Subscribe to Our Youtube Channel

Summary of Contents for Thermo Scientific thermoscientific Vanquish UHPLC System

- Page 1 Vanquish UHPLC System Operating Manual 4820.3601-EN Revision 4.0 • December 2019...

- Page 2 Copyright © 2019 Thermo Fisher Scientific Inc. All rights reserved. Original Operating Manual Trademarks Acrobat, Adobe, and Adobe Reader are trademarks of Adobe Systems Incorporated. Microsoft and Windows are trademarks of Microsoft Corporation. MP35N is a trademark of SPS Technologies. Torx is a trademark of Acument Intellectual Properties, LLC.

- Page 3 Contacting Us Contacting Us There are several ways to contact us: Ordering Information For ordering information or sales support for HPLC products, contact your local Thermo Fisher Scientific sales organization. For contact information, go to Contact Us on http://www.thermofisher.com. Technical Assistance For technical support for HPLC products, contact your local Thermo Fisher Scientific support organization.

- Page 4 Contacting Us Page 4 UHPLC System Operating Manual...

-

Page 5: Table Of Contents

Contents Contents 1 Using this Manual ................ 9 About this Manual .................... 10 Conventions...................... 11 1.2.1 Safety Messages.................. 11 1.2.2 Special Notices and Informational Notes .......... 11 1.2.3 Typographical Conventions .............. 12 Reference Documentation ................... 13 2 Safety.................. 15 Safety Symbols and Signal Words................. 16 2.1.1 Safety Symbols and Signal Words in This Manual ........ - Page 6 Contents 5 Installation................. 39 Safety Guidelines for Installation ................. 40 Installing the System .................... 41 Site Requirements .................... 43 5.3.1 Workbench.................... 43 5.3.2 Power Considerations ................ 44 5.3.3 Power Cord.................... 44 5.3.4 Condensation ................... 45 5.3.5 Operating Conditions ................ 45 Setting Up the Hardware.................. 46 5.4.1 System Stack Setup ..................

- Page 7 Contents 7 Maintenance and Service ............ 101 Introduction to Maintenance and Service............ 102 Safety Guidelines for Maintenance and Service.......... 103 General Rules for Maintenance and Service ............. 105 Routine and Preventive Maintenance............... 106 7.4.1 Maintenance Plan .................. 106 7.4.2 Cleaning or Decontaminating the System .......... 106 Transporting or Shipping the System ..............

- Page 8 Contents 11 Appendix.................. 141 11.1 Compliance Information.................. 142 11.1.1 Declarations of Conformity .............. 142 11.1.2 WEEE Compliance .................. 143 11.1.3 FCC Compliance.................. 143 11.1.4 Manual Release History................ 143 Index.................. 145 Page 8 UHPLC System Operating Manual...

-

Page 9: Using This Manual

• Using this Manual 1 Using this Manual This chapter provides information about this manual, the conventions used throughout the manual, and the reference documentation that is available in addition to this manual. UHPLC System Page 9 Operating Manual... -

Page 10: About This Manual

• Using this Manual About this Manual This manual provides instructions for installation, set up, start up, shut down, operation, maintenance and troubleshooting of your system. The layout of this manual is designed to provide quick reference to the sections of interest to the user. To obtain a full understanding of your system, read this manual thoroughly. -

Page 11: Conventions

• Using this Manual Conventions This section describes the conventions that are used throughout this manual. 1.2.1 Safety Messages The safety messages and precautionary statements in this manual appear as follows: • Safety messages or precautionary statements that apply to the entire manual and all procedures in this manual are grouped in the Safety chapter. -

Page 12: Typographical Conventions

• Using this Manual 1.2.3 Typographical Conventions These typographical conventions apply to the descriptions in this manual: Data Input and Output • The following appears in bold type: Input that you enter by the keyboard or that you select with the ¨... -

Page 13: Reference Documentation

• Using this Manual Reference Documentation In addition to this operating manual, other documentation is available for reference. Hardware Documentation Additional hardware documentation includes the following: • Operating manuals for the modules of the Vanquish system A printed version of the manual is shipped with each device. •... - Page 14 • Using this Manual Third-Party Documentation Refer also to the user documentation provided by the manufacturers of third-party components and materials, for example, Safety Data Sheets (SDSs). Page 14 UHPLC System Operating Manual...

-

Page 15: Safety

• Safety 2 Safety This chapter provides general and specific safety information and informs about the intended use of the system. UHPLC System Page 15 Operating Manual... -

Page 16: Safety Symbols And Signal Words

• Safety Safety Symbols and Signal Words 2.1.1 Safety Symbols and Signal Words in This Manual This manual contains safety messages to prevent injury of the persons using the system. The safety symbols and signal words in this manual include the following: Always be aware of the safety information. -

Page 17: Safety Symbols On The System

• Safety 2.1.3 Safety Symbols on the System For a list of the safety symbols that appear on a Vanquish system module or on labels affixed to a module, refer to the Operating Manual of the module. Follow the safety notices in these manuals to prevent the risk of operator injury or damage to the system. -

Page 18: Intended Use

• Safety Intended Use The intended use of the Vanquish system is to analyze mixtures of compounds in sample solutions. The system is for use by qualified personnel and in laboratory environment only. The Vanquish system and its modules are intended to be used as General Laboratory Equipment (GLE). -

Page 19: Safety Precautions

• Safety Safety Precautions 2.3.1 General Safety Information All users must observe the general safety information presented in this section and all specific safety messages and precautionary statements elsewhere in this manual during all phases of installation, operation, troubleshooting, maintenance, shutdown, and transport of the system. If the system is used in a manner not specified by Thermo Fisher Scientific, the protection provided by the system could be impaired. - Page 20 • Safety Installation System configuration without Charger Only skilled personnel are permitted to install the system and to establish the electrical connections according to the appropriate regulations. • Thermo Fisher Scientific recommends always having service personnel certified by Thermo Fisher Scientific perform the installation (for brevity, referred to as Thermo Fisher Scientific service engineer).

