Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for RayTek CS210

- Page 1 CS210 Kiln Shell Temperature Monitoring System Rev. B4 Feb 2015 58401...

- Page 2 Thank you for purchasing this Raytek product. Register today at www.raytek.com/register receive the latest updates, enhancements and software upgrades! © Raytek Corporation. Raytek and the Raytek Logo are registered trademarks of Raytek Corporation. All rights reserved. Specifications subject to change without notice.

- Page 3 In the event of failure of a product covered by this warranty, Raytek will repair the instrument when it is returned by the purchaser, freight prepaid, to an authorize Service Facility within the applicable warranty period, provided Raytek’s examination discloses to its satisfaction that the product was...

-

Page 4: Table Of Contents

Content Content .................................. 4 Safety Instructions ............................8 Technical Data ............................. 9 2.1 Specifications ............................... 9 2.2 Scope of Delivery ............................9 2.3 Weights and Dimensions ......................... 10 Description ..............................12 Pre-Installation ............................13 4.1 Environment .............................. 13 4.2 Scanner Distance to Kiln .......................... 13 4.3 Scanner Alignment ........................... - Page 5 6.2.8 <Historical management> ........................43 6.2.8.1 <Images> Tab ..........................43 6.2.8.2 <Others> Tab ..........................44 6.2.9 <LRM Configuration> .......................... 44 6.2.10 <Digital Output Management> ......................46 6.2.10.1 Repository of Digital Outputs ..................... 46 6.2.10.2 Digital Output Management detail ..................... 46 6.2.11 <Daily Report>...

- Page 6 7.2.14.1 Report Production History ......................75 7.2.14.2 Daily Report ..........................76 7.2.15 Command Line Options for Deneb ..................... 77 Database ..............................78 8.1 Concept ..............................78 8.2 Historic Review............................78 8.3 File Naming Convention ......................... 78 8.4 Backing Up all Data ..........................79 8.5 Restoring THR Data ..........................

- Page 7 11.4 Refractory Management ........................105 11.4.1 Configuration ............................ 105 11.4.1.1 Kiln State ........................... 105 11.4.1.2 Refractory Management ......................106 11.4.1.3 Brick Manufacturers ........................110 11.4.1.4 Brick Types ..........................110 11.5 3D Real Time View ..........................112 Troubleshooting ........................... 113 Drawings ............................... 114 13.1 CS212 Installation without Accessories .....................

-

Page 8: Safety Instructions

Incorrect use of 110 / 230 V electrical systems can result in electrical hazards and personal injury. All instrument parts supplied with electricity must be covered to prevent physical contact and other hazards at all times. CS210 Rev. B4 Feb 2015... -

Page 9: Technical Data

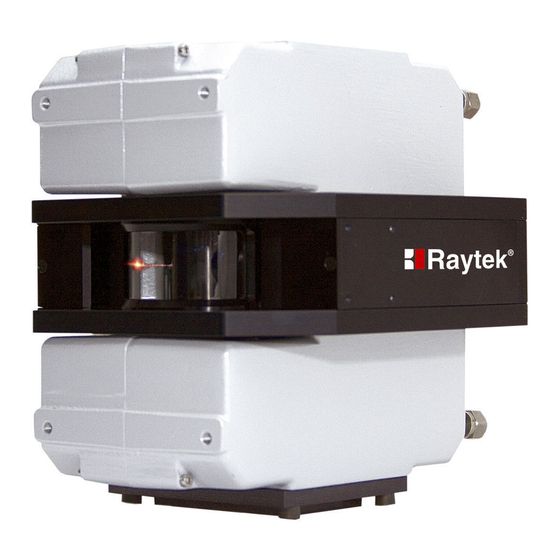

The standard CS211 package includes: Scanner: Linescanner MP150HR (CS212: 2 units, CS213: 3 units, CS214: 4 units) 7.5 m (24.6 ft) Ethernet cable 7.5 m (24.6 ft) power cable at 20 Hz scan speed at 20 Hz scan speed CS210 Rev. B4 Feb 2015... -

Page 10: Weights And Dimensions

Hex key wrench 5 mm Wrench 7x8 and 10x13 Key for locking/unlocking enclosure doors DVD: DataTemp CS Software (incl. manuals, presentations, tools) Documentation: CS210 Manual, MP150 Operating Instructions, MP150 Protocol Manual (on DVD only) 2.3 Weights and Dimensions Linescanner: Length: 180 mm (7.09 in) - Page 11 Height: 67 mm (2.64 in) Weight: 0.7 kg (1.5 lbs) System Connection Box: Width: 380 mm (15 in) Height: 380 mm (15 in) Deep: 210 mm (8.3 in) Weight: 9.8 kg (22 lb) - netto CS210 Rev. B4 Feb 2015...

