Siemens SINAMICS S120 Function Manual

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Summary of Contents for Siemens SINAMICS S120

- Page 1 Function Manual SINAMICS S120 Drive functions Edition 06/2019 www.siemens.com/drives...

- Page 3 Introduction Fundamental safety instructions Infeed SINAMICS Extended setpoint channel S120 Drive functions Servo control Vector control Function Manual U/f control (vector control) Basic functions Function modules Monitoring functions and protective functions Safety Integrated Basic Functions Applications Web server Basic information about the drive system Valid as of: Firmware version 5.2...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Table Of Contents

Table of contents Introduction..............................17 The SINAMICS converter family ....................17 General information about SINAMICS documentation............18 Usage phases and their documents/tools (as an example) ..........20 Where can the various topics be found?................21 Training and support ......................22 Using OpenSSL ........................23 General Data Protection Regulation ..................24 Fundamental safety instructions.........................25 General safety instructions.....................25 Warranty and liability for application examples ..............26... - Page 6 Supplementary conditions....................151 5.16.2 Important parameters (process-dependent).................155 5.16.3 Setting of the elasticity-based pole position identification ............156 5.16.4 Commutation angle offset commissioning support (p1990) ..........165 5.16.5 Overview of important parameters (see SINAMICS S120/S150 List Manual) .....165 Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

- Page 7 Table of contents 5.17 Vdc control ...........................167 5.18 Dynamic Servo Control (DSC) .....................171 5.19 Travel to fixed stop.......................176 5.20 Vertical axes.........................181 5.21 Variable signaling function ....................182 5.22 Central probe evaluation ......................184 5.22.1 Examples ..........................190 5.22.2 Function diagrams and parameters ..................191 5.23 Voltage precontrol ........................193 5.23.1...

- Page 8 Table of contents 6.15.2 Efficiency optimization for reluctance motors...............260 6.15.3 Function diagrams and parameters ..................261 6.16 Fast magnetization for induction motors ................262 6.17 Flying restart ........................266 6.17.1 Fast flying restart........................268 6.17.2 Flying restart for a synchronous reluctance motor ...............270 6.17.3 Messages and parameters....................271 6.18 Synchronization........................272...

- Page 9 Table of contents 8.12.4 Configuring a fault reaction ....................337 8.12.5 Function diagrams and parameters ..................337 8.13 DC braking ...........................339 8.13.1 Configuring the function via parameters ................339 8.13.2 Activating a function via fault reaction..................341 8.13.3 Activating a function via OFF fault responses..............341 8.13.4 Configuring a function as a response to a speed threshold ..........341 8.13.5...

- Page 10 Table of contents 8.25.1 SIMOTION mode .........................396 8.25.2 SINAMICS mode........................397 8.25.3 Zero mark emulation (SINAMICS mode) ................399 8.25.4 Synchronization of the zero marks (SINAMICS mode) ............402 8.25.5 Limit frequencies for TM41....................403 8.25.6 Example in the SINAMICS mode ..................404 8.25.7 Function diagrams and parameters ..................405 8.26 Upgrade the firmware and project..................407 8.26.1...

- Page 11 Table of contents 9.8.4.2 Flying referencing.........................482 9.8.4.3 Data set switchover......................483 9.8.4.4 Function diagrams and parameters ..................485 9.8.5 Referencing with several zero marks per revolution ............485 9.8.5.1 Evaluating BERO signals .....................487 9.8.6 Safely referencing under EPOS ...................488 9.8.7 Traversing blocks .........................491 9.8.8 Travel to fixed stop.......................496 9.8.9...

- Page 12 Table of contents 9.14.3.1 Activating the function ......................564 9.14.3.2 Measuring the function......................565 9.14.4 APC with encoder combination and differential position feedback: ........565 9.14.4.1 Important notes for parameterization ...................569 9.14.4.2 Measuring the function......................570 9.14.5 APC with acceleration feedback ..................570 9.14.5.1 Important notes for parameterization ...................575 9.14.5.2 Measuring the function......................576 9.14.6...

- Page 13 Table of contents 10.2.10 Motor with DRIVE-CLiQ .......................622 10.2.11 Temperature sensor evaluation ...................623 10.2.12 Function diagrams and parameters ..................623 10.3 Blocking protection.......................626 10.4 Stall protection (vector control only)..................627 Safety Integrated Basic Functions......................629 11.1 Latest information.........................629 11.2 General information......................631 11.2.1 Explanations, standards and terminology ................631 11.2.2 Supported functions ......................633 11.2.3...

- Page 14 Table of contents 11.11.2 Safety Logbook ........................684 11.11.3 Acceptance test........................684 11.11.3.1 Preparing the acceptance test .....................685 11.11.3.2 Carrying out an acceptance test (example) .................686 11.12 Overview of parameters and function diagrams (WV) ............689 Applications ..............................691 12.1 Application examples ......................691 12.2 Switch on infeed unit via a drive axis ...................694 12.3 Control Units without infeed control ..................697...

- Page 15 Table of contents 13.4.1 Overview ..........................747 13.4.2 Creating a parameter list......................747 13.4.3 Adding parameters.......................749 13.4.4 Selecting/entering parameters .....................750 13.4.5 Changing the parameter sequence..................750 13.4.6 Deleting parameters......................750 13.4.7 Changing the list properties ....................750 13.4.8 Deleting a parameter list ......................751 13.5 Backup and restore ......................752 13.5.1 Overview ..........................752 13.5.2...

- Page 16 Table of contents 14.5.5 Function diagrams and parameters ..................796 14.6 Inputs/outputs........................798 14.6.1 Digital inputs/outputs......................798 14.6.2 Use of bidirectional inputs/outputs on the CU ..............801 14.6.3 Analog inputs ........................802 14.6.4 Analog outputs ........................804 14.7 Write protection ........................805 14.8 Know-how protection......................808 14.8.1 Overview ..........................808 14.8.2 Know-how protection features....................809 14.8.3...

- Page 17 Controlling the drive using the BOP20 .................894 A.4.6 Important functions via BOP20 ....................894 Replacing an encoder for SIMOTICS motors...............896 Availability of hardware components..................898 Availability of SW functions ....................905 Functions of SINAMICS S120 Combi ..................916 Index.................................919 Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

- Page 18 Table of contents Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

-

Page 19: Introduction

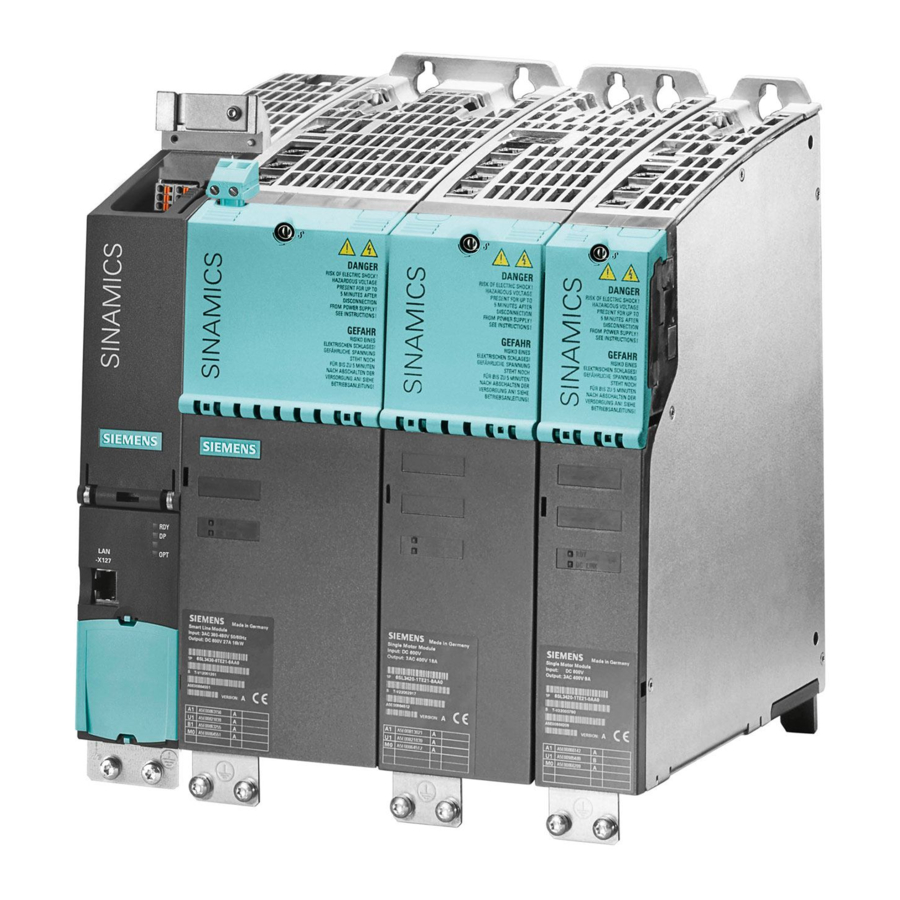

With the SINAMICS converter family, you can solve any individual drive task in the low-voltage, medium-voltage and DC voltage range. From converters to motors and controllers, all Siemens drive components are perfectly matched to each other and can be easily integrated into your existing automation system. -

Page 20: General Information About Sinamics Documentation

Siemens MySupport/Documentation You can find information on how to create your own individual documentation based on Siemens content and adapt it for your own machine documentation at the following address (https://support.industry.siemens.com/My/ww/en/documentation). Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2... - Page 21 1.2 General information about SINAMICS documentation Additional information You can find information on the topics below at the following address (https:// support.industry.siemens.com/cs/de/en/view/108993276): ● Ordering documentation/overview of documentation ● Additional links to download documents ● Using documentation online (find and search in manuals/information) Questions relating to the technical documentation Please send any questions about the technical documentation (e.g.

