Summary of Contents for Infors HT Ecotron

- Page 1 Operating Manual 2018-05-03 Ecotron Incubation Shaker Doc-ID: 77721 V02.00 - Original...

- Page 2 Infors GmbH Infors UK Ltd Infors Dachauer Str. 6 The Courtyard Business Centre Headoffice, Schweiz D-85254 Einsbach Dovers Farm, Lonesome Lane, Rittergasse 27 T +49 (0)8135 8333 Reigate CH-4103 Bottmingen F +49 (0)8135 8320 Surrey, RH2 7QT, UK T +41 (0)61 425 77 00 infors.de@infors-ht.com T +44 (0)1737 22 31 00 F +41 (0)61 425 77 01...

-

Page 3: Table Of Contents

Ecotron - Incubation Shaker Table of Contents General Information ............... 5 About this Manual ............5 Explanation of Special Notices ........6 1.2.1 Warning Notices ..........6 1.2.2 Other Notices..........6 Equipment Identification (Standard Identification Plate) 7 Declaration of Conformity ..........7 Customer Service and Services ........ - Page 4 Ecotron - Incubation Shaker Table of Contents Mains Connection ............26 Openings ..............27 3.6.1 Discharge Outlet ...........27 3.6.2 Air Vents ............27 Accessories ................28 Trays ................28 4.1.1 Tray with «Sticky Stuff» Adhesive Matting ...28 4.1.2 Tray with Pin Holders ........31 4.1.3 Tray with Sliding Bars ........33 Clamps and Other Holders ..........33...

- Page 5 Ecotron - Incubation Shaker Table of Contents 7.4.3 Activating and Deactivating Parameters ..58 Switching on the Interior Lighting......... 59 Switching off the Equipment ........59 Behaviour in Case of Interrupted Power Supply ..60 Using the Equipment as a Tempering Cover ....60 Rectifying Faults ..............

- Page 6 Ecotron - Incubation Shaker Table of Contents 12.4.1 Maximum Permissible Setpoints for the Rotation Speed ..........85 12.4.2 Information on Temperatures that can Actually be Reached ..........86 13 Index ..................87 Page 4 of 90 03 May 2018...

-

Page 7: General Information

Ecotron - Incubation Shaker General Information 1 General Information 1.1 About this Manual This manual enables the safe and efficient handling of the equip- ment. All the information and instructions in this operating manual comply with the current standards, legal regulations, the latest technologi- cal and scientific developments and the knowledge gained from the manufacturer’s many years of experience in this field. -

Page 8: Explanation Of Special Notices

Ecotron - Incubation Shaker General Information 1.2 Explanation of Special Notices 1.2.1 Warning Notices Warning notices in this manual are indicated by a coloured bar and begin with a signal word that signifies the degree of the hazard. DANGER The signal word “DANGER” indicates a dangerous situation that will lead to severe or even fatal injuries if not avoided. -

Page 9: Equipment Identification (Standard Identification Plate)

Ecotron - Incubation Shaker General Information 1.3 Equipment Identification (Standard Identification Plate) The identification plate is designed to allow clear identification of the equipment. It contains the following information: Manufacturer name and address Designation Category of equipment Type Equipment type (name) ... -

Page 10: Safety And Responsibility

Ecotron - Incubation Shaker Safety and Responsibility 2 Safety and Responsibility This section describes general considerations relating to user safety that must be taken into account when working with the equipment. In the remaining sections, warning notices are used only to high- light particular hazards directly arising from the actions being de- scribed in the section in question. -

Page 11: Intended Use, Incorrect Use And Misuse

Ecotron - Incubation Shaker Safety and Responsibility 2.1 Intended Use, Incorrect Use and Misuse Depending on its features, the equipment is designed to be used as an incubation shaker for cultivating microorganisms or cell cultures only under the following conditions: Cultivation of non-pathogenic microorganisms or cell ... -

Page 12: Cultivation Vessels To Be Used

Ecotron - Incubation Shaker Safety and Responsibility To use the equipment for special applications not covered by con- ventional, intended use, the equipment must be modified and certi- fied accordingly by the manufacturer. Any use of the equipment outside of a biological laboratory, i.e. in... -

