Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

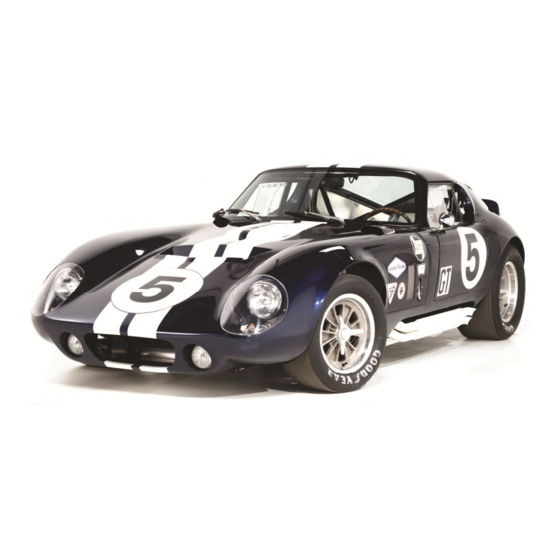

Summary of Contents for Factory Five Racing Type 65 Coupe

- Page 1 R E V I S I O N 3 J , A P R I L 2 0 1 3...

- Page 2 2013 Factory Five Racing Inc. 9 Tow Rd Wareham, MA 02571 Phone 508.291.3443 • Fax 508.291.3883...

-

Page 3: Table Of Contents

Table of Contents General Information ..................11 Foreword ......................11 Safety Notice ...................... 14 Safety Tips......................15 How to use This Book ..................16 What You Get ..................... 16 What You Need ....................17 Major Components ....................... 17 Serial Number Identification................19 Tools List ...................... - Page 4 Exhaust ........................35 Engine Removal ......................35 Front Suspension ......................36 Fuel Tank ........................37 Rear End ........................38 Fuel filter and connectors....................39 Donor Part Preparation ..................39 Rear Coil Springs ......................39 Solid Axle ........................40 Front Lower Control Arms ..................... 42 Fuel Filter Fittings ......................

- Page 5 Front Brakes ....................... 73 Donor Front Brakes ...................... 73 Complete kit Front Brakes .................... 73 Solid Axle Rear Suspension ................82 Spring Perch mounts ....................86 4 Link Rear Suspension ....................87 Optional 3 Link Rear Suspension .................. 87 Rear Axle installation ....................91 Optional Rear Coil-Over Shock Assembly ..............

- Page 6 Driver Floor ........................ 167 U-Joint Cover ......................168 Transmission Tunnel rear corners ................169 Cockpit rear wall ......................169 Cockpit rear corners ....................170 Fuel System...................... 170 Fuel Tank ........................170 Fuel Filter ........................174 Fuel Lines........................175 Brake System ....................179 Manual Brake Master Cylinder and pushrod..............

- Page 7 Fuel Injected application ..................... 217 Carbureted applications ....................218 Mass air meter, Air filter and Intake hose ............219 Engine Ground ....................219 Fuel Vapor Canister ..................220 Cooling System ....................221 Fan Mounting ......................221 Radiator Mounting ...................... 223 Radiator Aluminum .....................

- Page 8 Hood Latch ......................... 273 Nose Mounting ....................277 Hinge ......................... 277 Nose Side Locator Brackets..................282 Scoops ......................283 Rear Spoiler...................... 285 Radiator Aluminum ................... 286 Exhaust ......................289 Headers ........................289 Side Exhaust ......................290 Windshield area ....................291 Doors ........................

- Page 9 Fuel Filler Neck ....................342 Nose mounting ......................345 Door final fit ...................... 346 Hinge ......................... 346 Door Weather-Stripping ....................346 Door ........................... 347 Handles ........................348 Under door aluminum ..................348 Rear front splash guards .................. 349 Headlight/Turn signal wiring ................350 License Plate Light and Bracket ...............

- Page 10 Fuel Injectors ......................392 Upper Intake ....................... 392 Heads......................... 392 Cams ......................... 392 Headers ........................392 Timing ........................393 Under-drive Pulleys ....................393 Oil Cooler ........................393 Bellhousing ......................... 393 High Horsepower Transmissions ................394 Steering Rack ......................394 Spindles ........................394 Rear Suspension ......................

- Page 11 Engine ........................432 Transmission ......................432 Rear Axle Ratio ......................432 Front brakes ....................... 433 Rear Brakes ....................... 433 Master cylinder ......................433 Starter ........................433 Driveshaft ........................433 Clutch Cable, Quadrant ....................434 Speedometer cable ....................434 Mass Air Sensor ......................434 Oxygen Sensors ......................

-

Page 12: General Information

Chapter General Information Foreword f you are reading this, you are embarking on a mission to build your own car, or at least considering doing so. I wanted to share with you some of my experiences and lessons learned while working with literally thousands of people who have completed this... - Page 13 part of the very definition of always trying to go faster. The late Carroll Smith wrote something I really loved that speaks to this point. “There is no magic! The one basic truth of successful racecar preparation bears repeating. There is no magic. There is only logic, common sense, forethought, vast amounts of hard work, and a fanatic dedication to the task at hand”.

- Page 14 You will join a community of others who have earned their own… and THAT is the story of Factory Five Racing and that is what awaits you in this process.

-

Page 15: Safety Notice

If, while building, driving or racing this Factory Five Racing kit, should you become injured or die, it will be the result of your own conscious decision and we at Factory Five Racing, Inc., disclaim any responsibility of any kind. -

Page 16: Safety Tips

Safety Tips Read the manual. It is at least a good guide and place to start. Don’t take short cuts. Before starting work, make sure you have the proper tools, the required parts, and sufficient space for the job. -

Page 17: How To Use This Book

How to use This Book This Assembly manual is intended to help you build your Factory Five Kit. This book will not explain such things as engine or transmission building. A secondary purpose of this book is to use it as reference for owners that want to do maintenance work on their cars or for those that purchase finished cars, to understand their cars better. -

Page 18: What You Need

Engine/Exhaust parts: Kit comes with alternate drive pulley assembly, oil filter relocate kit, and exhaust assembly to adapt Mustang engine and headers to vintage side exit exhausts. Gauges and Dash and Electrical Assembly: Kit parts are included to adapt the Mustang wiring harness. - Page 19 Rear End: 1987-1998 Ford 8.8” rear axle. 1987-1993 width is optimal Paint: Most customers will send out the body and paint work to a professional body shop. Steering Rack: 1987-2004 Ford Mustang. Fuel tank/pump and filter: 1987-2004 Ford Mustang. Electrical: 1987-1993 Ford Mustang chassis and EFI harnesses with sensors, computer, ignition switch and turn signal stalk.

-

Page 20: Serial Number Identification

Serial Number Identification Factory Five Racing has included a Certificate of Origin along with a Nameplate for your kit. The serial number from the Certificate of Origin matches the number engraved on the 2”x 2” tube going across the car at the front of the cockpit. Below is an example of how the nameplate looks. The VIN number space is provided so that your state issued VIN number can be engraved if you so desire. -

Page 21: Tools List

Tools List The following lists detail the tools and supplies that are needed to build your kit. The “helpful” items are not crucial to the assembly but make life easier. Home Depot HUSKY®, Sears CRAFTSMAN®, and Snap-On tools are all guaranteed for life and we’ve found them to be more reliable over discount tools. -

Page 22: Required Supplies

Required Supplies Stick with name brand products like Eastwood, 3M, and Duplicolor. The Eastwood brand coatings are great for bringing weathered and oxidized parts up to show quality. PPG brand and DuPont brand paints are excellent. Engine degreaser Silicone Door and window sealant, GE Silicone II or equivalent - 4 tubes Coolant –... -

Page 23: Donor Parts And Prep

Chapter Donor Parts and Prep www.factoryfive.com 508-291-3443... -

Page 24: The 5.0L Mustang

This chapter deals with the Mustang parts needed in addition to our kit. Many people choose to use parts from a single Mustang donor. If you are not going to use a donor car but choose to acquire parts separately, this section may still be useful. The complete list of parts required to build the FFR Coupe is included in the Appendix of this manual. -

Page 25: Donor Parts Selection Tips

Donor Parts Selection Tips 87-93 Mustang The following are a few tips we’ve picked up over the years when dealing with used parts. In addition to the parts that come with the kit, you have to provide the running gear and some other parts that can be taken directly off a 1987-1993 Mustang. -

Page 26: Price

All Mustang Tommy www.ampperformance.com Performance Phoenix, AZ 800-454-8387 Thompson www.mustang-village.com Mustang Village Fontana, CA 909 823 7915 Scott or Tom www.cypressautorecyclers.com/factory5.html Cypress Auto Berkley, CA 510 451 3034 Mike Percy www.mustangdepot.com Mustang Depot Las Vegas, NV 702 281 4517 Price Whether you’re buying a complete salvage yard car or a bunch of parts, it’s important to remember which parts are worth money to the salvage yard and which ones are of little or no value. -