-

Page 12: Description

The CS210 system also adds OPC server functionality, a powerful SQL server for database applications, and full integration of all available accessories. Most notably, additional point sensors can be installed and configured to monitor portions of the kiln “shadowed”... -

Page 13: Pre-Installation

D ≥ Kiln where: D … Distance between scanner and kiln L … kiln length (required scan width) Scanner Figure 1: Distance between Scanner and Kiln CS210 Rev. B4 Feb 2015... -

Page 14: Scanner Alignment

A position indicator is mounted on the “colder” end of the kiln and generates a trigger pulse once per revolution to supply the CS210 system with data on the rotational speed of the kiln. The installer must mount a trigger bar onto the kiln shell as shown in the figure below. - Page 15 W25 Fibre optic cable from the first scanner to the second scanner (if used). Fibre optic cable to be – provided by customer. All copper cables must be shielded! The wires from W9, W10, W14, and W15 must be a twisted pair! Local building codes should be observed when selecting cables! CS210 Rev. B4 Feb 2015...

- Page 16 (MI shadow pyrometers via W14), longer cable lengths, or less gauges it must always be ensured, that the sensor will be supplied with the minimal voltage power! Linescanner: min. 18 VDC MR burning zone pyrometer: min. 20 VDC MI shadow pyrometer: min. 12 VDC CS210 Rev. B4 Feb 2015...

-

Page 17: Pc Requirements

CS Readscan default 2727 Linescanner Communication CS Readscan default 5048, 5058 Serial RS485 / RJ45 Ethernet Converter CS Readscan as accessory only Telnet for service only Windows Vista should work but it is not guaranteed. CS210 Rev. B4 Feb 2015... -

Page 18: Installation

6 M4 x 12 bolts. The slotted side of the protection channel faces downwards. The bolts must be inserted from inside the box (i.e. the nuts are outside). Make sure that the drain hole for rain water in the protective channel faces downwards! CS210 Rev. B4 Feb 2015... - Page 19 Open the back door. Insert the linescanner (with the mounted carrier) into the rail/carrier system. Lock in the linescanner in place with the latches and screw. Electrical Installation For best performance, the electrical installation of the CS210 System should correspond to one of the recommended installation configurations illustrated in section 13.1 CS212 Installation without Accessories, page 114.

-

Page 20: System Connection Box

Connect the socket and the plug for earth ground. If installing the CS210 system in a warm environment, water-cooling may be necessary. The tubes used for water may be run through the second grommet plate! 5.2 System Connection Box... -

Page 21: Cable Entry System

Snap-on mounting Lay cable into appropriate grommet and provide strain relief where necessary using cable ties. Use appropriate tool to punch through cover on base frame. Illustrations: © Murrplastik CS210 Rev. B4 Feb 2015... -

Page 22: Fibre Optic / Rj45 Ethernet Converter

4 Ethernet channels to support one or two scanners and the CS210 accessories. The Fibre Optic / RJ45 Ethernet Converter in the control room is converting the glass fibre signals back to TCP/IP Ethernet again. For further technical details see appendix 14.3... -

Page 23: Position Indicator

15 ft). Protecting the cable against mechanical stress is recommended. Since the position indicator is necessary to generate a trigger pulse for the CS210 system, a trigger bar must be welded onto the “colder“ end of the kiln and if possible close to the drive ring (see... -

Page 24: Fibre Optic Converter Box

The Fibre Optic Converter Box is located in the control room and connects the fibre optic cable from the field to the Ethernet interface of the computer. For more technical data, see section 14.2 Connection Box, page 128. Figure 10: Fibre Optic Converter Box CS210 Rev. B4 Feb 2015... -

Page 25: Configuration

Once you have selected the language, click on <Next> to continue. Next, select the path where you want to install the application and the folder where you want • the database to be installed. When finished, click on <Next>. CS210 Rev. B4 Feb 2015... - Page 26 On the last installation screen, you can activate the check box to import an old CS100 • configuration and a CS100 database into CS software. After closing the install setup you will be guided through the migration procedure. CS210 Rev. B4 Feb 2015...

