination Water Heater. WARNING INCORRECT OPERATION OF THIS WATER HEATER COULD RESULT IN SERIOUS INJURY AND ORDAMAGETO THE EQUIPMENT. -

Page 38: Hot Water Operation Procedures

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0007 HOT WATER OPERATION PROCEDURES NOTE All water heaters have a built-in Anti-Scald Protection device factory pre-set at 110°F. Once the unit has started, perform the following procedures with the temperature control valve open but, in the cold position. - Page 39 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0007 DECON SOLUTION INJECTOR OPERATION (G2-I AND G2S-I WATER HEATER ONLY) NOTE The entire water line down stream from the injector will have chemical solution injected into it. If the chemical solution injected makes the water unsafe to drink, label the water line.

- Page 40 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0007 DECON SOLUTION INJECTOR OPERATION (CONT) CHANGING FEED RATE The feed rate on the injector is adjustable, even while operating and under pressure. Rotate the Ratio Adjustment Sleeve, clockwise (CW) to decrease and counter-clockwise (CCW) to increase (see Figure 1), to change the Decon solution ratio.

- Page 41 G2 SERIES DECONTAMINATION WATER HEATER SHUTDOWN PROCEDURES GENERAL This Work Package details the shutdown procedures for the G2 Series Decontamination Water Heater. SHUTDOWN PROCEDURES To ensure minimal problems, read this manual carefully and follow all procedures. Failure to observe these procedures could result in serious injury or water heater damages.

-

Page 43: Chapter 3 - Operator Troubleshooting

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater CHAPTER 3 OPERATOR TROUBLESHOOTING REEVES G2 SERIES DECONTAMINATION WATER HEATER Part Number: 1006375 DHS Systems LLC... -

Page 45: Operator Troubleshooting Index

Use the corrective action for a given condition/ indication in the order listed. If the first repair attempt is unsuccessful, proceed to the next recommended corrective action to resolve the problem. If a fault is encountered that is not listed or that cannot be corrected by the corrective actions provided, contact Reeves EMS. WARNING To reduce the risk of electrocution, keep all connections dry and off the ground. - Page 46 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0009 Table 1. Operator Troubleshooting Index ITEM CONDITION/ INDICATION MECHANICAL BURNER Burner Motor will not operate WP 0010-2 Burner will not ignite WP 0010-2 Burner Motor will not run WP 0010-3...

- Page 47 Information as to how long the G2 Series Decontamination Water Heater has been operating, what systems were connected, whether any protective equipment or devices functioned, etc., can also help isolate a problem. Note that if in any doubt about how to proceed, contact Reeves EMS before taking action.

- Page 48 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0010 Table 1. Operator Troubleshooting – Mechanical. ITEM CONDITION/INDICATION POSSIBLE MALFUNCTION CORRECTIVE ACTION Burner Motor will not Heater switch is not in “ON” Check the switch position. operate. position. No Voltage to unit Check power source.

- Page 49 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0010 Table 1. Operator Troubleshooting – Mechanical (Cont). ITEM CONDITION/INDICATION POSSIBLE MALFUNCTION CORRECTIVE ACTION Burner will not ignite Dirty or clogged fuel nozzles. Remove and replace with new nozzle. (Cont) (Cont) Check fuel filter and fuel quality.

- Page 50 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0010 Table 1. Operator Troubleshooting – Mechanical (Cont). ITEM CONDITION/INDICATION POSSIBLE MALFUNCTION CORRECTIVE ACTION Burner runs, but will not Poor or improper fuel supply Check fuel type and quality. heat. Drain and clean fuel tank and system if necessary.

- Page 51 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0010 Table 1. Operator Troubleshooting – Mechanical (Cont). ITEM CONDITION/INDICATION POSSIBLE MALFUNCTION CORRECTIVE ACTION Burner discharges black Insufficient or improper air Adjust accordingly to the procedures smoke. supply or adjustment. listed in Maintenance every 3 months.

- Page 52 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0010 Table 1. Operator Troubleshooting – Mechanical (Cont). ITEM CONDITION/INDICATION POSSIBLE MALFUNCTION CORRECTIVE ACTION Fuel leaking from unit. Check fuel tank cap. Tighten fuel tank cap. Fuel tank is over filled.

- Page 53 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0010 Table 1. Operator Troubleshooting – Mechanical (Cont). ITEM CONDITION/INDICATION POSSIBLE MALFUNCTION CORRECTIVE ACTION No Hot Water. No heat or flame. Inspect transformer for proper (Cont) operation: A) 10,000VAC – spring to spring or ¾”...