Page 27: Disassembly Of A Mustang Donor For Parts

shoes on the unit. The drum pulls straight out, off the axle. Rear shoes are never really replaced until about 60-100K miles unless there was severe duty (read abuse) placed on the car. The easiest way to avoid engine work is to buy a donor car with an engine that runs. Everyone will tell you it runs, but it’s best to hear for yourself. -

Page 28: 87-95 Brake Power Booster

When in doubt, don’t throw it out. That one little OEM bolt could save you a trip to the auto parts store. 87-95 Brake Power Booster Socket set, wrenches or box wrenches for brake lines, tube cutter, tape, and marker pen. ... -

Page 29: Engine Bay Sensors And Electrical Connections

Remove the two bolts that secure the steering rack to the frame and lower the rack out of the car. Mustang steering rack with lines removed with rubber bushings and fasteners. Engine Bay Sensors and Electrical Connections Socket set, combination wrenches, Phillips head screwdriver, slip joint pliers, tape, marker, and bucket. -

Page 30: Interior

Remove and discard the front driver’s side plastic wheel well using a 7mm socket to loosen it from the body. Disconnect and remove the horns. They are located just forward of the wheel well on the driver’s side (accessed from the wheel well). Label and mark the connectors with tape. Interior ... -

Page 31: Computer

Unbolt and remove the pedal box. Computer Socket set. Mustang Computer and OEM plastic cradle. If you are going to run the car with a Carburetor you can disregard the EFI wiring harness part in this section. ... -

Page 32: Dash Wiring Harness

Remove the steering column mounts located under the dash above the driver floor. Allow the column to fall down. Remove the wiring connectors have from the turn signal and ignition switches. Remove the turn signal stalk Dash Wiring Harness Socket set, extension, regular, Torx and Phillips head screwdrivers, needle nose pliers, hammer, and marker tape. -

Page 33: Front Wiring Harness

Front Wiring Harness Socket set, extension, regular, Phillips head screwdrivers, needle nose pliers, hammer, and marker tape. Front wiring harnesses. Pull the rubber grommet out of the firewall into the engine bay. Remove the front light harness from the engine bay wall working from the starter solenoid area to the alternator. -

Page 34: Shifter And Shifter Handle

Release the cable sheath retainer clip. Pull the cable out and replace the clip on the cable. You may even want to tape it in place. Clutch cable and retainer circlip. Shifter and Shifter handle Socket set, Phillips head screwdriver. ... -

Page 35: Fuel Inertia Cut-Off Switch

Fuel Inertia cut-off switch Socket set, nut driver, Phillips head screwdriver, wire cutters to cut plastic fasteners, marker pen, and tape. Fuel inertia cut-off switch. It is recommended that a fuel inertia cut-off switch be used in the car. Inertia cut-off switch. -

Page 36: Exhaust

The transmission harness must be removed along with the rubber plug. This runs along the driver’s side of the transmission tunnel. Store the rear harness and transmission harness. Exhaust Wrenches, ” socket, socket extension, ratchet, adjustable wrench, hack saw. ... -

Page 37: Front Suspension

Use duct tape or zip ties to secure the lower radiator hose up to the power steering pump area so that it will not spill fluid as the engine is removed later. Get help with the next few steps, as the parts involved are heavy! Attach an engine hoist to the engine lift points at the driver’s front and passenger’s rear areas of the engine. -

Page 38: Fuel Tank

Lower A-arm w/bolts, brake caliper, spindle and brake rotor. Use a spring compression tool to remove the front springs or chain the spring to the chassis. Remove the three bolts that retain the struts to the top mounting plate. Slowly lower the Jack and the strut assembly will come out of the body mount (sometimes violently) and allow the lower control arm to go down. -

Page 39: Rear End

Open the gas cap to relieve any pressure built up in the tank. Remove the screws that hold the upper fuel cap and flange to the body of the car. Remove the set screw and metal ring collar retainer from the fuel neck where it meets the tank. Remove the fuel neck from the upper fuel fill area and slide the lower fuel tube out of the rubber grommet on the side of the tank. -

Page 40: Fuel Filter And Connectors

Remove the bolts and nuts from the lower rear Mustang control arm, where the arms are mounted to the body/chassis. Remove the bolts and nuts from the upper Mustang control arm, where the arms are mounted to the body/chassis. All of the arms should remain attached to the rear end assembly. Once off, place the bolts back into the arms and attach nuts so they do not get lost. -

Page 41: Solid Axle

Remove the rubber tubular spacer from inside the coil. Cut one full coil from the top of the spring for correct ride height setting. Cut the upper rubber spring seat so that during assembly of the kit, it will conform to the spring mount on the frame. - Page 42 If using a used rear axle, remove the lower shock mounts and the anti vibration weight under the pinion. Drill the lower control arm holes out with a ½” drill bit. www.factoryfive.com 508-291-3443...

-

Page 43: Front Lower Control Arms

The lower shock mount brackets will get used on the front lower control arms to mount the front shocks Front Lower Control Arms Hack saw, file grinder Remove the area, near the center of the spring mount to prevent damage to the coil-over unit thru any contact whatsoever. -

Page 44: Fuel Filter Fittings

Coil-over mounted in lower arm with clearance hole. Fuel Filter Fittings Razor knife Donor plastic fuel line fittings from fuel filter to body hard line and from return line from body hard line to fuel tank. Carefully with out damaging the plastic barb, cut the hard plastic off the plastic barbs. Barbed fitting removed from plastic hose. -

Page 45: Fuel Filler Neck

Fuel Tank At the locations on the tank where the tank straps come near the tank, use a pair of pliers and bend the bent parts flat. Fuel Filler Neck Hack saw Fuel Filler neck Cut the Mustang steel fuel neck in the mid-section after the 90 bend. Leave enough straight tube, to attach a hose clamp to each side. -

Page 46: Accelerator Pedal

Accelerator Pedal Remove the plastic part of accelerator pedal by pushing out the pin. Trim the accelerator pedal as shown, just above the plastic pedal support pad. It is possible to mount the original plastic pedal piece onto the shortened pedal if desired. This can be accomplished by squeezing the bottom of the trimmed pedal and drilling a hole for the stock pin. -

Page 47: Wiring Harness

87-93 Pedal box marked for cutting. Cut-off the marked area (bottom of the front mount flange) with a hack saw. This is necessary for steering shaft clearance. Wiring Harness Razor knife, electrical tape. Many people choose to cut down the wiring harness to use only the wires and leads that are needed. -

Page 48: Brake Power Booster Push-Rod

Brake Power Booster Push-rod Remove the master cylinder from the power booster. The power brake assembly is changed to a manual brake assembly for this kit. This simple modification is done on many SCCA Mustangs for improved brake feel. In a 2,100 lb. car, the feedback is good and power brakes are not really necessary. -

Page 49: Emergency Brake Handle

If you are using a Lakewood bell housing, trim the area around the starter so that is flush with the inspection cover. If you are not running emissions equipment, the only engine controls that need vacuum are the PCV valve in the valve cover and the fuel pressure regulator. The EGR can be left unhooked. Make sure to close off any extra vacuum ports. -

Page 50: Alternate Drive Pulley Preparation

Top: Trimmed handle. Bottom: Untrimmed handle. Trim the handle with grinder, it is very hard steel. Alternate Drive Pulley Preparation Cordless drill, ½” drill bit, needle nose pliers Alternate drive pulley template On 87-93 EFI cars, the pulley and fan belt supplied replace the A/C compressor and power steering pump. -

Page 51: Cleaning And Detailing

Remove the hydraulic lines. Drain all fluid by turning it, lock to lock, upside down over a collection pan. Dispose of the fluid properly. The rack is greased on the gears at the ends. The Mustang power rack is converted to a manual rack by removing the hydraulic lines from it and draining the fluid. -

Page 52: Disassembly Of The Kit

Chapter Disassembly of the kit www.factoryfive.com 508-291-3443... -

Page 53: Unpacking Your Kit

Unpacking Your Kit Customer picking up a kit at our Wareham, MA facility in June 2000. Please note that your boxes are numbered, when you read your packing list you will see that next to each assembly there is a number circled. This is the box number that the assembly was packaged in. The kit is packaged in the order that you will be using the parts. -

Page 54: Aluminum Removal

Lift in the exhaust recess and the rear wheel well. Body with sides supported. Aluminum Removal ¼” nut driver, jack stands, marker. Do one panel at a time. Be careful of the sharp aluminum edges, they can cut you. www.factoryfive.com 508-291-3443... - Page 55 Using a marker outline the underside of each panel where it contacts the chassis. This is done to locate where to drill rivet holes when the panels are permanently mounted later on. Mark each panel and take pictures of how the panels fit together (i.e. which is on top). Remove each panel after it has been marked until the chassis is bare.

- Page 56 Use jack-stands to position your frame in your workspace with plenty of room to move things around. www.factoryfive.com 508-291-3443...