-

Page 22: Usage Phases And Their Documents/Tools (As An Example)

● SINAMICS S210 Servo Drive System (D 32) ● SINUMERIK 840 Equipment for Machine Tools (Catalog NC 62) Installation/assembly ● SINAMICS S120 Equipment Manual for Control Units and Supplementary System Components ● SINAMICS S120 Equipment Manual for Booksize Power Units ●... -

Page 23: Where Can The Various Topics Be Found

SINAMICS S120 Function Manual Communication Safety Integrated Basic and Extended Functions SINAMICS S120 Safety Integrated Function Manual Basic Functions SINAMICS S120 Function Manual Drive Functions Commissioning Of a simple SINAMICS S120 drive with Getting Started STARTER Commissioning With STARTER SINAMICS S120 Commissioning Manual Commissioning... -

Page 24: Training And Support

Training and support Training At the following address (http://www.siemens.com/sitrain), you can find information about SITRAIN (Siemens training on products, systems and solutions for automation and drives). Technical Support Country-specific telephone numbers for technical support are provided in the Internet at the following address (https://support.industry.siemens.com/cs/ww/en/sc) in the "Contact"... -

Page 25: Using Openssl

Introduction 1.6 Using OpenSSL Using OpenSSL Many SINAMICS products include OpenSSL. The following applies to these products: ● This product contains software (https://www.openssl.org/) that has been developed by the OpenSSL project for use in the OpenSSL toolkit. ● This product contains cryptographic software (mailto:eay@cryptsoft.com) created by Eric Young. -

Page 26: General Data Protection Regulation

1.7 General Data Protection Regulation General Data Protection Regulation Compliance with the General Data Protection Regulation Siemens respects the principles of data protection, in particular the data minimization rules (privacy by design). For this product, this means: The product does not process neither store any person-related data, only technical function data (e.g. -

Page 27: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions WARNING Danger to life if the safety instructions and residual risks are not observed If the safety instructions and residual risks in the associated hardware documentation are not observed, accidents involving severe injuries or death can occur. ●... -

Page 28: Warranty And Liability For Application Examples

Fundamental safety instructions 2.2 Warranty and liability for application examples Warranty and liability for application examples Application examples are not binding and do not claim to be complete regarding configuration, equipment or any eventuality which may arise. Application examples do not represent specific customer solutions, but are only intended to provide support for typical tasks. -

Page 29: Industrial Security

In order to protect plants, systems, machines and networks against cyber threats, it is necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial security concept. Products and solutions from Siemens constitute one element of such a concept. - Page 30 Fundamental safety instructions 2.3 Industrial security WARNING Unsafe operating states resulting from software manipulation Software manipulations, e.g. viruses, Trojans, or worms, can cause unsafe operating states in your system that may lead to death, serious injury, and property damage. ● Keep the software up to date. ●...

-

Page 31: Infeed

● The recommended ON and OFF sequence for activating the SLMs must be adhered to. You can find further information on the wiring of Smart Line Modules with the Control Unit and for the recommended ON/OFF sequence in the Equipment Manual SINAMICS S120 Booksize power units. -

Page 32: Active Infeed

Infeed 3.1 Active Infeed Active Infeed Function description The Active Infeed control works in conjunction with the line reactor or an Active Interface Module and the Active Line Module as step-up controller. The level of the DC link voltage can be defined through parameters, and, by means of the control, it is independent of line voltage fluctuations. -

Page 33: Active Infeed Closed-Loop Control Booksize

Infeed 3.1 Active Infeed 3.1.1 Active Infeed closed-loop control booksize Overview The following figure gives an overview of the structure of an Active Infeed control. Figure 3-1 Schematic structure of Active Infeed Booksize Active Infeed control for Active Line Modules in Booksize design Active Line Modules of the Booksize format can be operated in the following modes depending on the parameterized line voltage (p0210): ●... - Page 34 Infeed 3.1 Active Infeed The DC link voltage setpoint (p3510) and the control type are preset as follows during commissioning in line with the connection voltage (p0210): Table 3-1 Presetting the control type and DC link voltage Booksize Supply voltage p0210 [V] 380...400 401...415 416...440...

-

Page 35: Active Infeed Closed-Loop Control Chassis

Infeed 3.1 Active Infeed Note When a Wideband Line Filter is connected, it must be parameterized with p0220 = 1...5. The temperature sensor must be connected to terminal X21 of the Active Line Module. The DC link voltage (p3510) can be set within the following limits: ●... - Page 36 Chassis-2 ALM. The necessary signal interconnections are described in the following manual: ● SINAMICS S120 Device manual for air-cooled Chassis power unit Opening and closing times of the contacts being used can be adjusted in parameter p0255 (power unit contactor monitoring time).

-

Page 37: Line Supply And Dc Link Identification

Infeed 3.1 Active Infeed The DC link voltage (p3510) can be set for both the ALMs for the Chassis format and the ALMs for the Chassis-2 format within the following limits: ● Upper limit: – Maximum DC link voltage (p0280) –... -

Page 38: Active Infeed Open-Loop Control

– Unlike identification over p3410 = 5, the automated controller setting leads to losses in the dynamic response. P3410 = 0 is automatically set when an identification routine is successfully completed. Additional identification methods are listed in the SINAMICS S120/S150 List Manual. 3.1.4 Active Infeed open-loop control... - Page 39 Infeed 3.1 Active Infeed Switching on the ALM Figure 3-3 Active Infeed power-up procedure Note The infeed unit can be switched on by issuing an enable signal at the EP terminals and a positive signal edge at OFF1 (p0840). Requirement ●...

- Page 40 Infeed 3.1 Active Infeed Switching off the controller with the OFF1 signal is delayed by the time entered in p3490. This allows the attached drives to be braked in a controlled manner. Before the infeed unit is switched off, the drives connected to the DC link should be in pulse inhibit mode. Control and status messages Table 3-2 Active Infeed open-loop control...

-

Page 41: Reactive Current Control

Infeed 3.1 Active Infeed 3.1.5 Reactive current control Function description A reactive current setpoint can be set to compensate the reactive current or to stabilize the line voltage in infeed operation. The total setpoint is the sum of the fixed setpoint p3610 and the dynamic setpoint via the connector input p3611. -

Page 42: Parameterizable Bandstop Filters For Active Infeed Controls In Chassis Format

Infeed 3.1 Active Infeed Example: Setting the harmonics controller The 5th and 7th harmonics harmonics are to be compensated. Table 3-4 Example parameters for the harmonics controller Index p3624 p3625 100 % 100 % The phase currents in parameter p0069[0 ... 2] (U, V, W) can be checked using the trace function of the commissioning tool. -

Page 43: Function Diagrams And Parameters

Active Infeed - current precontrol / current controller / gating unit (p3400.0 = 0) ● 8964 Active Infeed - signals and monitoring function, line frequency/Vdc monit. (p3400.0 = 0) Overview of important parameters (see SINAMICS S120/S150 List Manual) ● r0002 Infeed operating display ● r0046.0...29 CO/BO: Missing enable signals ●... - Page 44 Infeed 3.1 Active Infeed ● r3411[0...1] Infeed inductance identified ● r3412[0...1] Infeed DC link capacitance identified ● p3508 Infeed step-up factor maximum ● p3510 Infeed DC link voltage setpoint ● p3533 BI: Infeed, inhibit regenerative operation ● p3560 Infeed Vdc controller proportional gain ●...

-

Page 45: Basic Infeed

Infeed 3.2 Basic Infeed Basic Infeed Overview The following figure gives an overview of the structure of a Basic Infeed in Booksize format. Figure 3-4 Schematic structure of Basic Infeed Booksize The following figure gives an overview of the structure of a Basic Infeed in Chassis format. Figure 3-5 Schematic structure of Basic Infeed Chassis Drive functions... - Page 46 Infeed 3.2 Basic Infeed Description The Basic Infeed open-loop control can be used to switch on/off the Basic Line Module. The Basic Line Module is an unregulated infeed unit without regenerative feedback capability. The open-loop control firmware for the Basic Line Module is on the assigned Control Unit. The Basic Line Module and Control Unit communicate via DRIVE-CLiQ.

