Siemens SINAMICS S120 Commissioning Manual

With startdrive

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens SINAMICS S120

- Page 3 ___________________ Preface Fundamental safety ___________________ instructions ___________________ Startdrive commissioning SINAMICS tool ___________________ Fundamentals S120 Commissioning with Startdrive ___________________ Commissioning ___________________ Diagnostics Commissioning Manual ___________________ Appendix Valid for: Firmware version 5.1, Startdrive V15 11/2017 6SL3097-4AA10-0BP1...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

(mailto:docu.motioncontrol@siemens.com). Siemens MySupport/Documentation At the following address (http://www.siemens.com/mdm), you can find information on how to create your own individual documentation based on Siemens' content, and adapt it for your own machine documentation. Training At the following address (http://www.siemens.com/sitrain), you can find information about SITRAIN (Siemens training on products, systems and solutions for automation and drives). - Page 6 • SINUMERIK 840 Equipment for Machine Tools (Catalog NC 62) • Installation/assembly SINAMICS S120 Manual for Control Units and Additional System Components • SINAMICS S120 Manual for Booksize Power Units • SINAMICS S120 Manual for Booksize Power Units C/D Type •...

- Page 7 Relevant directives and standards You can obtain an up-to-date list of currently certified components on request from your local Siemens office. If you have any questions relating to certifications that have not yet been completed, please ask your Siemens contact person.

- Page 8 SINAMICS S devices showing the test symbols fulfill the EMC requirements for Australia and New Zealand. ● Quality systems Siemens AG employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

- Page 9 EMC limit values are ensured. Spare parts Spare parts are available on the Internet at the following address (https://www.automation.siemens.com/sow?sap-language=EN). Product maintenance The components are subject to continuous further development within the scope of product maintenance (improvements to robustness, discontinuations of components, etc).

- Page 10 This document contains recommendations relating to third-party products. Siemens accepts the fundamental suitability of these third-party products. You can use equivalent products from other manufacturers. Siemens does not accept any warranty for the properties of third-party products. Ground symbols Table 2...

- Page 11 Preface Notation The following notation and abbreviations are used in this documentation: Notation for faults and alarms (examples): Fault 12345 • F12345 Alarm 67890 • A67890 Safety message • C23456 Notation for parameters (examples): Adjustable parameter 918 • p0918 Display parameter 1024 •...

- Page 12 Preface Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

-

Page 13: Table Of Contents

Table of contents Preface ..............................5 Fundamental safety instructions ......................21 General safety instructions ..................... 21 Equipment damage due to electric fields or electrostatic discharge ........26 Warranty and liability for application examples ..............27 Industrial security ........................28 Residual risks of power drive systems ..................29 Startdrive commissioning tool ........................ - Page 14 Table of contents Fundamentals ............................61 Requirements for commissioning................... 61 Safety instructions for commissioning ................... 62 BICO interconnections ......................63 3.3.1 Binectors, Connectors ......................63 3.3.2 Interconnect BICO inputs ....................... 65 3.3.3 Interconnecting BICO outputs ....................67 Comparing parameter settings ....................70 Permanently save the settings ....................

- Page 15 Table of contents Establishing an online connection to the drive unit ............... 137 4.5.1 Overview ..........................137 4.5.2 Connection via standard Ethernet interface ................. 139 4.5.3 Online connection via PROFINET interface ................. 141 4.5.3.1 Using the PROFINET IO interface ..................141 4.5.3.2 Online access via PROFINET ....................

- Page 16 Table of contents Commissioning a drive ......................209 4.9.1 Using the control panel ......................209 4.9.2 Traversing the drive with speed specification ..............212 4.9.3 Basic positioner ........................213 4.9.3.1 Manual positioning ....................... 213 4.9.3.2 Relative positioning ......................214 4.9.3.3 Absolute positioning ......................

- Page 17 Table of contents 4.11 Configuring brake control ...................... 288 4.11.1 Overview ..........................288 4.11.2 Simple brake control ......................289 4.11.2.1 Basics............................ 289 4.11.2.2 Parameterizing the brake control ..................290 4.11.2.3 Opening the brake ........................ 294 4.11.2.4 Closing the brake ........................294 4.11.3 Extended brake control ......................

- Page 18 Table of contents Diagnostics via Startdrive ....................330 5.3.1 Device diagnostics ....................... 330 5.3.1.1 Example: Detecting and correcting a topology error............333 5.3.2 Trace function ........................336 5.3.2.1 Overview ..........................336 5.3.2.2 Creating or calling a trace ....................339 5.3.2.3 Configuring a trace .......................

- Page 19 Table of contents System rules, sampling times and DRIVE-CLiQ wiring ............392 A.5.1 Overview of system limits and system utilization ..............392 A.5.2 System rules ......................... 393 A.5.3 Rules on the sampling times ....................394 A.5.3.1 Rules when setting the sampling times ................394 A.5.3.2 Default settings for the sampling times .................

- Page 20 Table of contents Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

-

Page 21: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions WARNING Electric shock and danger to life due to other energy sources Touching live components can result in death or severe injury. • Only work on electrical devices when you are qualified for this job. •... - Page 22 Fundamental safety instructions 1.1 General safety instructions WARNING Electric shock due to equipment damage Improper handling may cause damage to equipment. For damaged devices, hazardous voltages can be present at the enclosure or at exposed components; if touched, this can result in death or severe injury.

- Page 23 • If you come closer than around 2 m to such components, switch off any radios or mobile phones. • Use the "SIEMENS Industry Online Support App" only on equipment that has already been switched off. Commissioning with Startdrive...

- Page 24 Fundamental safety instructions 1.1 General safety instructions WARNING Motor fire in the event of insulation overload There is higher stress on the motor insulation through a ground fault in an IT system. If the insulation fails, it is possible that death or severe injury can occur as a result of smoke and fire.

- Page 25 Fundamental safety instructions 1.1 General safety instructions WARNING Unexpected movement of machines caused by inactive safety functions Inactive or non-adapted safety functions can trigger unexpected machine movements that may result in serious injury or death. • Observe the information in the appropriate product documentation before commissioning.

-

Page 26: Equipment Damage Due To Electric Fields Or Electrostatic Discharge

Fundamental safety instructions 1.2 Equipment damage due to electric fields or electrostatic discharge Equipment damage due to electric fields or electrostatic discharge Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or devices that may be damaged by either electric fields or electrostatic discharge. NOTICE Equipment damage due to electric fields or electrostatic discharge Electric fields or electrostatic discharge can cause malfunctions through damaged... -

Page 27: Warranty And Liability For Application Examples

Fundamental safety instructions 1.3 Warranty and liability for application examples Warranty and liability for application examples The application examples are not binding and do not claim to be complete regarding configuration, equipment or any eventuality which may arise. The application examples do not represent specific customer solutions, but are only intended to provide support for typical tasks. -

Page 28: Industrial Security

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends to apply product updates as soon as available and to always use the latest product versions. Use of product versions that are no longer supported, and failure to apply latest updates may increase customer’s exposure to cyber threats. -

Page 29: Residual Risks Of Power Drive Systems

Fundamental safety instructions 1.5 Residual risks of power drive systems Residual risks of power drive systems When assessing the machine- or system-related risk in accordance with the respective local regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must take into account the following residual risks emanating from the control and drive components of a drive system: 1. - Page 30 Fundamental safety instructions 1.5 Residual risks of power drive systems 4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk to people with a pacemaker, implants or metal replacement joints, etc., if they are too close 5.

-

Page 31: Startdrive Commissioning Tool

Startdrive commissioning tool Overview The Startdrive integrated engineering tool is available for the configuration and parameterization of drive units in the TIA Portal. You can perform the following tasks, for example, with Startdrive: ● You create projects for drive-specific solutions. ●... -

Page 32: Structure Of The User Interface

Startdrive commissioning tool 2.2 Structure of the user interface Structure of the user interface 2.2.1 Project view for parameterizing the drive The following figure shows an example of the components of the project view: ① Project tree Used to display and edit components and project data. ②... -

Page 33: Project Navigation

Startdrive commissioning tool 2.2 Structure of the user interface 2.2.2 Project navigation Description The project tree is used to display and edit components and project data. After they have been inserted, drives are hierarchically displayed as follows in the project tree: Figure 2-2 Example: Project tree... -

Page 34: User Interface - Parameterization

Startdrive commissioning tool 2.3 User interface - parameterization User interface - parameterization 2.3.1 Modules in the hardware catalog As soon as the device configuration is active, a hardware catalog can be displayed/hidden at the right-hand edge of the program window. The device configuration automatically becomes active as soon as a drive device was inserted. - Page 35 Startdrive commissioning tool 2.3 User interface - parameterization The SINAMICS modules are arranged as follows in the hardware catalog: ① Available Control Units of type SINAMICS CU320-2 ② Active, Basic and Smart Line Modules ③ Power Modules (chassis format) ④ Single Motor Modules and Double Motor Modules ⑤...