-

Page 57: Chassis Assembly

Chapter Chassis Assembly www.factoryfive.com 508-291-3443... -

Page 58: Rivet Spacing Tool

Rivet Spacing Tool Packaged Aluminum In most cases we use a 3” rivet spacing when mounting aluminum panels to the chassis and a 2” spacing when mounting panel to panel. The rivet spacing tool has this hole spacing marked. The distance from the edge of the tool to the holes is correct to center the rivets on the ¾”... - Page 59 Put thread locker on the upper balljoint threads. Screw the upper ball joints into the control arms so that the balljoint angles out on the bottom www.factoryfive.com 508-291-3443...

- Page 60 Tighten the balljoint using the arm for leverage with a Vice holding the ball joint. Screw the grease fittings in to the ball joints and tighten with a ⅜” wrench. If assembling a complete Coupe kit with the FFR spindles, skip to the next section. Front upper control arm mounting with donor spindles Mount the upper control arms to the chassis with the grease fittings pointed up.

- Page 61 Front upper control arm mounting with FFR Spindles Mount the upper control arms to the chassis with the grease fittings pointed up. Use the mount holes that are vertical on the side of the 2”x 3” tube, not the top horizontal ones. www.factoryfive.com 508-291-3443...

- Page 62 Use a washer with the front locknut. Do not use a washer on the rear locknut. Torque the two bolts that hold the arm to the frame to 135-149Nm (100-110 lbft). www.factoryfive.com 508-291-3443...

-

Page 63: Pivot Endplay

Pivot endplay Adjust the locknuts on the ends of the pivot shaft so that there is minimal endplay but so the pivots can still rotate easily on the shaft. The pivots may be a little stiff at first but once on the car they will loosen slightly. Adjusting the upper control Arm ... - Page 64 Unpack the front shocks, coil-over’s and hardware. Double check the jam nut under the rod end and bump stop to make sure that it is tight. Screw the spring seat down on the sleeve so it is closer to the unthreaded end. Slide the coil sleeve over the body of the damper beginning at the end which has the rubber bump stop.

- Page 65 Slide the rubber bumper about two inches down on the shaft. Put the spring and hat on the shock and rotate the spring seat back up the sleeve so that the spring pushes the hat tight against the end of the shock. www.factoryfive.com 508-291-3443...

- Page 66 Install the snap ring on the spring hat so that it holds onto the shock end. Make sure that the slot in the snap ring and the slot in the spring hat are not aligned. Pass the shock assembly (with the body of the shock up) through the upper control arm and attach them to the lower control arm using the 0.43”...

-

Page 67: Spindles

Fasten the shock to the top mount with the fasteners and 0.675” spacers provided and torque both upper and lower mounts to 40 ft-lbs. Spindles If assembling a complete Coupe kit with the FFR spindles, skip to the next section. www.factoryfive.com 508-291-3443... - Page 68 Donor Spindles ” socket, Torque wrench, Needle Nose Pliers, Rubber Mallet IFS components, Mustang Spindles. Make sure the grease boot is in place on the lower ball joint then mount the spindle to the lower control arm. Attach the castle nut and torque the ball joint to 106-149Nm (80-110 lbft) and install a new cotter pin from the IFS components assembly.

- Page 69 Place the spacer under the castle nut to ensure that the cotter pin is at the correct height. Torque to 106- 149Nm (80-110 lbft) and install the cotter pin. Attach the upper ball joint to the spindle and torque to 75 ft-lbs and install the cotter pin. www.factoryfive.com 508-291-3443...

- Page 70 The upper ball joint boot will look crushed and out of shape when the car is in the air, this is OK. The boot will seat when the car is on the ground. Bolt the steering arms to the spindles with the taper facing down. Torque to 60 ft-lbs. www.factoryfive.com 508-291-3443...

- Page 71 The hub is a snug fit on the spindle and may require a light tap with a soft mallet to get in place. Torque the hub nut to 305-338Nm (225-250 ft-lbs). Using a large socket or a flat head screwdriver and rubber mallet, hit the dust cap onto the hub. www.factoryfive.com 508-291-3443...

-

Page 72: Front Suspension Torque Specs Chart

Front Suspension Torque Specs Chart Item Lbft Front lower control arm to frame 135-162 100-110 Front lower ball joint to spindle 106-163 80-120 Upper A-arm to frame 135-162 100-110 Upper ball joint to Spindle 95-122 70-90 Spindle hub nut 305-338 225-250 IFS Bracket ... - Page 73 Attach the upper ball joint to the spindle and torque to 75 ft-lbs and install the cotter pin. The upper ball joint boot will look crushed and out of shape when the car is in the air, this is OK. The boot will seat when the car is on the ground.

-

Page 74: Front Brakes

Front Brakes Sockets, Ratchet, Torque wrench, chassis grease, rags, brake cleaner, Mustang front brake calipers and rotors Make sure that your brake pads and rotors are in good condition. Donor Front Brakes Make sure that the hub bearings are greased correctly and adequately. Push the rotor onto the spindle. - Page 75 Install the caliper slider pins on the caliper using the supplied bolts and a 16mm wrench and 12mm socket. Torque to 23-26 ft/lbs. Install the slider grease boots on the slider pins. www.factoryfive.com 508-291-3443...

- Page 76 In the supplied hardware bag there are six steel clips that are designed to separate the pads from the caliper. These clips allow the pads to slide on a smooth surface and not wear on the caliper. The four clips that go on the ends of the hanger are different end to end, and must be installed with the long tab facing out.

- Page 77 www.factoryfive.com 508-291-3443...

- Page 78 The two clips that are left go in the center of the caliper with the tab sticking up through the center hole. Insert the clip from the inside of the caliper through the large center hole with the larger tab on the side facing the pistons then press down on the outer part of the clip so the small clip goes through the large hole and clips on.

- Page 79 Grease the slide pins using the supplied grease. Slide the caliper hanger onto the caliper. Push the rubber boots over the lip on the caliper bracket to seal the slider bolts correctly. www.factoryfive.com 508-291-3443...

- Page 80 Look at the back side of each brake pad to find the inside pads and the outside pads. The difference is the location of the studs that are on the back of each pad. The studs on the inside pads are out near the ends of the pad, while the studs on the outside pads are near the middle.

- Page 81 Install the brake pads in the Caliper. www.factoryfive.com 508-291-3443...

- Page 82 Clean the rotor with brake cleaner and push it onto the hub. Install the caliper on the spindle; make sure that the fluid bleeder is at the top of the caliper. Torque the caliper mounting bolts to 130Nm (95 ft-lb). www.factoryfive.com 508-291-3443...

-

Page 83: Solid Axle Rear Suspension

Solid Axle Rear Suspension ¾” sockets, ¾” wrench, ½” drill bit, drill, floor jack, jack stands, Torque Wrench www.factoryfive.com 508-291-3443... - Page 84 8.8” Rear axle assembly, Box 11 Solid axle Traction Lok brackets, Rear control arms. Use caution when working with the rear end assembly, it weights 225 lbs. Skip to the Independent Rear suspension if not installing a Solid axle. ...

- Page 85 Axle Bracket Passenger Side Temporarily put the lower shock bolt through the traction lock bracket and stock shock hole on the axle. www.factoryfive.com 508-291-3443...

- Page 86 Tighten the two short bolts. Torque to Ford Specs 75-95 Nm (55-70 lbft). Attach the lower control arms to the brackets on the axle using the bolt provided. Torque to 101-111Nm (75-82 lb-ft) The lower bolt holes provide more traction than the upper holes. www.factoryfive.com 508-291-3443...

-

Page 87: Spring Perch Mounts

If using Rear coil-over shocks, skip the next section. Spring Perch mounts ½” drill bit, drill, ¾” wrench, ¾” socket, ratchet Rear spring perches, Mustang springs and rubber isolator mounts Hold the spring perches up to the frame so the vertical perch mount is in between the 2”x 3” tube and the vertical frame mount. -

Page 88: Link Rear Suspension

Thread the cut rear springs onto the conical frame mounts all the way. Insert the cut rubber spring mount between the spring and the steel seat. Make sure the end of it is flush with the end of the spring mount. ... - Page 89 Upper Link Axle Mount If using the FFR Moser axle skip to the next section since the upper link bracket is welded to the axle. Test fit the two halves of the upper arm mount together. If it is hard to put all of the bolts in the mount holes, put in as many as you can then use a ½”...

- Page 90 The front attachment of the upper link axle mount attaches to the hole on the flange section of the pumpkin. This hole has some variance and may need to be drilled out from the bottom side using the mount as a guide. www.factoryfive.com 508-291-3443...

- Page 91 Install a jam nut on each of the rod ends, remembering that two of them are left hand thread. Insert the rod ends into the swedged tubes (one is right hand thread and one is left hand thread). The longer tube is the Panhard bar and the shorter one is the upper link. www.factoryfive.com 508-291-3443...