-

Page 47: Basic Infeed Open-Loop Control

Infeed 3.2 Basic Infeed Remedy ● activate the V control: dc_max – Vector control: p1240 = 1 (factory setting) – Servo control: p1240 = 1 – U/f control: p1280 = 1 (factory setting) ● Inhibit V control: dc_max – Vector control: p1240 = 0 –... - Page 48 Infeed 3.2 Basic Infeed Switching on the BLM Figure 3-6 Basic Infeed power-up procedure Note The infeed unit can be switched on by issuing an enable signal at the EP terminals and a positive signal edge at OFF1 (p0840). Requirement ●...

-

Page 49: Function Diagrams And Parameters

Line contactor closed ZSWAE.12 r0899.12 E_ZSW1.12 3.2.2 Function diagrams and parameters Function diagrams (see SINAMICS S120/S150 List Manual) ● 8710 Basic Infeed overview ● 8720 Basic Infeed - Control word, sequence control, infeed ● 8726 Basic Infeed - Status word, sequence control, infeed ●... - Page 50 Infeed 3.2 Basic Infeed Overview of important parameters (see SINAMICS S120/S150 List Manual) ● r0002 Infeed operating display ● r0046.0...29 CO/BO: Missing enable signals ● p0210 Device supply voltage ● p0840 BI: ON/OFF (OFF1) ● p0844 BI: No coast down / coast down (OFF2) ●...

-

Page 51: Smart Infeed

Infeed 3.3 Smart Infeed Smart Infeed Overview The following figure gives an overview of the structure of a Smart Infeed in Booksize format. Figure 3-7 Schematic structure of Smart Infeed Booksize The following figure gives an overview of the structure of a Smart Infeed in Chassis format. Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2... - Page 52 Infeed 3.3 Smart Infeed Figure 3-8 Schematic structure of Smart Infeed Chassis Description The firmware of the Smart Line Module is located on the assigned Control Unit. The Smart Line Module and Control Unit communicate via DRIVE-CLiQ. Features ● For Smart Line Modules with a power ≥ 16 kW ●...

-

Page 53: Line Supply And Dc Link Identification Routine For Smart Infeed Booksize

Identification using p3410 = 5 should preferably be used. P3410 = 0 is automatically set when an identification routine is successfully completed. For additional identification methods, see the SINAMICS S120/S150 List Manual. It may be necessary to reset the closed-loop controller to the factory settings if an identification run was unsuccessful, for example. -

Page 54: Extended Smart Mode

Infeed 3.3 Smart Infeed 3.3.2 Extended Smart Mode Requirement ● The Smart Mode is active (p3400.0 = 1). Function description The operating mode "Extended Smart Mode" represents and extension of the Smart Mode, and facilitates a higher efficiency no-load operation and partial load operation as well as a more rugged operating behavior. - Page 55 Infeed 3.3 Smart Infeed Switching on the SLM Figure 3-9 Smart Infeed power-up procedure Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

- Page 56 Infeed 3.3 Smart Infeed Note The infeed unit can be switched on by issuing an enable signal at the EP terminals and a positive signal edge at OFF1 (p0840). Requirement ● Commissioning takes place via the STARTER commissioning tool. ● No PROFIdrive telegrams activated. Switching off the SLM The Active Line Module is switched off by the same procedure used to switch it on, but in the reverse order.

-

Page 57: Function Diagrams And Parameters

Smart Infeed - Signals and monitoring functions, line voltage monitoring ● 8864 Smart Infeed - Signals and monitoring functions, line frequency and Vdc mon‐ itoring Overview of important parameters (see SINAMICS S120/S150 List Manual) ● r0002 Infeed operating display ● r0046.0...29 CO/BO: Missing enable signals ●... -

Page 58: Line Contactor Control

Infeed 3.4 Line contactor control Line contactor control Function description This function can be used to control an external line contactor. Opening and closing the line contactor can be monitored by evaluating the feedback contact in the line contactor. For the "Infeed", "Servo"... - Page 59 Note Pay attention to the continuous current-carrying capacity of the digital output (see SINAMICS S120 Equipment Manual for Control Units and Additional System Components). If necessary, use an auxiliary contactor! 2. Parameterize DI/DO 8 as an output (p0728.8 = 1).

-

Page 60: Pre-Charging And Bypass Contactor Chassis And Chassis-2

Further information You will find more detailed information in the following manual: ● SINAMICS S120 Manual for Chassis Power Units, Air-cooled Procedure during switch-on ● The precharging contactor is closed and the DC link is charged via the precharging resistors. -

Page 61: Extended Setpoint Channel

Extended setpoint channel Overview ● Servo control In servo control, the extended setpoint channel is deactivated through the factory setting. If an extended setpoint channel is required, it has to be activated. ● Vector control The extended setpoint channel is always activated in vector control. Function description In the extended setpoint channel, setpoints from the setpoint source are conditioned for motor control. - Page 62 Extended setpoint channel Features The function is characterized by the following features: ● Main/supplementary setpoint, setpoint scaling ● Direction limitation and direction reversal ● Suppression bandwidths and setpoint limitation ● Ramp-function generator Setpoint sources The closed-loop control setpoint can be interconnected from various sources using BICO technology, e.g.

- Page 63 Extended setpoint channel ● Deceleration ramp OFF1 via p1121[D] The deceleration ramp in p1121 is also effective when the "Extended setpoint channel" is deactivated. ● Deceleration ramp OFF3 via p1135[D] ● For PROFIdrive telegrams 2 to 103 and 999 only (free assignment) ●...

-

Page 64: 4.1 Motorized Potentiometer

Extended setpoint channel 4.1 Motorized potentiometer Motorized potentiometer Function description The "Motorized potentiometer" function is used to simulate an electromechanical potentiometer for setpoint input. You can switch between manual and automatic mode for setpoint input. The specified setpoint is routed to an internal ramp-function generator. Setting values, start values and braking with OFF1 do not require the ramp-function generator of the motorized potentiometer. - Page 65 Setpoint channel overview ● 2501 Internal control/status words - Control word, sequence control ● 3020 Setpoint channel - Motorized potentiometer Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1030[0...n] Motorized potentiometer configuration ● p1035[0...n] BI: Motorized potentiometer, setpoint, raise ●...

-

Page 66: Fixed Setpoints

Function diagrams (see SINAMICS S120/S150 List Manual) ● 3001 Setpoint channel overview ● 3010 Setpoint channel - Fixed speed setpoints Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1001[0...n] CO: Fixed speed setpoint 1 ● p1015[0...n] CO: Fixed speed setpoint 15 ●... -

Page 67: Speed Setpoint

● 3001 Setpoint channel overview ● 3030 Setpoint channel - Main setpoint / supplementary setpoint, setpoint scaling, jog‐ ging Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1070[0...n] CI: Main setpoint ● p1071[0...n] CI: Main setpoint scaling ● r1073 CO: Main setpoint effective ●... -

Page 68: Jogging

Extended setpoint channel 4.3 Speed setpoint ● r1077 CO: Supplementary setpoint effective ● r1078 CO: Total setpoint effective 4.3.2 Jogging Function description The "Jog" function is typically used to slowly move a machine part, e.g. a conveyor belt. The "Jog mode" can also be used to move a drive into the required position independent of the sequence. - Page 69 Extended setpoint channel 4.3 Speed setpoint Figure 4-4 Flow diagram: Jog 1 and jog 2 Features ● If both jog signals are issued at the same time, the current speed is maintained (constant speed phase). ● Jog setpoints are approached and exited via the ramp-function generator. ●...

- Page 70 Extended setpoint channel 4.3 Speed setpoint Flow diagram Figure 4-5 Jog sequence Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

- Page 71 Setpoint channel overview ● 2610 Sequence control - Sequencer ● 3030 Setpoint channel - Main/supplementary setpoint, setpoint scaling, jogging Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1055[0...n] BI: Jog bit 0 ● p1056[0...n] BI: Jog bit 1 ●...

-

Page 72: Direction Of Rotation Limiting And Direction Reversal

Function diagrams (see SINAMICS S120/S150 List Manual) ● 3001 Setpoint channel overview ● 3040 Setpoint channel - Direction limitation and direction reversal Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1110[0...n] BI: Block negative direction ● p1111[0...n] BI: Block positive direction ●... -

Page 73: Speed Limiting

Skip frequency bands, setpoint limitation, minimum speed Minimum speed Using parameter p1106[0...n], a minimum speed n_min s_src or minimum velocity can be set, which is wired via BICO. Function diagrams (see SINAMICS S120/S150 List Manual) ● 3001 Setpoint channel overview ● 3050... - Page 74 Extended setpoint channel 4.4 Speed limiting Overview of important parameters (see SINAMICS S120/S150 List Manual) Setpoint limitation ● p1080[0...n] Minimum speed ● p1082[0...n] Maximum speed ● p1083[0...n] CO: Speed limit in positive direction of rotation ● r1084 CO: Speed limit positive effective ●...

