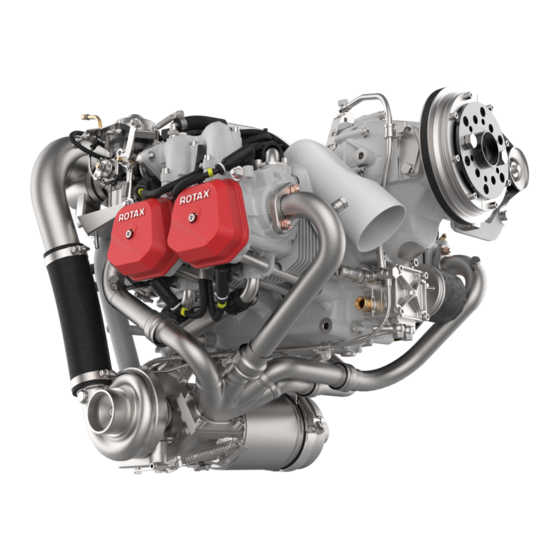

Rotax 914 F Manuals

Manuals and User Guides for Rotax 914 F. We have 2 Rotax 914 F manuals available for free PDF download: Maintenance Manual, Installation Manual

Rotax 914 F Maintenance Manual (274 pages)

Table of Contents

-

2 Index

9 -

-

Remarks12

-

-

4 Safety

12 -

-

Engine Views24

-

-

Fuel System32

-

-

-

-

Consumables76

-

1) Motor Oil77

-

8) Silastic77

-

-

-

-

24)Overhaul111

-

Special Checks113

-

-

Fuel System124

-

-

1) General124

-

4) Diaphragm127

-

8) Jets128

-

-

6) Fuel Pressure133

-

8) Fuel Tubes135

-

10) Fuel Pump136

-

-

1) Oil Pump142

-

5) Drain Screw147

-

6) Oil Tank148

-

8) Oil Tubes150

-

9) Oil Cooler150

-

-

Cooling System152

-

3) Magneto Hub154

-

13) Radiator162

-

15) Hose Clamps162

-

Ignition System164

-

4) Charging Coil166

-

-

1) Disassembly194

-

-

6) Servo Motor220

-

-

-

Electric Starter228

-

Sprag Clutch230

-

-

7) Vacuum Pump238

-

-

2) Valve Guides249

-

3) Valve Seats249

-

4) Valves249

-

5) Valve Springs250

-

6) Rocker Arms250

-

Push Rods255

-

-

16 Form Sheets

266 -

18 Reporting

271

Advertisement

Advertisement