-

Page 36: Device View

Startdrive commissioning tool 2.3 User interface - parameterization 2.3.2 Device view Configure the drive line-up in the "Device view". You insert components and edit the DRIVE- CLiQ connections. You can call the device view by double-clicking the "Device configuration" entry in the project tree. The device overview provides a tabular overview of all configured components and their data. -

Page 37: Parameterization Editor

Startdrive commissioning tool 2.3 User interface - parameterization 2.3.3 Parameterization editor The parameterizing editor comprises 2 tabs, under which you can parameterize the drive: ● In the function view, you parameterize the drive using a graphic user interface. The individual screen forms are based on the function diagrams – and include the parameters required. -

Page 38: Function View

Startdrive commissioning tool 2.3 User interface - parameterization 2.3.4 Function view You parameterize the drive using a graphical user interface in the "Function view". The individual screen forms are based on function diagrams and contain the required parameters. Note All parameters You can find all parameters of the drive in the "Parameter view (Page 39)". -

Page 39: Parameter View

Startdrive commissioning tool 2.3 User interface - parameterization 2.3.5 Parameter view The "Parameter view" (expert list) provides a clearly organized display of the parameters available for the device. Note Locked parameters None of the parameters with the padlock icon can be changed OFFLINE. To enter these parameters offline, use the appropriate screen forms and dialogs in the hardware configuration that you find in the device view. - Page 40 Startdrive commissioning tool 2.3 User interface - parameterization Parameter display The fields of the individual parameters are displayed in the list in color as follows: Editing level Offline color Online color Read only Gray Pale orange Read/write White Orange Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

-

Page 41: Inspector Window

Startdrive commissioning tool 2.3 User interface - parameterization 2.3.6 Inspector window Properties and parameters of the selected object are displayed in the inspector window. You can edit these properties and parameters. For example, you can specify non-specified S120 drive objects inserted in the device view. Structure The information and parameters in the inspector window are subdivided into various ①... -

Page 42: Device Configuration Detection

For each information type, there are additional subareas that can be displayed via secondary ② tabs The most important information type for SINAMICS S120 drives is the "Properties" area. The following secondary tabs are displayed in this area: ● General Display of the properties and settings of the drive device, drive object, or the hardware component. - Page 43 Startdrive commissioning tool 2.3 User interface - parameterization The dialog has the following structure: ① Creation information (optional) ② The components assigned to the modules or main components ③ Non-assignable components ④ Activates the parallel connection view. In the parallel connection view, only the parallel connection-capable components are displayed. ⑤...

-

Page 44: User Interface - Control Panel

Startdrive commissioning tool 2.4 User interface - Control panel User interface - Control panel The drive control panel (see Chapter "Using the control panel (Page 209)") is used to control and monitor individual drives. You traverse drives with the control panel by specifying values. Depending on the operating mode, these are, for example, speed setpoints. -

Page 45: User Interface - Trace Function

Startdrive commissioning tool 2.5 User interface - trace function User interface - trace function 2.5.1 Configuration The user interface of the trace function comprises several areas. The following figure shows the structure of the trace user interface in Startdrive as example: Project navigator Management and creation of the trace and measurements directly in the project tree and via shortcut menu commands. -

Page 46: Curve Diagram

Startdrive commissioning tool 2.5 User interface - trace function 2.5.2 Curve diagram The curve diagram displays the selected signals of a recording. Binary signals are shown in the lower diagram as bit track. You can adapt the display of the signals in the signal table and with the toolbar of the curve diagram. -

Page 47: Signal Table

Startdrive commissioning tool 2.5 User interface - trace function 2.5.3 Signal table The signal table lists the signals of the selected measurement and provides setting options for some properties. If recording data of installed traces is displayed and the settings are changed in the signal table, these settings are retained until there is a change to the offline mode. - Page 48 Startdrive commissioning tool 2.5 User interface - trace function The following table shows the settings and displays of the recorded signals: Column Description Signal or error symbol Signal Failsafe signal Signal from a data block Signal from a failsafe data block Calculated signal (formula) Error in the formula of the calculated signal Selection for the display in the curve diagram - a maximum of 16 signals can be selected.

- Page 49 Startdrive commissioning tool 2.5 User interface - trace function Column Description "Formula" Display or entry of a formula A formula can contain mathematical functions with numbers and signals. Use the formula editor to conveniently create formulas. Call of the formula editor for calculated signals Click on the icon to open the formula editor.

-

Page 50: Formula Editor

Startdrive commissioning tool 2.5 User interface - trace function 2.5.4 Formula editor The formula editor provides various mathematical functions for analyzing signals. Open the editor in the signal table by clicking the icon Configuration options and displays in the formula editor The following figure shows the display in Startdrive as example: Figure 2-13 Formula editor... - Page 51 Startdrive commissioning tool 2.5 User interface - trace function Field/ Description Mathematical functions Absolute value Calculates the size of a number. Examples → 5 ABS(5) → 3 ABS(-3) → 3.14 ABS(-3.14) Modulo Calculates the residual value of a division Examples →...

- Page 52 Startdrive commissioning tool 2.5 User interface - trace function Field/ Description Mathematical functions Simple subtraction with mean filter from 1st to 5th order If the specification of an order is missing, simple subtraction is performed with a 1st order filter. Examples →...

-

Page 53: Measurements (Overlay Measurements)

Startdrive commissioning tool 2.5 User interface - trace function 2.5.5 Measurements (overlay measurements) The "Measurements" tab displays the individual measurements and among other things provides the setting options for synchronization. Setting options and displays in the "Measurements" tab The following figure shows the display in Startdrive as example: ①... -

Page 54: Online And Diagnostics

Structure of the online diagnostics The following figure shows the structure of the working area: ① Online access ② Working area for online access and diagnostics Figure 2-15 Online access in SINAMICS S120 Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1... -

Page 55: Information System - Online Help

Startdrive commissioning tool 2.7 Information system - online help Information system - online help 2.7.1 General remarks on the information system The information system of the Startdrive in TIA Portal helps you solve your problems and offers the required help topics at each step of the configuration. While working with the program, you receive the following support: ●... - Page 56 Startdrive commissioning tool 2.7 Information system - online help Information system The information system opens in a separate window. The following figure shows the information system for Startdrive in the TIA Portal: The information system is divided into the following areas: ●...

- Page 57 Startdrive commissioning tool 2.7 Information system - online help Icons in the navigation area The following icons are available in the navigation area of the information system: Symbol Function Search for updates Starts the search for hardware manuals, which are available as an update. Print Prints out pages or sections of the information system.

- Page 58 Startdrive commissioning tool 2.7 Information system - online help Tooltip User interface elements offer brief information in the form of a tooltip. Tooltips, which have an arrow icon on the left, contain additional information in tooltip cascades. If you position the mouse pointer briefly over the tooltip or click the arrow icon, this information is displayed.

