Subscribe to Our Youtube Channel

Summary of Contents for HANGCHA CPCD15

- Page 1 1.5t -5t ROUGH TERRAIN FORKLIFT OPERATION AND MAINTENANCE MANUAL Original Instruction HANGCHA GROUP CO., LTD. OM23-RT01(05/2023)

- Page 2 If the load shape is complicated, the heaviest part should be placed in the center of the fork and close to the load-backrest. Note: The model tonnage number displayed below is calculated at a load center distance of 500mm. © Aug 2023, HANGCHA GROUP CO., LTD.

- Page 3 Contents I. Instructions for use ..........................1 II. Forklift truck component names ......................4 1.Instrument ............................5 2. Controls and switches ........................35 3. Body and other parts ........................42 III. Safety regulations ..........................47 IV. Daily safety checks ..........................54 V. Forklift truck structure and stability .....................59 VI.

- Page 5 I. Instructions for use In order to ensure personal and equipment safety, the driver should follow the following precautions: 1. Only drivers with proper training and a valid license should operate the vehicle; 2. Check each control and alarm device before driving, if any damage or defects are found they should be repaired before operation;...

- Page 6 equipment as well as loading and unloading of containers in wharf yards. 21. In the event of a breakdown, the truck should be first moved to a place where it does not obstruct traffic. If the breakdown is caused by the brake system or steering system, the truck should be carried away with a suitable vehicle (see the vehicle handling content);...

- Page 7 the exhaust system or the truck. Do not regenerate in gas stations, dusty places or other flammable and explosive areas. 36. When the regeneration is carried out while parked, a warning sign indicating high temperature and danger should be placed near the exhaust. 37.

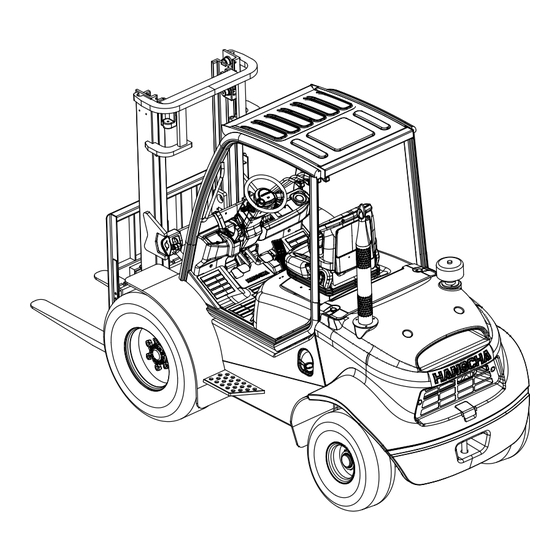

- Page 8 II. Forklift truck component names 1. Fork 2. Backrest 3. Tilt cylinder 4. mast 5. Lifting hydraulic 6. Steering wheel 7. Overhead guard 8. Driver’s seat cylinder 9. Hood 10. Counterweight 11. Rear wheel 12. Frame 13. Front wheel...

- Page 9 1.Instrument CPCD25/30/35-XW33E-RT CPCD25/30/35-XW43E-RT D. Accumulator alarm A. Water temperature gauge B. Fuel gauge C. Stopwatch indicator light E. Neutral start indicator G. Gearbox oil temperature F. OPS indicator light H. Parking indicator light light alarm light J. Oil-water separator K. Engine oil pressure alarm I.

- Page 10 Instrument Status Display Fuel gauge [B] When the ignition key switch is in the ┃ (open) position, the fuel gauge will display the approximate fuel quantity in the fuel tank. It is recommended to fill up the fuel tank everyday after work. Water temperature gauge [A] When the ignition key switch is in the ┃...

- Page 11 Stopwatch [C] the starting switch is in the (Start) position. It turns off when the engine is started. When the engine is running and the gearbox oil When the ignition key switch is in the ┃ (open) temperature exceeds the normal range (60℃ position, the stopwatch will start running.

- Page 12 indicator light [N] when the engine is started. The light turns on when the water precipitation reaches a certain level while the is engine Left steering Right steering running. indicator light indicator light If the light continues to turn on or flash when Before the truck turns left, the combination switch lever should be pushed forward, the front the is engine running, the engine should be shut...

