Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Thermo Scientific PrintMate A79510100

- Page 1 Thermo Scientific PrintMate Operator Guide A79510100 Issue 2...

- Page 3 Tel: +44 (0) 1928 562 600; Fax: +44 (0) 1928 562 627; Web: www.thermo.com/pathology Anatomical Pathology USA, 4481 Campus Drive, Kalamazoo, MI 49008, USA Tel: 1-800-522-7270; Fax: +1 269-372-2674; Web: www.thermo.com/pathology Standards The Thermo Scientific PrintMate meets the following CE Mark requirements: Low Voltage Directive 2006/95/EC, as amended by 93/68/EEC...

- Page 5 Symbols The following symbols and conventions may be used throughout this document and on the instrument: This symbol is used on the equipment, or in a document, to indicate that instructions must be followed for safe and correct operation. If this symbol appears on the instrument, always refer to the operator guide.

-

Page 7: Table Of Contents

Table of Contents Introduction ..............................1 General Safety ..............................1 Disposal of Sealed Lead Acid Batteries ......................2 Chemical Safety ............................... 2 Environment..............................3 Warranty Statement ............................3 Product Return Safety Declaration........................4 How To Use This Guide..........................5 Introduction ..............................5 The PrintMate Product Range ......................... - Page 8 PrintMate A79510100 Issue 2 Computer Not Responding ........................54 Tape Errors..............................55 Poor Print Quality ............................. 56 No Print ..............................57 Part of Print is Missing ..........................58 Lower Line of Print is Misaligned ......................59 Print is Faint.............................. 60 Print Rubs Off Cassette Easily ........................

-

Page 9: Introduction

Safety Information Introduction Thermo Fisher Scientific products are designed for convenient and reliable service; however, incorrect actions by a user may damage the equipment, or cause a hazard to health. The following sections contain important information for the safe setup and use of the instrument. All users must read and understand the following sections before using the instrument. -

Page 10: Disposal Of Sealed Lead Acid Batteries

PrintMate A79510100 Issue 2 Disposal of Sealed Lead Acid Batteries In cases where there are two back-up batteries, these should always be replaced as a pair at the recommended service interval. If the instrument has mainly been operated in very low temperatures, or has been exposed to frequent Mains failures, the batteries should be replaced every year. -

Page 11: Environment

Safety Information Environment This product is required to comply with the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC. It is marked with the following symbol: Thermo Fisher Scientific has contracted with one or more recycling / disposal companies in each EU Member State, and this product should be disposed of or recycled through them. -

Page 12: Product Return Safety Declaration

PrintMate A79510100 Issue 2 Product Return Safety Declaration... -

Page 13: How To Use This Guide

How To Use This Guide Introduction The Thermo Scientific PrintMate is a high-speed cassette labelling instrument designed for use in laboratories by operators familiar with cassette labelling techniques and laboratory equipment. Before operating PrintMate, users should have read and understood the Safety Information as well as the LabWriter Operator Guide (A79510105). -

Page 14: The Printmate Product Range

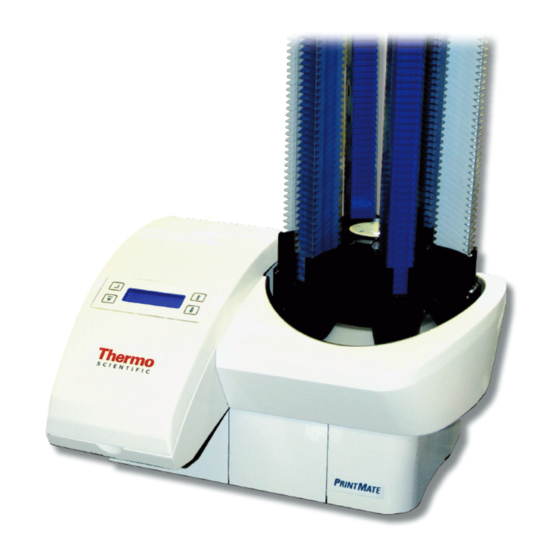

PrintMate A79510100 Issue 2 The PrintMate Product Range The PrintMate product range consists of 3 different models with varying cassette capacity. The methods of operation for each of these instruments are identical. -

Page 15: Introduction

Operator Guide Introduction Identification of Parts The following diagrams identify the different components of PrintMate. PrintMate with doors closed PrintMate with doors open... - Page 16 PrintMate A79510100 Issue 2 PrintMate external connections PrintMate print head...