-

Page 27: Cs Configuration

At this point, a valid user and password must be entered for the selected profile. If this is the first login, a single profile will be seen, and that profile is normally <Raytek>. Predetermined user for CS Config (valid also for the program components CS Deneb and ReadScan): Username: <ADMIN>... -

Page 28: General Options

The data format (256 pixel / 512 pixel / 1024 pixel, 1 byte / 2 byte and 100 / 200 lines) must not be mixed. The same resolution is used for every scanner connected and all database backups loaded into the system! CS210 Rev. B4 Feb 2015... -

Page 29: Communications Settings> Tab

OPC (OLE for Process Control) is an industrial standard for the data exchange between applications based DCOM model from Microsoft. further information http://www.opcfoundation.org/ The CS OPC server supports Data Access in version 2.0 only! CS210 Rev. B4 Feb 2015... - Page 30 Figure 17: General Options: <Communication settings> Tab <Send DTR signal with alarms> enables the output of a system alarm signal via the CS interface box (for scanners communicating via COM) or a digital output module (for scanners communicating via Ethernet). CS210 Rev. B4 Feb 2015...

- Page 31 Dirty lens alarm status for pyrometer 1 (shadow pyrometer only) .Pyrometer 1.Type String Pyrometer used for: <burningZone> or <shadowPyrometer> .Pyrometer 2.Burning zone Integer Temperature of the burning zone for pyrometer 2 (burning zone pyrometer only) CS210 Rev. B4 Feb 2015...

-

Page 32: E-Mail> Tab

To configure the email address for the recipient see section 6.2.14.2.1 <General> Tab, page 53. To configure an email be sent in the event of an alarm see section 6.2.14.2.3 <Others> Tab, page 55, under <Readscan>. Figure 19: Example for an Outgoing Alarm Email CS210 Rev. B4 Feb 2015... -

Page 33: Colours And Axes Definition

This tab lets you configure the appearance for the different axes shown in the graphical representation of the thermogram, as well as the units representing the kiln diameter. It also lets you configure the type font used for the axes in the graphical representation of the thermogram. CS210 Rev. B4 Feb 2015... -

Page 34: Kiln Settings

Figure 22: Kiln settings <Rotation velocity> is the parameter that defines the minimum kiln speed that the system expects before launching a non-synchronized alarm. When not synchronized, the system will not save any CS210 Rev. B4 Feb 2015... -

Page 35: Position Of Scanners / Pyrometers

The position of the scanners can be adapted very comfortable by using the mouse. For doing so, make a right mouse click in the drawing area to open the context menu <Settings>. Being in that mode, the left/right cursor keys can be used to change the Alpha angle dynamically. CS210 Rev. B4 Feb 2015... -

Page 36: Settings> For Scanner Or Pyrometer

It is also possible to assign an output for the alarm in case the internal temperature exceeds the maximum setting. The parameters that we are describing are applicable for scanners and also for pyrometers. CS210 Rev. B4 Feb 2015... - Page 37 90° scanner field of view. The relay contacts are available on the terminal line in the system connection box, see Figure 8 Connection to the internal Alarm Relay , on page 21. CS210 Rev. B4 Feb 2015...

-

Page 38: Special Commands

If the difference exceeds the maximal allowed threshold then an alarm is being triggered. 6.2.5 <Special Commands> This library allows the user to execute commands either individually or as groups via the command groups (templates) function. CS210 Rev. B4 Feb 2015... -

Page 39: Alarm Zones

Then you will have to open the port and introduce the command to be executed. Afterwards, click on the button to run it. Wrong set commands can suspend the whole CS210 system! 6.2.6 <Alarm zones>... -

Page 40: Alarm Zone Configuration Detail

(adjacent to the Zone number) corresponding to the zone to be edited. By a right mouse click an existing zone can be split into two ones. Figure 30: Alarm zone configuration detail CS210 Rev. B4 Feb 2015... -

Page 41: Alarm Zone Definition

Obviously, just one of them is the actual active configuration selectable by the <Set active> button. The buttons along the lower toolbar are used to create new configurations, and also to edit or delete existing ones. CS210 Rev. B4 Feb 2015... -

Page 42: Refractory Configuration Detail

It is possible to adjust the size of a zone directly in that dialog box. To do this, you need to drag the edges of the lower bar (adjacent to the Zone number) corresponding to the zone to be edited. Figure 33: Refractory configuration detail CS210 Rev. B4 Feb 2015... -

Page 43: Refractory Zone Definition

As to the long term history, in the example every day at 00:00 hours, one representative thermogram will be stored based on the average of all thermograms in the short term history for that one day. CS210 Rev. B4 Feb 2015... -

Page 44: Others> Tab

<Live Ring Migration system activated>. Once this box is checked, the dialogue screen will be completed with many more opportunities to enter data, as you will see in the figure below. CS210 Rev. B4 Feb 2015... - Page 45 For instance, if the value is 1, at the first incident, the system will generate an alarm to warn the user. If the value is 2, the system will not take action CS210 Rev. B4 Feb 2015...