-

Page 21: Personal Protective Equipment

• Safety 2.3.3 Personal Protective Equipment Wear personal protective equipment and follow good laboratory practice to protect you from hazardous substances. The appropriate equipment depends on the hazard. For advice on the hazards and the equipment required for the substances you are using, refer to the material handling and safety data sheet provided by the vendor. -

Page 22: General Residual Hazards

• Safety 2.3.4 General Residual Hazards Pay attention to the following general residual hazards when working with the system: WARNING—Hazardous Substances Solvents, mobile phases, samples, and reagents might contain toxic, carcinogenic, mutagenic, infectious, or otherwise harmful substances. The handling of these substances can pose health and safety risks. •... - Page 23 • Safety WARNING—Self-Ignition of Solvents Solvents with a self-ignition temperature below 150 °C might ignite when in contact with a hot surface (for example, due to leakage in the chromatography system). Avoid the use of these solvents. WARNING—Hazardous Vapors Mobile phases and samples might contain volatile or flammable solvents.

-

Page 24: In Case Of Emergency

• Safety CAUTION—Sparking due to Electrostatic Discharge Liquid flowing through capillaries can generate static electricity. This effect is particularly present with insulating capillaries and non- conductive solvents (for example, pure acetonitrile). Discharge of electrostatic energy might lead to sparking, which could constitute a fire hazard. -

Page 25: Solvent And Additive Information

• Safety Solvent and Additive Information 2.4.1 General Compatibility To protect optimal functionality of the Vanquish system, observe these recommendations on the use of solvents and additives: • The system must be used with reversed-phase (RP) compatible solvents and additives only. •... -

Page 26: Allowed Ph Ranges

• Safety 2.4.2 Allowed pH Ranges Allowed pH ranges (standard system configuration): System Allowed Remarks (Standard pH ranges Configuration) Vanquish Core 1-13 • pH values of 2 or less: The application time should be as short as possible. Flush the system Vanquish 2-12 thoroughly after these applications. -

Page 27: Further Information

• Safety 2.4.4 Further Information • For information about the materials that are used in the flow path of the Vanquish system, see System Specifications (} page 130). • Follow any specific recommendations presented in other sections of this manual. Refer also to the operating manuals for all modules in the Vanquish system. - Page 28 • Safety Page 28 UHPLC System Operating Manual...

-

Page 29: System Overview

• System Overview 3 System Overview This chapter introduces you to the system and the main components. UHPLC System Page 29 Operating Manual... -

Page 30: System Description (Standard Configuration)

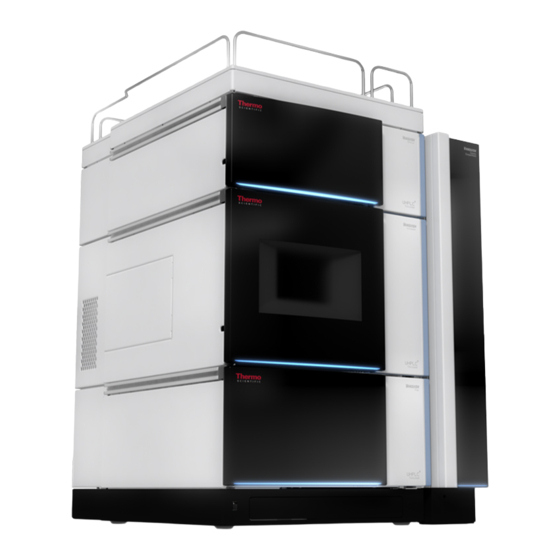

• System Overview System Description (Standard Configuration) The Vanquish system is designed for use in high performance liquid chromatography (HPLC) and ultra-high performance liquid chromatography (UHPLC) applications. The table shows the standard configurations of three Vanquish systems as an example: Module Core system Flex system... -

Page 31: Solvent Rack

• System Overview 3.1.1 Solvent Rack The solvent rack provides a secure location for placing solvent reservoirs. It can store, for example, 6 x 1 L of solvent and 2 x 0.25 L of wash liquid as shown in the figure. The maximum volume for an individual reservoir should not exceed 5 L. -

Page 32: System Base

• System Overview 3.1.2 System Base The system base is a mandatory part of the Vanquish system. It is the bottom part of the system stack and carries the pump, autosampler, and detector in a standard configuration. It provides: • A power button for power on/off control of all modules •... -

Page 33: Operation

Operating the System from the Software (} page 92). TIP The system can be operated also with other data systems, such as Thermo Scientific Xcalibur . In this case, installation of additional software is required in addition to the data system software. For details, contact the Thermo Fisher Scientific sales organization. - Page 34 • System Overview Page 34 UHPLC System Operating Manual...