- Page 13 Applicable truck models:CPCD25/30/35-XW33C-RT4,CPCD25/30/35-XW43C-RT4, CPCD25/30/35-XG72E-RT2,CPCD25/30/35-XG72C-RT4,CPCD25/30/35-X2W33E-RT2, CPCD25/30/35-X2G72E-RT2,CPCD15/18-XW33C-RT4,CPCD15/18-XW33E-RT2,CPCD50-XW65E-RT2, CPCD50-XW65C-RT4,CPCD50-XW70E-RT2,CPCD50-XW70C-RT4,CPCD50-XW95E-RT2, CPCD50-XW95C-RT4 Water temperature gauge It is recommended to fill up the fuel tank everyday after work . Stopwatch When the ignition key switch is in the ┃ (open) position, the water temperature gauge is active, When the ignition key switch is in the ┃...

- Page 14 The light displays the battery charge status, turns on when the starting switch is in the ┃ In general, the light turns on when the starting (open) position, and turns off when the engine switch is in the (start) position, and turns off is started.

- Page 15 parking brake is applied. In order to drive the truck, the parking brake lever (e.g. hand brake lever) should be released; when the brake is When the light turns on, it indicates that there is released, the light turns off. a fault and the forklift truck must be stopped immediately and the fault must be addressed Caution...

- Page 16 The indicator light in the 1.5t -3.5t forklift truck is not operative.

- Page 17 Instruments of China-IV forklift trucks (G92/G98/G87) 1. Homepage display ① Instrument self-test: When the instrument is powered on, the system starts the self-test. ② Fault code warning display: Displays the fault code. ③ DPF indicating display: Displays DPF-related indicator lights (without this function).

- Page 18 Regen indicator light a light load as much as possible to increase the exhaust temperature and extend the time between regens. Caution There are three kinds of working state: passive As the regeneration temperature is high, regen, driving regen, parked regen, and service there should not be any combustible regen (aftersales solution).

- Page 19 ③Release the accelerator pedal. interfere with the regen process except in ④Keep the direction lever in the neutral situations that endangers the safety of the position (gear N). vehicle or personnel, to prevent adverse effects ⑤Warm up the forklift truck until the water on the system.

- Page 20 Water temperature gauge Warning If active regen has been inhibited, the exhaust filter and exhaust will become When the ignition key switch is in the ┃ (open) blocked and the working performance of the position, the water temperature gauge is active, forklift truck will be degrade until the engine displaying the engine coolant temperature;...

- Page 21 Preheat indicator light [diesel forklift truck] Caution After the cumulative hours reaches the first 100h and 350h and a certain The light turns on for a short period after the period, the “wrench” icon will flash for switch is moved to the ┃...

- Page 22 -120℃), the alarm light will turn on. Caution If the alarm light turns on, please stop Vehicle-mounted terminal fault indicator light: operation immediately reduce the light “! ” turns on when there are any faults engine speed to cool down until the light in the vehicle-mounted terminal turns off.

- Page 23 When the light turns on, it indicates that the 2. Operating instructions for instrument keys: filter of the air intake system is blocked and the Caution truck must be stopped to clean the filter. Please ensure the handbrake is pulled up and Seat safety belt alarm indicator light (optional the gear-shifting switch is in the “N”...

- Page 24 setting. 2.3 English/Chinese settings When the cursor stops at "CN/EN", press “Key 3” to switch between English and Chinese.

- Page 25 CAN Bus Instrument (W98/W97) Key 4 Key 3 Key 2 Key 1 Kubota Engine Homepage 1. Instrument indicator lights Water temperature gauge everyday after work . Stopwatch When the ignition key switch is in the ┃ (open) When the ignition key switch is in the ┃...

- Page 26 Charging indicator light forklift, the parking brake lever (e.g. hand brake lever) should be released; when the lever is released, the light turns off. The light displays the battery charge status, Warning turns on when the starting switch is in the ┃...

- Page 27 with an electronically controlled engine] When the light turns on, it indicates that there is a fault and the forklift must be stopped When the engine is running and the gearbox immediately. oil temperature exceeds the normal range (60 Maintenance personnel can press the right key ℃-120℃), the alarm light will turn on.