Page 13: Qualified Personnel

Ecotron - Incubation Shaker Safety and Responsibility Cultivating organisms of risk category 2 When cultivating pathogenic organisms of risk category 2, special measures must be taken to stop the organisms from escaping. The user is responsible for this. When using the equipment under protection category 2, stainless steel clamps of the correct size must be used to affix the flasks. -

Page 14: User

Ecotron - Incubation Shaker Safety and Responsibility 2.3.2 User General The term “user” applies to all persons who come into contact with the equipment in any way and perform work on or with it. This pri- marily applies to the following activities, which can be performed by the manufacturer’s own specialists or a variety of other persons (it... -

Page 15: Operator

Ecotron - Incubation Shaker Safety and Responsibility 2.3.3 Operator The “operators” are a specific sub-group of users distinguished by the fact that they work with the equipment. They are the true target audience for this operating manual. Qualified technicians Only technicians who have been trained for working in a biological laboratory can be considered for the role of operator. -

Page 16: Responsibility Of The Provider

Ecotron - Incubation Shaker Safety and Responsibility 2.5 Responsibility of the Provider The equipment is used for industrial and scientific purposes. As such, the provider of the equipment is individually liable with regard to the legal requirements relating to occupational health and safety in a biological laboratory. -

Page 17: Electrical Current

Ecotron - Incubation Shaker Safety and Responsibility 2.6.1 Electrical Current The equipment is operated electronically. There is an immediate risk of fatal injury if contact is made with live parts. The following points must be observed in order to avoid the risk of... -

Page 18: Incorrect Auxiliary Supplies And Consumables

Ecotron - Incubation Shaker Safety and Responsibility 2.6.3 Incorrect Auxiliary Supplies and Consumables The use of incorrect auxiliary supplies and consumables can lead to both equipment failure and injury/damage to health. The auxiliary supplies and consumables required for use with the equipment are specified in the relevant sections of this manual. -

Page 19: Dangerous Gases

Ecotron - Incubation Shaker Safety and Responsibility 2.7.2 Dangerous Gases The use or production of dangerous – i.e. toxic or asphyxiant – gases such as CO or N entails a significant health risk, espe- cially in enclosed spaces. In order to prevent high emissions of dangerous gases, the follow-... -

Page 20: Safety Features

Ecotron - Incubation Shaker Safety and Responsibility 2.8 Safety Features The equipment comes with the following safety features: Main switch with emergency switching off In addition to allowing you to switch the equipment on and off nor- mally, the main switch also works as an emergency switch. If the main switch is switched off, all circuits of the equipment are discon- nected completely from the grid. -

Page 21: Warning Symbols On The Equipment

Ecotron - Incubation Shaker Safety and Responsibility 2.9 Warning Symbols on the Equipment The following warning symbols (stickers) are placed on the equip- ment: Position On the casing of the control rack. Meaning The control rack may only be opened by qualified electricians. Turn off the equipment and pull out the power plug before commencing any work on the electrical system. -

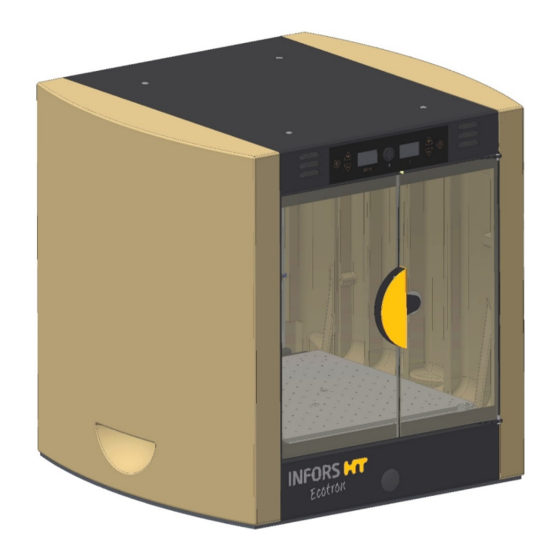

Page 22: Setup And Function

Ecotron - Incubation Shaker Setup and Function 3 Setup and Function 3.1 Setup of the Basic Unit Polyurethane casing Handle Main switch/emergency switch Back wall (cooling unit connection) Control rack with operating panel 10 Door (plexiglass) Expansion slot 11 Door handle... - Page 23 Brief description The Ecotron incubation shaker is used to cultivate micro-organisms in a laboratory environment. The Ecotron has been designed as an incubation shaker but can optionally be used as an incubation cover without the shaker for tempering different types of equip- ment.