- Page 54 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0010 Table 1. Operator Troubleshooting – Mechanical (Cont). ITEM CONDITION/INDICATION POSSIBLE MALFUNCTION CORRECTIVE ACTION No Hot Water. No heat or flame. Check the fuel pump. (Cont) A) Inspect the fuel pump coupler for wear (should have 1/8”...

-

Page 55: Chapter 4 - Operator Maintenance Instructions

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater CHAPTER 4 OPERATOR MAINTENANCE INSTRUCTIONS REEVES G2 SERIES DECONTAMINATION WATER HEATER Part Number: 1006375 DHS Systems LLC... -

Page 57: Service Upon Receipt

References WP 0005, WP 0006, WP 0007, WP 0008 GENERAL The following procedures are required to be performed by the operator in order to prepare the G2 Series Decontamination Water Heater and its contents for use. SITE SELECTION To ensure minimal problems with set-up of the G2 Series Decontamination Water Heater and good operation of... -

Page 59: Pmcs Introduction

PMCS INTRODUCTION GENERAL This Work Package provides data necessary to keep the G2 Series Decontamination Water Heater operational ready. PMCS are performed to keep the equipment in operational condition. The checks are used to find, correct, and report problems. Personnel trained on the equipment are required to perform the tasks as indicated in Operator PMCS (WP 0013), Table 1. - Page 61 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0013 OPERATOR MAINTENANCE INSTRUCTIONS G2 SERIES DECONTAMINATION WATER HEATER SERVICE – PMCS INITIAL SETUP: References WP 0005, WP 0006, WP 0007, WP 0008 Table 1. Operator Preventive Maintenance Checks and Service...

- Page 62 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0013 Table 1. Operator Preventive Maintenance Checks and Service (Cont). ITEM TO BE EQUIPMENT NOT ITEM INTERVAL CHECKED PROCEDURE READY/ OR SERVICED AVAILABLE IF: LEAKS BEFORE Fuel Leak Visually inspect for fuel leaks. Tighten if...

- Page 63 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0013 Table 1. Operator Preventive Maintenance Checks and Service (Cont). ITEM TO BE EQUIPMENT NOT ITEM INTERVAL CHECKED PROCEDURE READY/ OR SERVICED AVAILABLE IF: INJECTOR ASSY (G2-I AND G2S-I Only) BEFORE...

- Page 64 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0013 Table 1. Operator Preventive Maintenance Checks and Service (Cont). ITEM TO BE EQUIPMENT NOT ITEM INTERVAL CHECKED PROCEDURE READY/ OR SERVICED AVAILABLE IF: GAUGES 3 MONTH Test fuel Verify fuel pressure gauge operates...

- Page 65 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0013 CAUTION The items listed in the following table must be performed after each use for the G2-I and G2S-I Decontamination Water Heater ONLY. Table 2. Operator Functional Services. ITEM TO BE...

-

Page 67: G2 / G2-I Equipment Maintenance Procedures

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 OPERATOR MAINTENANCE INSTRUCTIONS G2 SERIES DECONTAMINATION WATER HEATER G2 / G2-I EQUIPMENT MAINTENANCE PROCEDURES GENERAL This work package provides information needed by the Operator when performing the following services to the G2 / G2-I Decontamination Water Heater. - Page 68 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE BURNER MOTOR ASSEMBLY PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Splined Wrench or Socket Materials/Parts Equipment Condition Drain Pan or Bucket...

- Page 69 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVAL OF THE BURNER MOTOR ASSEMBLY (CONT): b. Using a ¼” open end wrench, loosen and remove escutcheon plate mount screw and escutcheon plate. c. Remove the nozzle and electrode assembly from the air tube, being careful not to damage the electrodes or insulators while handling.

- Page 70 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 INSTALLATION OF THE BURNER MOTOR ASSEMBLY (CONT): c. Install the escutcheon plate and mount screw hand tight. d. Line up the index mark made during the removal of the nozzle assembly.

- Page 71 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 BURNER AIR ADJUSTMENT MAINTENANCE PROCEDURES PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Smoke Spot Tester (If Available) Materials/Parts Equipment Condition Equipment Powered Down...

- Page 72 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 BURNER AIR ADJUSTMENT MAINTENANCE PROCEDURES (CONT): 5. Open the air shutter by two increments. (Example – if air shutter was set at 2, then move it to 4). 6. Repeat steps 3 - 5 until a smoke puff is noticed.

- Page 73 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE FUEL PUMP/SOLENOID PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools References General Mechanics Tool Kit Materials/Parts Equipment Condition Waste Fuel Container Equipment Powered Down Rags Power Source Disconnected...

- Page 74 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 INSTALLATION OF FUEL PUMP/SOLENOID: 2. Installing the fuel pump/solenoid as follows: a. Install fuel pump/solenoid assembly into burner motor housing. b. Loosely thread (2) mount bolts into the fuel pump housing; do not tighten at this time.