-

Page 59: Opening The Information System

Startdrive commissioning tool 2.7 Information system - online help 2.7.2 Opening the information system Opening the information system with the menu To access the information system on the home page, follow these steps: 1. Select "Display help" command from the "Help" menu. The start page of the information system opens. - Page 60 Startdrive commissioning tool 2.7 Information system - online help Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

-

Page 61: Fundamentals

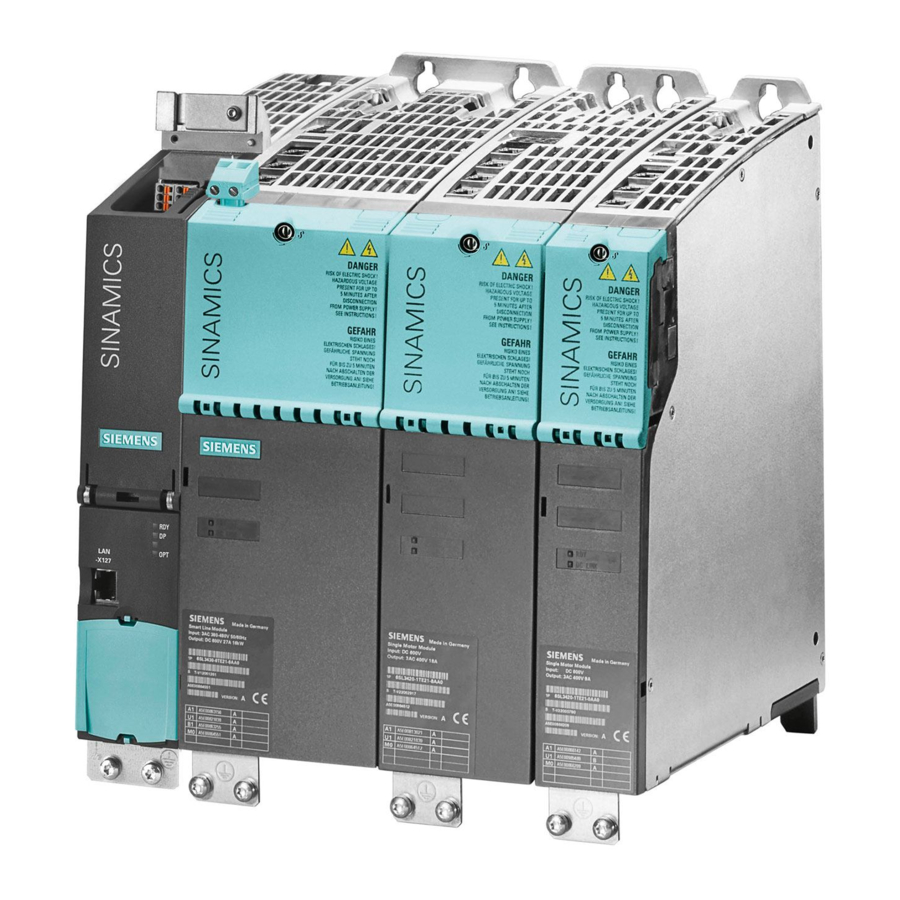

● A programming device (PG/PC) ● Startdrive commissioning tool ● A communication interface, e.g. PROFINET, Ethernet ● Completely wired-up drive line-up (see SINAMICS S120 manuals) A configuration example with booksize components and PROFINET communication is shown in the following figure:... -

Page 62: Safety Instructions For Commissioning

• Observe the safety instructions provided in the hardware documentation. • When assessing the risk, take into account residual risks. Note Please observe the installation guidelines and safety instructions in the SINAMICS S120 Manuals. Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1... -

Page 63: Bico Interconnections

Further information Detailed information on BICO technology and BICO connections can be found in Section "Basics of the drive system" in the SINAMICS S120 Drive Functions Function Manual. In Startdrive for S120, the parameterization is possible via: ● Parameter view ●... - Page 64 Fundamentals 3.3 BICO interconnections Binectors, BI: Binector input, BO: Binector output A binector is a unitless digital (binary) signal that can assume a value of 0 or 1. Binectors are subdivided into binector inputs (signal sink) and binector outputs (signal source).

-

Page 65: Interconnect Bico Inputs

Fundamentals 3.3 BICO interconnections 3.3.2 Interconnect BICO inputs Use a connection dialog to connect binector or connector inputs. Connecting a signal To make a connection, proceed as follows: 1. Click the binector or connector icon of the signal that you want to connect ( A connection dialog for the selection of the possible parameters opens. - Page 66 Fundamentals 3.3 BICO interconnections The last set signal source is displayed in the "Selected source" field. If a connection was not available previously, the value 0 is displayed. 2. Select the parameter that you want to connect. If connectable bits of the parameter are available, they are displayed in a drop-down list. Figure 3-3 BICO dialog input: Parameter bits opened 3.

-

Page 67: Interconnecting Bico Outputs

Fundamentals 3.3 BICO interconnections 3.3.3 Interconnecting BICO outputs Use the connection dialog to connect binector or connector outputs. Connecting a signal To make a connection, proceed as follows: 1. Click the binector or connector icon of the signal that you want to connect ( A connection dialog for the selection of the possible parameters opens. - Page 68 Fundamentals 3.3 BICO interconnections The last set signal sink is displayed in the "Selected sinks" field. If a connection was not available previously, the text "No sink selected" is displayed. 2. Activate the check boxes for the parameters that you want to connect. If connectable bits of the parameter are available, they are displayed in a drop-down list.

- Page 69 Fundamentals 3.3 BICO interconnections Multiple connections at outputs Several interconnections can be set simultaneously for a parameter, which for reasons of space however, cannot be displayed in the interconnections field. Clicking the icon next to the interconnection field opens a list, which shows all of the active parameter interconnections.

-

Page 70: Comparing Parameter Settings

Fundamentals 3.4 Comparing parameter settings Comparing parameter settings The current parameter values of a drive object can be compared with another parameter set using the comparison function in the parameter view. The following comparisons are possible: ● Offline - Factory setting ●... - Page 71 Fundamentals 3.4 Comparing parameter settings Icons in the "Comparison" column Icon Meaning The comparison values are equal and error-free. Offline - Factory setting: The comparison values are different and error-free. Online - Offline: The comparison values are different and error-free. Online - Factory setting: The comparison values are different and error-free.

-

Page 72: Permanently Save The Settings

Fundamentals 3.5 Permanently save the settings Permanently save the settings Saving configurations in the project In Startdrive, settings are predominantly made via screen forms. The complete project must be saved in order that the settings made are permanently active. 1. Click "Save project" in the toolbar. - Or - 2. -

Page 73: Restoring Factory Settings

Fundamentals 3.6 Restoring factory settings Restoring factory settings In online operation, you can restore the factory settings for the drive control. 1. Establish an online connection (Page 137) to your drive unit. 2. Click the icon in the function view of the active Startdrive project. The factory settings are restored. -

Page 74: Loading Project Data From A Drive Unit

Fundamentals 3.7 Loading project data from a drive unit Loading project data from a drive unit Requirement ● A project is open. ● The hardware configuration and software to be loaded must be compatible with the Startdrive. If the data on the device was created with a previous program version or with a different configuration software, please make sure they are compatible. - Page 75 Fundamentals 3.7 Loading project data from a drive unit 3. Check the alarms in the "Upload preview" dialog, and select the necessary actions in the "Action" column. As soon as uploading becomes possible, the "Upload from device" button is enabled. 4.

- Page 76 Fundamentals 3.7 Loading project data from a drive unit Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

-

Page 77: Commissioning

Commissioning Call Startdrive Note The following procedure is based on the Windows 7 operating system. Operation can deviate slightly for other operating systems Call the Startdrive application 1. Click on the Startdrive icon of your user interface. - or - 2. -

Page 78: Commissioning Workflow

Commissioning 4.2 Commissioning workflow Commissioning workflow A drive can be commissioned in two ways: ● Create a project offline in Startdrive The components of the drive are combined offline in Startdrive. ● Create a project by reading out a device configuration The components of the drive are read-out online and supplemented offline when required. -

Page 79: Check Lists To Commission Sinamics S

Commissioning 4.3 Check lists to commission SINAMICS S Check lists to commission SINAMICS S Checklist for commissioning booksize power units The following checklist must be carefully observed. Read the safety instructions in the manuals before starting any work. Table 4- 1 Checklist for commissioning (booksize) Check Are the environmental conditions in the permissible range? - Page 80 Commissioning 4.3 Check lists to commission SINAMICS S Checklist for commissioning chassis power units The following checklist must be carefully observed. Read the safety instructions in the manuals before starting any work. Table 4- 2 Checklist for commissioning (chassis) Activity Are the environmental conditions in the permissible range? Are the components correctly installed in the cabinets? Is the specified air flow for cooling the devices ensured?