-

Page 24: Functions

Ecotron - Incubation Shaker Setup and Function 3.2 Functions 3.2.1 Standard Function - Shaking Mechanics The table (2) moves in circles speeds of 20 to 550 min . The de- flection of the circular movement is 25 mm. The table moves in clockwise circles. - Page 25 Ecotron - Incubation Shaker Setup and Function Drip tray To collect any leaked liquids in case of a flask breakage, the equip- ment features a drip tray (1) underneath the table. To clean the drip tray, the four hexagonal socket screws of the table can be loosened and the table can be removed (see chapter 12.4.1 "Maxi-...

-

Page 26: Standard Function - Tempering

To retrofit the equipment with a cooling system, the back wall can be dismantled and replaced with a prefabricated back wall with a heat exchanger. To do this, contact INFORS HT (see contact details on page 2). Page 24 of 90... - Page 27 Ecotron - Incubation Shaker Setup and Function Internal cooling On the “internal cooling” version, the cooling unit is installed in cas- ing mounted on the back wall. The internal cooling unit is supplied with power directly via the equipment. The cooling liquid circulates in a closed circuit.

-

Page 28: Control Rack

Ecotron - Incubation Shaker Setup and Function 3.3 Control Rack All of the electronics and control electronics of the equipment are located in the control rack in the top part of the equipment. When a flask breaks, the electrical components are thus ideally protected from liquid. -

Page 29: Openings

Ecotron - Incubation Shaker Setup and Function Prior to connecting the equipment, make sure that the voltage val- ues of the equipment match those of the local power supply. The mains connection must be easily accessible at all times so that the equipment can be disconnected from the power supply quickly in case of an emergency. -

Page 30: Accessories

Ecotron - Incubation Shaker Accessories 4 Accessories In the following section, the available accessories for the equip- ment are described. For special applications, please contact our customer service for advice (for contact information, see page 2). 4.1 Trays The table features threaded holes which make it possible to mount holders directly on the table. - Page 31 Ecotron - Incubation Shaker Accessories ATTENTION If cultivation is started at low temperatures and the temperature is then increased, condensation can form on the flasks because these are heated up slower than the ambient air. This can lead to the flasks coming off the adhesive matting.

- Page 32 Ecotron - Incubation Shaker Accessories To remove vessels, gently and evenly pull or push on the neck and wait a few seconds. Never use force! In case of large vessels, it can take 20 to 30 seconds until ...

-

Page 33: Tray With Pin Holders

Ecotron - Incubation Shaker Accessories Maximum rotation speeds with «Sticky Stuff» To ensure that the flasks do not detach from the adhesive matting, the maximum permissible speed is limited when using adhesive matting. INFORMATION The following guidelines only apply to undamaged, completely dry adhesive matting free of grease. - Page 34 Ecotron - Incubation Shaker Accessories Ring spacers (10 mm high) are placed on the pins individu- ally. Depending on the type of tray loading, this makes it pos- sible to remove individual plates or stacks of plates. Quickload spacers are long plastic strips (4 mm high) that ...

-

Page 35: Tray With Sliding Bars

Ecotron - Incubation Shaker Accessories 4.1.3 Tray with Sliding Bars Trays with sliding bars allow you to incubate vessels of any shape. The sliding bars can be affixed to any point on the support bars. This also allows you to affix bottles with vertical walls and a curved base. -

Page 36: Clamps

Ecotron - Incubation Shaker Accessories 4.2.1 Clamps The clamps of various sizes required for individual fitting can be ordered separately to be assembled by users. Stainless steel clamps The following stainless steel clamps are available: For flask type Volume Erlenmeyer... -

Page 37: Test Tube Holders

Ecotron - Incubation Shaker Accessories 4.2.2 Test Tube Holders Test tube holders are used to securely affix different sized test tubes. Test tube holders can be screwed onto a universal table tray or placed on «Sticky Stuff» adhesive matting. The following test tube holders are available (details and special types on request): For long test tubes, Ø... -

Page 38: Box For Microtitre Plates

Ecotron - Incubation Shaker Accessories 4.3 Box for Microtitre Plates Overview The box for microtitre plates is used for low-vapour cultivation of microtitre plates and deep well plates. It protects cultures from drafts in the incubation chamber and also offers a stable container in which cultures can be transported. - Page 39 Ecotron - Incubation Shaker Accessories Loading the box for microtitre plates To improve transfer of oxygen to the cultures and facilitate the re- moval of the plates, spacers (Quickload spacers) (1) can be placed between the individual layers. Prior to loading, the Quickload spac- ers must be removed.