-

Page 35: Unpacking

• Unpacking 4 Unpacking This chapter provides information for unpacking the system and informs you about the scope of delivery. UHPLC System Page 35 Operating Manual... -

Page 36: Unpacking

• Unpacking Unpacking Damaged Packaging, Defective on Arrival Inspect the shipping container for signs of external damage and, after unpacking, inspect the system for any signs of mechanical damage that might have occurred during shipment. If you suspect that the system may have been damaged during shipment, immediately notify the incoming carrier and Thermo Fisher Scientific about the damage. -

Page 37: Scope Of Delivery

• Unpacking Scope of Delivery The following items are included in the delivery: • System base • Solvent rack • Solvent reservoirs • Ship Kit For details about the kit content, see Ship Kit (} page 135). • Printed system operating manual UHPLC System Page 37 Operating Manual... - Page 38 • Unpacking Page 38 UHPLC System Operating Manual...

-

Page 39: Installation

• Installation 5 Installation This chapter specifies the requirements for the installation site and describes how to set up, install, and configure the system. UHPLC System Page 39 Operating Manual... -

Page 40: Safety Guidelines For Installation

• Installation Safety Guidelines for Installation Pay attention to the following safety guidelines: Observe all warning messages and precautionary statements presented Safety Precautions (} page 19). Observe all warning messages and precautionary statements presented in the Safety Guidelines for Installation section in the Operating Manual for the individual modules of the Vanquish system. -

Page 41: Installing The System

• Installation Installing the System The Vanquish system is installed and set up by a Thermo Fisher Scientific service engineer, including all modules and options or parts shipped with them. The service engineer checks that the installation is correct and that the Vanquish system and modules operate as specified. - Page 42 • Installation 7. Recommended: Perform Instrument Installation Qualification. In the Chromeleon software, a wizard is available to guide you through the qualification process. On the Chromeleon 7 Console: Click Tools > Instrument Qualification > Installation Qualification. Follow the instructions in the Instruments Installation Qualification Operating Instructions.

-

Page 43: Site Requirements

• Installation Site Requirements The operating environment is important to ensure optimal performance of the device. This section provides important requirements for the installation site. Note the following: • Make sure that the installation site has enough power outlets for all devices in the system. -

Page 44: Power Considerations

• Installation 5.3.2 Power Considerations CAUTION—Electric Shock or Damage to the Device Connecting the device to a line voltage higher or lower than specified could result in personal injury or damage to the device. Connect the device to the specified line voltage only. 5.3.3 Power Cord The power cords are designed to match the wall socket requirements of... -

Page 45: Condensation

• Installation 5.3.4 Condensation NOTICE—Condensation in the device can damage the electronics. • When using, shipping, or storing the device, avoid or minimize conditions that can lead to a build-up of condensation in the device. For example, avoid significant or fast changes in environmental conditions. -

Page 46: Setting Up The Hardware

• Installation Setting Up the Hardware This section describes how to set up the hardware and provides information about the system connectors and cables. 1. Set up the system stack. For details, see System Stack Setup (} page 46). 2. Connect the required signal cables. For details, see Signal Cable Connections (} page 54). - Page 47 • Installation Figure 3: Vanquish system, standard configuration (example) Description Solvent Rack Detector Autosampler Pump System Base Column Compartment UHPLC System Page 47 Operating Manual...

- Page 48 • Installation 5.4.1.1 Installing the System Stack NOTICE Moving the Vanquish system stack after installation even over short distances on the workbench can damage and impair the functionality of the system base. • Therefore, install the system stack at the final location. •...

- Page 49 • Installation 5. Loosen the screws on the carrying handles, using a screwdriver (Torx T20). Do not remove the screws from the carrying handles completely. Figure 5: Carrying handles Component Carrying handles Attachment screw (one on each carrying handle) 6. Remove the two carrying handles by sliding them off the rails toward the rear.

- Page 50 • Installation 9. Connect the waste lines (see Connecting the Waste Lines (} page 70)). 10. Attach the column compartment to the system stack (see next section). NOTICE Some modules have shipping locks. To avoid damage to the system when the system is turned on, loosen them or remove them properly. Refer to the Operating Manual for each module for information on shipping locks that need to be removed.

- Page 51 • Installation For installation of the standard configuration, follow the instructions below. Parts required • 4 T-slot nuts • 2 crosspieces • 4 screws • 4 spacers Tools required Screwdriver, Torx T20 Follow these steps 1. Align the screw holes of the two T-slot nuts, the spacers and the crosspiece.

- Page 52 • Installation 3. Slide the T-slot nuts of the mounting bar in the rail on the system housing and push until stop. The grooves on the mounting bars must face upwards. Make sure, that the orientation of the crosspiece is as indicated on the picture. 4.

- Page 53 • Installation 5. Lift the column compartment into vertical position. 6. To insert the holding knobs in the grooves on the mounting bar, grasp the column compartment by its sides and slightly lift the column compartment up. Figure 9: Attaching the column compartment to the system stack 5.4.1.3 Moving the System Stack after Installation Moving the Vanquish system stack even over short distances on the...

-

Page 54: Signal Cable Connections

• Installation 5.4.2 Signal Cable Connections This section provides details on the cables and interfaces used to connect the system to a computer or other devices, and details on how to interlink the system modules with each other. 5.4.2.1 Connector Overview The following connectors are provided on the system modules for power line connection and for signal connections: Figure 10: Connectors (here: pump) - Page 55 • Installation TIP Thermo Fisher Scientific recommends using the USB ports only as described above. If the USB ports are used for any other purpose, Thermo Fisher Scientific cannot ensure proper functionality. 5.4.2.2 USB Connections All USB connections require standard USB A-to-B type cable. Figure 11: USB cable The flat, rectangular end of the cable is the "A"...

- Page 56 • Installation Connecting the USB Cables USB Cable Overview Figure 12: USB cable connections (example) Description USB connection: From pump to detector From autosampler to pump From column compartment to detector From detector to computer Page 56 UHPLC System Operating Manual...