- Page 81 Commissioning 4.3 Check lists to commission SINAMICS S Activity Have the digital and analog signals been routed with separate cables? Has the distance from power cables been observed? Has the cabinet been properly grounded at the points provided? Has the connection voltage for the fans in the chassis components been adapted accordingly to the supply voltages? For operation on non-grounded supply systems: Has the connection bracket for the interference suppression at the Infeed Module or the Power Module been removed?

-

Page 82: Creating A Project Offline In Startdrive

Commissioning 4.4 Creating a project offline in Startdrive Creating a project offline in Startdrive 4.4.1 Creating a new project or loading a project For projects, the choice is yours: ● You create a completely new project (see "Create new project"). ●... - Page 83 Commissioning 4.4 Creating a project offline in Startdrive 2. Enter the project data here: – Project name: Startdrive automatically counts each new project. – Path: The simpler the archive path for the project, the faster the project can be loaded. –...

- Page 84 Commissioning 4.4 Creating a project offline in Startdrive Opening an existing project If you wish to change the data of an existing project, then you can load this project at any time. 1. Click "Open existing project" in the secondary navigation in the portal view of Startdrive. A selection of the projects last used is displayed to the right in the detailed view.

- Page 85 Commissioning 4.4 Creating a project offline in Startdrive Click "Browse", double-click the required project in your directory structure, select project file "*.ap15". Figure 4-4 Opening an existing project from the directory Note In Startdrive, it is possible to determine the Startdrive version which last processed a project by its respective extension.

-

Page 86: Recommended Order Of Creation

Commissioning 4.4 Creating a project offline in Startdrive This information is generated and administered in the user administration of the TIA Portal. Detailed information on project protection can be found in the Startdrive online help under "Using user administration". 4.4.2 Recommended order of creation After a new project has been created, the required components must be inserted into the device configuration –... -

Page 87: Inserting The Drive Unit

Commissioning 4.4 Creating a project offline in Startdrive 4.4.3 Inserting the drive unit Requirement You have created a project (Page 82) or have opened an existing project. Inserting a drive unit via the project view Proceed as follows to insert new drive units in the project view: 1. - Page 88 Commissioning 4.4 Creating a project offline in Startdrive Ensure that the version number indicated on the right in the dialog correlates with the version number of your memory card on the drive unit. If the version numbers do not match, it will not be possible to go online later. On creation, the current firmware version is always suggested.

- Page 89 Commissioning 4.4 Creating a project offline in Startdrive 4. Select the drive unit from the list, and if required enter a different device name in the input field at the top left (default: "Drive unit_x"). Ensure that the version number indicated on the right in the dialog correlates with the version number of your memory card on the drive unit.

- Page 90 Commissioning 4.4 Creating a project offline in Startdrive If the "Open device view" option is activated, then the drive unit is immediately created in the device view. Figure 4-7 Inserting a drive unit Inserting a device in the network view Alternatively, you can insert a drive unit in the network view.

-

Page 91: Inserting An Infeed Unit

Commissioning 4.4 Creating a project offline in Startdrive 4.4.4 Inserting an infeed unit 4.4.4.1 Inserting a space holder for an infeed unit Requirement ● A project has been created. ● The Control Unit is inserted in the device configuration. Note Sequence Generally, the infeed is inserted in the configuration immediately after the drive in the device view. - Page 92 Commissioning 4.4 Creating a project offline in Startdrive Inserting an infeed You insert an infeed using the hardware catalog 1. Open "Line Modules" in the hardware catalog. Active Line Modules, Basic Line Modules and Smart Line Modules can be selected. 2.

- Page 93 Commissioning 4.4 Creating a project offline in Startdrive 3. Drag the unspecified infeed to the device view. Figure 4-9 Infeed inserted Result Generally, the DRIVE-CLiQ connection is automatically established. The unspecified infeed must now be specified in more detail. Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

-

Page 94: Specifying An Infeed Unit

Commissioning 4.4 Creating a project offline in Startdrive 4.4.4.2 Specifying an infeed unit Up until now, only an unspecified component envelope (space holder) exists. This component envelope must now be specified in more detail by using an article number so that the components in the device view correspond to what you have installed in your actual drive system. - Page 95 Commissioning 4.4 Creating a project offline in Startdrive 3. In the secondary navigation of the inspector window, select "Line Module - Selection – ALM" A list of the Line Modules available is displayed to the right in "Line Module - Selection". Figure 4-11 Line Module - Selection 4.

-

Page 96: Interconnecting Several Infeed Units In Parallel

Commissioning 4.4 Creating a project offline in Startdrive Data of the selected infeed unit is assigned to the unspecified infeed unit. The white area turns dark gray. As default setting, a DRIVE-CLiQ connection is established between interfaces X100 and X200. Result The infeed unit is inserted and specified. - Page 97 Commissioning 4.4 Creating a project offline in Startdrive Connecting infeed units in parallel To connect infeed units (Line Modules) in parallel with already added modules, proceed as follows: 1. Open "Line Modules" in the hardware catalog. 2. If you have not yet inserted any infeed unit, drag the desired, non-specified infeed unit into the device view and specify this infeed unit (refer to Chapter "Specifying an infeed unit (Page 94)").

-

Page 98: Editing Components In The Device View

Commissioning 4.4 Creating a project offline in Startdrive 4.4.4.4 Editing components in the device view Editing components The various components are displayed graphically in the device view. The device view provides the following editing options: ● Moving the component ● Deleting the component The editing options are subsequently described using an infeed unit as example. - Page 99 Commissioning 4.4 Creating a project offline in Startdrive Deleting the component Delete the components that you no longer require. 1. Right-click in the gray border. A shortcut menu opens. Figure 4-15 Deleting a DRIVE-CLiQ component 2. To delete the DRIVE-CLiQ component, select "Delete" from the shortcut menu. The component is deleted from the editor.

-

Page 100: Editing A Drive-Cliq Connection

Commissioning 4.4 Creating a project offline in Startdrive 4.4.4.5 Editing a DRIVE-CLiQ connection DRIVE-CLiQ connections Blue lines are used to visualize the DRIVE-CLiQ connections between the various components. The connections must be created in accordance with the real wiring in the offline project. - Page 101 Commissioning 4.4 Creating a project offline in Startdrive Drawing the DRIVE-CLiQ connection A DRIVE-CLiQ connection is drawn between two DRIVE-CLiQ ports. 1. Left-click the output port and keep the mouse button pressed. Figure 4-17 Drawing the DRIVE-CLiQ connection 2. Drag the blue line displayed to the target port. A connection is established between the two ports.

-

Page 102: Inserting A Motor Module Or Power Module

Commissioning 4.4 Creating a project offline in Startdrive 4.4.5 Inserting a Motor Module or Power Module When you create a Power Module or Motor Module, the "SERVO" drive object type (high dynamic drives) is active by default. However, if you are using the "VECTOR" drive object type (universal drives) in your hardware device configuration, you can change the type of the module in Startdrive. -

Page 103: Inserting And Specifying A Motor Module

Commissioning 4.4 Creating a project offline in Startdrive 4.4.5.1 Inserting and specifying a Motor Module Using the hardware catalog, you insert a Motor Module in an unspecified form. 1. Open "Motor Modules" in the hardware catalog. A selection can be made from the following Motor Modules: –... - Page 104 Commissioning 4.4 Creating a project offline in Startdrive 3. Drag the unspecified Motor Module into the device view. Figure 4-19 Motor Module inserted The DRIVE-CLiQ connection is automatically established. 4. Click the Motor Module in the device view. Ensure that you click in the white area of the Motor Module.

- Page 105 Commissioning 4.4 Creating a project offline in Startdrive 6. In the secondary navigation of the inspector window, select "Motor Module - Selection - xxx". Figure 4-20 Motor Module specified All Motor Modules for the "SERVO" drive object type (default setting for first call) are displayed in the list.

-

Page 106: Inserting And Specifying A Power Module

Commissioning 4.4 Creating a project offline in Startdrive 4.4.5.2 Inserting and specifying a Power Module You can add a Power Module in unspecified form via the hardware catalog. 1. Open the "Power Modules" item in the hardware catalog. The following Power Modules are available for selection: –... - Page 107 Commissioning 4.4 Creating a project offline in Startdrive 4. In the device view, click the Power Module. Make sure that you click on the white area of the Power Module. 5. Open the Inspector window if it has still not been opened or displayed. 6.