-

Page 17: System Interaction

Operator Guide List of parts Item Description Touch Panel and Display Cassette Hopper Cassette Tube Carousel Print Door Print Head Waste Spool Access USB Connection 9-Pin Serial Port Collection System Connector Fuse Power Connector Power Switch Cassette Clamp Conveyor Belt Hot Foil Tape Output Drum System Interaction... -

Page 18: System Specification

PrintMate A79510100 Issue 2 System Specification Mechanical Specification Note Parameters listed are for the 12 hopper model. 810 mm (with cassette tubes) / 290 mm Height (without cassette tubes) Width 435 mm Depth 380 mm Weight 17 kg (with cassette tubes) -

Page 19: Basic Operation

Operator Guide Basic Operation Loading Procedure: Loading Cassette Tubes with Hopper Removed Loading Cassette Tubes with Hopper In-Situ Loading Single Cassettes Into Hopper Loading Hoppers Onto the Carousel Changing the Foil Tape: Removing the Used Foil Tape ... -

Page 20: Loading Procedure

PrintMate A79510100 Issue 2 Loading Procedure There are two methods of loading Cassette Tubes into Hoppers. Loading can be carried out with the Hopper removed from the Carousel or in-situ. Loading Cassette Tubes with Hopper Removed To load Cassettes Tubes containing up to 75 Cassettes into a Hopper: ... - Page 21 Operator Guide Place the Hopper on a flat surface so that it is stood upright as shown. Unpack a Tube of Cassettes and remove the End-Cap as shown. Note Ensure the Cassette Tube is oriented as shown to avoid the Cassettes spilling out of the Tube. ...

- Page 22 PrintMate A79510100 Issue 2 Lower the Tube into the open top of the Hopper, being sure to keep a finger on the bottom for as long as possible; there is a Loading Slot provided for this purpose. Remove finger from the Loading Slot and allow the Cassettes to fall into position as shown.

- Page 23 Operator Guide Loading Cassette Tubes with Hopper In-Situ To load Cassettes Tubes containing up to 75 Cassettes into a Hopper: Use the Control Panel to rotate the Carousel so that an empty Hopper is at the front of the instrument. ...

- Page 24 PrintMate A79510100 Issue 2 Lower the Cassette Tube into the open top of the Hopper, being sure to keep a finger on the bottom for as long as possible; there is a Loading Slot provided for this purpose. ...

- Page 25 Operator Guide Loading Single Cassettes Into Hoppers To load individual Cassettes into Hoppers: Without removing the Hopper from the Carousel, drop a Cassette into the open top of the Hopper. Note Ensure the Cassette is oriented as shown. Note If the cassettes have lids, ensure they are fully closed before use.

- Page 26 PrintMate A79510100 Issue 2 Loading Hoppers Onto the Carousel The Hoppers are loaded onto the Carousel as follows: Identify the features on the Hopper and Carousel shown below. Position the Hopper above the Carousel and lower it as shown.

- Page 27 Operator Guide Warning Failure to ensure all mating parts are properly engaged may cause damage to the instrument and / or the hoppers. Warning Ensure the hopper door is closed and the hopper slider is fully retracted before loading onto the carousel.