-

Page 92: Rear Axle Installation

Upper Link Attach the short upper link tube to the axle upper link mount using the ¼” spacers on either side of the rod end. Rear Axle installation Have someone help with this step, the rear axle is very heavy and mistakes can result in serious injury. - Page 93 Make sure that the rear jack stands are positioned under the 4” round tube as far back as possible to prevent the frame from tipping up once the axle is mounted Do not hold the end of the axle from the bottom of the disc, if the axle falls, the axle can crush your fingers and result in serious injury.

- Page 94 Attach the lower control arms to the frame mounts. Jack the rear axle up. If using a 4 link, attach the upper control arms to the frame. www.factoryfive.com 508-291-3443...

-

Page 95: Optional Rear Coil-Over Shock Assembly

If using a 3 Link, attach the upper link to the frame. If using the stock Mustang shocks, skip the next section. Optional Rear Coil-Over Shock Assembly Snap ring pliers, ¾” wrench, ¾” socket, ratchet, ruler, marker, hack saw. ... - Page 96 Unpack the rear shocks, coil over’s and hardware. Double check the jam nut under the rod end and bump stop to make sure that it is tight. Screw the spring seat down on the sleeve so it is closer to the unthreaded end. The center high part of the set should be pointed away from the unthreaded end.

- Page 97 Slide the rubber bumper about two inches down on the shaft. Put the spring on the shock, then install the spring hat on the shaft end of the shock and push the rubber bumper up against it. Rotate the spring seat back up the sleeve so that the spring pushes the hat tight against the end of the shock.

- Page 98 Assembled solid axle Koni coil-over shock. Use zip ties to hold the spring to the spring hat. Attach the body end of the shock to the upper shock mount using the two equal length (1.09”) spacers. www.factoryfive.com 508-291-3443...

- Page 99 Jack the rear axle up so the rod end of the shocks can be mounted on the axle through the shock mount hole. www.factoryfive.com 508-291-3443...

-

Page 100: Rear Shocks

Rear shocks Torque wrench, ratchet, ¾” socket, 15mm wrench Mustang vertical shocks, quad shocks, quad shock brackets, Quad shock fasteners assembly, rear spring perches, rear traction Lok brackets/fasteners. Attach the rear vertical shocks at the top through the holes in the plates located in the trunk area using the Mustang rubber bushings and fasteners. - Page 101 Passenger side Driver Side Check for shock clearance on brake lines, emergency brake cables, brake calipers, frame and axle parts. Check to make sure that the spring is seated correctly on the shock. www.factoryfive.com 508-291-3443...

-

Page 102: Link Rear Suspension Torque Specs Chart

Mount the quad shocks and their brackets to the rectangular frame plate hanging under the 2”x 3” tube behind the axle. Attach the rear end axle straps (included with the kit). These cables will prevent drive shaft binding if you happen to achieve airborne status. The rear end straps bolt to the front bolt of the quad shock up high, and back side of the vertical shock down low. -

Page 103: Panhard Bar Frame Mount

Panhard Bar Frame mount Attach the Panhard Bar frame mount to the inside of the quad shock brackets, the forward leg will attach to the back of the angled 2”x 3” tube. Do not tighten the quad shock bracket bolts yet. www.factoryfive.com 508-291-3443... - Page 104 For the front mount, use a ½” drill bit and drill through the sleeve on the mount. Make sure before drilling that the hole is away from the side of the 2”x 3” tube so that a nut can be attached on the back of the bolt from the bottom of the tube.

- Page 105 The Panhard bar mounts to the car using the ½” bolts and spacers. Install the Panhard bar to the passenger side traction lock bracket. Three spacers are used in the front (2) 0.375" and (1) 0.25". The rear uses the thin 0.125" shim. It will be necessary to adjust the length some to fit, make sure that you adjust the same amount on both sides.

- Page 106 Attach the Panhard bar to the frame mount using the spacers provided. There should never be less than ¾” of threads screwed into either the Panhard bar or the upper arm. www.factoryfive.com 508-291-3443...

-

Page 107: Link Rear Suspension Torque Specs Chart

To set the pinion angle, make sure that your ride height is where you want it, and then adjust the upper arm until the desired angle is reached. We usually run about 2° up on the rear axle, but you can adjust this to fit your particular set-up. -

Page 108: Irs Center Section

IRS Center Section Mount the rear center section to the chassis. It installs from the bottom with the driveshaft flange pointing straight up and the axle holes lined up front to back with the chassis. Use one rear bolt through the rear cover to hold it in place. - Page 109 Slide the bushing sleeves into the bushings from the top. Through bolt the two front bushings and the remaining rear mount with the mounting hardware and tighten. www.factoryfive.com 508-291-3443...

-

Page 110: Lower Control Arms

Lower Control Arms Screw the rod ends with jam nuts into the lower control arm. Screw the forward joint in all the way then back out 4 turns. www.factoryfive.com 508-291-3443... - Page 111 Mount the lower arms to the chassis with the shock mount hanging down below the arm. The rear bolt can be slip in place with no shims for now. Shim the front bolts using 3 shims on the front side of the rod end on both the left and right arms.

-

Page 112: Irs Rear Coil-Over Shock Assembly

IRS Rear Coil-Over Shock Assembly Snap ring pliers, ¾” wrench, ¾” socket, ratchet, ruler, marker, hack saw. Roadster/Coupe rear shock kit The rear shocks are pre-valved at the factory in compression and rebound for good street use. The shocks can be adjusted in rebound as per Koni’s instructions if so desired. - Page 113 Screw the spring seat down on the sleeve so it is closer to the unthreaded end. The center high part of the set should be pointed away from the unthreaded end. Slide the coil sleeve over the body of the damper beginning at the end which has the rubber bump stop. The unthreaded end of the sleeve goes first so that it will sit on the snap ring on the shock body.

- Page 114 Put the spring on the shock, then install the spring hat on the shaft end of the shock and push the rubber bumper up against it. Rotate the spring seat back up the sleeve so that the spring pushes the hat tight against the end of the shock.

- Page 115 Assembled solid axle Koni coil-over shock. Use zip ties to hold the spring to the spring hat. Mount the coil-over to the chassis mount using the two of the smaller length spacers on either side. The body of the shock goes toward the top. Mount the lower control arm to the coil-over with the remaining large and small spacers.

-

Page 116: Cv Axles

CV Axles Push the CV joints into the rear axle and let them rest on the lower arm. Spindles Slide the splined end of the outer CV joint into the hub and mount the spindle to the lower arm. www.factoryfive.com 508-291-3443... -

Page 117: Upper Control Arms

Upper Control arms Screw in the rod end and jam nut into the upper arm and attach it to the chassis using a short equal length spacer on either side of the rod end. Attach the upper arm to the spindle and tighten all of the spindle mounting hardware. www.factoryfive.com 508-291-3443... -

Page 118: Quad Shock Installation

Quad shock Installation Attach the body end of the Quad shock to the upper arm of the IRS with the supplied metric bolt. Attach the shaft end of the Quad shock to the rear quad shock bracket hole on the frame using the washer on the outside of the quad shock as shown in the picture. -

Page 119: Rear Calipers And Rotors

Rear Calipers and Rotors Push the slotted rotor onto the spindle. Attach the caliper to the spindle using the OEM T-Bird bolts. Width Adjustment Mount your wheels and tires. Lower the frame off the jack stands. With the car on the ground, check the ride height of the car to the bottom of the 4” frame rail ... - Page 120 Place a straight edge on the rotor wheel mounting surface on each side of the suspension and measure across the car to find the suspension width. With these axles, it is recommended that the rear suspension should measure 59.00” for the standard width or 54.00”...

-

Page 121: Optional Irs Brakes

Adjust the rod ends the same number for turns for the front and rear rod ends on the lower control arm and upper control arm as required so that If the number of turns done is the same for all control arms on one side of the suspension, an alignment is not needed after the installation. - Page 122 Insert a hex head bolt through the Caliper Mount Bracket hole so that the threads will point out. www.factoryfive.com 508-291-3443...

- Page 123 From the outside in, insert two hex head bolts through the Spindle caliper mount holes then through the caliper mount bracket. Torque the bolts to 87-101Nm (64-75 lbft). Place the caliper mount spacers on the bolts facing out. www.factoryfive.com 508-291-3443...

- Page 124 Place the brake rotor on the spindle Load the caliper with the brake pads Put a dot of Locktite on the threads of the two bolts with the spacers on. Attach the caliper to the caliper mount bracket. Hand tighten both bolts starting with the top on first. Keep the head of the bolt near the caliper adapter bracket in order to tighten it.