- Page 75 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE FUEL PUMP FLEXIBLE COUPLING PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools References General Mechanics Tool Kit Materials/Parts Equipment Condition Drain Pan or Bucket Equipment Powered Down...

- Page 76 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 INSTALLATION OF FLEXIBLE COUPLING; 2. Install the fuel pump/solenoid as follows: a. Slide the flexible coupling onto the fuel pump/solenoid shaft. b. Install fuel pump/solenoid assembly into burner motor housing.

- Page 77 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE ELECTRONIC IGNITER ASSEMBLY PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Equipment Powered Down Power Source Disconnected REMOVAL OF THE ELECTRONIC IGNITER ASSEMBLY: 1.

- Page 78 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 INSTALLATION OF THE ELECTRONIC IGNITER ASSEMBLY (CONT): h. Reinstall the electronic igniter and base plate assembly; ensure the igniter springs are contacting the electrodes tangs and electrical wires are not pinched.

- Page 79 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE FUEL NOZZLE AND ELECTRODE ASSEMBLY PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Clean White Lint Free Cloth Torque Wrench...

- Page 80 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE FUEL NOZZLE (CONT): NOTE Use care to avoid bending the electrodes. c. Insert the new fuel nozzle into the nozzle adapter and finger tight. d. Using a ¾” open end wrench, hold the nozzle adapter; using a 5/8” open end wrench securely tighten the nozzle (torque to 90 inch pounds).

- Page 81 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 INSTALLATION OF THE FUEL NOZZLE AND ELECTRODE ASSEMBLY (CONT): Install and tighten splined nut using a splined wrench. g. Using a 7/16” open end wrench, reconnect and tighten the fuel nozzle tube B-nut.

- Page 82 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE FUEL TANK ASSEMBLY PROCEDURES PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Waste Fuel Container or Equivalent...

- Page 83 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE FUEL FILTER/WATER SEPARATOR PROCEDURES PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Waste Fuel Container or Equivalent...

- Page 84 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE DECON SOLUTION TANK STRAINER (G2-I WATER HEATER ONLY) INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Clean Water Equipment Powered Down...

- Page 85 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 INJECTOR MAINTENANCE PROCEDURES (G2-I WATER HEATER ONLY) INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Chlorine Bleach Equipment Powered Down Power Source Disconnected...

- Page 86 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 REMOVE AND REPLACE POWER SWITCH PROCEDURES PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Equipment Powered Down Power Source Disconnected REMOVAL OF POWER SWITCH: 1.

- Page 87 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 INSTALLATION OF POWER SWITCH (CONT): c. Raise control panel and keep pressure against the panel while installing the mount bolts. d. Using a 7/16” open end wrench, install and tighten (4) bolts, (4) lock washers and (4) flat washers.

- Page 88 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0014 SEASONAL MAINTENANCE PROCEDURES INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Equipment Powered Down Power Source Disconnected WINTERIZING THE G2 / G2S-I WATER HEATER For storage and transportation purposes in subfreezing ambient temperatures, it will be necessary to winterize the water heater.

-

Page 89: G2S / G2S-I Equipment Maintenance Procedures

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 OPERATOR MAINTENANCE INSTRUCTIONS G2 SERIES DECONTAMINATION WATER HEATER G2S / G2S-I EQUIPMENT MAINTENANCE PROCEDURES WORK INPROGRESS GENERAL This work package provides information needed by the Operator when performing the following services to the G2S / G2S-I Decontamination Water Heater. - Page 90 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE BURNER MOTOR ASSEMBLY WORK INPROGRESS PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Splined Wrench or Socket Materials/Parts Equipment Condition...

- Page 91 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVAL OF THE BURNER MOTOR ASSEMBLY (CONT): b. Using a ¼” open end wrench, loosen and remove escutcheon plate mount screw and escutcheon plate. c. Remove the nozzle and electrode assembly from the air tube, being careful not to damage the electrodes or insulators while handling.

- Page 92 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 INSTALLATION OF THE BURNER MOTOR ASSEMBLY (CONT): c. Install the escutcheon plate and mount screw hand tight. d. Line up the index mark made during the removal of the nozzle assembly.

- Page 93 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 BURNER AIR ADJUSTMENT MAINTENANCE PROCEDURES WORK INPROGRESS PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Smoke Spot Tester (If Available) Materials/Parts Equipment Condition...

- Page 94 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 BURNER AIR ADJUSTMENT MAINTENANCE PROCEDURES (CONT): 5. Open the air shutter by two increments. (Example – if air shutter was set at 2, then move it to 4). 6. Repeat steps 3 - 5 until a smoke puff is noticed.