- Page 57 • Installation Follow these steps 1. On the autosampler, pump, and column compartment, connect the "B" connector of a USB cable to the USB port. 2. Connect the "A" connector of the USB cable from the pump to the USB hub on the UV/VIS detector. Connect the "A" connector of the USB cable from the other modules to the USB hub on the UV/VIS detector or pump.

- Page 58 • Installation Connecting the System Interlink Cables System Interlink Cable Overview Figure 14: USB and system interlink cable connections (example) Description System interlink connection: From system base to pump From pump to autosampler From autosampler to detector From detector to column compartment Page 58 UHPLC System Operating Manual...

-

Page 59: Power Connections

• Installation Follow these steps 1. Connect one end of the system interlink cable to the System Interlink port on the system base, and the other end to a System Interlink port on the pump. 2. Connect one end of the system interlink cable to the free System Interlink port on the pump, and the other end to a System Interlink port on the autosampler. -

Page 60: Cable Clips

• Installation 5.4.4 Cable Clips The cable clips can be used to guide signal and power cables in an orderly fashion. The pump and the detector each have one cable clip on each side and the autosampler has two cable clips on each side. The location of the cable clips/cutouts for the cable clips is shown below. -

Page 61: System Base Lock

• Installation 5.4.5 System Base Lock A lock is integrated into the system base. Unlock the system base if you want to move the system base and lock it if you want to prevent it from being moved on the workbench. If your system configuration includes one column compartment, you can switch between the moveable and stationary mode using the system base locking tools shipped with the system base. - Page 62 • Installation 4. Insert one locking tool into the lock port on the other side of the system base. Figure 19: Inserting locking tools into the system base (top view) 5. Unlock the system base by turning the locking tools as shown below. In the unlocked position, the locking tools cannot be removed from the system base.

- Page 63 • Installation 5.4.5.2 Locking the System Base When the system base is in movable mode and one column compartment is installed, locking tools are already inserted into the system base. The following instructions and images assume that the column compartment is installed on the right side of the system. 1.

-

Page 64: Setting Up The Flow Connections

• Installation Setting Up the Flow Connections 5.5.1 General Information and Guidelines This section gives an overview on the flow connections to and from the system and describes the installation of the waste lines. For details on tubing and capillary connections within and between the modules, refer to the Operating Manual of each module. -

Page 65: Flow Connections Overview

• Installation 5.5.2 Flow Connections Overview The picture illustrates the liquid flow path through the system: Figure 22: Flow connections in the Vanquish system (example) The Vanquish system has been designed for optimized and simple leak liquid and waste handling: • Leak liquid from the solvent rack, detector, autosampler, and pump flows through pipes from the modules to the system base drain port. -

Page 66: Guiding Capillaries And Tubing Through The System

• Installation Setting up the System Flow Connections 1. Connect the waste lines (see Connecting the Waste Lines (} page 70)). 2. Set up the flow connections for the pump. For details, refer to the Operating Manual of the pump. 3. Set up the flow connections for the autosampler. For details, refer to the Operating Manual of the autosampler. - Page 67 • Installation Tubing Chase, Tubing Guide, Tubing Bracket To guide certain tubes and lines (solvent tubing, wash liquid tubing, detector waste line) from the top module to the bottom module in the Vanquish system stack, the stackable modules have a tubing chase on the inside right.

-

Page 68: Connecting Fittings, Capillaries, And Tubing

• Installation Dual System Arrangements The number of tubes may exceed the capacity that the tubing guides can hold. In this case, it is recommended to place the solvent lines in the tubing guides and route any additional tubes freely in the tubing chase. Guide Holes and Capillary Clips Guide holes and capillary clips are provided at specific positions on the system modules. - Page 69 • Installation 5.5.4.2 Connecting Viper Capillaries This section describes how to connect Viper™ capillaries. All Viper flow connections in the Vanquish system are designed to be finger-tight. To connect Viper capillaries with knurls, follow these steps: NOTICE • Tighten or loosen Viper capillaries only with your fingers. Do not use tools other than the knurl that comes with the capillary.

-

Page 70: Connecting The Waste Lines

• Installation Resolving Leakage of Viper Fittings with Knurls 1. Tighten the connection a little more. 2. If leakage continues, remove the capillary. 3. Clean the capillary ends carefully by using a lint-free tissue wetted with isopropanol. 4. Reinstall the capillary. 5. - Page 71 • Installation Figure 26: Overview of waste lines in the system (example) Description Drainage from the modules in the stack to the system base System drain port Waste line for system drainage Module waste lines: Detector waste line Pump waste line (here in VH-P10 pump) Drainage from the column compartment: Column compartment drain port Waste line for column compartment drainage...

- Page 72 • Installation Make the following connections: • Connect a waste line to the system drain port (see Connecting the Waste Line to the System Drain Port (Drain Tubing) (} page 73)). • When the waste line is set up, test the drain system (see Testing the Drain System (} page 74)).

- Page 73 • Installation 5.5.5.2 Connecting the Waste Line to the System Drain Port (Drain Tubing) Parts required • Drain tubing from ship kit • Elbow connection piece from ship kit • Suitable waste container Follow these steps 1. Push an elbow connection piece into the system drain port as far as it goes in to establish a self-sealing connection.

- Page 74 • Installation 3. To prevent liquid from flowing back into the system, the entire drain tubing must remain below the drain port. Avoid the formation of siphons. TIP To allow the waste liquid flowing off properly and avoid liquid accumulation in the system base, the end of the waste line must not be submerged in waste liquid (see figure below): •...

