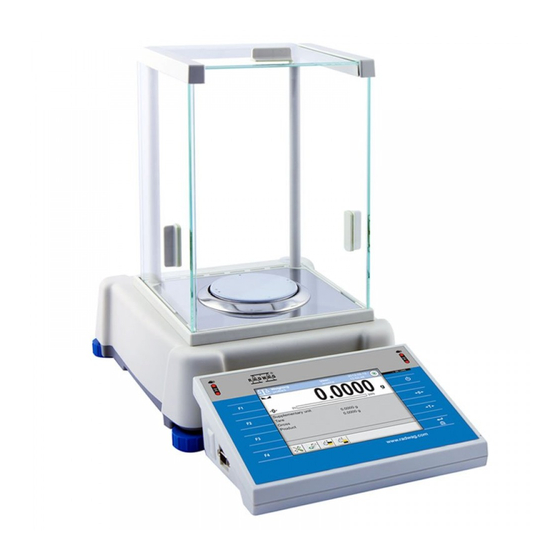

User Manuals: RADWAG 3Y Series Analytical Balances

Manuals and User Guides for RADWAG 3Y Series Analytical Balances. We have 1 RADWAG 3Y Series Analytical Balances manual available for free PDF download: User Manual

Advertisement