-

Page 75: Ramp-Function Generator

Extended setpoint channel 4.5 Ramp-function generator Ramp-function generator Function description The "Ramp-function generator" function is used to limit the acceleration in the event of abrupt setpoint changes and thus helps to prevent load surges throughout the complete drive train. The ramp-up time p1120[0...n] and ramp-down time p1121[0...n] can be used to set mutually independent acceleration and deceleration ramps. - Page 76 Extended setpoint channel 4.5 Ramp-function generator Figure 4-8 Ramp-up and ramp-down with the basic ramp-function generator Specific features of the extended ramp-function generator The extended ramp-function generator is characterized by the following features: ● Ramp-up time T p1120[0...n] ● Ramp-down time T p1121[0...n] ●...

- Page 77 Extended setpoint channel 4.5 Ramp-function generator Figure 4-9 Extended ramp-function generator Scaling of the up ramp and the down ramp In order to be able to influence the ramp times set in parameters p1120 and p1121 cyclically via PROFIdrive telegrams, scaling is available for the ramp times. ●...

-

Page 78: Ramp-Function Generator Tracking

Extended setpoint channel 4.5 Ramp-function generator 4.5.1 Ramp-function generator tracking Overview A ramp-function generator (RFG) can be operated with or without tracking. Figure 4-10 Ramp-function generator tracking Without ramp-function generator tracking ● p1145 = 0 ● Drive accelerates until t2 although setpoint < actual value With standard ramp-function generator tracking ●... - Page 79 Extended setpoint channel 4.5 Ramp-function generator Standard RFG tracking If the load torque exceeds the torque limit of the drive and so causes the actual speed to diminish, the ramp-function generator output is not tracked to the actual speed value. If the torque limit is overshot during the ramp-up because the ramp-up time was selected too small, the effective ramp-up time of the ramp-function generator lengthens.

-

Page 80: Signal Overview, Function Diagrams And Important Parameters

The tracking continues for a polarity change. 4.5.2 Signal overview, function diagrams and important parameters Signal overview (see SINAMICS S120/S150 List Manual) ● Control signal STW1.2 OFF3 ● Control signal STW1.4 Enable ramp-function generator ● Control signal STW1.5 Start/stop ramp-function generator ●... - Page 81 Extended setpoint channel 4.5 Ramp-function generator Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1051[0...n] CI: Speed limit in RFG, positive direction of rotation ● p1052[0...n] CI: Speed limit RFG, negative direction of rotation ● p1083[0...n] CO: Speed limit in positive direction of rotation ●...

- Page 82 Extended setpoint channel 4.5 Ramp-function generator Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

-

Page 83: Servo Control

Servo control Function description The servo control mode enables operation with a high dynamic response and precision for a motor with motor encoder. The motor connected to servo control is simulated in a vector model based on data from the equivalent circuit diagram. -

Page 84: Comparison Between Servo Control And Vector Control

Servo control 5.1 Comparison between servo control and vector control Comparison between servo control and vector control The basic features and properties of the SERVO and VECTOR control modes are compared in the following table. Table 5-1 Comparison: Servo control/vector control Subject Servo control Vector control... - Page 85 Servo control 5.1 Comparison between servo control and vector control Subject Servo control Vector control Connectable motors ● Synchronous servomotors ● Synchronous motors (including torque motors) ● Permanent-magnet synchronous motors ● Permanent-magnet synchronous motors ● Induction motors ● Induction motors ●...

- Page 86 Servo control 5.1 Comparison between servo control and vector control Subject Servo control Vector control Maximum output frequency with ● 2600 Hz with 31.25 μs / 16 kHz ● 300 Hz with 250 μs/4 kHz closed-loop control or with 400 μs/5 kHz ●...

- Page 87 Servo control 5.1 Comparison between servo control and vector control Subject Servo control Vector control Note: Additional information on connecting power units in parallel is provided in Chapter "Parallel connection of power units (Page 515)". Permissible range of the ratio be‐ The permissible range of the ratio be‐...

-

Page 88: Influencing Calculation Of The Open-Loop Control And Closed-Loop Control Parameters

The value is only used for 1FK2 motors. An overview of the influenced parameters and the set values is provided in the "SINAMICS S120/S150 List Manual". Calling the calculation You call the calculation of the parameters, which influence the technological application, as follows: ●... -

Page 89: Setpoint Addition

Servo control 5.3 Setpoint addition Setpoint addition Function description Setpoint addition allows up to 2 speed setpoints to be combined. While main and supplementary setpoints used in the setpoint channel are influenced by speed limits and the ramp-function generator, the speed setpoint is directly active here. As a consequence, up ramps and down ramps of a ramp-function generator are eliminated. - Page 90 3. To activate the interpolator for the down ramp, in the drop-down list for p1189[0], select "Yes". Function diagrams (see SINAMICS S120/S150 List Manual) ● 3080 Setpoint channel - ramp-function generator selection, status word, tracking Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1121[0...n] Ramp-function generator ramp-down time ● p1135[0...n] OFF3 ramp-down time ●...

-

Page 91: Speed Setpoint Filter

Servo control 5.4 Speed setpoint filter Speed setpoint filter Function description The "Speed setpoint filter" function allows you to hide or to attenuate certain frequency ranges. Speed setpoint filters do not have any effect on the stability of the speed controller, because they lie in the setpoint channel. - Page 92 4. Then save the modified project settings. Function diagrams (see SINAMICS S120/S150 List Manual) ● 5020 Servo control - Speed setpoint filter and speed precontrol Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1414[0...n] Speed setpoint filter activation ● p1415[0...n] Speed setpoint filter 1 type ●...

-

Page 93: Speed Controller

Servo control 5.5 Speed controller Speed controller Function description For operation with a controller, the speed controller regulates the speed of the motor based on the actual values of the encoder. For operation without a controller, the speed controller regulates the speed of the motor based on calculated speed actual values. Special characteristics of the speed controller include: ●... - Page 94 Servo control 5.5 Speed controller Free K adaptation The free K adaptation is active during operation with encoder, as well as during operation without encoder. The free K adaptation provides an added factor for the speed-dependent adaptation during operation with encoder. Figure 5-4 Overview: free adaptation Speed-dependent K...

-

Page 95: Torque-Controlled Operation

Function diagrams (see SINAMICS S120/S150 List Manual) ● 5050 Servo control - Speed controller adaptation (K adaptation) Overview of important parameters (see SINAMICS S120/S150 List Manual) Free Kp_n adaptation ● p1455[0...n] CI: Speed controller P gain adaptation signal ● p1456[0...n] Speed controller P gain adaptation lower starting point ●... - Page 96 Servo control 5.5 Speed controller Activating torque-controlled operation To initiate torque-controlled operation, proceed as follows: 1. Set torque-controlled operation as follows: – p1300 = 2 or p1501 = "1" signal 2. Enter the torque setpoint using the following parameter: – p1511: Signal source for supplementary torque 1 –...

- Page 97 ● 5060 Servo control - Torque setpoint, switchover control mode ● 5610 Servo control – torque limiting/reduction, interpolator Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1300[0...n] Open-loop/closed-loop control operating mode ● r1406.8...12 CO/BO: Control word, speed controller ●...

-

Page 98: Torque Setpoint Limitation

Servo control 5.6 Torque setpoint limitation Torque setpoint limitation Function description The torque setpoint can be limited to a maximum permissible value in all four quadrants. Different limits can be parameterized for motor and regenerative modes. Figure 5-7 Current / torque setpoint limitation The torque setpoint is limited with the following steps: ●... - Page 99 Servo control 5.6 Torque setpoint limitation Features The connector inputs of the function are initialized with fixed torque limits. If required, the torque limits can also be defined dynamically during operation. ● A control bit can be used to select the torque limitation mode. The following alternatives are available: –...

- Page 100 Negative values at r1534 or positive values at r1535 represent a minimum torque for the other torque directions and can cause the drives to rotate if no counteractive load torque is generated (see function diagram 5630 in the SINAMICS S120/S150 List Manual). Example: torque limits with / without offset...

- Page 101 Servo control - Motoring/generating torque limit ● 5630 Servo control - Upper/lower torque limit ● 5640 Servo control - Mode changeover, power/current limiting Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p0640[0...n] Current limit ● p1400[0...n] Speed control configuration ●...

