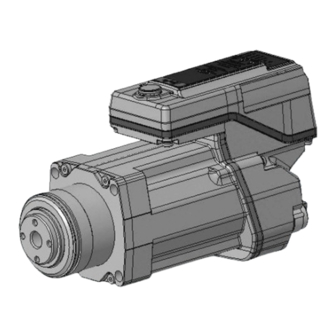

Danfoss VLT ISD 511 Manuals

Manuals and User Guides for Danfoss VLT ISD 511. We have 1 Danfoss VLT ISD 511 manual available for free PDF download: Operating Manual

Danfoss VLT ISD 511 Operating Manual (156 pages)

Brand: Danfoss

|

Category: Servo Drives

|

Size: 15 MB

Table of Contents

Advertisement

Advertisement