-

Page 28: Changing The Foil Tape

PrintMate A79510100 Issue 2 Changing the Foil Tape When the Foil Tape has been used up the Touch Panel on PrintMate will display a message stating that the Foil Tape needs replacing. Remove the Used Foil Tape Fit the Foil Tape Roll... - Page 29 Operator Guide Fitting the Foil Tape Roll Unpack a roll of Foil Tape. The Foil Tape has a Leader to facilitate loading, and a Sticky Tab to connect the Tape to the Leader and the Waste Spool. Note An empty cardboard tube is packed with the new roll of Foil Tape for use as a new Waste Spool. To load the Foil Tape: ...

- Page 30 PrintMate A79510100 Issue 2 Fit the new roll of Foil Tape by pushing it onto the Load Spool. Note Ensure the roll is pushed fully onto the Load Spool so that the retaining legs hold it securely in place.

- Page 31 Operator Guide Close the Print Door. Using the Touch Panel on PrintMate, take up the slack on the tape using the Tape Feed option. Ensure the Foil Tape is being pulled through PrintMate by the rotating Waste Spool Shaft. ...

-

Page 32: Using A Barcode Reader

PrintMate A79510100 Issue 2 Using a Barcode Reader It is possible to connect a Barcode Reader to the computer running LabWriter Application via an external connection port (eg. USB or Serial Port). Thermo Fisher Scientific strongly recommends the Symbol® Barcode Reader, which can be purchased as an accessory (see Appendix A). - Page 33 Operator Guide Safety Information Warning The Symbol® Barcode Reader uses Class 1 and Class 2 lasers during normal operation. Note Class 1 laser devices are not considered harmful when used for their intended purpose. Class 2 laser scanners use a low power, visible light diode; Momentary exposure to Class 2 lasers is not known to be harmful.

- Page 34 PrintMate A79510100 Issue 2 Barcode Reader Setup To setup the Symbol® Barcode Reader: Remove the Symbol® Barcode Reader and the Stand from the packaging. Attach the RJ-45 Connector to the base of the Symbol® Barcode Reader. Attach the USB Connector to an available USB Port on the computer.

- Page 35 Operator Guide Position the Stand in a convenient location. Place the Symbol® Barcode Reader face down in the Stand Cradle, as shown, with the cable at the back. Note The top portion of the stand is adjustable and can be set to the preferred position by the user to ensure comfortable scanning.

- Page 36 PrintMate A79510100 Issue 2 Barcode Reader Configuration To configure the Barcode Reader for use with the LabWriter Application, scan the following barcodes in the order shown. Set defaults barcode. HID keyboard emulation barcode. Note When each barcode has been scanned, the Barcode Reader will emit a beep and will stop responding to the trigger being pressed for a few seconds.

- Page 37 Operator Guide Barcode Information The Symbol® Barcode Reader can read both Linear Barcodes and 2-Dimensional Barcodes. Example of a linear barcode. Example of a two-dimensional barcode. When scanning barcodes the barcode should be positioned as shown below.

- Page 38 PrintMate A79510100 Issue 2 Barcode Reader Troubleshooting Problem Cause Remedy Barcode reader not working. No power to barcode reader. Check system power. Ensure power supply is connected. Incorrect interface cable Ensure correct interface used. cable is used. Interface /power cables are Ensure all cable connections loose.

-

Page 39: Using The Touch Panel

Operator Guide Using the Touch Panel The Touch Panel located on the Print Door is used to perform a variety of functions. The function of the buttons on the Touch Panel is dependant on the screen. The LCD Display will indicate the function of each button as appropriate. More details of specific screen operation can be found on the Quick Reference Cards (A79510120) supplied with the PrintMate. -

Page 40: Installation And Setup

PrintMate A79510100 Issue 2 Installation and Setup Setting Up PrintMate Setting Up Printmate: Unpacking Siting the PrintMate Setting up the Electrical Connections... - Page 41 Operator Guide Unpacking To unpack PrintMate: Remove uppermost foam piece. Remove the Leads, Hoppers and Output Chute pieces. Remove the foam tray. Lift out PrintMate and the surrounding foam pieces and place onto a suitable level surface.