-

Page 102: Current Setpoint Filter

Servo control 5.7 Current setpoint filter Current setpoint filter The current setpoint filters 1 to 4 are activated by default. If more than 4 current setpoint filters are required, you can activate current setpoint filters 5 to 10 in offline mode in the object properties of the drive. - Page 103 Servo control 5.7 Current setpoint filter 10.Make the setting p1699 = 0 to start calculating the filter data. 11.Then save the modified project settings. Parameterization example Four current setpoint filters connected in series can be parameterized as follows, for example: ●...

- Page 104 Servo control 5.7 Current setpoint filter Additional examples The following examples demonstrate the features of the parameterizable current setpoint filters. Low-pass 2nd order (PT2 filter) The following figure shows the transfer function for low-pass 2nd order. = Denominator natural fre‐ quency = Denominator damping Table 5-2...

- Page 105 Servo control 5.7 Current setpoint filter ● Denominator natural frequency f ● Denominator damping Band-stop filter with defined notch depth Table 5-4 Example: Band-stop filter with defined notch depth Filter parameters Amplitude log frequency curve Phase frequency curve Blocking frequency f 500 Hz Bandwidth f = 500 Hz...

- Page 106 Servo control 5.7 Current setpoint filter Band-stop filter with defined reduction Table 5-5 Example: Band-stop filter with defined reduction Filter parameters Amplitude log frequency curve Phase frequency curve Blocking frequency f 500 Hz Bandwidth f = 500 Hz Notch depth K = -∞ dB Reduction ABS = -20 dB General conversion to parameters for general order filters: ●...

- Page 107 0.02 dB Denominator frequency = 900 Hz Denominator damping D = 0.15 dB Function diagrams (see SINAMICS S120/S150 List Manual) ● 5700 Servo control - Current control, overview ● 5710 Servo control - Current setpoint filters 1 ... 4 ● 5711 Servo control - Current setpoint filters 5 …...

- Page 108 Servo control 5.7 Current setpoint filter Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p0108[0...n] Drive object function module ● p1400[0...n] Speed control configuration ● p1656[0...n] Current setpoint filter activation ● p1657[0...n] Current setpoint filter 1 type ● p1658[0...n] Current setpoint filter 1 denominator natural frequency ●...

-

Page 109: Current Controller

The P gain of the current controller can be reduced (depending on the current) by means of current controller adaptation. Current controller adaptation can be deactivated with the setting p1402.2 = 0. Function diagrams (see SINAMICS S120/S150 List Manual) ● 5700 Servo control - Current control, overview ●... - Page 110 Servo control 5.8 Current controller Overview of important parameters (see SINAMICS S120/S150 List Manual) Current control ● p1701[0...n] Current controller reference model dead time ● p1715[0...n] Current controller P gain ● p1717[0...n] Current controller integral time Current and torque limitation ●...

-

Page 111: Autotuning

Servo control 5.9 Autotuning Autotuning Function description The term "Autotuning" comprises all drive-internal functions that adapt controller parameters during operation based on internal measured variables. The set parameters are written in the parameters, but are not saved permanently. Applications The main applications of the autotuning functions are: ●... - Page 112 Servo control 5.9 Autotuning Function description With One Button Tuning (OBT), the mechanical drive train is measured using short test signals and the controller parameters are optimally adapted to the existing mechanics. As this concerns a drive-internal function, no external engineering tool is required. Restrictions Only the motor measuring system is taken into account when optimizing the position controller.

- Page 113 Servo control 5.9 Autotuning Configuring the function The following settings are possible via parameter p5301: Effect The speed controller gain is determined and set with the aid of a noise signal. Any required current setpoint filters are determined and set with the aid of a noise signal. In this way, a higher dynamic response can be achieved in the speed control loop.

- Page 114 Servo control 5.9 Autotuning Measuring via noise excitation The test signals comprise, on the one hand, a noise excitation during which the drive executes a motion with a superimposed noise signal for a few seconds. The following settings are required for this: ●...

- Page 115 Servo control 5.9 Autotuning Additional settings and displays The following table provides an overview of further settings and displays in the parameters. Parameter Adjustment range Factory set‐ Setting / display (with explanations) ting p5271[0... ‑ 0000 1100 bi Configuration of the OBT. The following settings are possible: ●...

-

Page 116: Online Tuning

Servo control 5.9 Autotuning Parameter Adjustment range Factory set‐ Setting / display (with explanations) ting p5308 0 to 30000 degrees 0 degree Distance limiting for the OBT: 0 to 30000 mm 0 mm ● Following activation of the OBT (p5300), the traversing range in positive and negative direction is restricted to the set distance limiting specified in degrees. - Page 117 Servo control 5.9 Autotuning NOTICE Unstable controller when manually changing the controller parameters during autotuning If you wish to manually change a controller parameter that the online tuning automatically sets, then this can result in an unstable controller and therefore material damage. ●...

- Page 118 Servo control 5.9 Autotuning Note Function and supplementary conditions for the inertia estimator Please observe the notes in chapter Moment of inertia estimator (Page 540). Note Resetting the inertia estimator Through deactivation and renewed activation of the online tuning, the estimated load moment of inertia and the load torques are reset.

- Page 119 Servo control 5.9 Autotuning ● Do not change the Kp (speed controller gain). ● Activate the torque precontrol. Automatic pre-assignment When the "Online tuning" function is activated, settings are made that ensure the safe operation of the online tuning. Current setpoint filter The natural frequency of the first PT2 filter behaves proportional to the current controller and speed controller cycles.

-

Page 120: Adaptation Of The Control Parameters

Servo control 5.9 Autotuning Application examples Online tuning is applied in the following cases: ● Positioning axes A positioning axis application can always be used when an axis performs a point-to-point motion independently of other axes. p5302.7 = 0 must be set. The axis is thus optimized for positioning without overshoot. -

Page 121: Problem Handling

Servo control 5.9 Autotuning Position controller Two cases can be selected for the position control via bit p5271.0: ● p5271.0 = 0 (not active) In this case, the position controller acts like a normal closed-loop P controller. The position controller gain (servo gain factor) is adapted depending on the estimated dynamic response of the speed control loop and the sample times. -

Page 122: Current Setpoint Filter Adaptation

Servo control 5.9 Autotuning Motor hums at very low speeds If the drive has an encoder with poor resolution, the motor may hum at very low speeds or at standstill. Remedy ● Increase the actual speed value smoothing (p1441) or reduce the dynamic response (p5272). - Page 123 Servo control 5.9 Autotuning Function description The function is used to automatically shift a selected current setpoint filter to a mechanical resonant frequency. Detailed descriptions on the principle of operation of the current setpoint filter adaptation as well all of the parameters that are linked with the adaptation can be found later in this chapter.

- Page 124 Servo control 5.9 Autotuning Note Deviation with activated online tuning (p5300 = 2) The denominator damping of the adapted filter is set automatically. You can also overwrite this setting. Further explanations for the principle of operation If, after the pulse enable, a resonant frequency has been excited to such a degree that the internal activation threshold is exceeded, the adaptation moves the band-stop filter to this resonant frequency.

- Page 125 Servo control 5.9 Autotuning Supplementary conditions ● Due to the operating principle of the adaptation, the base adaptation algorithm can only work reliably with systems that have one single mechanical resonant frequency. Undesirable movements of the adapted filter between the resonances can occur for systems with several mechanical resonant frequencies.

-

Page 126: Stability Of The Speed Control Loop

Servo control 5.9 Autotuning Start value of the adaptation The frequency with which the adaptation starts at the pulse enable is always the current blocking frequency of the filter. It can be read in parameter r5285 and in the frequency parameters of the filter. -

Page 127: Remedy For Insufficient Adaptation

However, observe the stability of the control loop with this setting. 5.9.4 Function diagrams and parameters Overview of important faults (see SINAMICS S120/S150 List Manual) ● F07419 Drive: Incorrect current setpoint filter adaptation Overview of important parameters (see SINAMICS S120/S150 List Manual) ●... - Page 128 Servo control 5.9 Autotuning ● p5284[0...n] Current setpoint filter adaptation activation threshold ● r5285[0...n] Current setpoint filter adaptation current frequency ● p5292 FFT tuning dynamic response factor ● r5293 FFT tuning speed controller P gain identified ● r5294[0...5] FFT tuning zero position identified ●...

-

Page 129: Notes About The Electronic Motor Model

Servo control 5.10 Notes about the electronic motor model 5.10 Notes about the electronic motor model A model change takes place within the speed range p1752 · (100 % - p1756) and p1752. With induction motors with encoder, the torque image is more accurate in higher speed ranges; the effect of the rotor resistance and the saturation of the main field inductance are corrected. -

Page 130: Increased Stall Power At The Voltage Limit

Servo control 5.11 Increased stall power at the voltage limit 5.11 Increased stall power at the voltage limit Function description As a result of a new voltage management, in operation, the spindle power can be briefly increased to the stall power limit. The stall power limit is the range in which the motor power is limited as a result of the maximum converter output voltage. - Page 131 Servo control 5.11 Increased stall power at the voltage limit An increased stall power (p1402.6 = 1) provides an improvement for both synchronous and induction motors in the following ranges: ● For induction motors, the stall power decreases with the speed (see "voltage limiting Characteristics"...