- Page 95 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE FUEL PUMP/SOLENOID WORK INPROGRESS PROCEDURES REQUIRE VERIFICTAION INITIAL SETUP: Tools and Special Tools References General Mechanics Tool Kit Materials/Parts Equipment Condition Waste Fuel Container Equipment Powered Down...

- Page 96 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 INSTALLATION OF FUEL PUMP/SOLENOID: 2. Installing the fuel pump/solenoid as follows: a. Install fuel pump/solenoid assembly into burner motor housing. b. Loosely thread (2) mount bolts into the fuel pump housing; do not tighten at this time.

- Page 97 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE FUEL PUMP FLEXIBLE COUPLING WORK INPROGRESS PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools References General Mechanics Tool Kit Materials/Parts Equipment Condition Drain Pan or Bucket...

- Page 98 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 INSTALLATION OF FLEXIBLE COUPLING; 2. Install the fuel pump/solenoid as follows: a. Slide the flexible coupling onto the fuel pump/solenoid shaft. b. Install fuel pump/solenoid assembly into burner motor housing.

- Page 99 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE ELECTRONIC IGNITER ASSEMBLY WORK INPROGRESS PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Equipment Powered Down Power Source Disconnected REMOVAL OF THE ELECTRONIC IGNITER ASSEMBLY: 1.

- Page 100 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 INSTALLATION OF THE ELECTRONIC IGNITER ASSEMBLY (CONT): h. Reinstall the electronic igniter and base plate assembly; ensure the igniter springs are contacting the electrodes tangs and electrical wires are not pinched.

- Page 101 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE FUEL NOZZLE AND ELECTRODE ASSEMBLY WORK INPROGRESS PROCEDURES REQUIRE VERIFCATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Clean White Lint Free Cloth...

- Page 102 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE FUEL NOZZLE (CONT): NOTE Use care to avoid bending the electrodes. c. Insert the new fuel nozzle into the nozzle adapter and finger tight. d. Using a ¾” open end wrench, hold the nozzle adapter; using a 5/8” open end wrench securely tighten the nozzle (torque to 90 inch pounds).

- Page 103 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 INSTALLATION OF THE FUEL NOZZLE AND ELECTRODE ASSEMBLY (CONT): Install and tighten splined nut using a splined wrench. g. Using a 7/16” open end wrench, reconnect and tighten the fuel nozzle tube B-nut.

- Page 104 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE FUEL TANK ASSEMBLY PROCEDURES WORK INPROGRESS PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Waste Fuel Container or Equivalent...

- Page 105 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE FUEL FILTER/WATER SEPARATOR PROCEDURES PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Waste Fuel Container or Equivalent...

- Page 106 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 INSPECTION AND CLEANING SUCTION TUBE SCREEN PROCEDURES (G2S-I ONLY) PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Clean Water Equipment Powered Down...

- Page 107 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 INJECTOR MAINTENANCE PROCEDURES (G2S-I ONLY) INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Chlorine Bleach Equipment Powered Down Power Source Disconnected NOTE The following maintenance procedures should be performed after each use of the Injector Assembly with a Decon solution.

- Page 108 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 REMOVE AND REPLACE POWER SWITCH PROCEDURES PROCEDURES REQUIRE VERIFICATION INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Equipment Powered Down Power Source Disconnected REMOVAL OF POWER SWITCH: 1.

- Page 109 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 INSTALLATION OF POWER SWITCH (CONT): c. Raise control panel and keep pressure against the panel while installing the mount bolts. d. Using a 7/16” open end wrench, install and tighten (4) bolts, (4) lock washers and (4) flat washers.

- Page 110 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0015 SEASONAL MAINTENANCE PROCEDURES INITIAL SETUP: Tools and Special Tools Personnel Required General Mechanics Tool Kit Materials/Parts Equipment Condition Equipment Powered Down Power Source Disconnected WINTERIZING THE G2S / G2S-I WATER HEATER For storage and transportation purposes in subfreezing ambient temperatures, it will be necessary to winterize the water heater.

-

Page 111: Chapter 5 - Destruction Of Equipment

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater CHAPTER 5 DESTRUCTION OF EQUIPMENT REEVES G2 SERIES DECONTAMINATION WATER HEATER Part Number: 1006375 DHS Systems LLC... - Page 113 Built-in self-destruction devices should be set off even if the major item containing equipment with self-destruction devices is to be destroyed. These devices should be permitted to do their work at least partially before incendiaries or explosives (especially the latter) are set off. Currently, the G2 Series Decontamination Water Heater contains no built-in self-destruction devices.