- Page 40 Ecotron - Incubation Shaker Accessories Technical data Container with top plate and tray Description Value Size 465 x 280 mm Weight 4.23 kg Filter, paper, round, Ø 185 mm Screws for microtitre tray M4 x 8 hexalobular Screws for microtitre box...

-

Page 41: Transport And Storage

Ecotron - Incubation Shaker Transport and Storage 5 Transport and Storage WARNING Improper transport, use of incorrect auxiliary equipment and careless handling of the equipment may lead to injuries and significant damage to property. – Never lift or transport the equipment alone. -

Page 42: Transporting The Equipment

Ecotron - Incubation Shaker Transport and Storage 5.3 Transporting the Equipment Transport when delivered (packaged equipment) Depending on its features and destination, the equipment is either delivered on an oversized special pallet or in a sea crate. For transport to the assembly location or longer transports in general, we recommend transporting the equipment with a forklift or trolley. -

Page 43: Installation

Ecotron - Incubation Shaker Installation 6 Installation 6.1 Requirements for the Installation Site 6.1.1 Operating Conditions at the Installation Location To achieve optimal and reproducible results, the equipment should be set up in stable ambient conditions without strong temperature or humidity fluctuations. -

Page 44: Minimum Distances To The Equipment

Ecotron - Incubation Shaker Installation 6.1.2 Minimum Distances to the Equipment When setting up the equipment, the following minimum distances must be observed to ensure adequate ventilation and access to the most important connections: Minimum distances to the basic unit... -

Page 45: Installing The Equipment

Ecotron - Incubation Shaker Installation Placing equipment with cooling under a bench When placing the equipment with cooling under a bench, observe the following: The minimum distance between the equipment and the un- derside of the bench top is 100 mm. -

Page 46: Stacking Equipment

Ecotron - Incubation Shaker Installation 6.2.2 Stacking Equipment To save space, two units of equipment can be stacked on top of one another. The optional stack set is required to do so. ATTENTION If you operate stacked equipment without an installed stack set, you run the risk of the top unit moving due to vibrations and con- sequently falling down. - Page 47 Ecotron - Incubation Shaker Installation To stack two units, proceed as follows: Procedure Remove the four cover caps (1) on the top of the bottom unit from the threaded holes. Screw the four hexagonal socket head screws (3) with one spring washer (4), disc (5) and centring sleeve (6) each into the threaded holes.

-

Page 48: Establishing The Power Supply

Ecotron - Incubation Shaker Installation 6.2.3 Establishing the Power Supply Two different versions of the equipment are available for different mains voltages: 230 V 50/60 Hz 115 V 60 Hz Prior to connecting the power supply, check whether the voltage value on the identification plate matches the local mains voltage. -

Page 49: Operation

Ecotron - Incubation Shaker Operation 7 Operation 7.1 Switching on the Equipment ATTENTION The equipment can start up automatically if this option has not been deactivated correctly beforehand. Any objects flying around the incubation chamber can damage the equipment and the cultivation vessels if the equipment starts up automatically. -

Page 50: Loading And Unloading The Equipment

Ecotron - Incubation Shaker Operation CAUTION If the loading mass of the table is too high or too low or the load is distributed unevenly, high rotation speeds can cause vibra- tions. This can result in the equipment moving uncontrollably and potentially falling off the table. -

Page 51: Fitting The Holders

Ecotron - Incubation Shaker Operation 7.2.2 Fitting the Holders ATTENTION The threaded holes of the table can be damaged if the fastening screws are not screwed straight into the thread: – Place the screws vertically on the drill holes. –... - Page 52 Ecotron - Incubation Shaker Operation Screw sizes ATTENTION If screws that are too long or too short are used to affix the hold- ers, the holders cannot be mounted properly on the table. Not properly mounted holders can become loose during operation and therefore lead to property damage.