-

Page 125: Driver Front Footbox Aluminum

Tighten the top mount bolt with a ¾” wrench. Driver Front Footbox Aluminum Drill, ” drill bit, rivet tool, caulk gun, silicone Firewall and Driver Footbox Front aluminum, Secondary body fasteners. If you are installing a heater/defroster it is much easier to cut the firewall before installing. Refer to those instructions for the template. -

Page 126: Pedal Box

Pedal Box ⅜”, ” sockets, ”, ” hex key, drill, ” wrench, ⅛”, ¼”, ” drill bits, silicone, rivet tool, marker. Mustang pedal box, pedal box hardware, cockpit aluminum. www.factoryfive.com 508-291-3443... -

Page 127: Mustang Pedal Box

Mustang Pedal Box www.factoryfive.com 508-291-3443... - Page 128 Position the Mustang pedal box on the two angled ¾” tubes over the driver’s feet, and attach using two short ⅜” bolts and two washers to the front wall at the front of the foot box. There are four holes on the Mustang pedal assembly on top of the ¾” tubing. Mark these holes on the tubes.

- Page 129 The right hole for the master cylinder must also be marked on the pedal box. Use the laser cut hole in the foot box steel as a guide to mark the Mustang pedal box. Remove the pedal assembly. Drill ¼” holes completely through the ¾” tubing for the pedal box. Use a ”...

-

Page 130: Complete Kit Pedal Box

Reinstall the pedal box assembly in the driver’s footbox; use the ¼”x 1.50” screws from the pedal box fastener assembly with a fender washer next to the head. Leave all the hardware hand tight. Complete kit pedal box ½”, ”... - Page 131 This pedal box is set-up to use either a hydraulic clutch or a cable clutch. The parts and instructions required for a cable clutch installation are included in this kit. Unpack the pedal box assembly. Now is a good time to paint all of the bare steel brackets. Use snap ring pliers to remove one of the retaining clips from the brake pedal pivot sleeve and pull the sleeve to remove the pedal.

- Page 132 Place the brake switch mount between the brake pedal mount tabs on the side closest to the brake pedal pivot holes and drill a ” hole through the brake switch mount hole and the pedal box. Attach the brake switch mount to the pedal box using the black #10 screw and locknut. www.factoryfive.com 508-291-3443...

- Page 133 Clutch Cable Quadrant Using snap ring pliers, remove one of the retaining clips from the clutch pedal pivot sleeve. Push the pivot sleeve out and remove the pedal and remove the second snap ring from the clutch pedal pivot sleeve. www.factoryfive.com 508-291-3443...

- Page 134 Using snap ring pliers, attach one of the snap rings to the new longer pivot sleeve provided. Push the pivot sleeve through the clutch quadrant from the left side. If necessary, chase the quadrant hole with a ½” drill bit so that the quadrant can slide on the pivot sleeve. www.factoryfive.com 508-291-3443...

- Page 135 Put one of the Wilwood pedal washers on the pivot sleeve next to the quadrant. Remove the snap ring holding the master cylinder mount to the clutch pedal, push the pivot sleeve out and remove the master cylinder mount. www.factoryfive.com 508-291-3443...

- Page 136 Attach the Wilwood pedals to the underside of the mounting bracket using three button head screws and locknuts and the stud. The stud should get mounted on the left side next to the clutch pedal pivot sleeve boss. A tap in with a hammer and punch will get the stud to stick while tightening.

- Page 137 Attach the Clutch pedal stop mount to the bottom of the pedal box using two ¼” socket head screws, spacers and locknuts. Put the actuator in a vise and snug up the bolts with a ” hex key. Do not overtighten and strip the threads.

- Page 138 Slide the Quadrant and new pivot sleeve assembly through the hole in the side of the Wilwood pedal bracket and remount the clutch pedal. Put the remaining thin washer and snap ring on the pivot sleeve. www.factoryfive.com 508-291-3443...

- Page 139 Put locktite on the ” bolt threads. Insert the ” bolt through the clutch pedal and thread into the actuator. Snug up the bolt using a ” hex key. This ” bolt is only used to hold the pedal in position when the pedal is not being pushed depending on the pedal height.

- Page 140 Place the pedal box assembly in the drivers footbox. Make sure that the brake pedal goes in front of the ¾” cross tube on the frame. Unpack the pedal box hardware from the secondary chassis components box. www.factoryfive.com 508-291-3443...

- Page 141 Insert three ⅜” x 1” socket head screws from the pedal box hardware assembly and the one included in this pedal assembly through the front of the footbox and through the pedal box mount. Push the rear pedal box mount onto the master cylinder mount studs and use a few of the jam nuts from the Wilwood pedal assembly to temporarily hold the rear mount in place.

- Page 142 Tighten two of the front ⅜” screws then use a marker to mark the locations of the rear mount holes on the ¾” tubes. Loosen the bolts and remove the pedal box assembly from the footbox then use a ¼” drill bit and drill to drill through the ¾”...

- Page 143 Reinstall the pedal box assembly in the driver’s footbox; use the ¼”x 1.50” screws from the pedal box fastener assembly with a fender washer next to the head. Leave all the hardware hand tight. Master Cylinders Place a jam nut from the Wilwood pedals onto each of the master cylinder threaded shafts. www.factoryfive.com 508-291-3443...

- Page 144 Put one of the master cylinders onto one of the brake master cylinder mounts and turn the threaded shaft into the threaded mount on the brake pedal. As a starting point, thread the shaft in until you can see it is flush on the other side of the mount.

- Page 145 Tighten all the remaining hardware mounting the pedal box to the chassis. Thread the jam nut onto the ⅜”x 1.25” screw provided in the quadrant box. www.factoryfive.com 508-291-3443...

-

Page 146: Accelerator Cable

From the underside, push the screw through the quadrant pedal stop mount plate and hand tighten the locknut on the screw. Accelerator Cable ” hex key, ⅜”, ”, ½” wrenches, wire cutters. Pedal box hardware, Accelerator cable components. ... - Page 147 Using a pair of wire cutters, cut the cable at the location marked. Remove and discard the included ball stud. It is for carbureted applications Push and twist the included ball stud retainer onto the end of the cable. Do not tighten the set screw yet. Insert the pedal end of the cable into the foot box.

-

Page 148: Accelerator Pedal

The engine end will get installed later. Accelerator Pedal ” hex key, ” wrench, pliers OEM accelerator pedal, accelerator cable components Hold the accelerator pedal up to the mount on the ¾” tube at the front of the foot box. The higher you can mount the pedal the better the pedal will be positioned on your foot. - Page 149 The Accelerator cable is designed to be used with all types of engines, carbureted or fuel injected. The stock cable has the barrel end on it for the 4.6L throttle body and the ball for a Mustang accelerator pedal. Unpack the throttle pedal and separate the arms.

- Page 150 Bolt the pedal to the mount plate using the ¼”x ¾” screws and locknuts Unpack the throttle cable and cut the cylinder end off. Make sure your cutters are very sharp so as not to fray the cable. www.factoryfive.com 508-291-3443...

- Page 151 Thread the inner cable through the cable retaining lock nut from the accelerator cable components assembly. Route the cable through the hole in the firewall and slide the sheath back over the cable. www.factoryfive.com 508-291-3443...

-

Page 152: Steering System

Tighten the cable sheath to the firewall with the retaining nut. A piece of tape on the end of the cable will help prevent it from backing out of the sheath. Check the full range of the accelerator pedal travel to ensure that there are no interferences with the pedal or travel. - Page 153 Loosely mount the flange bearing to the footbox front with the set screw toward the inside of the footbox. Both sides of the flange mount to the front side of the footbox plate. Loosely mount the top pillow block to the chassis with the set screw toward the rear of the car. www.factoryfive.com 508-291-3443...

- Page 154 Slide the steering shaft into the footbox from the engine bay through the lower bearing. 87-93 Power steering racks have a different spline than a manual steering rack and the 94-04 Power rack uses a “Pyramid” shaped end. All of these lower adapters are available from FFR. www.factoryfive.com 508-291-3443...

-

Page 155: Steering Rack

Steering Rack Needle Nose Pliers, ¾” wrench, ¾” socket, Ratchet, 1.50” wrench or Adjustable wrench. Mustang Power steering rack, Steering System Hardware 87-93 steering rack and fasteners (hydraulic lines removed). If not already in, insert the stock rubber bushings and kit spacer sleeves into the rack. Pull back the rubber boot on the inner tie rod and remove the inner tie rod from the steering rack. - Page 156 Use thread locker on all of the steering shaft screws that do not have jam nuts and the adapter screws. www.factoryfive.com 508-291-3443...

- Page 157 The inner Tie Rod Extensions are for stock Power Steering Racks only, not for manual steering racks. If using the power rack and you have not already done this in the donor prep stage, cut 1.75” off the end of the inner tie rod. Put a dot of thread lock on the threads of the steering rack and attach the steering rack extension to the steering rack using a 1.50”...

- Page 158 Put a dot of thread lock on the threads of the steering rack extension and attach the Mustang inner tie rods to the steering rack. Push the boot back onto the steering rack body and attach with zip ties. The track of the FFR Coupe front end is narrower than the Mustang. Screw in the tie rod ends until the wheels are straight.

- Page 159 The outer tie rods may come with either a castle nut and cotter pin or a nylon locknut. Attach the tie rod to the spindle, torque the nut to 25 ft-lbs. If a castle nut is used, torque the nut then install the cotter pin.