-

Page 46: Digital Output Management

The PowerOn value will be the output value that a digital output acquires when starting up. More technical data for the available output modules are described in appendix see section 14.6 Output Modules, page 132. CS210 Rev. B4 Feb 2015... -

Page 47: Daily Report

That menu opens a dialog to create a report for a certain time span containing the relevant system information like zone temperatures, alarm events and error data. The output for the resulting report can be a screen view, a printing machine, or a pdf file. Figure 40: Daily Report CS210 Rev. B4 Feb 2015... -

Page 48: Management Of Errors

In the <Error detail> view you can see all details for each single error: the period of time that the error existed (there’s a chance that it’s still active), which device experienced the error, a brief comment about the problem and its control status (the user, the date and the comment). CS210 Rev. B4 Feb 2015... -

Page 49: Error List

An error list can be filtered via an identifier or by starting and end date. By clicking on the <Export> button you may convert a list into different formats such as pdf, xls, and rtf. CS210 Rev. B4 Feb 2015... -

Page 50: Management Of Alarms

This shows the alarms registered in the system. From this screen, we can display all the alarm details. Similar detail can be displayed by clicking on <Alarms list>, which appears as a pop-up menu when the user clicks on the printer icon. Alarm details Alarm list Figure 44: Repository of alarms CS210 Rev. B4 Feb 2015... -

Page 51: Alarms Detail

Using this screen you can print reports of all alarms registered in the system. These lists or reports are fully configurable by using selection filters and sorting criteria. Selection filters allow filtering information using: • Alarm identifier Starting date • Ending date • State • Control • CS210 Rev. B4 Feb 2015... -

Page 52: Users

Each user can be assigned an appropriate security level to maintain system integrity. 6.2.14.1 Users Repository This window shows all users currently registered in the system. There is always one default user, with the preset user code of ‘ADMIN’ and no password. CS210 Rev. B4 Feb 2015... -

Page 53: User's Detail

There are the main tabs <General>, <Permission>, and <Others>. 6.2.14.2.1 <General> Tab This tab contains personal information, such as name and password, e-mail address, telephone number, cell phone and fax. CS210 Rev. B4 Feb 2015... - Page 54 Within this detail, you can display and edit each user’s permissions, or in other terms their access to the system. These permissions set individual access restrictions for each user for several system components like Config, DBCheck, Deneb, and ReadScan. Figure 49: User detail: <Permissions> Tab CS210 Rev. B4 Feb 2015...

- Page 55 Under <Deneb> the users can define their personal preferences in regard to system audible alarms. Figure 50: User detail: <Others> Tab Under <ReadScan> the users can activate the check box to send emails in case of alarms. CS210 Rev. B4 Feb 2015...

-

Page 56: Update Readscan

Some options may be disabled since they rely upon the user’s permissions! 6.2.15 <Update ReadScan> If Configuration values change the ReadScan program must be restarted. You can find <Update ReadScan> under <Utilities> of the CS Config. CS210 Rev. B4 Feb 2015... -

Page 57: Operation

NOT stop the service! To close CS Readscan, right-click on the small Readscan icon on the tray and select the menu entry <Close>! Figure 53: Closing of ReadScan via the task bar CS210 Rev. B4 Feb 2015... -

Page 58: Control> Tab

This tab shows information on the scanners configured to work with the system. In normal circumstances, the information shown becomes updated at the end of each kiln rotation. If communication is interrupted the information will be updated as soon as detection takes place. CS210 Rev. B4 Feb 2015... -

Page 59: Pyrometers> Tab

In normal circumstances, the information will be updated when new data is received from the system. However, it will not be possible to report about ring slip until the kiln has finished its current lap. If communication is interrupted the information will be updated as soon as detection takes place. CS210 Rev. B4 Feb 2015... -

Page 60: Opc Server> Tab

It also gives out information about every image that the system chooses to save. Clicking the right mouse button activates a pop-up menu, which lets you copy, print, save and delete all of the information displayed. CS210 Rev. B4 Feb 2015... -

Page 61: Cs Runtime Software: Deneb

Overlaid on this image are the user-defined alarm zones (with maximum limits). Highlighted in red color would be those alarm areas where there is any active alarm caused by too hot temperatures. CS210 Rev. B4 Feb 2015... - Page 62 • Time elapsed since the lap was displayed • Location and temperature at the cursor location in the current thermogram • Internal temperatures of the temperature sensors (Scanners and pyrometers) • • Burning zone temperature CS210 Rev. B4 Feb 2015...

- Page 63 Both in the chart and the thermogram, you can zoom into a specific area of the kiln. To do so, click and drag from left to right, creating a square surrounding the area of interest! CS210 Rev. B4 Feb 2015...