- Page 28 In the second case, it prompts that the parking After confirmed that regen should be started. surrounding environment around the forklift truck is safe, regen can be Parking regen conditions: restarted, which generally should not The forklift truck should be parked on exceed 40 min.

- Page 29 fault light should turn on at the same time. Inhibit indicator light When the light turns on, it indicates that the regen status of the engine is restricted and driving regen or parking regen is inhibited. Caution When working in an environment that is ...

- Page 30 2. Operating instructions for instrument keys 2.1 Engine fault information display page (1) Kubota diesel engine No faults Fault present ① Enter the engine fault information display page: Homepage=》Key 4 ② Fault query page selection: Press key 2 or key 3 again for page selection (the page selection key is not displayed when there are no faults) ③...

- Page 31 2.3 Setting page (1) Operations on the setting page Setting 高级设置 保养提醒 Back 返回 Enter the setting page: Homepage=》Key 1 Enter the maintenance page: Homepage=》 Key 1=》 Key 2, to enter the maintenance repair page Enter the emissions system setting page: Homepage= 》 Key 1= 》 Key 3, to enter the ...

- Page 32 (3) Maintenance repair page a. Remaining hours query page Reset 重置 返回 Back The remaining hours can be observed on the page Reset: Press Key 2 to be redirected to the maintenance hour reset page, and reset the remaining hours to the set initial value (maintenance cycle interval). Back to the setting page: Press Key 1 b.

- Page 33 CAN Bus Instrument(W95/W65) In addition to the normal gauges, the XF series forklift truck also adopts the latest FW Murphy instrument which can monitor the operation status of the engine and devices and display all their parameters on an easy-to-read 3.8" QVGA black-and-white LCD. The display not only handles complex engine diagnostics, but also enables basic engine alarm and shutdown control.

- Page 34 Common engine faults This indicator light is used to indicate the engine exhaust temperature. When it turns on, it indicates that the engine exhaust temperature is too high and the driver must stop the forklift truck, check the engine exhaust device and When the light turns on, it indicates that there is reduce its temperature.

- Page 35 △ approximate fuel level in the fuel tank. ! Caution: It is recommended to fill up the fuel tank If the light continues to turn on or flash during everyday after work . , operation, it indicates that the charging is Brake indicator light abnormal immediate...

- Page 36 value in the current cursor position, “ ” is used to move the cursor, “ ” is used to return to the previous menu, and “ ” is used to confirm the password. Input the correct password to enter the transmission calibration page.

- Page 37 1. REGEN MODE refers to the engine regen. Press the “YES” key and the system will enter mode, including the following conditions: the regen. mode. AUTO: The regen. mode of the engine was Press the “CANCEL” key and the system will return to the previous menu.

- Page 38 current fault information, the (ADDRESS) “00” is displayed on the upper right part of the page. indicates the engine and “03” indicates the Exhaust filter inlet temperature is displayed on transmission. Identify the engine fault or the lower left part of the page. transmission fault based on the “ADDRESS”...

- Page 39 2. Controls and switches 1. Control and Switch Diagram of the 1.5t-3.5t Forklift Truck 1. Steering wheel 2. Horn 3. Combination light switch 4. Ignition key switch 5. Lifting lever 6. Tilt lever 7. Cup holder 8. Instrument 9. Rocker switch 10.

- Page 40 Steering wheel [1] To turn on the headlights and the front signal light, turn this switch to align the position Turn right Turn left marker on the switch handle with the corresponding symbol on the switch body. Controls the driving direction of the truck Anticlockwise rotation Ignition key switch [4] turns the truck to the left;...

- Page 41 continuously rotate for more than 5s and the Move to the interval between consecutive starts should be left Tilt 120s. Lifting lever [5] Move to the right Lower This lever is used to move the sideshift frame to the left or right. Lift Push forward –...

- Page 42 1. Alarm light switch: normal driving will cause serious When pressing down, the alarm light will flash; damage to the tires, drive shafts and when pressing up, the alarm light will turn off. other components. Therefore, please 2. Rear headlight switch: push the differential lock switch upward When pressing down, the rear headlight will when driving normally.

- Page 43 4. Differential lock switch limited to 10km/h. (China IV forklift trucks Press down to lock the differential; press up to only) The rocker switch in forklift trucks with a cab unlock the differential. may be different in configuration. Additional The differential lock is a mechanism installed functions like ventilation and demisting.