- Page 114 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0016 DEMOLITION (EXPLOSIVES) Explosives refer to TNT, plastic explosives, as well as fragmentation grenades. Explosives are most effective against structures and components which will not burn, or are too heavy or too strong to be easily demolished by mechanical means.

-

Page 115: Destruction Procedures

G2 SERIES DECONTAMINATION WATER HEATER DESTRUCTION PROCEDURES SCOPE This work package is for guidance of those whose duty it is to render inoperable or destroy the G2 Series Decontamination Water Heater which is in imminent danger of capture by an enemy. METHOD OF DESTRUCTION Command decision, according to the tactical situation will determine when the using organization is to destroy a G2 Series Decontamination Water Heater. -

Page 117: Chapter 6 - Illustrated Parts Breakdown (Ipb)

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater CHAPTER 6 ILLUSTRATED PARTS BREAKDOWN REEVES G2 SERIES DECONTAMINATION WATER HEATER Part Number: 1006375 DHS Systems LLC... - Page 119 The following WP identifies the G2 and G2-I Water Heaters Illustrated Parts Breakdown (IPB) and Spare Parts Lists. The G2 Series Water Heaters consists of a self-heating water system with or without mobile Decon injection system designed to connect to a Reeves S and XB Decon Shelter which support various operations.

- Page 120 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I ILLUSTRATED PARTS BREAKDOWN & SPARE PARTS LISTS G2 / G2-I FRESH WATER INLET SUBASSEMBLY (COIL) TO BURNER HEATER CHAMBER TO REGULATOR FRESH WATER INLET 25 24 Laynard attaches...

- Page 121 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 2. G2 / G2-I Fresh Water Inlet Subassembly. National Illus Part Stock Description Number Number Number RD30025F Adapter, Copper 1 ½”C x FIP RD30020F Reducer, FTG, 1-1/2” x ¾” FTC-C RD30001P* Tube, Copper ¾”dia x 6”L...

- Page 122 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I FRESH WATER OUTLET SUBASSEMBLY FROM REGULATOR FRESH WATER OUTLET TO SHOWER TO INJECTOR INLET FRESH WATER OUTLET TO SHOWER Figure 3. G2 / G2-I Fresh Water Outlet Subassembly.

- Page 123 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 3. G2 / G2-I Fresh Water Outlet Subassembly. National Illus Part Stock Description Number Number Number RD30005F Elbow, Copper, ¾” C – FTG, 90° RD30030F Fitting, Tee, Copper ¾”...

- Page 124 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I HOT WATER SUBASSEMBLY FROM COIL OUTLET TO REGULATOR Figure 4. G2 / G2-I Hot Water Subassembly. Part Number: 1006375 0018-6 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 125 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 4. G2 / G2-I Hot Water Subassembly. National Illus Part Stock Description Number Number Number RD30075F Pipe, Nipple, Brass (Threaded) ¾” x 4”L RD30045F Elbow, Brass 5/8” x ¾” FL - FIP RD30001H Hose, Gas 16”...

- Page 126 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I CONTROL PANEL SUBASSEMBLY P/O 10 P/O 12 P/O 12 Figure 5. G2 / G2-I Control Panel Subassembly. Part Number: 1006375 0018-8 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 127 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 5. G2 / G2-I Control Panel Subassembly. National Illus Stock Part Number Description Number Number RDSA2100 Assembly, Control Panel Complete 1008105 Knob, Handle (Incl Mounting Screw), Brass RD300485 Screw, Phil Flat Hd, 10-24 x ¾”L, SS...

- Page 128 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I TEMPERATURE (MIXING VALVE) ASSEMBLY P/O 1 P/O 1 IN FROM IN FROM COIL OUTLET FRESH WATER SUPPLY TO INJECTOR INLET Figure 6. G2 / G2-I Temperature (Mixing Valve) Assembly.

- Page 129 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 6. G2 / G2-I Temperature (Mixing Valve) Assembly. National Illus Part Stock Description Number Number Number RD300050 Valve, Mixing 3500 1009669 Stop, Check, Straight 3/4” Rough Bronze RD30010F Adapter, Copper ¾” FTG-MIP...

- Page 130 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I FUEL FILTER / WATER SEPARATOR ASSEMBLY P/O 1 P/O 2 P/O 2 Figure 7. G2 / G2-I Fuel Filter / Water Separator Assembly. Part Number: 1006375 0018-12 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers.