-

Page 64: Main>

The status bar provides information on the area selected, and by moving the border the size can be easily edited. CS210 Rev. B4 Feb 2015... - Page 65 The data will be displayed, and the length and lines of the chart options will adjust automatically. To exit the Marking mode and come back to zoom mode, just click on the <Go to mode Zoom> icon. CS210 Rev. B4 Feb 2015...

-

Page 66: Main>

This screen shows the internal temperature of scanners and pyrometers. The data is recorded at the point of completion of the lap currently being displayed. It will be refreshed after each kiln lap. Figure 65: Internal temperatures screen CS210 Rev. B4 Feb 2015... -

Page 67: Secondary>

The screen has several tabs explained below. 7.2.7.1 <Kiln view> Tab This screen shows a graphical representation of the kiln with the lap time for each ring to complete the current lap, and the offset (slip) relative to the driven tire. CS210 Rev. B4 Feb 2015... -

Page 68: Vertical> Tab

Figure 68: <Vertical> Tab of the LRM view 7.2.7.3 <Horizontal> Tab Almost identical to the screen described above (section 7.2.7.2 <Vertical> Tab), this chart is rotated by 90°. CS210 Rev. B4 Feb 2015... -

Page 69: Time Trend> Tab

7.2.7.5 <Space trend> Tab This one tab displays the offset for each tire (slip) on a line chart allowing the operator to see the evolution of such offsets and easily compare the data for each tire. CS210 Rev. B4 Feb 2015... -

Page 70: Secondary>

The slider changes the font size for the displayed areas. Figure 72: <Areas of Interest> Window 7.2.9 <Secondary> <Errors> The <Errors> screen shows all errors recorded by the system with the following features: CS210 Rev. B4 Feb 2015... -

Page 71: Secondary>

This screen is basically the same just explained above in the section 7.2.8 <Secondary> < Interest> , page 70. The only difference being that the information shown in this case is about alarms instead of errors. CS210 Rev. B4 Feb 2015... - Page 72 Operation Figure 75: Alarms’ screen CS210 Rev. B4 Feb 2015...

-

Page 73: Graphic>

Activating the <Stop> button will stop the data-loading process. The area to be studied can be graphically selected in the ‘real time view’, as described in section 7.2.1 <Main> <Real time>, page 61! CS210 Rev. B4 Feb 2015... -

Page 74: Graphic>

This chart displays the same data as the histogram but in a line chart format. The lines are colour coded showing maximum temperature (red), average temperature (green) and minimum temperature (blue). As before the area of interest, time period of interest and temperature are all user defined. CS210 Rev. B4 Feb 2015... -

Page 75: Graphic>

Under the <Report Production History> dialog, the operator can select the desired report for the current or past days. The output generates a summary for the considered days in regard to the refractory zones and the kiln states. CS210 Rev. B4 Feb 2015... -

Page 76: Daily Report

Operation Figure 79: Exemplary Dialog for Historical Reports 7.2.14.2 Daily Report Be referred to the description in section 6.2.11 <Daily Report>, page 47. CS210 Rev. B4 Feb 2015... -

Page 77: Command Line Options For Deneb

Then, the program call would be: Deneb.exe $LOGIN ADMIN $PASSWORD 1234 $PROFILE RAYTEK /REALTIME Example 2: User TEST without password and RAYTEK profile with short and long term history view • Then, the program call would be: Deneb.exe $LOGIN TEST $PROFILE RAYTEK /SHORT /LONG CS210 Rev. -

Page 78: Database

The second data element represents the latest short term image in the backup file. The third data element represents the earliest long term image in the backup file. The fourth data element represents the latest long term image in the backup file. CS210 Rev. B4 Feb 2015... -

Page 79: Backing Up All Data

After restoring the <backup.bak>, simply copy the remaining THR backup files into the public backup folder of the CS system. After a restart, Readscan will pick up the backup files and make them available for historic review. CS210 Rev. B4 Feb 2015... -

Page 80: Options

The entire system will be operational before the final acceptance and sign-off by the customer. Raytek does not provide construction, erection, mechanical, electrical or building services. Prior to the start- up service the scanner housings should be installed in the designated locations per our recommendations. -

Page 81: Accessories

Laser Distance Meter (XXXSYSLDM) for distances up to 60 m (197 ft), recommended for an • exact gathering of the linescanner-to-kiln geometry 10.2 Software Refractory Management software package for handling kiln refractories (…RFM) • • 3D Real Time View of the rotating kiln (…3D) CS210 Rev. B4 Feb 2015... -

Page 82: Serial Rs485 / Rj45 Ethernet Converter

Dimensions (W x H x D) 55 x 140 x 95 mm (2.1 x 5.5 x 3.7 in) Mounting DIN-rail Power Power input 12 to 48 VDC, redundant dual inputs Power connector terminal block Power consumption CS210 Rev. B4 Feb 2015... -