- Page 75 • Installation 5.5.5.4 Installing the Detector Waste Line Parts required • Detector waste line TIP The detector waste line connects the flow cell outlet through the detector waste outlet to the waste. • For instructions on how to connect the waste line through the detector waste outlet to the waste, follow the steps below.

- Page 76 • Installation 3. Route the free end of the waste line into a waste container. Figure 31: Guiding the waste line to the waste container 4. Ensure proper drainage of the waste from the detector. You may need to cut the waste line to length. 5.

- Page 77 • Installation Ensuring Proper Drainage of Waste 1. Position the waste container below the level of the system stack. To prevent solvent vapors from evaporating back into the system, make sure that the distance is sufficient. 2. Make sure the drain tubing is neither bent nor pinched. 3.

-

Page 78: Turning On The System

• Installation Turning On the System NOTICE Before turning on power to the Vanquish system, verify that any shipping locks have been properly loosened or removed to avoid damage to the system. Refer to the Operating Manual for each module for information on shipping locks that need to be removed. -

Page 79: Setting Up The System In The Software

• Installation Setting Up the System in the Software This section describes the basic steps for operating the Vanquish system with the Chromeleon 7 software. For additional information, refer to the Help and documents provided with the software. This manual assumes that the Chromeleon software is already installed on the data system computer and a valid license is available. - Page 80 3. In the Add module to instrument dialog box, on the Manufacturers list, select Thermo Scientific HPLC: Vanquish and on the Modules list, select the module you want to add, for example, Vanquish Binary Pump. Repeat this step for each module of the system.

-

Page 81: Flushing The System

• Installation Flushing the System This section describes how to flush the Vanquish system after installation. As certain system components are filled with isopropanol during shipment, flushing is required before the system can be operated. Flushing the System without Column Follow these steps: NOTICE To avoid damage to other modules in the Vanquish system, verify the... - Page 82 • Installation Page 82 UHPLC System Operating Manual...

-

Page 83: Operation

• Operation 6 Operation This chapter provides information for routine operation and for shutdown. UHPLC System Page 83 Operating Manual... -

Page 84: Introduction To This Chapter

• Operation Introduction to this Chapter The information in this chapter assumes that the initial setup of the system has already been completed. If this is not the case, refer to the instructions in Installation (} page 39). Software descriptions in this manual refer to Chromeleon 7. Terminology may be slightly different with other software versions. -

Page 85: Safety Guidelines For Operation

• Operation Safety Guidelines for Operation When operating the system, pay attention to the following safety guidelines: Observe all warning messages and precautionary statements presented Safety Precautions (} page 19). Observe all warning messages and precautionary statements presented in the Safety Guidelines for Operation section in the Operating Manual for the individual modules of the Vanquish system. -

Page 86: Power On/Off Control

• Operation Power On/Off Control For easier handling, you can use the power button on the front left of the Vanquish system base (system power button) for power on/off. Observe the following: • All modules in the Vanquish system that are connected to the system base via system interlink cables are turned on or off simultaneously when the system power button is pressed. -

Page 87: Preparing The System For Operation

• Operation Preparing the System for Operation This section gives information on any additional steps that are required to prepare the system for operation and sample analysis. Before Operating the System for the First Time Prepare the system for the first-time operation, observing the following: NOTICE Flush the system flow path thoroughly before operating the device for the first time:... - Page 88 • Operation System Equilibration System equilibration should include the following operations: • Purging the pump (all channels, including those not used for the application) • Flushing the entire chromatography system with the starting solvent to rinse out any solvent from a previous analysis run •...

-

Page 89: Use Of Solvents And Additives

• Operation Use of Solvents and Additives Particles entering the chromatography system can block capillaries and valves, increase wear, and damage the column or system. Especially with aqueous solvents, algae and other microorganisms can grow and deposit in the chromatography system and block the solvent line filters. Blocked capillaries or filters can cause increased or unstable system pressure. - Page 90 • Operation • The pumps are shipped with the following piston seals: Pump Piston Seals VC‑pumps except The pumps are shipped with UHMW-PE piston seals. Using VC‑P21 and VC‑P33 tetrahydrofuran, ketones, or ammonium hydroxide as solvents can damage the seals. Under harsh conditions, consider replacing the UHMW-PE piston seals with carbon-fiber filled PTFE piston seals (part no.

- Page 91 • Operation • Never leave buffers, salt solutions, or aggressive solvents in the system for a longer period without flow. • Note the special properties of the solvents, such as viscosity, boiling point, or UV absorption. • If a charged aerosol detector is connected in the system flow path: Observe the specific mobile phase guidelines for the detector in the Vanquish Charged Aerosol Detector Operating Manual.

-

Page 92: Operating The System From The Software

• Operation Operating the System from the Software This section describes the basic steps for operating the Vanquish system with the Chromeleon software. For additional information, refer to the Help and documents provided with the software that you are using. 6.6.1 Starting the Instrument Controller and Client 1. -

Page 93: Controlling The System From The Epanel Set

• Operation 6.6.2 Controlling the System from the ePanel Set When the chromatography system is not running an automated analysis, you can control the system modules from the ePanel Set. Use the ePanel Set to view status information and perform commands. To access the ePanel Set: 1. -

Page 94: Monitoring The Baseline

• Operation 3. On the ePanel Set, click the tab for a module. 4. Use the controls (for example, buttons, sliders) to perform commands. 5. If a function that you want to perform is not available on a panel, press the F8 key to open the Command window. From this window, you can access all commands that are available for the system. -

Page 95: Running Automated Sample Analysis

• Operation 6.6.4 Running Automated Sample Analysis Automated sample analysis with the chromatography system involves creating and running a sequence. In a sequence, you determine how the injections of a sample are analyzed and in which order they are processed. Each injection of a sequence is processed by using an instrument method, which defines the property values and timed control commands for each module. - Page 96 • Operation Starting the new sequence 1. On the Sequence Control Bar, click Start. 2. The sequence is appended to the queue and a Ready Check is performed. If the Ready Check passes and if the instrument is not currently running another sequence, the sequence is started.