-

Page 53: Fitting The Tray

Ecotron - Incubation Shaker Operation 7.2.3 Fitting the Tray The table features threaded holes which make it possible to mount holders and clamps directly on the table. Alternatively, trays with fixtures can be ordered from the manufacturer and fitted onto the table. - Page 54 Ecotron - Incubation Shaker Operation The intermediate base can be flipped over to be used at two differ- ent heights: Upper position (in the image at the top): Permitted incubation of Erlenmeyer flasks up to 2 L of volume on the shaker (de- pending on the height of the sealing plug).

-

Page 55: Notices On Loading The Table

Ecotron - Incubation Shaker Operation 7.2.5 Notices on Loading the Table Observe the following notices when loading the table: Place the cultivation flasks symmetrically in the middle of the table. If any of the vessels protrude over the edge of the table, they ... -

Page 56: Overview Of Display And Operating Elements

Ecotron - Incubation Shaker Operation 7.3 Overview of Display and Operating Elements All equipment functions can be controlled directly via the operating panel on the front of the equipment. The operating panel comprises the following elements: Main switch/emergency switch Power supply on/off function symbol Temperature control On/Off button View box for “Rotation speed”... - Page 57 Ecotron - Incubation Shaker Operation View boxes The current actual values, setpoints, alarm messages and error messages are displayed on one or both of the LED displays using three-letter abbreviations. During normal operation, the current actual value for the “Ro- ...

-

Page 58: Adjusting, Activating And Deactivating Parameters

Ecotron - Incubation Shaker Operation 7.4 Adjusting, Activating and Deactivating Parameters 7.4.1 Overview of Parameters Rotation speed (RPM) During set-up, the rotation speed entered as a setpoint in min displayed as a whole number. The settings that can be made range... -

Page 59: Setting The Parameter Setpoint

Ecotron - Incubation Shaker Operation 7.4.2 Setting the Parameter Setpoint To set the setpoint for a parameter, proceed as follows: Procedure Press the Plus or Minus button (1) to set the setpoint you want to use for the selected parameter (rotation speed on the left, temperature on the right). -

Page 60: Activating And Deactivating Parameters

Ecotron - Incubation Shaker Operation 7.4.3 Activating and Deactivating Parameters Activating parameters To activate a parameter, proceed as follows: Procedure Press the On/Off button (1) to activate the desired parameter (rotation speed on the left, temperature on the right). The parameter is activated immediately. The display briefly shows the message ON and then the current actual value of the parameter. -

Page 61: Switching On The Interior Lighting

Ecotron - Incubation Shaker Operation 7.5 Switching on the Interior Lighting The interior lighting is switched on automatically in the following situations: When the equipment is switched on using the main switch When the door is opened or closed ... -

Page 62: Behaviour In Case Of Interrupted Power Supply

Ecotron - Incubation Shaker Operation 7.7 Behaviour in Case of Interrupted Power Supply If the power supply to the equipment is interrupted during a running cultivation process (e.g. by flicking the main switch or in case of a power failure), all parameter setpoints are stored. If the power sup- ply is restored, the equipment automatically restarts with the last stored setpoints. - Page 63 Ecotron - Incubation Shaker Operation Detach the cable from the shaker to the control rack and pull it out of the cable duct. To detach the plug, you have to push the release lever at the bottom of the plug.

-

Page 64: Rectifying Faults

Ecotron - Incubation Shaker Rectifying Faults 8 Rectifying Faults The following section describes possible reasons for faults and how to resolve them. If you encounter a fault that cannot be resolved by following the instructions below, please contact your nearest Infors representa- tive. - Page 65 Ecotron - Incubation Shaker Rectifying Faults Error during temperature Check the function of the temperature sensor. In Operator measurement. case of a defect, contact your local Infors repre- sentative. Heater fan not Contact your local Infors representative and re- Operator place the control rack (see chapter 10.2, page...