Page 83: Led Indicators

Insert the Advantech driver utility DVD for the Serial RS485 / RJ45 Ethernet Converter into the DVD drive (e.g. E:\) on the host PC. Use Windows explorer to execute the setup program, the path for the setup program on the DVD should be: E:\Utility& Driver\SerialDeviceServerConfigurationUtility\Serial_Device_Server_Config uration_Utility_[Version]_Release_[date].exe CS210 Rev. B4 Feb 2015... - Page 84 Click the <Select All> button and press <Map Selected Ports> button. All selected serial ports will be mapped to virtual COM ports in sequential order. Figure 82: Mapping of Virtual Ports The COM ports in the <Virtual Com Ports> listing are now available for use by Windows applications. CS210 Rev. B4 Feb 2015...

- Page 85 In the example above port 1 is assigned to the virtual COM port 10 to be used in the CS software configuration. It is not recommended to change the pre-set configuration for the four ports of the serial device <XXXSYSCS210CON>! CS210 Rev. B4 Feb 2015...

-

Page 86: Fan Control

Wiring, page 121. Alternatively to the field installation of the digital output modules in the system connection box, the hardware can also be installed in the control room. Please contact the technical support for further details. CS210 Rev. B4 Feb 2015... -

Page 87: Lrm - Live Ring Migration

Indicator (LRM) Junction Junction Junction Figure 84: Monitoring of Rings For an overview of a CS210 system with LRM, see section 13.2 CS212 Installation with Accessories, page 115. Delivery: • Position indicator with junction box, 3 position indicators delivered for monitoring of 3 tires... -

Page 88: Position Indicator

PLC counter rotation time. The trigger bar for the position indicator is welded directly onto the tire. Position indicator Junction box Figure 85: Position Indicator and Trigger Bar 20 mm (0.79 in) Position indicator Junction box Figure 86: Mounting the Position Indicator CS210 Rev. B4 Feb 2015... -

Page 89: Wiring

Cable Requirements, page 14. The CS210 position indicator (master) must be wired to the <kiln trigger> labeled input on the terminal line of the LRM remote control box! All subsequent LRM position indicators must be wired to the inputs <Ring 1>, <Ring 2> and so. -

Page 90: Shadow Monitoring

You may connect up to 32 units. Make sure to deactivate the preset shunt resistor for all units except for the last one in the chain. The switch for activating the shunt is found on CS210 Rev. B4 Feb 2015... - Page 91 10 : 1 (90% energy) Head ambient temperature 0 to 180°C (32 to 356°F) Head cable length 8 m (26 ft.) Protection rate (head) IP65 (NEMA-4) Digital interface RS485 For other technical data see MI3 operators manual. CS210 Rev. B4 Feb 2015...

-

Page 92: Burning Zone Monitoring

Blast gate assembly with quartz window Sighting tube, 30 cm length, stainless steel Adjustable pipe adapter assembly Air flow regulator Air pressure regulator Water ¼” NPT Figure 90: Installing the Burning Zone Pyrometer CS210 Rev. B4 Feb 2015... - Page 93 0 to 50°C (32 to 122°F) with ThermoJacket up to 315°C (600°F) Cable length 15 m (49 ft.) Digital interface RS485 For other technical data see MR operators manual and the ThermoJacket operators manual. CS210 Rev. B4 Feb 2015...

-

Page 94: Internal Heater

-20 to 70°C (-4 to 158°F) Storage temperature -45 to 70°C (-49 to 158°F) Figure 91: Internal Heater (left: photo, right: connection) For more detailed information see section 13.4 System Connection Box Wiring, page 117. CS210 Rev. B4 Feb 2015... -

Page 95: Auxiliary Software

11.1.2 Connecting to the database On the <DBCheck> main screen the user has to select an available profile to connect to the database. Figure 92: <DBCheck> main screen Click on <Profiles…> Click on <Select> CS210 Rev. B4 Feb 2015... -

Page 96: Migrating Pre-Existing Cs100 Data

<Temperatures> (saved images subsequent to the date shown). Click on <Migrate> button to start the migration process. Depending on the amount of data to be migrated, the migration process could take twenty or thirty minutes or more. CS210 Rev. B4 Feb 2015... -

Page 97: Import And Export Cs Configurations

Auxiliary Software CS210 has many features that did not exist in CS100 and therefore parameters for these functions will not be migrated. Further, the system physical configuration may have changed since the original installation. Therefore we strongly recommend that you... -