- Page 131 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 7. G2 / G2-I Fuel Filter / Water Separator Assembly. National Illus Part Stock Description Number Number Number 1007414 Assembly, Fuel Filter/Water Separator RDSP0150 Filter, Fuel (Incl both O-rings)

- Page 132 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I FUEL TANK ASSEMBLY To Fuel Pump To Fuel Filter Figure 8. G2 / G2-I Fuel Tank Assembly. Part Number: 1006375 0018-14 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 133 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 8. G2 / G2-I Fuel Tank Assembly. National Illus Part Stock Description Number Number Number 1007410 Cap, Vented Fuel 1007411 Tank, Fuel 10 Gallon 1007412 Strap, Fuel Tank, Metal 1001792 Screw, Cap, Hex Hd, ¼-20 x 1-1/2”L...

- Page 134 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I BRAKE & WHEEL ASSEMBLY P/O 3 Figure 9. G2 / G2-I Brake and Wheel Assembly. Part Number: 1006375 0018-16 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 135 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 9. G2 / G2-I Brake and Wheel Assembly. National Illus Part Stock Description Number Number Number 1005858 Nut, Lock, Nylon Insert, ¼-20 1005374 Washer, Flat, ¼” RDSP0325 Brake Assembly RD300150 Screw, Cap, Hex Hd, ¼-20 x ¾”L...

- Page 136 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I BURNER MOTOR ASSEMBLY *NOTE: Complete Assembly Excludes #18,19,20,27,28,29 P/O 4 To fuel tank Figure 10. G2 / G2-I Burner Motor Assembly. Part Number: 1006375 0018-18 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers.

- Page 137 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 10. G2 / G2-I Burner Motor Assembly. National Illus Part Stock Description Number Number Number Assembly, Burner Motor Complete (Excludes #18, 19, RDSP0145 20, 27, 28 and 29) RDSP0334...

- Page 138 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2-I DECON SOLUTION SUBASSEMBLY TO DECON OUTLET TO SHOWER FROM INJECTOR OUTLET TO DECON OUTLET TO SHOWER Figure 11. G2-I Decon Solution Subassembly. Part Number: 1006375 0018-20 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers.

- Page 139 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 11. G2-I Decon Solution Subassembly. National Illus Part Stock Description Number Number Number RD30060F Adapter, Steel, 5/8” x ¾” FL-FIP RD30010F Adapter, Copper, ¾” FTG-MIP RD30030F Fitting, Tee, Copper, ¾”...

- Page 140 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2-I INJECTOR ASSEMBLY Fig. 3 TO DECON FROM FRESH SOLUTION WATER OUTLET OUTLET Figure 12. G2-I Injector Assembly. Part Number: 1006375 0018-22 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 141 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 12. G2-I Injector Assembly. National Illus Part Stock Description Number Number Number RDSA2015 Assembly, Injector, MiniDos 10 RD30045F Elbow, Brass, 5/8” x ¾” FL-FIP RD30015H Hose, Gas 34” 1009779 Hose, Suction, ½”dia x 5’...

- Page 142 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2-I INJECTOR INLET T-STRAINER / FILTER ASSEMBLY Figure 13. G2-I Injector Inlet Filter (T-Strainer) Assembly. Part Number: 1006375 0018-24 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 143 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 13. G2-I Injector Inlet Filter (T-Strainer) Assembly. National Illus Part Stock Description Number Number Number RD30005 Assembly, Filter Water Banjo, w/100 Mesh Screen 1009769 Head, T-Strainer 1009770 Screen, Mesh 100...

- Page 144 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2-I MINIDOS INJECTOR SUBASSEMBLY NOTE: Old Style Bypass Lever includes Pin. If Replacement Is Needed, Must Order Items #1, #2, and #3. Figure 14. G2-I MiniDos Injector Subassembly. Part Number: 1006375...

- Page 145 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 14. G2-I MiniDos Injector Subassembly. National Illus Part Stock Description Number Number Number 1009777 Ring, Locking, Cotter 1009780 Lever, Bypass, On / Off 1009781 Pin, Upper Shaft (for Bypass Lever)

- Page 146 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2-I DECON SOLUTION TANK ASSEMBLY P/O 1 P/O 1 Figure 15. G2-I Decon Solution Tank Assembly. Part Number: 1006375 0018-28 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 147 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 15. G2-I Decon Solution Tank Assembly. National Illus Part Stock Description Number Number Number Assembly, Tank Solution (includes gauge and in-line RD300070 filter) RD30175Q Coupler, 3/8”MIP, Quick Connect Gauge, Decon Solution, 2-1/4” Threaded Cap w/8”...

- Page 148 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I OPTIONAL EXHAUST STACK P/O 1 Figure 16. Optional Exhaust Stack. Part Number: 1006375 0018-30 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 149 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 Table 16. Optional Exhaust Stack. National Illus Stock Part Number Description Number Number RDSP0081 Adapter, Stack, Exhaust, G2 Heater 5310-01-525-0177 HW903-6012-1 Washer, Flat, 13/64”ID (for #10 Screw) Screw, Phil Rd Hd, 10-32 x ¾”L, Steel, Z-...

