User Manuals: YASKAWA Sigma-7-S Series Servo Motor

Manuals and User Guides for YASKAWA Sigma-7-S Series Servo Motor. We have 2 YASKAWA Sigma-7-S Series Servo Motor manuals available for free PDF download: Product Manual

YASKAWA Sigma-7-S Series Product Manual (561 pages)

SERVOPACK with MECHATROLINK-III Communications References, AC Servo Drive

Brand: YASKAWA

|

Category: Servo Drives

|

Size: 10 MB

Table of Contents

-

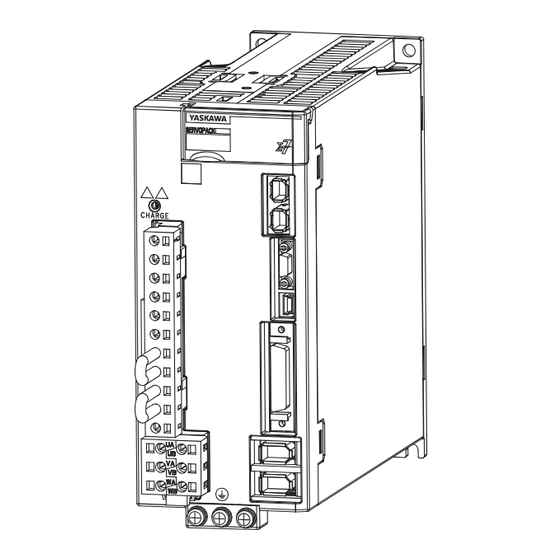

Part Names42

-

Functions51

-

Functions61

-

Holding Brake166

-

-

Preparations182

-

Applicable Tools183

-

-

Software Limits216

-

-

-

Linear Encoder233

-

Software Reset237

-

Preparations237

-

Applicable Tools237

-

-

-

Preparations240

-

Applicable Tools241

-

-

-

Preparations259

-

Applicable Tools260

-

-

-

Precautions264

-

Preparations264

-

-

-

Program Jogging266

-

Origin Search271

-

-

-

Tuning279

-

-

-

Tuning Functions283

-

Diagnostic Tool284

-

-

-

Outline294

-

Restrictions294

-

Applicable Tools295

-

-

Custom Tuning320

-

-

Outline334

-

Preparations335

-

Applicable Tools335

-

-

Manual Tuning359

-

Diagnostic Tools374

-

Easy FFT376

-

Easy FFT377

-

Monitoring380

-

Alarm Tracing395

-

-

-

Risk Assessment409

-

Related Commands412

-

Stopping Methods414

-

-

-

-

Procedure417

-

-

-

Maintenance420

-

-

Alarm Displays424

-

Warning Displays468

-

Parameter Lists488

-

-

Appendices550

-

Advertisement

YASKAWA Sigma-7-S Series Product Manual (111 pages)

SERVOPACK with Hardware Option Specifications Dynamic Brake

Brand: YASKAWA

|

Category: Servo Drives

|

Size: 2 MB

Table of Contents

-

Warranty25

-

Part Names

36 -

Precautions

53 -

Outline

78 -

-

Maintenance84

-

-

Index

109 -

Revision History

110

Advertisement