-

Page 97: Shutting Down The System

• Operation Shutting Down the System If the system will not be operated for some time, observe the general guidelines outlined below. Interrupting Operation of the System for a Short Period To interrupt operation of the system for a short period (short-term shutdown), for example, overnight, observe these guidelines for the Vanquish system modules, as required by your system arrangement: •... - Page 98 • Operation Interupting Operation of the System for a Longer Period To interrupt operation for a longer period, follow the instructions below. Also observe the instructions and guidelines for the long-term shutdown of the in the Operating Manual for each module. 1.

- Page 99 • Operation 3. Turn off the system with the system power button on the system base. If one of the modules shall be removed from the system stack, turn off all system modules with their main power switch. Pressing the system power button will not be sufficient to turn off the power to the devices completely.

- Page 100 • Operation Page 100 UHPLC System Operating Manual...

-

Page 101: Maintenance And Service

• Maintenance and Service 7 Maintenance and Service This chapter gives general guidelines on maintenance and transport of the system. UHPLC System Page 101 Operating Manual... -

Page 102: Introduction To Maintenance And Service

• Maintenance and Service Introduction to Maintenance and Service This chapter describes the routine maintenance that the user may perform for the system. Additional maintenance or service procedures must be performed only by service personnel certified by Thermo Fisher Scientific (for brevity, referred to as Thermo Fisher Scientific service personnel). -

Page 103: Safety Guidelines For Maintenance And Service

• Maintenance and Service Safety Guidelines for Maintenance and Service When performing maintenance or service procedures, pay attention to the following safety guidelines: Observe all warning messages and precautionary statements presented Safety Precautions (} page 19). WARNING—High Voltage High voltages are present inside the device that could cause an electric shock. - Page 104 • Maintenance and Service CAUTION—Hot Surfaces Surfaces inside the system may become hot during operation. Touching hot parts might cause burns. Allow hot surfaces to cool down before starting replacement or maintenance procedures. CAUTION—Hydrostatic Pressure Solvent may spill when you open the flow path. This is due to hydrostatic pressure in the system when the solvent reservoirs are located above the pump outlet.

-

Page 105: General Rules For Maintenance And Service

• Maintenance and Service General Rules for Maintenance and Service For successful maintenance and service procedures, follow these rules and recommendations: • Use only the replacement parts specifically authorized and qualified for the device by Thermo Fisher Scientific. • Before opening the flow path to replace capillaries in the system, turn off the pump flow and wait until the system pressure is down to zero. -

Page 106: Routine And Preventive Maintenance

• Maintenance and Service Routine and Preventive Maintenance Optimum system performance, maximum uptime of the system, and accurate results can be obtained only if the system is in good condition and properly maintained. 7.4.1 Maintenance Plan Perform the maintenance procedures in the table on a regular basis. The frequency given in the table is a suggestion. - Page 107 • Maintenance and Service NOTICE Wipe up all liquids spilled onto the system immediately. If surfaces are exposed for longer periods, these liquids can cause damage. Decontamination Decontamination is required, for example, when leakage or spillage has occurred, or before service or transport of the system. Use a suitable cleaning detergent or disinfectant to ensure that the treatment renders the system safe to handle.

- Page 108 • Maintenance and Service Preparations 1. Turn off the power to the system and disconnect the power cord from the power source. Follow these steps 1. Wipe the surfaces clean with a clean, dry, soft, lint-free cloth or wipe. If necessary, slightly dampen the cloth or wipe with a solution of lukewarm water and a suitable cleaning detergent.

-

Page 109: Transporting Or Shipping The System

• Maintenance and Service Transporting or Shipping the System NOTICE Moving the Vanquish system stack even over short distances on the workbench can damage and impair the functionality of the system base. Observe the following: • Configuration with one column compartment: Before moving the system stack, unlock the system base using the locking tools. - Page 110 • Maintenance and Service Removing the System 1. Slide the carrying handles that were installed when the system was Modules shipped on the rails at the right and left of the module from the rear as shown in the figure below. The final position of the handles must match the foam spacers used for transport (about 15 cm from the rear of the module to the center of the handle).

- Page 111 • Maintenance and Service Shipping the Solvent Rack and System Base To ship the solvent rack and/or system base, follow these steps: 1. Follow the unpacking instructions in this manual in the reverse order. Use only the original packing material and shipping container. If the original shipping container is not available, appropriate containers and packing material can be ordered from the Thermo Fisher Scientific sales organization.

- Page 112 • Maintenance and Service Page 112 UHPLC System Operating Manual...