-

Page 160: Upper Steering Shaft

Steering rack installed. Upper Steering Shaft ”, ”, ” hex keys, ½” wrench, rubber mallet Steering system hardware Unpack the upper steering shaft from the primary chassis components box. Slide the steering shaft through the upper bearing and start it in the lower shaft. www.factoryfive.com 508-291-3443... - Page 161 Turn the steering shaft so the recessed bosses for the spring washers are facing up and set the washers in place. Then tap the upper shaft down until the upper clip just disappears into the lower shaft. Tighten the upper and lower bearings. Also tighten the set screw on the upper shaft. www.factoryfive.com 508-291-3443...

-

Page 162: Cockpit Aluminum

Cockpit Aluminum Drill, ⅛” drill bit, rivet tool, Silicone, caulking gun, #8 self tapping screws, #8 hex nut driver, ruler, marker, Acetone or carburetor cleaner, rags. Packaged aluminum, mounted aluminum, Secondary body fasteners. Do one panel at a time. Be careful of the sharp aluminum edges, they can cut you. Passenger Footbox Locate the passenger footbox top and drill and mark the holes in the top flat surface only. - Page 163 Silicone this panel where it meets the chassis and rivet along the bottom of the 2” square frame crossbar only. Use one of the original screws to temporarily hold it to the other small chassis tube. Drill the tunnel front A-shaped piece where it meets the chassis and silicone and rivet it in place. www.factoryfive.com 508-291-3443...

- Page 164 Mark and drill the two vertical edges of the passenger footbox inside wall. Silicone and rivet the panel to the front tunnel “A” and the footbox top. Mark the holes in the passenger footbox front panel upper and outer edges but do not drill yet. Silicone the panel and install with the temporary screws then drill through both panels and rivet it in place.

- Page 165 Silicone the flanges for the passenger footbox floor then install and rivet it in place. The floor sits on top of the flanges from the footbox walls. Silicone the remaining flanges then install the outer wall/top on the footbox with rivets. Make sure the rear edge is flush to the chassis and not caught up on the door hinge before you start riveting.

-

Page 166: Passenger Floor

Passenger Floor Drill the passenger side floor where it was marked to attach to the chassis. Mark the two front flanges but do not drill yet. www.factoryfive.com 508-291-3443... - Page 167 Silicone the chassis where the aluminum floor will touch. The main chassis rails are not riveted to but still need a bead of silicone run along the tops. The top edge of the tunnel is not riveted yet but gets silicone as well.

-

Page 168: Driver Floor

Driver Floor Drill silicone and install the driver’s footbox floor. The outer flange does not get drilled yet. Silicone, drill, and install the driver side floor. Drill, silicone and install the inner footbox wall. The front flange tucks in behind the front. Put a little silicone on both sides of this flange. -

Page 169: U-Joint Cover

U-Joint Cover Mark the rear tunnel cover where it meets the chassis then silicone and rivet it in place. www.factoryfive.com 508-291-3443... -

Page 170: Transmission Tunnel Rear Corners

Transmission Tunnel rear corners The inner rear corner pieces tuck behind the tunnel sides and sit on top of the floor. Mark the rivet spacing on the top edge and silicone and rivet the three flanges that make contact. Cockpit rear wall Mark and drill the rear cockpit wall. -

Page 171: Cockpit Rear Corners

Cockpit rear corners The outer cockpit corners get marked on the bottom flange and where they meet the chassis. Drill silicone and rivet these in place. Fuel System Fuel Tank ” deep socket, ratchet, hammer, ” hex key, floor jack, friend. ... - Page 172 Unpack the ¾” square plastic end caps from the secondary body fasteners. Push the four plastic end caps into the tubes hanging down in front and behind the gas tank. www.factoryfive.com 508-291-3443...

- Page 173 Hang the fuel tank straps from the rear mount of the chassis using two of the strap fasteners. The longer strap goes on the passenger side. Using a jack, raise the tank up into place on the chassis. Make sure the plastic cover is in position below the tank.

- Page 174 Bolt the straps in with the strap fasteners and drop the jack. Tighten only the driver’s side strap as the passenger one will be removed for aluminum fitment later on. www.factoryfive.com 508-291-3443...

-

Page 175: Fuel Filter

Fuel Filter Tube bender, ” drill bit, drill, rivet tool, marker, tape measure, flat head screwdriver, ” wrenches Insulated clip hardware, Fuel line components, ¼”, ” fuel lines, Mustang Fuel filter and mount, Mustang tank to filter nylon hose, Mustang fuel vapor hose. ... -

Page 176: Fuel Lines

Fuel Lines Unpack the fuel lines and the fuel line assembly which is in the secondary chassis components box. The larger ” line is the send fuel line to the engine. If you are running a return system then there is ¼”... - Page 177 The fuel line routing will depend on your style of fuel pump, whether it is in-line, in-tank, or mounted on the engine. The most important things are: To route the lines so that they are protected by the chassis; not close to any heat source or moving parts;...

- Page 178 From the filter we generally run the lines down the 2”x 3” tube behind the rear cockpit wall and alongside the outside of the main 4” frame tube. Which side of the frame you run down may depend on where you are hooking up to your fuel rail, carburetor, or pressure regulator.

- Page 179 Fasten the lines to the 2”x 2” square cockpit outriggers with the insulated line clips and ” rivets. If you are going to use the mustang Fuel vapor line, run it along with the other fuel lines. www.factoryfive.com 508-291-3443...

-

Page 180: Brake System

Brake System Tube bender, ”, ¼” drill bits, drill, rivet gun, marker, tape measure, razor knife, round file or sand paper, brake fluid, ” hex key, ½”, ” wrenches. Pedal box hardware, Insulated clip hardware, Brake line components, ”... - Page 181 Tighten all of the mounting bolts for the pedal box and master cylinder. www.factoryfive.com 508-291-3443...

- Page 182 Install the push rod from the power booster into the master cylinder and insert the white plastic bushing in the ring end. Hold the rod between the two ears of the brake light switch and slide it over the brake pedal post. Put the clip through the hole in the pedal so that the push rod will not come off.

-

Page 183: Front Flexible Brake Lines

The small aluminum piece packed in the assembly is not used for this application. Tighten all the remaining hardware mounting the pedal box to the chassis. Front flexible brake lines Unpack the hardware from the brake line components. Lay out the various lengths of brake line so you can see what you have to work with. Like the fuel lines, there are many ways to run these lines but you must be very careful to keep them protected from moving parts, heat, or being to close to the bottom of the car. -

Page 184: Hard Brake Lines

Push the brake line adapters through the brackets from the outside in and install the clips that hold them in place. If removed, attach the front brake line to the caliper making sure there is a crush-washer on either side of the fitting. - Page 185 From the distribution block, run one of the longer 60” brake lines over to the right side brake hose mount. The line will bend very easy but be careful not to kink it. When you are happy with the routing use the small insulated line clips and ”...

- Page 186 Run the brake line up the back of the 2”x 3” tube. At this point your routing will depend on your rear brakes. 87-95 Mustang solid axles have a single flex line that runs to the middle of the axle then out to the calipers. Newer axles and the FFR rear brakes run the flexible brake lines direct from the chassis to the caliper (the IRS is done like this, there is an extra length of line and a T to allow similar routing to the front.) If using the 87-95 Mustang mount, drill two holes for the Mustang brake bracket on the underside of the...

- Page 187 Attach the “T” adapter to the flexible brake line and route the hard brake line coming from the front to the “T”. www.factoryfive.com 508-291-3443...

- Page 188 Run a 60” brake line from the “T” up the ¾” tube to the front fuel tank mount tubes and over to the passenger side ¾” tube. An alternative to running it this way would be to run it across the backside of the 2”x 3”...

-

Page 189: Banjo Bolt Torque Specs

Attach the hard brake line to the flexible brake line. Make sure that your flex lines will not interfere with anything in the suspension, wheels during travel or turning full lock to lock. Tighten the banjo bolts on the calipers Banjo bolt torque specs 87-95 Front Brake hose to caliper Banjo bolt –... -

Page 190: Wiring Harness

Wiring Harness ⅜” socket, regular head screwdriver, slip joint pliers, ⅛”, ” drill bits, drill, #8 nut driver, electrical tape, wire cutters. Misc. electrical components, wiring harness mounting hardware, insulated clip hardware If during this section, you decide to cut your harness, wait until after the car has been started then remove sections one at a time, starting the car after each cut to make sure it runs. -

Page 191: Rear Harness

Rear Harness Run rear harness from the hole in the driver foot box inside wall, along inside the transmission tunnel with the battery cable and straight back to the rear of the frame. Use zip ties, insulated line clips, and the wire loom to hold the wires and battery cable. -

Page 192: Transmission Harness

Transmission Harness Transmission harness Push the harness plugs through the hole in the driver's side floor aluminum. Harness plug in floor aluminum Run the harness forward into the corner to the ¾” tube at the foot box front. Then go up and along the angled ¾”... -

Page 193: Headlight Harness

Headlight Harness The headlight harness is started at the alternator and runs forward to the passenger headlight area, then goes under the fan shroud to the driver’s side headlight area and then rearward to the coil and starter relay area. The Mustang is wider than the FFR Coupe in front and there is extra wiring between the headlights. -

Page 194: Starter Solenoid

The dash harness begins at the coil area and goes rearward to the large hole in the front of the driver’s side foot box. The key to routing the dash harness is to start on the inside of the foot box and push the smaller items through the large hole from the inside. - Page 195 Red/blue wire (+) Battery cable Yellow wire Green wire Black cable to Starter Orange/Dark Blue wire Starter Solenoid Wiring Old Starter www.factoryfive.com 508-291-3443...