- Page 44 Caution In the event of brake system failure or an emergency, the lever can be engaged for emergency braking. Do not use the hand brake to slow down during normal use. Adjusting lever for steering wheel tilt angle [16] When the pedal is pressed, the oil pressure of the hydraulic clutch will drop.

- Page 45 Step on the brake pedal to fully stop the truck before changing the driving direction; push the lever forward to engage gear I and then rotate backward to gear II from gear I; and then push the lever backward to engage gear III from gear II.

- Page 46 3. Body and other parts when the forklift truck has stopped. For safety reasons, do not adjust the Load-backrest driver's seat when driving. The load-backrest ensures the stable loading of cargo. The forklift truck must not be operated For front and rear adjustment and ...

- Page 47 daily operation to protect yourself and reduce permission, the truck is fitted with a locking injury if the forklift rolls over. hood; in order to open the internal ·Unfasten the safety belt combustion engine hood, the lock handle should be pulled. The internal combustion engine hood can then be released.

- Page 48 released with a socket spanner; the bolt should be tightened with a socket spanner Warning during reinstallation The engine must be shut down during maintenance and repairs are carried out Water tank lid and additional water tank under the internal combustion engine The additional water tank is under the internal hood.

- Page 49 There is an opening on the lower beam Caution of the fork arm carrier for loading and When refuelling, the forklift truck must unloading forks. be stopped, the engine must be shut Do not use the fork in the open position ...

- Page 50 lock, remove the headlight, replace the bulb with a new one and then fit the cover. 4、 Loosen the two fixing screws of the LED width light, remove it to check for any damage; if it is damaged, cut the lead wire near the soldering point, replace the panel with a new one, re-solder it to its original position and replace it.

- Page 51 III. Safety regulations increased if necessary. Caution 1. Only trained and approved operators can The forklift may not be used underground. operate the forklift truck. It may not be used in flammable and Oil/water leakage, deformation explosive environments. looseness should regularly checked;...

- Page 52 19. Slow down and sound the horn when passing through intersections other junctions with poor visibility; limit the speed to 1/3 of the maximum driving speed of the truck. 14. Other people must not sit on the fork, pallet or forklift truck. 20.

- Page 53 from losing balance. cause vehicle vibration and noise. Attachments on forklift should Warning considered as vehicle loads. Do not use the forklift truck in sand, snow, lightning, rain, wind and other bad weather conditions. 26. The mast should tilt backward and the height of cargo should be lowered as much as possible when the truck is operated under load.

- Page 54 Caution Be careful not to let the forks touch the road surface, to avoid damaging the fork tip and road surface. 30. Know the load curves of the forklift truck and accessories, and do not overload. It is very Do not place your hands between the inner dangerous artificial additional...

- Page 55 41. Reduce the forward tilt angle as much as 37. Do not lift cargo at high speed. Cargo possible when stacking for unloading; when should be fixed securely before lifting the fork. the height of the cargo is slightly higher or Pause before lifting cargo and only lift after lower than that of the stacking layer, the cargo confirming there are no obstacles.

- Page 56 damaged or missing labels, signs and marks. 55. The exhaust temperature is very high 47. Various accessories provided for the user, during regeneration, personnel should stay such as rotating clamps, flat holding clamps, away from the exhaust pipe. sideshift forks, and booms are to be used exclusively.

- Page 57 Warning Fire risk If there are flammable gases, vapors, liquids, dust or fibers in the operating area of the forklift truck with an internal combustion engine, fires may be caused when the hot engine surface and exhaust fumes are exposed to them. The surface temperature of engine and exhaust parts may exceed the ignition temperatures of common solvents, fuel oil, engine oil,...

- Page 58 IV. Daily safety checks the level is between the two scale marks. 1. Leakage check: Electrolyte, hydraulic oil, cooling liquid and hydraulic transmission oil Warning Do not drive the truck if a fuel leak is found; start the engine only after eliminating the leakage.

- Page 59 with an mast no greater than 4 m. The scale line “M” marks the lower limit of the high mast, and the hydraulic oil level must be higher than this scale line for trucks with mast over 4 m and trucks equipped with attachments.

