Table of Contents

Advertisement

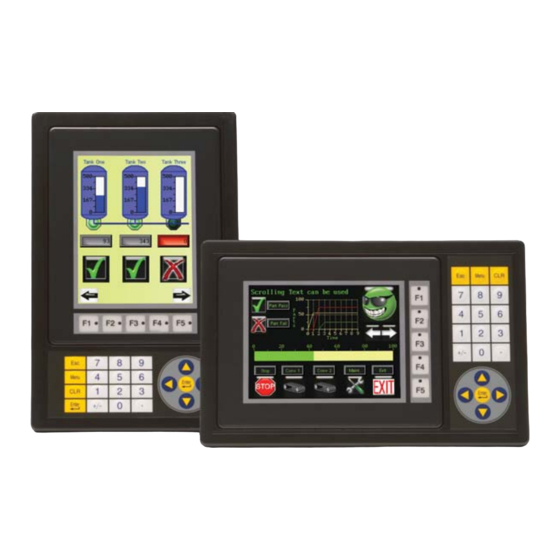

4-inch and 6-inch Color Micro-Graphic Panels

®

Hardware User Manual

EA1-TCL-M

C-more 6" Color Micro-Graphic Panel

shown in Portrait Mode

C-more 6" Color Micro-Graphic Panel

shown in Landscape Mode

C-more 4" Color Micro-Graphic Panel

shown in Landscape Mode

C-more 6" Color Micro-Graphic Panel Installed in a

21-button Portrait Keypad Bezel EA-MG6-BZ2P

C-more 6" Color Micro-Graphic Panel Installed in a

20-button Landscape Keypad Bezel EA-MG6-BZ2

Advertisement

Table of Contents

Need help?

Do you have a question about the C-more EA1-T4CL and is the answer not in the manual?

Questions and answers