- Page 42 PrintMate A79510100 Issue 2 Warning PrintMate weighs approximately 12 kg (26 lbs), and help may be required to ensure safe lifting. Taking care not to let the unit fall, remove the remaining foam pieces.

- Page 43 Operator Guide Open the Print Door and remove the Transit Fixing Screw. Warning Failure to remove the Transit Fixing Screw before operation may result in damage to the instrument. The Transit Fixing Screw should be placed in the Bracket for safe storage whilst not in use.

- Page 44 PrintMate A79510100 Issue 2 Locating PrintMate Warning PrintMate must be located on a level surface capable of supporting the weight of the instrument and the PrintMate should be positioned so that it has a minimum of 100 mm (4 in) gap on all sides, as well as sufficient space above it to allow Hoppers and Cassette Tubes to be connected and removed.

- Page 45 Operator Guide Electrical Connections and Start-Up Procedure Note The following instructions assume that the LabWriter Application has been pre-installed. If this is not the case refer to the LabWriter Operator Guide (A79510105) Chapter 1 - Installing the Software. The PC and PrintMate should be connected as follows: ...

- Page 46 PrintMate A79510100 Issue 2 Connect the USB (Type B) Connector to the back of PrintMate. The PC should emit a chime and indicate that it has found a USB device. The LabWriter Application should now be able to be run and setup in accordance with the instructions...

-

Page 47: Connecting The Output Chutes

Operator Guide Connecting the Output Chutes The Output Chutes included with PrintMate fit on either (or both) of the two inner output positions (Outputs 1 and 2). They can be connected so that they dispense either to the left or the right of the instrument as required. The Output Chutes are assembled and connected as follows: ... - Page 48 PrintMate A79510100 Issue 2 Slide the Upper Chute along the Lower Chute so that the two pieces are securely located together. The assembled Output Chute(s) should be fitted into the underside of PrintMate so that the Ball Spring Plunger locates fully into the Location Hole.

-

Page 49: Changing The Com Port Settings

Operator Guide Changing the COM Port Settings During the LabWriter Installation process (see LabWriter Operator Guide, Chapter 1 - Installing the LabWriter Application) the software should automatically detect the PrintMate and determine the correct COM Port Setting. However, if LabWriter does not detect the PrintMate instrument the COM Port can be set manually. The procedure for this is as follows: ... - Page 50 PrintMate A79510100 Issue 2 The PrintMate connection will be listed as a USB Serial Port with a COM number after it. Note the COM Port number that the PrintMate is using. Run the LabWriter Application and enter the Admin Area (see LabWriter Operator Guide, Chapter 2 - Admin Logon).

- Page 51 Operator Guide Expand the COM Port property and select the appropriate COM number from the drop-down list in the field next to Port. Click on the Search icon at the top of the screen. After a pause LabWriter should display the following window to show that it has found the PrintMate. ...

-

Page 52: Troubleshooting

PrintMate A79510100 Issue 2 Troubleshooting Carousel Error Error Message / Symptom Possible Cause Remedy Carousel Error Obstructions on or around the Check for, and remove if Carousel. necessary, any obstructions which may be preventing the Carousel from rotating. ... -

Page 53: Fail To Detect Cassette

Operator Guide Fail to Detect Cassette Error Message / Symptom Possible Cause Remedy Fail to detect Cassette Cassette blockage when exiting Open the Print Door and Hopper. remove any visible Cassette. Use the Touch Panel or PC to continue. ... -

Page 54: Hopper Empty' Warning Displayed When Not Empty

PrintMate A79510100 Issue 2 'Hopper Empty' Warning Displayed When Not Empty Error Message / Symptom Possible Cause Remedy Hopper Empty warning displayed Cassette blockage when exiting Open the Print Door and when not empty Hopper. remove any visible Cassette. -