- Page 132 (p0327 > 90°, p0328 > 0). The increased power applies both for motors as well as when generating. p1402.3 is not relevant for synchronous motors. Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p0326[0...n] Motor stall torque correction factor ●...

-

Page 133: U/F Control

Servo control 5.12 U/f control 5.12 U/f control Overview With U/f control, the following components and data can be checked: ● Motor Module ● Power cable between the Motor Module and motor ● Motor ● DRIVE-CLiQ cable between the Motor Module and motor ●... - Page 134 Servo control 5.12 U/f control Note Restricted applications for U/f control U/f control must only be used as a diagnostic function (e.g. check of the motor encoder function). In order to obtain a pure diagnostic mode without any influence on actual values, the resonance damping must be deactivated (p1338 = 0).

- Page 135 Servo control 5.12 U/f control Commissioning U/f control Before commissioning the U/f control, observe the following information: Note The run-up at the current limit (p0640) permits a quick run-up of the drive, e.g. when operating the drive with variable moments of inertia. Only the ramp-function generator stops when the current limit (p0640) is reached.

- Page 136 Function diagrams (see SINAMICS S120/S150 List Manual) ● 5300 Servo control - U/f control for diagnostics ● 5650 Servo control - Vdc_max controller and Vdc_min controller Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p0304[0...n] Rated motor voltage ● p0310[0...n] Rated motor frequency ●...

-

Page 137: Optimizing The Current And Speed Controller

Servo control 5.13 Optimizing the current and speed controller 5.13 Optimizing the current and speed controller Overview The following tools are available for tuning the controllers: ● Function generator in the commissioning tool ● Trace in the commissioning tool ● Measuring function in the commissioning tool ●... - Page 138 Servo control 5.13 Optimizing the current and speed controller Example 1: Measuring the speed controller frequency response By measuring the speed controller frequency response and the control system, critical resonant frequencies can, if necessary, be determined at the stability limit of the speed control loop and dampened using one or more current setpoint filters.

-

Page 139: Encoderless Operation

Servo control 5.14 Encoderless operation 5.14 Encoderless operation Overview Both encoderless and mixed operation (without/with encoder) is possible in the servo control. Encoderless operation with the motor model allows a higher dynamic response and greater stability in the servo control than a standard drive with U/f control. Compared with drives with an encoder, however, speed accuracy is lower and the dynamic response and smooth running features deteriorate. - Page 140 Servo control 5.14 Encoderless operation account the thermal motor load, as the current entered in p1612 is impressed in I/f-controlled operation also without load. Note Encoderless operation is not permitted for vertical axes or similar. Encoderless operation is not suitable for a higher-level closed-loop position control either. The starting behavior of synchronous motors from standstill can be improved further by parameterizing the pole position identification (p1982 = 1).

- Page 141 Servo control 5.14 Encoderless operation Figure 5-17 Area switchover Note In closed-loop control operating mode "Speed controller without encoder", a rotor position encoder is not required. Temperature evaluation remains active, even when the encoder is parked. This state can be identified at parameter r0458.26 = 1. When parameter r0458.26 = 0, temperature sensing is also deactivated.

- Page 142 Servo control 5.14 Encoderless operation 4. If the total moment of inertia has not already been determined using the rotating measurement, you have the possibility of determining the total moment of inertia as follows: – If an encoder is being used, and the motor has a restricted traversing path (e.g. encoderless operation is only used when an encoder develops a fault or only for the upper speed range): Determine the moment of inertia using the rotating measurement of the motor data...

- Page 143 ● 5060 Servo control - Torque setpoint, switchover control mode ● 5210 Servo control - Speed controller without encoder Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p0341[0...n] Motor moment of inertia ● p0342[0...n] Ratio between the total and motor moment of inertia ●...

-

Page 144: Motor Data Identification

Servo control 5.15 Motor data identification 5.15 Motor data identification Requirement ● The first commissioning has been completed. The following must be fulfilled: – The electrical motor data (motor datasheet) or rating plate data have been entered. – The calculation of the motor and control parameters (p0340) has been completed. Function description The motor data identification (MotID) is used as a tool to determine the motor data, e.g. - Page 145 Servo control 5.15 Motor data identification Note Completion of the individual identification runs can be read via parameters r3925 to r3928. The enable signals OFF1, OFF2, OFF3 and "enable operation" remain effective and can interrupt the MotID routine. If there is an extended setpoint channel (r0108.08 = 1), p1959.14 = 0 and p1959.15 = 0 and direction limiting (p1110 or p1111) is active there, then this is observed at the instant of the start via p1960.

- Page 146 Servo control 5.15 Motor data identification Motor data Motor data input requires the following parameters: Table 5-8 Motor data Induction motor Permanent-magnet synchronous motor ● p0304 rated motor voltage ● p0305 rated motor current ● p0305 rated motor current ● p0311 rated motor speed ●...

-

Page 147: Motor Data Identification For Induction Motors

Servo control 5.15 Motor data identification Parameters to control the MotID The following parameters influence the MotID: Table 5-10 Parameters for control Stationary measurement (MotID) Rotating measurement ● p0640 current limit ● p0640 current limit ● p1215 motor holding brake configuration ●... - Page 148 Servo control 5.15 Motor data identification Determined data (gamma) Data that is accepted (p1910 = 1) r1932 d inductance r0377 motor leakage inductance total (gamma) p0353 motor series inductance p0356 motor leakage inductance p0358 motor rotor leakage inductance p1715 current controller P gain p1717 current controller integral time r1934 q inductance identified r1936 magnetizing inductance identified...

-

Page 149: Motor Data Identification For Synchronous Motors

Servo control 5.15 Motor data identification Determined data (gamma) Data that is accepted (p1960 = 1) r1969 moment of inertia identified p0341 motor moment of inertia · p0342 ratio between the total moment of inertia and that of the motor + p1498 load moment of inertia r1973 encoder pulse number identified Note:... - Page 150 Servo control 5.15 Motor data identification Table 5-14 Data determined using p1960 for synchronous motors (rotating measurement) Determined data Data that are accepted (p1960 = 1) r1934 q inductance identified p0356 motor stator leakage inductance r1935 q inductance identification current p0391 current controller adaptation starting point Kp p0392 current controller adaptation starting point Kp adapted...

- Page 151 Servo control 5.15 Motor data identification Figure 5-19 Equivalent circuit diagram for synchronous motor and cable Overview of important parameters (see SINAMICS S120/S150 List Manual) ● r0047 Identification status Standstill measurement ● p1909[0...n] Motor data identification, control word ● p1910...

-

Page 152: Pole Position Identification

Absolute encoders are automatically identified when commissioning or after an encoder has been replaced based on the saved serial number. As a consequence, for Siemens linear motors 1FN1, 1FN3 and 1FN6, p1990 = 1 is automatically set after commissioning or after an encoder has been replaced. -

Page 153: Supplementary Conditions

5.16 Pole position identification Note Use default setting When using standard Siemens motors, the automatically pre-selected setting should be kept. Determining the suitable method On the basis of the following table, you can determine the PolID methods that are suitable for... - Page 154 Servo control 5.16 Pole position identification Saturation-based PolID The following notes and supplementary conditions apply to the saturation-based PolID: ● The technique can be performed for both braked and non-braked motors. ● The technique can only be performed for a speed setpoint = 0 or from standstill. ●...

- Page 155 Servo control 5.16 Pole position identification ● Drive axis motion corresponds to the deflection (motion in the μm to mm range). Uncontrollable axis motion is completely ruled out during the measurement. WARNING Uncontrollable axis motion as a result of incorrect settings With incorrect settings during the elasticity-based PolID, uncontrollable axis motion can occur when enabling the axis after the measuring procedure, which can cause death or severe injury.

- Page 156 Servo control 5.16 Pole position identification Pole position correction with zero marks The pole position identification routine provides coarse synchronization. If zero marks exist, the pole position can be automatically compared with the zero mark position once the zero mark(s) have been passed (fine synchronization).