Page 98: Creating A Backup File

From this moment, a daily backup copy will be automatically created on the set time. The folder entered for the backup copy must not be edited, removed or deleted since ReadScan must recognize it in order to periodically access it. CS210 Rev. B4 Feb 2015... -

Page 99: Reset Database

Go to <Operations> and select <Reset database>. Clicking on the <Empty BD now> button starts the CS software with an empty database by deleting all data in the SQL database. To avoid accidental data loss, a backup copy will be stored automatically in the CS subfolder BACKUP. CS210 Rev. B4 Feb 2015... -

Page 100: Remote Access From A Client Pc

Start the <DBCheck.exe> file on the remote PC Open the <Connection Profile> Under <Data origin> add port 1433 (TCP/IP port of the SQL database) to the selected profile (comma as separator). Figure 93: Connection Profiles CS210 Rev. B4 Feb 2015... -

Page 101: Device Testing Programme: Pcomm

If the connection wouldn’t go through, an error message will be displayed. The vertical bar on the right-hand side of the thermal image (see red arrow) shows the on/off status of the kiln trigger. CS210 Rev. B4 Feb 2015... -

Page 102: Pyrometer

If, on the other hand, any of the options has not been properly entered, or if the connection with any of the devices did not go through, an error message will be displayed. CS210 Rev. B4 Feb 2015... -

Page 103: Digital Output

If, on the other hand, any of the options has not been properly entered, or if the connection with any of the devices did not go thru, an error message will be displayed. Figure 98: Digital Output screen CS210 Rev. B4 Feb 2015... -

Page 104: Lrm

If the selected device is a <LRM> and its options have been correctly configured, the system will start the connection with that device. Once connected, the information from each ring will begin to display on the screen as soon as a kiln trigger actuates the proximity sensor. Figure 99: LRM Screen CS210 Rev. B4 Feb 2015... -

Page 105: Refractory Management

Once you finish with a new configuration and everything is ready for a new production, you can click on the <Start production> state in the kiln state chart. The system will automatically apply the refractory operations in the database. If you go to the Refractory Management, you will see in the CS210 Rev. B4 Feb 2015... -

Page 106: Refractory Management

On the other hand, if a zone is partially covered by a new zone, then the old zone will be reduced to its uncovered part. CS210 Rev. B4 Feb 2015... - Page 107 It is possible to adjust the size and position of a refractory zone directly on the right hand review area under the <Operations> screen. CS210 Rev. B4 Feb 2015...

- Page 108 A newly entered zone will take precedence over all existing zones that it might overlap. Thus, the overlapped area is cropped from the existing zones and the new zones parameters will take effect. Figure 104: Adding a Refractory Zone CS210 Rev. B4 Feb 2015...

- Page 109 Within the dialog for adding/reviewing drillings, the user can define the date, position and thickness of a drilling. Figure 106: Adding a Drilling <Operations> Tab / <Shell Repair> <Shell repairs> are managed very similar to <Zone changes> or <Drillings>, but they don’t show up in the refractory view. CS210 Rev. B4 Feb 2015...

-

Page 110: Brick Manufacturers

11.4.1.4 Brick Types The following dialog shows up the current brick types, as well as a toolbar at the bottom to add and delete them. Click the <+> marked button to add a new brick type. CS210 Rev. B4 Feb 2015... - Page 111 Give a unique color for the brick type to identify the brick easily under the refractory configuration view. Do not use signal colors like red because it will optically collide and obstruct the clarity of the screen view and the real alarm signals, which typically use the red color. CS210 Rev. B4 Feb 2015...

-

Page 112: Real Time View

Move the 3D kiln to the desired perspective and click on the <+> button to save that view. Predefined views can be called accessed directly under the drop down box. A double-click on the kiln showing the refractory (context menu: <Show refractory>) centers the kiln on the clicked position. CS210 Rev. B4 Feb 2015... -

Page 113: Troubleshooting

• Restart the CS software with an empty database temporarily! • Use only Raytek supplied position indicators! To get quick help send a detailed error report to Raytek including the current CS configuration and/or the complete CS database! See more in section 11.1.4... -

Page 114: Drawings

Drawings 13. Drawings 13.1 CS212 Installation without Accessories For more detailed information see section 4.5 Cable Requirements, page 14. CS210 Rev. B4 Feb 2015... -

Page 115: Cs212 Installation With Accessories

Drawings 13.2 CS212 Installation with Accessories For more detailed information see section 4.5 Cable Requirements, page 14. CS210 Rev. B4 Feb 2015... -

Page 116: Cs21X With Multiple Scanners

The drawing above shows the principle design of a CS21x system with up to 4 scanners. The detailed wiring is the same for all scanners. The position indicator for the kiln can be connected to any of the connection boxes. CS210 Rev. B4 Feb 2015... -

Page 117: System Connection Box Wiring

Drawings 13.4 System Connection Box Wiring CS210 Rev. B4 Feb 2015... - Page 118 Potential free relay contact, capacity max. 30 V, 1 A white Trigger + Trigger input: + 5 to + 24 VDC green Trigger - Trigger input GND yellow Functional input Not used pink Functional input Not used gray shield black CS210 Rev. B4 Feb 2015...