- Page 150 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 THIS PAGE INTETIONALLY LEFT BLANK Part Number: 1006375 0018-32 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 151 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0018 G2 / G2-I WATER HEATER WIRING SCHEMATIC Figure 17. G2 / G2-I Wiring Schematic. END OF WORK PACKAGE Part Number: 1006375 0018-33/34 blank DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 153 The following WP identifies the G2S and G2S-I Water Heaters Illustrated Parts Breakdown (IPB) and Spare Parts Lists. The G2S Series Water Heaters is a smaller version of the G2 Series Water Heater. The G2S / G2S-I consists of a self-heating water system with or without mobile Decon injection system designed to connect to a Reeves S and XB Decon Shelter which support various operations.

- Page 154 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S / G2S-I ILLUSTRATED PARTS BREAKDOWN & SPARE PARTS LISTS G2S / G2S-I FRESH WATER INLET SUBASSEMBLY TO REGULATOR TO COMBUSTION CHAMBER 9 10 FRESH WATER INLET Laynard attaches to Fuel Tank mount bolt Figure 2.

-

Page 155: Rd30005F Elbow, Copper ¾" C - Ftg

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 2. G2S / G2S-I Fresh Water Inlet Subassembly. National Illus Part Stock Description Number Number Number RD30001H Hose, Gas, 16”L RD300060 Gauge, Pressure 2”dia RD30455F Elbow, Brass, ¼” FL-FIP, ¼”... - Page 156 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S FRESH WATER OUTLET SUBASSEMBLY TO FRESH WATER OUTLET (28" HOSE) TO FRESH WATER OUTLET Figure 3. G2S Fresh Water Outlet Subassembly. Part Number: 1006375 0019-4 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

-

Page 157: Rd30050F Ea

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 3. G2S Fresh Water Outlet Subassembly. National Illus Part Stock Description Number Number Number RD30010H Hose, Gas, 28”L RD30060F Adapter, Steel, 5/8” x ¾”, FL-FIP RD30010F Adapter, Copper ¾” FTG - MIP RD30030F Fitting, Tee, Copper ¾”... - Page 158 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S / G2S-I TEMPERATURE (MIXING VALVE) ASSEMBLY P/O 1 P/O 1 IN FROM IN FROM COIL OUTLET FRESH WATER SUPPLY Figure 4. Temperature (Mixing Valve) Assembly. Part Number: 1006375 0019-6 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers.

- Page 159 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 4. Temperature (Mixing Valve) Assembly National Illus Part Stock Description Number Number Number RD300050 Valve, Mixing 3500 1009669 Stop, Check, Straight ½” Rough Bronze RD30010F Adapter, Copper ¾” FTG-MIP...

- Page 160 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S / G2S-I CONTROL PANEL 3, 4, 5 Figure 5. G2S / G2S-I Control Panel Part Number: 1006375 0019-8 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 161 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 5. G2S / G2S-I Control Panel National Illus Stock Part Number Description Number Number RDSP0155 Switch, Power, Rocker 1009768 Screw, Cap, Flange Hex Hd, M6-1.00 x 20mm RDSP0210 Cord, Power, Electric with GFCI, 120V, 15A...

- Page 162 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S / G2S-I FUEL TANK & FUEL FILTER / WATER SEPARATOR ASSEMBLY P/O 2 P/O 1 P/O 2 Figure 6. G2S / G2S-I Fuel Tank and Fuel Filter / Water Separator Assembly.

- Page 163 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 6. G2S / G2S-I Fuel Tank and Fuel Filter / Water Separator Assembly. National Illus Part Stock Description Number Number Number 1007414 Assembly, Fuel Filter/Water Separator RDSP0150 Filter, Fuel (Incl both O-rings)

- Page 164 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S / G2S-I BRAKE AND WHEEL ASSEMBLY Figure 7. G2S / G2S-I Brake and Wheel Assembly. Part Number: 1006375 0019-12 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 165 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 7. G2S / G2S-I Brake and Wheel Assembly. National Illus Part Stock Description Number Number Number 1009789 Grip-Handle RDSP0245 Handle, Brake, (Painted) 1009790 Screw, Cap, Hex Hd, 5/16-18 x 1-1/4”L Gr5 1009791 Washer, Flat, SAE, 5/16”...

- Page 166 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S / G2S-I BURNER MOTOR ASSEMBLY 29 RESERVED. Return to Fuel Tank From Fuel Tank Figure 8. G2S / G2S-I Burner Motor Assembly. Part Number: 1006375 0019-14 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers.