-

Page 108: Making Detailed Settings

Commissioning 4.4 Creating a project offline in Startdrive 4.4.5.3 Making detailed settings Further detail settings can be carried out in the inspector window for Motor Modules and Power Modules: ● Motor Module settings/Power Module settings Allows the modification of the preallocated supply voltage. Indicates the standard for power settings of converter and motor. -

Page 109: Connecting Several Modules In Parallel

Commissioning 4.4 Creating a project offline in Startdrive 4. If a drive object type is set for the "VECTOR" module, it is possible to set further additional data. Select the menu "Power Module Details > Power Module Additional Data" in the inspector window. - Page 110 Commissioning 4.4 Creating a project offline in Startdrive Connecting Motor Modules or Power Modules in parallel Parallel connection using a Motor Module as an example is explained below. 1. Open "Motor Modules" in the hardware catalog. 2. If you have not yet inserted any Motor Module in the device configuration, drag the desired, non-specified Motor Module into the device view and specify it (see Chapter "Inserting and specifying a Motor Module (Page 103)").

-

Page 111: Changing The Drive Object Type

Commissioning 4.4 Creating a project offline in Startdrive 4.4.5.5 Changing the drive object type The drive object type can be changed in the Motor Modules drop-down list or in the Power Modules drop-down list as well as in the project information of the drive axis. Requirement A Power Module or a Motor Module is created and, if required, specified in Startdrive in the device configuration. - Page 112 Commissioning 4.4 Creating a project offline in Startdrive Setting the drive object type in the project information 1. If the device configuration is not active in your Startdrive project, call it via the project tree. 2. Select the desired drive axis in the device configuration. 3.

-

Page 113: Inserting A Motor

Commissioning 4.4 Creating a project offline in Startdrive 4.4.6 Inserting a motor Startdrive manages the motor data of numerous motors in a motor list. Motors can therefore be quickly specified via the Inspector window. If you want to manage the motors in your device configuration that are not contained in the motor list, you can acquire the most important motor data, such as the rating plate values of the motor, manually in the Inspector window. -

Page 114: Inserting And Specifying Motors From The Motor List

Commissioning 4.4 Creating a project offline in Startdrive 4.4.6.1 Inserting and specifying motors from the motor list Inserting and specifying a motor You can insert motors in unspecified form using the hardware catalog. 1. Open "Motors" in the hardware catalog. The following motor types are available for selection: –... - Page 115 Commissioning 4.4 Creating a project offline in Startdrive 3. Drag the unspecified motor to the lower area of the Motor Module. Figure 4-30 Motor inserted 4. Click the unspecified motor in the device view. 5. Open the Inspector window if it has still not been opened or displayed. Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

- Page 116 Commissioning 4.4 Creating a project offline in Startdrive 6. In the secondary navigation of the Inspector window, select "Motor - Selection - ...". 7. Based on the article number, select a motor with the appropriate motor encoder from the list. Figure 4-31 Motor specified The data of the selected motor are assigned to the unspecified motor.

-

Page 117: Inserting And Specifying Motors That Are Missing From The Motor List

Commissioning 4.4 Creating a project offline in Startdrive 4.4.6.2 Inserting and specifying motors that are missing from the motor list The mandatory fields for entering motor data manually are pink. Inserting and specifying a motor via motor data entry You can insert motors in unspecified form using the hardware catalog. 1. - Page 118 Commissioning 4.4 Creating a project offline in Startdrive 3. Drag the unspecified motor to the lower area of the Motor Module. Figure 4-33 Motor inserted 4. Click the unspecified motor in the device view. 5. Open the Inspector window if it has still not been opened or displayed. 6.

- Page 119 Commissioning 4.4 Creating a project offline in Startdrive 7. If you also want to acquire the optional motor data and circuit diagram data, activate the "Activate the display of the ..." options in the "Rating plate values" screen form. The additionally activated subareas are displayed in the secondary navigation under "Motor details".

-

Page 120: Inserting Measuring Systems

This is the reason that high quality encoders must be used for motor encoders. – Siemens motors that have already been configured are created in the device view with the matching encoder and the encoder evaluation. - Page 121 Commissioning 4.4 Creating a project offline in Startdrive Available measuring systems (encoder) The following encoder types are supported in Startdrive: ● DRIVE-CLiQ encoder These encoders are parameterized when downloading - and after an upload, are correctly displayed. ● SIN/COS encoders Incremental encoders that supply a sinusoidal/cosinusoidal type signal are also available with SSI protocol.

- Page 122 Commissioning 4.4 Creating a project offline in Startdrive Requirement ● A project has been created. ● The Control Unit is inserted in the device configuration. ● An infeed is inserted. In case of doubt, you can also add the infeed at a later point in time. However, in this case, you must manually wire the "infeed"...

- Page 123 Commissioning 4.4 Creating a project offline in Startdrive 2. Select the unspecified encoder in the device overview. Figure 4-35 Encoder selected Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

- Page 124 Commissioning 4.4 Creating a project offline in Startdrive 3. Drag the unspecified encoder to the lower area of the Motor Module. Figure 4-36 Encoder inserted An encoder and a Sensor Module are created. 4. Click the unspecified encoder in the device view. 5.

- Page 125 Commissioning 4.4 Creating a project offline in Startdrive 6. In the secondary navigation of the Inspector window, select "Measuring system - Selection - ...". Figure 4-37 Encoder specified 7. Select the required encoder in the "Measuring system - Selection - ..." list. The data of the selected encoder are assigned to the unspecified encoder.

-

Page 126: Specifying The Encoder Evaluation

Commissioning 4.4 Creating a project offline in Startdrive 4.4.7.2 Specifying the encoder evaluation Requirement You have already specified an encoder. The non-specific encoder evaluation is displayed. Specifying the encoder evaluation Various Sensor Modules are available for the encoder evaluation. Different types are offered for selection depending on the encoder. - Page 127 Commissioning 4.4 Creating a project offline in Startdrive The Sensor Modules that are available are listed in the inspector window. Figure 4-39 Encoder evaluation specified 2. Select your Sensor Module. Result The Sensor Module has been specified. Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

-

Page 128: Encoder System Connection

Commissioning 4.4 Creating a project offline in Startdrive 4.4.7.3 Encoder system connection Description The Sensor Modules evaluate the signals from the connected motor encoders or external encoders and convert the signals so that they can be evaluated by the Control Unit. The encoder system can only be connected to SINAMICS via DRIVE-CLiQ. -

Page 129: Inserting Additional System Components

Commissioning 4.4 Creating a project offline in Startdrive 4.4.8 Inserting additional system components Various system components can be inserted (additionally) in the device configuration of your drive: ● CBE20 Communication Board ● Terminal Module ● Terminal Board ● VSM10 Voltage Sensing Module Since the handling of these system components differs when inserting, the insertion procedure is described separately in the following for each system component. -

Page 130: Adding A Terminal Module

Commissioning 4.4 Creating a project offline in Startdrive Inserting the CBE20 in the Control Unit The CBE20 is a versatile Communication Board that can be used in Startdrive with the "SINAMICS-Link" communication profile. 1. Open "Supplementary system components > Communication Boards" in the hardware catalog. - Page 131 Commissioning 4.4 Creating a project offline in Startdrive Adding Terminal Modules With Terminal Modules, you can expand the interfaces of the Control Unit. They are connected to the Control Unit via DRIVE-CLiQ. Terminal Modules do not have to be specified any further. 1.

-

Page 132: Adding A Terminal Board

Commissioning 4.4 Creating a project offline in Startdrive 4.4.8.3 Adding a Terminal Board Requirement ● A project has been created. ● A Control Unit is contained in the device configuration. ● No Communication Board CBE20 is contained in the device configuration. TB30 and CBE20 cannot be created simultaneously in the device configuration. - Page 133 Commissioning 4.4 Creating a project offline in Startdrive Adding a Terminal Board Terminal Board TB30 is a terminal module with which it is possible to expand the interfaces of the Control Unit. The Terminal Board is inserted into the option slot of the Control Unit. The Terminal Board does not have to be specified any further.