- Page 60 to the mast (including two-section/three-section full-free mast) with a lift height of no more than 6m; “70” refers to the hydraulic oil level applicable to the mast (including two-section/three-section full-free mast) with a lift height of no more than 7m. 7.

- Page 61 Press the horn button and check whether the Warning sound is normal. 14. Seat adjustment and safety belt check The forklift truck tires require very high Pull the seat adjusting lever back, adjust the pressure to bear loads; tiny deformation driver's seat to a comfortable position for your of the rim or surface damage to the tire hands and feet, release the seat adjusting lever,...

- Page 62 20. Check whether the differential lock function is normal. 21. Check if the 4WD function is normal (4WD truck only). Warning Do not drive the truck if you find anything weird or wrong. Report problems to your supervisor You can obtain the Table of Periodic Maintenance and Lubrication Cycles from the dealer.

- Page 63 V. Forklift truck structure and stability Be aware that the structure and stability of the forklift truck are very important to safe operation. Forklift truck structure Caution The basic components of the forklift truck are the lifting device (forks and mast) and the forklift truck itself at the rear (with tires).

- Page 64 Center of gravity and stability Caution The center of gravity of the forklift truck depends on the combined center of gravity of the forklift truck. When the forklift truck is unloaded, the center of gravity remains unchanged; when it is loaded, the center of gravity is formed by the combined center of gravity of the forklift truck and the load.

- Page 65 Bearing Capacity Chart Caution The chart shows the relationship between the location of the load center distance and the maximum load. Check whether the load and the SUBTRACT 200kg WITH SIDESHIFTER load center distance are within the allowable range of the Bearing Capacity Chart before loading. If the load shape is complicated, the heaviest part should be placed in the center of the fork and close to the LOAD CENTRE POSITION...

- Page 66 VI. Operation Caution Diesel engine Caution Step on the accelerator to make it run at If the forklift truck has any damage or intermediate speed after the diesel faults, it should not be started before engine is started; preheat the engine repairing.

- Page 67 start moving. Gear shift a)Stop the truck before shifting gear. b)Toggle the shift lever. Slowing down Slightly release the accelerator pedal, and step on the brake pedal, if necessary. 3. Loading Steering a ) Adjust the fork spacing to keep cargo The forklift truck is different from ordinary balanced.

- Page 68 i)Tilt the mast backwards Caution Do not tilt the mast when the load is lifted above 2m. Do not get off the truck or leave the truck when the load is at a high level. 5. Unstacking a) Slow down when the forklift truck approaches the place to pick up the cargo.

- Page 69 VII. Various signs/labels: 两驱/四驱切换开关 驱动桥差速锁开关 注意 两驱/四驱切换开关:车辆正常运行请选择两驱模式;当驱动桥动力 输出不足时,可使用四驱模式; 驱动桥差速器锁开关:车辆正常运行请关闭,避免转弯时损坏差速器 和存在翻车隐患;当驱动桥轮胎打滑时,可使用驱动桥差速器锁功能; 其他情况下,请操作者按需使用。 起吊方法 排放控制诊断系统 载 荷 曲 线 图 门架型号 属具型号 最大起升高度A 产品编号 工业用途,依据标准GB/T 26949.2-2013 越野用途,依据标准GB/T 26949.13-2017 实 际 起 重 量 门架垂直状态承载能力 载 荷 中 心 距 B P a rke d re g e n e ra tio n m u st b e d o n e M IN I R P M E m issio n s...

- Page 70 otherwise, your safety will be at risk. Truck can Hold TIP OVER! Risk of serious Tight INHURY Lean Away Brace or DEATH! WARNING Faste Seatblet Do Not Jump! From Impact Feet 6. Load curve sign It shows the relationship between the location of the load center distance and the maximum load or maximum lift height.

- Page 71 16. Engine hood opening label ② ① 9. Antifreeze label Move the steering wheel forward and lean the backrest forward before opening the engine 11. Tie-down point label hood. Return the steering wheel and backrest to original positions after closing the engine hood.