-

Page 157: Important Parameters (Process-Dependent)

Servo control 5.16 Pole position identification 5.16.2 Important parameters (process-dependent) Important parameters (process-dependent) The table below gives you an overview of the important parameters depending on the PolID method selected: Saturation-based Motion-based Elasticity-based p0325 p0329 p1980 Value 0, 1 or 4 Value 10 Value 20 p1981... -

Page 158: Setting Of The Elasticity-Based Pole Position Identification

Servo control 5.16 Pole position identification 5.16.3 Setting of the elasticity-based pole position identification Overview The technique described in the following is an example of the setting of the elasticity-based pole position identification (PolID) for linear motors and rotary motors. ●... - Page 159 Servo control 5.16 Pole position identification 6. Select the following signals of the configured drive in the device trace. – r76: Current actual value field-generating – r479[0]: Diagnostics encoder position actual value Figure 5-20 Device trace: Select signals The following figure shows further settings in the device trace. In order to obtain good, useful measurement results, we recommend that you set the displayed values.

- Page 160 Servo control 5.16 Pole position identification 9. Set the value "1" in parameter p1982[0] (PolID selection). You have now activated the elasticity-based PolID. Note Setting of further parameters Further parameters do not have to be set. Leave the other parameters in the factory setting. 10.Click the button ("Start trace") to start the trace.

- Page 161 Servo control 5.16 Pole position identification 12.Compare the deflection at the starting point of the measurement (2) with the deflection at the end point of the measurement (3). The following figure shows the measurement result. A guide line (1) is shown for the optical alignment and aligned as reference line at the starting point (2) of the measurement.

- Page 162 Servo control 5.16 Pole position identification Signal (red/top): Measuring current Signal (blue/bottom): Deflection ① Guide line ② Starting point of the measurement ③ End point of the measurement ④ Amplitudes of measuring currents 1 to 12 (p3093) Figure 5-23 Measurement result: Brake too weak 13.Compare the height of the deflection amplitudes in both directions and determine optically the highest amplitude in the measurement result.

- Page 163 Servo control 5.16 Pole position identification 14.Determine the stroke of the maximum deflection. The maximum deflection corresponds to the highest deflection (peak) in the measurement result. The stroke corresponds to the calculated difference between the lowest (3) and the highest point (4) of the deflection amplitude.

- Page 164 Servo control 5.16 Pole position identification 15.To calculate the value for parameter p3094[0] (PolID elasticity-based deflection expected), set the determined value (difference) in the appropriate formula. – For linear motors: – For rotary motors: 16.Enter the calculated value in the expert list in parameter p3094[0] (PolID elasticity-based deflection expected) of the configured drive.

- Page 165 Servo control 5.16 Pole position identification 18.To check the result, restart the trace and enable the configured drive. The measurement result is displayed. Figure 5-25 Measurement result after the configuration Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

- Page 166 If required, change the values in parameters p3090 to p3096 when repeating the technique. Check the measurement results. Also observe all steps of the procedure for the elasticity-based PolID. If repeated attempts to perform the technique fail, please contact the Siemens Support (https://support.industry.siemens.com/cs/ww/en/). Drive functions...

-

Page 167: Commutation Angle Offset Commissioning Support (P1990)

When fault F07414 occurs, p1990 is automatically started; if p1980 ≠ 99 and p0301 does not refer to a catalog motor with an encoder that is adjusted in the factory. 5.16.5 Overview of important parameters (see SINAMICS S120/S150 List Manual) Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p0325[0...n] Motor pole position identification current 1st phase ●... - Page 168 Servo control 5.16 Pole position identification ● p1980[0...n] PolID procedure ● p1981[0...n] PolID maximum distance ● p1982[0...n] PolID selection ● p1983 PolID test ● r1984 PolID angular difference ● r1985 PolID saturation curve ● r1986 PolID saturation curve 2 ● r1987 PolID trigger curve ●...

-

Page 169: Vdc Control

Servo control 5.17 Vdc control 5.17 Vdc control Function description The Vdc control monitors the DC voltage in the DC link for overvoltage and undervoltage. If an overvoltage or undervoltage is identified in the DC link line-up, a subsequent response can be set with the Vdc control via p1240. - Page 170 Servo control 5.17 Vdc control control dc_min Figure 5-26 Switching V control on/off (kinetic buffering) dc_min In the event of a power failure, the Line Module can no longer supply the DC link voltage, particularly if the Motor Modules in the DC link line-up are drawing active power. To maintain the DC link voltage in the event of a power failure (e.g.

- Page 171 Servo control 5.17 Vdc control control dc_max Figure 5-27 Switching the V control on/off dc_max With Infeed Modules without feedback or in the event of a power failure, the DC link voltage can increase until it reaches the shutdown threshold when drives in the DC link line-up are decelerated.

- Page 172 ● 5300 Servo control - U/f control for diagnostics ● 5650 Servo control - Vdc_max controller and Vdc_min controller Overview of important parameters (see SINAMICS S120/S150 List Manual) ● r0056.14 CO/BO: Status word, closed-loop control: Vdc_max controller active ● r0056.15 CO/BO: Status word, closed-loop control: Vdc_min controller active ●...

-

Page 173: Dynamic Servo Control (Dsc)

● Standard telegrams 5 and 6 ● SIEMENS telegrams: 5, 6, 105, 106, 116, 118, 125, 126, 136, 138, 139, 146, 148, 149 and Further PZD data telegram types can be used with the telegram extension. It must be observed that SERVO control mode supports a maximum of 20 PZD setpoints and 28 PZD actual values. - Page 174 Servo control 5.18 Dynamic Servo Control (DSC) Operating states The following operating states are possible for DSC (for details, see function diagram 3090 in the SINAMICS S120/S150 List Manual): Operating state for DSC Meaning Speed/torque precontrol with linear As a result of the step-like torque precontrol in the position con‐...

- Page 175 Servo control 5.18 Dynamic Servo Control (DSC) Channel p1155 for speed setpoint 1 and channel r1119 for the extended setpoint are disconnected when DSC is active. p1160 for speed setpoint 2 and p1430 for the speed precontrol are added to the speed setpoint from the DSC (see function diagram 3090). Deactivating the DSC If the interconnection is removed at the connector input for KPC or XERR (p1191 = 0 or p1190 = 0), the DSC structure is dissolved and the "DSC"...

- Page 176 ● 5020 Servo control - Speed setpoint filter and speed precontrol ● 5030 Servo control - Reference model/pre-control balancing/speed limiting Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1160[0...n] CI: Speed controller, speed setpoint 2 ● p1190 CI: DSC position deviation XERR ●...

- Page 177 Servo control 5.18 Dynamic Servo Control (DSC) ● r1407.0...26 CO/BO: Status word, speed controller Speed setpoint from DSC DSC position controller limited DSC with spline on Speed precontrol for DSC with spline on Torque precontrol for DSC with spline on ●...

-

Page 178: Travel To Fixed Stop

Servo control 5.19 Travel to fixed stop 5.19 Travel to fixed stop Function description This function can be used to move a motor to a fixed stop at a specified torque without a fault being signaled. When the stop is reached, the specified torque is established and is then continuously available. - Page 179 Servo control 5.19 Travel to fixed stop Figure 5-28 Signals for "Travel to fixed stop" When PROFIdrive telegrams 2 to 6 are used, no torque reduction is transferred. When the "Travel to fixed stop" function is activated, the motor ramps up to the torque limits specified in p1520 and p1521.

- Page 180 Servo control 5.19 Travel to fixed stop Signal chart Figure 5-29 Signal chart for "Travel to fixed stop" Commission PROFIdrive telegrams 2 to 6 To commission the PROFIdrive telegrams 2 to 6, proceed as follows: 1. Activate the "Travel to fixed stop" function via the parameter setting p1545 = "1". 2.

- Page 181 ● 5630 Servo control - Upper/lower torque limit ● 8012 Signals and monitoring functions – Torque messages, motor locked/stalled Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p1400[0...n] Speed control configuration ● r1407.7 CO/BO: Status word speed controller;...

- Page 182 Servo control 5.19 Travel to fixed stop ● p2194[0...n] Torque threshold value 2 ● p2199.11 CO/BO: Status word monitoring; Torque utilization < torque threshold value 2 Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

-

Page 183: Vertical Axes

Servo control - Torque setpoint, switchover control mode ● 5620 Servo control - Motoring/generating torque limit ● 5630 Servo control - Upper/lower torque limit Overview of important parameters (see SINAMICS S120/S150 List Manual) ● r0031 Actual torque smoothed ● p1511[0...n] CI: Supplementary torque 1 ●... -

Page 184: Variable Signaling Function

Servo control 5.21 Variable signaling function 5.21 Variable signaling function Function description Using the "Variable signaling" function, BICO interconnections and parameters that have the attribute "traceable" can be monitored; otherwise they can also be recorded using the "Device trace" commissioning function. Note The variable signaling function works with an accuracy of 8 ms. - Page 185 Diagram: Variable signaling function Function diagrams (see SINAMICS S120/S150 List Manual) ● 5301 Servo control - variable signaling function Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p3290 Variable signaling function, start ● p3291 CI: Variable signaling function signal source ●...