Page 55: Dispense Error

Operator Guide Dispense Error Error Message / Symptom Possible Cause Remedy Dispense error Cassette blockage when exiting Open the Print Door and Hopper. remove any visible Cassette. Use the Touch Panel or PC to continue. Cassette blockage in Hopper. Remove the Hopper at the output position and use the Touch Panel or PC to... -

Page 56: Dispense Lever Fails To Reset

PrintMate A79510100 Issue 2 Dispense Lever Fails to Reset Error Message / Symptom Possible Cause Remedy Dispense lever fails to reset Cassette blockage when exiting Open the Print Door and Hopper. remove any visible Cassette. Use the Touch Panel or PC to continue. -

Page 57: Conveyor Error

Operator Guide Conveyor Error Error Message / Symptom Possible Cause Remedy Conveyor error Cassette misfeed on Conveyor. Open the Print Door and remove any visible Cassette. Use the Touch Panel or PC to continue. Cassette Clamp not retracting fully. Press the top of the Clamp Solenoid down and then release. -

Page 58: Output Error

PrintMate A79510100 Issue 2 Output Error Error Message / Symptom Possible Cause Remedy Output error Cassette misfeed into Output Open Print Door. Drum. Manually rotate Output Drum and remove any Cassettes. Check that no Cassettes are trapped under the Output Drum or Conveyor block. -

Page 59: Output Drum Error

Operator Guide Output Drum Error Error Message / Symptom Possible Cause Remedy Output Drum error Cassette misfeed into Output Open Print Door. Drum. Manually rotate Output Drum and remove any Cassettes. Check that no Cassettes are trapped under the Output Drum or Conveyor block. -

Page 60: Loud Knocking Noise On Power-Up

PrintMate A79510100 Issue 2 Loud Knocking Noise On Power-Up Error Message / Symptom Possible Cause Remedy Loud knocking noise on power-up Transit Fixing has not been Ensure instrument is removed. switched off. Open the Print Door and remove the Transit Fixing (see Chapter 3 - Unpacking). -

Page 61: Instrument Not Responding

Operator Guide Instrument Not Responding Error Message / Symptom Possible Cause Remedy Instrument not responding Software error. Check connections. Switch off PrintMate, wait 5 seconds then switch back Wait until the Touch Panel Display says PrintMate Ready before resuming operation. -

Page 62: Computer Not Responding

PrintMate A79510100 Issue 2 Computer Not Responding Error Message / Symptom Possible Cause Remedy Computer not responding Software error. Check connections. Close down the LabWriter Application and restart it. Hold down Ctrl + Alt + Delete to display the Windows Security dialog box. -

Page 63: Tape Errors

Operator Guide Tape Errors Error Message / Symptom Possible Cause Remedy Tape errors Tape feed error Check whether Tape has run out and replace if necessary (see Chapter 2 - Changing the Foil Tape). Check whether Tape is slack - use the Tape Feed function on the Touch Panel to remove any slack if... -

Page 64: Poor Print Quality

PrintMate A79510100 Issue 2 Poor Print Quality Error Message / Symptom Possible Cause Remedy Poor print quality Cassette colour. Check that Cassette colour is included on Appendix C - Approved Cassette List. -

Page 65: No Print

Operator Guide No Print Error Message / Symptom Possible Cause Remedy No Print Transit Fixing has not been Switch off PrintMate. removed. Open Print Door. Remove Transit Fixing as shown in Chapter 3 - Setting Up PrintMate. ... -

Page 66: Part Of Print Is Missing

PrintMate A79510100 Issue 2 Part of Print is Missing Error Message / Symptom Possible Cause Remedy Part of print is missing. Print Template set up incorrectly. Ask Administrator to check Print Template setup. Use Print to Screen function to check print layout. -

Page 67: Lower Line Of Print Is Misaligned

Operator Guide Lower Line of Print is Misaligned Error Message / Symptom Possible Cause Remedy Lower line of print is misaligned Print Template set up incorrectly. Ask Administrator to check Print Template setup. Use Print to Screen function to check print layout. -