-

Page 113: Troubleshooting

• Troubleshooting 8 Troubleshooting This chapter is a guide to troubleshooting issues that may arise during operation of the system. UHPLC System Page 113 Operating Manual... -

Page 114: General Information About Troubleshooting

• Troubleshooting General Information about Troubleshooting This section gives information about operating issues that might occur during the operation of a Vanquish system. If you are unable to resolve a problem following the instructions given here or if you experience problems that are not covered in this section, contact Thermo Fisher Scientific Technical Support for assistance. -

Page 115: System Troubleshooting

• Troubleshooting System Troubleshooting This section is a guide to troubleshooting issues that may arise during operation of the Vanquish system. Locate the table for the type of symptom you have, find the possible cause, and use the description of the solution to help you solve your problem quickly. -

Page 116: Ghost Peaks, Negative Peaks And Spikes

• Troubleshooting Possible Cause Remedial Action Capillaries clogged Replace the capillaries. Sample loop clogged Replace the sample loop (refer to Split Sampler Operating Manual). Solvent selector/ Contact Technical Support. proportioning valve defective 8.2.2 Ghost Peaks, Negative Peaks and Spikes Ghost peaks Possible Cause Remedial Action Contamination... -

Page 117: Peak Area Precision

• Troubleshooting Possible Cause Remedial Action Electrical interferences Avoid operation of equipment generating strong electric or magnetic fields in close from other instruments proximity. Do not connect equipment that may cause power disturbances to the same power network used to supply the system. Column temperature •... - Page 118 • Troubleshooting Pump problems Possible Cause Remedial Action Piston seals in pump Replace the seals (refer to Pump Operating Manual). leaking Air trapped in pump Purge the pump (refer to Pump Operating Manual). head Baseline fluctuations See "Periodic baseline fluctuations" in Baseline (} page 121).

-

Page 119: Flow

• Troubleshooting 8.2.4 Flow No flow Possible Cause Remedial Action Leak in system Find and eliminate the leak. Inlet and/or outlet Clean the inlet check valve or outlet check valve, and replace the check valve if check valve necessary (refer to Pump Operating Manual). contaminated or defective Air trapped in pump... -

Page 120: Pressure

• Troubleshooting 8.2.5 Pressure Pressure pulsation or inconstant pressure Possible Cause Remedial Action Air trapped in the Purge the pump (refer to Pump Operating Manual). system Inlet and/or outlet Clean the inlet check valve or outlet check valve, and replace the check valve if check valve necessary (refer to Pump Operating Manual). -

Page 121: Retention Time Variation

• Troubleshooting 8.2.6 Retention Time Variation Decreasing retention times Possible Cause Remedial Action Improper mobile phase Check premixed mobile phase. Perform an OQ gradient accuracy test. A solvent composition selector/proportioning valve may be defective. Contact Technical Support. Increasing flow rate Check flow rate settings. - Page 122 • Troubleshooting Possible Cause Remedial Action UV/VIS lamp not stable Allow the lamp and optics to warm up for at least 60 minutes. If the lamp is old, you may need to replace the detector lamp (see Detector Operating Manual). A new lamp may need burn-in time before the first analysis. For details, refer to the Detector Operating Manual.

-

Page 123: Temperature Control

• Troubleshooting Possible Cause Remedial Action UV/Vis lamp defective Check that the lamp is correctly installed. Replace the lamp (refer to Detector or not properly Operating Manual). installed Piston calibration value Verify that the calibration value of the piston (imprinted on the rear of the piston) mismatch corresponds to the related piston calibration value in the Chromeleon software. -

Page 124: Power And Communication

• Troubleshooting Post-column cooler does not reach set temperature Possible Cause Remedial Action Post-column cooler not Verify that the post-column cooler screws are tightened and the post-column installed correctly cooler is seated properly. Autosampler does not reach set temperature Possible Cause Remedial Action Ambient temperature Reduce the ambient temperature (for example, by ventilating the room), and/or... -

Page 125: System Diagnostics

• Troubleshooting Module cannot be operated from the chromatography software Possible Cause Remedial Action No connection • Check the USB connections from the system to the computer, see Signal Cable between module and Connections (} page 54). If the module uses a USB hub on another module, check computer that the module that provides the hub is turned on. - Page 126 • Troubleshooting 8.2.10.1 Basic Tightness Test The Basic Tightness Test checks the tightness of the pump and autosampler. Follow these steps 1. Run the test from the Chromeleon software. Refer to the Chromeleon Help. The test runs automatically without further user interaction. 2.

- Page 127 • Troubleshooting 8.2.10.3 Intensity Test The Intensity Test is a test to measure the intensity of the detector lamp and the transmission performance ("intensity") of the optics. The test is available for the diode array detector and for the variable wavelength detector.

- Page 128 • Troubleshooting Page 128 UHPLC System Operating Manual...

-

Page 129: Specifications

• Specifications 9 Specifications This chapter provides important system specifications. UHPLC System Page 129 Operating Manual... -

Page 130: System Specifications

• Specifications System Specifications The physical conditions of a standard system are specified as follows: Type Specification Materials in the flow path For materials in the flow path, refer to the Operating Manuals for the modules in your system. For solvent and additive information, see Solvent and Additive Information (} page 25). -

Page 131: Solvent Rack And System Base Specifications

• Specifications Solvent Rack and System Base Specifications The physical conditions of the solvent rack and system base are specified as follows. For specifications of the other modules in the Vanquish system, refer to the Specifications section in the Operating Manual for each module. - Page 132 • Specifications Page 132 UHPLC System Operating Manual...