- Page 196 New Starter When the wire harness is installed, mount the fuse panel (Use the diagram in Appendix A to determine the correct shape) to the 2”x 2” dash hoop support and between the two ¾” x ¾” frame tubes in the driver’s side footbox using the aluminum bracket provided and a few of the self-tapping screws.

-

Page 197: Engine Harness

Engine Harness ⅜” socket, regular head screwdriver, slip joint pliers, ” and ⅛” drill bits, drill, #6 nut driver, electrical tape, wire cutters. Mustang engine harness, engine harness assembly The aluminum is laser cut for the EFI (Electronic Fuel Injection) rubber grommets, the kit comes with block-off covers if a carbureted engine is used. - Page 198 Use the drilled holes and cable tie trick to hold the extra harness to the top of the passenger foot box. The harness splits into two on top of the foot box. The short, smaller harness goes forward and connects to the mass air sensor and to the harness on the engine for the O sensors and oil level sender.

- Page 199 If you are running EFI without emissions equipment, the vacuum/electrical solenoids located on top of the foot box along with the vacuum reservoir on the firewall are not necessary. Plug the vacuum outlets on the intake remove the unused parts. Use screws provided with kit to mount the vacuum controls and BAP (Barometric Air Pressure) sensor to the firewall.

-

Page 200: Ignition And Turn Signal Stalk

Computer ground near driver’s foot box Ignition and Turn signal stalk Hack saw, ” socket, ” drill bits, drill. Dash Electrical Components, Mustang ignition switch and turn signal stalk. Mount the turn signal stalk with the stalk pointed towards the seat as high as possible between the plate steel that also holds the windshield and the vertical ¾”... - Page 201 on the driver’s side at the rear of the trunk area. This can be used if the Coupe fuel cell kit is used. Place the battery tray, on top of the trunk floor, with half of the plate on each side of the cross brace located on the driver side of the trunk.

-

Page 202: Battery Cables

Battery tray mounted in rear trunk corner for fuel cell. Duct tape the hooks into the holes to help in the assembly process. Place the battery onto the tray with the positive terminal on the driver’s side. One by one, wipe clean of any grease/oil on the hook bolt. Using JB Weld or silicone, cover each hook before they are inserted into the holes drilled for them. -

Page 203: Trunk Aluminum

If the starter solenoid was mounted behind the engine, run the cable up the transmission tunnel front wall behind where the engine will sit and to the solenoid. If the starter solenoid was mounted to the 1” tube near the master cylinder, run the cable to the front of the floor/tunnel bend and along the edge to the front of the driver’s foot box. -

Page 204: Rear Wall

Rear Wall ” drill bit, silicone, rivet gun, caulk gun, ” wrench, ” hex key. Mounted Aluminum, Packaged Aluminum, secondary body fasteners Position the panel on the frame overlapping the side wall tabs. Mark where the rivets will go by tracing around the tubes the same way previously done. Remove the panel and apply silicone to the frame and side wall tabs. -

Page 205: Floor

Floor With the rear taillight harness tied up and secure, silicone and install the lower trunk floor. Drivetrain Preparation Aftermarket TKO 500 and TKO 600 prep Hack saw or Reciprocating saw, ¾” socket, ratchet Transmission, Polyurethane engine/transmission mount kit ... - Page 206 Trim off the unused mounting boss on the bottom of the case. www.factoryfive.com 508-291-3443...

-

Page 207: 87-93 Alternate Drive Pulley

Trim it flush or just below the pad for the transmission mount. 87-93 Alternate Drive Pulley ¾” socket, ¾” wrench. Alternate drive pulley components If you are using under-drive pulleys or eliminating the smog pump do not drill the A/C bracket according to the diagram. - Page 208 Place the aluminum sleeve on the bolt with the flange towards the pulley wheel, so that it slides inside the pulley. Install the bolt assembly on the A/C bracket (previously drilled in the disassembly section), using the lock nut provided. Pull the tension pulley back with a pry bar carefully and install the fan belt.

-

Page 209: Engine/Transmission Installation

new pulley is not lined up properly and is too far in, use the arbor shims included with the kit to go between the aluminum sleeve and the pulley wheel, effectively pushing the assembly outwards. Engine/Transmission Installation Engine hoist, chain, ¾”, ”... -

Page 210: Driveshaft

Tighten the transmission mount to the frame. Driveshaft 14mm wrench, thread locker Mustang driveshaft and fasteners If not already done, the driveshaft should be shortened to the length specified in the appendix for the engine/transmission combination being used. Slip the shortened driveshaft up into the rear of the transmission. - Page 211 The Mustang driveshaft bolts should have thread locker on them already. If thread locker is not there, put a small bead on each bolt. Fit the driveshaft snug against the yoke and install the bolts and tighten. You can put the transmission in gear to stop the driveshaft from turning while you tighten.

-

Page 212: Fuel Lines To Engine

Fuel Lines to engine flat head screwdriver Fuel line components Finish running your fuel system by hooking up either to your carburetor or fuel rail. Here we mounted a pressure regulator on the firewall and ran a single line over to the rail. www.factoryfive.com 508-291-3443... -

Page 213: Clutch Cable

Clutch Cable Insulated clip hardware. Route the clutch cable down to the bellhousing. Using zip ties or insulated clips tie the cable safely away from the headers and the moving steering components. It can be fastened to the engine using the bracket on the cable to the front lower bolt that holds the starter cable just before it leaves the block or, to the lower engine bay ¾”... - Page 214 Connect the clutch cable to the bellhousing and the clutch fork. www.factoryfive.com 508-291-3443...

-

Page 215: Complete Kit Clutch Cable And Firewall Adjuster

Complete kit Clutch Cable and Firewall Adjuster Push the firewall adjuster into the front of the footbox and attach to the front of the pedal box using the screws provided and a ” hex key and an ” wrench. Pull the rubber mount off the end of the clutch cable. www.factoryfive.com 508-291-3443... -

Page 216: Speedometer Sending Unit

Use a razor knife, file or grinder to remove the plastic barbs from the plastic shaft. Slide the clutch cable boss through the adjuster and loop the cable over the quadrant. Speedometer Sending Unit 11mm deep socket, ratchet. Mustang speedometer sending unit. - Page 217 Put a little oil on the o-ring and install the sender in your transmission. Use the original bolt to hold the sending unit in place. Plug the wire harness connector into the sender. www.factoryfive.com 508-291-3443...

-

Page 218: Accelerator Cable

Accelerator Cable ” hex key, ⅜”, ” wrenches Insulated clip hardware. Fuel Injected application Attach the engine end of the cable sheath to the cable mount on the intake using ⅜” and ” wrenches. Put a dab of silicone on the rear edge of the rubber wipe then push the rubber wipe back onto the threads. -

Page 219: Carbureted Applications

Stop tab on accelerator pedal. After driving the car for the first time you may want to adjust the pedal locations for optimum heal/toe and shoe size differences. Make sure the accelerator cable is tied up and out of the way of moving or hot parts as well. Carbureted applications Attach the cable sheath to your cable mount on the engine. -

Page 220: Mass Air Meter, Air Filter And Intake Hose

Attach the engine end of the cable sheath to the cable mount on the engine using ⅜” and ” wrenches and push the cable wiper onto the remaining threads. Push the ball stud retainer onto the ball stud. Push/pull the cable into the retainer so that the cable is tight. Tighten the set screw in the retainer using a ”... -

Page 221: Fuel Vapor Canister

Bolt the ground strap to the hole and then run the other end to a boss on the block. In this case we used an engine mount bolt. Fuel Vapor Canister Drill, ” drill bit, ⅜” socket Wire harness mounting hardware, Mustang Fuel vapor canister www.factoryfive.com 508-291-3443... -

Page 222: Cooling System

The emissions canister can be mounted to the right side of the engine bay on outside of the 1” horizontal tubing just behind the mass air meter. Drill two ” holes through the canister bracket OEM holes. Mount with two #14 screws. Attach the vent hose from the gas tank to the canister and the hose leading to the engine. - Page 223 Angle the lower mounting tabs at a 45 angle outward then adjust them so that the mounting bolts will again go through the flange and the nut will go on the bolt. Mark the upper and lower mount tab holes on the radiator flanges. Mark where the lower mount tabs can be trimmed.