- Page 167 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 8. G2S / G2S-I Burner Motor Assembly National Illus Part Stock Description Number Number Number 1009800 Assy, Fuel Hose ¼” ID x 13” L (Fuel Pump to Tank or...

- Page 168 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S-I FRESH WATER OUTLET SUBASSEMBLY TO INJECTOR INLET FILTER (22" HOSE) TO FRESH WATER OUTLET Figure 9. G2S-I Fresh Water Outlet Subassembly. Part Number: 1006375 0019-16 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

-

Page 169: Rd30015F Ea

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 9. G2S-I Fresh Water Outlet Subassembly. National Illus Part Stock Description Number Number Number RD30005H Hose, Gas, 22”L RD30060F Adapter, Steel, 5/8” x ¾”, FL-FIP RD30010F Adapter, Copper ¾” FTG - MIP RD30030F Fitting, Tee, Copper ¾”... - Page 170 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S-I DECON SOLUTION SUBASSEMBLY Figure 10. G2S-I Decon Solution Subassembly. Part Number: 1006375 0019-18 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

-

Page 171: Rd30045F

Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 10. G2S-I Decon Solution Subassembly. National Illus Part Stock Description Number Number Number RD30045F Elbow, 5/8” x ¾” FL – FIP, Brass RD30010H Hose, Gas, 28” RD30060F Adapter, Steel, 5/8” x ¾” FTG-MIP RD30010F Adapter, Copper, ¾”... - Page 172 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S-I INJECTOR ASSEMBLY Fig. 3 INLET OUTL ET TO DECON FROM FRESH SOLUTION WATER OUTLET OUTLET Figure 11. G2S-I Injector Assembly. Part Number: 1006375 0019-20 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 173 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 11. G2S-I Injector Assembly. National Illus Part Stock Description Number Number Number RDSA2015 Assembly, Injector, MiniDos 10 RD30070F Pipe, Nipple, PVC80, ¾” Close RD30045F Elbow, Brass, 5/8” x ¾” FL-FIP RD30015H Hose, Gas 34”...

- Page 174 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S-I INJECTOR INLET FILTER (T-STRAINER) ASSEMBLY Figure 12. G2S-I Injector Inlet Filter (T-Strainer) Assembly. Part Number: 1006375 0019-22 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 175 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 12. G2S-I Injector Inlet Filter (T-Strainer) Assembly. National Illus Part Stock Description Number Number Number RD300005 Assembly, Filter Water Banjo, w/100 Mesh Screen 1009769 Head, T-Strainer 1009770 Screen, Mesh 100...

- Page 176 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S-I MINIDOS INJECTOR REPLACEMENT PARTS NOTE: Old Style Bypass Lever includes Pin. If Replacement Is Needed, Must Order Items #1, #2, and #3. Figure 13. G2S-I MiniDos Injector Replacement Parts.

- Page 177 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 Table 13. G2S-I MiniDos Injector Replacement Parts. National Illus Part Stock Description Number Number Number 1009777 Ring, Locking, Cotter 1009780 Lever, Bypass, On / Off 1009781 Pin, Upper Shaft (for Bypass Lever)

- Page 178 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 THIS PAGE INTENTIONALLY LEFT BLANK Part Number: 1006375 0019-26 DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 179 Operation & Maintenance w/IPB G2 Series Decontamination Water Heater 0019 G2S / G2S-I WIRING SCHEMATIC Figure 14. G2S / G2S-I Wiring Schematic. END OF WORK PACKAGE Part Number: 1006375 0019-27/28 blank DHS Systems LLC This document contains information proprietary to DHS Systems LLC and is intended solely for use by its customers. No portion of this document may be...

- Page 181 DHS SYSTEMS LLC LIMITED WARRANTY Effective As Of January 1, 2011 ® DHS Systems LLC provides a limited warranty that all DRASH (Deployable Rapid Assembly Shelter) products shall be free from defects in materials and workmanship for the period of time shown in the Warranty Schedule below. This warranty shall be for the benefit of the original purchaser and shall inure to the benefit of any additional end users of the product, shall begin on the date of shipment to the original purchaser and extend for the period of time shown in the Warranty Schedule set forth below (but in no event in...

- Page 182 Any warranty claims must be filed with DHS Systems LLC within 90 days after the alleged defect has first been identified. All claims must be mailed or faxed to the following: DHS SYSTEMS LLC 33 Kings Highway Orangeburg, NY 10962-1802 Attn: Customer Service, Logistics Phone: 845-359-6066 Fax: 845-365-2114 email: drash@drash.com...

Need help?

Do you have a question about the G2 series and is the answer not in the manual?

Questions and answers