-

Page 134: Adding The Vsm10 Voltage Sensing Module

Commissioning 4.4 Creating a project offline in Startdrive 4.4.8.4 Adding the VSM10 Voltage Sensing Module Voltage Sensing Modules (VSM) can be used for 2 different drive objects: ● Infeed unit Is used for voltage measurement, e.g. for the "mains transformer" function. A VSM10 allows an exact recording of the line voltage curve and supports the fault-free operation of the Line Modules in unfavorable network conditions. - Page 135 Commissioning 4.4 Creating a project offline in Startdrive Result The VSM10 is inserted in the selected drive object. The required DRIVE-CLiQ connections are drawn automatically. Figure 4-43 Example: Voltage Sensing Module VSM10 inserted in infeed unit The VSM10 does not have to be specified any further. Commissioning with Startdrive Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1...

- Page 136 Commissioning 4.4 Creating a project offline in Startdrive Operation of several VSMs per Line Module You can add a total of up to three VSMs to each Line Module using drag and drop. Note Activating the "Line transformer" function module If you operate several VSMs on one Line Module, you must activate the "Line transformer"...

-

Page 137: Establishing An Online Connection To The Drive Unit

Commissioning 4.5 Establishing an online connection to the drive unit Establishing an online connection to the drive unit 4.5.1 Overview For Control Units of type CU320-2 PN, there are 2 interfaces available with which the drive unit can be accessed online. Interfaces for the online connection First you connect your PC to the appropriate Control Unit interface. - Page 138 Commissioning 4.5 Establishing an online connection to the drive unit IP addresses in the project A CU320-2 PN is created with the following IP addresses in a project in TIA Portal: ● Ethernet commissioning interface X127: The addresses correspond to the addresses that have already been assigned in the drive unit.

-

Page 139: Connection Via Standard Ethernet Interface

Commissioning 4.5 Establishing an online connection to the drive unit Selecting the preferred PG/PC interface If you prefer to use a specific network interface of your PG/PC to establish an online connection, you can preset this interface. 1. Select the "Options > Settings" menu. The settings of the TIA Portal are displayed. - Page 140 Commissioning 4.5 Establishing an online connection to the drive unit Going online 1. Select the drive unit with which you want to go online in the project navigation (or in the device view). 2. Click the button. The "Go online" dialog opens. Figure 4-46 Go online 3.

-

Page 141: Online Connection Via Profinet Interface

Commissioning 4.5 Establishing an online connection to the drive unit 7. In order to search for the drive unit with the set parameters, click "Start search". The devices that are found are displayed in the table of results. 8. Select your drive unit from the table. 9. -

Page 142: Online Access Via Profinet

Commissioning 4.5 Establishing an online connection to the drive unit 4.5.3.2 Online access via PROFINET Use online access Get the TIA Portal to search for the drive via the online access of your computer. Requirement ● You have inserted a CU320-2 PN Control Unit. ●... -

Page 143: Assigning An Ip Address

Commissioning 4.5 Establishing an online connection to the drive unit 4. Select the drive, and if necessary assign an IP address and device name, see also the Chapters "Assigning an IP address (Page 143)" and "Assigning PROFINET device names (Page 145)". Figure 4-48 PROFINET with IP address The drive is displayed with the device name (in this case, drive_1) and the IP address. - Page 144 Commissioning 4.5 Establishing an online connection to the drive unit Procedure To assign an IP address, proceed as follows: 1. Double-click "Online & Diagnostics" under "Online access" in the project navigator. 2. Double-click the "Functions" entry in the secondary navigation of the working area. 3.

-

Page 145: Assigning Profinet Device Names

Commissioning 4.5 Establishing an online connection to the drive unit 4.5.3.4 Assigning PROFINET device names Assigning a name In addition to the IP address, the drive must also be assigned a device name for operation in a PROFINET subnet. The name must comply with the DNS name syntax; for detailed information, review the TIA Portal online help. -

Page 146: Comparing Ip Addresses

Commissioning 4.5 Establishing an online connection to the drive unit 4.5.3.5 Comparing IP addresses IP address and the subnet mask in the project After you have assigned an IP address to the drive, check the IP address and subnet mask set in the project. -

Page 147: Setting The Pg/ Pc Interface

Commissioning 4.5 Establishing an online connection to the drive unit 4.5.3.6 Setting the PG/ PC interface The PROFINET communication between the drive and the PG/PC is performed via an Ethernet interface. For PROFINET communication, the IP address and the subnet mask of the PG/PC interface must lie within the number range of the PROFINET subnet. - Page 148 Commissioning 4.5 Establishing an online connection to the drive unit Adding an IP address in the subnet 1. Click in the toolbar on button The "Go online" dialog opens. Figure 4-53 Selecting a device for online connection 2. Select the device and click "Connect" to confirm. 3.

- Page 149 Commissioning 4.5 Establishing an online connection to the drive unit 4. Click "Yes" to assign the IP address. Figure 4-55 IP address added 5. Confirm with "Yes". The interface has been assigned the IP address within the PROFINET subnet. Result ●...

-

Page 150: Restoring Factory Settings

Commissioning 4.5 Establishing an online connection to the drive unit Displaying and deleting temporary IP addresses You can display and also delete all temporarily assigned addresses. 1. Navigate in the project navigation at "Online access" to the appropriate interface. 2. In the shortcut menu, click "Properties". 3. - Page 151 Commissioning 4.5 Establishing an online connection to the drive unit Procedure To restore the factory settings, proceed as follows: 1. Open the "Online & diagnostics" entry at "Online access". 2. Open the entry "Functions" in the secondary navigation. 3. Double-click the "Restore factory settings" entry in the secondary navigation. The dialog box with the current settings is displayed.

-

Page 152: Alternatively: Creating A Project With A Device Configuration Derived From The Hardware

Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware Alternatively: Creating a project with a device configuration derived from the hardware 4.6.1 Creating a new project For projects, the choice is yours: ● You create a completely new project (see "Create new project"). ●... - Page 153 Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware 2. Enter the project data here: – Project name: Startdrive automatically counts each new project. – Path: The simpler the archive path for the project, the faster the project can be loaded. –...

-

Page 154: Inserting The Drive Unit

Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware 4.6.2 Inserting the drive unit Requirement You have created a project (Page 152) or have opened an existing project. Inserting a drive unit via the project view Proceed as follows to insert new drive units in the project view: 1. -

Page 155: Deriving The Hardware Device Configuration

Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware Ensure that the version number indicated on the right in the dialog correlates with the version number of your memory card on the drive unit. If the version numbers do not match, it will not be possible to go online later. - Page 156 Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware Result The topology of the drive unit is read out. Existing DRIVE-CLiQ interconnections are transferred directly from the actual topology of the drive unit. The "Device configuration detection" dialog opens. Figure 4-61 Example: Device configuration detection - all components assigned All components found in the actual topology of the drive unit are displayed in an overview...

- Page 157 Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware Selecting the drive object type of the motor controls After the device configuration has been read out, the drive object type in the header of the dialog box is automatically set to "High dynamic (servo)".

- Page 158 Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware Deleting a component 1. Select the components which are to be deleted. 2. Call the "Delete" shortcut menu. The component is deleted. Note All components in the "Non-assignable components" folder prevent the creation of this read- out actual topology of the drive unit in the device configuration.

-

Page 159: Transferring The Determined Device Configuration To Startdrive

Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware 4.6.4 Transferring the determined device configuration to Startdrive Note Overwriting existing data in the device configuration If components already exist in the device configuration of the drive unit from which you started discovery of the device configuration, they will be deleted or overwritten when data are created by the automatic configuration. - Page 160 Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware Result The topology is created in the device configuration of the selected drive unit. The original status of the online connection is re-established, as it was upon implementation of "Detection of the device configuration".

-

Page 161: Revising The Configuration

Commissioning 4.6 Alternatively: Creating a project with a device configuration derived from the hardware 4.6.5 Revising the configuration Optimally, all components are transferred specified to the device configuration during an automatic configuration and do not have to be subsequently specified or supplemented. If this is the case, a message is shown in the message display that the automatic device configuration has been performed without error. -

Page 162: Basic Parameterization Of The Drive Objects

Commissioning 4.7 Basic parameterization of the drive objects Basic parameterization of the drive objects 4.7.1 Control Unit 4.7.1.1 Web server Activating and configuring the web server The web server provides information on a SINAMICS device via its web pages. Access is via an Internet browser. - Page 163 Commissioning 4.7 Basic parameterization of the drive objects Calling up the web server configuration 1. In the project navigation, select menu "Drive control > Parameter". The corresponding detailed view is displayed at the right. 2. In the secondary navigation, call menu "Basic parameterization > Web server". The detailed view is updated.