-

Page 186: Central Probe Evaluation

From the sampling values of the position signals of the various axes, the control interpolates the times of the actual position values at the probe instant. Three evaluation procedures are implemented in SINAMICS S120 for this purpose. The evaluation procedures can be set using parameter p0684: ●... - Page 187 Servo control 5.22 Central probe evaluation Central measuring with/without handshake Both measuring procedures have the following points in common: ● Setting the input terminal in p0680. ● Signal source, synchronization signal in p0681. ● Signal source, control word probe p0682. ●...

- Page 188 Servo control 5.22 Central probe evaluation = master application cycle time (time frame in which the master application generates MAPC new setpoints) ● Transfer, control word probe (BICO p0682 to PZD3) at the start instant To in the MAPC cycle. ●...

- Page 189 Servo control 5.22 Central probe evaluation Central measurement without handshake (max. 16 signal edges) With p0684 = 16, you activate the evaluation procedure without handshake for the central probe evaluation. You can evaluate up to 16 signal edges from a maximum of 2 probes simultaneously within a DP cycle.

- Page 190 Servo control 5.22 Central probe evaluation The PZDs of the probe time stamp are BICO parameters, which are automatically connected with the indices of the new parameter r0565[16] when the telegram block is selected. After the measuring function has been activated, for several measured values per DP cycle, the acquired time stamps are saved in the indices of r0565[0...15] for transfer, corresponding to their sequence in time starting with the oldest measured value.

- Page 191 Servo control 5.22 Central probe evaluation Reference time stamp Probe bit, binary values Edge selection bit Reference MT_ZS2 Bits 4...6: Bit 7: 000: MT_ZS2 from MT1 0: MT_ZS2 falling edge 001: MT_ZS2 from MT2 1: MT_ZS2 rising edge ‑ 110: MT_ZS2 from MT7 111: MT_ZS2 from MT8 Reference MT_ZS3 Bits 8...10...

-

Page 192: Examples

Servo control 5.22 Central probe evaluation 5.22.1 Examples Examples of probe evaluation Hex values in MT_ZSB from the above example: ● 0 hex = time stamp from probe 1, falling edge ● 8 hex = time stamp from probe 1 rising edge ●... -

Page 193: Function Diagrams And Parameters

● 2423 PROFIdrive - Manufacturer-specific/free telegrams and process data ● 4740 Encoder evaluation - Probe evaluation, measured value memory, encoders 1 ... Overview of important parameters (see SINAMICS S120/S150 List Manual) ● r0565[0...15] CO: Probe time stamp ● r0566[0...3] CO: Probe time stamp reference ●... - Page 194 Servo control 5.22 Central probe evaluation ● r0686[0...7] CO: Central probe measuring time, rising edge ● r0687[0...7] CO: Central probe measuring time, falling edge ● r0688 CO: Central probe status word display ● r0898.0...14 CO/BO: Control word, sequence control ● r0899.0...15 CO/BO: Drive object status word ●...

-

Page 195: Voltage Precontrol

Servo control 5.23 Voltage precontrol 5.23 Voltage precontrol Function description Using voltage precontrol (p1703), the dynamic response of the q current controller can be increased independent of the current controller setting - all the way up to the limit that is physically possible. - Page 196 Servo control 5.23 Voltage precontrol p0391 0.33 A p0392 10.23 A p0393 39.31% p0356 10.16 mH Figure 5-34 Example 1: Adaptation characteristic Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

- Page 197 Servo control 5.23 Voltage precontrol p0391 2.09 A p0392 11 A p0393 90.67% p0356 18.24 mH Figure 5-35 Example 2: Adaptation characteristic Determining the voltage feedforward control You determine the voltage feedforward control in several optimization steps. Proceed as follows: 1.

- Page 198 Servo control 5.23 Voltage precontrol 3. Measure a current controller setpoint step and correct the value p1703. – Repeat the current controller setpoint step until the current actual value reaches the setpoint without any overshoot or undershoot (see the following sample displays). Figure 5-36 Example: Voltage precontrol p1703 too low Drive functions...

- Page 199 Servo control 5.23 Voltage precontrol Figure 5-37 Example: Voltage feedforward control p1703 is okay Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

- Page 200 Servo control 5.23 Voltage precontrol Figure 5-38 Example: Voltage precontrol p1703 too high Drive functions Function Manual, 06/2019, 6SL3097-5AB00-0BP2...

- Page 201 Servo control 5.23 Voltage precontrol 4. The result can be improved by compensating the voltage emulation error (only for synchronous motors). – To do this, activate function module "Extended torque control (Page 442)" (r0108.1). – Determine the voltage emulation error with the stationary motor data identification (p1909.14 = 1 and p1910).

- Page 202 Servo control 5.23 Voltage precontrol 4. Measure a current controller setpoint step change again (see figure below) Figure 5-40 Example: Prior to optimizing The measurement result in the example indicates that after reaching the setpoint, the current decays according to an exponential function (1-exp(-t/Tsm)). You estimate the smoothing time based on the time from the point of contact of the initial tangent with the final value straight line.

-

Page 203: Function Diagrams And Parameters

Legend for the measurement diagrams Torque-generating current setpoint Torque-generating current setpoint unsmoothed Quadrature-axis voltage setpoint 5.23.1 Function diagrams and parameters Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p0340[0...n] Automatic calculation of motor/control parameters ● p0356[0...n] Motor stator leakage inductance Drive functions... - Page 204 Servo control 5.23 Voltage precontrol ● p0391[0...n] Current controller adaptation, starting point Kp ● p0392[0...n] Current controller adaptation, starting point Kp adapted ● p0393[0...n] Current controller adaptation, P gain adaptation ● p1402[0...n] Current control and motor model configuration ● p1428[0...n] Speed precontrol symmetrizing dead time ●...

-

Page 205: Vector Control

Vector control Operating principle The motor connected to a vector control is simulated in a vector model based on data from the equivalent circuit diagram. The motor module is emulated as precisely as possible to obtain the best results regarding control precision and control quality. Versions The vector control is available in the following versions: ●... - Page 206 Vector control Differences with respect to vector U/f control Compared with vector U/f control, vector control offers the following benefits: ● Stability for load and setpoint changes ● Short rise times for setpoint changes (→ better control behavior) ● Short settling times for load changes (→ better response to disturbances) ●...

- Page 207 Vector control Subject Servo control Vector control Note: Additional information on the sampling conditions is provided in subchapter "Rules regarding sampling times (Page 838)" in this manual. Connectable motors ● Synchronous servomotors ● Synchronous motors (including torque motors) ● Permanent-magnet synchronous motors ●...

- Page 208 Vector control Subject Servo control Vector control Maximum output frequency with ● 2600 Hz with 31.25 μs / 16 kHz ● 300 Hz with 250 μs/4 kHz closed-loop control or with 400 μs/5 kHz ● 1300 Hz with 62.5 μs / 8 kHz ●...

- Page 209 Vector control Subject Servo control Vector control Note: Additional information on connecting power units in parallel is provided in Chapter "Parallel connection of power units (Page 515)". Permissible range of the ratio be‐ The permissible range of the ratio be‐ The permissible range of the ratio be‐...

-

Page 210: Technology Application (Application) (P0500)

Vector control 6.1 Technology application (application) (p0500) Technology application (application) (p0500) Function description Using parameter p0500, you can influence the calculation of open-loop control and closed-loop control parameters. The default setting helps you find suitable values for standard applications. You can make preassignments for the following technological applications: Value p0500 Application Standard drive (vector) Pumps and fans... -

Page 211: Vector Control Without Encoder (Slvc)

Vector control 6.2 Vector control without encoder (SLVC) Vector control without encoder (SLVC) Function description During operation via the "Sensorless vector control" function (SLVC), the position of the flux and actual speed must be determined using the electric motor model. The motor model is buffered by the incoming currents and voltages. - Page 212 Vector control 6.2 Vector control without encoder (SLVC) setpoint static) and p1611 (additional acceleration torque) to the required maximum torque. The drive can then generate the static or dynamic load torque that occurs. ● If, for induction motors (ASM), p1610 is set to 0%, then only the magnetizing current r0331 is impressed.

- Page 213 Vector control 6.2 Vector control without encoder (SLVC) Advantages of the controlled operation down to f = 0 Hz Closed-loop operation to approx. 0 Hz (can be set using parameter p1755) and the possibility to start or reverse at 0 Hz directly in closed-loop operation (can be set using parameter p1750) result in the following benefits: ●...

- Page 214 Vector control 6.2 Vector control without encoder (SLVC) As a consequence, the "Passive load" function is automatically activated. Note If p0500 is parameterized when commissioning the motor, the calculation is carried out automatically via p0340 and p3900. p0578is is then set automatically. Closed-loop control without changeover between closed-loop and open-loop speed control is restricted to applications with passive load: A passive load only has a reactive effect on the drive torque of the driving motor at the starting...

-

Page 215: Permanent-Magnet Synchronous Motors