-

Page 133: Accessories, Consumables And Replacement Parts

• Accessories, Consumables and Replacement Parts 10 Accessories, Consumables and Replacement Parts This chapter describes the standard accessories that are shipped with the system and the accessories that are available as an option. This chapter also provides information for reordering consumables and replacement parts. -

Page 134: General Information

• Accessories, Consumables and Replacement Parts 10.1 General Information The system must be operated only with the replacement parts and additional components, options, and peripherals specifically authorized and qualified by Thermo Fisher Scientific. Accessories, consumables, and replacement parts are always maintained at the latest technical standard. -

Page 135: Ship Kit

• Accessories, Consumables and Replacement Parts 10.2 Ship Kit The ship kit includes the items listed in the table. The kit content is subject to change and may vary from the information in this manual. See the content list included in the kit for the most recent information about the kit content at the time when the system is shipped. - Page 136 • Accessories, Consumables and Replacement Parts Ship Kit for Vanquish Flex and Horizon system Item Quantity in shipment Fuses kit, Vanquish system The kit includes the appropriate fuses for the Vanquish system modules. Viper inline filter Viper union Tubing connector, straight, for tubing I.D. 1.0 – 2.0 mm, set of 5 Tubing connector, tapered, I.D.

-

Page 137: Optional Accessories

• Accessories, Consumables and Replacement Parts 10.3 Optional Accessories Item Part No. IonBench including stack mounting kit 6036.1720 Stack stabilizer kit 6036.1710 Manual injection valve 6230.1600 To inject samples in the fluidic path manually with a syringe. Method Transfer Kit 6036.2100 Contains a loop capillary kit to adjust the system gradient delay volume to the desired HPLC method. -

Page 138: Consumables And Replacement Parts

• Accessories, Consumables and Replacement Parts 10.4 Consumables and Replacement Parts 10.4.1 Capillaries and Tubing Single Parts Description Part No. Capillary pump-autosampler, SST, I.D. x length 0.18 x 350 mm (for 6040.2375 Core systems) Capillary pump-autosampler, MP35N, I.D. x length 0.1 x 350 mm 6042.2340 (for Horizon and Flex systems) Active pre-heater, MP35N, I.D. x length 0.1 x 380 mm 6732.0110 Passive pre-heater, SST, I.D. x length 0.18 x 530 mm (for Core... -

Page 139: Solvents And Wash Systems

• Accessories, Consumables and Replacement Parts Viper Capillary Kits Vanquish Description Part No. Core System Viper capillary kit, Vanquish Core system, including (parts are 6036.2302 available separately, see table in section Single Parts): • Capillary, SST, I.D. x length 0.18 x 350 mm • Passive pre-heater, SST, I.D. x length 0.18 x 530 mm Vanquish Horizon Description Part No. -

Page 140: Fuses And Cables

• Accessories, Consumables and Replacement Parts 10.4.3 Fuses and Cables Description Part No. Fuses kit, Vanquish system 6036.0002 The kit includes the appropriate fuses for the Vanquish system modules. System interlink cable 6036.0004 USB cable, type A to type B, high-speed, USB 2.0 6035.9035 Cable length: 1 m USB cable, type A to type B, high-speed, USB 2.0... -

Page 141: Appendix

• Appendix 11 Appendix This chapter provides additional information about compliance. UHPLC System Page 141 Operating Manual... -

Page 142: Compliance Information

• Appendix 11.1 Compliance Information Thermo Fisher Scientific performs complete testing and evaluation of its products to ensure full compliance with applicable domestic and international regulations. For details on compliance, also see the Compliance Information section in the Operating Manual for each module in the Vanquish system. 11.1.1 Declarations of Conformity CE Declaration of Conformity The device has satisfied the requirements for the CE mark and is... -

Page 143: Weee Compliance

• Appendix 11.1.2 WEEE Compliance This product is required to comply with the European Union’s Waste Electrical & Electronic Equipment (WEEE) Directive. It is marked with the following symbol: Figure 37: WEEE symbol Thermo Fisher Scientific has contracted with one or more recycling or disposal companies in each European Union (EU) Member State, and these companies should dispose of or recycle this product. - Page 144 • Appendix Page 144 UHPLC System Operating Manual...

-

Page 145: Index

Index Index condensation.......... 45, 59 connectors............ 54 accessories .......... 37, 133 consumables .......... 133, 138 additives ............ 25 information .......... 25 use............... 89 decontamination ........ 106, 107 algae .............. 89 delivery............. 37 audit trail............ 114 Diagnostics ............. 125 digital I/O............ 54 drainage ............ 70 buffer use ............ 89 buffers .............. 25 concentration.......... 25 ePanel Set............ 93 information .......... 25 equilibration............. 88 use............... 89 eWorkflow............ 95... - Page 146 Index signal cable connections ...... 54 site requirements........ 43 peak shape ............. 115 software setup .......... 79 pH range............ 26 system ............ 41 power connections........... 59 system stack.......... 48 power considerations........ 44 waste lines........... 70 power cord ............ 44 intended use............. 18 power on/off ............ 86 Interlink ............ 32, 54 power up the system........ 78 protective clothing ........... 21 leak liquid ............ 70 LED bar ............ 114...

- Page 147 Index site requirements .......... 43 condensation......... 45, 59 transport ............ 109 operating conditions ........ 45 troubleshooting.......... 113 power considerations........ 44 baseline ............. 121 power cord .......... 44 communication ......... 124 workbench .......... 43 flow ............ 119 Smart Shutdown.......... 97 general information ........ 114 Smart Standby .......... 97 ghost peaks .......... 116 Smart Startup ........... 88 negative peaks .......... 116 solvent peak area precision ........ 117 chloride concentration........ 26...

- Page 148 www.thermofisher.com Thermo Fisher Scientific Inc. 168 Third Avenue Waltham Massachusetts 02451...

Need help?

Do you have a question about the thermoscientific Vanquish UHPLC System and is the answer not in the manual?

Questions and answers