- Page 72 If an attachm ent is installed the actual capacity at m axim um lifting height , refer to the m odel plate of the attachm ent or the rated capacities and load centers graph. HANGCHA GRO UP CO .,LTD. Add: 666 Xiangfu Road, Hangzhou,Zhejiang,China(311305)

- Page 73 22. Hazard label (Label for keep clear of mast) T he pri nt posi t i on Warning: Danger to your life. If you become of t ruck body seri se num ber trapped between the mast and instrument stand or overhead guard, you will be at risk of serious injury.

- Page 74 2WD: normally, it indicates that the forklift is in the regen active status. At that time, manual D IFFEREN TIAL LO CKER SW ITCH O F D RIVE AXLE intervention is not required and normal working status can be maintained. When the indicator light automatically turns off, it indicates that the particulate treatment is completed.

- Page 75 The driver should pay attention to safety, Em i ssi ons should not leave the site, and should monitor the engine conditions during regen. The driver should not stop the engine 1. Press "Regen" to turn on parking regen. during regen;...

- Page 76 28、Noise label 31、Euro 5 emission label (W97/W98 engine There are several types, please refer to only) the ones pasted on the car. 29、China IV emission label (G92/G98 engine only) 30、Emission control diagnosis system label (G92/G98 engine only)

- Page 77 VIII. Lifting, handling and towing of the forklift truck Lift the forklift truck •Tie the steel rope on the lifting hole and counterweight lifting hook at both ends of the beam of outer mast firmly and lift the forklift truck with the lifting device. Caution Do not wind the steel rope around the overhead guard when lifting the forklift truck.

- Page 78 Caution • Do not tow trucks with defective steering systems or damaged brake systems. • Obey traffic rules when towing a truck on the highway. Warning • Only attach the steel rope to the specified position. • Do not suddenly apply load on the steel rope.

- Page 79 IX. Usage and maintenance methods for the lead-acid battery 1. Lead-acid battery and use The battery is used as the power source to start the engine, and it is used to replace the power supply of the voltage regulator and overload generators. Light weight, low failure rate, easy to use and maintain.

- Page 80 4) A regular schedule should be formulated and batteries should be charged once every 30-45 days. 5) When the observation window does not display green, the battery should be checked and charged or replaced. Inspection of low-maintenance battery As the ambient temperature around the forklift truck is high, batteries consume water; please keep an eye on the liquid level during use;...

- Page 81 During recharging, the hydrogen produced by batteries is flammable and explosive. Therefore, pay attention to the following matters before operation: · If batteries that are still installed on the truck are recharged, the ground cable has to be disconnected. · When connecting and disconnecting battery charger cables, the power switch on the charger should be off.

- Page 82 X. Use, installation and safety rules for accessories Hangcha selects accessories, such as the flat clamp, rotating clamp, roll clamp, string rod, side shifter and others in accordance with ISO2328 Fork Lift Trucks-Hook-on Type Fork Arms and Fork Carriers- Mounting Dimensions.

- Page 83 accessories; (10) When accessories are faulty, they should not be used until the fault has been eliminated. The following inspection and maintenance should be carried out frequently (1) Check whether the spacing between the lower beams of the forks of the forklift truck and the lower hooks of accessories conform to the requirements of the accessory manual.

- Page 85 XI. OPS (Operator Presence Sensing) system instruction OPS system (only limited to electric reversing hydraulic trucks) The OPS (Operator Presence Sensing) system is mainly used for safety, when the operator is not in the correct driving position, the forklift cannot be driven and transported, thereby reducing accidents caused by misuse.

- Page 86 In the event of the following conditions, the forklift truck should be stopped in a safe place and Hangcha agency should be contacted for inspection. When you are ready to start the forklift truck, and you pull the shift switch to forward gear 1 or backward gear 1, the neutral indicator light will flash.

- Page 87 Caution Some models are not equipped with an “ ”OPS indicator light on the instrument panel.

- Page 88 Notes...

- Page 89 HANGCHA GROUP CO., LTD. National customer service hotline: 400-884-7888 For: OVERSEAS USERS ■Address: 666Xiangfu Road, Hangzhou,Zhejiang, China ■Fax: 0086-571-88926789 0086-571-88132890■ ZIP:311305 ■Web: http://www.hcforklift.com■E-mail: sales@hcforklift.com...

Need help?

Do you have a question about the CPCD15 and is the answer not in the manual?

Questions and answers