-

Page 224: Radiator Mounting

Trim the excess off the lower fan mount tabs. Attach the fan to the radiator using the black #10 x 1” screws on the top and the #10 x ” screws on the bottom. Make sure that the fan blades do not hit the sides of the fan housing once the fan is attached to the shroud. - Page 225 Install the radiator from above the frame. Attach some stick on weather stripping to the underside of the radiator top mount bracket. Position the top mount bracket so that the small tab sticking up is on the rearward side of the bracket. www.factoryfive.com 508-291-3443...

-

Page 226: Radiator Aluminum

While holding the bracket on top of the radiator, mark the location of the mount bracket holes on the 1”x 1” tubes. Do not let the end of the bracket overhang the tube, another piece of aluminum will be attached to the outside of the tube later (see picture below). Remove the top mount bracket and drill through the 1”x 1”... - Page 227 Large radiator duct mounted. Insert the radiator duct aluminum from behind the radiator. Attach the driver and passenger side duct brackets to the top of the 1”x 1” tubes and the sides of the main duct using ⅛” rivets and Silicone. www.factoryfive.com 508-291-3443...

- Page 228 Passenger side bracket Driver side bracket www.factoryfive.com 508-291-3443...

-

Page 229: Stainless Radiator Hoses

Stainless Radiator Hoses Unpack the stainless radiator hose kit and remove the hose connectors from the boxes. Use the smaller sections of tube inside the adapters to fit them to smaller fittings on the radiator and intake. www.factoryfive.com 508-291-3443... - Page 230 Then fit the larger adapters over them. Upper radiator hose Start at the engine and route the tube along the top of the passenger side duct bracket. www.factoryfive.com 508-291-3443...

- Page 231 The kit includes a remote fill adapter that should be installed at the highest point in the cooling system which is the return hose back to the radiator. www.factoryfive.com 508-291-3443...

-

Page 232: Fan Wiring

Mark the tube where it needs to be cut so that the tube will just touch the attaching location. Remove the tube from the vehicle. Cut the tube using a hack saw or if available a cut-off wheel. If necessary clean the end up with tin snips or a grinder. - Page 233 Fan mounting components, dash electrical components There are a few ways to run the electric fan. The kit includes a relay, wiring, and a thermostat switch to get used with the relay to turn the fan on and off at 185°F. The alternative way is to use the relay with a dash mounted on/off switch Dash mounted on/off switch ...

- Page 234 Ground the black electric fan wire to the frame. Connect the other electric fan wire to the #87 tab on the fan relay. Attach the #85 ground tab to the thermostat switch. Connect the #86 and #30 tabs to a +12V 30A fuse in the fuse panel. www.factoryfive.com 508-291-3443...

-

Page 235: Emergency Brake

Emergency Brake ½” deep socket, ” hex key, marker, scissors, hacksaw. Mustang E-brake handle, brake line components Push the U-nuts from the brake line components onto the E-brake handle. Bolt the handle to the mount bracket using the kit fasteners. The holes are slotted so the handle can get positioned properly to allow room for your hand around the handle. - Page 236 Your E-brake cables should be from the same car as your rear brakes. 87-92 Mustang cables or the FFR cables mount to the bracket up near the 2”x 3” tube. Route the cables through the upper bracket in the transmission tunnel until the sheath end clicks in place. www.factoryfive.com 508-291-3443...

- Page 237 Route the inner cable down under the chassis and hook them to the T cable. www.factoryfive.com 508-291-3443...

-

Page 238: Emergency Brake Boot

Route the remaining cable back to the calipers and attach. Make sure your routing is out of the way of any moving parts and the cable has slack to move with the axle. Pull up on the handle a few times to make sure the self tensioner works and there are no problems with the cable. -

Page 239: Interior Aluminum

Interior Aluminum Transmission Tunnel Cover Drill, ⅛” drill bit, Silicone, Caulking gun, Rivet gun Secondary Body Fasteners Components, Packaged Aluminum, mounted aluminum Remove the seats, roll bar, and harnesses and silicone and install the transmission tunnel top. www.factoryfive.com 508-291-3443... - Page 240 Silicone and install the shifter hole cover. Make sure it does not interfere with the movement of the shift lever. Silicone and install the tunnel plug patch panel if not using the Mustang transmission harness. www.factoryfive.com 508-291-3443...

-

Page 241: Driver Footbox

Driver Footbox Silicone and install the front patch panel. Seats Harness ¾” wrench, ¾” socket, ½” drill bit, drill, ratchet Seat Harness/Fasteners Unpack the seat harnesses and hardware. www.factoryfive.com 508-291-3443... - Page 242 Bolt the lap harness in position. Remove the mounting tab from the harness. Loop the harness over the roll bar crossbar. www.factoryfive.com 508-291-3443...

- Page 243 The shoulder harnesses are side specific so make sure you have the sides correct. Follow the manufacturer’s directions inside the seat harness boxes on how to loop the harness straps through the slider bracket. www.factoryfive.com 508-291-3443...

-

Page 244: Shifter Handle And Boot

Adjust the harnesses to where they fit you comfortably. Shifter Handle and Boot ½” wrench, ⅛”drill bit, drill, Phillips head screwdriver, marker, thread lock Shifter handle components Unpack the shift handle and bolt it to the transmission. These bolts have a tendency to rattle loose so use a little thread locker. - Page 245 Push the boot and trim rind down over the handle so it sits flush on the tunnel. Using a silver marker or white paint marker, mark your screw holes on the tunnel. www.factoryfive.com 508-291-3443...

- Page 246 Remove the boot and drill ⅛” holes in the spots you marked. Re-install the boot and screw down to the tunnel with the countersunk screws. A small screwdriver can help to locate the holes. www.factoryfive.com 508-291-3443...

- Page 247 Screw the two piece knob onto the shift handle and tighten so the shift pattern is in the correct orientation. www.factoryfive.com 508-291-3443...

-

Page 248: Seats

Seats ” drill bit, drill, ” hex key, ½” deep socket, marker Seat mount hardware, seats These instructions show the install of the more popular Roadster street seat. Racing seats with less padding give more room, the more upright the angle of the seat the more room to straighten out your legs. - Page 249 Using the rivet heads as a guide mark where the rails of the seat frame are above the seat mounting plates. Drill the first hole for the seat mounting and install the bolt. www.factoryfive.com 508-291-3443...

-

Page 250: Nameplate

Drill the remaining holes for mounting the seats and install the bolts. Nameplate ” drill bit, rivet gun, drill www.factoryfive.com 508-291-3443... -

Page 251: Steering Wheel

Secondary body fasteners, certificate of origin envelope Factory Five Racing has included a Certificate of Origin along with a Nameplate for your kit. The serial number from the Certificate of Origin matches the number engraved on the 2”x 2”... - Page 252 Bolt the steering wheel to the boss. The pattern is not symmetrical so it will only line up in one direction. www.factoryfive.com 508-291-3443...

- Page 253 Bolt the steering wheel assembly to the steering shaft. Use thread-locker on this bolt. www.factoryfive.com 508-291-3443...

-

Page 254: Rolling Chassis Check

Rolling Chassis Check Front Suspension Now is a good time to double check all your hardware, make sure your wiring and hoses are away from extreme heat and moving parts, make sure the steering turns freely lock to lock, and make sure your brake flex lines have enough slack for the full range of wheel movement. - Page 255 Transmission Fill the transmission with fluid and install the shifter assembly. Leave the shift handle and knob off for now. www.factoryfive.com 508-291-3443...

- Page 256 Engine Fill the engine with Oil and coolant. Both these fluids should be rechecked after you have started the engine for the first time. Make sure there is some coolant in the overflow to start out, about full is good. Get the engine up to temperature and check for leaks and make sure the fan is working.

- Page 257 Suspension All of the suspension and steering components that have grease fitting need to be greased. With a grease gun squeeze grease into each fitting on all the control arms, including rear lowers on a slid axle, and tie rods. www.factoryfive.com 508-291-3443...

-

Page 258: Rattle Patrol

Power Steering System Bleeding If not running power steering, skip this section. Raise the front wheels off the ground if they are not already Turn the steering wheel all the way to the left. Fill the reservoir to the full cold level and leave the cap off. Turn the steering wheel lock to lock 20 times checking the fluid level every few times. -

Page 259: Left Footbox Aluminum

If you just can’t get comfortable with the standard configuration some things you can do to increase room or comfort include: Trim the pedal pads for more room between pedals. Cut down or remove altogether the gas pedal pad. ... -

Page 260: Body Section

Chapter Body Section www.factoryfive.com 508-291-3443... -

Page 261: Weatherstrip

The Body and panel mounting are a critical part of how your car will end up looking when it is finished. Whether you are having a body shop paint your car or doing it yourself, the best results will be from fully mounting the body, all the panels and getting them to fit properly and then removing the body for the paint process. -

Page 262: Body Mounting