Page 68: Print Is Faint

PrintMate A79510100 Issue 2 Print is Faint Error Message / Symptom Possible Cause Remedy Print is faint Cassette Clamp error. Open Print Door and print a Cassette. Check Cassette is held securely during printing and does not move until the Cassette Clamp releases it. -

Page 69: Print Rubs Off Cassette Easily

Operator Guide Print Rubs Off Cassette Easily Error Message / Symptom Possible Cause Remedy Print rubs off Cassette easily Cassette Clamp error. Open Print Door and print a Cassette. Check Cassette is held securely during printing and does not move until the Cassette Clamp releases it. -

Page 70: Barcodes Will Not Scan

PrintMate A79510100 Issue 2 Barcodes Will Not Scan Error Message / Symptom Possible Cause Remedy Barcodes will not scan Print Template set up incorrectly. Ask Administrator to check Print Template setup. Use Print to Screen function to check print layout. -

Page 71: Print Contains Incorrect Information

Operator Guide Print Contains Incorrect Information Error Message / Symptom Possible Cause Remedy Print contains incorrect Print Template set up incorrectly. Ask Administrator to check information Print Template setup. Use Print to Screen function to check print layout. ... -

Page 72: Cleaning And Maintenance

PrintMate A79510100 Issue 2 Cleaning and Maintenance Cleaning Procedure To ensure continuous reliable operation the following cleaning procedures should be carried out on a weekly basis: Use damp cloth and a 10% commercial, Hypochlorite bleach solution in water to wipe the outer covers and Output Chutes (if fitted). -

Page 73: Changing Fuses

Operator Guide Warning Inspect the instrument for obvious damage or wear whenever it is being cleaned. Changing Fuses To replace the fuses: Disconnect the Power Lead from the Mains Power Supply. Remove the Power Lead from the Power Connector. ... -

Page 74: Appendices

PrintMate A79510100 Issue 2 Appendices Appendix A - Spares and Accessories Spares and Accessories list Item Order Number Hot Foil Tape (Pk. of 5) A79510013 Collection System A79510014 Basic LabWriter Software CD A79510018 PC with Preloaded LabWriter Software A79510021 Collection Trays (Pk. of 4) -

Page 75: Appendix B - Repacking Instructions

Operator Guide Appendix B - Repacking Instructions Note Before repacking the PrintMate use the Touch Panel to move the Print Head to the Transit position. -

Page 76: Appendix C - Approved Cassette List

PrintMate A79510100 Issue 2 Appendix C - Approved Cassette List Approved Cassette Types The following Cassette types have been approved for use with the Thermo Scientific PrintMate: Shandon Biopsy Processing/Embedding Cassette Type II Shandon Processing/Embedding Cassette Type II ... -

Page 77: Index

Index 9-Pin Serial Port .............7 Earth Leakage ............10 Electrical Safety............1 Accessories..............1 Electrical Specification ......... 10 Altitude ..............10 Environment............1 Environmental Specification ........ 10 Barcode 2-Dimensional ..........29 Foil Tape Linear...............29 Fitting ............. 21 Barcode Reader.............24 Removing ............20 Configuring .............28 Frequency ............ - Page 78 PrintMate A79510100 Issue 2 Button .............39 Recommended Operation, Temperature....10 Hole..............39 Relative Humidity ..........10 Hook ...............18 Replacement Parts..........1 Recess ..............18 Returns, Product............ 1 RoHS Directive ............. 1 Mains Power Supply..........1 Maintenance Contract..........1 Safety Information ..........1 Mechanical Specification ........10 Service Contracts ...........

- Page 79 Index Warranty Statement ..........1 WEEE Directive ............ 1 Waste Spool ............20 Weight..............10 Access............7, 20 Width ..............10 Shaft ..............21...

Need help?

Do you have a question about the PrintMate A79510100 and is the answer not in the manual?

Questions and answers