- Page 164 Commissioning 4.7 Basic parameterization of the drive objects Restricting web server access to just secure connections Using the default configuration of the web server, you can access the SINAMICS frequency converter via an HTTP connection or via the encrypted HTTPS connection. Using the configuration, access can be restricted so that only a secure HTTPS connection is possible.

- Page 165 4.7 Basic parameterization of the drive objects Setting or changing web server user accounts For SINAMICS S120, the rights of both user accounts "SINAMICS" and "Administrator" are permanently defined and cannot be changed by users. The user "Administrator" has full rights by default. However, the standard "SINAMICS" user only has restricted access rights.

- Page 166 Commissioning 4.7 Basic parameterization of the drive objects Defining a password for a user You can create a password for both users "SINAMICS" and "Administrator" as follows: 1. Click on "Specify password". The "Specify password" dialog opens. Figure 4-66 Specifying the password 2.

- Page 167 Commissioning 4.7 Basic parameterization of the drive objects Deleting the password for user "SINAMICS" You can delete the password of user "SINAMICS" as follows: 1. Click the "Delete password" button. The "Delete password" dialog opens. Figure 4-67 Deleting the password 2.

-

Page 168: Configuring Inputs/Outputs Of The Control Unit

Commissioning 4.7 Basic parameterization of the drive objects 4. Repeat the password in the "Confirm password" field. For security reasons, the password entries displayed in the input fields are encrypted. The entry is checked. If the entry is correct, the message "Password has been changed" is displayed. - Page 169 Commissioning 4.7 Basic parameterization of the drive objects Changing the view of the screen form The view of this screen form can be reduced to the essentials via a checkbox. Changing the function of one of the bidirectional digital inputs/outputs is not possible in the optimized view. The view of the screen form can also be switched to a simulation mode.

- Page 170 Commissioning 4.7 Basic parameterization of the drive objects Measuring sockets The measuring sockets output the analog signals. Any freely interconnectable signal can be output at any measuring socket. A measuring socket can be used, for example, to output the actual speed value (r0063) to a measuring instrument connected to the measuring socket. Figure 4-69 Measuring socket Note...

- Page 171 Commissioning 4.7 Basic parameterization of the drive objects Limitation on/off (p0784) With the "Limitation" drop-down list, select whether the output value of the measuring socket is to be restricted to the limit values of the characteristic curve for the required measuring socket.

- Page 172 Commissioning 4.7 Basic parameterization of the drive objects Define characteristic curve The scaling specifies the processing of the measured signal. This requires the definition of a straight line with two points. 1. Click the "Scaling" button in the adjustment range of a measuring socket. The "Scaling CU320 measuring socket Tx"...

- Page 173 1. Enter the required offset value in the "Offset" field for the relevant measuring socket. Function diagrams (see SINAMICS S120/S150 List Manual) Diagnostics - measuring sockets (T0, T1, T2) • 8134 Overview of important parameters (see SINAMICS S120/S150 List Manual) Adjustable parameters CI: Measuring sockets signal source • p0771[0...2] Measuring sockets characteristic curve value x1 •...

-

Page 174: Infeed Unit

Commissioning 4.7 Basic parameterization of the drive objects 4.7.2 Infeed unit 4.7.2.1 Overview Infeed units (Line Modules) Line Modules contain the central line infeed for the DC link. Various Line Modules can be selected to address the various application profiles: ●... -

Page 175: Function Modules

Commissioning 4.7 Basic parameterization of the drive objects 4.7.2.2 Function modules For the infeed, you can activate function modules offline as required. The function modules that can be activated are listed in the "Function modules" screen form. Figure 4-71 Example: Function modules for an ALM Note Function modules which can be activated are dependent upon the configuration selected for the infeed unit. - Page 176 Commissioning 4.7 Basic parameterization of the drive objects The function modules that can be used are presorted in two areas: ● Frequently used function modules – Master/slave Redundant operation of several ALMs on one DC link. – External Braking Module Control of an external Braking Module in order to be able to collect braking energy in the event of a power failure.

-

Page 177: Line Data / Operating Mode

Commissioning 4.7 Basic parameterization of the drive objects 4.7.2.3 Line data / operating mode You set the most important parameters for the operation of an infeed in the function view of the "Line data / operating mode" screen form. The corresponding parameters are displayed depending on the infeed type. - Page 178 Commissioning 4.7 Basic parameterization of the drive objects Setting the line data and operating mode The parameters in this screen form are assigned default values when creating the device. 1. Enter a value for the device supply voltage in the "Device supply voltage" field (p0210). 2.

-

Page 179: Enable Logic

Commissioning 4.7 Basic parameterization of the drive objects 4.7.2.4 Enable logic You can connect several signal sources for the enables in the function view of the "Enable logic" mask. Figure 4-73 Enable logic Procedure 1. Interconnect the signal source via "p0840" for "OFF1 (low active)". 2. -

Page 180: Line Contactor Control

Commissioning 4.7 Basic parameterization of the drive objects 4.7.2.5 Line contactor control This function allows an external line contactor to be controlled. The closing and opening of the line contactor can be monitored by evaluating the feedback contact of the line contactor. Figure 4-74 Infeed: Line contactor control The line contactor can be controlled with the following drive objects via r0863.1:... -

Page 181: Drive Axes Servo Drives

Commissioning 4.7 Basic parameterization of the drive objects 4.7.3 Drive axes SERVO drives 4.7.3.1 Overview Basic parameterization of the drive axes You can carry out basic parameterization for the following data of the drive axis/axes: ● Function modules ● Control mode ●... -

Page 182: Function Modules

Commissioning 4.7 Basic parameterization of the drive objects 4.7.3.2 Function modules For the drive axis used, you can activate function modules offline as required. The function modules that can be activated are listed in the "Function modules" screen form. Figure 4-75 Example: Function modules - for drive axes Note The display of the function modules that can be activated is dynamic and depends on the... -

Page 183: Control Mode

Commissioning 4.7 Basic parameterization of the drive objects 4.7.3.3 Control mode Control types Speed control (with and without encoder) and torque control are available for SERVO drives. Figure 4-76 Control mode ● Speed control The speed control of a variable-speed drive has the task of following the speed according to a specified setpoint (reference variable) as precisely as possible and without overshoot. -

Page 184: Important Parameters

Commissioning 4.7 Basic parameterization of the drive objects 4.7.3.4 Important parameters Description You define the basic properties of the drive control using the important parameters. Figure 4-77 Important parameters Parameters Designation Description p1121 Ramp-down time Ramp-down time which the drive requires to decelerate from maximum speed (p1082) to standstill. -

Page 185: Sampling Times/Pulse Frequency

Commissioning 4.7 Basic parameterization of the drive objects 4.7.3.5 Sampling times/pulse frequency As of a pulse frequency of 800 Hz, it is recommended that you enter the sampling times and the pulse frequency for the drive. The setting is made using the following screen form: Figure 4-78 Sampling times/pulse frequency Commissioning with Startdrive... - Page 186 Commissioning 4.7 Basic parameterization of the drive objects Setting the defaults The sampling times are preset via parameter p0112. 1. Select one of the following defaults via the drop-down list (p0112): – [0] Expert – [1] xLow – [2] Low –...

- Page 187 Commissioning 4.7 Basic parameterization of the drive objects Entering the sampling times manually If you have set "Expert" in p0112, you can manually configure each of the following sampling times for the following control loops (p0115): ● p0115[0]: Sampling times for internal control loops, current controller ●...

-

Page 188: Enable Logic

Commissioning 4.7 Basic parameterization of the drive objects 4.7.3.6 Enable logic If telegrams were connected during commissioning, these interconnections are displayed here and an additional specification is not required. If no telegrams were specified previously, then you must connect the required signal sources via the enable logic. - Page 189 Commissioning 4.7 Basic parameterization of the drive objects Connecting signal sources 1. Connect the signal source for the "Infeed operation" (p0864) command. 2. Connect the signal source for the "OFF1 (low active)" command (p0840). This command corresponds to control word 1 bit 1 (STW1.1) in the PROFIdrive profile. 3.