-

Page 66: Fault Tables

Ecotron - Incubation Shaker Rectifying Faults Alarm message Meaning The rotation speed is too high. Possible cause Measures Personnel Error when measuring the ro- Switch the equipment off and then on again. Operator tation speed. The drive control system is... - Page 67 Ecotron - Incubation Shaker Rectifying Faults Faults related to the “Rotation speed” parameter Fault The table does not move. Possible cause Measures Personnel The “Rotation speed” parame- Activate the parameter. Operator ter is not activated. The table is blocked by for- Dismantle table and remove foreign objects.

- Page 68 Ecotron - Incubation Shaker Rectifying Faults Fault The shaker drive accelerates too quickly or runs too fast. Possible cause Measures Personnel Error when measuring the ro- Switch the equipment off and then on again. Operator tation speed. The drive control system is...

-

Page 69: Returning For Repair

Ecotron - Incubation Shaker Rectifying Faults 8.3 Returning for Repair The provider must return the equipment or the faulty component part(s) to the manufacturer if, after consulting the service depart- ment of the local dealer or the manufacturer, on-site diagnosis and/or repair is not possible. -

Page 70: Maintenance And Cleaning

Ecotron - Incubation Shaker Maintenance and Cleaning 9 Maintenance and Cleaning DANGER To prevent life-threatening electric shocks, always switch off the equipment and disconnect it from the power supply before carry- ing out any maintenance or cleaning. 9.1 Maintenance The equipment requires hardly any maintenance. This reduces the running costs to certain regular checks and cleaning. -

Page 71: Cleaning And Disinfection

Ecotron - Incubation Shaker Maintenance and Cleaning 9.2 Cleaning and Disinfection If substances, in particular hazardous substances, are spilled in or on the equipment, the equipment has to be cleaned and disin- fected thoroughly. Furthermore, the equipment should be cleaned and disinfected on a regular basis to ensure proper operation. - Page 72 Ecotron - Incubation Shaker Maintenance and Cleaning Dust Over time, dust can collect on the vents and other exposed parts (e.g. heat exchangers). It can be removed carefully with a vacuum cleaner. Clean drip tray You can clean the drip tray using water (max. 2 L) and mild deter- gent.

-

Page 73: Disinfection

Ecotron - Incubation Shaker Maintenance and Cleaning INFORMATION The drip tray is not suitable for steam sterilisation in the auto- clave. If it gets severely contaminated it can be disposed of and replaced at low cost. 9.2.2 Disinfection Only use quaternary ammonium compounds for wipe-down disin- fection. -

Page 74: Spare Parts

Ecotron - Incubation Shaker Spare Parts 10 Spare Parts Replacing the most common spare parts is very easy and can be performed by the provider. To do this, follow the instructions in the next chapters. You can source spare parts from a licensed dealer or manufacturer (on this subject, see the addresses on page 2). -

Page 75: Replacing Control Rack

Ecotron - Incubation Shaker Spare Parts 10.2 Replacing Control Rack If the electronics fail (control of the shaker drive and tempering) or if there is a defect in the operating panel, power supply unit or fan, only one component has to be replaced, the control rack. To do so,... -

Page 76: Replacing The Lighting Element Of The Interior Lighting

Ecotron - Incubation Shaker Spare Parts Never cover the air vents on the rear of the equipment. Completely pull out the control rack from the front of the equipment. To re-mount the control rack, proceed in reverse order. 10.3 Replacing the Lighting Element of the Interior Lighting... -

Page 77: Replacing The Drip Tray

Ecotron - Incubation Shaker Spare Parts 10.4 Replacing the Drip Tray If the drip tray gets very dirty or damaged, it can be removed and replaced. To do so, proceed as follows: INFORMATION The drip tray is not suitable for steam sterilisation in the auto- clave. -

Page 78: Replacing The Liner On The Table

Ecotron - Incubation Shaker Spare Parts 10.5 Replacing the Liner on the Table The liners on the bottom of the table hold and guide the table. Dirty or damaged liners can result in the equipment not running smoothly and cause vibrations. Dirty or damaged liners are easy to replace. -

Page 79: Disassembly And Disposal

Ecotron - Incubation Shaker Disassembly and Disposal 11 Disassembly and Disposal The equipment must be disassembled and disposed of in an envi- ronmentally friendly manner if it is no longer in use. INFORMATION When returning the equipment for disassembly or disposal, it is... - Page 80 Ecotron - Incubation Shaker Disassembly and Disposal WARNING Electronic waste, electronic components, lubricants or other auxiliary materials/supplies are subject to hazardous waste reg- ulations and may only be disposed of by registered specialist disposal firms. For disposal, the system units are to be disassembled and disman- tled into individual material groups.