-

Page 119: Fibre Optic Converter Box Wiring

Drawings 13.5 Fibre Optic Converter Box Wiring CS210 Rev. B4 Feb 2015... -

Page 120: Position Indicator Wiring

The W8 cable for the position indicator is only to be wired to the system connection box like shown below for the standard CS210 system! In case of using the LRM accessory the position indicator is connected to the LRM connection box in the field directly! -

Page 121: Fan Control Wiring

Drawings 13.7 Fan Control Wiring Fan Control Output Module Next module System Connection Box CS210 Rev. B4 Feb 2015... -

Page 122: Lrm Wiring

Drawings 13.8 LRM Wiring The internal wiring for the position indicators 4, 5, 6 – the dotted lines – does not come as factory default. Figure 113: Wiring Scheme for LRM Remote Control Box CS210 Rev. B4 Feb 2015... -

Page 123: Terminal Wiring W8

Drawings 13.8.1 Terminal Wiring W8 Junction Box LRM Remote Control Box Position Indicator (CS210) Kiln trigger ground Kiln trigger input Kiln trigger VDC Shield Figure 114: Terminal Wiring for the Position Indicator (Kiln Trigger) Junction Box LRM Remote Control Box... -

Page 124: Terminal Wiring W9

+24 Vdc Trigger bottom shield Ring 1 +24 Vdc shield Ring 3 +24 Vdc Trigger shield +24 Vdc Ring 5 shield Ring 6 shield Scanner bottom +24 Vdc shield +24 Vdc Ring 4 shield +24 Vdc CS210 Rev. B4 Feb 2015... -

Page 125: Shadow Monitoring Wiring

Drawings 13.9 Shadow Monitoring Wiring MI Connection Box Next System Connection Box CS210 Rev. B4 Feb 2015... -

Page 126: Burning Zone Wiring

Drawings 13.10 Burning Zone Wiring MR Connection Box System Connection Box CS210 Rev. B4 Feb 2015... -

Page 127: Appendix - Technical Data

1.5 to 3 bar (air must be cleaned) Scope of delivery: stainless steel box with air purge and all mounting parts adjustable mounting bracket allowing aiming along any axis grommets and grommet plate spare removable window Options: air – water heat exchanger CS210 Rev. B4 Feb 2015... -

Page 128: Connection Box

2.5 mm² (AWG 14) Power input max. 110 W (for the system connection box XXXCS210CONBOX) max. 30 W (for the fibre optic converter box XXXHSFICBOX) Fuse 6 A (fuse only with system connection box XXXCS210CONBOX) CS210 Rev. B4 Feb 2015... -

Page 129: Fibre Optic / Rj45 Ethernet Converter

6.5 W Environment Operating temperature -10 to 60°C (14 to 140°F) Storage temperature -40 to 85°C (-40 to 185°F) Operating humidity 5 to 95% RH Protection 4.000 V ESD (Ethernet), 3.000 V Surge (EFT for power) CS210 Rev. B4 Feb 2015... -

Page 130: Connection Box For Accessories

90 x 225 x 130 mm (3.54 x 8.85 x 5.11 in.) Weight 1.8 kg (3.96 lb) Protection Rate: IP65 (NEMA 4) Delivery: Connection Box Cable grommet plate Set of grommets for different cable sizes CS210 Rev. B4 Feb 2015... -

Page 131: Position Indicator

No. 2: active 24 V / 300 mA max. short circuit protected Junction Box Pin 2 (brown cable): + 24 VDC ( 7 to 40 VDC), ripple max. 15 % Pin 3 (black cable): output active Pin 1 (blue cable): CS210 Rev. B4 Feb 2015... -

Page 132: Output Modules

72 x 122 x 25 mm (2.8 x 4.8 x 1 in.) 14.6.1 Digital Output Module 7043 (16 channels) Figure 118: Wiring Example for connection to a PLC 14.6.2 Relay Output Module 7067 (7 channels) Figure 119: Wiring the 7067 Module CS210 Rev. B4 Feb 2015... -

Page 133: Notes

Notes 15. Notes CS210 Rev. B4 Feb 2015...

Need help?

Do you have a question about the CS210 and is the answer not in the manual?

Questions and answers