-

Page 190: Drive Axes Vector Drives

Commissioning 4.7 Basic parameterization of the drive objects 4.7.4 Drive axes VECTOR drives 4.7.4.1 Overview Basic parameterization of the drive axes You can carry out basic parameterization for the following data of the drive axis/axes: ● Function modules ● Control mode ●... -

Page 191: Function Modules

Commissioning 4.7 Basic parameterization of the drive objects 4.7.4.2 Function modules You can connect various function modules for the associated deployed drive axis or for the deployed infeed. The function modules that can be activated are listed in the "Function modules"... -

Page 192: Control Mode

Commissioning 4.7 Basic parameterization of the drive objects 4.7.4.3 Control mode Control types The following control types are available for VECTOR drives: ● U/f control with linear characteristic ● U/f control with linear characteristic and FCC ● U/f control with parabolic characteristic ●... -

Page 193: Important Parameters

Commissioning 4.7 Basic parameterization of the drive objects Selecting the control type 1. Select one of the control modes listed above (p1300). The screen form is structured according to the selected control mode. Terminology for the use of linear motors When linear motors are used, a linear motion is executed instead of a rotary motion. -

Page 194: Drive Settings

Commissioning 4.7 Basic parameterization of the drive objects 4.7.4.5 Drive settings No entries are required on this page for motors with DRIVE-CLiQ interface or motors of the motor database. Figure 4-83 Drive settings Setting the automatic calculation of motor/control parameters 1. - Page 195 Commissioning 4.7 Basic parameterization of the drive objects Setting the calculation of the controller data 1. Select one of the following options for the calculation of the controller data in the "Calculation controller data" (p0340) drop-down list: – No calculation The motor data is not calculated.

-

Page 196: Enable Logic

Commissioning 4.7 Basic parameterization of the drive objects 4.7.4.6 Enable logic If telegrams were connected during commissioning, these interconnections are displayed here and an additional specification is not required. If no telegrams were specified previously, then you must connect the required signal sources via the enable logic. - Page 197 Commissioning 4.7 Basic parameterization of the drive objects Interconnecting signal sources 1. Connect the signal source for the "Infeed operation" (p0864) command. 2. Connect the signal source for the "OFF1 (low active)" command (p0840). This command corresponds to control word 1 bit 1 (STW1.1) in the PROFIdrive profile. 3.

-

Page 198: Important Optimization Steps

Commissioning 4.7 Basic parameterization of the drive objects 4.7.5 Important optimization steps 4.7.5.1 Performing automatic controller optimization Using the "Automatic controller optimization" function (Auto Servo Tuning = AST), controller data of the speed controller loop (K , current setpoint filter) can be optimized. Figure 4-85 Automatic controller optimization Commissioning with Startdrive... - Page 199 Commissioning 4.7 Basic parameterization of the drive objects The following settings can be made as input parameters for the optimization. ● Measured signals – Amplitude Enter the amplitude of the measuring signal excitation as a percentage of the rated torque. As a rule, the drive can be optimized well with the amplitude presetting.

- Page 200 Commissioning 4.7 Basic parameterization of the drive objects Requirements: ● Startdrive is in online mode. ● Operation has been enabled. ● The SERVO type is set for the drive axis. ● The speed controller is active. ● Operation with encoder has been set. ●...

- Page 201 Commissioning 4.7 Basic parameterization of the drive objects 3. Confirm your entries with "OK". The "Measured signals" dialog closes. You can then specify the optimization type. 4. Select the desired optimization type in the "Optimization objective" drop-down list. – Robust (default setting) –...

- Page 202 Commissioning 4.7 Basic parameterization of the drive objects After you have made the optimization settings, you can start the measurements. 1. Click "Start" at the top right in the "Auto Servo Tuning" screen form. The following 4 consecutive measurements are now started to automatically optimize the controller: –...

- Page 203 Commissioning 4.7 Basic parameterization of the drive objects Accepting, checking and saving optimized values in the drive 1. Click "Accept calculated values". The optimized values are taken into the drive and saved there in the RAM. In the table, the values from the "Calculated value" column are transferred to the "Active value"...

-

Page 204: Stationary/Rotating Measurement

Commissioning 4.7 Basic parameterization of the drive objects 4.7.5.2 Stationary/rotating measurement Motor identification (MotID) provides a means of determining motor data, for example, of third-party motors. To improve control properties of the motor, the MotID should be performed. The main motor identification components are the stationary and rotating measurements. - Page 205 Commissioning 4.7 Basic parameterization of the drive objects Requirements ● Startdrive is in the online mode. Assume master control You require master control for the selected drive to perform the motor identification. Master control has to be activated before the optimization measurements are started. 1.

- Page 206 Commissioning 4.7 Basic parameterization of the drive objects After performing the basic parameterization and subsequent download, the "Stationary measurement" measurement type is active as the "Calculation of motor/control parameters" has already been performed. 1. Click the "1" icon in the "Infeed " area to switch on the infeed. 2.

-

Page 207: Loading The Project To The Target Device

Commissioning 4.8 Loading the project to the target device Loading the project to the target device In order to set up your project, you need to load the project data you generated offline on the connected drive units. This project data is generated, for example when configuring hardware, networks, and connections or when programming the user program or when creating recipes. - Page 208 Commissioning 4.8 Loading the project to the target device 3. Check the messages in the "Load preview" dialog. Activate the required actions in the "Action" column to perform a secure download. Figure 4-88 Example: Load preview As soon as downloading becomes possible, the "Load" button is enabled. 4.

-

Page 209: Commissioning A Drive

Commissioning 4.9 Commissioning a drive Commissioning a drive 4.9.1 Using the control panel Traverse the drive and test the settings that have already been made with the control panel (see also the overview in Section "Drive control panel (Page 44)"). WARNING Non-observance of the safety instructions for the drive control panel The safety shutdowns from the higher-level controller have no effect with this function. - Page 210 Commissioning 4.9 Commissioning a drive Calling the control panel 1. In the project tree, select the "Drive unit_x > Drive axis_x > Commissioning" menu. 2. In the commissioning secondary navigation, select the "Control panel" menu. When an online connection has been established, the bar in the header area is shown in color.

- Page 211 Commissioning 4.9 Commissioning a drive Activating the infeed If an infeed is available in your drive, then the infeed must also be activated. If it is not activated, no further drive release can be set. 1. Click the "1" icon at "Infeed" to switch on the infeed. Deactivating the control panel When you deactivate the control panel, you return the master control.

-

Page 212: Traversing The Drive With Speed Specification

Commissioning 4.9 Commissioning a drive 4.9.2 Traversing the drive with speed specification After you have set the drive enables, in the "Control Panel" screen form specify the operating mode and switch on the motor. Specifying the setpoint To specify the setpoint, proceed as follows: 1. -

Page 213: Basic Positioner

Commissioning 4.9 Commissioning a drive 4.9.3 Basic positioner 4.9.3.1 Manual positioning Performing manual positioning in the drive control panel With manual positioning, you traverse the drive endlessly or with jog position-controlled with a defined velocity and acceleration. Requirement ● Startdrive is in online mode. ●... -

Page 214: Relative Positioning

Commissioning 4.9 Commissioning a drive 4.9.3.2 Relative positioning Using relative positioning Use the "Relative positioning" function to traverse an axis a defined distance with the aid of the control panel. Requirement ● Startdrive is in online mode. ● The "Basic positioner" function module is activated. ●... -

Page 215: Absolute Positioning

Commissioning 4.9 Commissioning a drive 4.9.3.3 Absolute positioning Using absolute positioning With "Absolute positioning" you traverse the axis to an absolute position. The function is oriented towards "Direct setpoint specification / MDI". Requirement ● Startdrive is in online mode. ● The "Basic positioner" function module is activated. ●... -

Page 216: Modify Traversing Block

Commissioning 4.9 Commissioning a drive 4.9.3.4 Modify traversing block Using "Modify traversing blocks" You traverse the programmed traversing blocks with "Modify traversing blocks". You can test individual traversing blocks or all programmed traversing blocks in an automatic run. Requirement ● Startdrive is in online mode. ●... -

Page 217: Note Regarding The Control Panel