-

Page 81: Technical Data And Specifications

Ecotron - Incubation Shaker Technical Data and Specifications 12 Technical Data and Specifications 12.1 Dimension Drawings 03 May 2018 Page 79 of 90... -

Page 82: Specifications Of The Basic Equipment

Ecotron - Incubation Shaker Technical Data and Specifications 12.2 Specifications of the Basic Equipment 12.2.1 Weight and Dimensions Mass Description Value Unit Individual unit without cooling 63 kg Individual unit with internal cooling 78 kg Individual unit with external cool-... -

Page 83: Electrical Connection And Performance Values

Ecotron - Incubation Shaker Technical Data and Specifications Table dimensions Description Value Unit Width 425 mm Depth 425 mm 12.2.2 Electrical Connection and Performance Values Electrical connection values Description Type 230 V Type 115 V Unit Value Voltage Frequency range... -

Page 84: Materials

Ecotron - Incubation Shaker Technical Data and Specifications 12.2.4 Materials Component Material Casing PUR – IHS, Zinkor Incubation chamber PUR – IHS, Zinkor, aluminium (ano- dised), stainless steel, PMMA, PVC Table Aluminium (anodised) 12.2.5 Emissions Description Value Unit Sound pressure <... -

Page 85: Specifications Of Parameters

Ecotron - Incubation Shaker Technical Data and Specifications Description Permitted Products Coolant Approved for the food and pharmaceutical sectors Freezing point < -40°C Copper corrosion: < -0.6 g/m Temperature range: -40°C to +150°C General detergent Mild neutral cleaning agent... -

Page 86: Temperature Parameter

Ecotron - Incubation Shaker Technical Data and Specifications 12.3.2 Temperature Parameter Description Value Unit Ventilation Radial fan with round heating element Power 400 W Air circulation 110 m Lowest temperature 5 °C (above ambient temperature, without op- tional cooling) Lowest temperature 10 °C... - Page 87 Ecotron - Incubation Shaker Technical Data and Specifications 12.4.1 Maximum Permissible Setpoints for the Rotation Speed The following guidelines for maximum rotation speeds are speci- fied to prevent damage. Hence, they must be observed though fur- ther restrictions (e.g. tray with «Sticky Stuff» adhesive matting) must be taken into account.

- Page 88 Ecotron - Incubation Shaker Technical Data and Specifications 12.4.2 Information on Temperatures that can Actually be Reached The temperatures that can actually be reached depend on a variety of factors, such as the ambient temperature, the ventilation and the temperature of the other equipment in the stack. As such, the fol- lowing guideline values only apply to individual units (no guaran- tees).

- Page 89 Ecotron - Incubation Shaker Index 13 Index Versions ............24 Cooling liquid ............ 83 accessories Cross-flow fan ........... 24 Microtitre box ..........36 Cultivation process Accessories ............28 Starting ............58 Sticky Stuff adhesive matting ......28 Stopping ............59 Test tube holders ..........

- Page 90 Ecotron - Incubation Shaker Index Maintenance ..........68 positioning ............ 43 Halogen lamp Positioning ............ 42 Position ............26 stack ............. 44 Specification ..........81 storing ............40 Heating ............. 84 Switching off ..........59 Hi ..............62 Switching on ..........47 Holders transport ............

- Page 91 Ecotron - Incubation Shaker Index With Sticky Stuff ..........31 establish ............46 Mains connection .......... 26 Messages Specification ..........81 Hi ..............62 Power values Lo ..............62 Electrical ............81 Microtitre box Protection classes ..........9 Fit ..............49 Overview ............

- Page 92 Ecotron - Incubation Shaker Index throw ............. 83 Tempering Ventilation ............. 84 Fault .............. 66 Speeds Functional description ........24 reachable temperatures ....... 86 with microtitre box ........37 Securing ............18 With Sticky Stuff ........... 31 Specification ..........84 Stack set ............

Need help?

Do you have a question about the Ecotron and is the answer not in the manual?

Questions and answers